Air conditioner oiling device

An oil injection device and air-conditioning technology, which is applied in the direction of liquid variable displacement machinery, variable displacement pump components, machines/engines, etc., can solve the problems of low efficiency, time-consuming and laborious injection, etc., and achieve convenient operation, high degree of automation, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

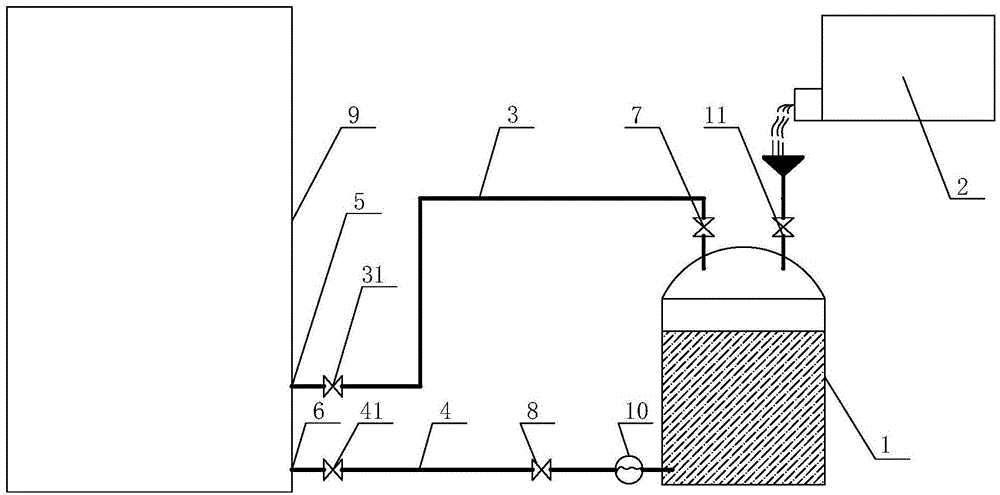

[0022] An air-conditioning oil injection device provided by the present invention has a structure such as figure 1 As shown, it includes an oil filling tank 1, the oil filling tank 1 is connected to the oil tank 2 through an oil pipe, and an oil filling valve 11 is arranged on the oil pipe connecting the oil filling tank 1 and the oil tank 2, and the oil filling valve 11 is preferably a shut-off valve. The oil filling tank 1 is connected with the exhaust port end 5 of the air-conditioning compressor 9 through the first connecting pipe 3, the oil filling tank 1 is connected with the air inlet end 6 of the compressor 9 through the second connecting pipe 4, and the first connecting pipe 3 And the tail end of the oil pipe is positioned at the top of the oil filling tank 1, the tail end of the second connecting pipe 4 is positioned at the bottom of the oil filling tank 1, and the first connecting pipe 3 and the second connecting pipe 4 can adopt leather tubes or flexible pipes. The...

Embodiment 2

[0031] This embodiment provides another air conditioner oil injection device, the structure of which is basically the same as that of the air conditioner oil injection device described in Embodiment 1, which includes an oil injection tank connected to the oil tank through an oil pipe, The tank is connected to the exhaust port of the air conditioner compressor through the first connecting pipe, and the oil filling tank is connected to the air inlet end of the compressor through the second connecting pipe. The first connecting pipe is provided with a booster valve, and the second connecting pipe There is an oil discharge valve on it.

[0032] The difference is that the air-conditioning oil injection device of this embodiment also includes a controller, which is respectively connected to the boost valve, the oil discharge valve and the oil injection valve, and the pressure boost valve, the oil discharge valve and the oil injection valve are all solenoid valves. In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com