Tool for repairing and grinding center holes of output shaft of aero-engine and repairing and grinding work method of tool

A technology of engine output and aero-engine, which is applied in the direction of manufacturing tools, metal processing equipment, and other manufacturing equipment/tools, etc., to achieve the effects of shortening the required time, ensuring the quality of repair and research, and the effect of simple and reliable repair and research work methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

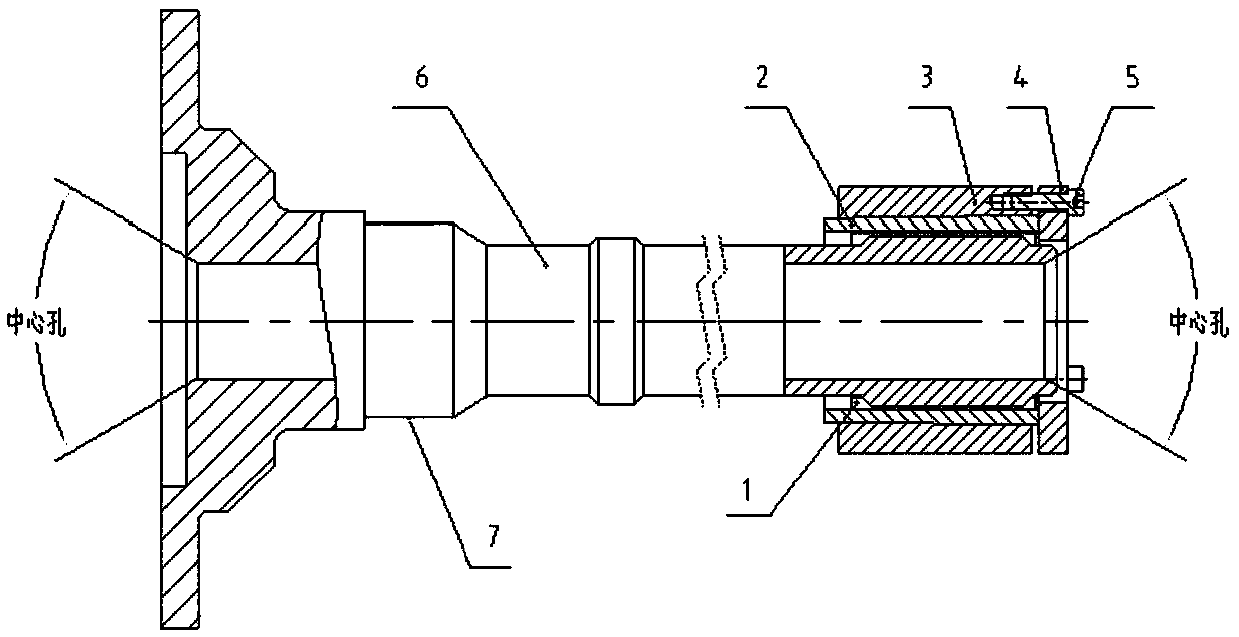

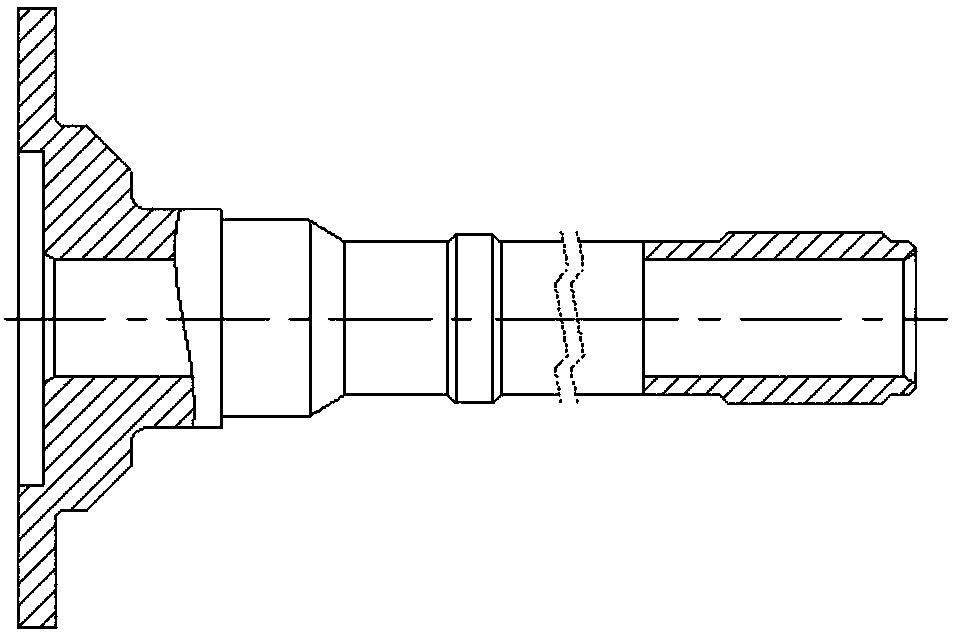

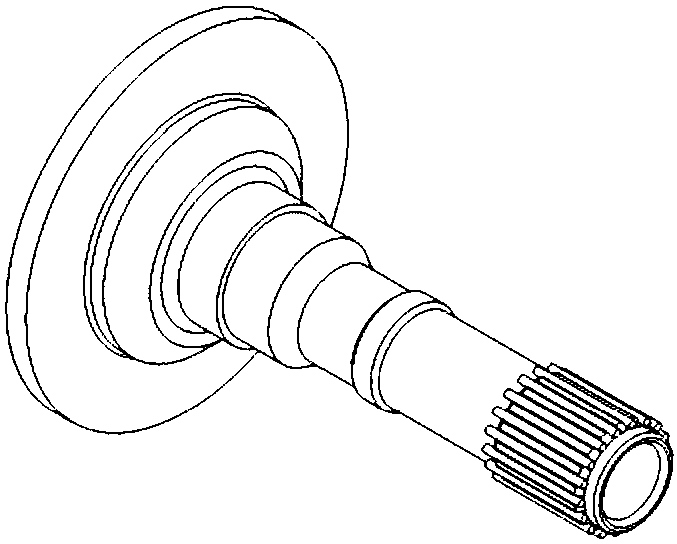

[0031] The method for repairing and researching the center hole of the output shaft of the aeroengine described in the first embodiment includes a method for repairing the left center hole of the engine output shaft 6 and a method for repairing the right center hole.

[0032] The method for repairing the left central hole of the engine output shaft 6: first install the tooling of the present invention on the spline groove at the right end of the engine output shaft 6, place the outer circular surface 7 of the engine output shaft 6 on a lathe Supported on the central center frame, the outer circular surface of the outer taper sleeve 3 is clamped on the lathe chuck, the lathe is turned on and the outer circular surface of the outer taper sleeve 3 is dialed with a dial indicator to find alignment, and the outer circular surface of the outer tapered sleeve 3 is aligned with a turning tool The left center hole of the output shaft 6 of the engine is turned and repaired, and the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com