Patents

Literature

182 results about "Machine repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System, method,computer product and website for automobile collision repair

InactiveUS20130218761A1Convenience to workIncrease profitabilityFinanceReservationsModern lifeFull service

A system, method, computer product and website for provides full service concierge style vehicle mechanical repair, collision repair, aftermarket installation services and restoration services. The system, method, computer product and website relate to new and improved means for coordinating automobile collision and mechanical repair services. The claimed invention is also adaptable for use with restoration and aftermarket installation services. More specifically, the claimed invention relates to use of a secure website to offer an exclusive, comprehensive and convenient concierge style auto repair solution for modern lifestyle type customers.

Owner:KWASNY DAVID J

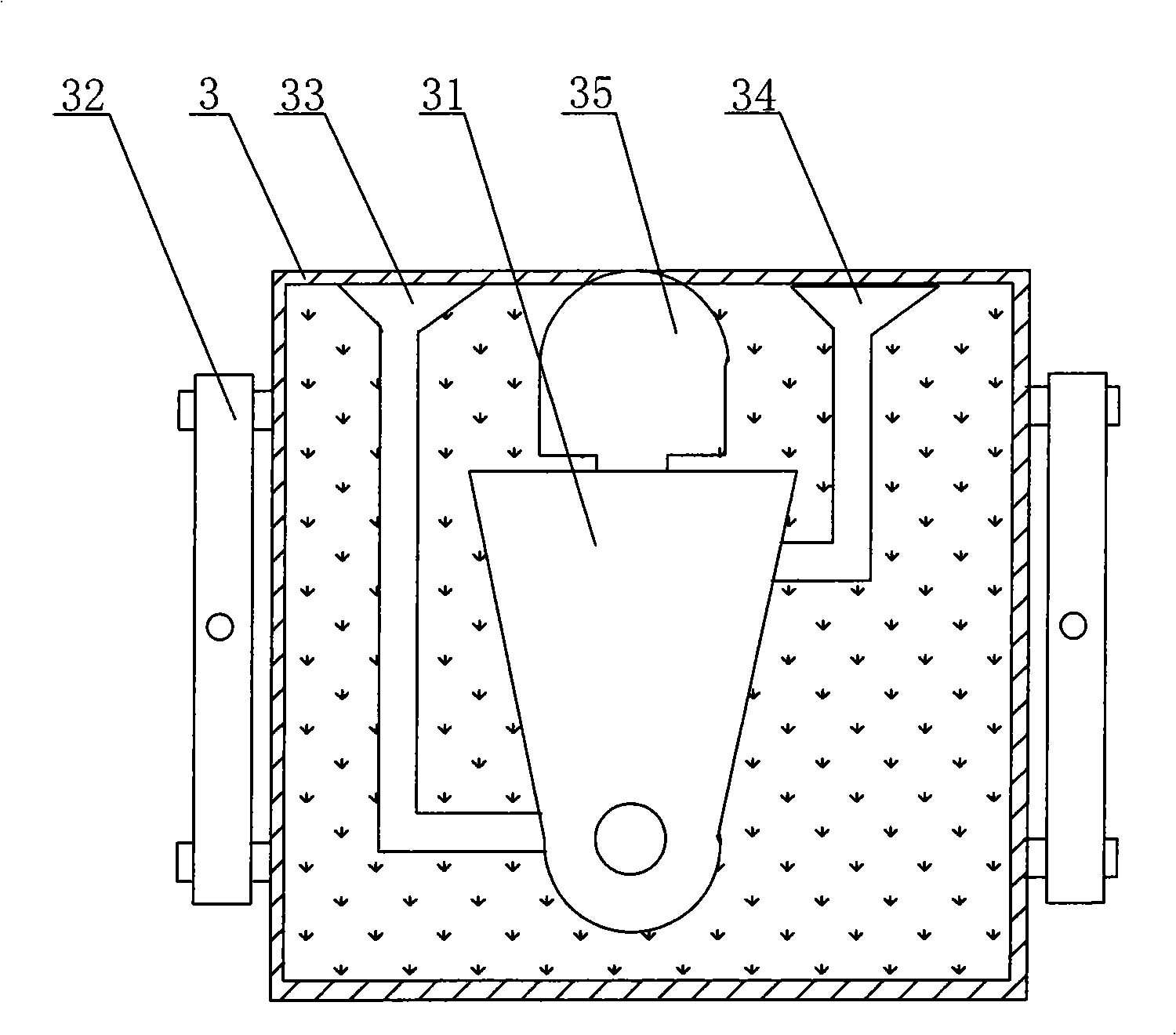

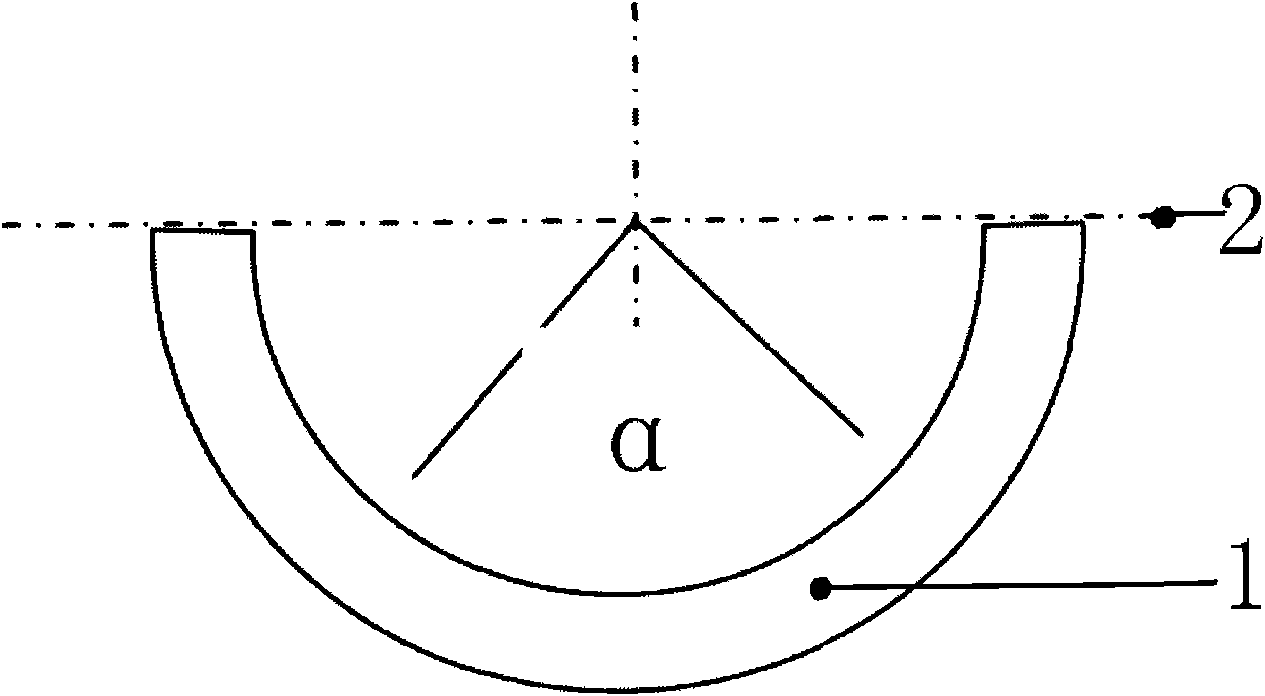

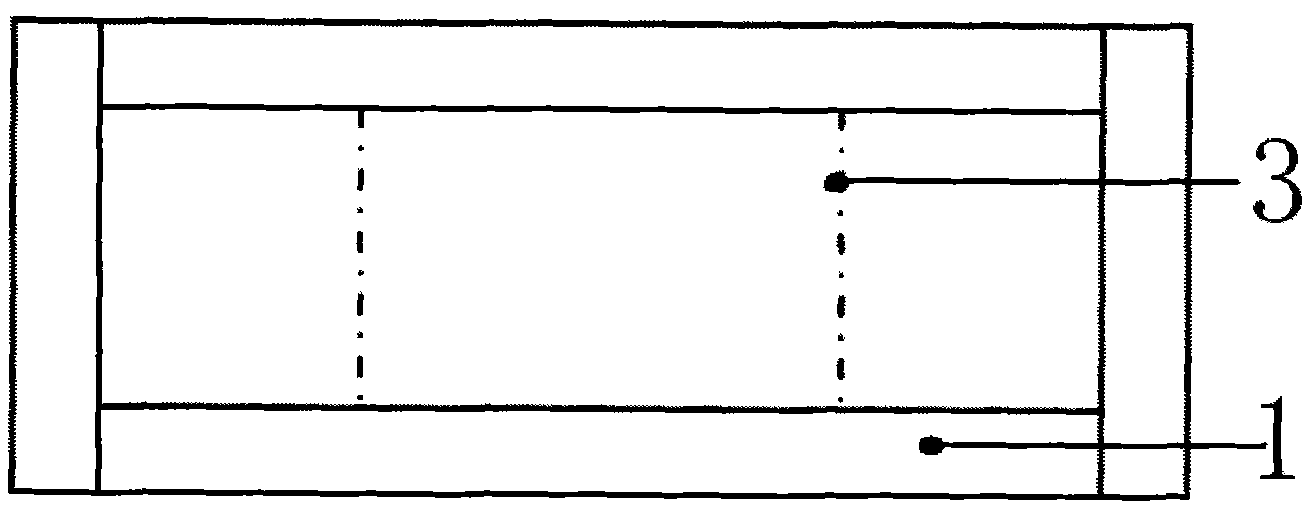

Device and method for casting composite hammer head

InactiveCN101406930AImprove wear resistanceExtended service lifeFoundry mouldsFoundry coresCrack resistanceWear resistance

The invention discloses a device for casting a compound hammerhead and a method for casting the same, wherein the device comprises a casting box consisting of an upper mould plate and a lower mould plate through compounding, two sides of the casting box are provided with box clamps, a die cavity of which the shape is fit close with that of the hammerhead is arranged in the casting box, the top end of the die cavity is provided with a riser head, the left side and the right side of the die cavity are provided with a pouring channel I and a pouring channel II respectively, and opening parts of the other ends of the pouring channel I and the pouring channel II are arranged on the top of the casting box. The method comprises the following steps: pouring molten metal I into the pouring channel I so that the molten metal I flows into the bottom of the die cavity under the action of gravity; and when the molten metal I begins to pre-harden, pouring molten metal II into the pouring channel II so that the molten metal II flows onto the molten metal I in the die cavity under the action of gravity, and then adding a heat-generating agent into the die cavity so that the molten metal I and the molten metal II are fused integrally to form the hammerhead. The method uses two metals to cast the hammerhead through thermal compound, so on the basis of keeping the original toughness, the wearing resistance of the hammerhead is increased, the crack resistance of a hammer handle is reliable, the production cost is greatly reduced, the service life of the hammerhead is prolonged, and the mechanical maintenance rate is low.

Owner:金培良

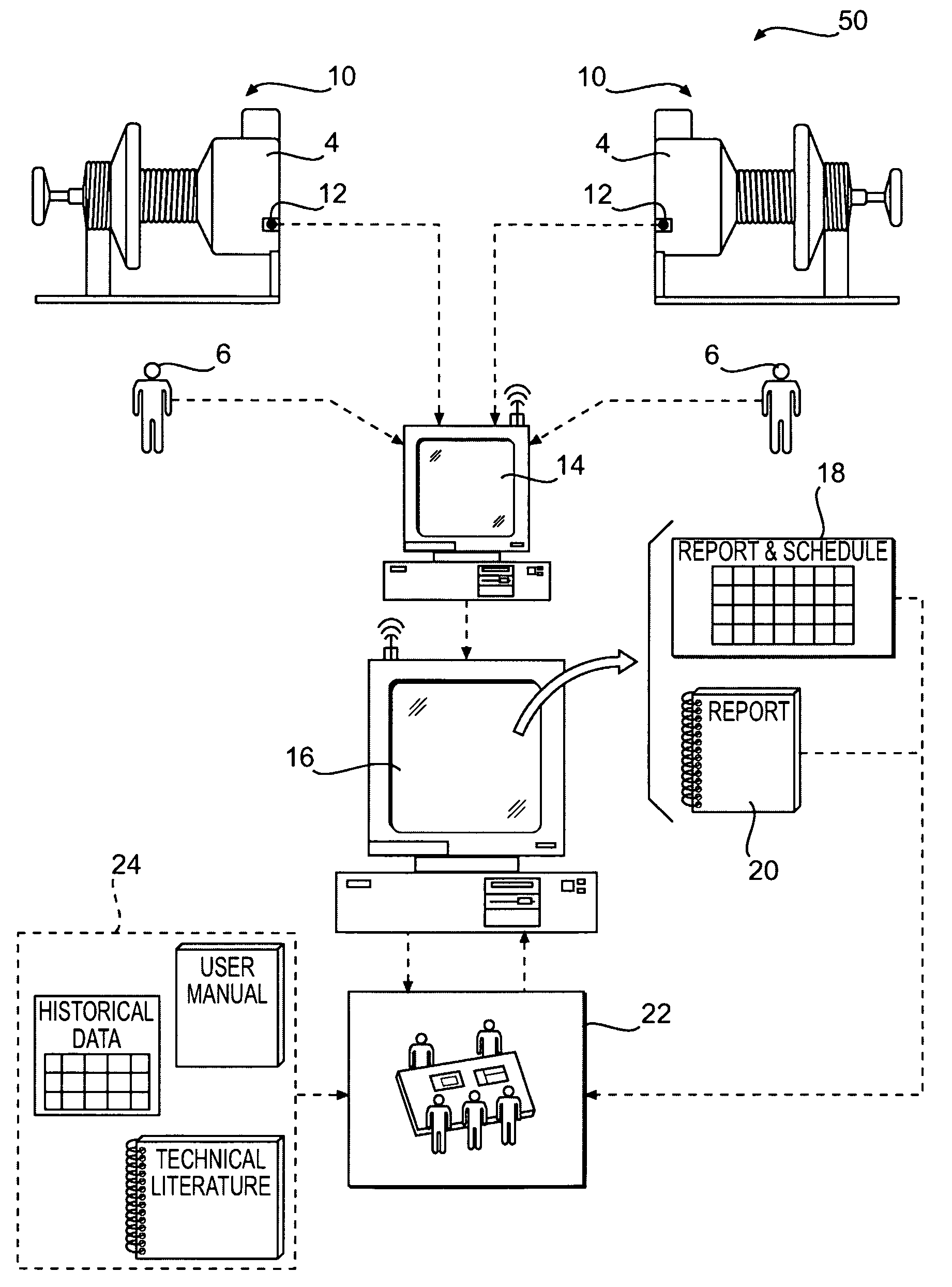

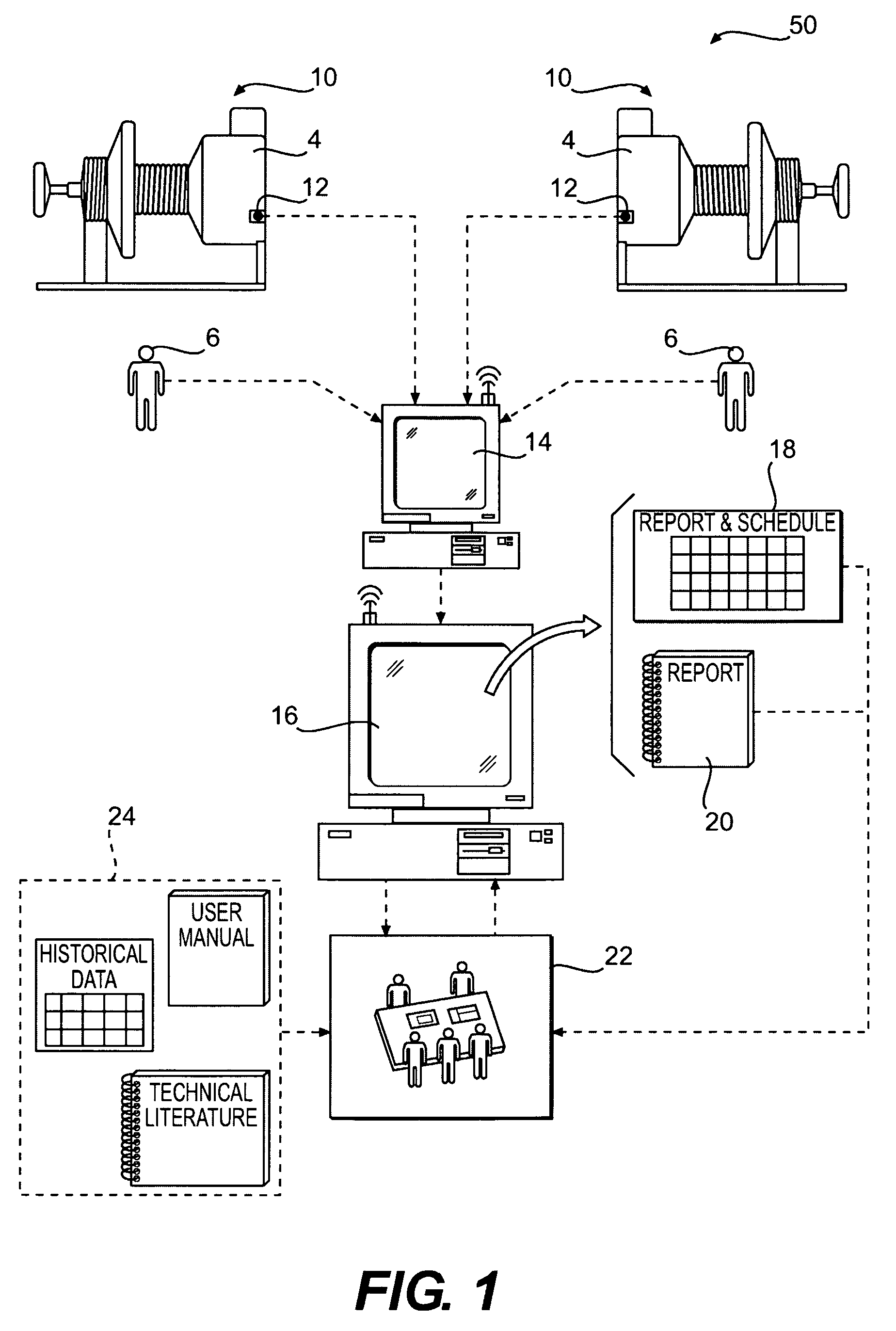

Maintenance management of a machine

ActiveUS7496475B2Programme controlTesting/monitoring control systemsMaintenance managementCritical factors

Methods of providing maintenance management of a machine are disclosed. In one embodiment, the method involves identifying a machine component failure that, if not repaired, will result in a functional failure of the machine. A criticality factor is assigned to the machine component failure based on at least a probability of occurrence of the functional failure and a consequence of the functional failure to a machine user. A maintenance task is generated to repair the machine component failure, and a triggering condition that activates the maintenance task is defined. The method further involves conducting a machine repair in response to a detection of the triggering condition, and maintaining a record that includes information relating to the conducted machine repair. The method of providing maintenance management is also modified based on at least the record.

Owner:SOLAR TURBINES

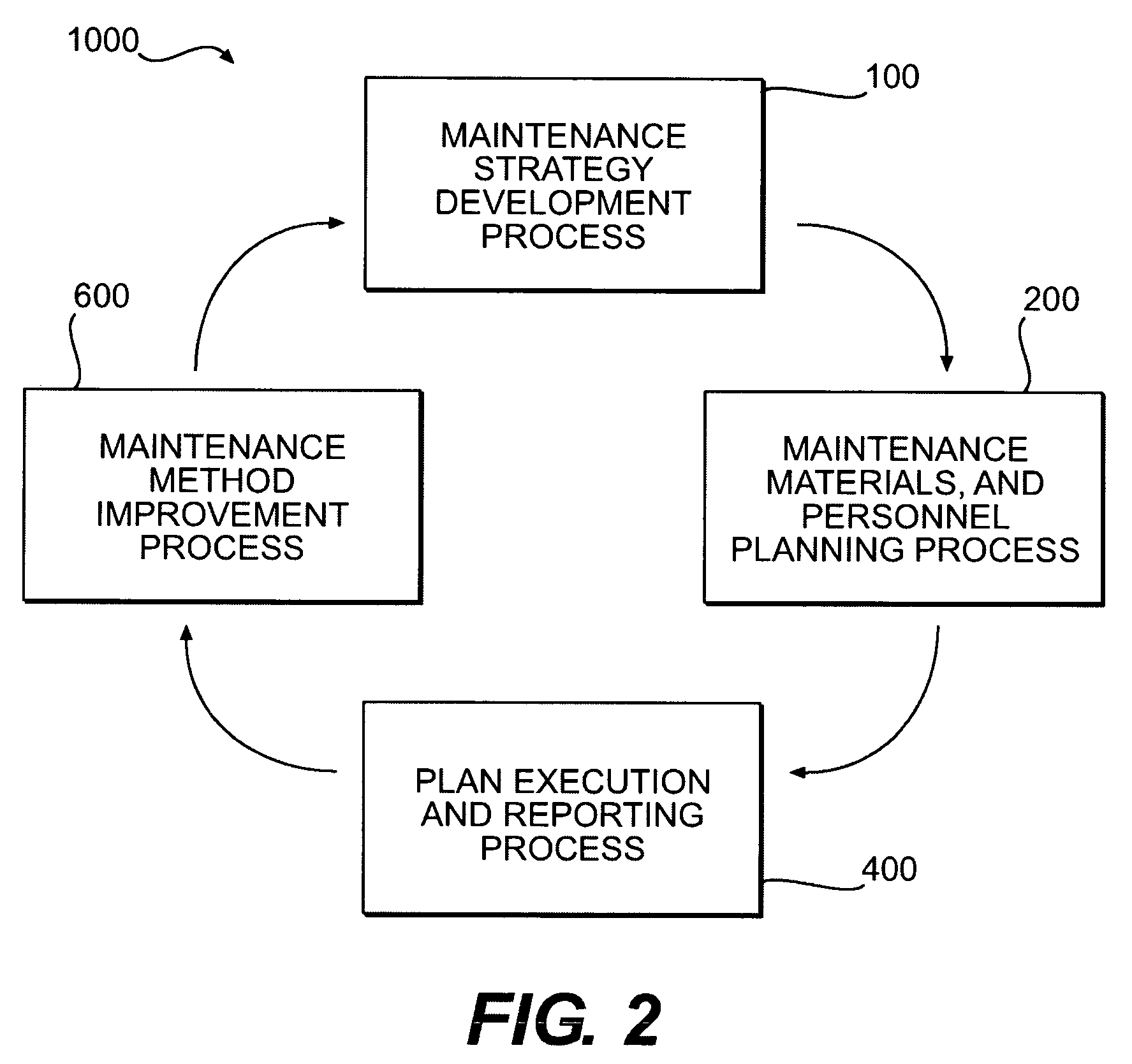

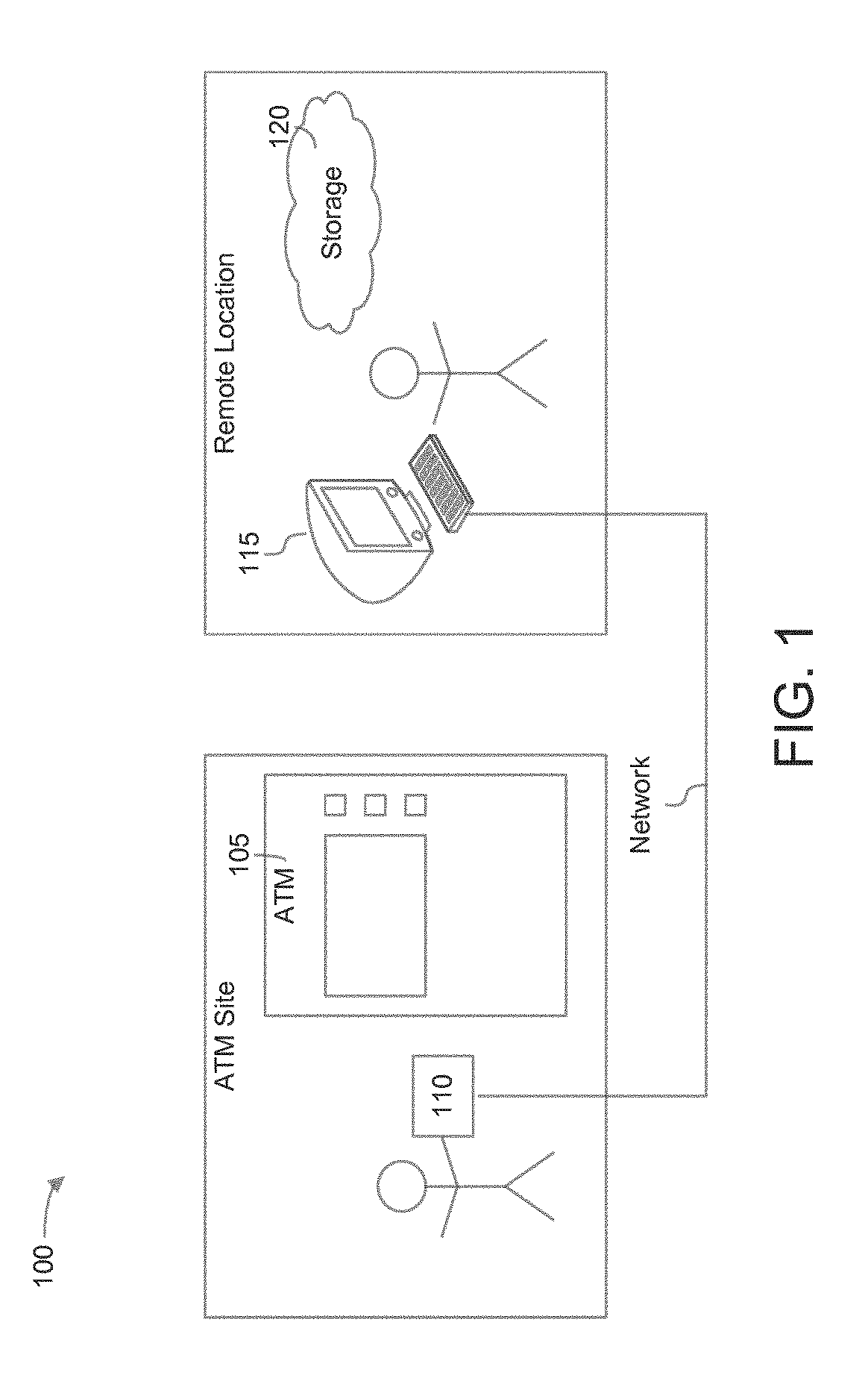

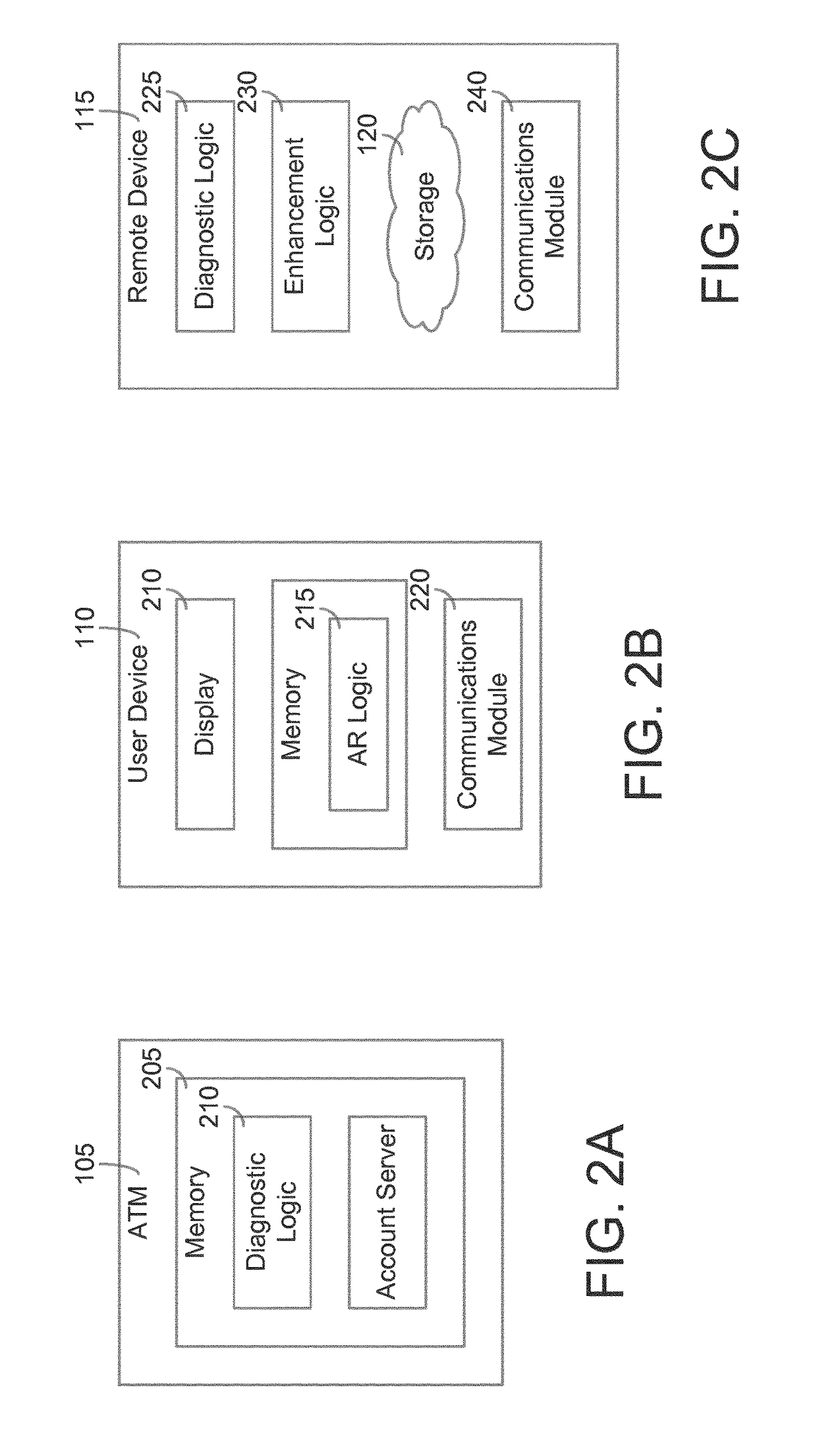

Systems and methods for automated teller machine repair

ActiveUS9846996B1Complete banking machinesCathode-ray tube indicatorsComputer hardwareDisplay device

One embodiment of the disclosure relates to a system of servicing an automated teller machine (ATM) using a display configured to display augmented reality images. The electronic device may be configured to receive low-level diagnostic information from the malfunctioning ATM. Data may be transferred to a central location, wherein the data is analyzed and a solution to the problem of the malfunctioning ATM is determined and transferred back to the electronic device. In some embodiments, the electronic device displays components of the ATM using augmented reality such that a technician viewing the display may visualize the components of the ATM and receive instructions regarding the repair or care of the ATM.

Owner:WELLS FARGO BANK NA

Scraping method of main bearing shell of ball mill

The invention belongs to machines and tools for machine repair and inspection, and in particular relates to a scraping method of the main bearing shell of a ball mill after the main bearing shell of the ball mill is out of order. The scraping method is mainly applicable to sliding bearings cast by using babbitt metal or copper, and accurately defines the parameters and steps for scraping the main bearing shell by four main steps of demarcating border lines, finding a basal plane, uniformly spotting and approving by stress, thereby greatly shortening the inspection and repair time and improving the inspection and repair efficiency. The invention has the advantages of ensuring successful scraping once, preventing repeated inspection and repair, greatly shortening the inspection and repair time every time and reducing the labor intensity of workers.

Owner:NANJING MEISHAN METALLURGY DEV

Permeable reactive barrier (PRB) taking loaded nano zero-valence iron as filler and application thereof

InactiveCN104961223AWater contaminantsWater/sewage treatment by magnetic/electric fieldsIn situ remediationMass ratio

The invention relates to a permeable reactive barrier (PRB) taking a loaded nano zero-valence iron composite magnetic material as a filler. Magnets are placed at the two sides of the PRB so as to form a magnetic field, the magnetic field is vertical to a water flow direction, and the PRB is filled with a Hangjin clay 2# loaded nano zero-valence iron composite magnetic material, natural zeolite and persulfate, wherein the mass ratio of a nano zero-valence iron composite magnetic material to Hangjin clay 2# is 1: (4-5). The invention also discloses a method for in-situ remediation of polluted groundwater by using the PRB. Compared with the current methods for improving the reaction activity of nano zero-valence iron, the PRB provided by the invention has the advantages of being simple in use, not consuming any chemical substance, reducing dosage of medicament and being environmentally-friendly and energy-saving and has a very high popularization and application value in actual water pollution control machine repair engineering.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

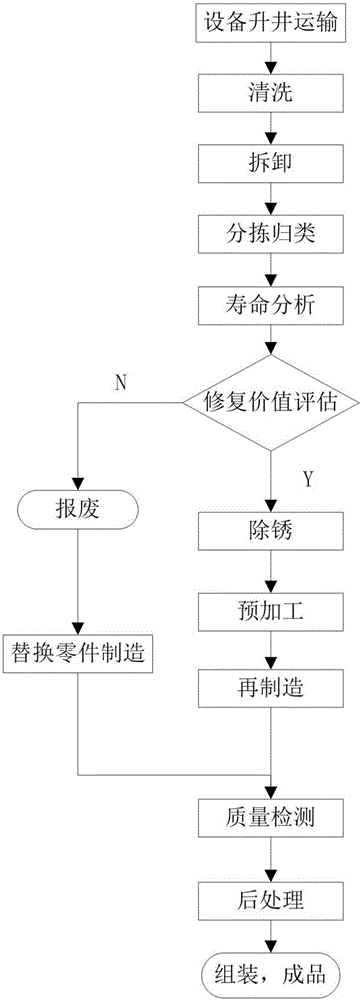

Mine waste machine repair process

InactiveCN106624626AReduce usageReduce maintenance costsWelding apparatusSurface engineeringQuality control

The invention discloses a mine waste machine repair process, and belongs to the field of machine remanufacturing. The process comprises the steps of: cleaning and sorting, analysis and estimation, derusting and premachining, repair and remanufacturing, quality inspection and assembly. The mine waste machine repair process uses waste mine mechanical products as blanks, uses the remanufacturing quality control and the advanced surface engineering technology for repairing failed surfaces to recover geometric sizes, reduces the use of new materials in the remanufacturing process to the greatest extent, recovers and promotes the product quality and performances, prolongs the product service life, improves the product reliability, reduces the maintenance costs of remanufactured products, reduces the energy consumption and the pollution emission generated in chain production, realizes the equipment performance promotion and great-leap-forward development requirements under lower cost, and excavates additional values contained in waste parts to the greatest extent.

Owner:甘肃兰煤机械制造有限公司

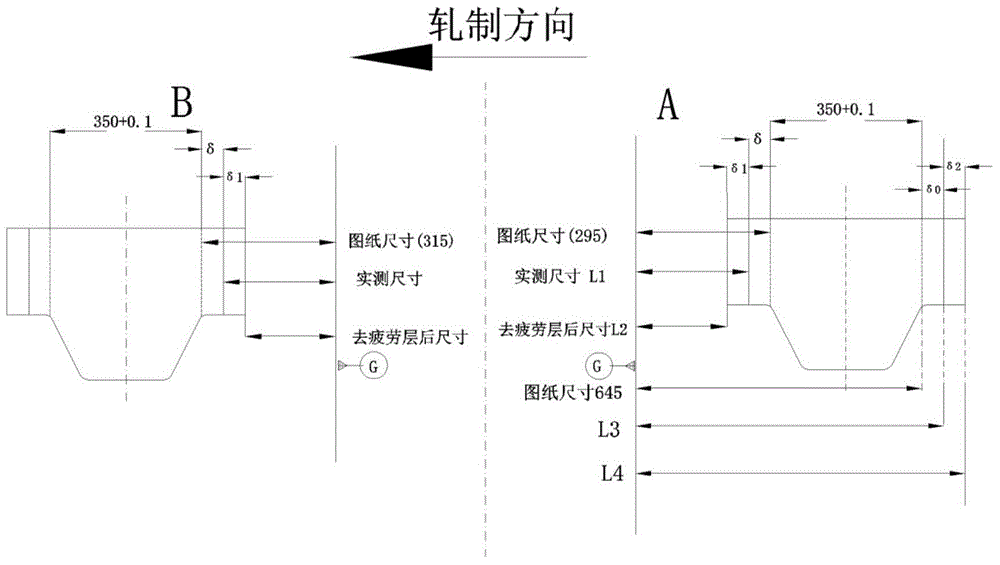

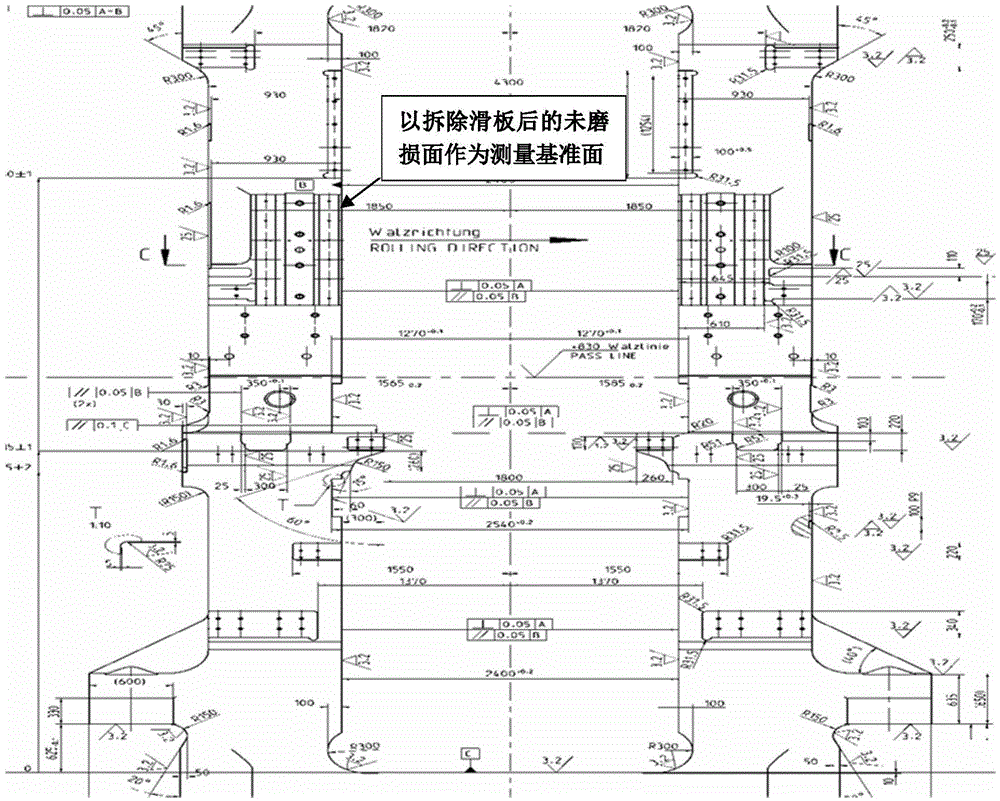

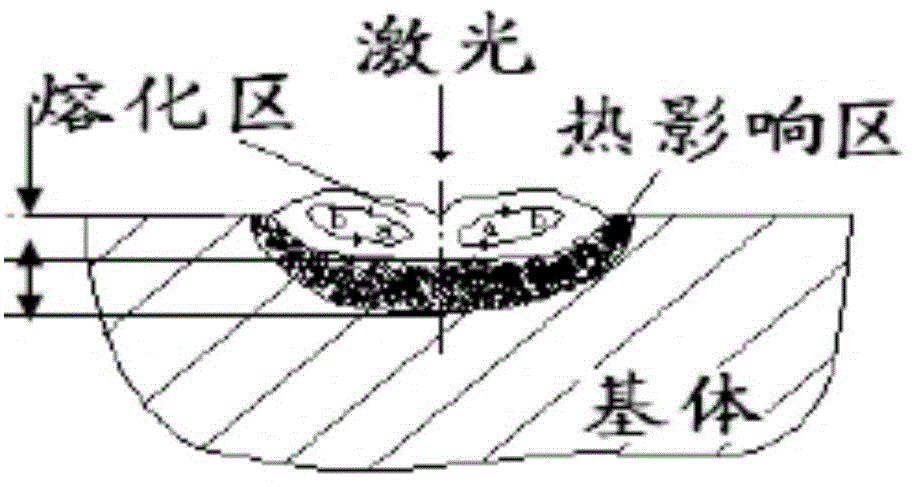

Laser cladding and on-line machining repair method for roughing mill housing roller positioning groove

ActiveCN104439881AGuaranteed repair effectQuality assuranceMetal rolling stand detailsMetal rolling arrangementsHeat-affected zoneEngineering

The invention relates to a laser cladding and on-line machining repair method for a roughing mill housing roller positioning groove, and belongs to the technical field of surface modification and equipment repair. Machining equipment comprises a 2500 movable boring and milling machine, an all-solid-state laser device, a mechanical hand, a manipulator, a pneumatic powder feeder, a self-made construction platform and the like. The technological process includes the steps of building the platform, leading in the equipment, adjusting, centering and fixing the equipment, performing rough machining, performing precision measurement for flaw detection, performing laser cladding, performing precision measurement for flaw detection, fine machining, performing precision measurement for flaw detection and tracking to verify the effect. The laser cladding and on-line machining repair method has the advantages that the equipment strength is not affected, hot stress influence during repair welding is avoided, while equipment accuracy is recovered, the outage time can be shortened, and the repair cost can be reduced; a metal base material can be effectively protected from abrasion or corrosion by selecting a repair material, the problem is prevented from occurring again, and the service life of the equipment is greatly prolonged; as only the surface of the base material is melt in a micro mode in the laser machining process, the area of a laser cladding heat affected zone is one tenth that of a heat affected zone of argon arc welding.

Owner:SHOUGANG CORPORATION

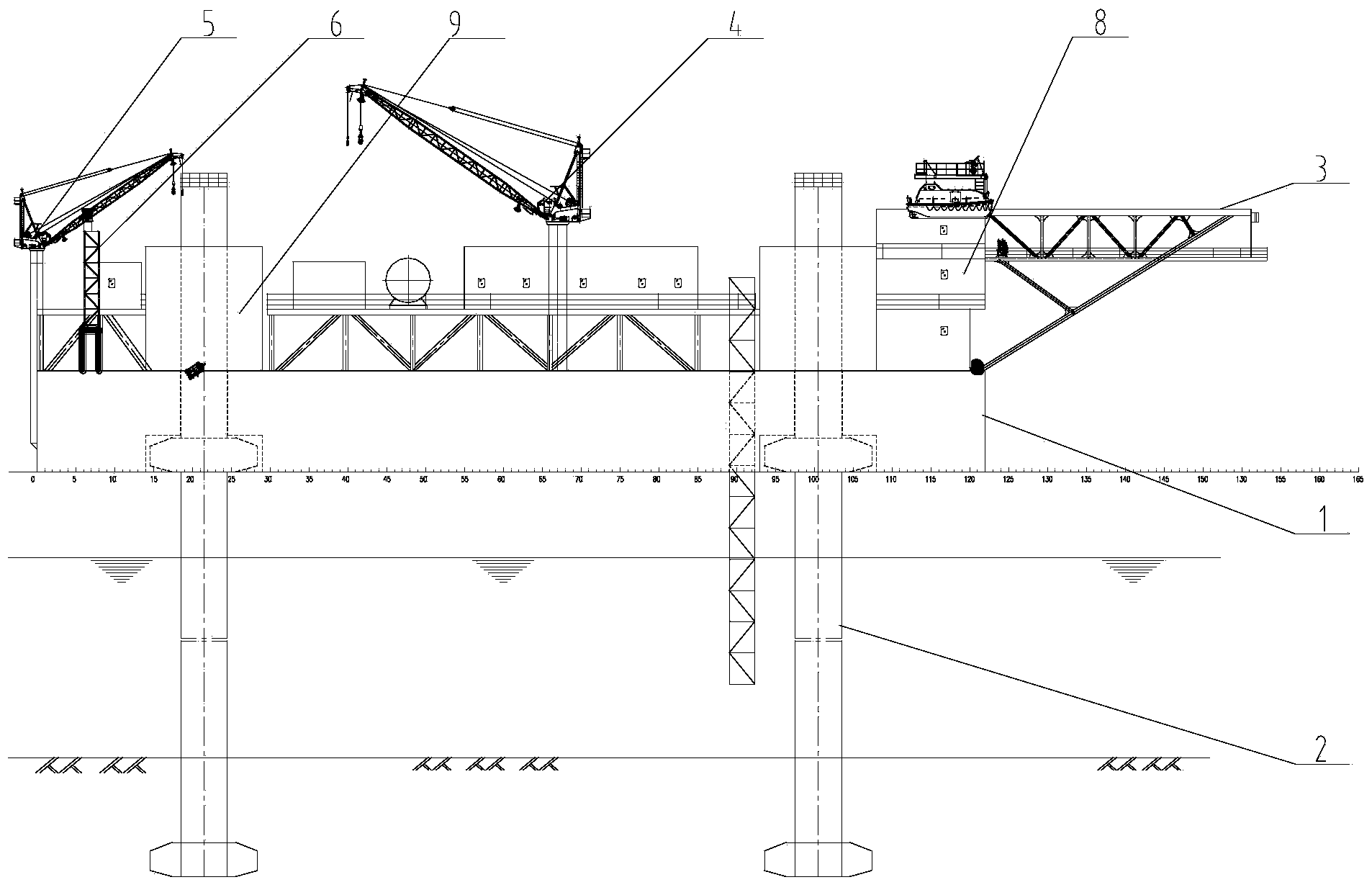

Self-installation oil production platform

The invention discloses a self-installation oil production platform. The oil production platform is a self-elevating-type platform and a crude oil tank is arranged in a platform body. A pipeline trestle is arranged on the stern portion of a main deck, a flare boom and a flare liquid separation tank are arranged on a starboard on the stern portion of the main deck, the bow portion of the main deck is provided with an emergency generator room, an emergency distribution room, a machine repair room, a hydraulic station, nitrogen generating equipment and a tool room, oil gas processing equipment and an oil conveying arm are arranged on the stern portion of a second-layer deck and the midship portion of the second-layer deck is provided with a hot oil boiler room, a transformer room, an oil production distribution room, a main distribution room, a main generator room and a natural gas generator room. The characteristics that an offshore drilling platform is movable and pile legs are in place are used in the self-installation oil production platform, the self-installation oil production platform integrates the functions of a fixed platform and the FPSO function, has the functions such as oil gas processing, crude oil storage and exportation, sewage treatment and life support, can be used repeatedly, greatly reduces the investment cost of oilfield development, and provides a technical support for marginal field development.

Owner:CNOOC ENERGY TECH & SERVICES

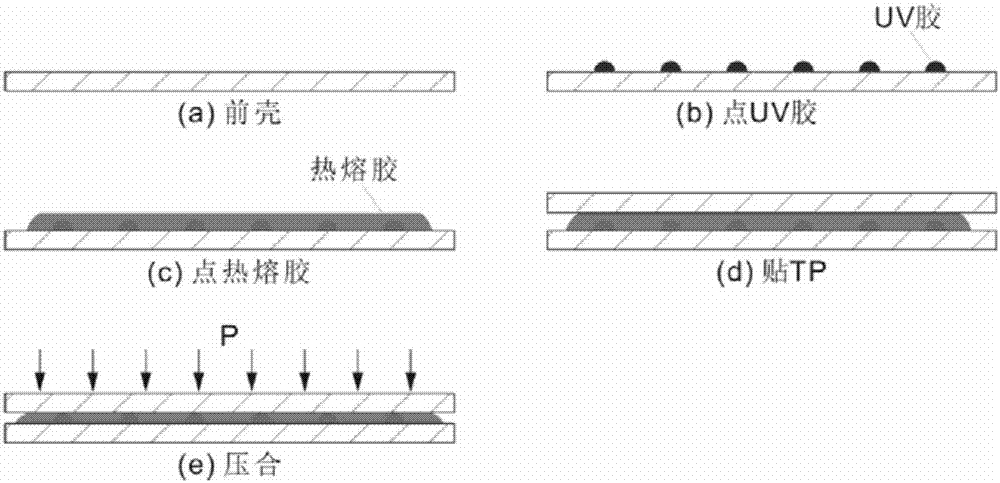

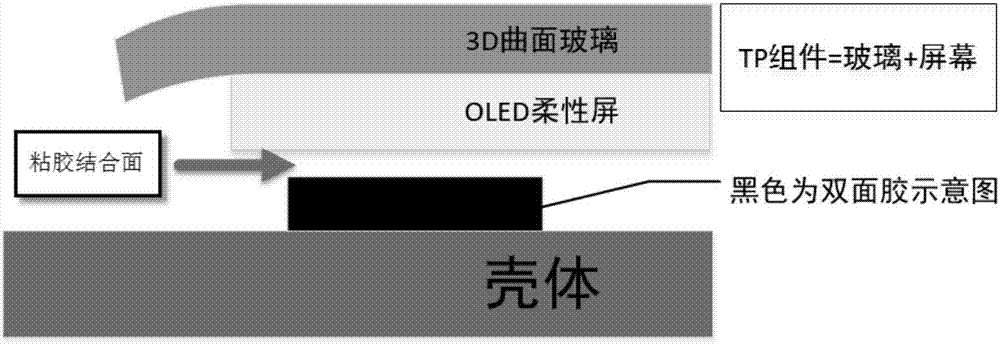

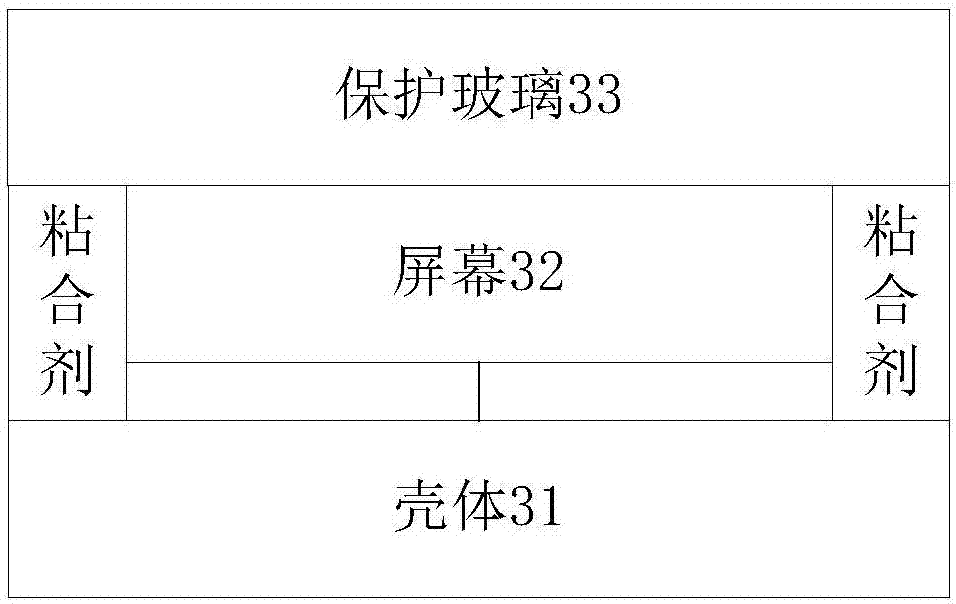

Terminal as well as assembly method and device

PendingCN107154989APrevent overflowProtection display functionTelephone set constructionsAdhesiveProtective glasses

The invention provides a terminal as well as an assembly method and device. The terminal comprises a shell, a screen and protective glass, wherein the screen is arranged between the shell and the protective glass; the upper surface of the screen is adhered to a preset region of the lower surface of the protective glass; and the region, besides the preset region, of the lower surface of the protective glass, the side surface of the screen and the shell are connected with one another through an adhesive. According to the terminal, by connecting the region, besides the preset region, of the lower surface of the protective glass, the side surface of the screen and the shell with one another through the adhesive, the adhesive can be prevented from overflowing to the upper surface of the protective glass; as the adhesive only exists on the side surface of the screen, at a disassembly stage, the adhesive needs to be disassembled from the side surface of the screen only without damaging the screen, so that the disassembly efficiency and the whole machine repair efficiency are improved, and the whole machine cost is lowered; and the adhesive on the side surface of the screen can prevent liquid from damaging the screen.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

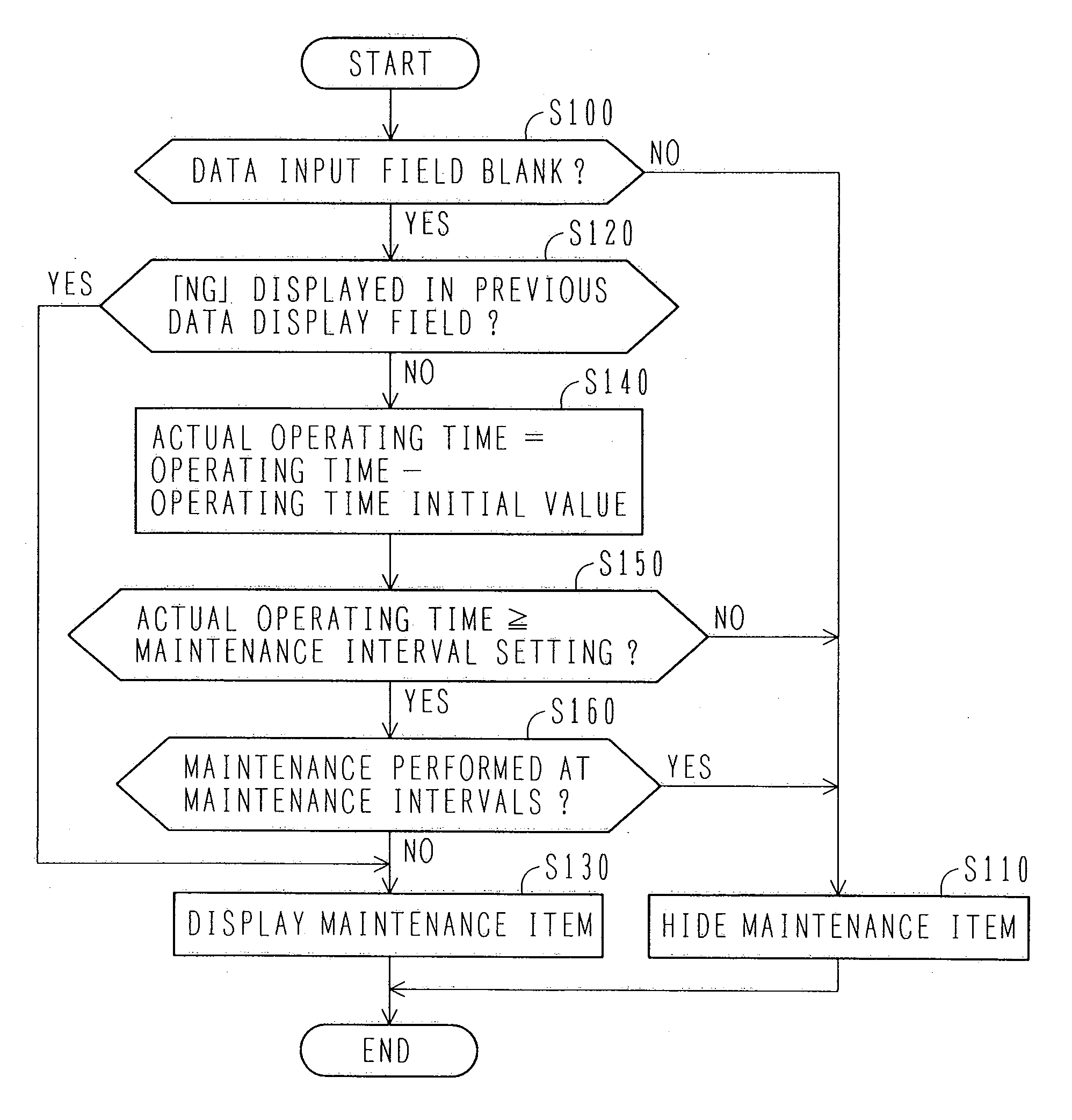

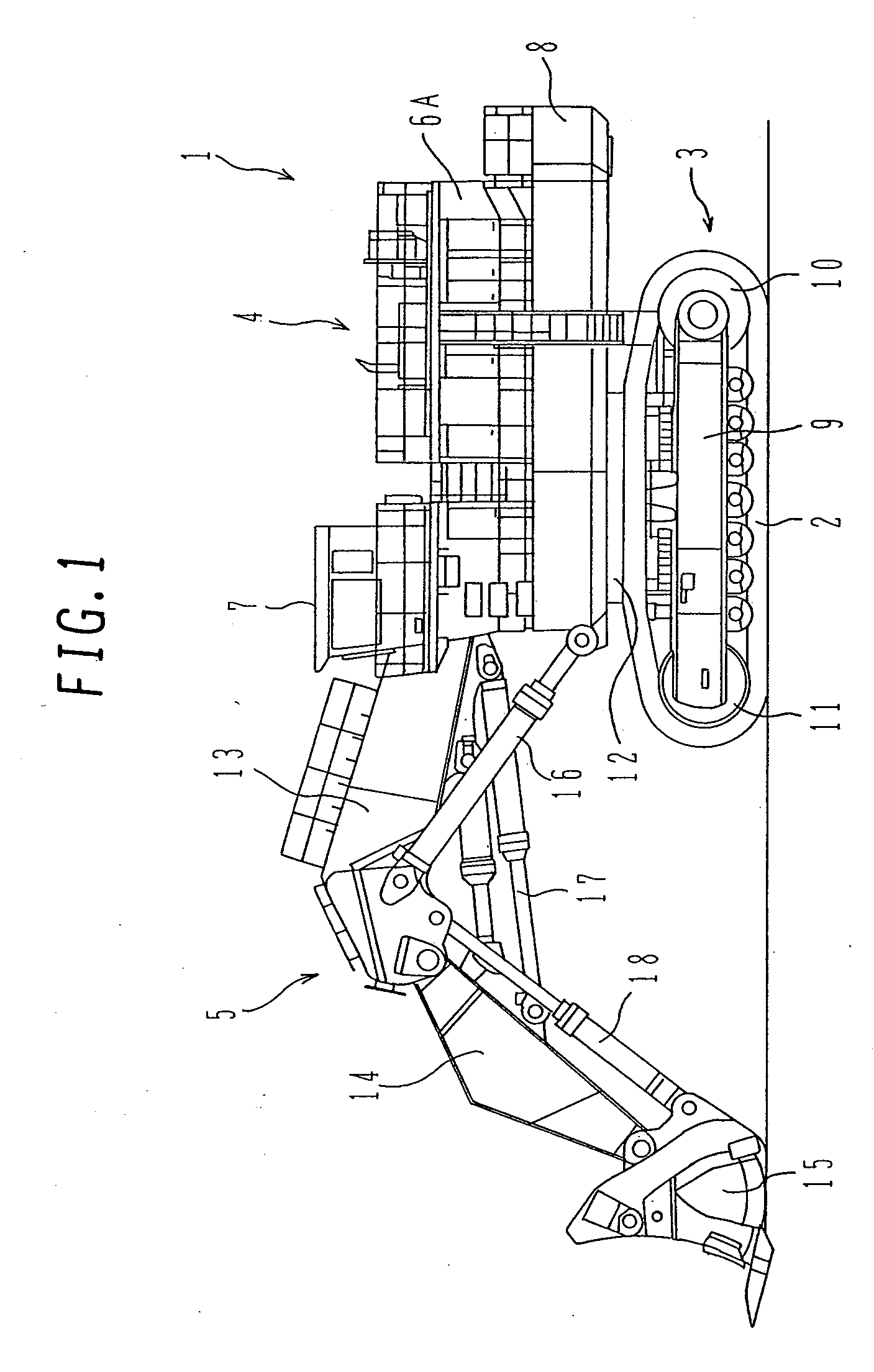

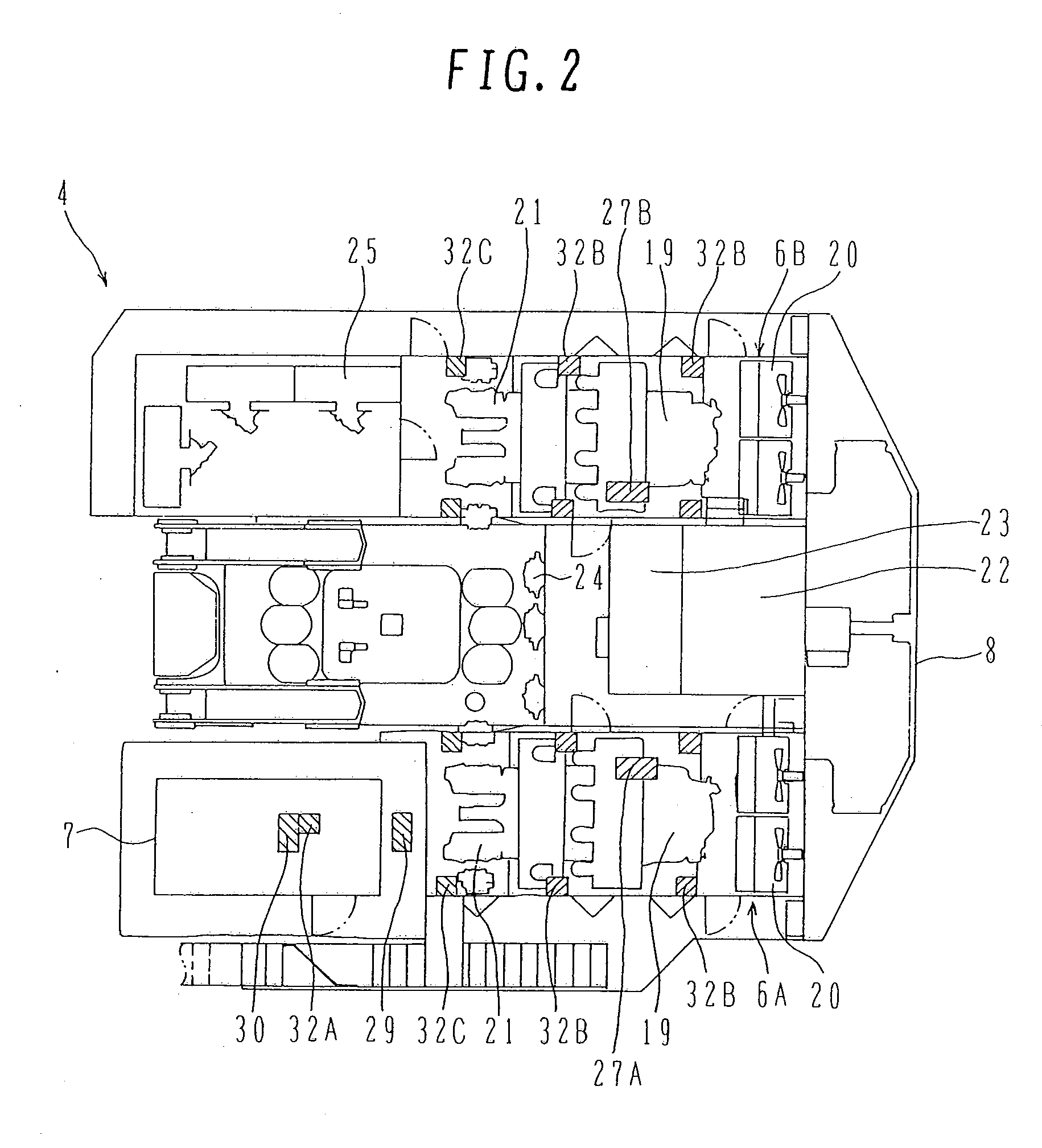

Maintenance history information management system for construction machine

InactiveUS20090265064A1Improve reliabilityHigh precisionVehicle testingData processing applicationsTemporal informationMachine maintenance

The present invention provides a maintenance history information management system for a construction machine that is capable of enhancing the reliability of temporal information about maintenance history data. A data recording device 30 is incorporated in a hydraulic excavator 1 or other construction machine to process operating time or date and time. A mobile terminal 34 includes a CPU 36 for displaying construction machine maintenance items on a monitor 38. A worker can input data for the maintenance items as the maintenance history data. The mobile terminal 34 inputs the operating time or date and time from the data recording device 30 via first a communication cable and a communication connector and stores the input operating time or date and time in a storage device 35 in association with the maintenance history data.

Owner:NIHON KENKI CO LTD

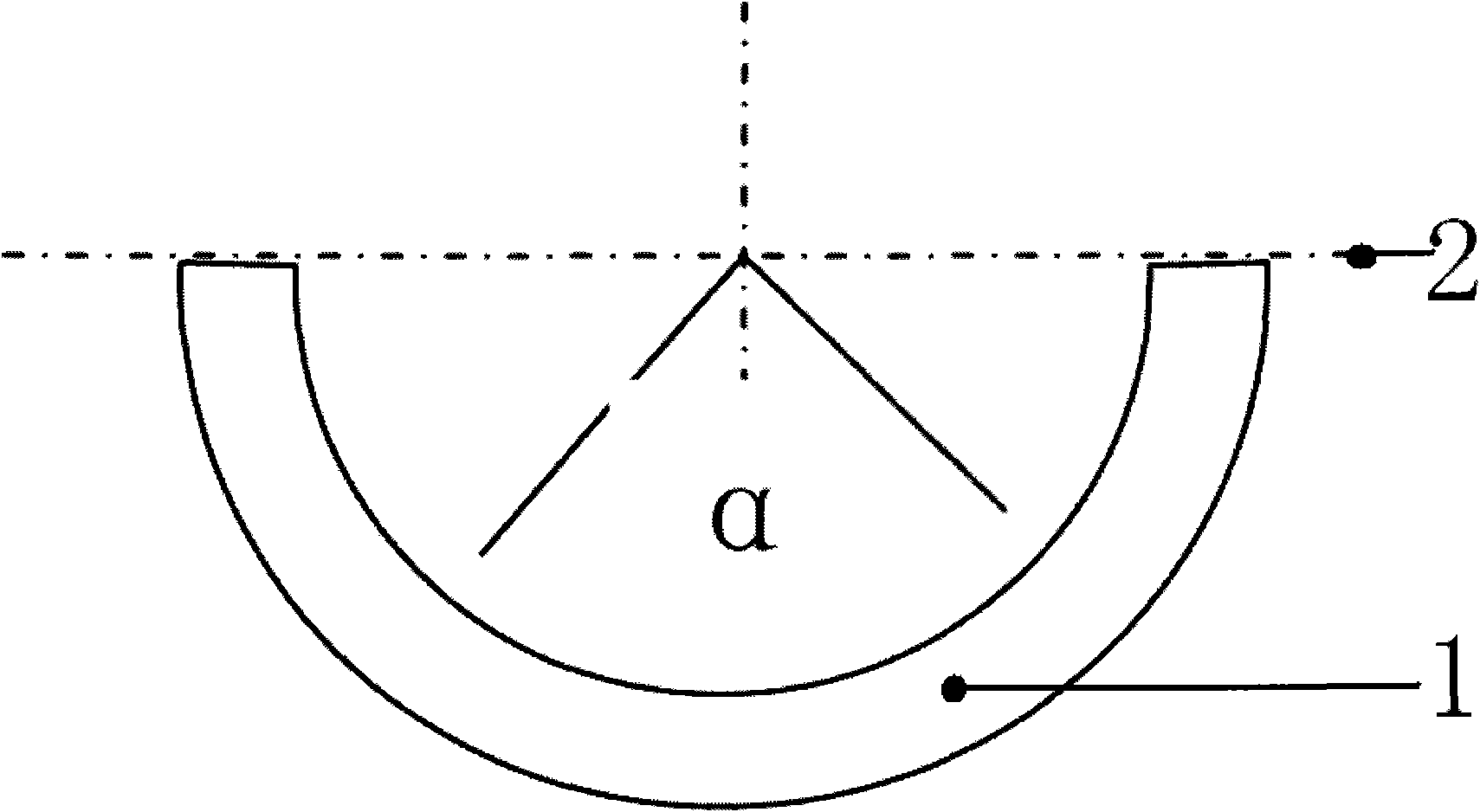

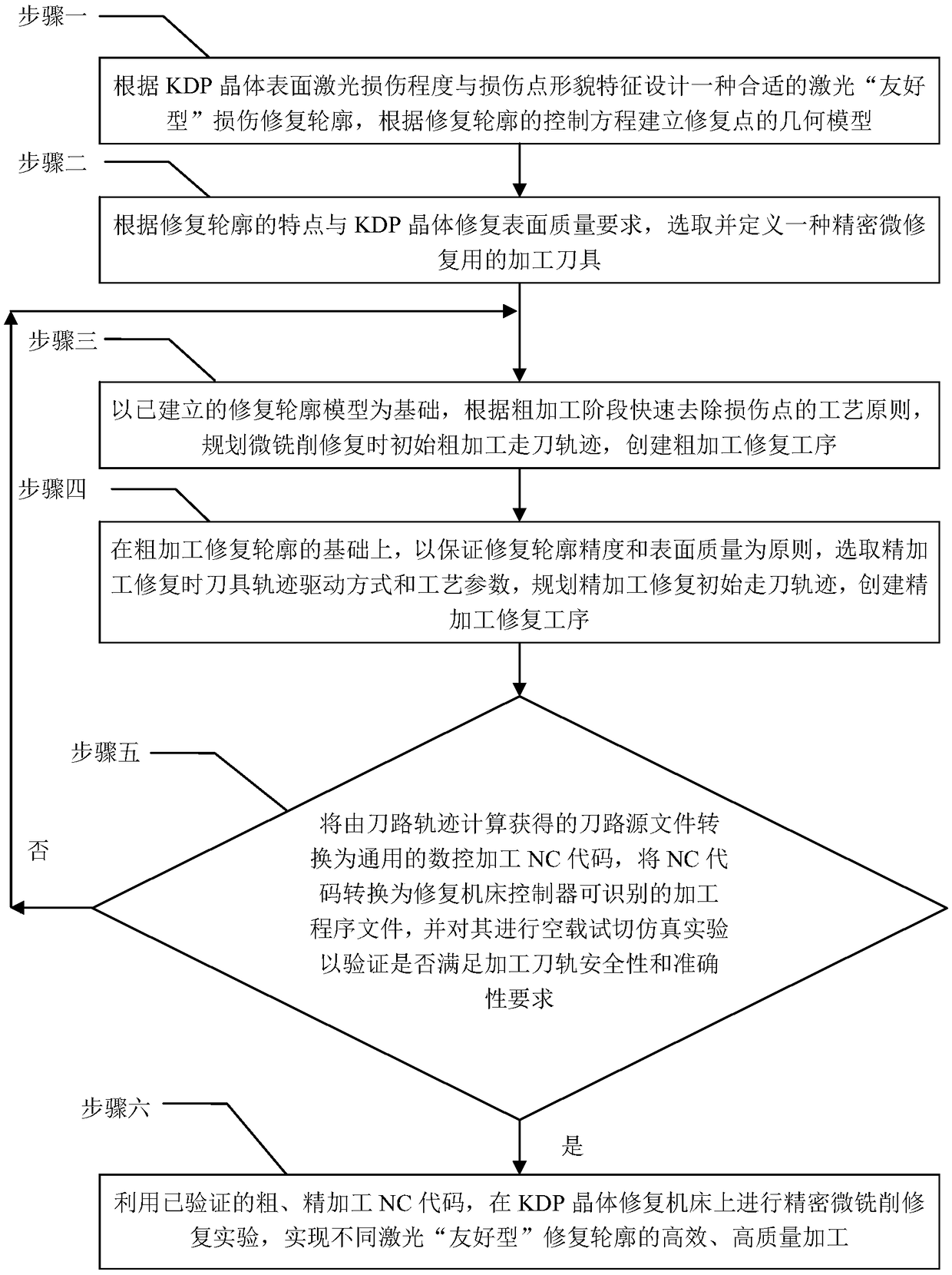

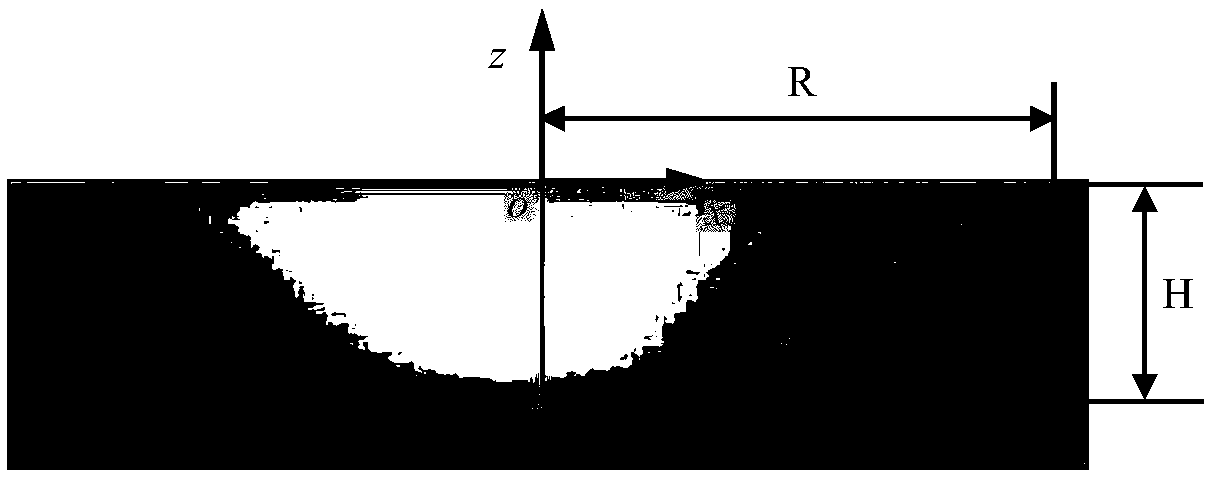

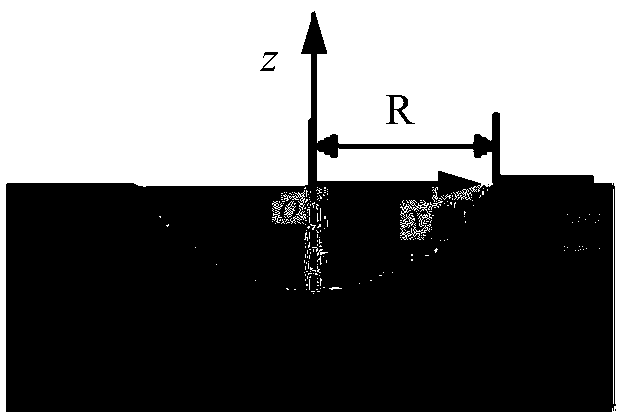

Micro-milling repair technical method for laser damage of surface of large-diameter KDP crystal element

ActiveCN108705692ARemove completelyReduce the proportion of repaired areaFine working devicesNumerical controlEngineering

The invention discloses a micro-milling repair technical method for the laser damage of the surface of a large-diameter KDP crystal element, and belongs to the technical field of repair machining of optical materials and optical elements in order to solve the problems that during repair of laser damage points of the surface of a soft and fragile KDP crystal element, the repair outline is simplex,the repaired surface quality is poor, and the efficiency is low. A geometric model of repairing points is built according to a control equation of the repair outline. A machining tool is selected. A rough machining repair procedure is built. A finish machining repair procedure is built. A tool path source file worked out according to the track of a tool path is converted into common numerical control machining NC codes, and the NC codes are converted into a machining program file capable of being recognized by a repair machine tool controller. A precise micro-milling repair experiment is carried out on a KDP crystal repair machine tool through the rough and finish machining NC codes, and efficient and high-quality machining of different laser friendly repairing outlines is realized. The increase behavior of laser damage points of the surface of the crystal element can be delayed, the laser damage resistance of the crystal element is improved, and the service life of the crystal elementis prolonged.

Owner:HARBIN INST OF TECH

Mechanical maintenance tool kit

InactiveCN108581994AEasy to adjustAchieve regulationWork tools storageOther workshop equipmentEngineeringMoisture absorption

The invention discloses a mechanical maintenance tool kit. The mechanical maintenance tool kit comprises a tool kit body. The left and right opposite inner sidewalls of the tool kit body are symmetrically provided with a plurality of grooves. A bearing plate is clamped to the two grooves in bilateral symmetry. The left and right ends of the bearing plate are both provided with cylindrical grooves.A reset spring is arranged each cylindrical groove. One end of each reset spring is fixedly connected with the inner wall of the corresponding cylindrical groove. The other end of each reset spring is fixedly connected with a limiting rod. The sidewall of the tool kit body is provided with limiting holes matched with the limiting rods. A moisture absorption fan is fixedly embedded at the upper end of the tool kit body. the internal spatial distribution of the tool kit can be adjusted. The mechanical maintenance tool kit is suitable for arrangement of different sizes of maintenance tools, canachieve a good dehumidification function and facilitates storage of the tools.

Owner:广西劢梦科技有限公司

Method for recycling waste polyurethane rigid foamed plastic

InactiveCN103006467AImprove adsorption capacityIncrease frictionCosmetic preparationsToilet preparationsPrillStain

The invention discloses a method for recycling waste polyurethane rigid foamed plastic. The method comprises the following steps: grinding the waste polyurethane rigid foamed plastic into particles which can sieve by 60 mesh sieves; then adding a paste detergent according to a mass ratio of the waste polyurethane rigid foamed plastic particles to the paste detergent of 1:(0.2 to 0.6); placing the mixture into an auger machine to uniformly stir the mixture; and after packaging, obtaining a detergent for washing oil stain or stainless steel products polluted by dirt. According to the invention, as the waste polyurethane rigid foamed plastic particles are mixed with the paste detergent, friction generated when the detergent is in contact with skin and adsorption of the detergent to the oil stain are effectively improved; and moreover, due to the crisp and soft particles, damage to the skin cannot be caused. The method has the advantages that on one hand, the waste polyurethane rigid foamed plastic is recycled; and on the other hand, one detergent which is very suitable for garagemen or machine repair workers to use is obtained and the effect of really changing waste into valuable is realized.

Owner:孟扬

System for maintenance of thermal power generation equipment and method

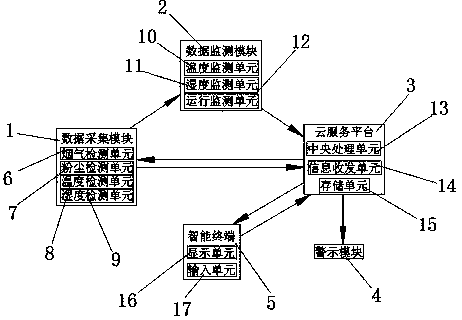

InactiveCN108897303AEasy to formulateEasy maintenance reference planElectric testing/monitoringTransmissionComputer moduleData acquisition

The invention discloses a system for maintenance of thermal power generation equipment, which comprises a thermal power plant equipment operation module, a data acquisition module, a data monitoring module, a mechanical maintenance database, a cloud service platform, a warning module and an intelligent terminal, wherein the output end of the thermal power plant equipment operation module is connected with the input ends of the data acquisition module and the data monitoring module respectively; the output end of the cloud service platform is connected with the input ends of the mechanical maintenance database, the warning module and the intelligent terminal; the output end of the intelligent terminal is connected with the input ends of the data acquisition module and the cloud service platform; and the intelligent terminal comprises an input unit, a modification unit, a judgment unit and a display unit. The system can carry out real-time monitoring on the thermal power plant equipmentthrough control on the intelligent terminal, a maintenance plan can be worked out when a problem is discovered and a warning is given. The invention also provides a using method for the system for maintenance of the thermal power generation equipment. The operation is convenient and quick, and promotion is facilitated.

Owner:丘莲清

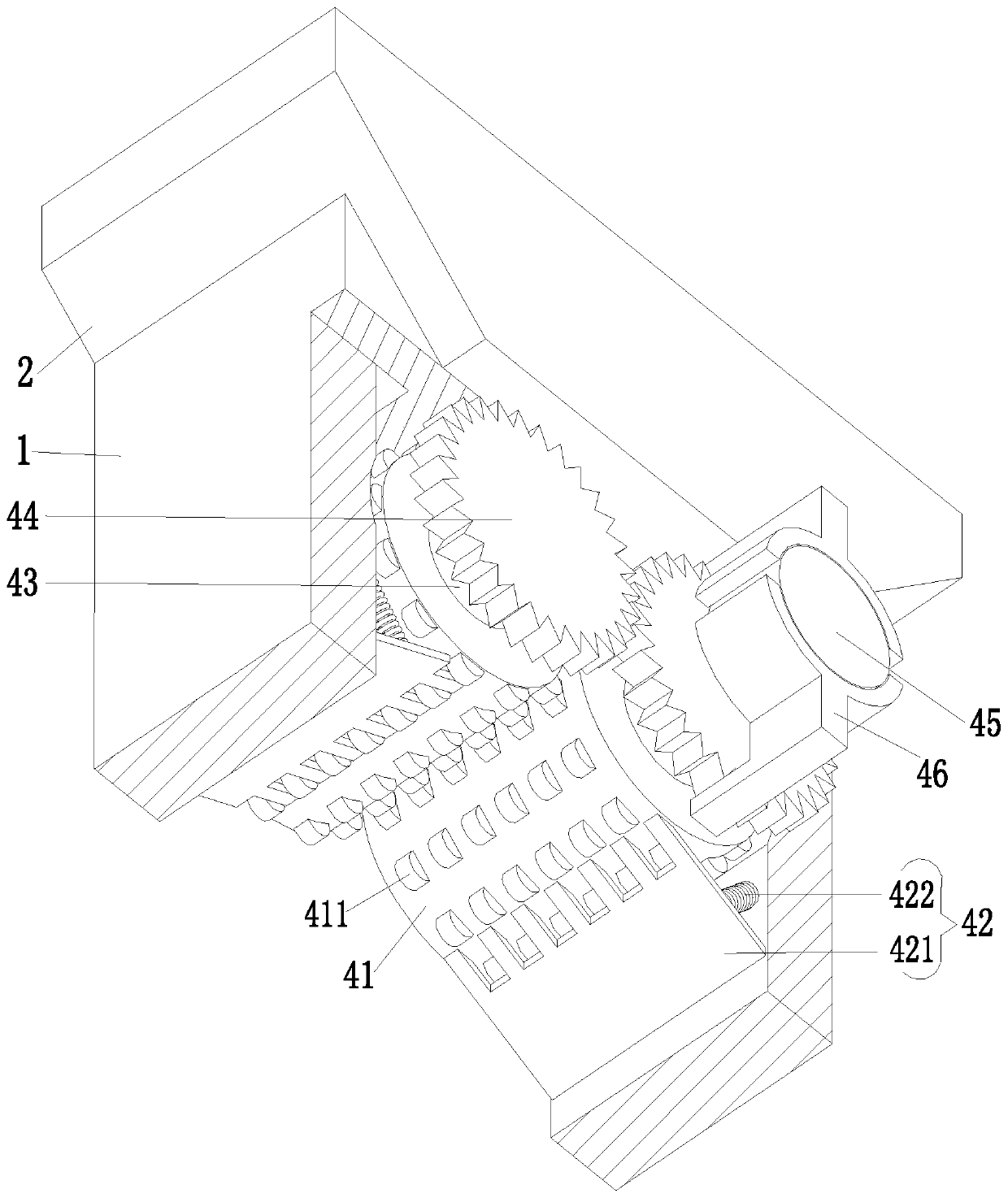

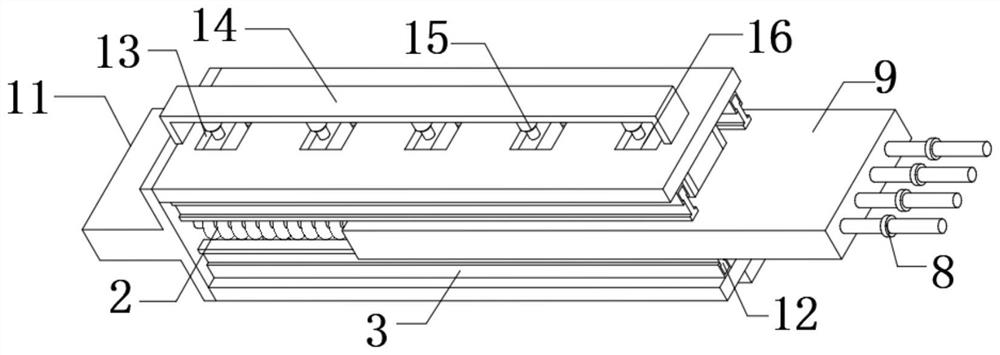

Recycling processing treatment system for steelmaking processing waste steel slag

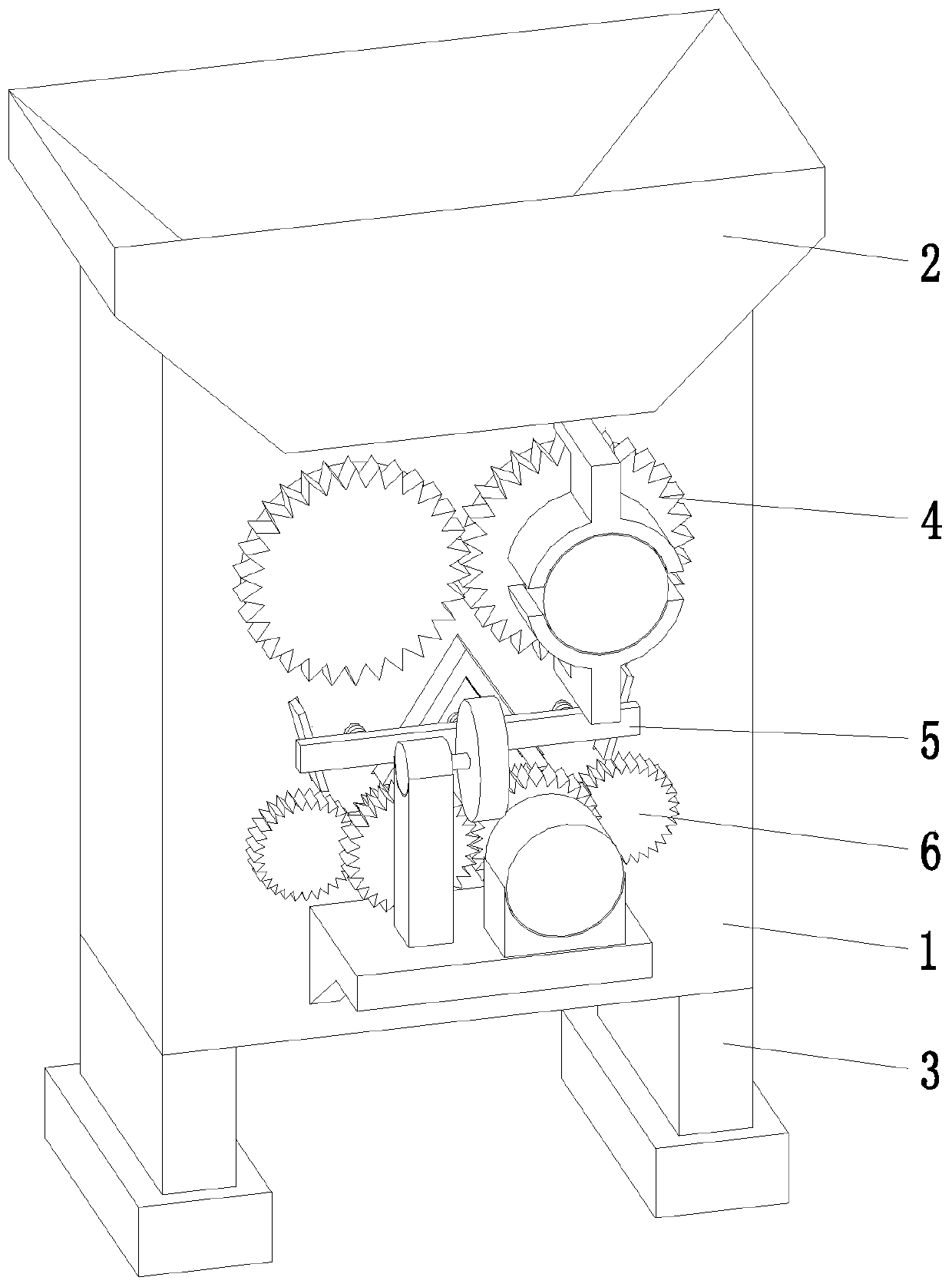

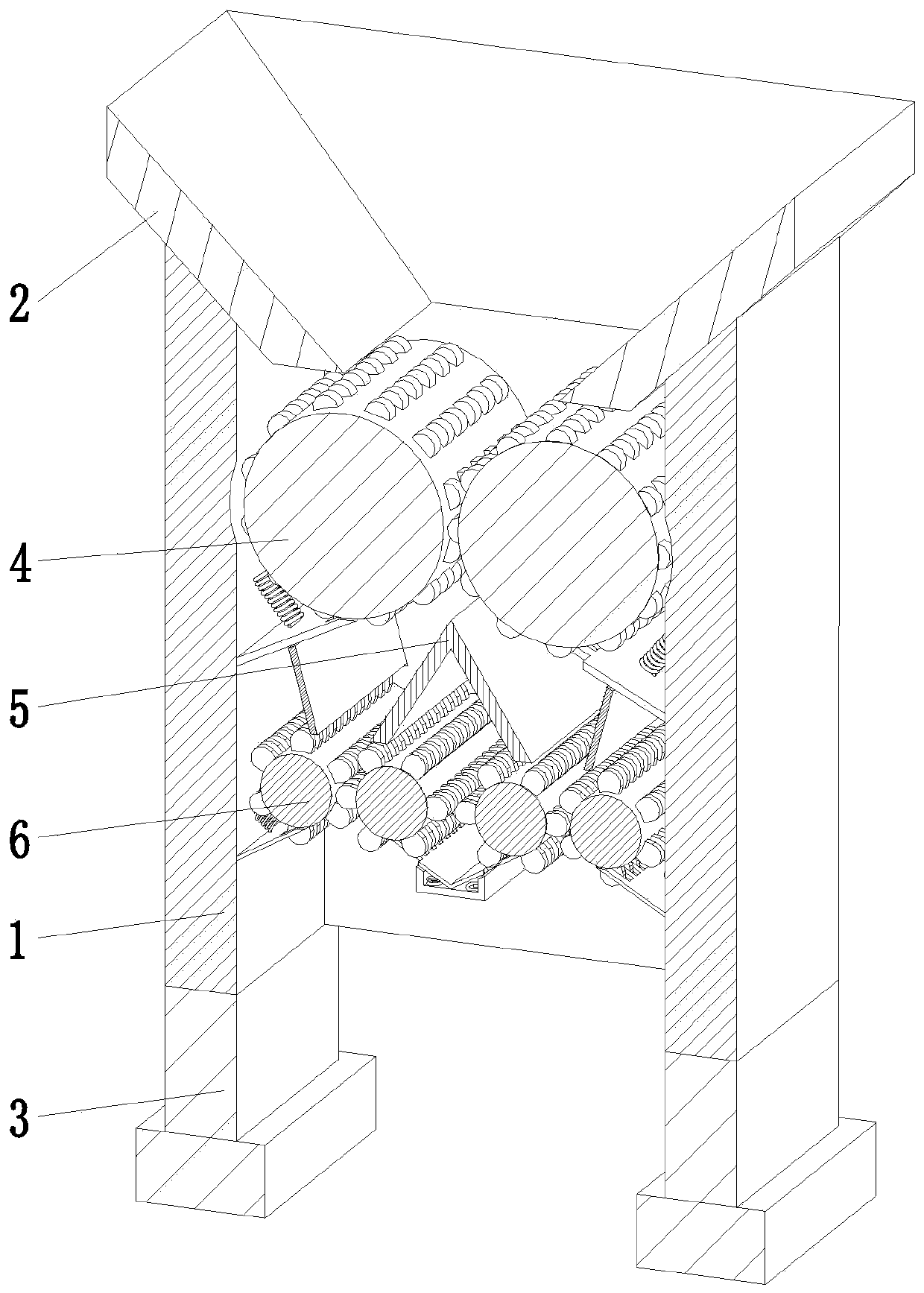

ActiveCN111589521AImprove jaw crushing efficiencySave electricitySolid waste disposalGrain treatmentsSteelmakingProcess engineering

The invention relates to a recycling processing treatment system for steelmaking processing waste steel slag. The system comprises a shell, a flow guide frame, supporting plates, a first crushing mechanism, a shaking mechanism and a second crushing mechanism, wherein the shell is of a concentric-square-shaped structure with openings in the upper end and the lower end, the flow guide frame is installed at the upper end of the shell, the supporting plates are symmetrically installed on the left side and the right side of the lower end of the shell, and the first crushing mechanism, the shaking mechanism and the second crushing mechanism are sequentially arranged in the shell from top to bottom. With the system, the following problems existing when an existing large jaw crusher is used for carrying out jaw crushing on the steel slag can be solved: after the steel slag is subjected to jaw crushing of a primary degree, a finer jaw crusher needs to be used for carrying out secondary jaw crushing on the steel slag, and consequently, the jaw crushing efficiency of the steel slag is low; the steel slag is easily adhered to the surfaces of jaw crushing columns, so that the jaw crushing columns are easily stuck by the adhered steel slag, and then the jaw crusher is frequently maintained; and the jaw crushing effect of the existing machine is poor, so that ball-milling time of the steel slag after jaw crushing needs to be prolonged.

Owner:日照山河超细材料科技有限公司

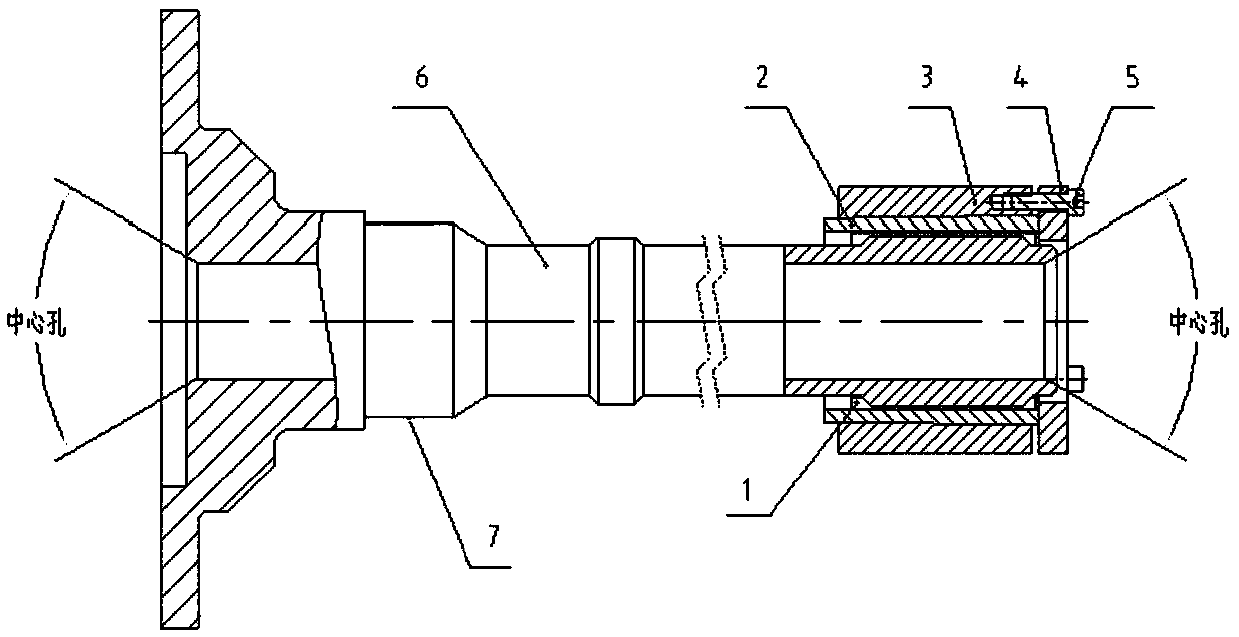

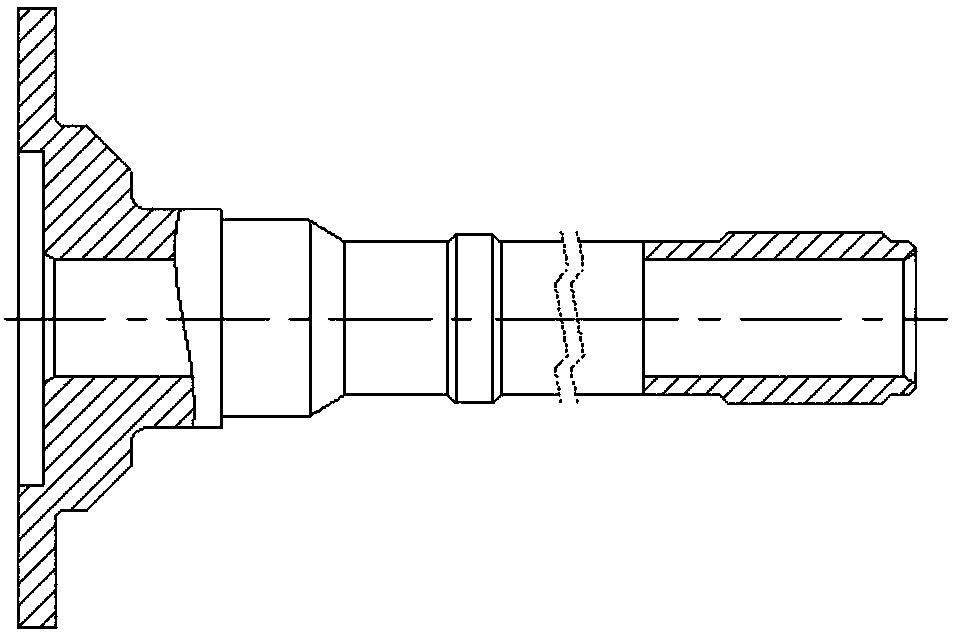

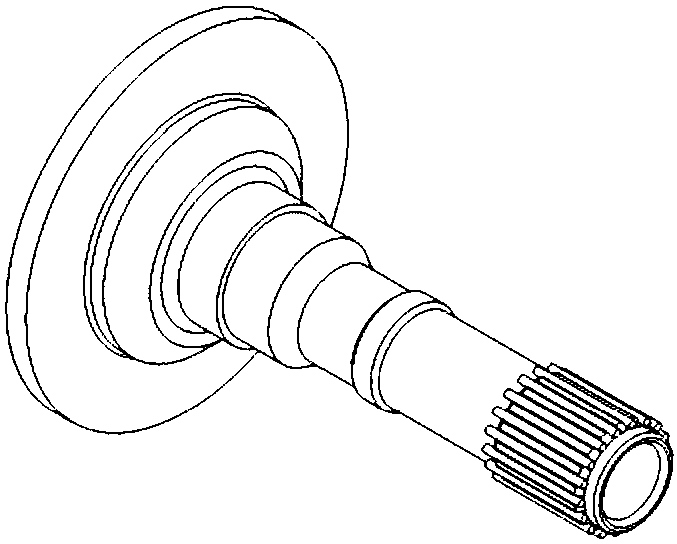

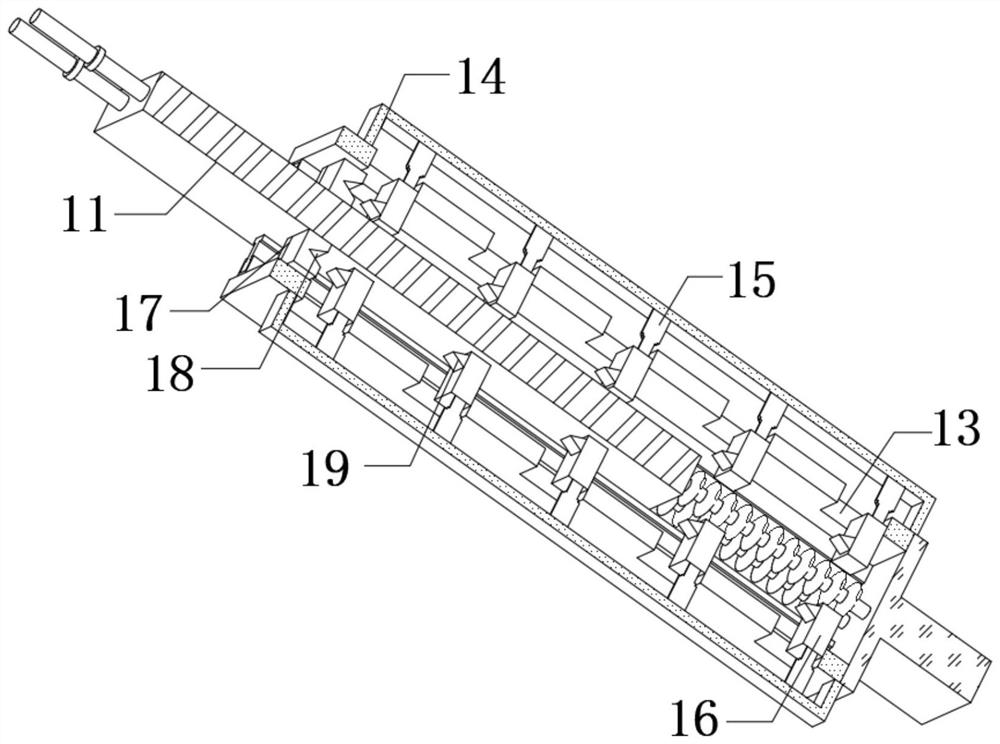

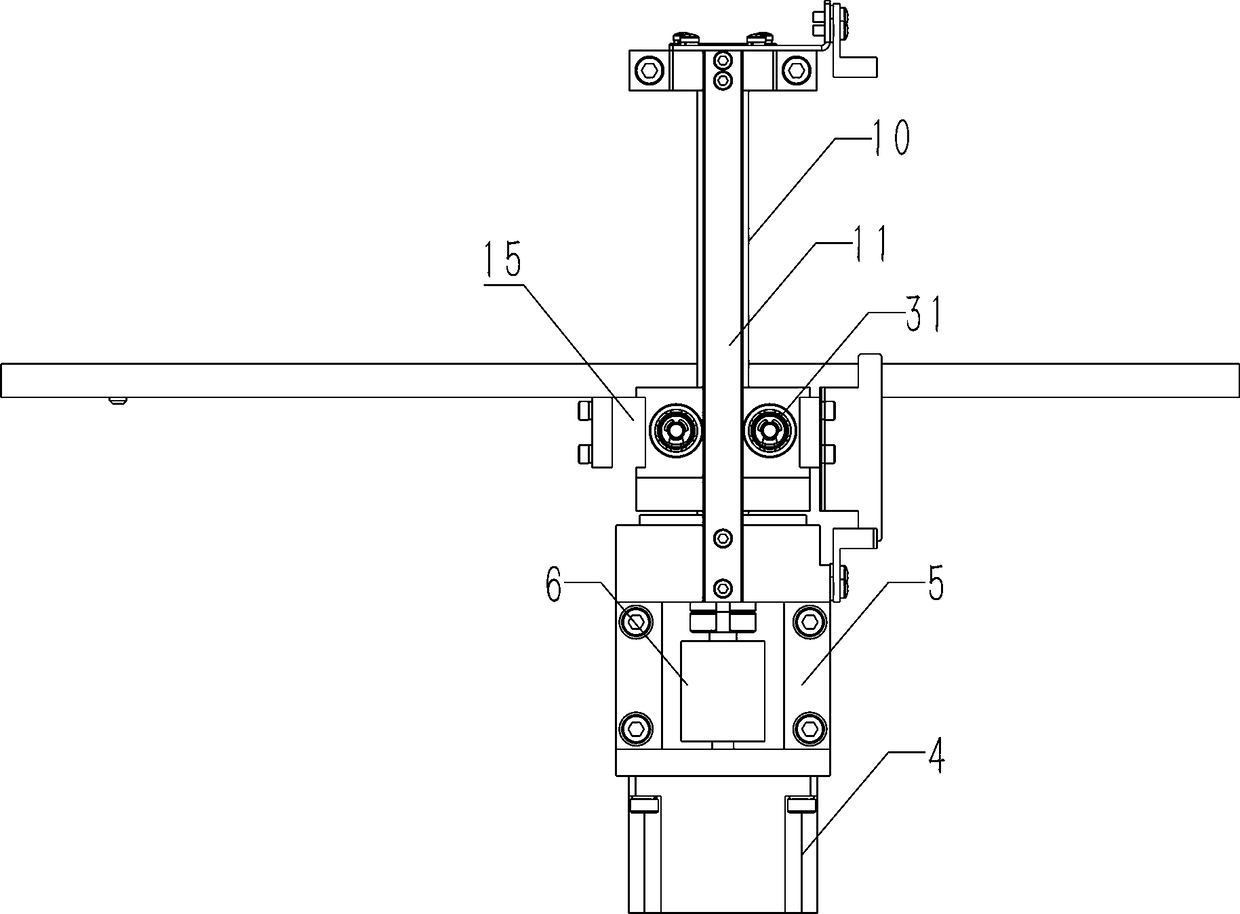

Tool for repairing and grinding center holes of output shaft of aero-engine and repairing and grinding work method of tool

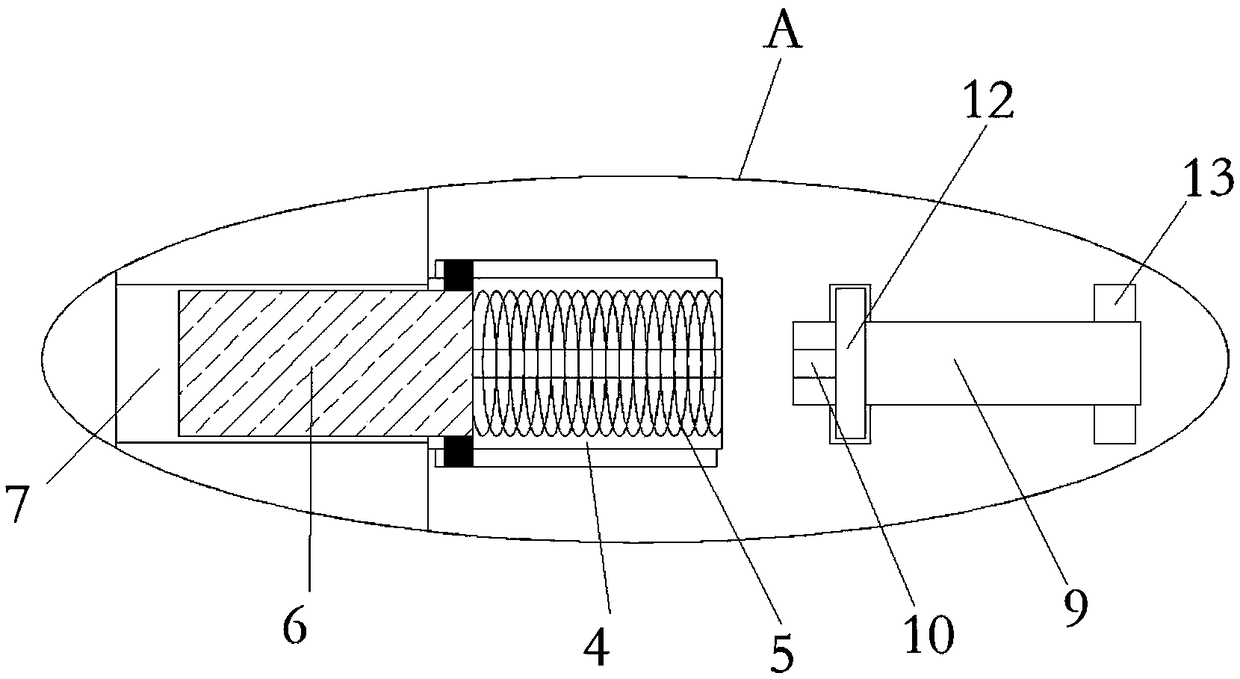

PendingCN108381188AAvoid damage to the output shaftSimple structureRevolution surface grinding machinesOther manufacturing equipments/toolsInstabilityEngineering

The invention relates to a tool for repairing and grinding center holes of an output shaft of an aero-engine and a repairing and grinding work method of the tool. The tool comprises rolling rods, aninner taper sleeve, an outer taper sleeve, a pressing plate and a screw, wherein the rolling rods are arranged and placed in a spline groove of the output shaft at equal intervals in a circumferentialmode, an inner hole of the inner taper sleeve is in contact compression with the rolling rods, and the inner conical surface of the outer taper sleeve is compressed with the outer conical surface ofthe inner taper sleeve in a cooperating mode; and the left end face of the pressing plate is in contact compression with the right end face of the inner taper sleeve, the screw penetrates through a through hole in the pressing plate and is in threaded connection with a threaded hole in the end face of the inner taper sleeve. The tool is simple in structure and easy to machine; according to the repairing and grinding work method of the tool, manual hand scraping repairing and grinding in the prior art is replaced by machining repairing and grinding, so that instability of manual repairing and grinding is eliminated, and the phenomenon that the output shaft is damaged by a hand scraper in the manual repairing and grinding process can be effectively avoided; and the repairing and grinding working method of the tool is simple, convenient and reliable, and on the premise of guaranteeing the repairing and grinding quality, the time required for repairing and grinding is shortened.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

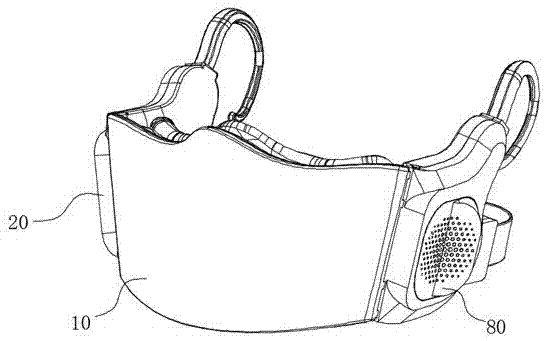

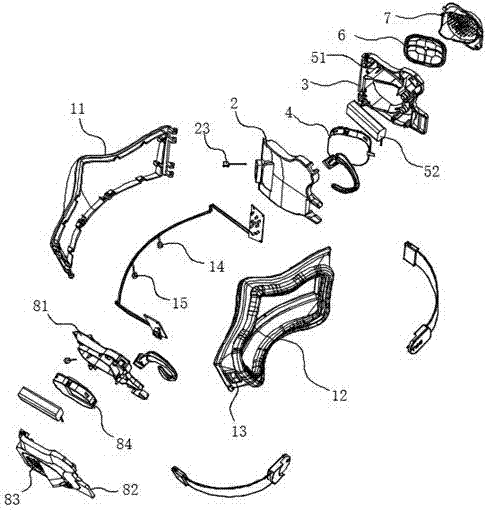

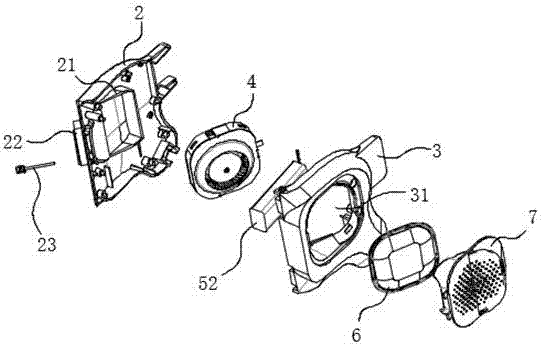

Face mask with replaceable filter element

PendingCN107961456AEasy to replaceEasy maintenanceFire rescueRespiratory apparatusStructural engineeringMechanical engineering

The invention discloses a face mask with a replaceable filter element. The face mask comprises a face mask body and an air inlet module arranged on one side of the face mask body. A filter assembly isarranged on an air inlet channel. The filter assembly comprises a detachably-connected filter element and a filter net cover which covers the outer side of the filter element and is detachably connected, and the beneficial effects that filter element replacement and whole machine repairing are convenient.

Owner:深呼吸创造智能科技(天津)有限公司

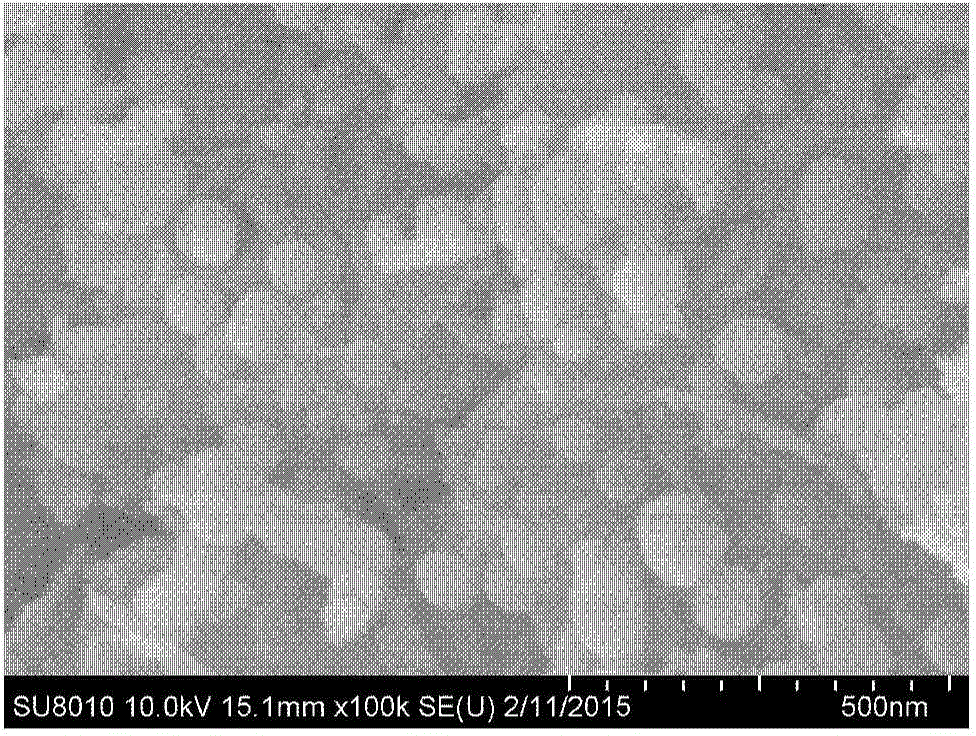

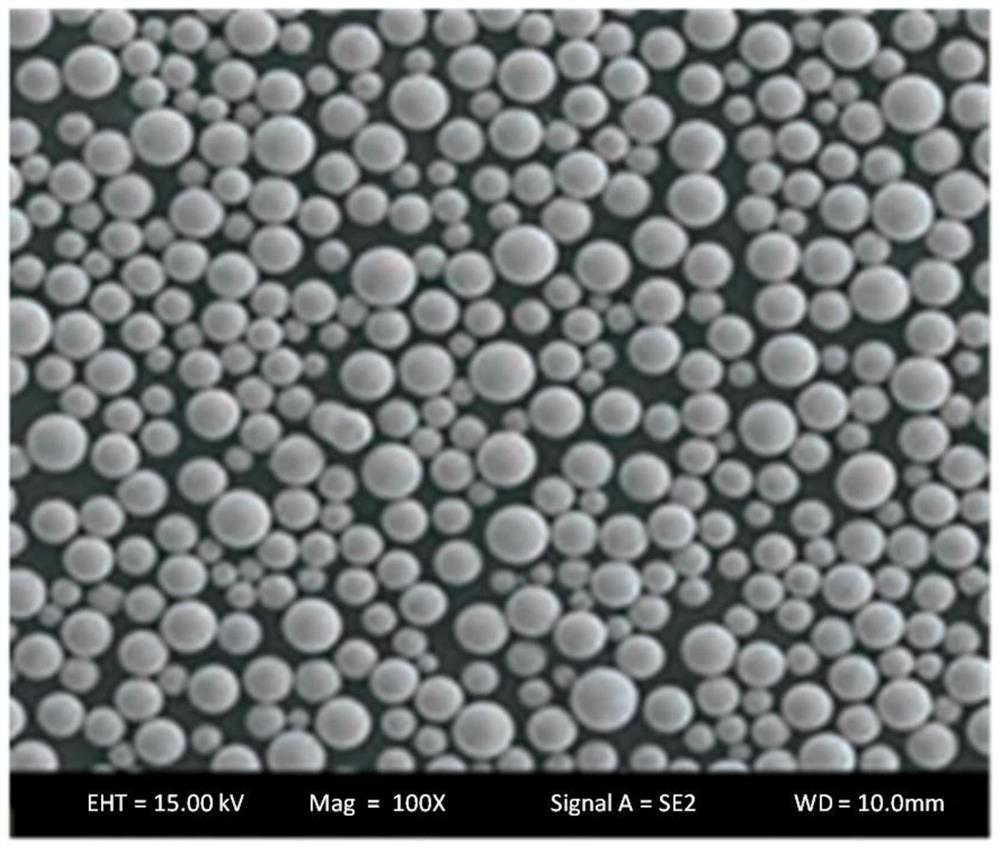

Alloy powder for laser cladding repair of mining hydraulic stand column middle cylinder and repair method

ActiveCN113046625AReduce formationReduce the ratioMetallic material coating processesLaser processingAlloy coating

The invention relates to laser machining repair, in particular to alloy powder for laser cladding repair of a mining hydraulic stand column middle cylinder and a repair method. In order to solve the problem that during laser cladding repair of the mining hydraulic middle cylinder, an alloy coating is prone to pitting corrosion and consequently the corrosion life is short, the invention provides the alloy powder for laser cladding repair of the mining hydraulic stand column middle cylinder, which is high in pitting corrosion resistance and long in service life, and the repair method. The alloy powder comprises 15.0-17.0 wt% of Cr, 1.5-2.0 wt% of Ni, 1.5-2.0 wt% of Co, 0.8-1.2 wt% of Mo, 0.0-0.4 wt% of Mn, 0.1-0.2 wt% of Nb, 0.07-0.14 wt% of C, 0.06-0.12 wt% of N, 0.03-0.06 wt% of Ce, 0.6-1.0 wt% of B, 0.8-1.2 wt% of Si, and the balance Fe. The addition of the Co element can expand the austenite region, so that the toughness is increased, the wear resistance is improved, the pitting corrosion resistance of a cladding layer is further improved, and the service life is prolonged.

Owner:XIAN BESAME LASER TECH CO LTD

Roller grinding method

InactiveCN103341798APrevent deviationImprove rolling efficiencyRevolution surface grinding machinesSurface roughnessStrip steel

The invention belongs to the field of metallurgical machinery maintenance, and discloses a roller grinding method. 80# or 100# is adopted in a grinding wheel of a grinding machine. The transverse moving speed of the Z-axis of the grinding machine is 2000mm / min, the continuous feed rate of the X-axis is 0.015mm / min, the grinding pressure is 1.0-1.5Pa, and the surface roughness of a roller is 0.2-0.7um. According to the roller grinding method, the phenomenon of strip steel deviation can be avoided effectively, the rolling efficiency of strip steel is improved, and the quality of strip steel products is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

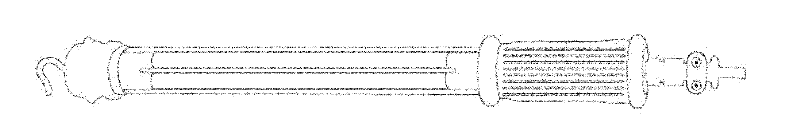

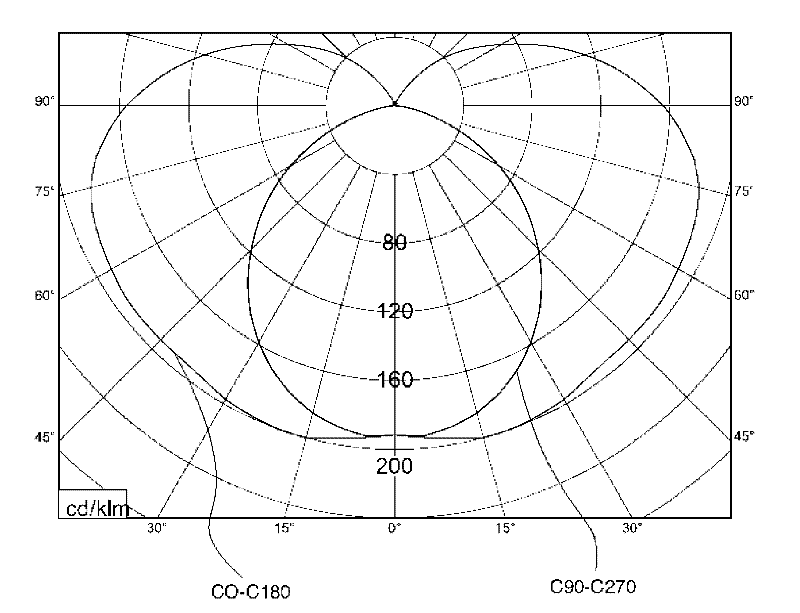

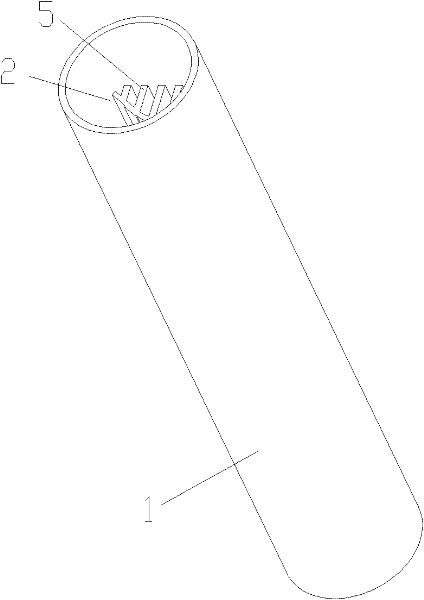

LED lamp

InactiveCN102537764AMeet the light distribution requirementsUniform light outputPoint-like light sourceLighting heating/cooling arrangementsLight beamEngineering

The invention is suitable for the field of illumination, and provides an LED lamp. The LED lamp comprises a lamp tube, and a fixing plate arranged in the lamp tube and having a V-shaped cross section, wherein the fixing plate is provided with facing surfaces and opposite surfaces; a plurality of cooling ribs are arranged on the facing surfaces of the fixing plate; and a plurality of LEDs are uniformly distributed on the opposite surfaces of the fixing plate. According to the LED lamp, the plurality of LEDs are uniformly distributed on the two opposite surfaces of the fixing plate with the V-shaped cross section, so that the light beams emitted by the LEDs are superposed to achieve uniform light emission and large light emission angle and light intensity; the light distribution curve of the LED lamp is close to that of a fluorescent lamp to meet the requirement on light distribution of the LED lamp; and the LED lamp has excellent seismic performances and impact resistance. In addition, as an illumination device, the LED lamp can be used as a machine repair light or a tent light.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Method for grinding disc scissors

A method for grinding disc scissors belongs to the metallurgical machinery maintenance field. The method is characterized by including the steps that on a grinding machine, a 80# grinding wheel is used for roughly grinding the disc scissors for 1 hour, and a 150# grinding wheel is used for accurately grinding and polishing the disc scissors until the roughness of the disc scissors is 0.1 micrometer. By the adoption of the method for grinding the disc scissor, the grinding accuracy of the disc scissors can be improved, slitting and trimming can be normally conducted when a pair of scissors is longitudinally cut, and quality of strip steel products is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

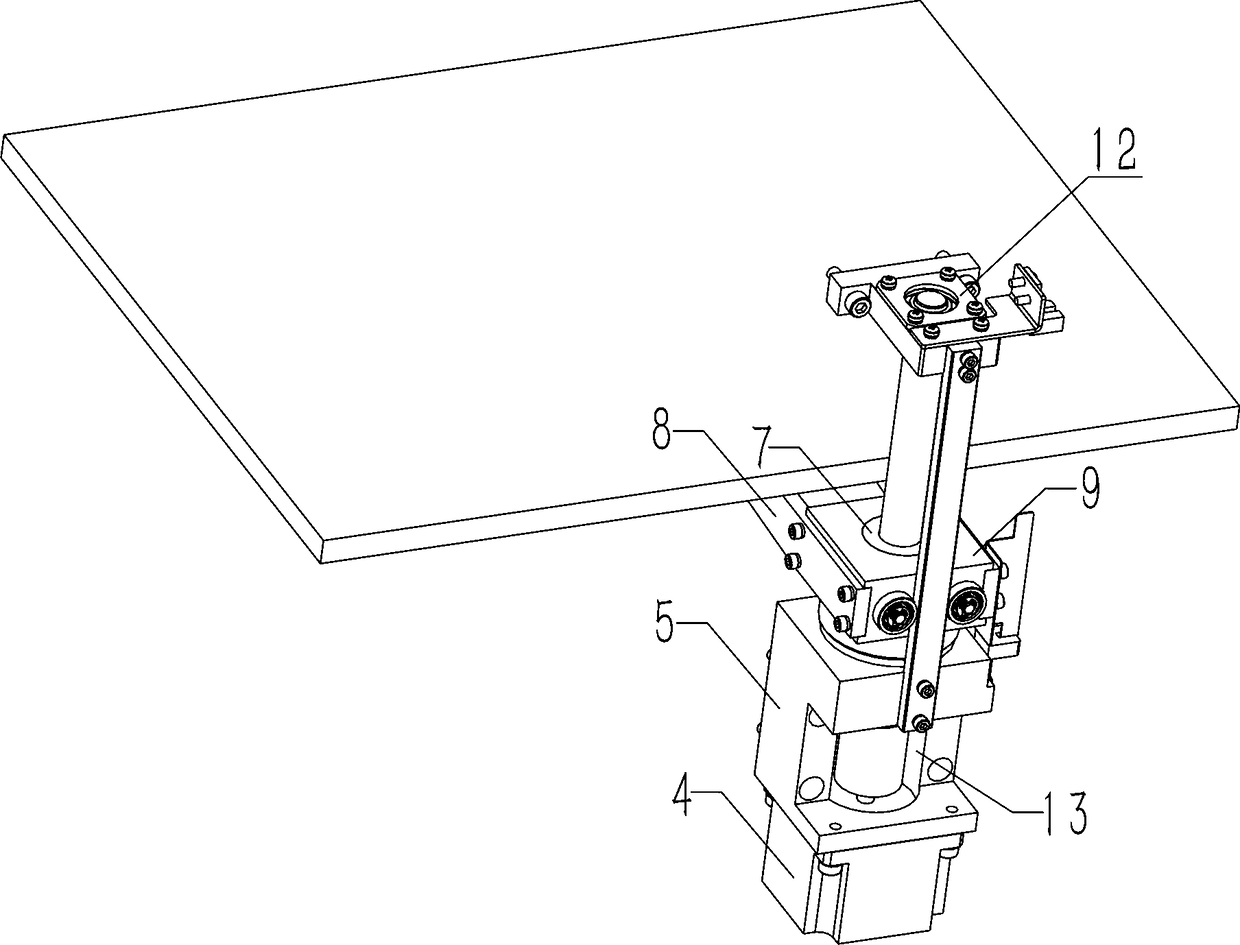

Mechanical device supporting and maintenance device

InactiveCN111847314AReduced gravitational potential energyReduce security risksLifting framesVibration suppression adjustmentsHydraulic cylinderEngineering

The invention belongs to the technical field of mechanical maintenance, and particularly relates to a mechanical device supporting and maintenance device. The device aims to solve the problems that when maintained, existing mechanical equipment is always directly suspended to be conveniently maintained, but with increase of the weight of the mechanical equipment, the gravity damage to a fixing frame of the mechanical equipment is larger, meanwhile, the mechanical equipment is suspended, the gravitational potential energy of the mechanical equipment for descending is larger with increase of theweight, and potential safety hazards are larger. The device comprises a bottom plate, and the outer wall of the top of the bottom plate is fixedly connected with two supporting seats. By arranging ahydraulic cylinder, ejecting blocks, connecting blocks and a pressure reducing plate, the height of a placing plate is adjusted according to the weight of the mechanical equipment when the mechanicalequipment is maintained, so that the gravitational potential energy of the mechanical equipment is reduced; due to the ejecting blocks distributed in layers, the connecting blocks on the pressure reducing plate are limited, so that the height of the pressure reducing plate is adjusted, then the height of the placing plate is adjusted, and the potential safety hazards are reduced.

Owner:鲁仲斐

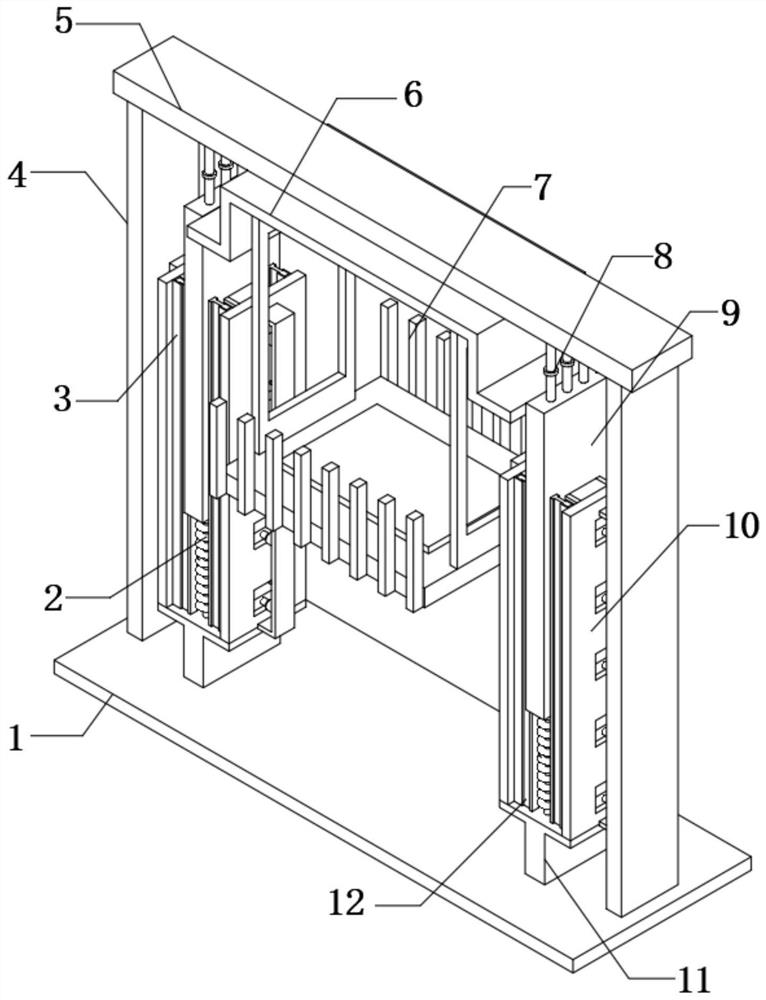

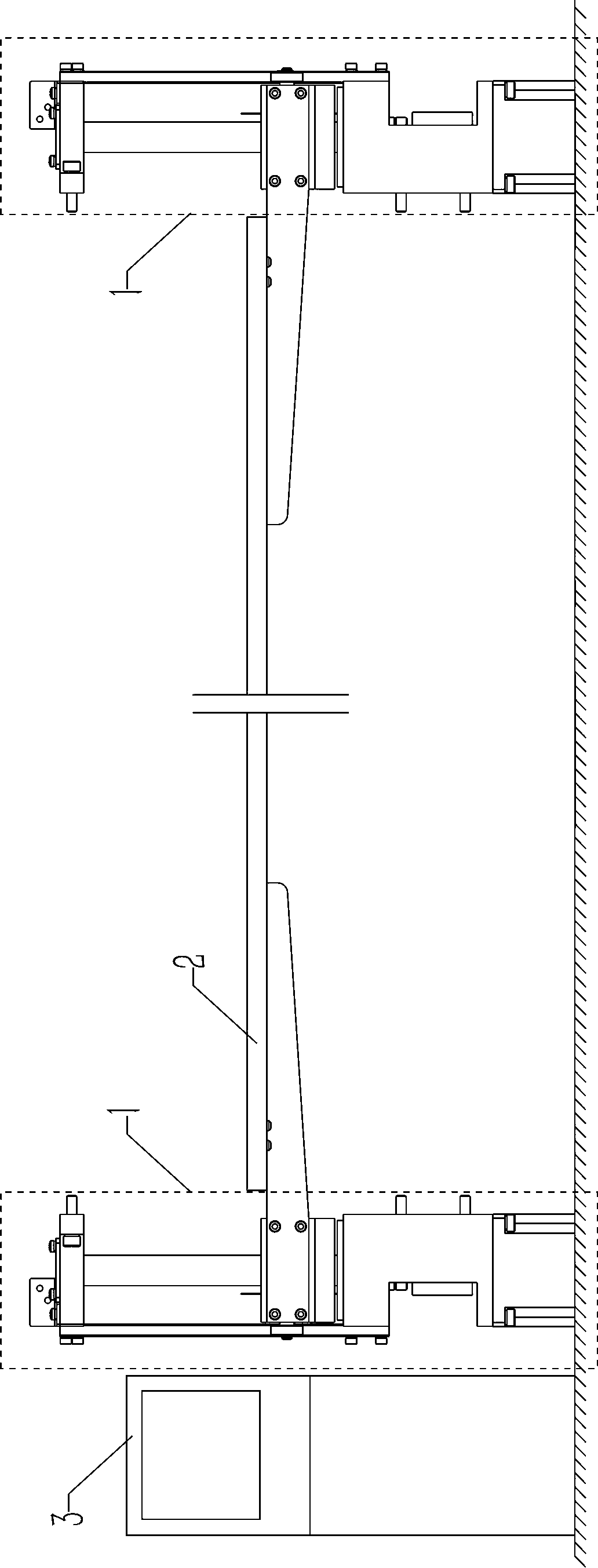

Lifting platform for mechanism maintenance

PendingCN108439253AEasy to implementSatisfied with the useLifting framesCommunication controlIndustrial engineering

The invention discloses a lifting platform for mechanism maintenance. The lifting platform comprises a left lifting control mechanism, a right lifting control mechanism, a mechanism maintenance tableboard and a communication control cabinet, wherein the mechanism maintenance table board is positioned between the left lifting control mechanism and the right lifting control mechanism and is automatically lifted through the two lifting control mechanism. The lifting platform is easy to operate; people arrange the dismounted spare parts on the mechanism maintenance table board for maintaining orresearching, and meanwhile, a mechanism to be maintained is wholly lifted to reach certain height through the mechanism maintenance table board and then the mechanism to be maintained can be maintained. Therefore, the lifting platform meets that many people can use in match. The whole lifting platform for the mechanism maintenance is simple in structure, and convenient to use; manpower is saved during use, so that the working efficiency is improved; and the lifting platform is high in popularization and application value; a motor is provided for driving, so that the lifting platform driving mode and the loading capacity are improved, and as a result, the stability of the lifting platform is ensured, and the working efficiency is improved.

Owner:林伟蒸

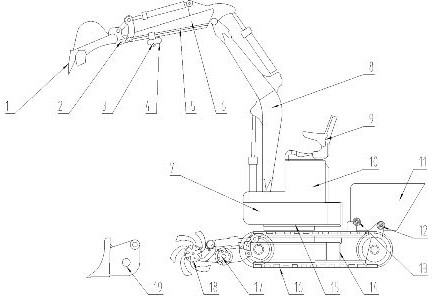

Agricultural comprehensive treatment machine

The invention relates to an agricultural comprehensive treatment machine. The agricultural comprehensive treatment machine is composed of an excavation soil loosening bucket, a fast-assembly bayonet,a movable hoisting hook, a voice overload alarm, a hook moving guide rail, an excavation upper arm, a rotary machine base, an excavation lower arm, an operation seat, a power box, a self-unloading hopper, a goods hopper overturning shaft, a goods hopper overturning control lock, a walking chassis, machine base rotation driving teeth, a crawler belt, a functional fast-assembly frame, a rotary tillage ridge building assembly, a bulldozing, soil turning and ditching assembly and the like. The self-unloading hopper is installed at the rear end of the walking chassis, the functional fast-assembly frame is installed at the front lower portion to replace the rotary tillage ridge building assembly and the bulldozing, soil turning and ditching assembly, an excavation arm is installed at the upper front end of the rotary machine base, and the hoisting hook is installed at the lower edge of the excavation upper arm; and the machine can be used for farming and renovating a farmland in agriculturaluse, can be used as a small engineering machine to realize transfer, bulldozing and excavation of a certain weight in idle time, and can also be used for safely hoisting an object with a certain weight, so that convenience is brought to mechanical maintenance, replacement of functional parts, small engineering construction and the like, and the machine is suitable for different application scenesof agricultural operation and engineering construction.

Owner:CHONGQING MAOTIAN MACHINERY

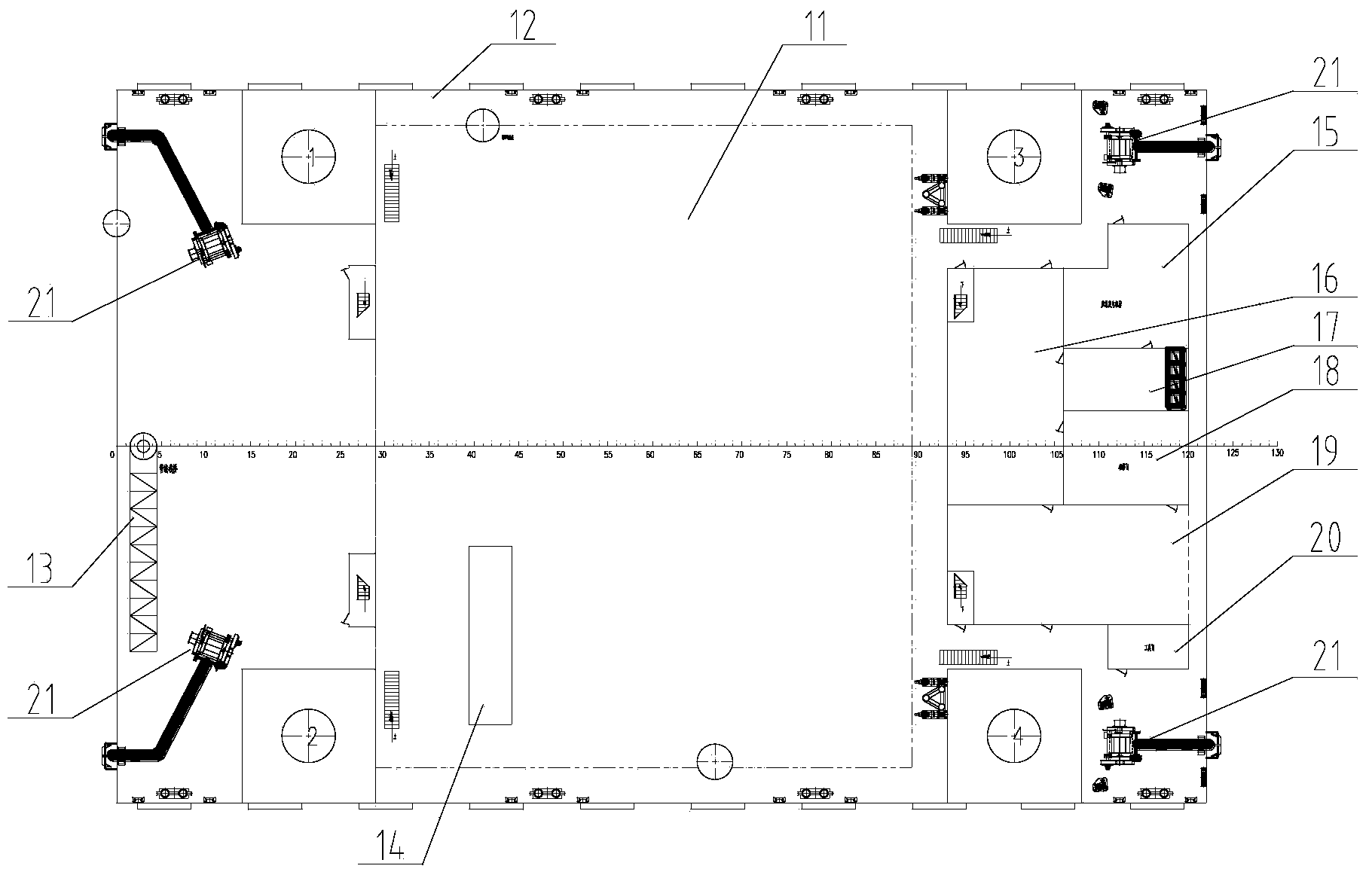

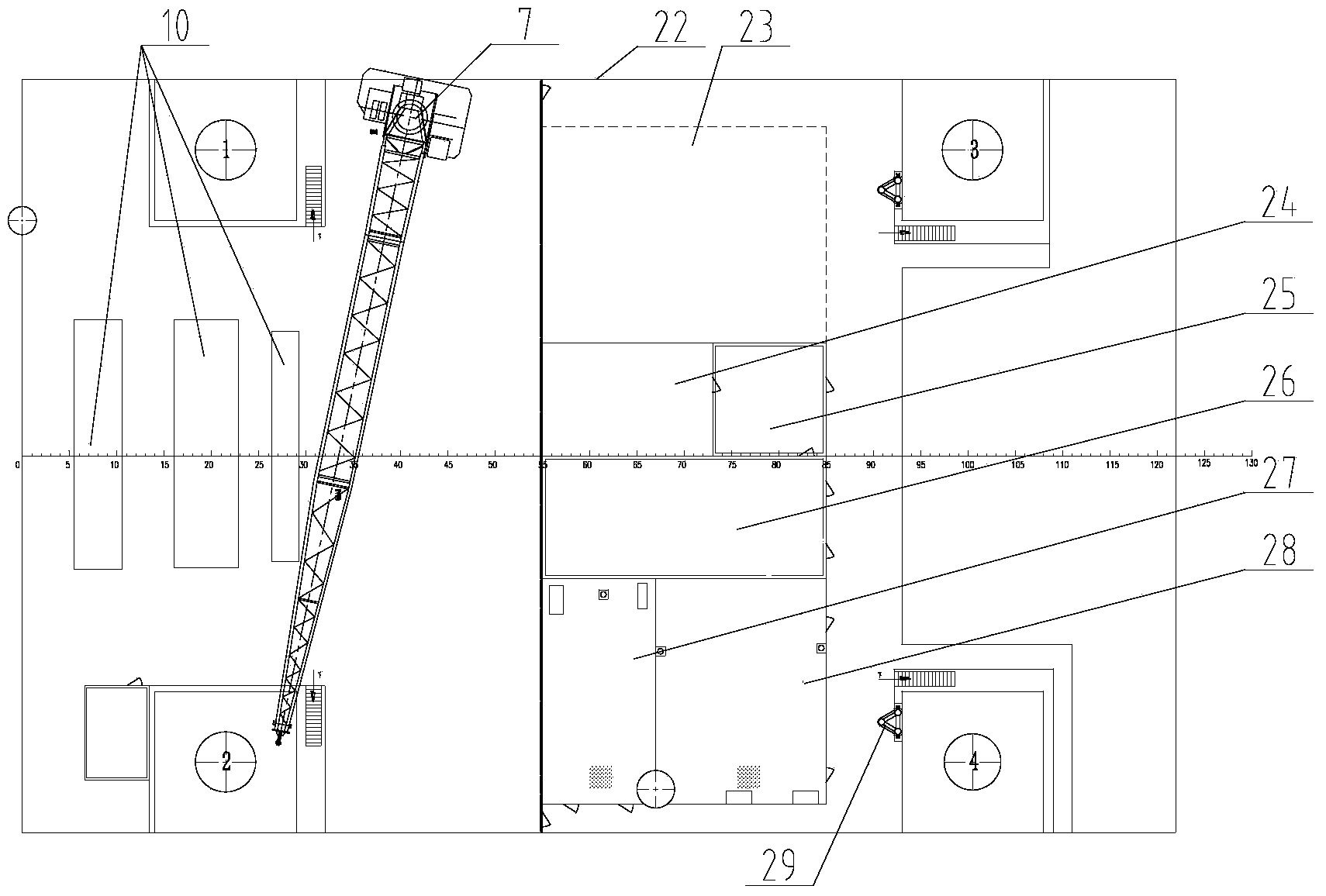

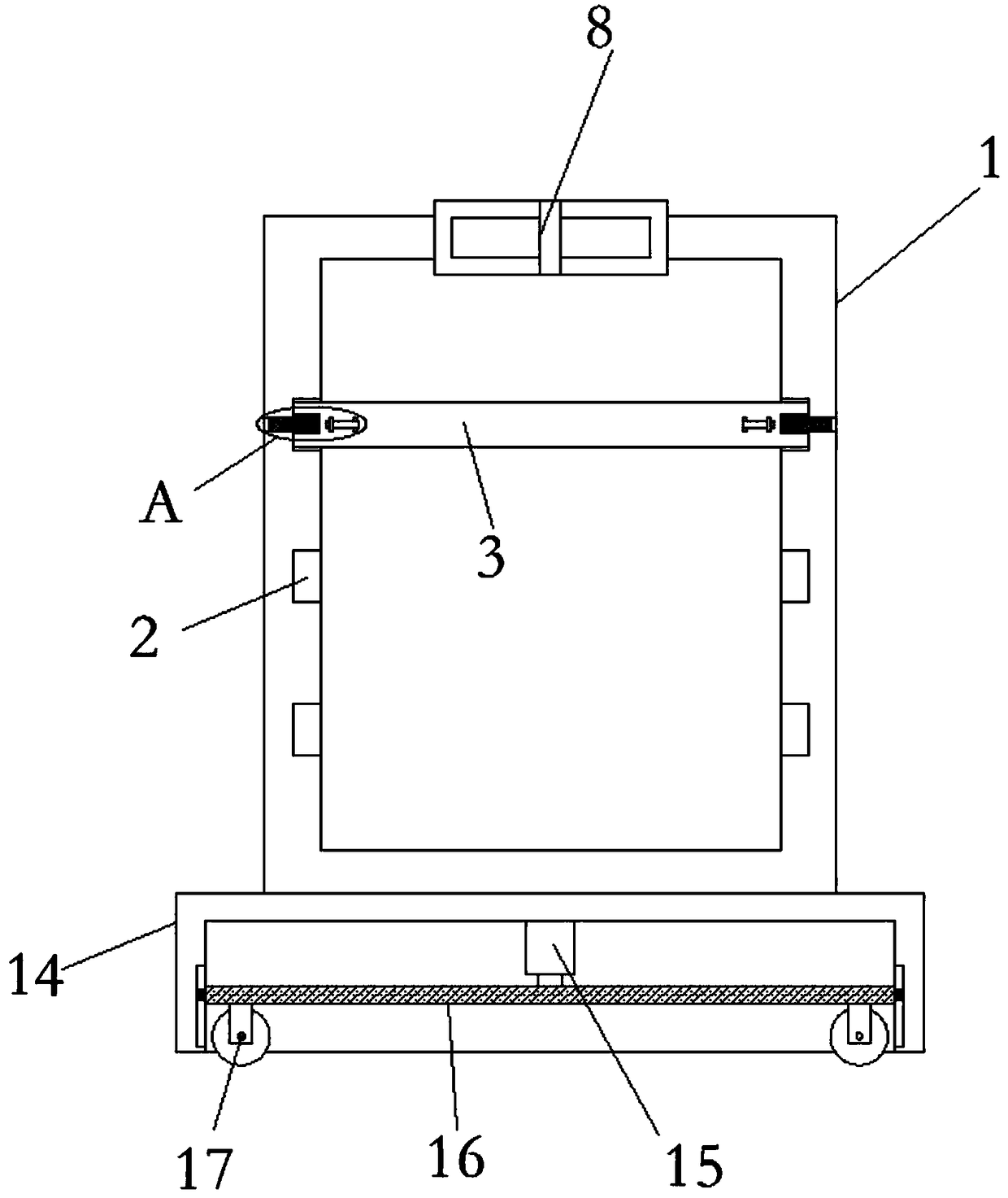

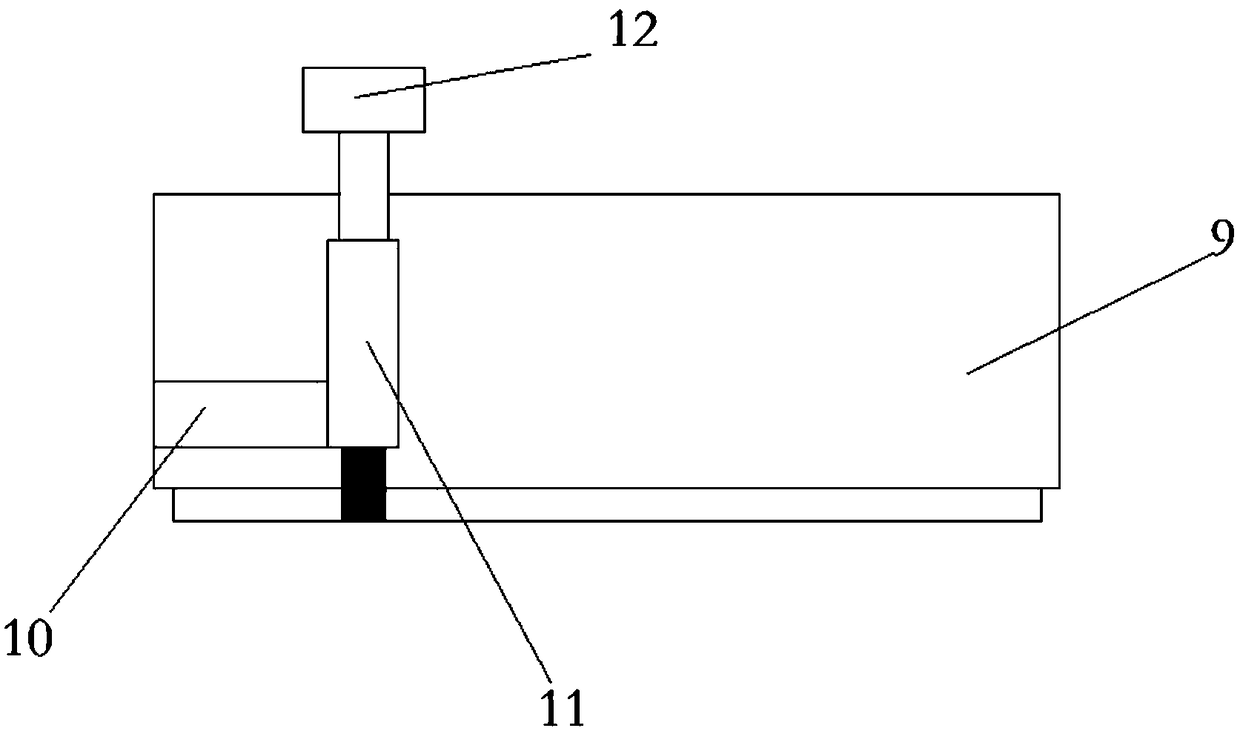

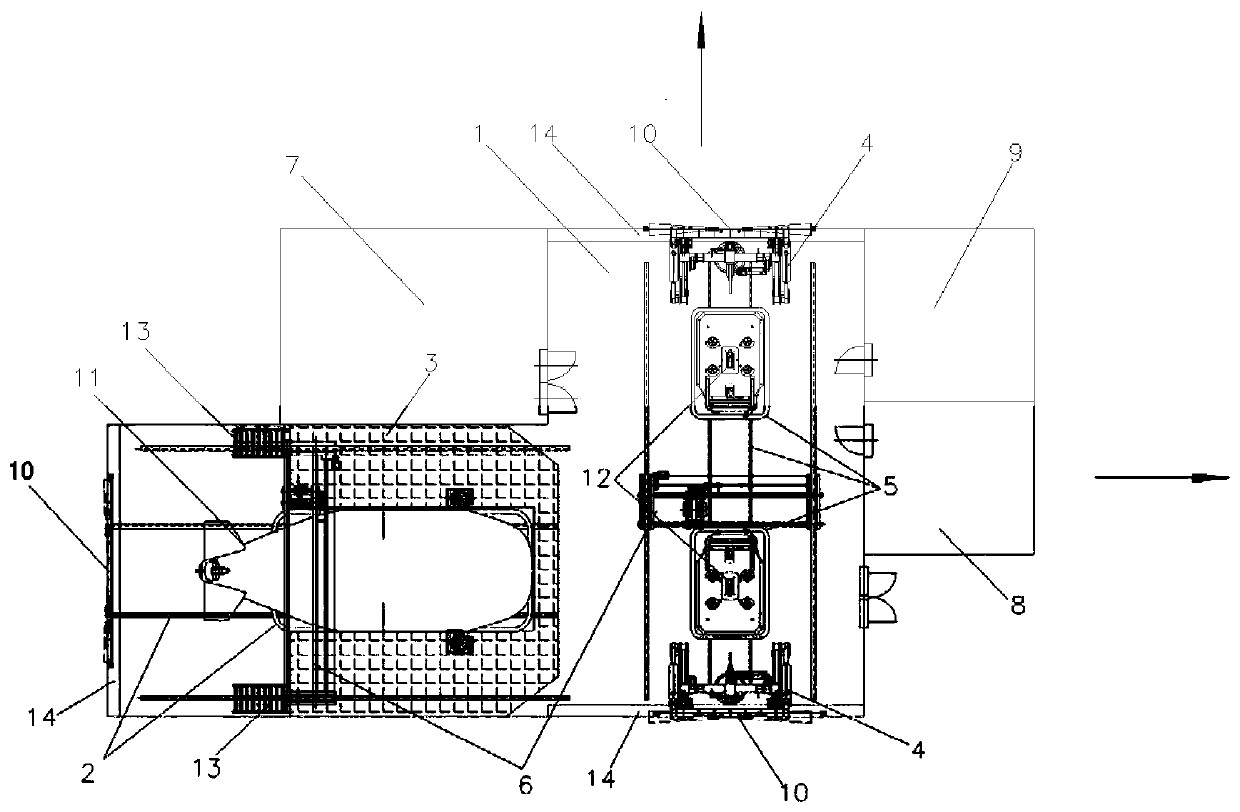

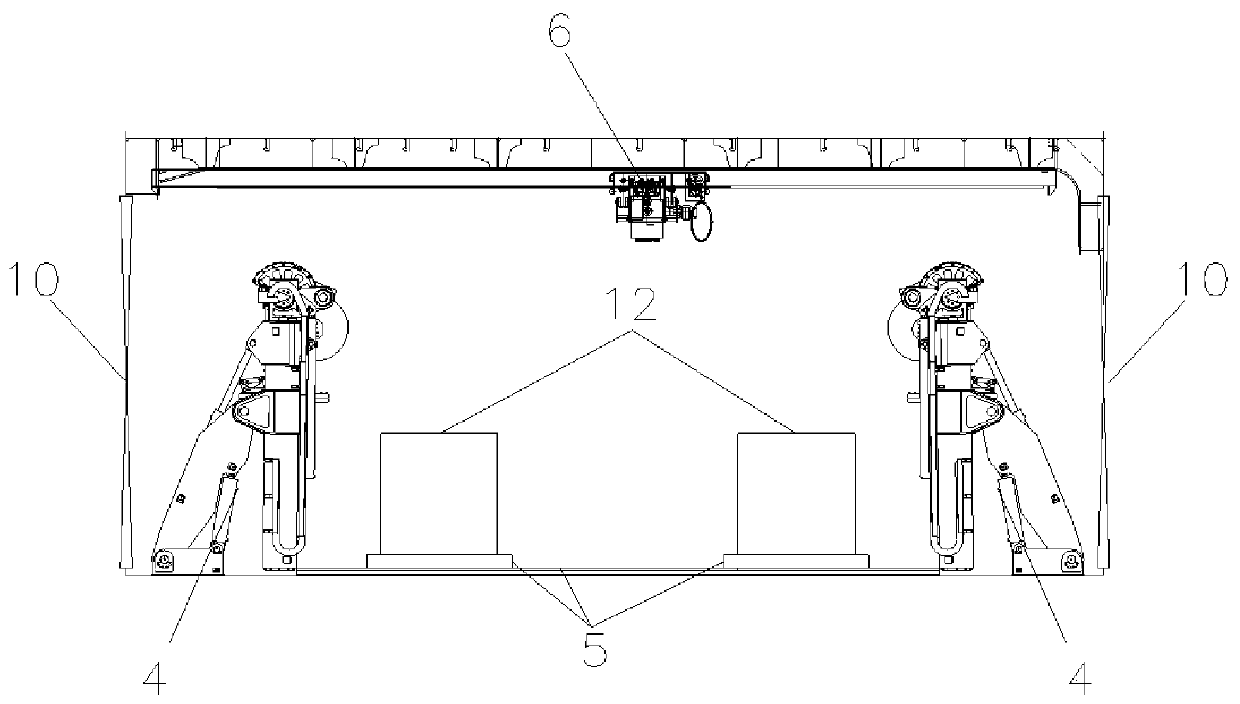

Maintenance system for multiple underwater vehicles on ship

InactiveCN111547206AAdd supportImprove space utilizationBoats storing/fasteningMarine engineeringOn board

The invention discloses a maintenance system for multiple underwater vehicles on a ship. The system comprises a submersible repository, a submersible track, a transport vehicle, a submersible maintenance platform, a small submersible retracting and releasing system, a hoisting crane, a mechanical maintenance room, an electronic maintenance room and a spare part room, wherein the submersible repository is located on an exposed deck of a ship, and the submersible rail and transport vehicle, the submersible maintenance platform, the small submersible retracting and releasing system, the hoistingcrane, the mechanical maintenance room, the electronic maintenance room and the spare part room are located in the repository and located in the peripheral area respectively. The system has the advantages that feasibility is provided for simultaneous storage and maintenance of multiple underwater vehicles on a ship, centralized development of maintenance work is facilitated, the space utilizationrate is greatly increased, the use performance of the underwater vehicles is greatly improved, and the service life of the underwater vehicles is greatly prolonged.

Owner:708TH RES INST OF CSSC

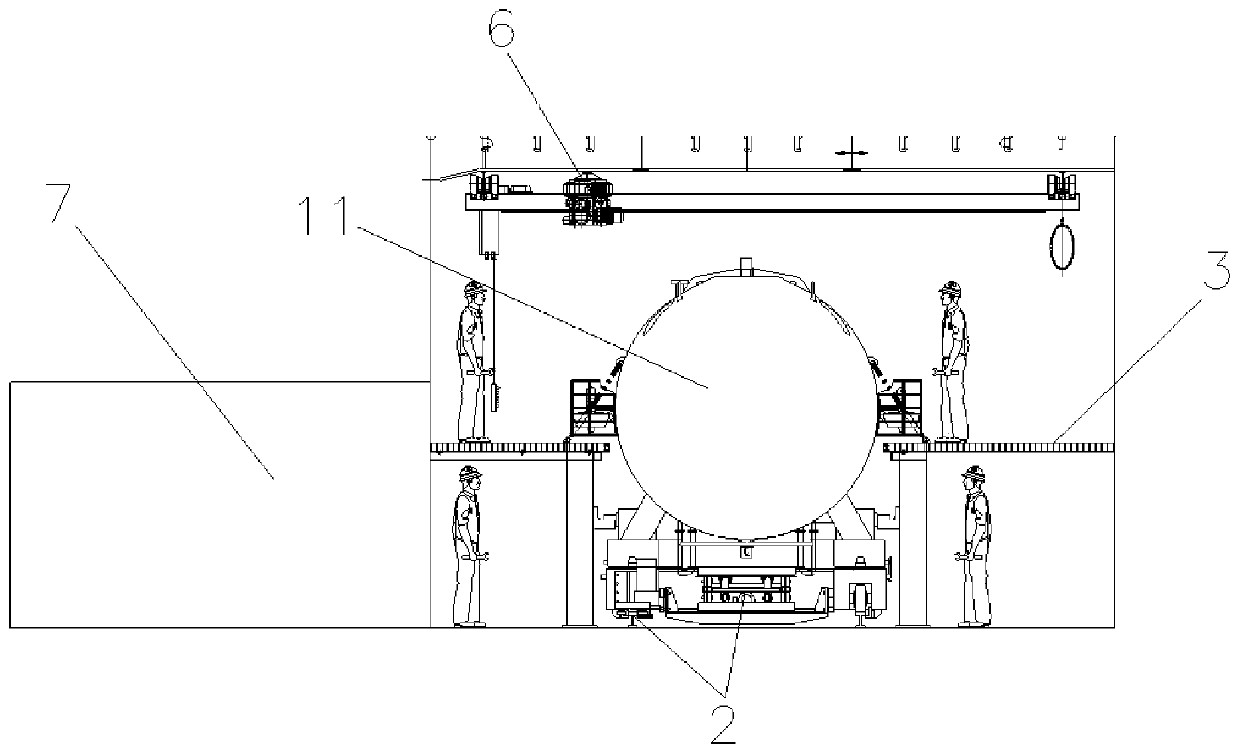

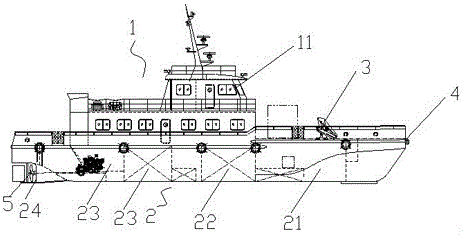

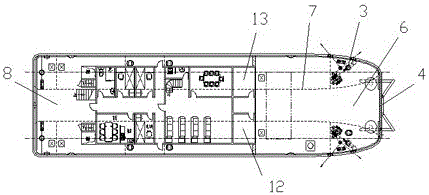

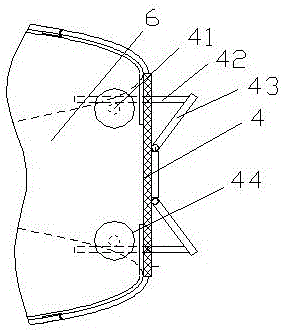

Intertidal zone seaborne operation and maintenance catamaran

ActiveCN106627979AChange the direction of thrust arbitrarilyAdvance and retreat freelyHydrodynamic/hydrostatic featuresSpecial purpose vesselsPropellerSuper structure

The invention relates to an intertidal zone seaborne operation and maintenance catamaran. A lower-layer catamaran body comprises two symmetric long and thin single ship bodies, a deck is laid on an opening of the lower-layer single ship body, an upper-layer building is built at the rear position of the middle of the deck, and the deck is divided by the upper-layer building to form a front deck body and a rear deck body; the a kunckle crane is mounted on the front deck body. The upper-layer building comprises a lower-layer living and working area and an upper-layer ship steering area, and comprises a machine repair room and a material storage room; the machine repair room and the material storage room are located at the front end, towards the upper-layer building of the front deck body, of the lower-layer living and working area. The intertidal zone seaborne operation and maintenance catamaran has the advantages that catamaran body design is adopted, a flat head landing end opening is designed in the stem and cooperates with a propeller on the stern, and therefore the intertidal zone seaborne operation and maintenance catamaran can be close to wind power equipment during maintenance; the bottoms of the single ship bodies are flat, so that the operation and maintenance catamaran has the function of bottom sitting; the machine repair room and the material storage room are additionally arranged, therefore, machining of small maintenance products is convenient; the machine repair room and the material storage room are arranged close to the front side of the front deck body, the front deck body is broad, and material carrying is convenient.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

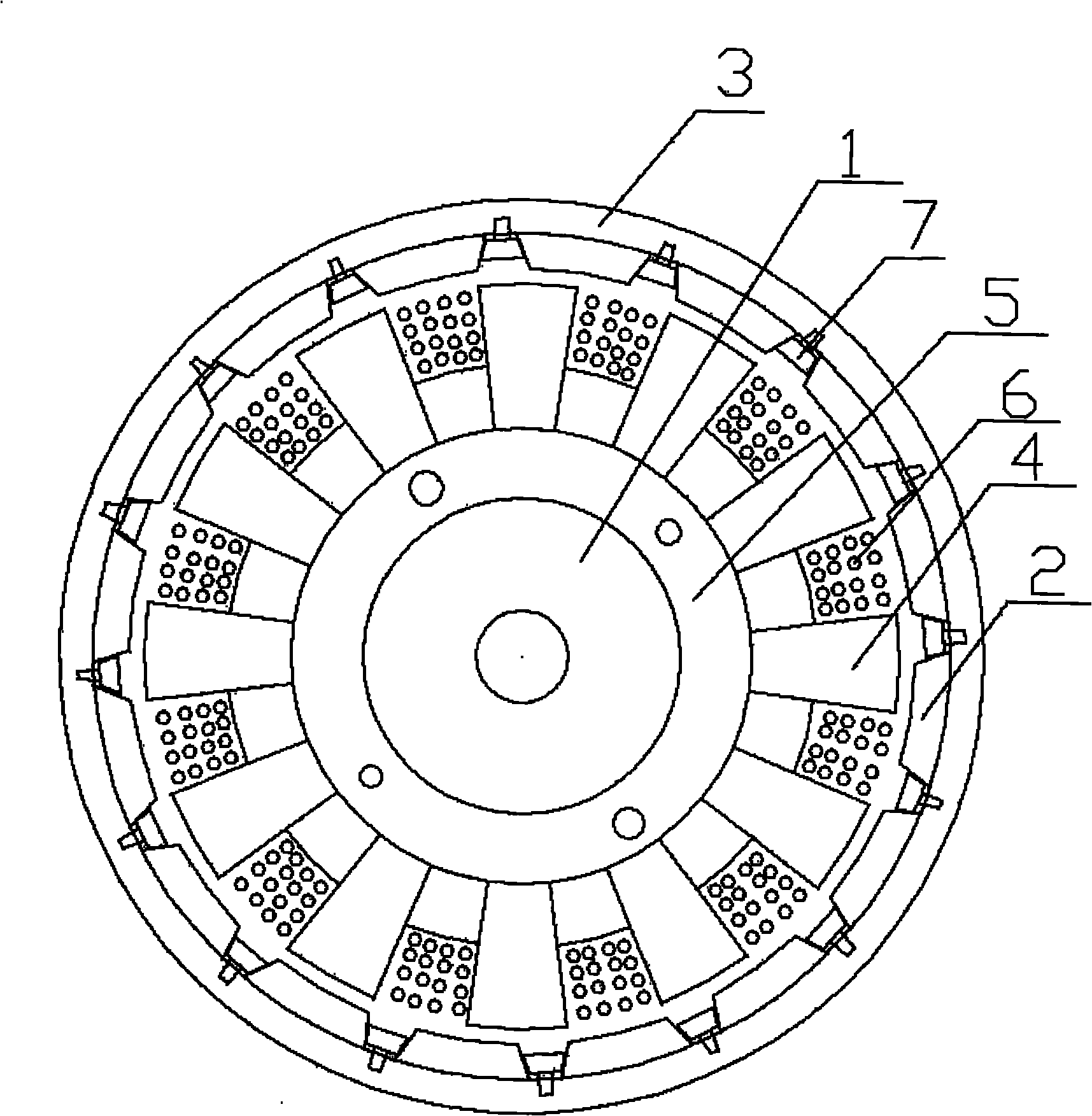

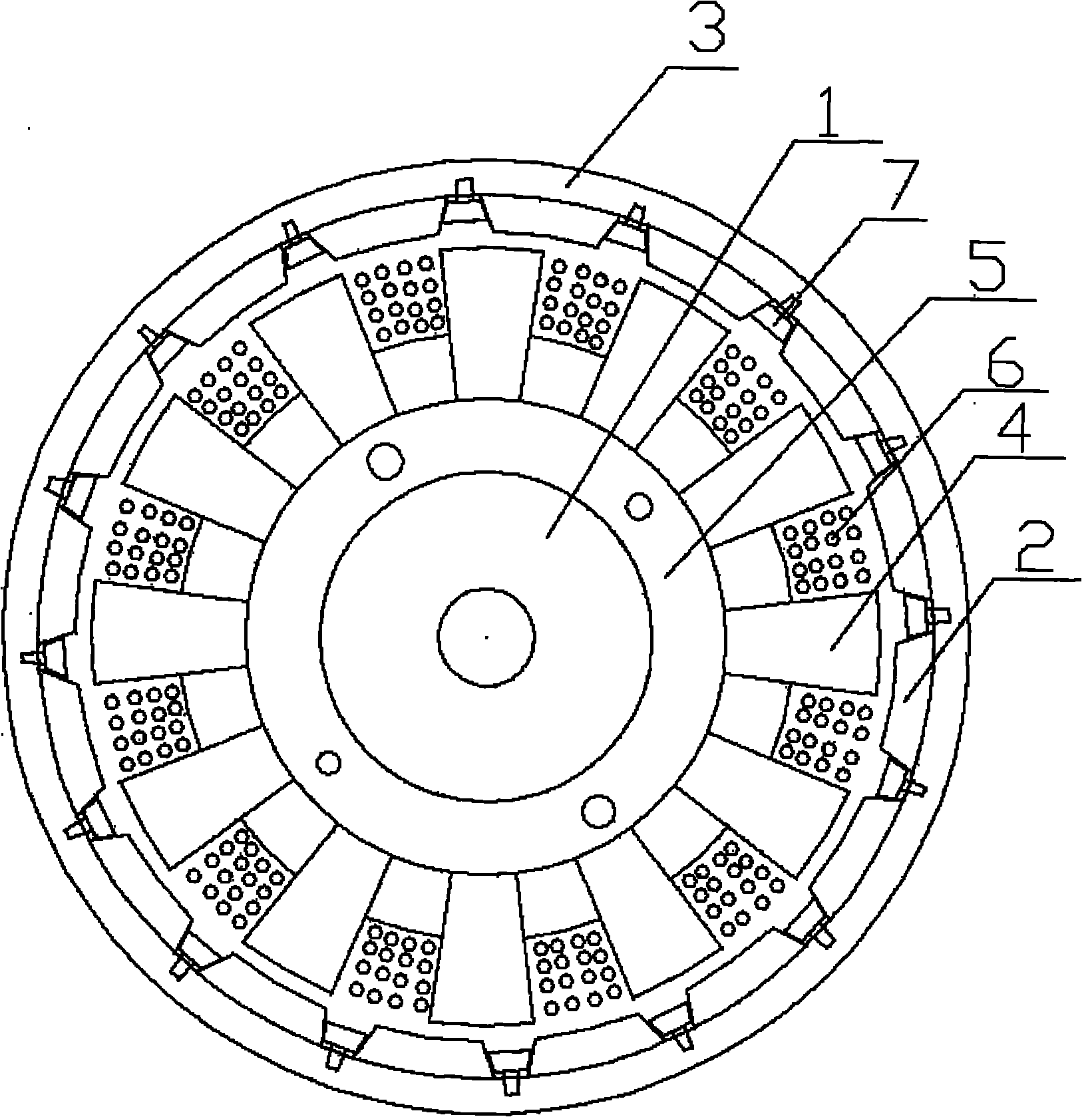

Direct current permanent magnetic upper wheel motor

InactiveCN101882820AZero lossNo mechanicalMagnetic circuit stationary partsOperational costsElectric machine

The invention relates to a motor, in particular to a direct current permanent magnetic upper wheel motor for use in an oil field pumping unit. The direct current permanent magnetic upper wheel motor has a structure that: a stator silicon steel sheet is fixed on a spindle by a stator inner ring locking plate; coil windings are wound on the stator silicon steel sheet; and a permanent magnet is arranged between the stator silicon steel sheet and an outer rotor ring. The invention has the advantages that: the motor is suitable for the power outputs of various lifting machines and replaces the mechanical transmission parts of the conventional lifting machines; the output power of the motor act directly to improve working conditions; zero friction and zero loss of the machines are realized; as mechanical friction and loss are avoided, electric energy is saved by about 40 to 60 percent; the maintenance period is prolonged; and as the repair and maintenance cost of the machines are avoided, the equipment operation cost is reduced considerably.

Owner:沈阳昊灵达新技术研究所有限公司

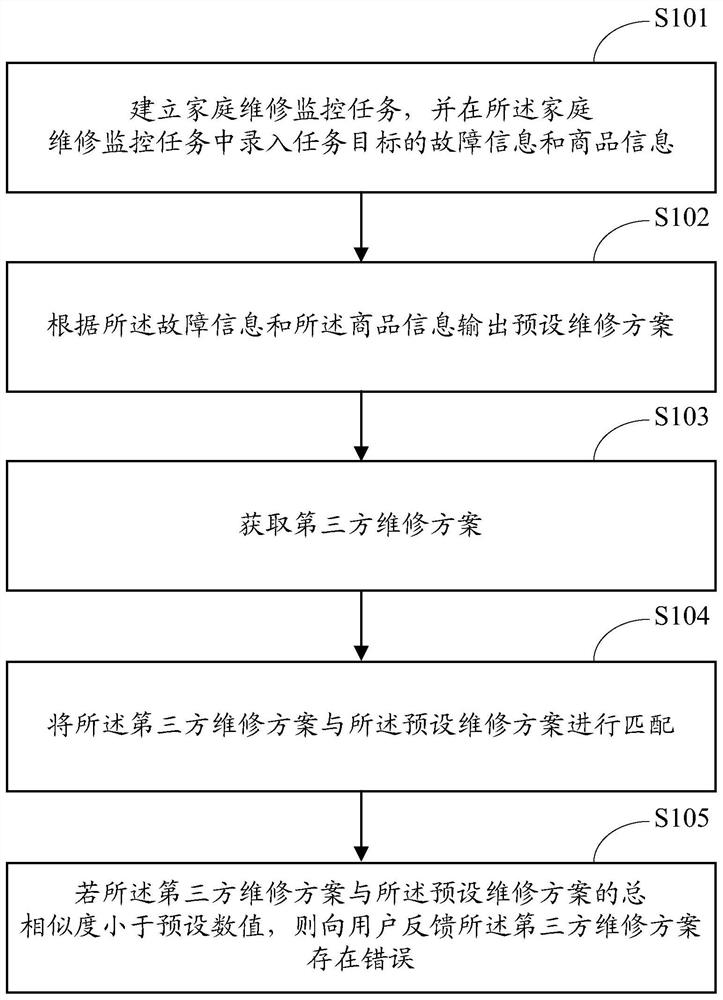

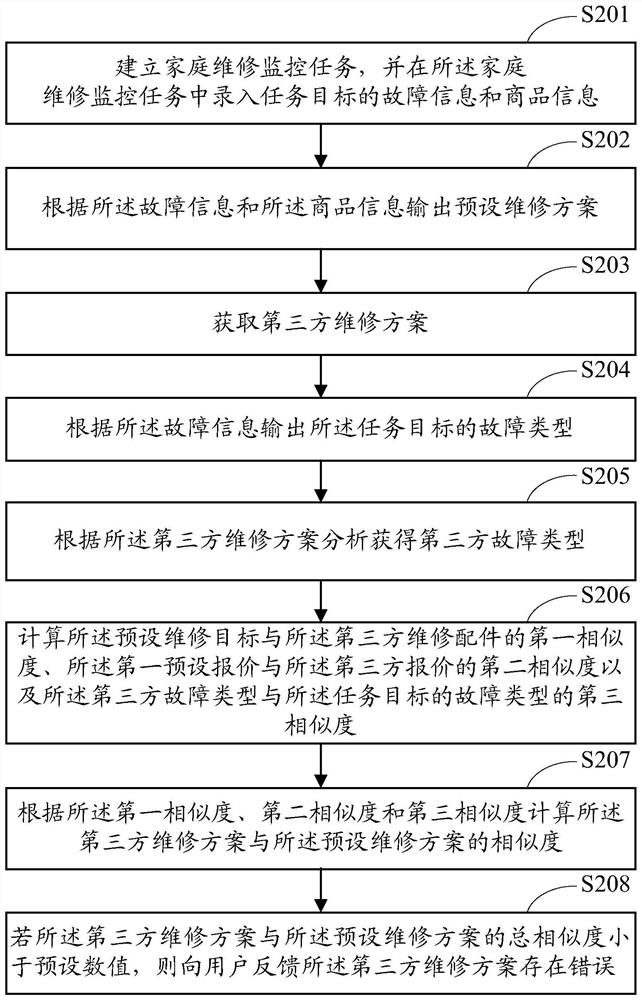

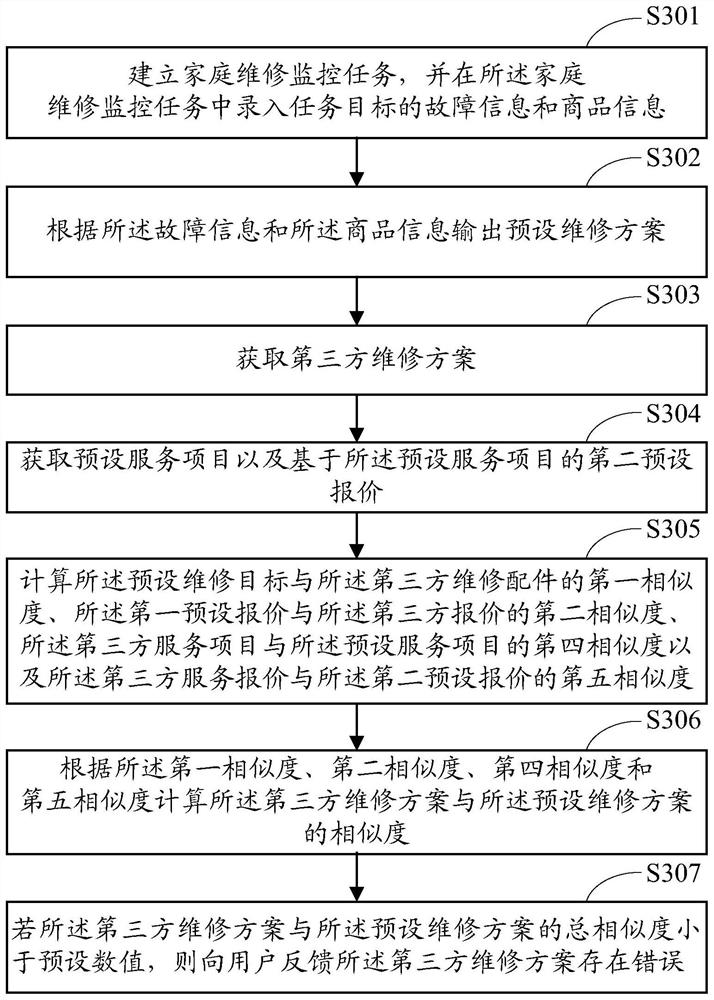

Home maintenance monitoring method and device and terminal equipment

ActiveCN111898774AAvoid economic lossCharacter and pattern recognitionBuying/selling/leasing transactionsThird partyTerminal equipment

Owner:重庆啄木鸟网络科技有限公司

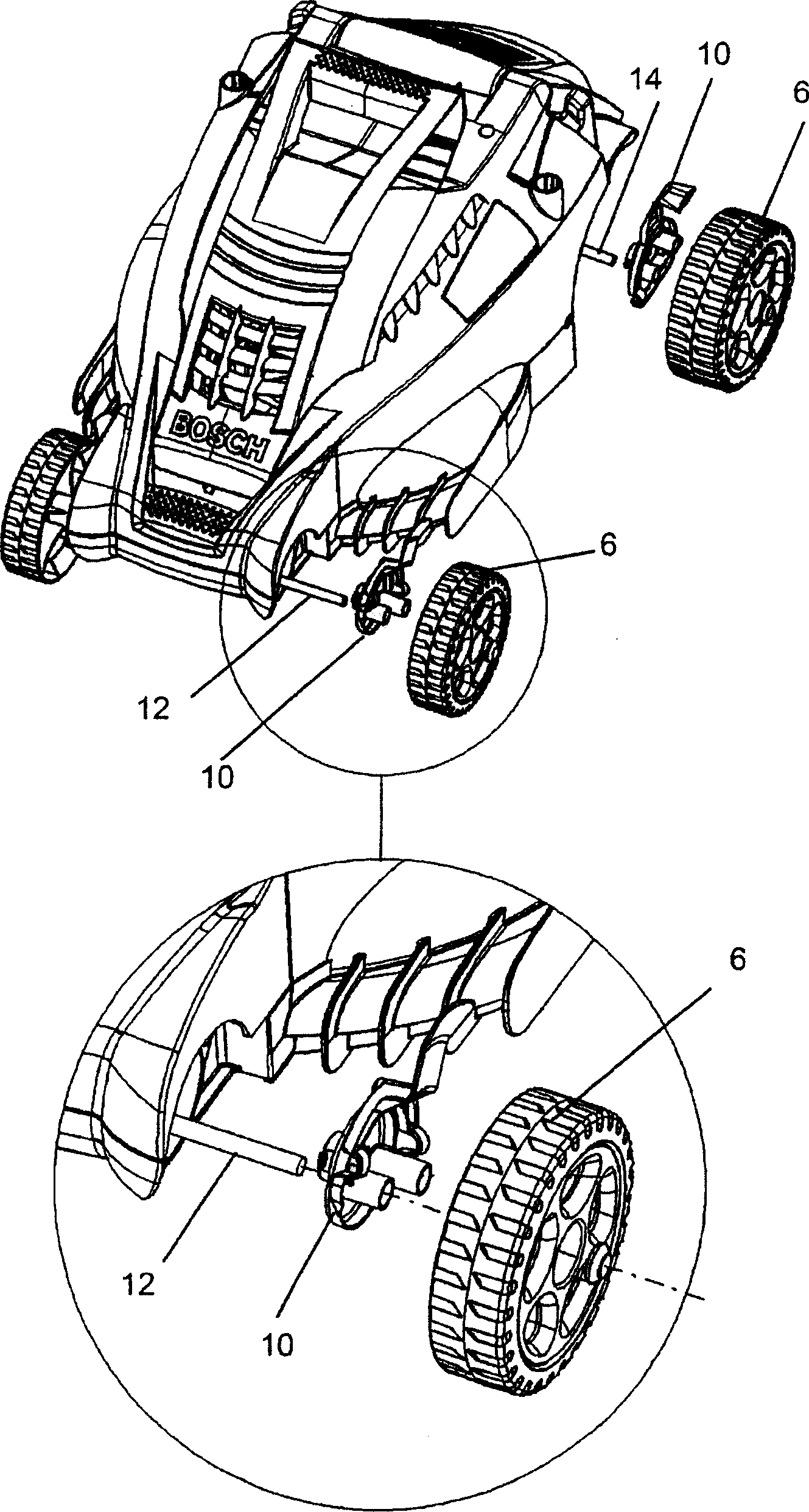

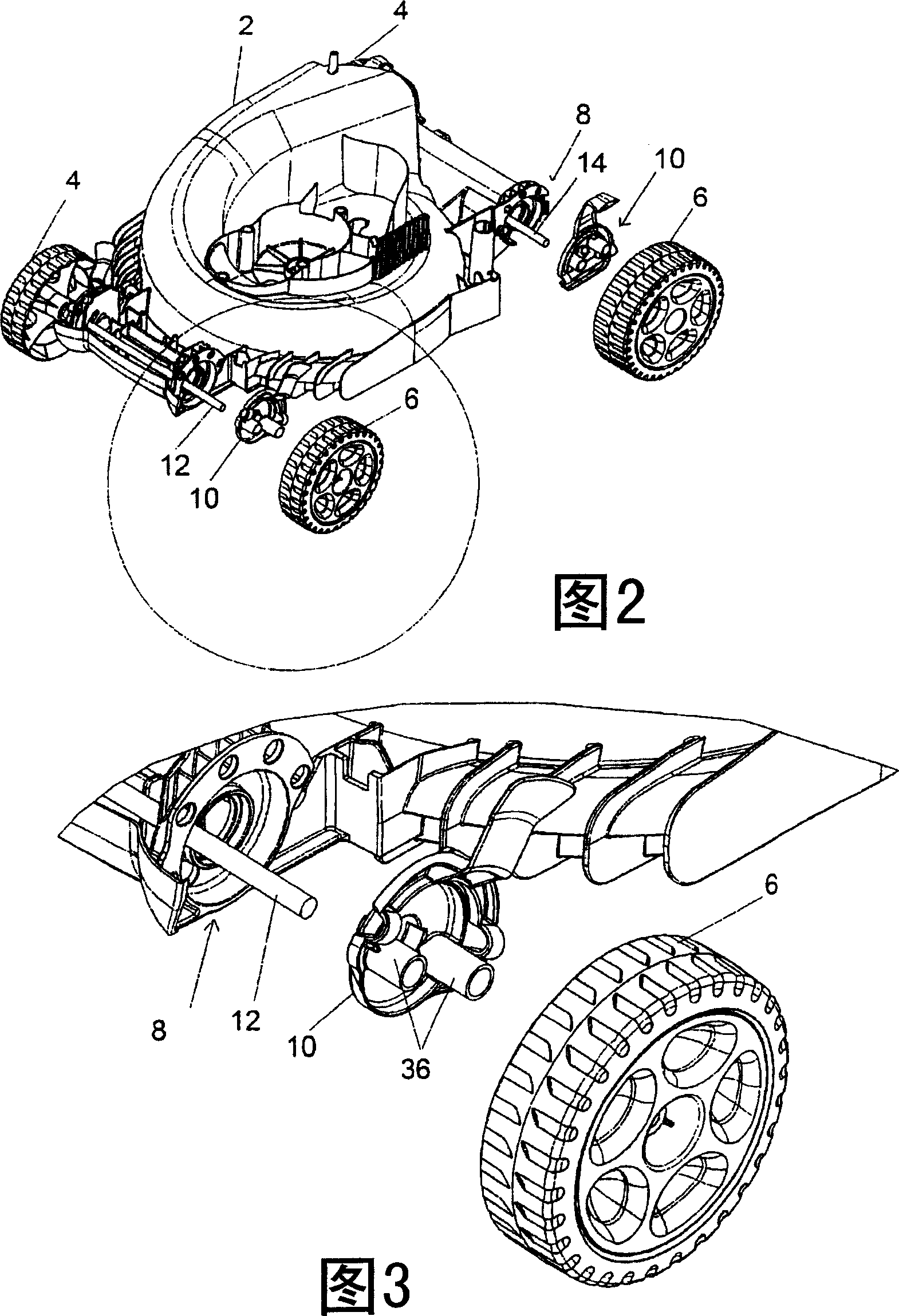

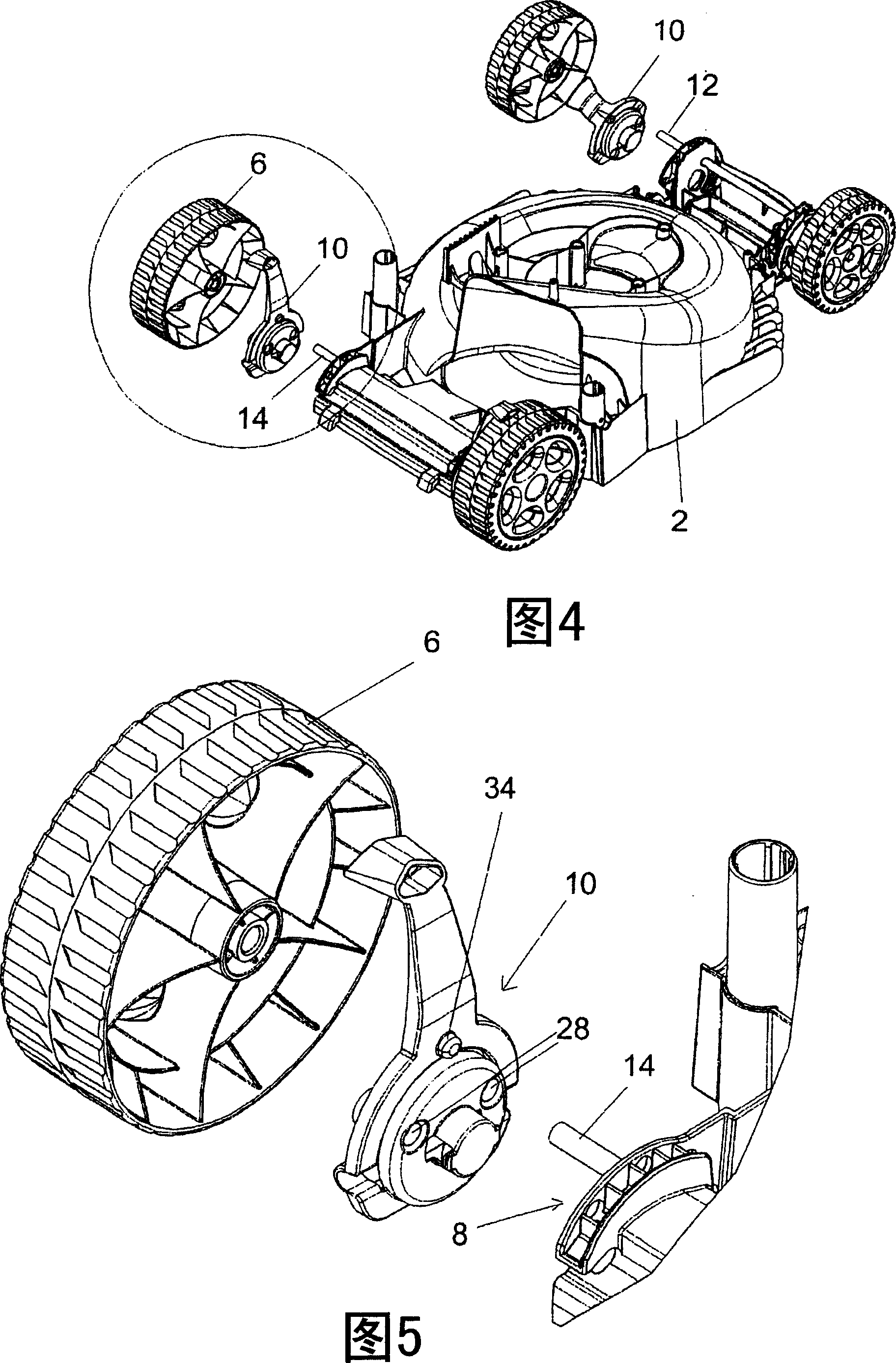

Lawn care apparatus

The present invention relates to improvements in or relating to lawncare apparatus. In particular, it relates to apparatus for adjusting the working height of a lawncare machine. We describe a lawncare apparatus comprises a chassis, at least one axle defining a first axis (12), the axle having first and second axle ends, and a wheel (6) mounted for rotation at each of said first and second axle ends; wherein each of said first and second axle ends is carried by a respective adjustment member (10) mounted for rotation about a respective second axis (24) upon the chassis of the machine, wherein the second axis is non-coaxial with the first axis. Preferably, each axle is mounted for pivotal movement about the second axis within an arcuate slot (18) in the chassis.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com