Patents

Literature

48results about How to "Guarantee the quality of training" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual reality rehabilitation training system and method

InactiveCN104991639AIncrease interest in trainingReduce dependencyInput/output for user-computer interactionData processing applicationsComputer moduleSmall footprint

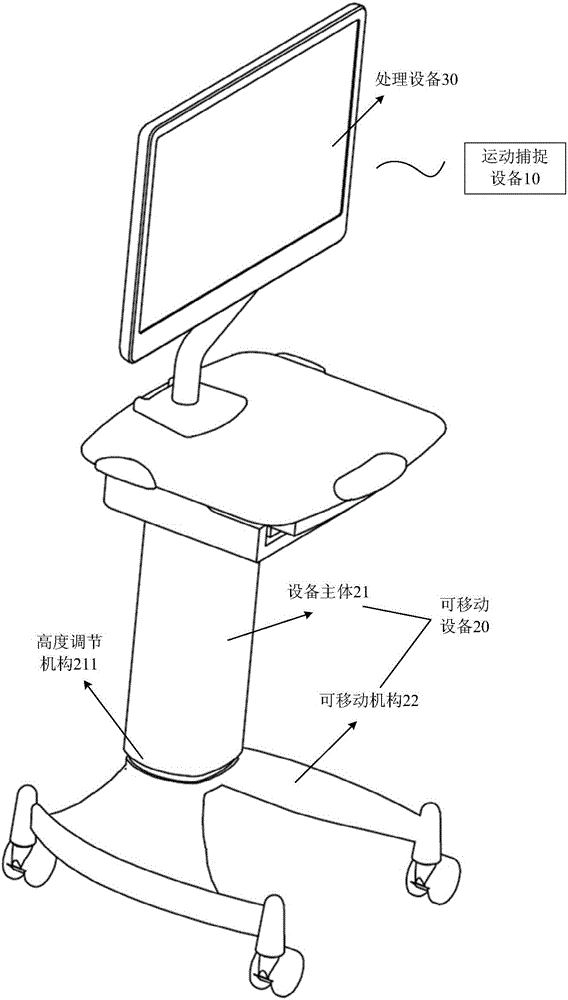

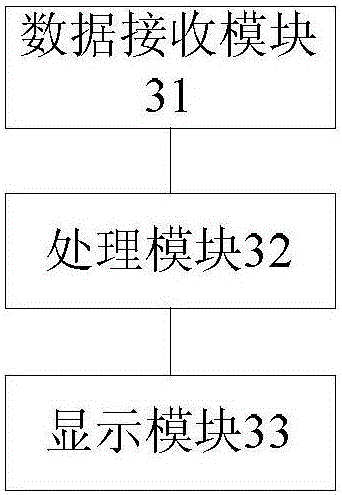

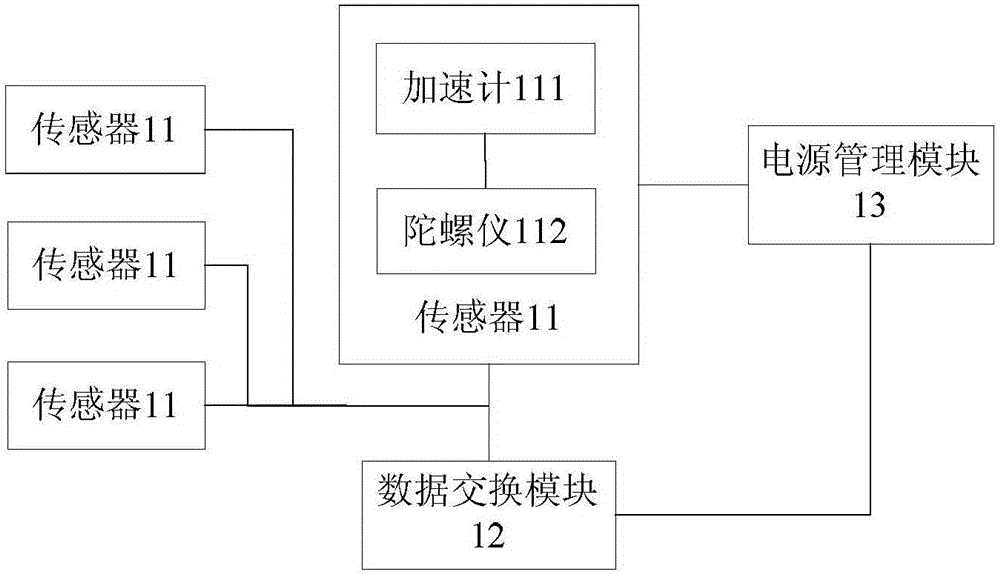

The invention discloses a virtual reality rehabilitation training system and method. The system comprises a motion capture device, a mobile device and a processor. The processor is installed in the mobile device to form an integrated bedside device, and the processor is connected with the motion capture device. The motion capture device is used for acquiring patient's limb motion data in real time. The processor comprises a data receiving module, a processing module and a displaying module. The data receiving module is used for receiving the limb motion data. The processing module is used for emitting a driving signal, and assessing training on a patient according to the limb motion data to obtain an assessment result. The display module is used for displaying changes of three-dimensional human model's actions in real time according to the driving signal, and the assessment result. The mobile device comprises a device main body and a mobile mechanism connected at the lower end of the device main body, the device main body is provided with a height adjusting mechanism used for adjusting the height of the device main body. The virtual reality rehabilitation training system is low in cost, small in land occupation and convenient to move, so the system can be disposed beside a patient's bed.

Owner:CHINA REHABILITATION RES CENT

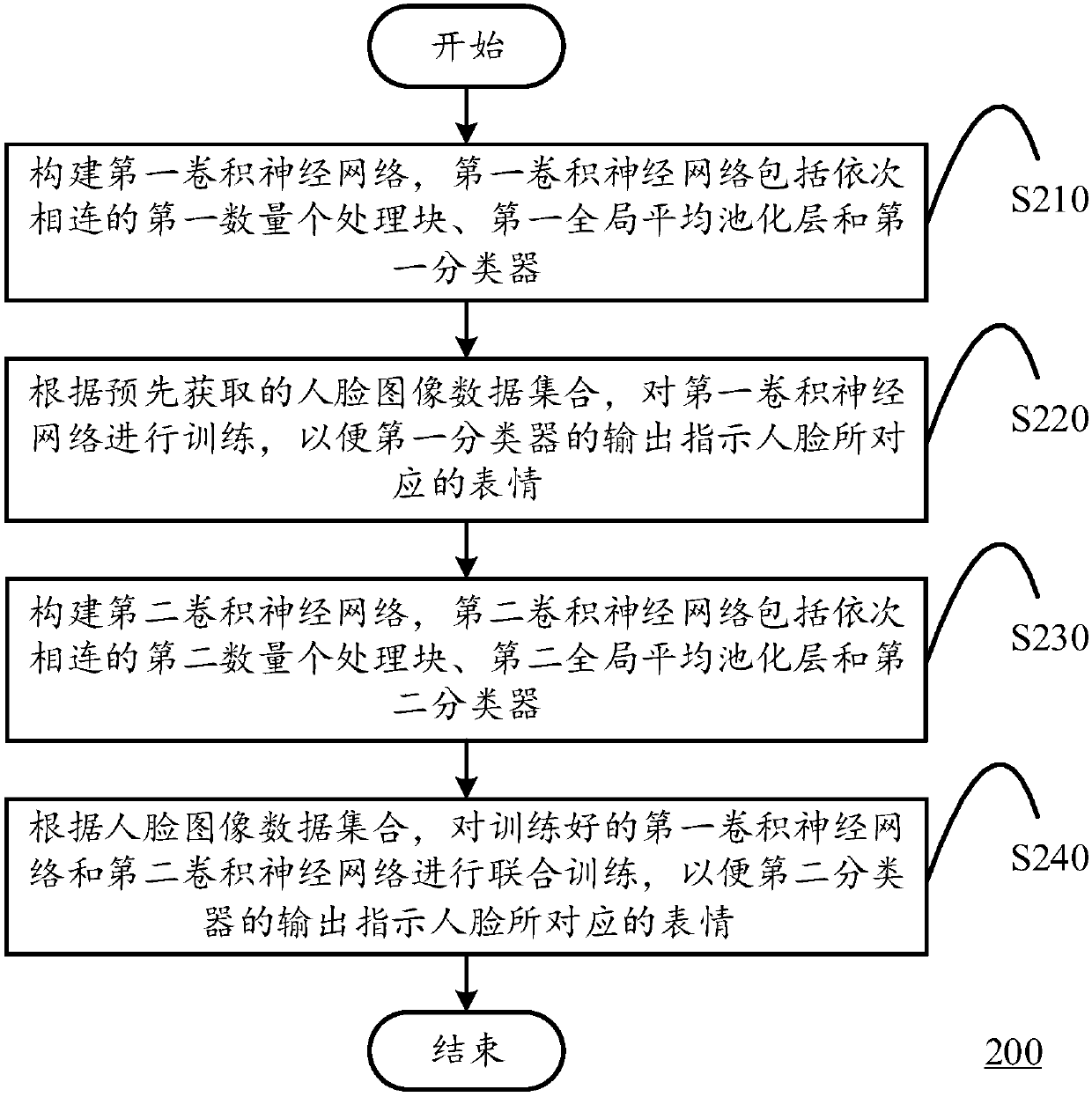

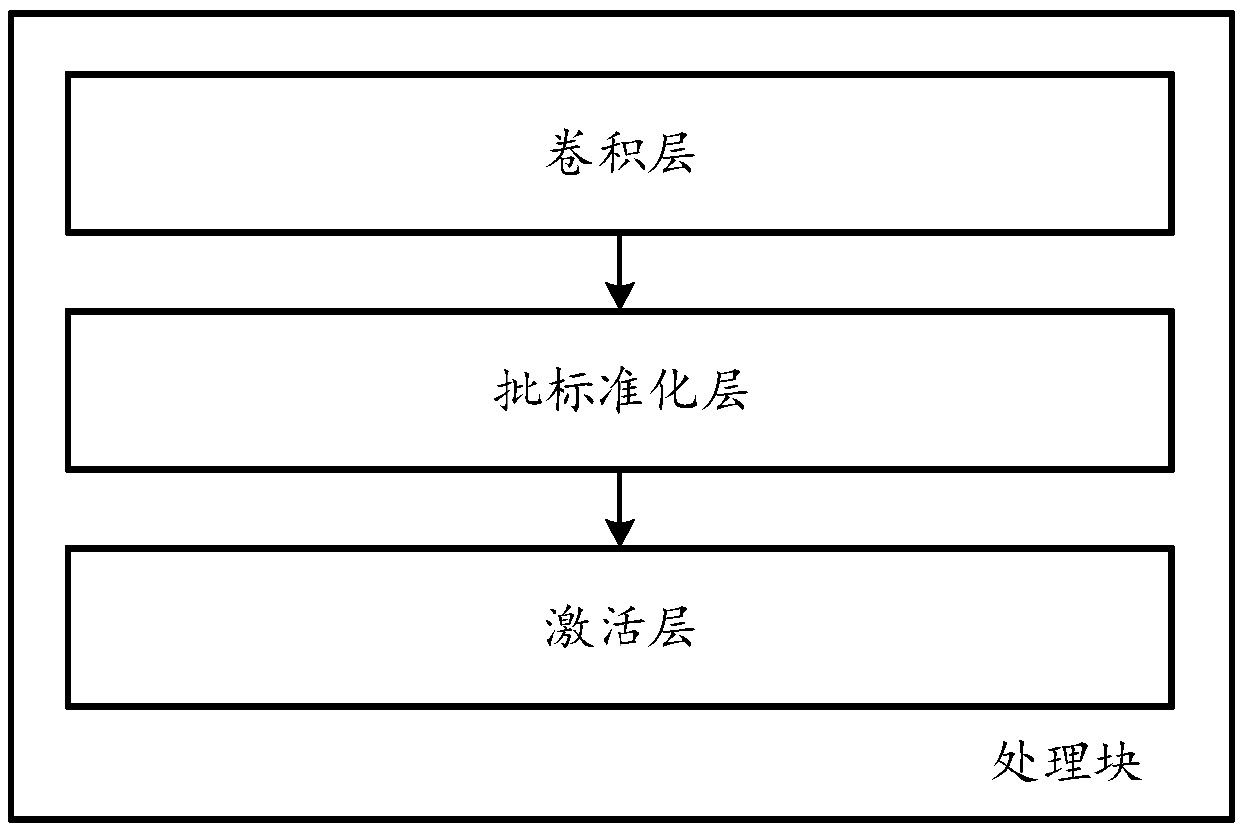

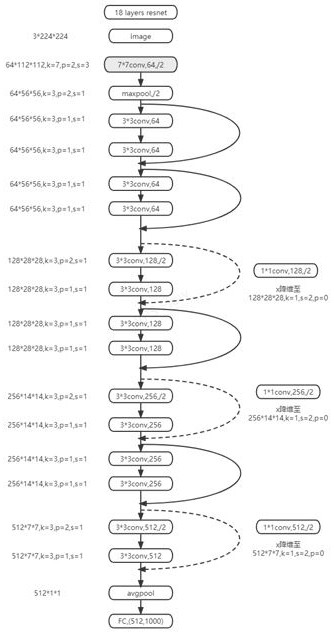

Generation method of convolutional neural networks and expression recognition method

ActiveCN108197602ASpeed up the convergence processIncrease training speedNeural architecturesNeural learning methodsPattern recognitionData set

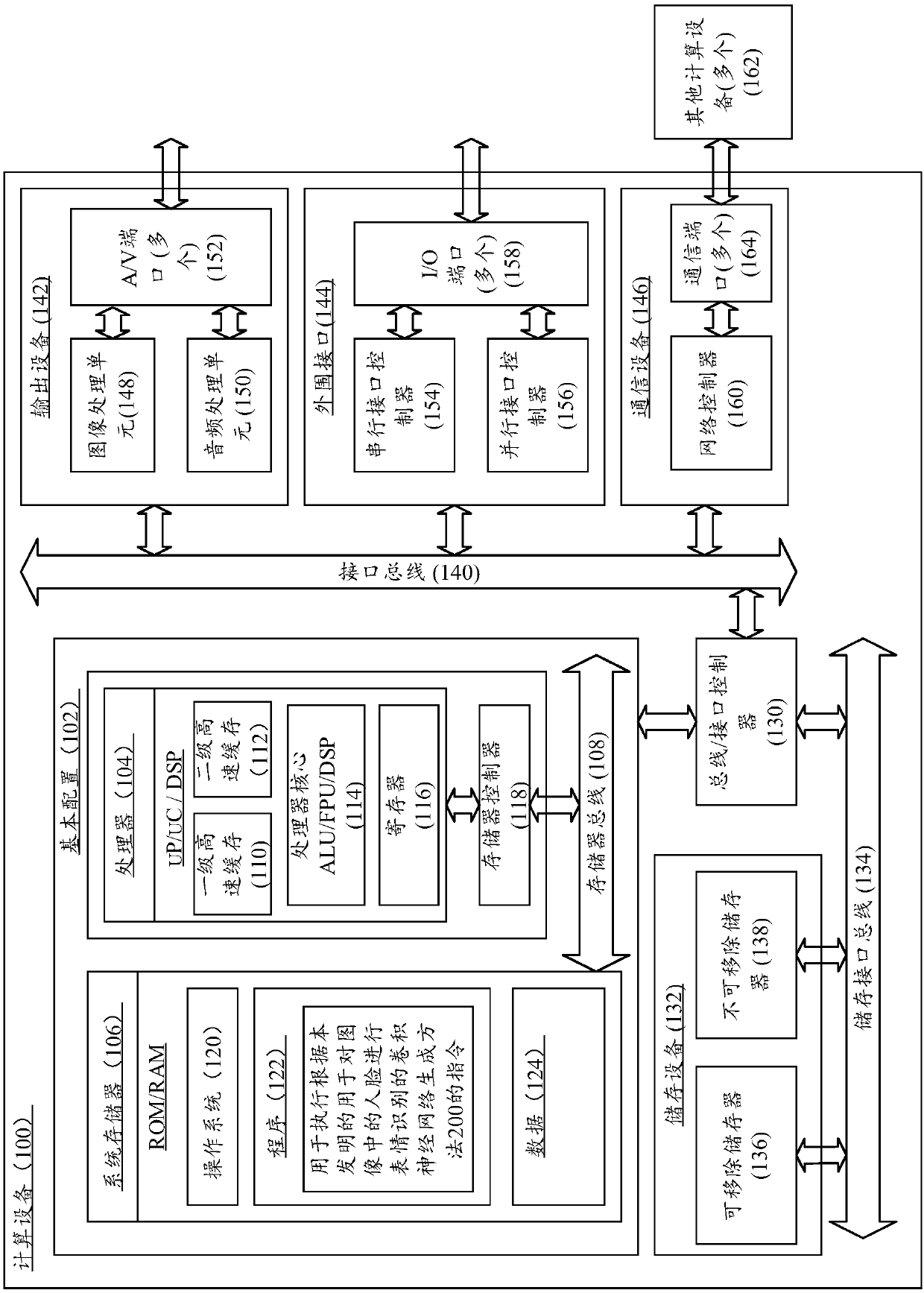

The invention discloses a generation method of convolutional neural networks for conducting expression recognition on the human face in an image, an expression recognition method, calculation equipment and a mobile terminal. The generation method of the convolutional neural network comprises the steps that the first convolutional neural network is established, wherein the first convolutional neural network comprises a first number of processing modules, a first overall average pooling layer and a first classifier which are connected in sequence; according to a pre-acquired facial image data set, the first convolutional neural network is trained, and the first classifier outputs and indicates an expression corresponding to the human face conveniently, wherein the facial image data set comprises multiple pieces of facial image information; the second convolutional neural network is established, wherein the second convolutional neural network comprises a second number of processing modules, a second overall average pooling layer and a second classifier which are connected in sequence; according to the facial image data set, the trained first convolutional neural network and second convolutional neural network are subjected to joint training, and the second classifier outputs and indicates the expression corresponding to the human face conveniently.

Owner:XIAMEN MEITUZHIJIA TECH

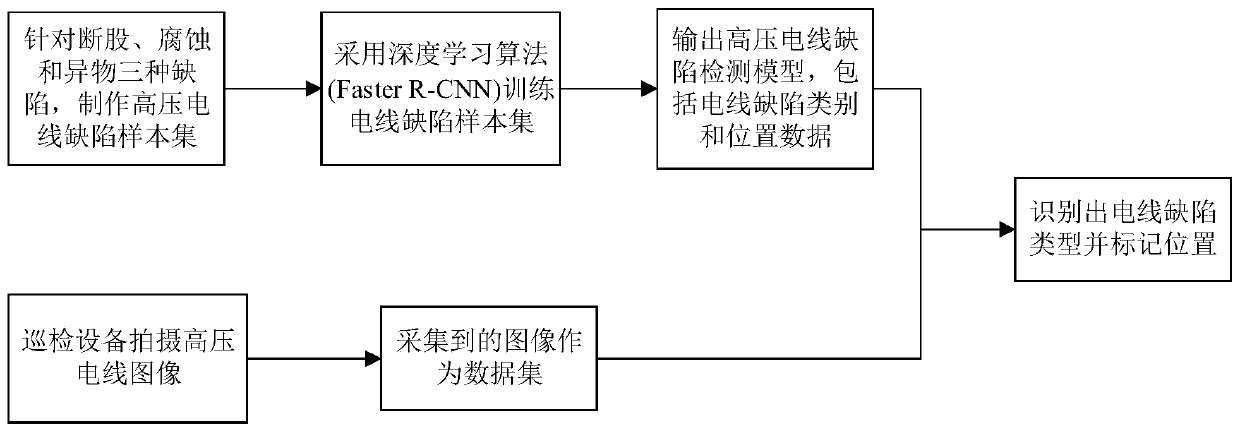

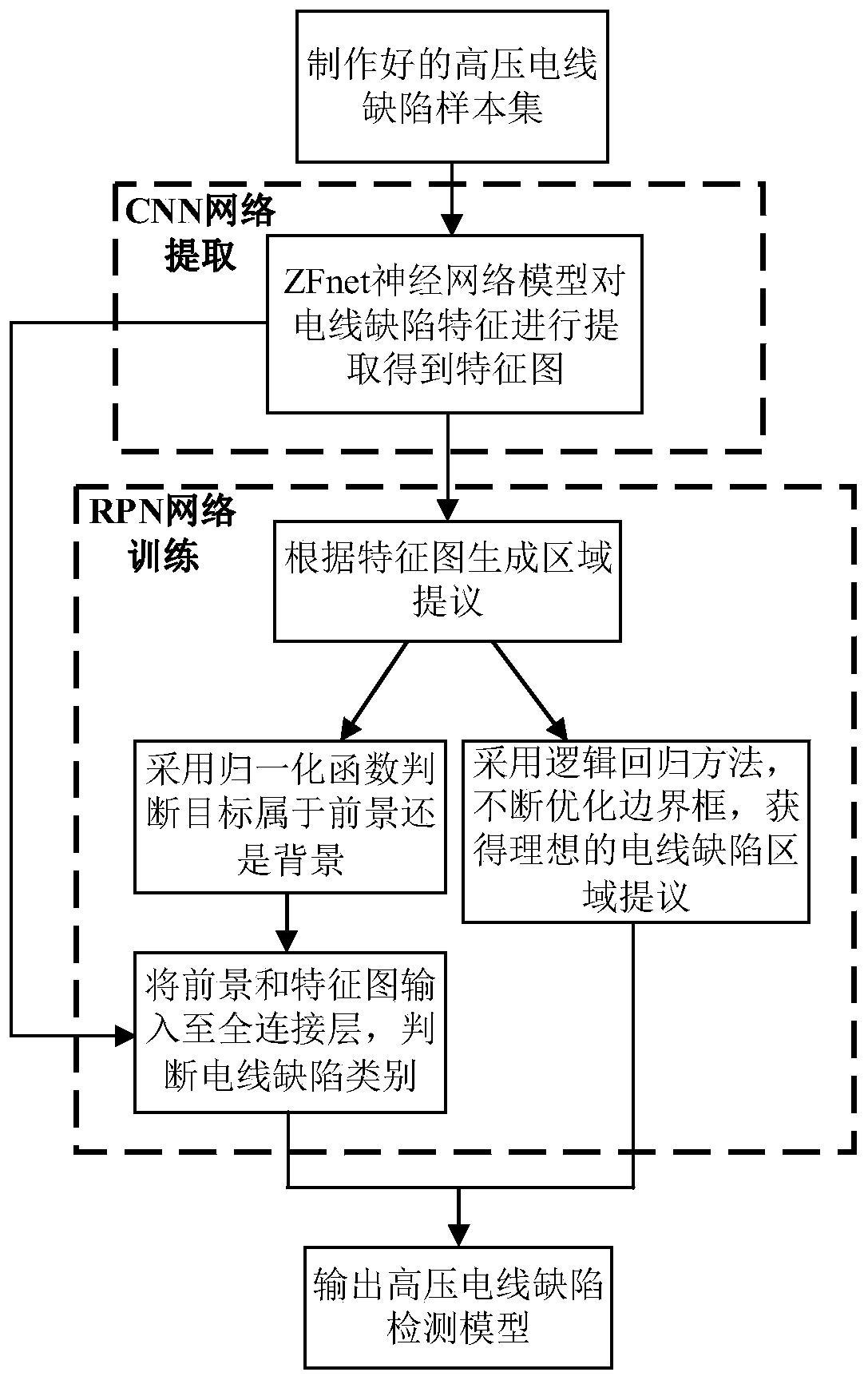

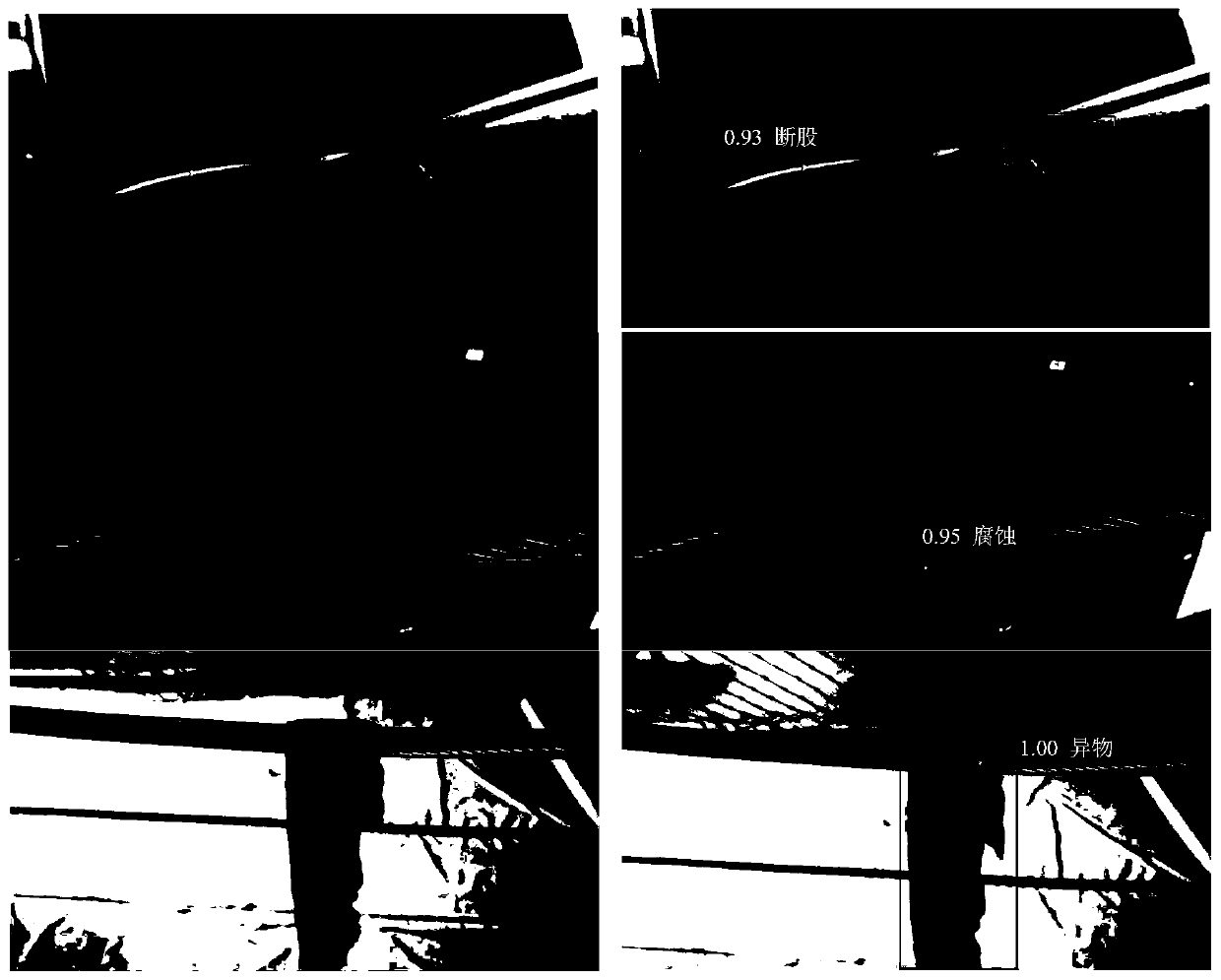

A high-voltage wire defect detection method based on a regional convolutional neural network

InactiveCN109886947AGuarantee the quality of trainingSimplified training stepsImage analysisAlgorithmNetwork generation

The invention discloses a high-voltage wire defect detection method based on a regional convolutional neural network. The method comprises the steps of obtaining a high-voltage wire image defect sample set; inputting the high-voltage wire image into a convolutional neural network, and extracting defect features in the high-voltage wire image to obtain a feature map; inputting the feature map intoan area proposal network additionally provided with a full connection layer, generating a proposal area by the area proposal network, and judging the proposal area; inputting the proposal area and thefeature map which belong to the foreground into a full connection layer for defect classification; correcting and processing the boundary of the proposal area, and optimizing the boundary to obtain amore accurate proposal area; and repeating the steps to iterate the regional proposal network until the training is completed, and obtaining the high-voltage wire defect detection model with the trained parameters to carry out actual defect detection. According to the invention, the Faster R-CNN algorithm is used to identify and position the wire defects, and the method has the advantages of highidentification speed, extremely high accuracy and good robustness.

Owner:ZHEJIANG SCI-TECH UNIV

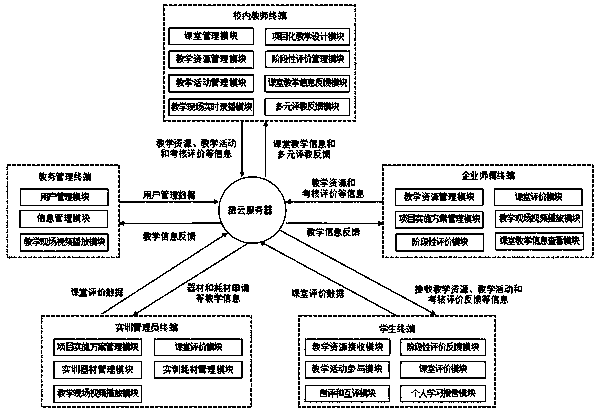

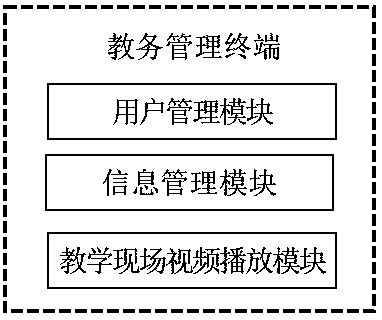

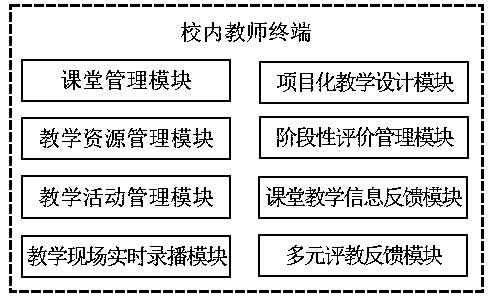

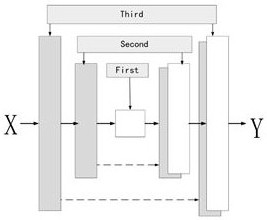

Informatization teaching system and method based on school-enterprise cooperation project courses

PendingCN110335183APromote in-depth cooperationCultivate professional abilityOffice automationResourcesInformatizationComputer science

The invention relates to an informatization teaching system and method based on school-enterprise cooperation project courses, and belongs to the technical field of education. The informatization teaching system based on the school-enterprise cooperation project course comprises a micro-cloud server and a user terminal which can realize data communication with each other. The micro-cloud server isused for transmitting, storing, analyzing and processing the teaching whole-process data generated by all the user terminals, such as teaching organization, teaching management, teaching implementation, teaching evaluation and teaching feedback, and feeding back the optimized data to the corresponding user terminals in the form of reports. According to the system, all user terminals are connectedtogether by using a cloud technology; mutual communication among students, teachers in schools, enterprise teachers and practical training managers is promoted, the system timely and effectively feeds back teaching information to the teachers, guides the teachers to rectify teaching, timely and effectively feeds back personal learning information of the students to the students, guides the students to complete knowledge point review, and facilitates implementation of school-enterprise cooperation project courses.

Owner:KUNMING UNIV OF SCI & TECH

Earthworm raising material as well as preparation method and application thereof

InactiveCN107836574AImprove the level of recycling of waste resourcesHigh economic valueFood processingAnimal feeding stuffHumic acidEdible mushroom

The invention discloses an earthworm raising material as well as a preparation method and application thereof, and relates to the technical field of earthworm ecological cultivation. The raising material disclosed by the invention is prepared from raw materials of fresh cow dung, kitchen waste, wood bran, corn straw, bagasse and edible mushroom waste residues. The preparation method of the earthworm raising material comprises the following steps of crushing the raw materials, performing natural pile fermentation under the humidity of 50-70% for 15 days, and after the pile fermentation is completed, sprinkling clean water to obtain the earthworm raising material. A method for feeding earthworms with the raising material comprises the following steps of using the earthworm raising material as an earthworm breeding substrate, inoculating the earthworms with the earthworm raising material in the mass ratio of the earthworms to the earthworm raising material being 1 to 30, and performing breeding; and after the earthworm raising material is completely digested by the earthworms, collecting the earthworms and earthworm cast. According to the earthworm raising material disclosed by the invention, on the base of guaranteeing the earthworm culturing quality, high-quality earthworm cast rich in high humic acid is obtained, the waste resource reusing level is further increased, besides, the economic value of the earthworms is also increased, and unification of environmental benefits and economic benefits is achieved.

Owner:广西南宁市地满金蚯蚓养殖专业合作社

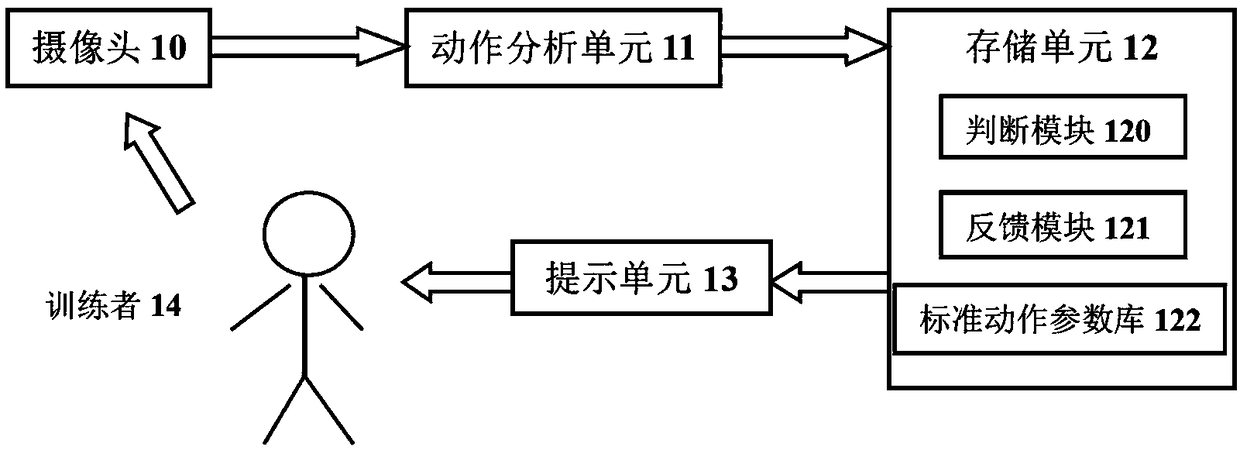

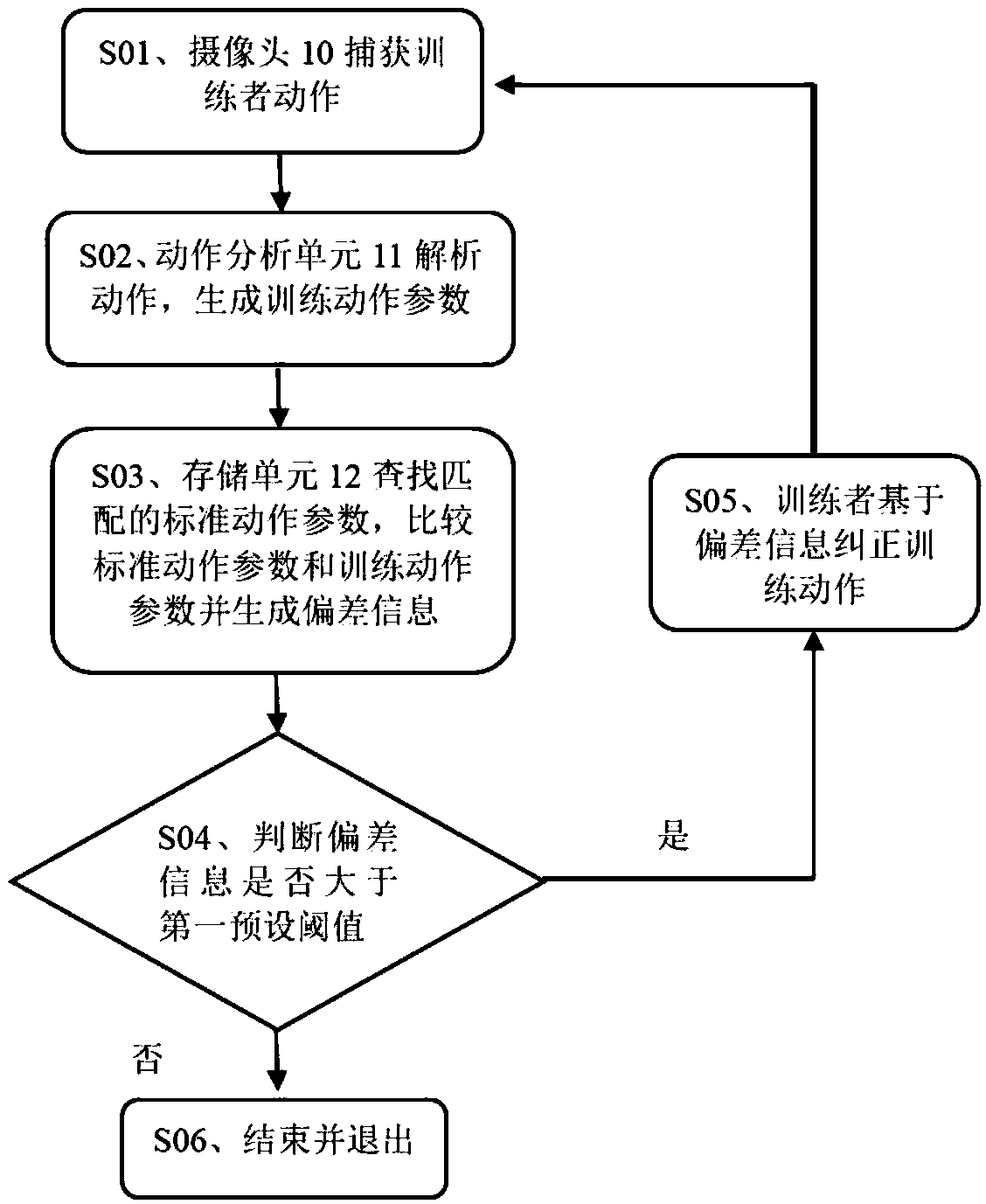

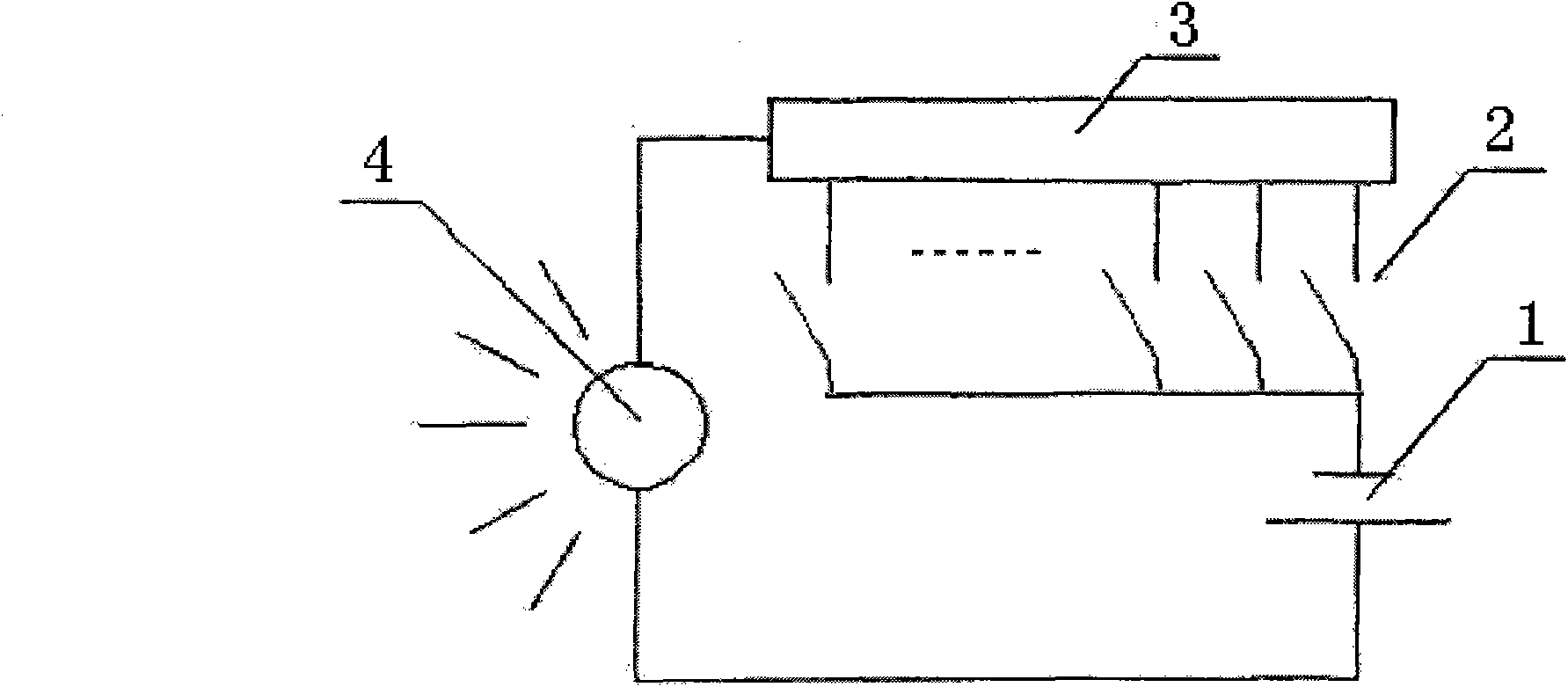

Body-movement comprehensive training device

ActiveCN108339257AImprove training efficiencyShorten training timeSport apparatusSimulationBody movement

The invention relates to a body-movement comprehensive training device. The body-movement comprehensive training device comprises a camera, a movement analysis unit, a storage unit and a reminding unit. According to the body-movement comprehensive training device, a current training movement is captured based on the camera, and the training movement is analyzed through the movement analysis unit to obtain corresponding movement parameters; the corresponding movement parameters are compared with matched standard movement parameters stored in the storage unit to obtain deviation information; when the deviation information is larger than a first preset threshold value, the reminding unit reminds users of deviations existing in the current movement, and reminds the users of how to correct thedeviations. The intelligent feedback process of the current training movement of the users is achieved, the users gradually adjust the training movement to be similar to a standard movement based on the intelligent feedback process, training efficiency is improved, training time is shortened, and the training quality is guaranteed.

Owner:泰安高新教育服务有限公司

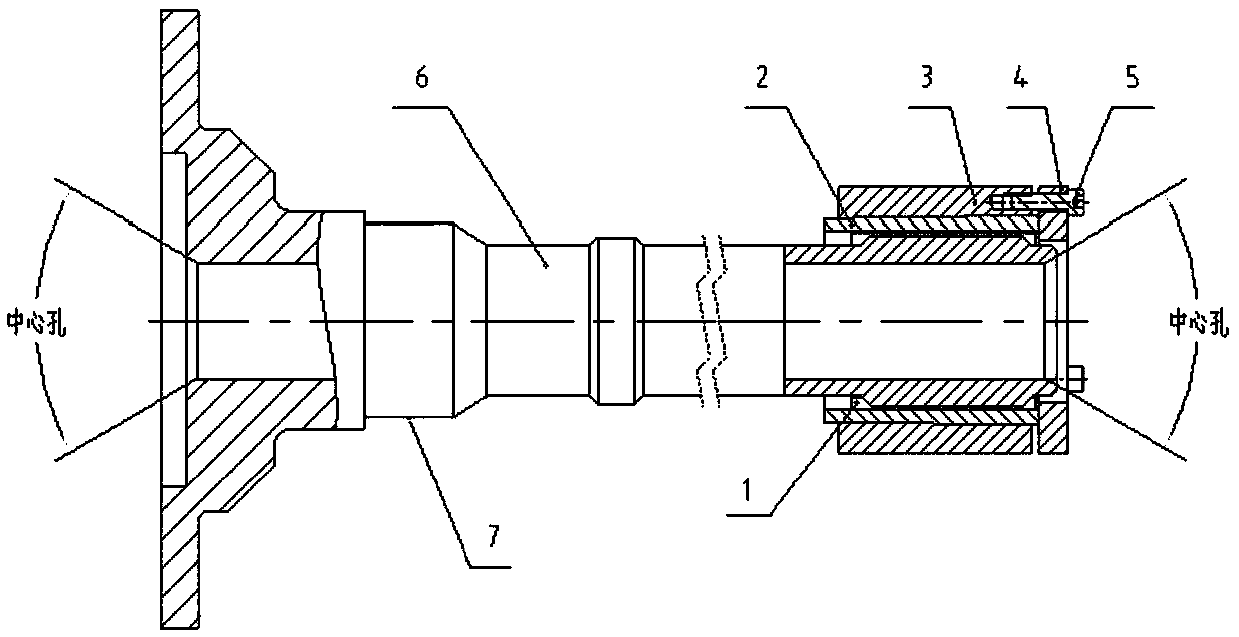

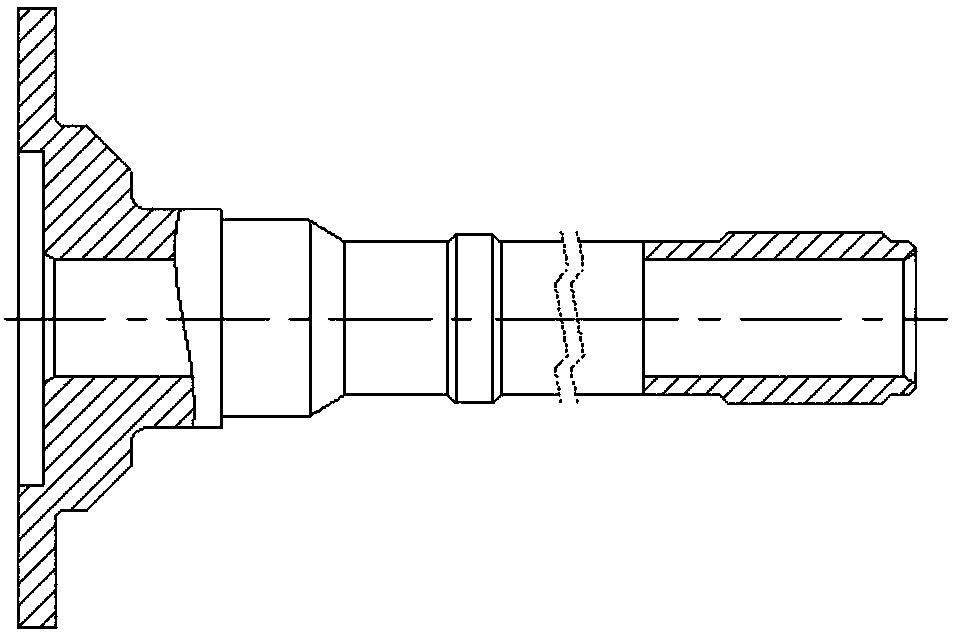

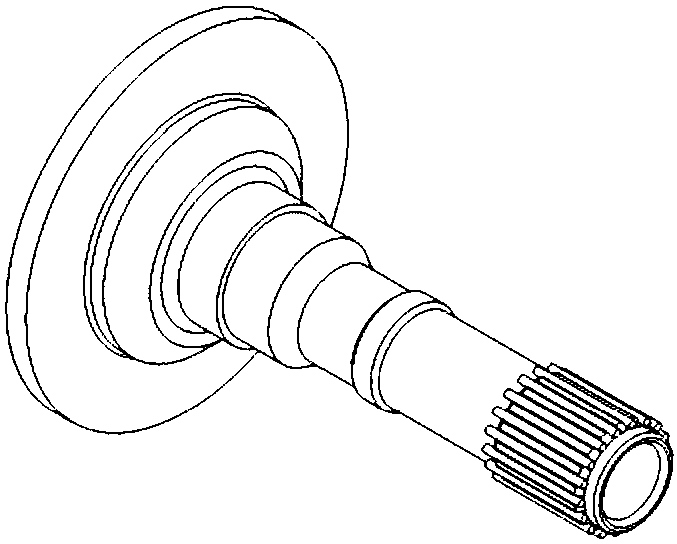

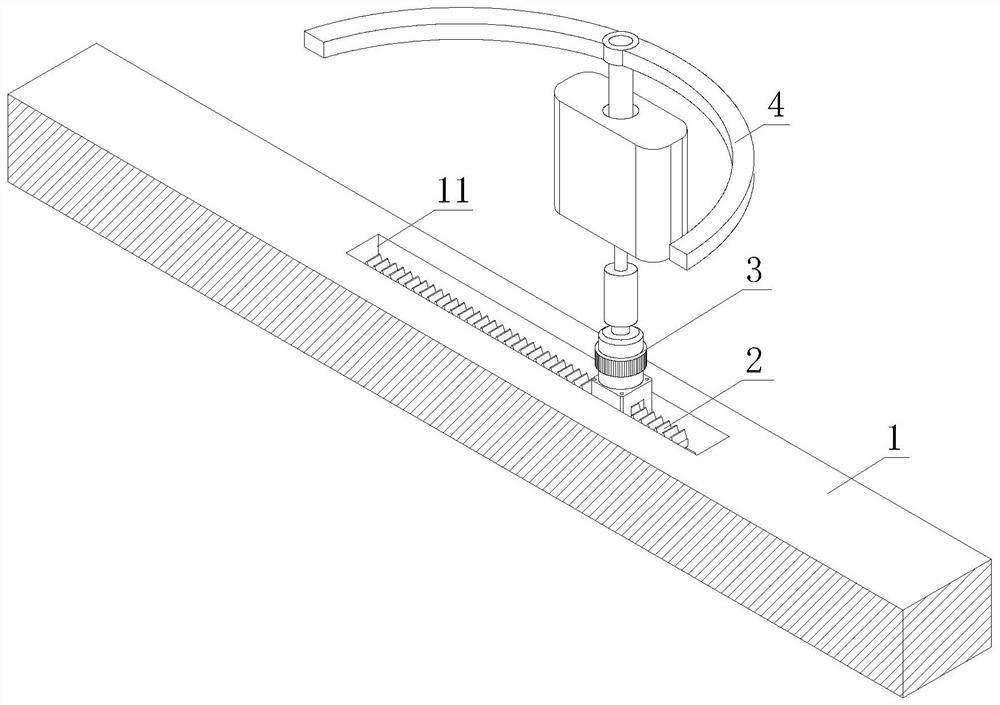

Tool for repairing and grinding center holes of output shaft of aero-engine and repairing and grinding work method of tool

PendingCN108381188AAvoid damage to the output shaftSimple structureRevolution surface grinding machinesOther manufacturing equipments/toolsInstabilityEngineering

The invention relates to a tool for repairing and grinding center holes of an output shaft of an aero-engine and a repairing and grinding work method of the tool. The tool comprises rolling rods, aninner taper sleeve, an outer taper sleeve, a pressing plate and a screw, wherein the rolling rods are arranged and placed in a spline groove of the output shaft at equal intervals in a circumferentialmode, an inner hole of the inner taper sleeve is in contact compression with the rolling rods, and the inner conical surface of the outer taper sleeve is compressed with the outer conical surface ofthe inner taper sleeve in a cooperating mode; and the left end face of the pressing plate is in contact compression with the right end face of the inner taper sleeve, the screw penetrates through a through hole in the pressing plate and is in threaded connection with a threaded hole in the end face of the inner taper sleeve. The tool is simple in structure and easy to machine; according to the repairing and grinding work method of the tool, manual hand scraping repairing and grinding in the prior art is replaced by machining repairing and grinding, so that instability of manual repairing and grinding is eliminated, and the phenomenon that the output shaft is damaged by a hand scraper in the manual repairing and grinding process can be effectively avoided; and the repairing and grinding working method of the tool is simple, convenient and reliable, and on the premise of guaranteeing the repairing and grinding quality, the time required for repairing and grinding is shortened.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

Gray level image colorization method based on generative adversarial network

PendingCN114581552AGuaranteed generalization qualityEasy to optimizeTexturing/coloringNeural architecturesColor imageData set

The invention discloses a grayscale image colorization method based on a generative adversarial network, and the method comprises the steps: firstly, selecting a quantitative color image group in a COCO image data set, carrying out the decoloring processing, making a training set, constructing a generative adversarial network architecture, enabling a generator model to complete the pre-training in the generative adversarial network architecture, and carrying out the image colorization. And then alternately training the discriminant model and the pre-trained generative model, adjusting parameters to obtain a trained model, and inputting test data into the model to realize gray level image colorization. Through the pre-training method and process of the generator, the training method and data set optimization are greatly improved, the training time is greatly shortened on the basis of ensuring the training quality and the generalization quality of the finally generated image, and the method has flexibility; and training and testing are carried out on a COCO data set by utilizing a U-Net thought, so that the defects that manual intervention is needed and fine coloring work of a large-size image pixel level is difficult to carry out in a traditional method can be reduced to a great extent.

Owner:NANJING UNIV OF POSTS & TELECOMM

Culture system for microbial culture and culture method thereof

PendingCN110862911AReduce deathReduce riskBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention relates to the technical field of microbial culture, and particularly relates to a culture system for microbial culture and a culture method thereof. The culture system comprises a culture cylinder for microbial culture, the culture system further comprises a temperature control cabin, a temperature control cavity capable of keeping the temperature in the cavity stable is formed in the temperature control cabin; all or the lower part of the culture cylinder is arranged in the temperature control cavity; wherein the culture cylinder comprises a cylinder body with a closed lower end and an open upper end and a cover body matched with the open upper end of the cylinder body, the internal space of the cylinder body is divided into a culture medium cavity and a gas cavity from bottom to top, the culture medium cavity is used for containing a culture medium suitable for microorganism growth, and a gas replacement device is further arranged in the cylinder body. According to themicroorganism culture system, the temperature control cavity is arranged, and the temperature in the temperature control cavity is controllable and adjustable, so that the temperature in the culturecylinder, particularly the temperature of the culture medium cavity, is at the temperature suitable for growth, development and propagation of microorganisms, and the good culture quality of the microorganisms is ensured.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

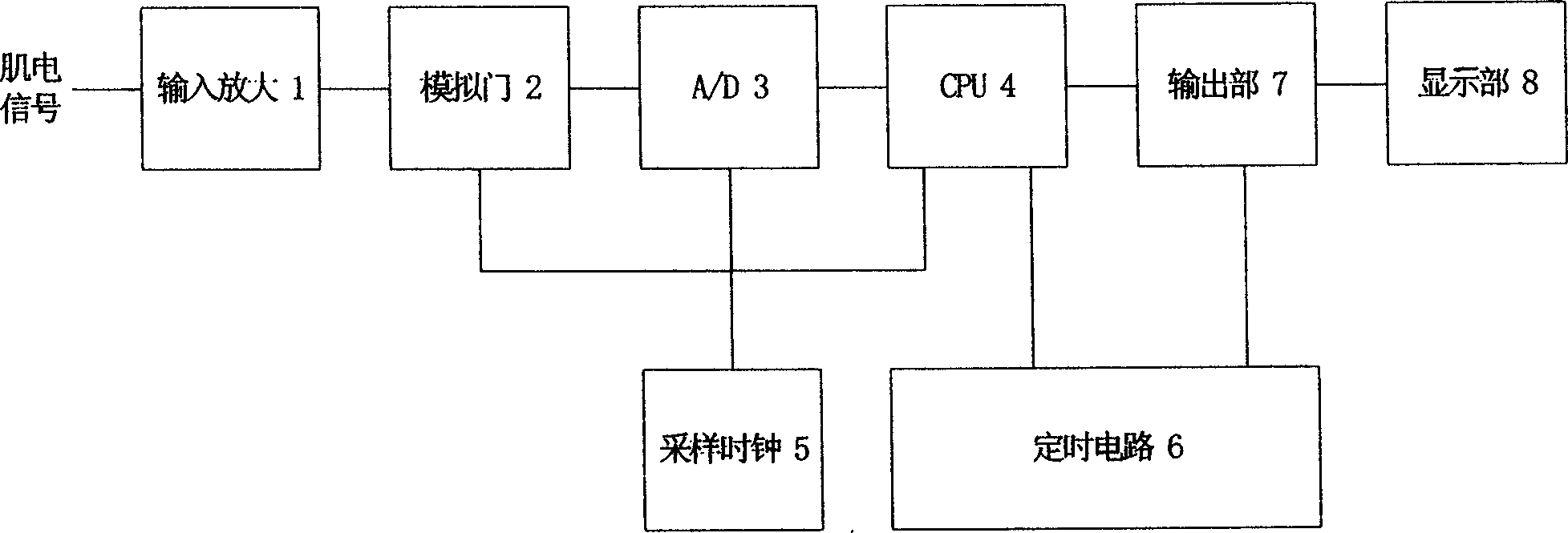

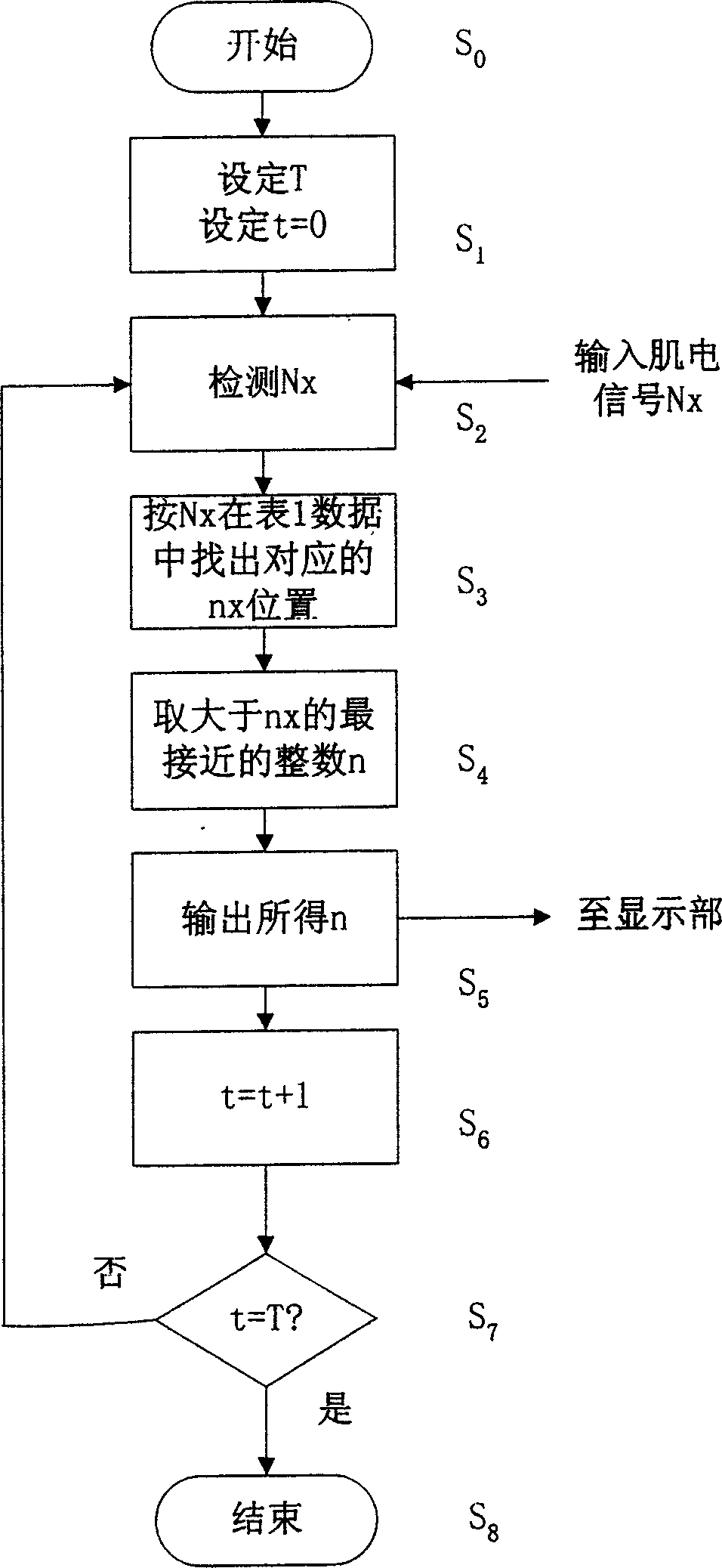

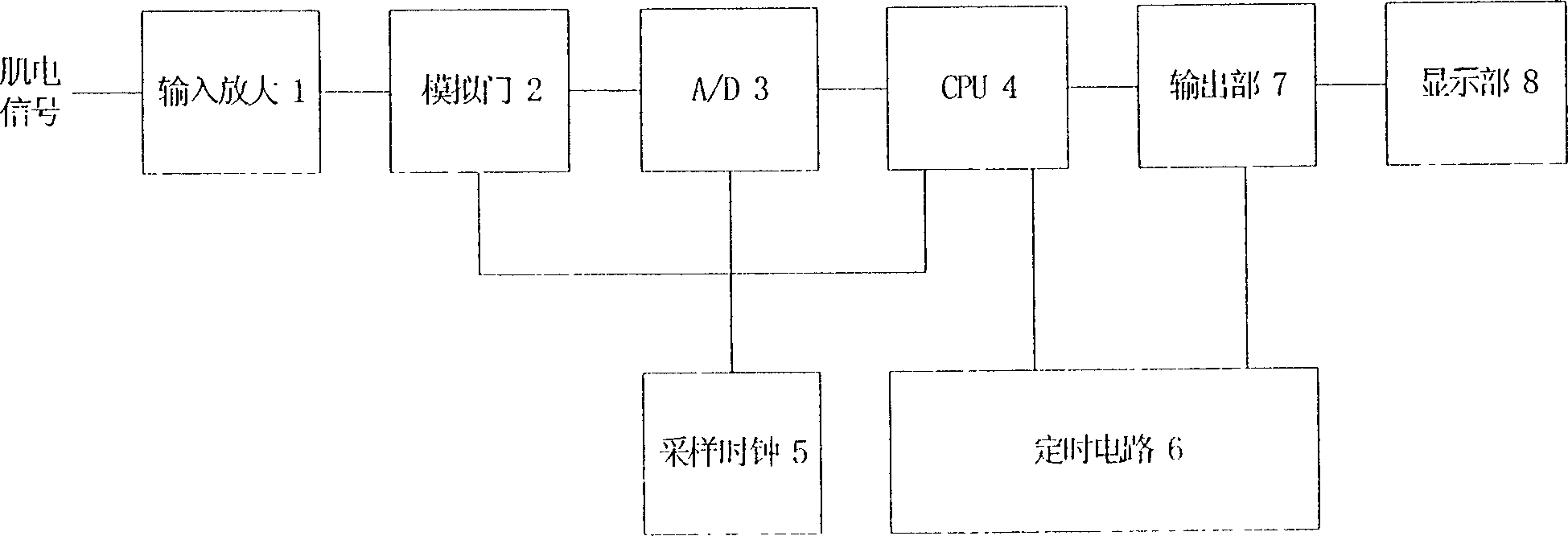

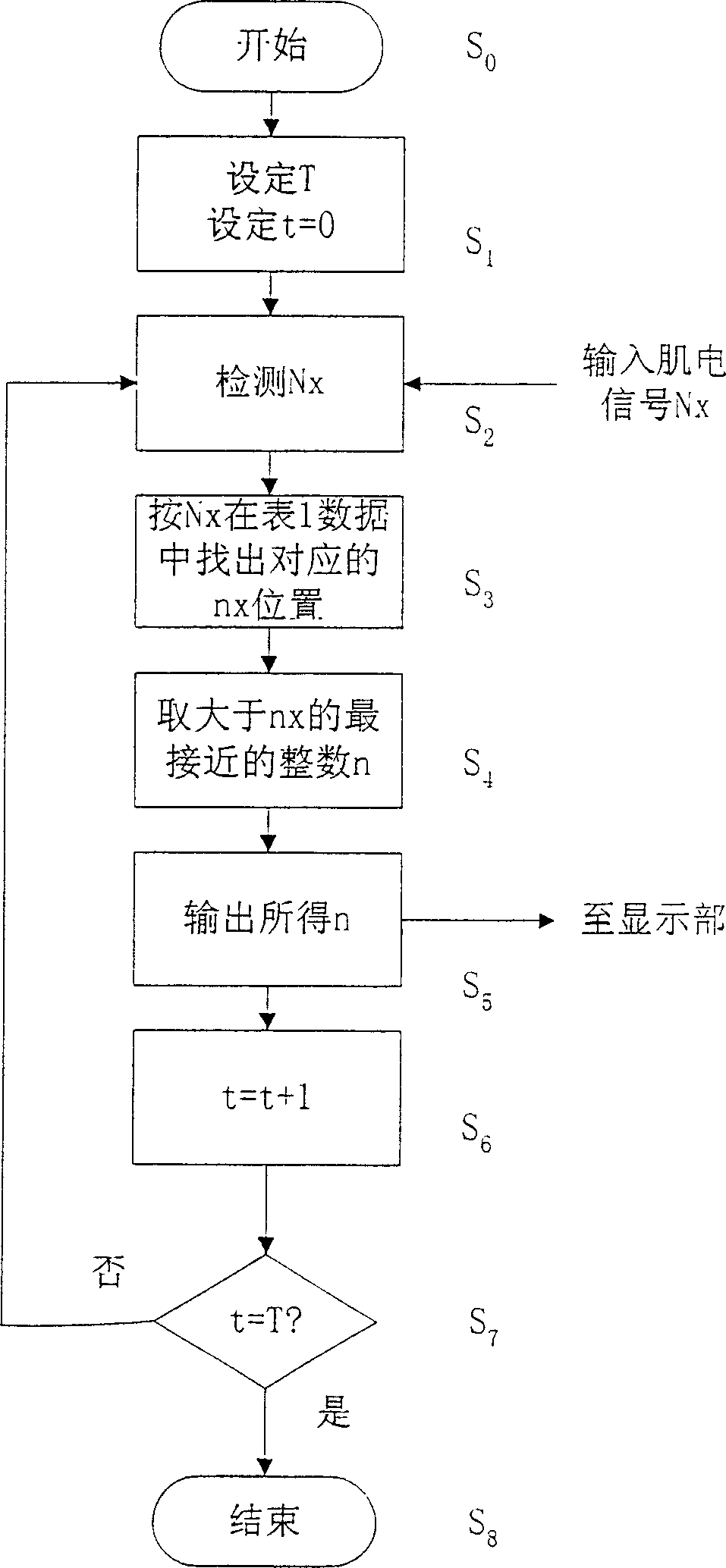

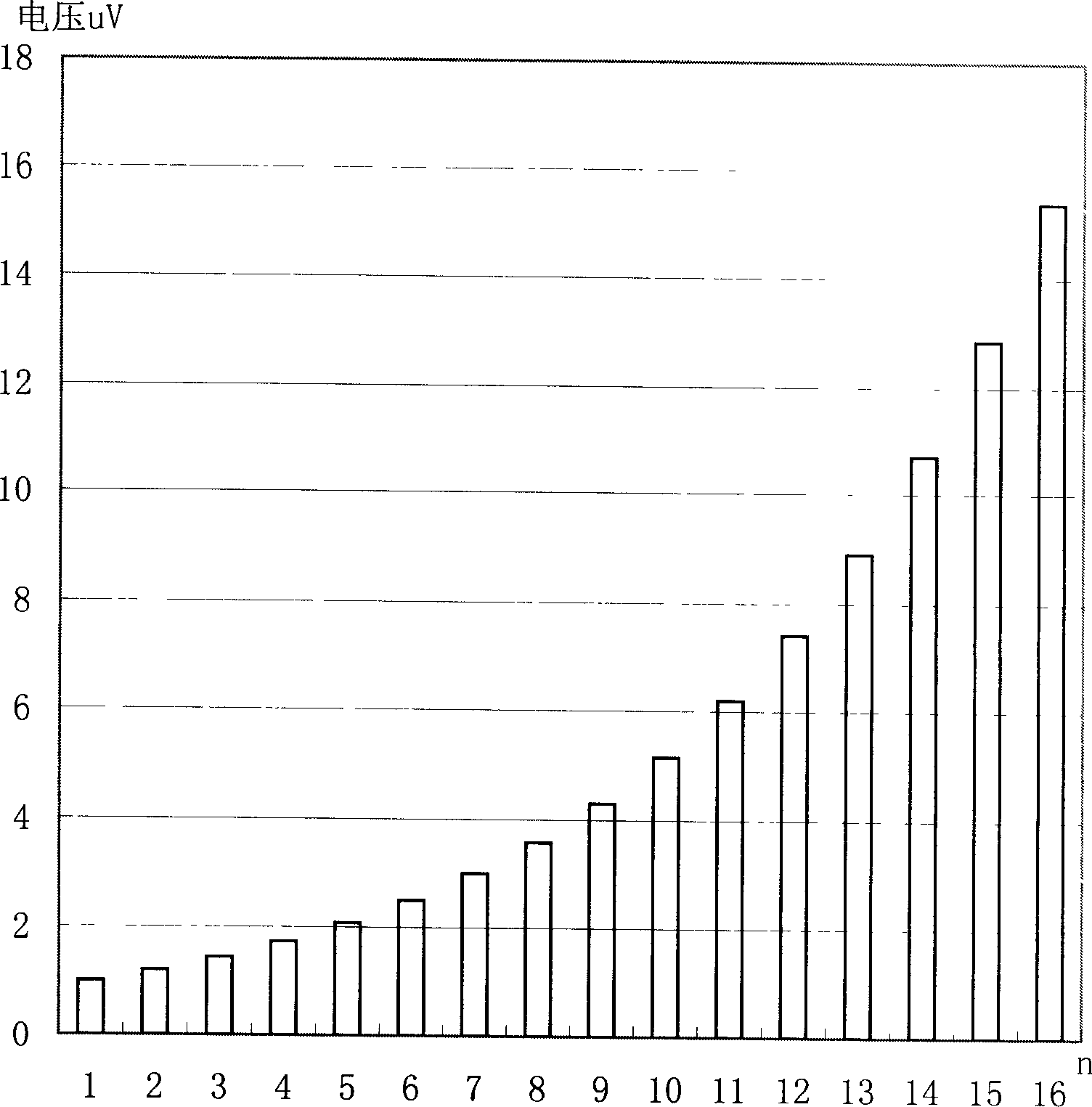

Muscle bioelectricity biofeedback instrument possessing range and sensitivity automatic adjusting device

InactiveCN1541613AFunctionalWill not interfere or affect the training processDiagnostic recording/measuringSensorsElectromyographic biofeedbackEngineering

The present invention is one myoelectrical biological feedback instrument with automatic measurement range and sensitivity regulator. According to that during feedback training, the myoelectrical feedback sensitivity is required to be increased with the reduced myoelectrical amplitude, one scheme is proposed with multistage displayed myoelectrical amplitude and unequal gradually raised myoelectrical amplitude difference between adjacent stages. In the scheme, the display sensitivity increases with the reduced myoelectrical amplitude, all the myoelectrical amplitude values are displayed, and the there is no need for the trainee to regulate measurement range and sensitivity, being favorable to the trainee to relax in training.

Owner:北京泰达新兴医学工程技术有限公司 +1

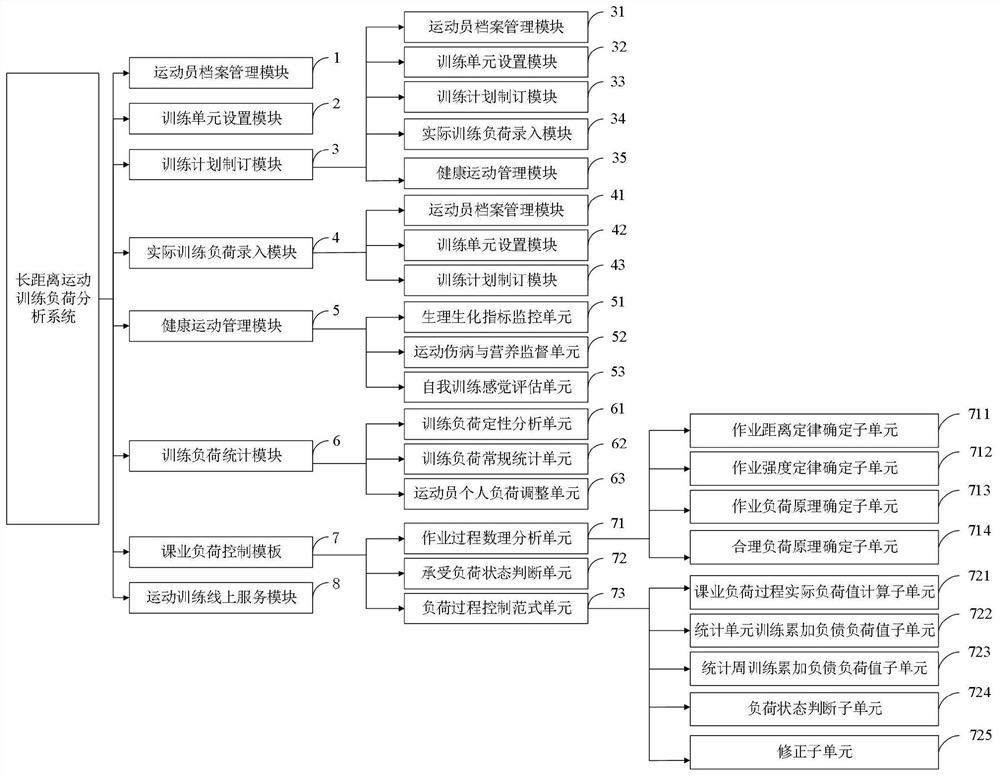

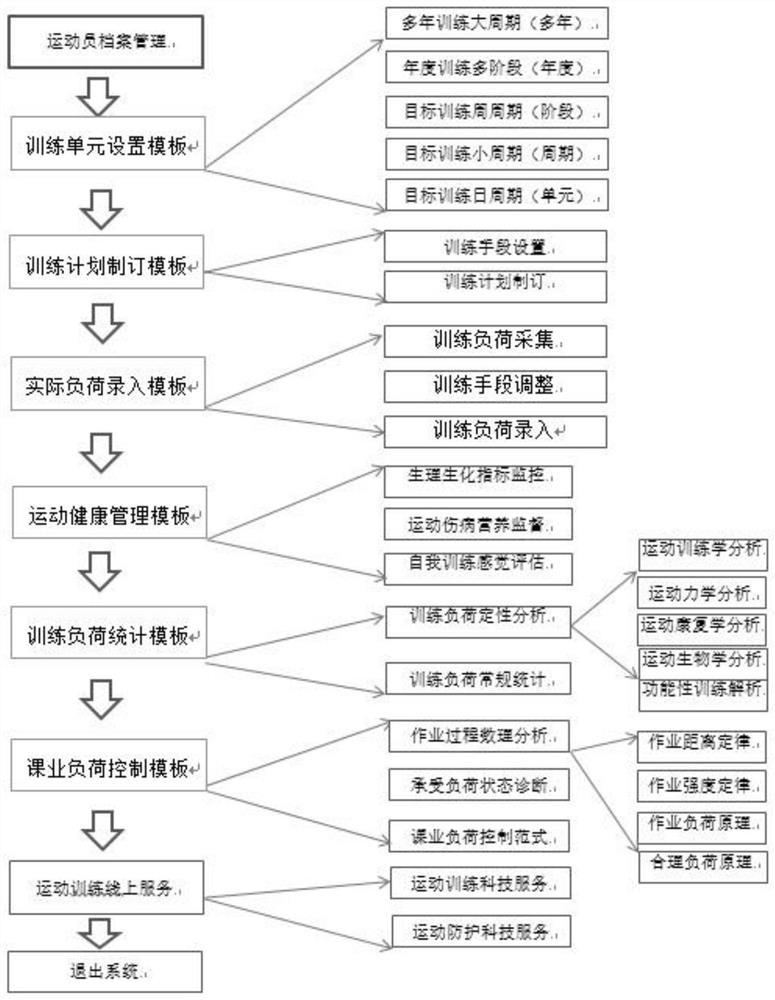

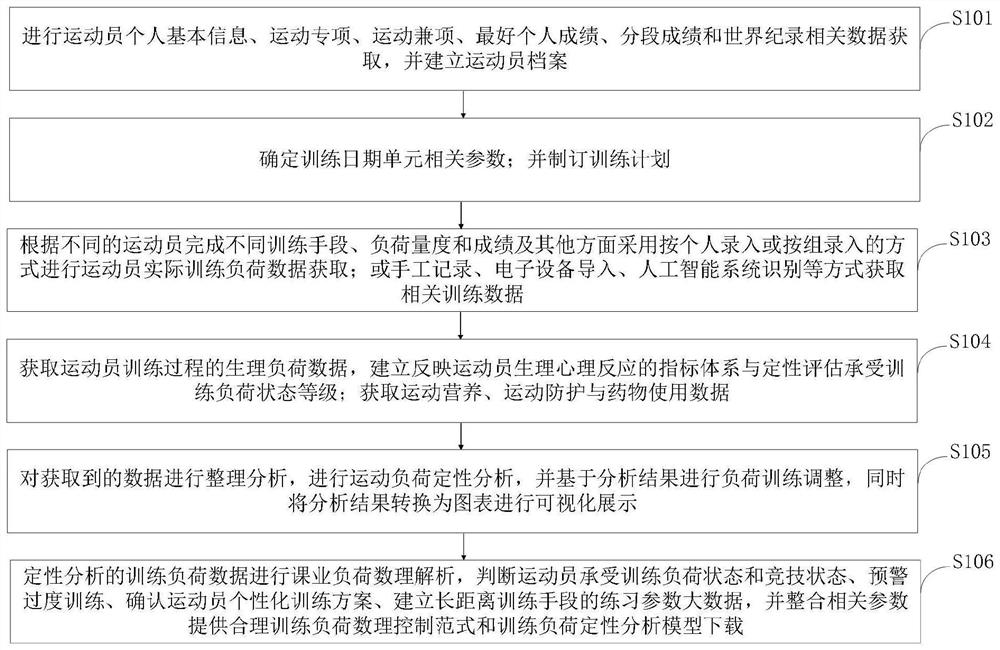

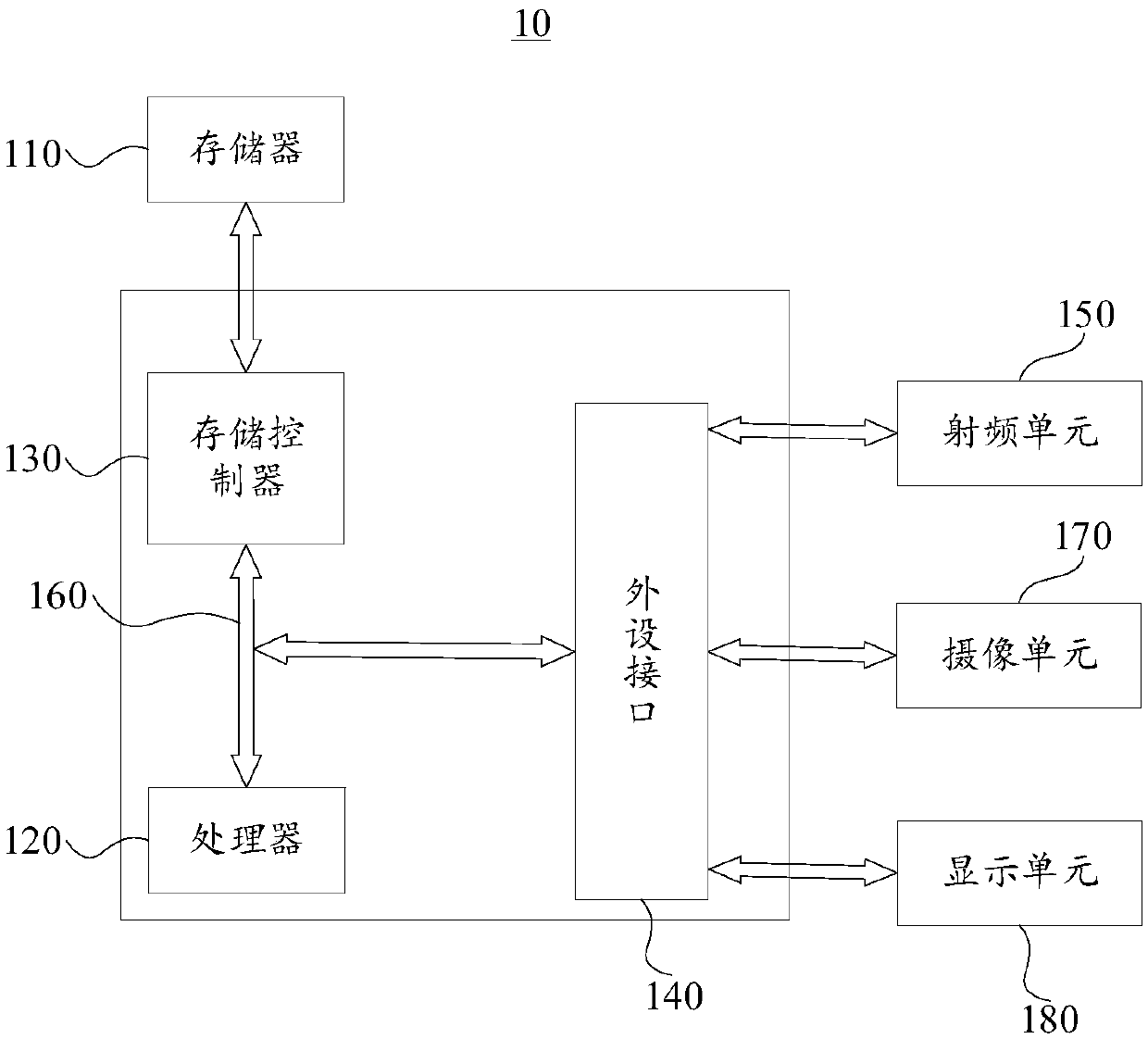

Long-distance exercise training load analysis system

PendingCN112349413AFlexibleFunction increasePhysical therapies and activitiesHealth-index calculationTraining planAthletic training

The invention belongs to the technical field of exercise data analysis, and discloses a long-distance exercise training load analysis system and analysis method. The system comprises an athlete archive management module, a training unit setting module, a training plan making module, an actual training load input module, a health exercise management module, a training load statistics module, a curriculum load control module and an exercise training online service module. According to the method, the competitive state of long-distance athletes or the exercise load bearing state of personal fitness exercises can be reflected more objectively, practical reference and implementation effective control are provided for scientific exercise training or fitness health management, and the method haswide popularization value and commercial development prospects.According to the invention, the actual exercise load bearing state of a long-distance athlete or enthusiast can be tracked and analyzed,and over-training is warned; the plug-in visual online long-distance exercise training and functional training guidance function not only provides intelligence support for competitive exercise training, but also provides science and technology service for exercise protection, and market value is developed.

Owner:HUNAN CITY UNIV

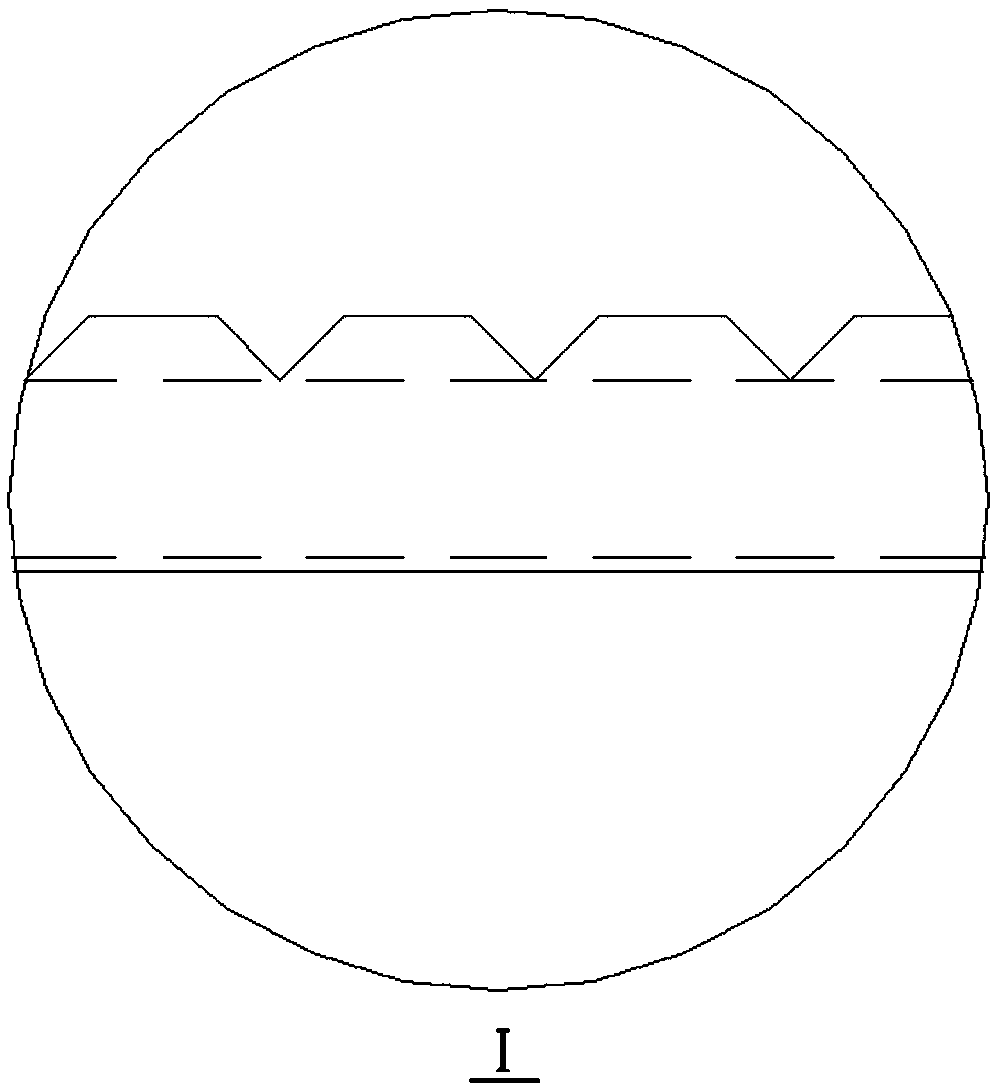

Flying saucer target special for movement training

The invention discloses a special sports training flying saucer target. According to the weight percentage, the training flying saucer target is prepared by any one (5 to 30 percent) of polypropylene resin, polythene resin, ABS resin, vinyl acetate resin or polyvinyl chloride resin filled with master batch or calcium powder of 70 to 95 percent. The raw materials adopted by the shooting training flying saucer target of the invention can not leave abandoned objects during the use, and can not cause the pollution to the environment; during the training process, the flying saucer target is not easy to break when the flying saucer target is thrown and falls to the ground, and can be repetitively used for a plurality of times, thereby saving the training cost. The product of the invention is just the same as the standard flying saucer target used in the sports competition in size, weight and so on; the flying saucer target has steady air flight and can fully assure the training quality of the athletes.

Owner:苏彬

Flying saucer target special for movement training

The invention discloses a special sports training flying saucer target. According to the weight percentage, the training flying saucer target is prepared by any one (5 to 30 percent) of polypropylene resin, polythene resin, ABS resin, vinyl acetate resin or polyvinyl chloride resin filled with master batch or calcium powder of 70 to 95 percent. The raw materials adopted by the shooting training flying saucer target of the invention can not leave abandoned objects during the use, and can not cause the pollution to the environment; during the training process, the flying saucer target is not easy to break when the flying saucer target is thrown and falls to the ground, and can be repetitively used for a plurality of times, thereby saving the training cost. The product of the invention is just the same as the standard flying saucer target used in the sports competition in size, weight and so on; the flying saucer target has steady air flight and can fully assure the training quality of the athletes.

Owner:苏彬

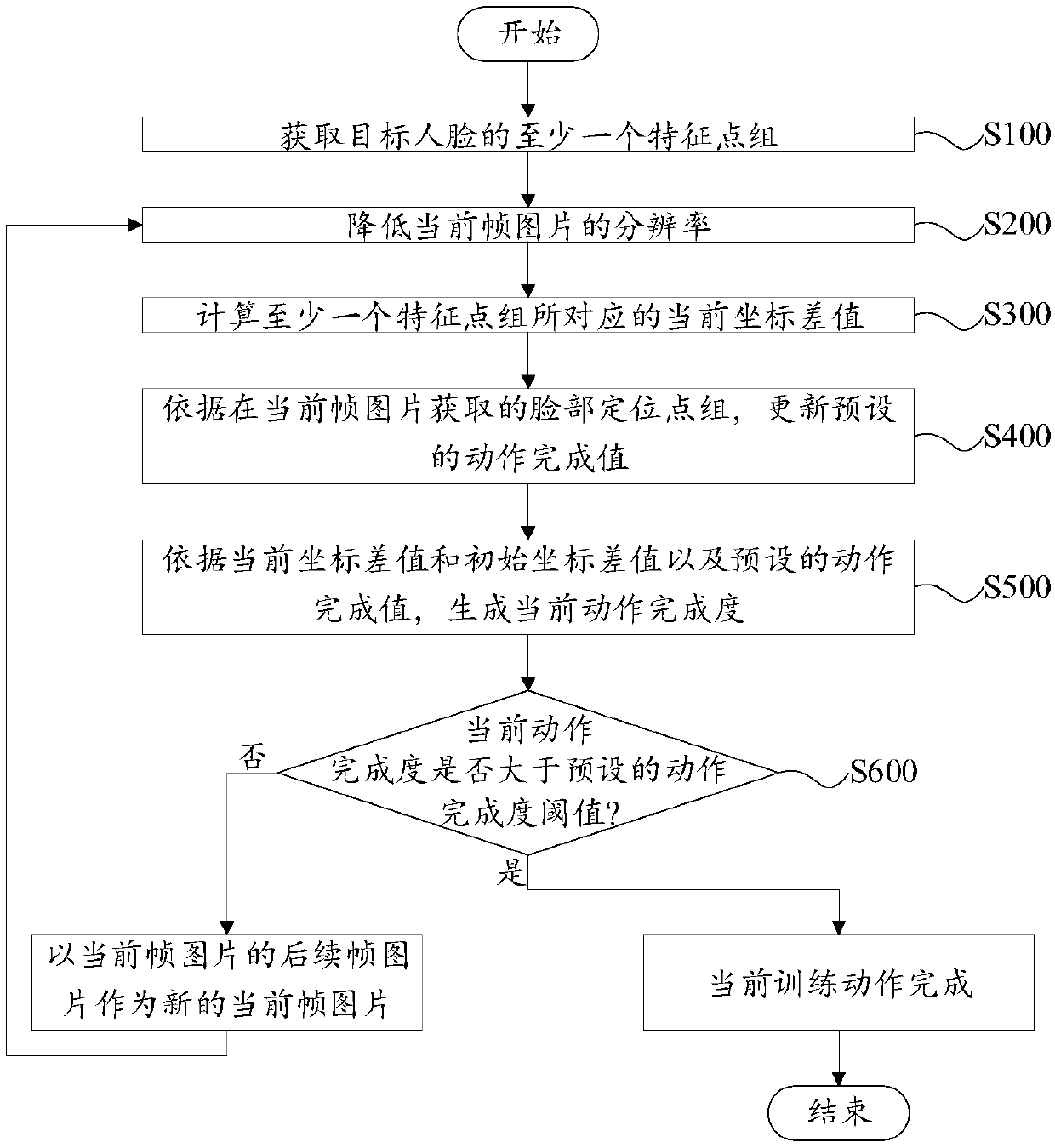

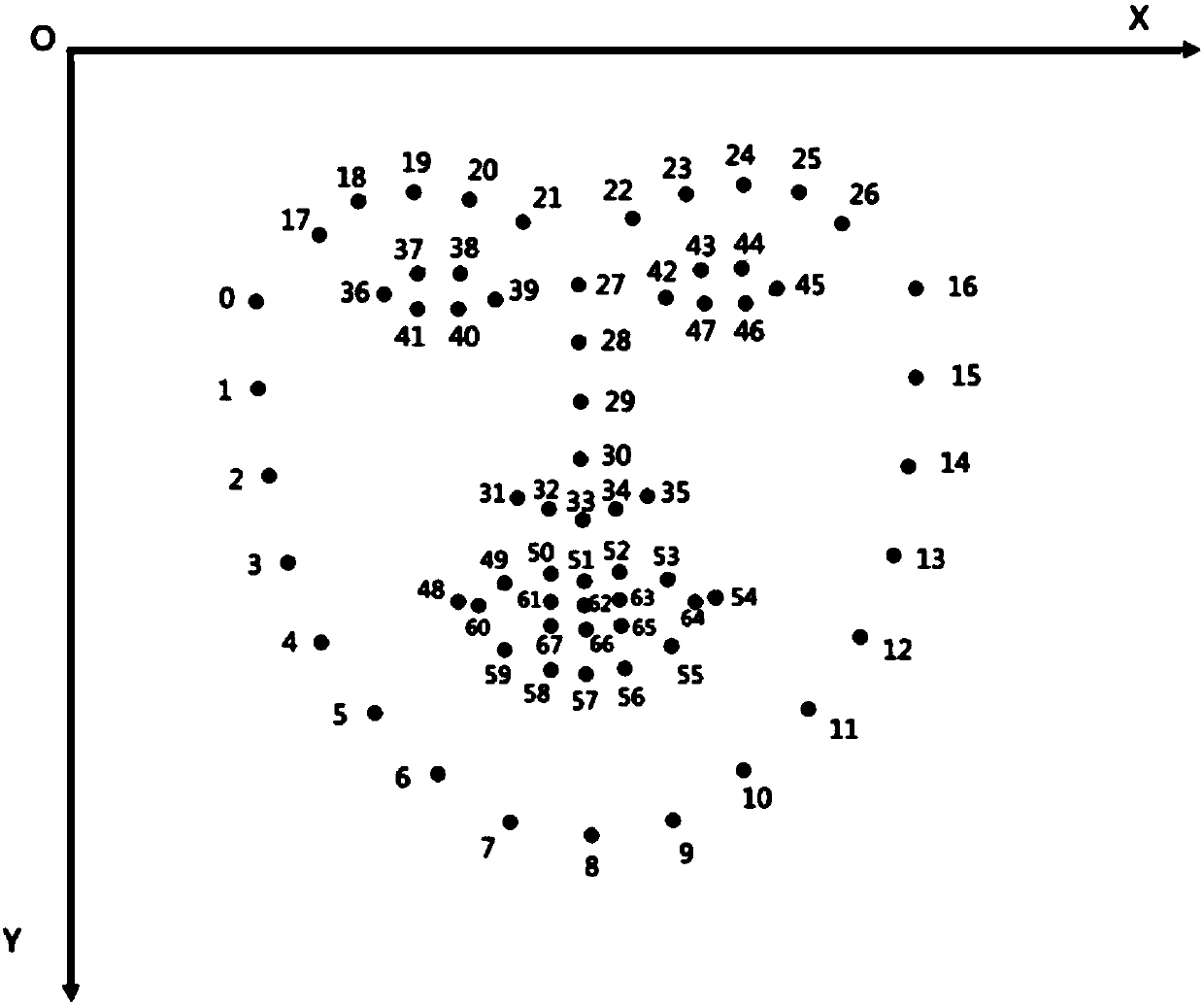

Facial muscle training method and device and electronic equipment

ActiveCN109659006AGuarantee the quality of trainingPhysical therapies and activitiesCharacter and pattern recognitionTraining - actionPhysical medicine and rehabilitation

The embodiment of the invention provides a facial muscle training method and device and electronic equipment, and relates to the field of virtual rehabilitation training, the method comprises the following steps: obtaining at least one feature point group of a target face, each feature point group comprising two feature points; Calculating a current coordinate difference value corresponding to theat least one feature point group, the current coordinate difference value being a coordinate difference value of the at least one feature point group in the current frame of picture; According to thecurrent coordinate difference value, the initial coordinate difference value and a preset action completion value, the current action completion degree is generated, and the initial coordinate difference value represents the coordinate difference value of at least one feature point group in the initial state; And when the current action completion degree is greater than a preset action completiondegree threshold, determining that the current training action is completed. According to the facial muscle training method and device and the electronic equipment provided by the embodiment of the invention, whether the current training action is completed or not can be fed back when a user carries out facial muscle training, and the facial muscle training quality is ensured.

Owner:SHENZHEN INST OF ADVANCED TECH

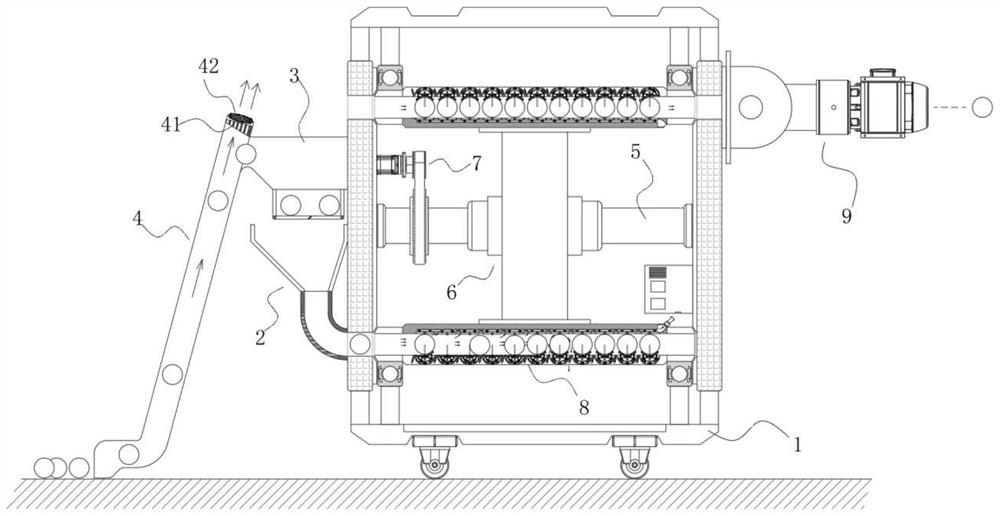

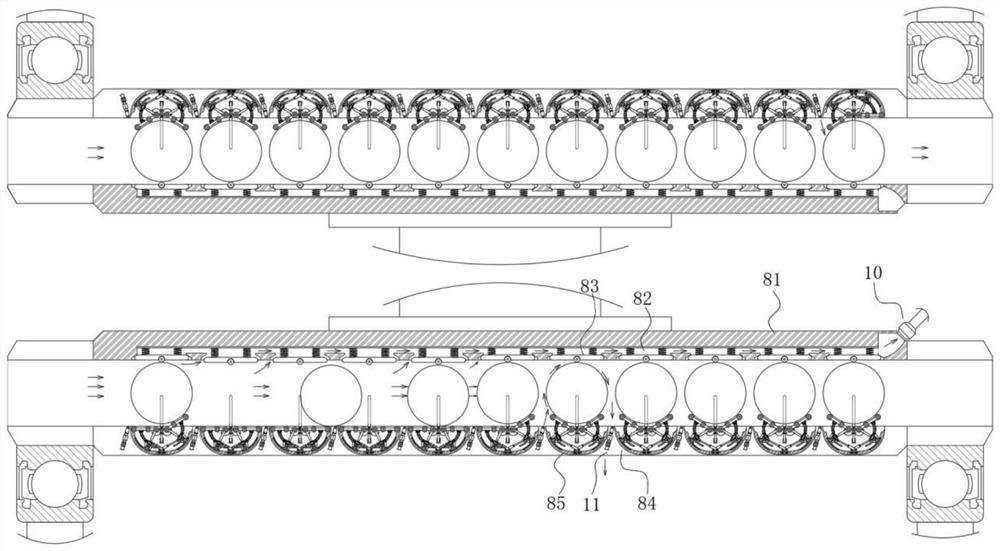

Table tennis ball serving device with picking function

InactiveCN114011039AImprove orderImprove smooth performanceBall sportsRacket sportsElectric machineryEngineering

The invention discloses a table tennis ball serving device with a picking function, which comprises a collecting vehicle, the left side plate of the collecting vehicle is provided with vertically symmetrical feeding cavities, the right side plate of the collecting vehicle is provided with a discharging cavity flush and corresponding to the upper part of the left side plate, and the outer side end, corresponding to the discharging cavity, of the right side plate is provided with the ball serving device; a collecting hopper which is mounted at the outer side end of the feeding cavity below the left side plate; a storage box which is located above the collecting hopper and fixed to the left side plate, the left side end of the storage box communicates with a collecting pipe, a breathable partition net is installed in the end, higher than one side of the storage box, of the collecting pipe, and a draught fan is installed above the breathable partition net; a rotating shaft, the left end and the right end of the rotating shaft are rotationally connected to the inner side walls of the left side plate and the right side plate and connected with the output end of a motor through a belt, the motor is fixed to the left side plate, and the outer side of the rotating shaft is fixedly sleeved with a rotating plate; and collecting devices which are mounted on the outer side ring wall of the rotating plate and are arranged in a circumferential manner.

Owner:枣庄科技职业学院

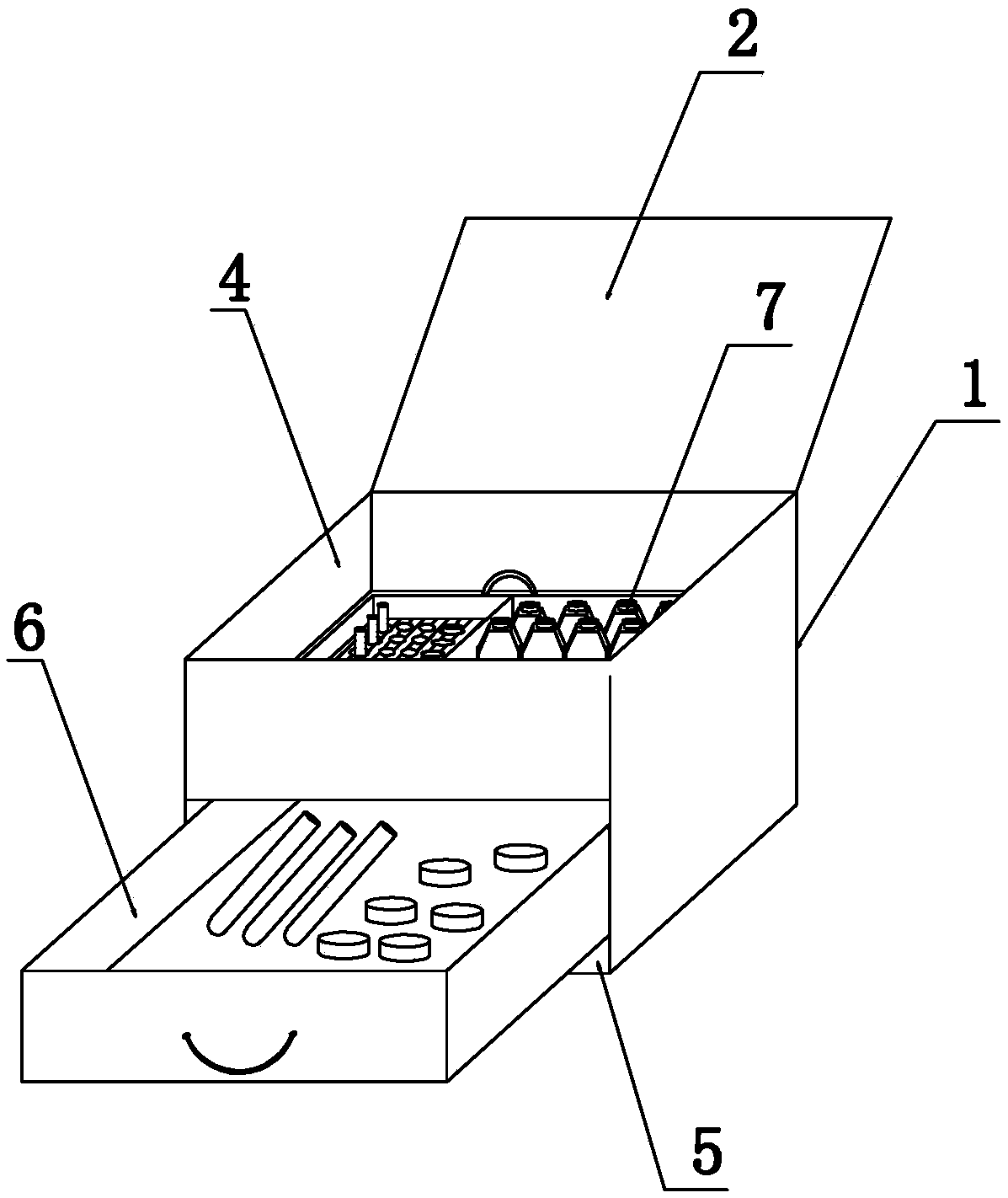

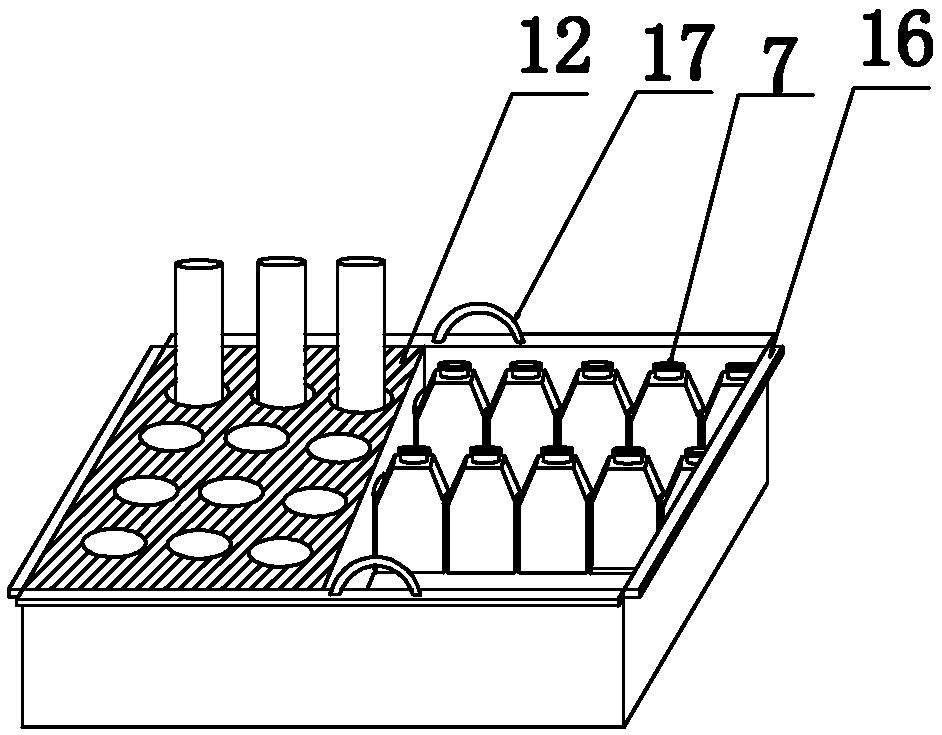

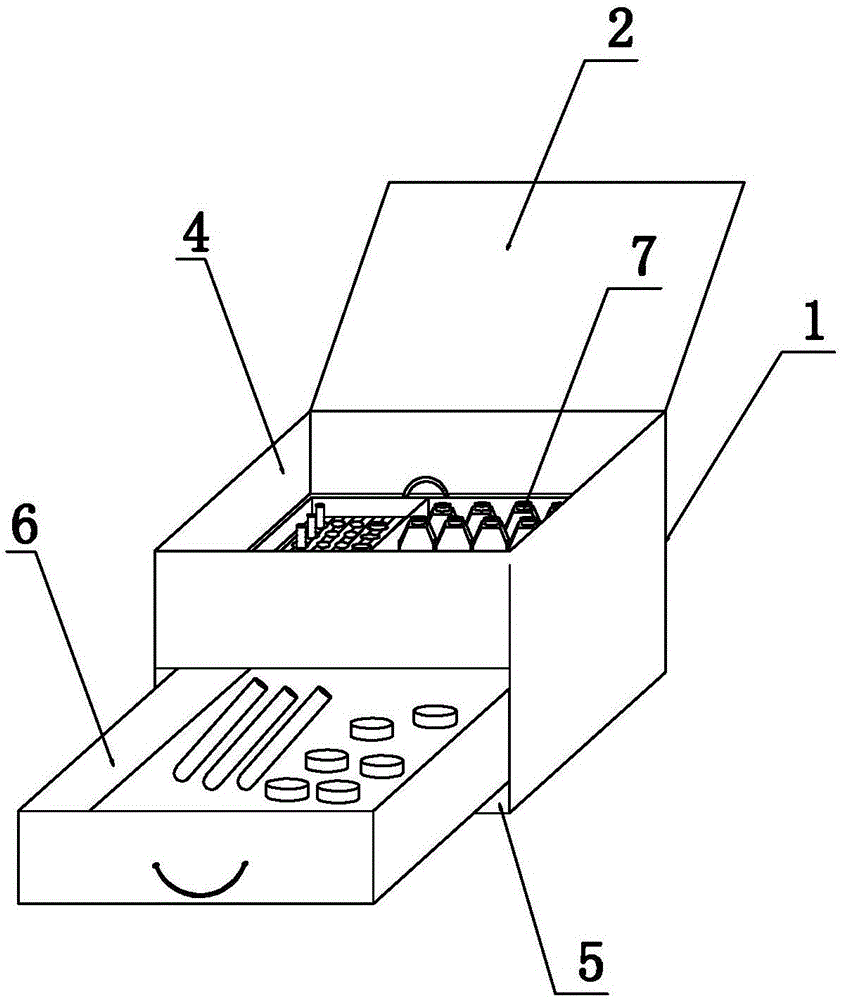

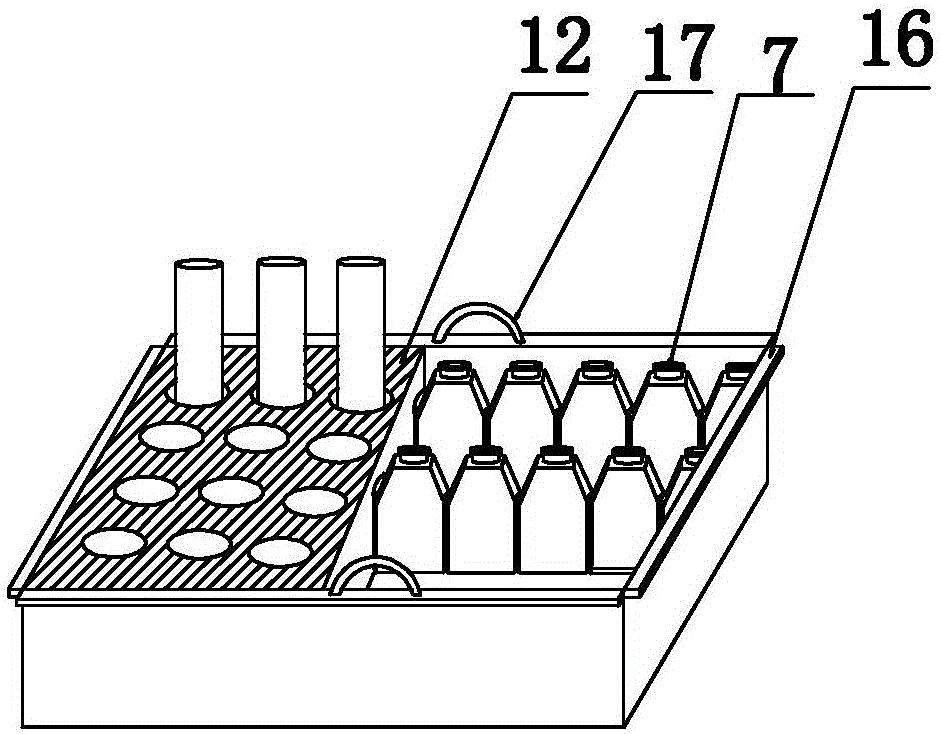

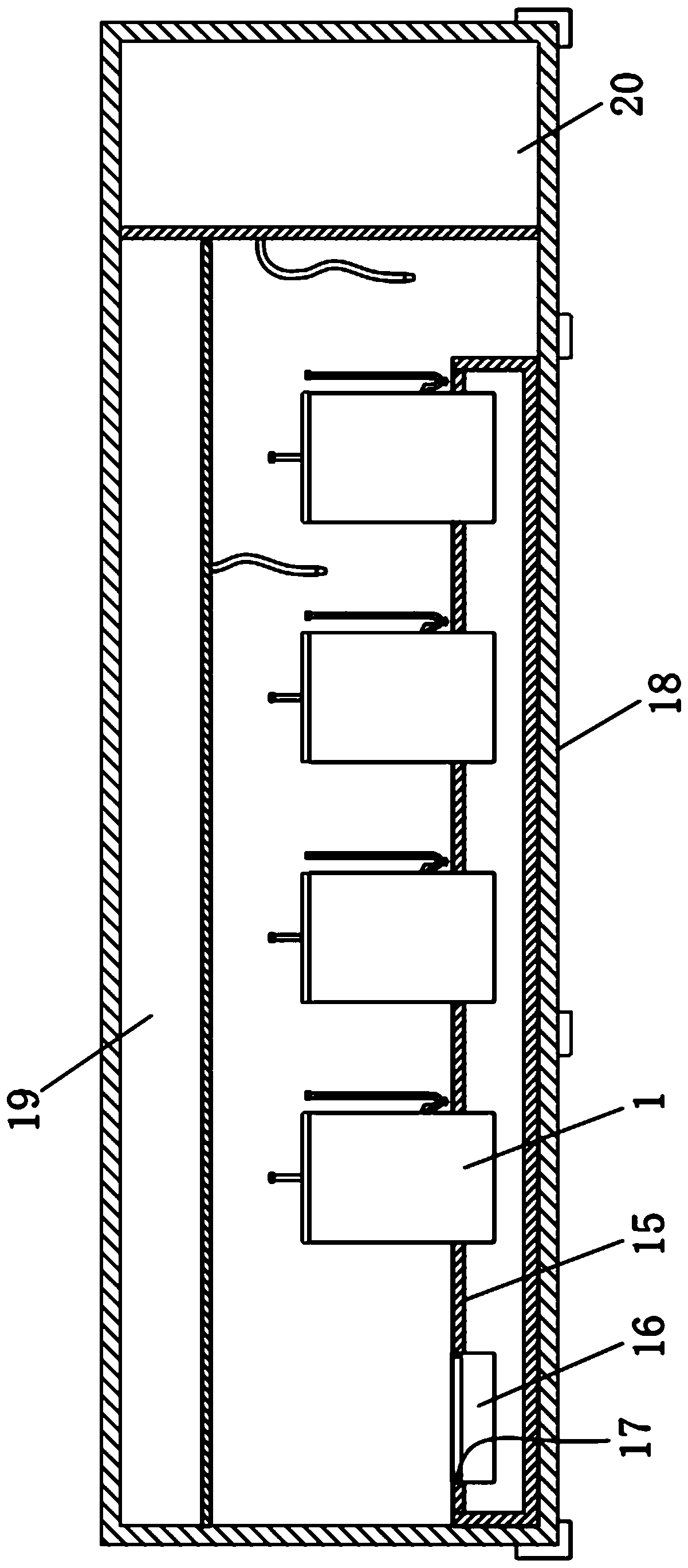

A kit and culture method for culturing mesenchymal stem cells

ActiveCN106190837BNo differentiationGuarantee the quality of trainingCulture processSkeletal/connective tissue cellsMesenchymal stem cellCell survival rate

The invention provides a kit for culturing mesenchymal stem cells and a culturing method. The kit comprises a kit body and a kit cover hinged to the kit body; a partition plate is transversely arranged in the kit body, the kit body is internally divided into a reagent storage box and a tool box, the tool box is internally provided with a drawing box, the reagent storage box is internally provided with multiple reagent bottles which contain an umbilical cord preservation solution, a culture solution, additives, growth factors I, growth factors II, digestive juice, a cleaning solution and a culture-medium. The kit is simple in structure and is specially used for culturing the mesenchymal stem cells, the culturing efficiency of the mesenchymal stem cells is improved, more mesenchymal stem cells can be cultured in large quantities, demands of people can be met, and the economic cost is reduced; meanwhile, reagent formulas of the reagents in the kit are reasonable and effective, the nutritional requirements of mesenchymal stem cell growth can be met, value added growth of the mesenchymal stem cells is effectively promoted, and the cell survival rate is increased.

Owner:BEIJING YULONG SHENGSHI BIOTECH CO LTD

Muscle electricity biofeedback instrument possessing range and sensitivity automatic adjusting device

InactiveCN1256915CFunctionalWill not interfere or affect the training processDiagnostic recording/measuringSensorsElectricityElectromyographic biofeedback

Owner:北京泰达新兴医学工程技术有限公司 +1

Basketball jump training obstacle device between travels and training method

ActiveCN113041590AGuaranteed blocking efficiencyIncreased lateral interception rangeSport apparatusPhysical medicine and rehabilitationEngineering

The invention discloses a basketball jump training obstacle device between travels and a training method, and belongs to the technical field of training obstacle devices, the basketball jump training obstacle device comprises a training field foundation, a mounting groove is formed in the training field foundation, a transverse moving assembly is mounted in the mounting groove, and a steering lifting adjusting assembly is mounted above the transverse moving assembly; a barrier device body is connected to the upper portion of the steering lifting adjusting assembly, and a bouncing device is arranged in the barrier device body. According to the basketball jump training obstacle device and the training method, the blocking form is effectively simulated, left-right moving blocking can be carried out, the blocking efficiency is guaranteed, the transverse intercepting range is widened, the adaptability of the whole obstacle device is improved, the use convenience of a user is improved, adjustment can be carried out according to needs, the training quality is guaranteed, and the human shape is effectively simulated; the training quality is improved, multi-angle movement can be achieved, the functions are practical, the effect is good, high adjustable performance can be guaranteed, and the working efficiency is improved.

Owner:JILIN NORMAL UNIV

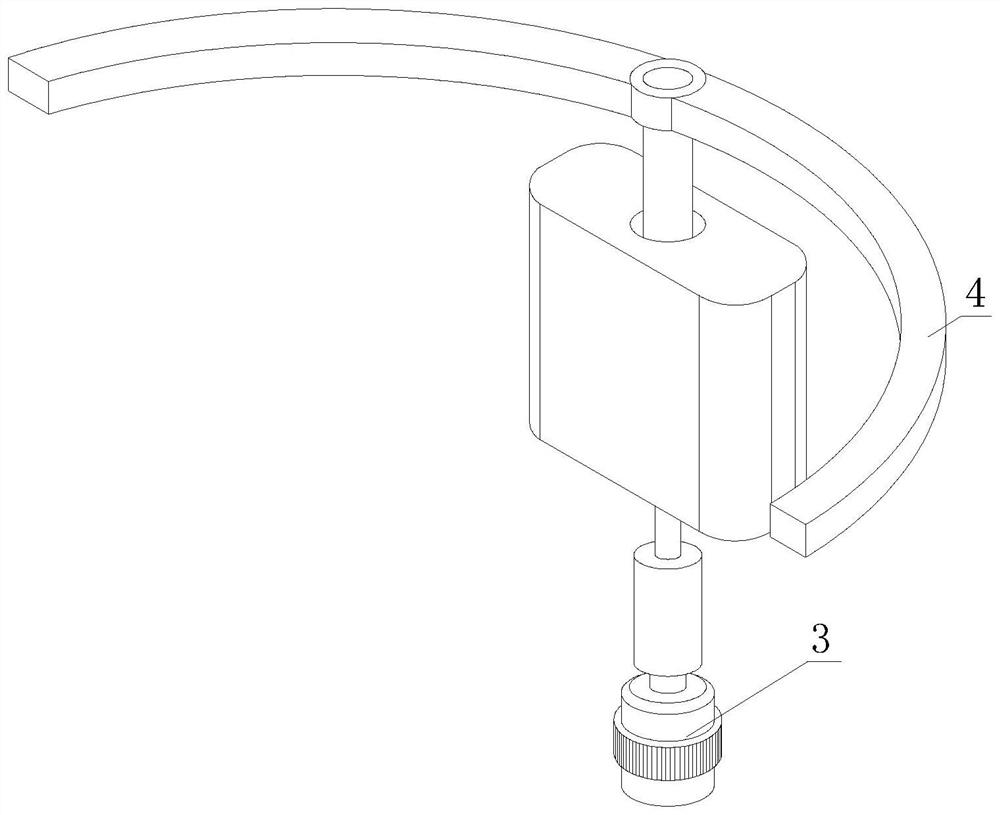

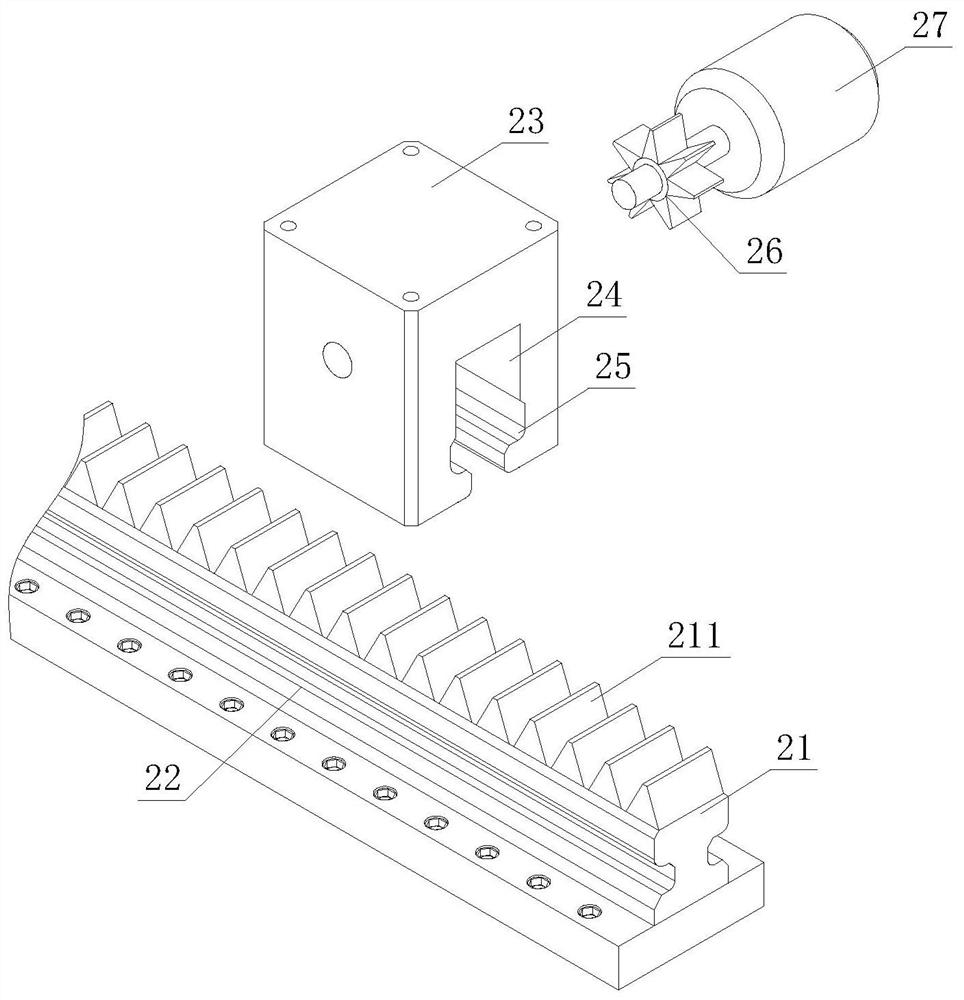

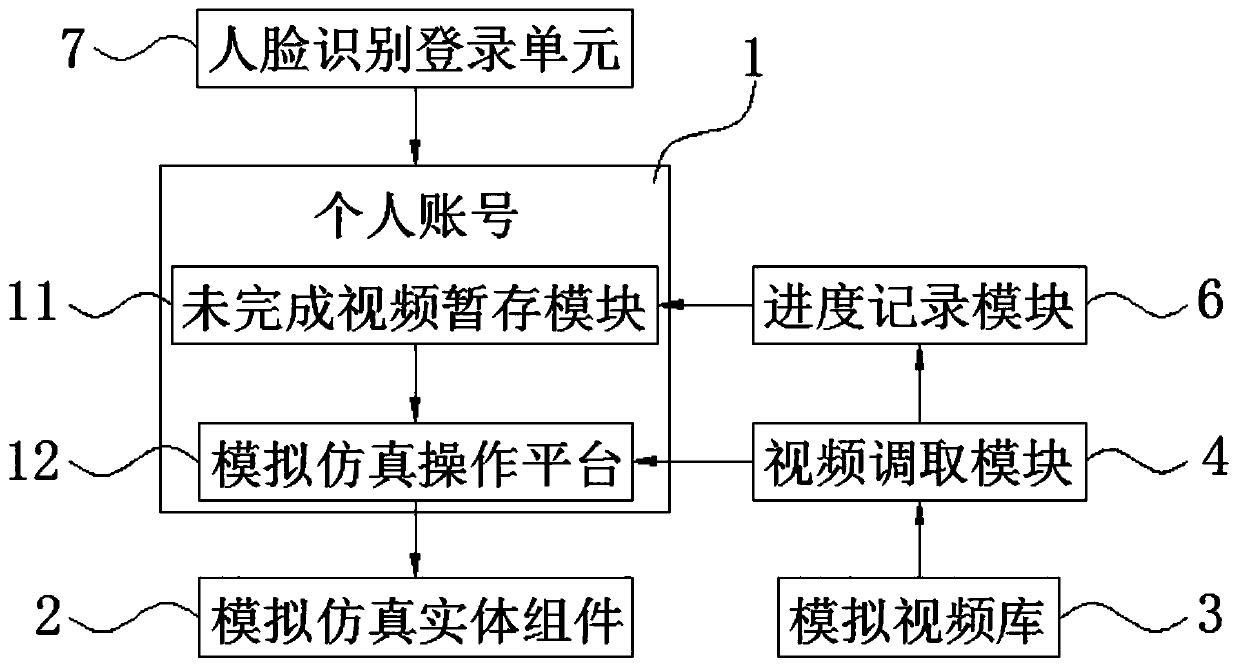

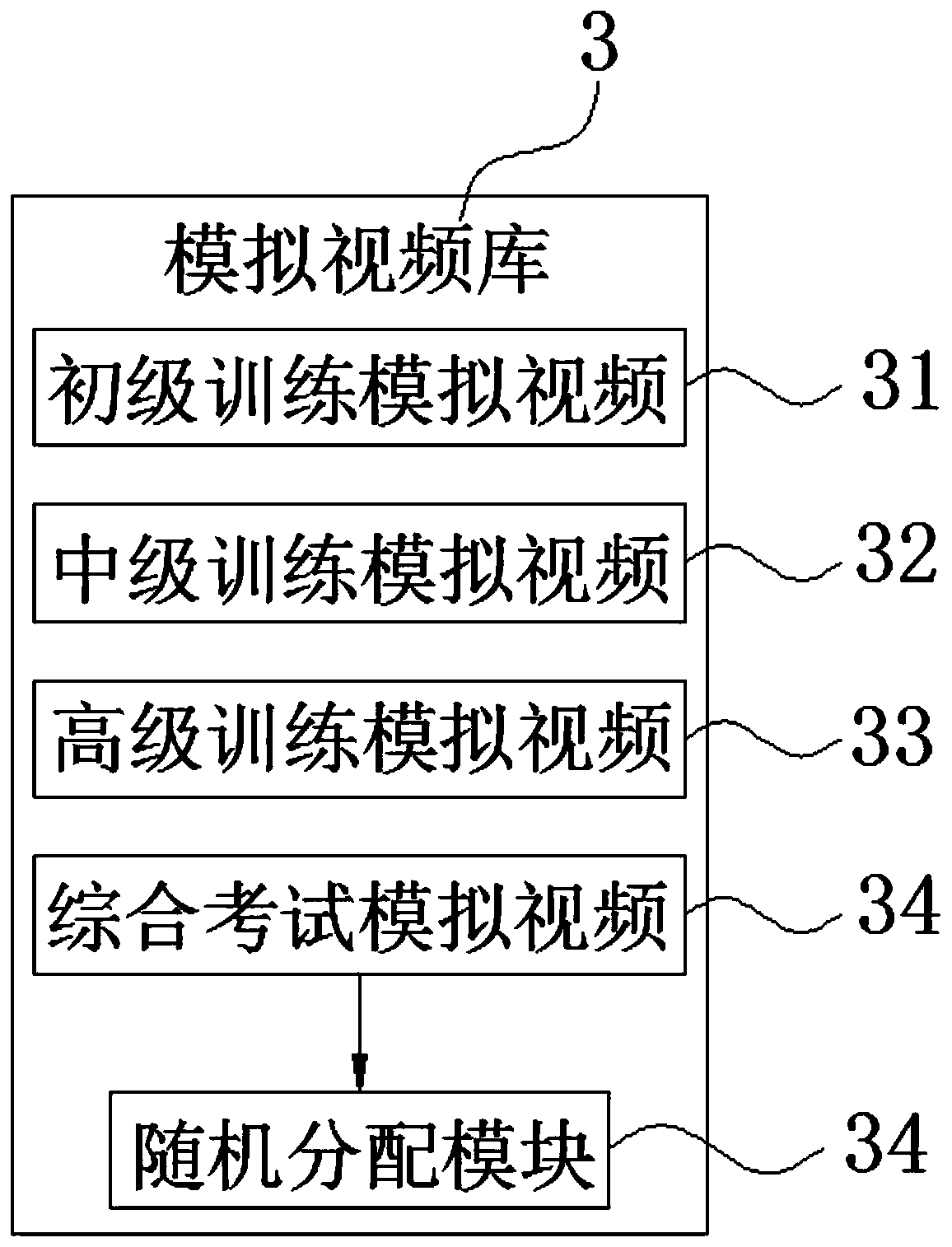

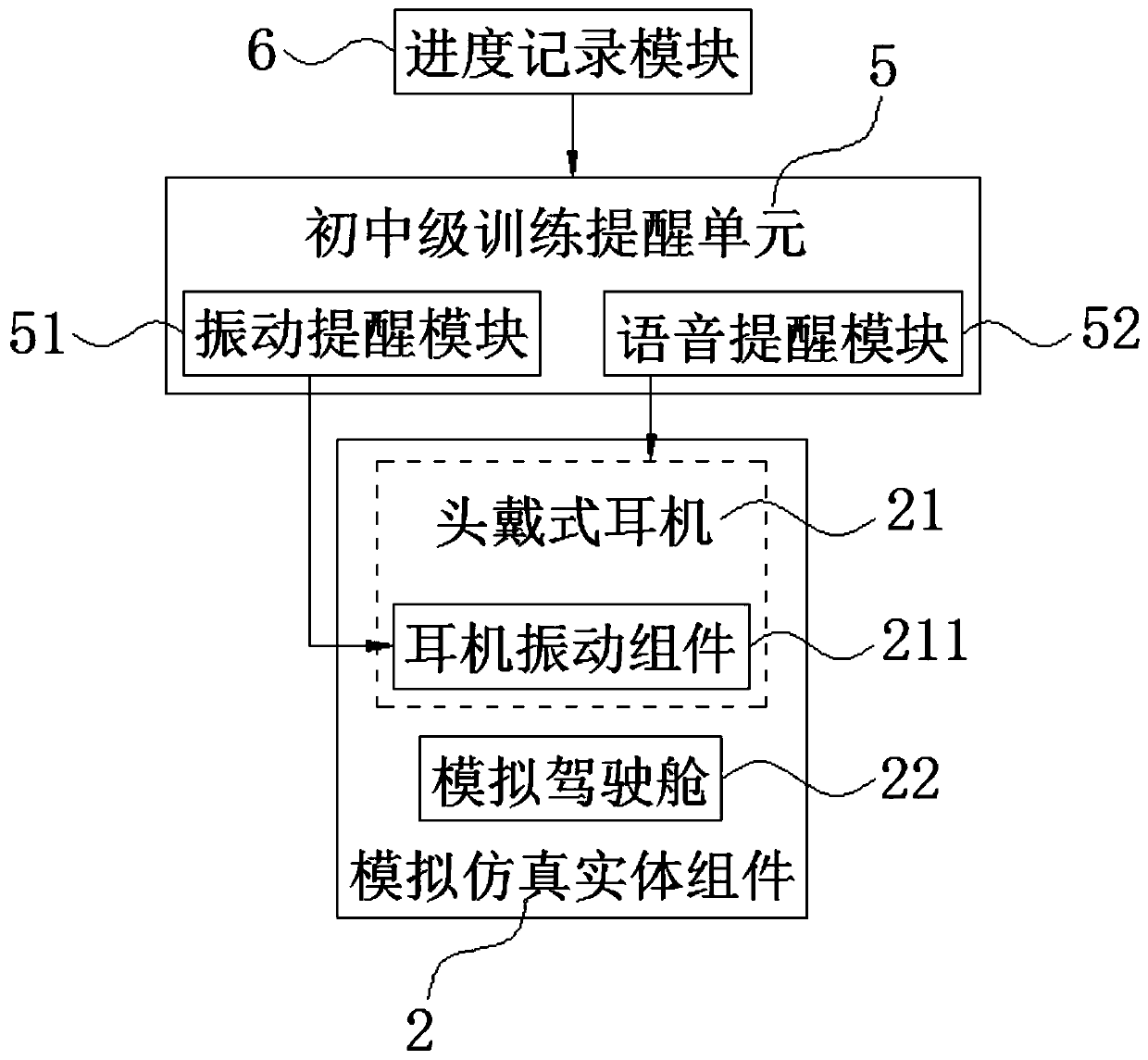

Environmental sanitation mechanical analog simulation device

InactiveCN110444068AGet rid of dependenceImprove guidanceCosmonautic condition simulationsSimulatorsThree levelVideo retrieval

The invention discloses an environmental sanitation mechanical analog simulation device. The device comprises a personal account, an analog simulation entity assembly and an analog video database, wherein the output end of the analog video database is connected with the input end of a video retrieval module. The invention relates to the technical field of analog simulation devices. For the environmental sanitation mechanical analog simulation device, the teaching analog video is divided into three levels including the primary level, the secondary level and the higher level, so that a beginnercan perform progressive learning, during primary training, a voice reminding module is matched with voice broadcast of a headset for reminding some concern points, during secondary-level training, a vibration reminding module is matched with a headset vibration assembly, so that the headset vibrates, further, voice broadcast is replaced for carrying out reminding, while during higher-level training, no reminding is carried out, thus a good guiding effect is achieved at the earlier stage, later, a learner gradually gets rid of the feeling of dependency in a progressive manner, independent studycan be carried out, and thus the capacity for coping with various emergency events can be cultivated.

Owner:安徽荣航机电配件有限公司

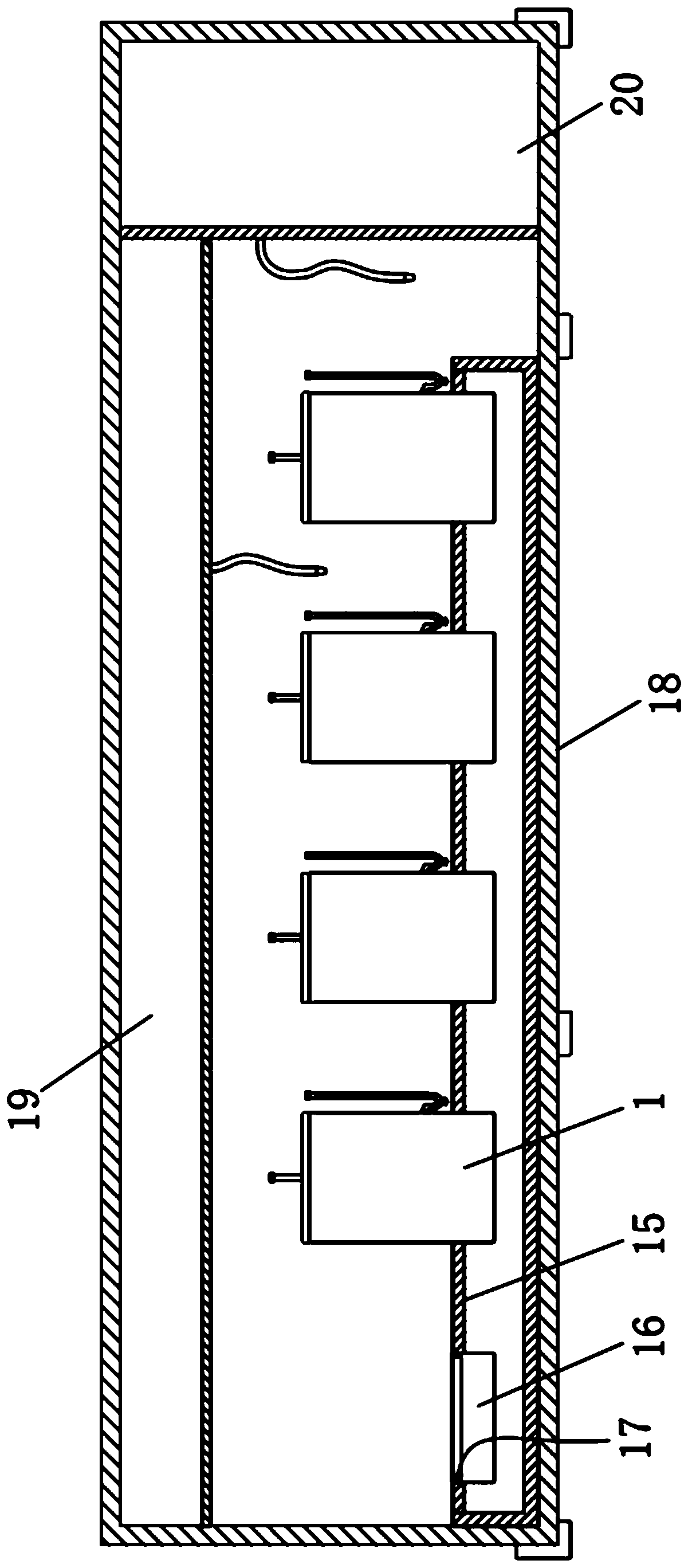

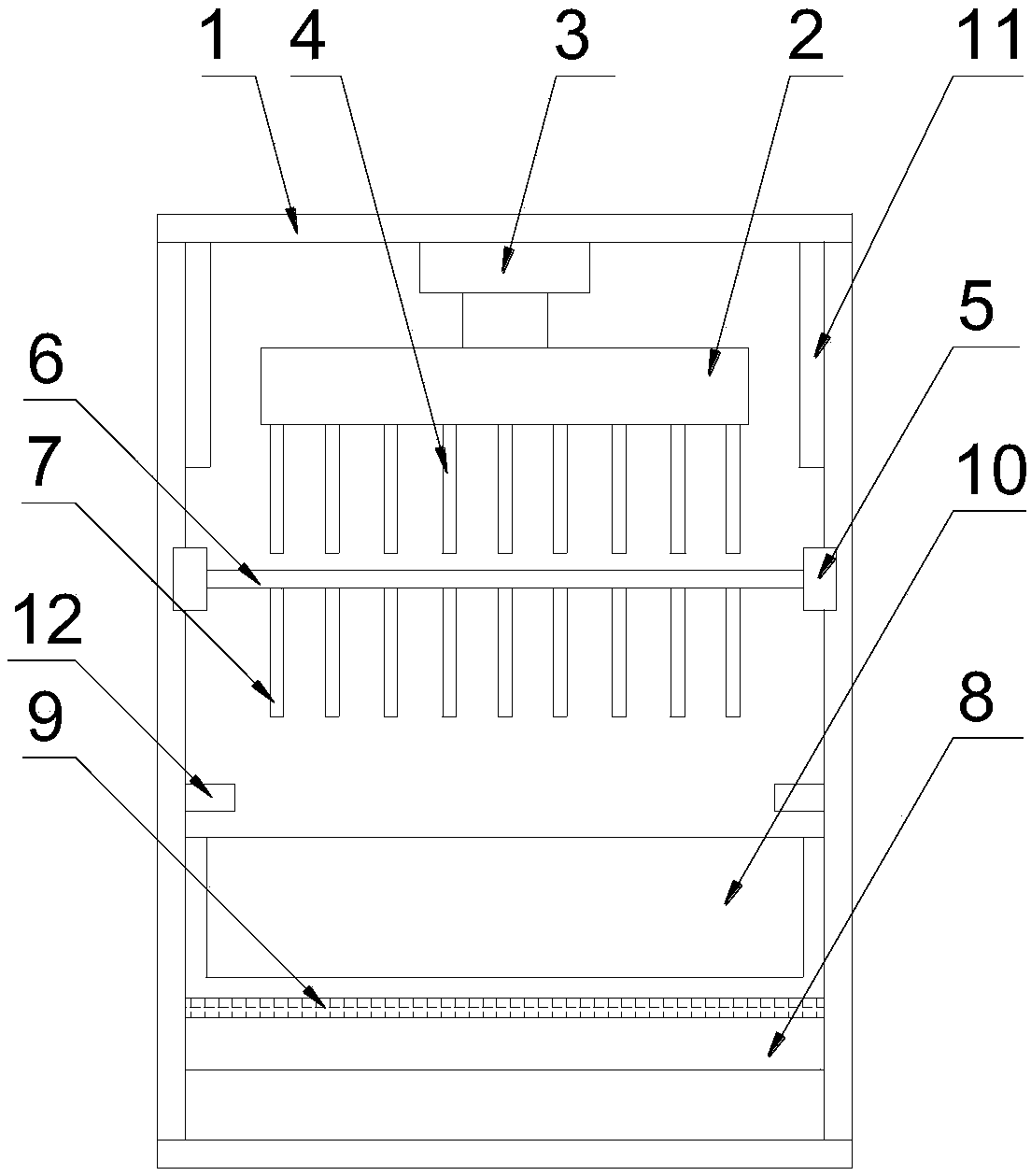

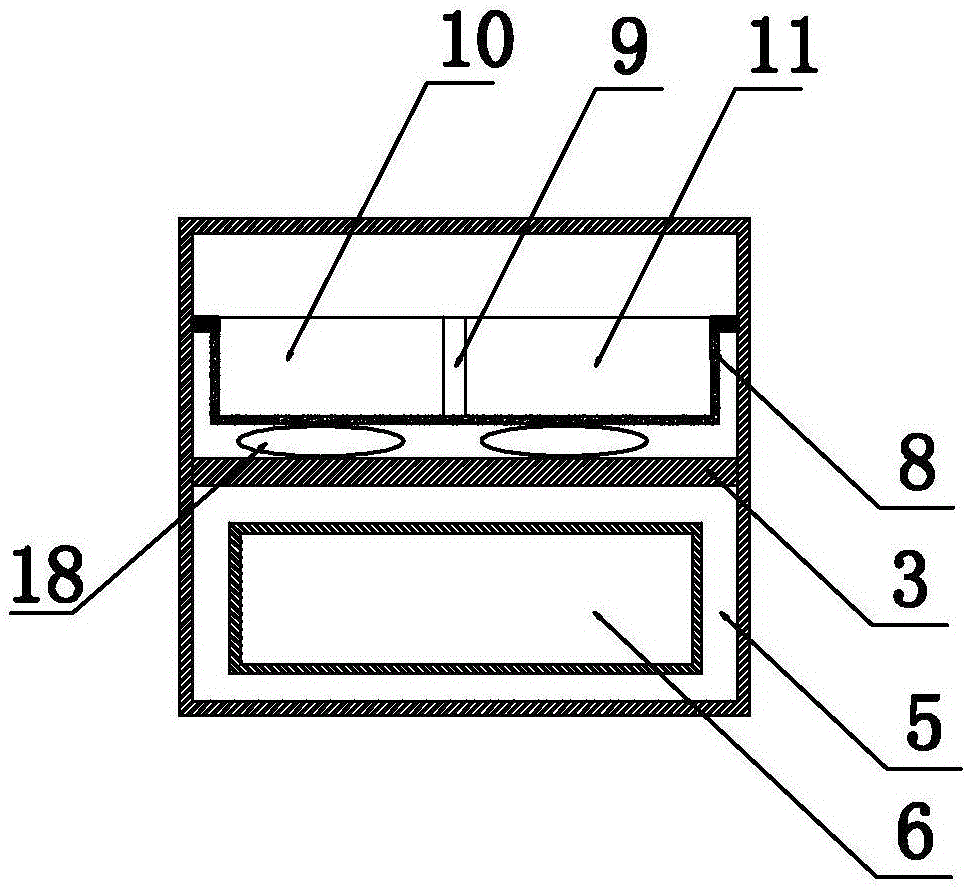

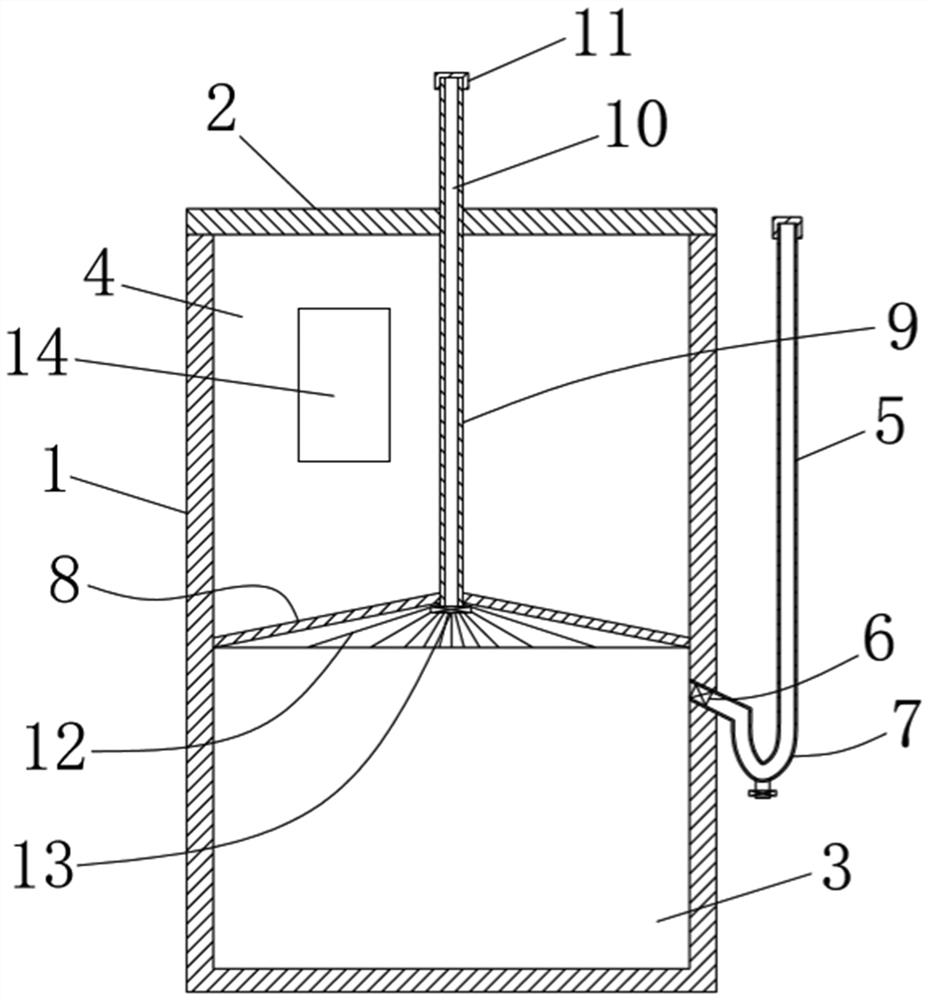

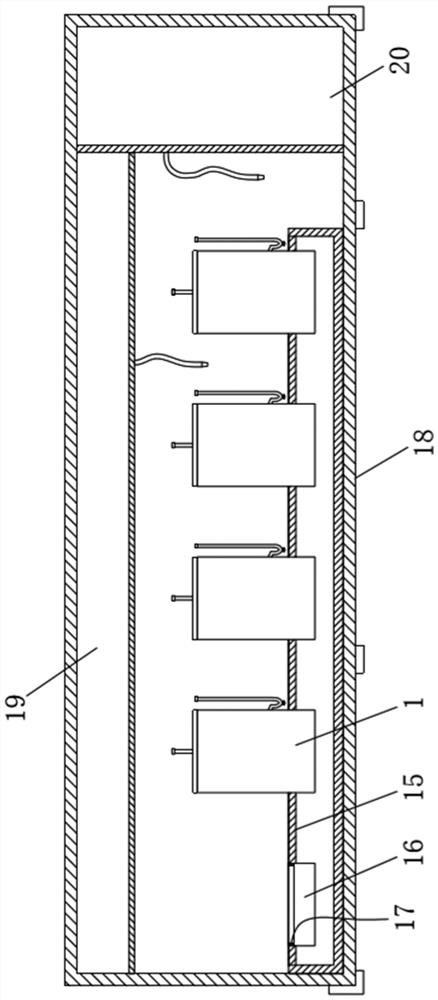

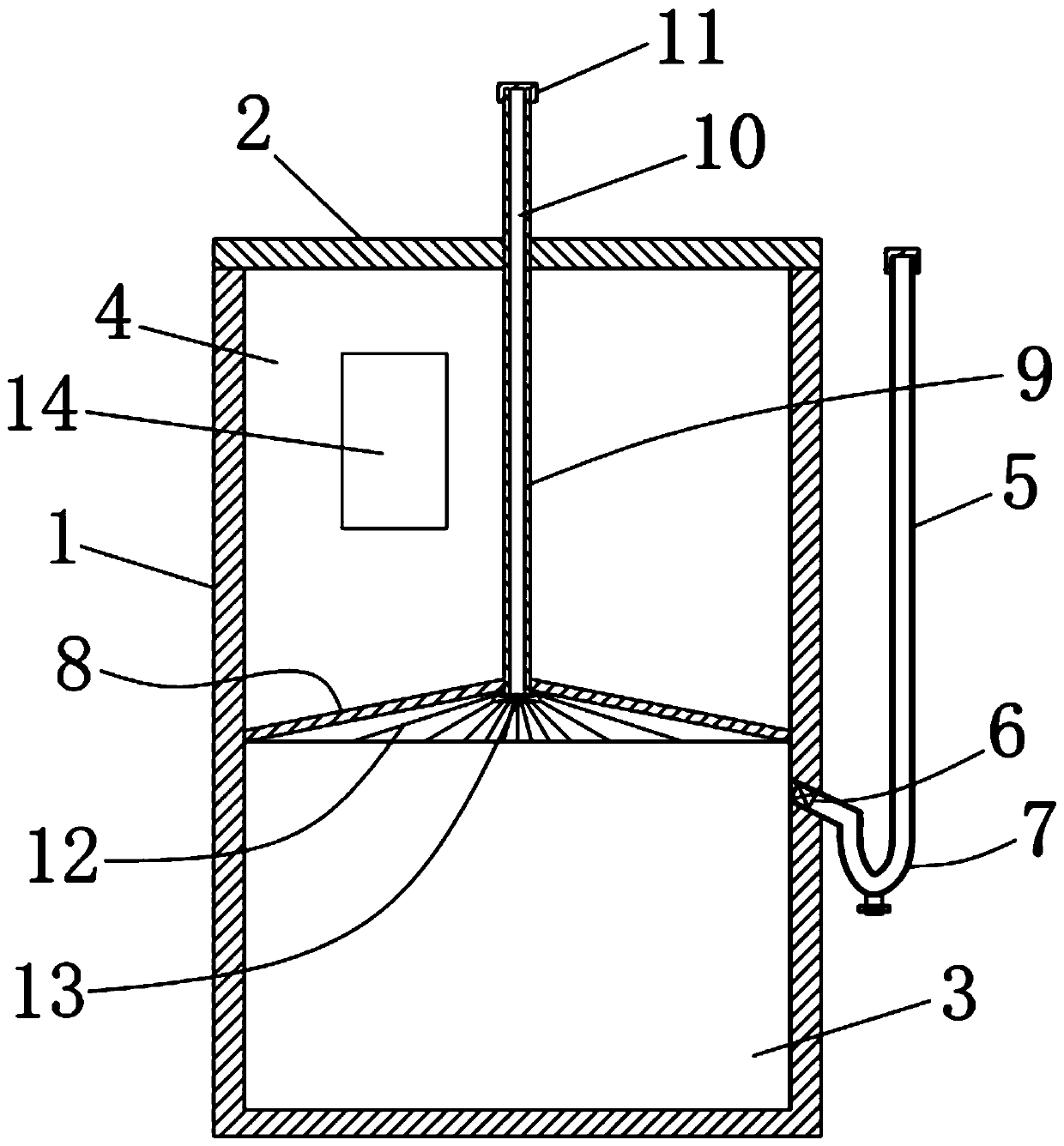

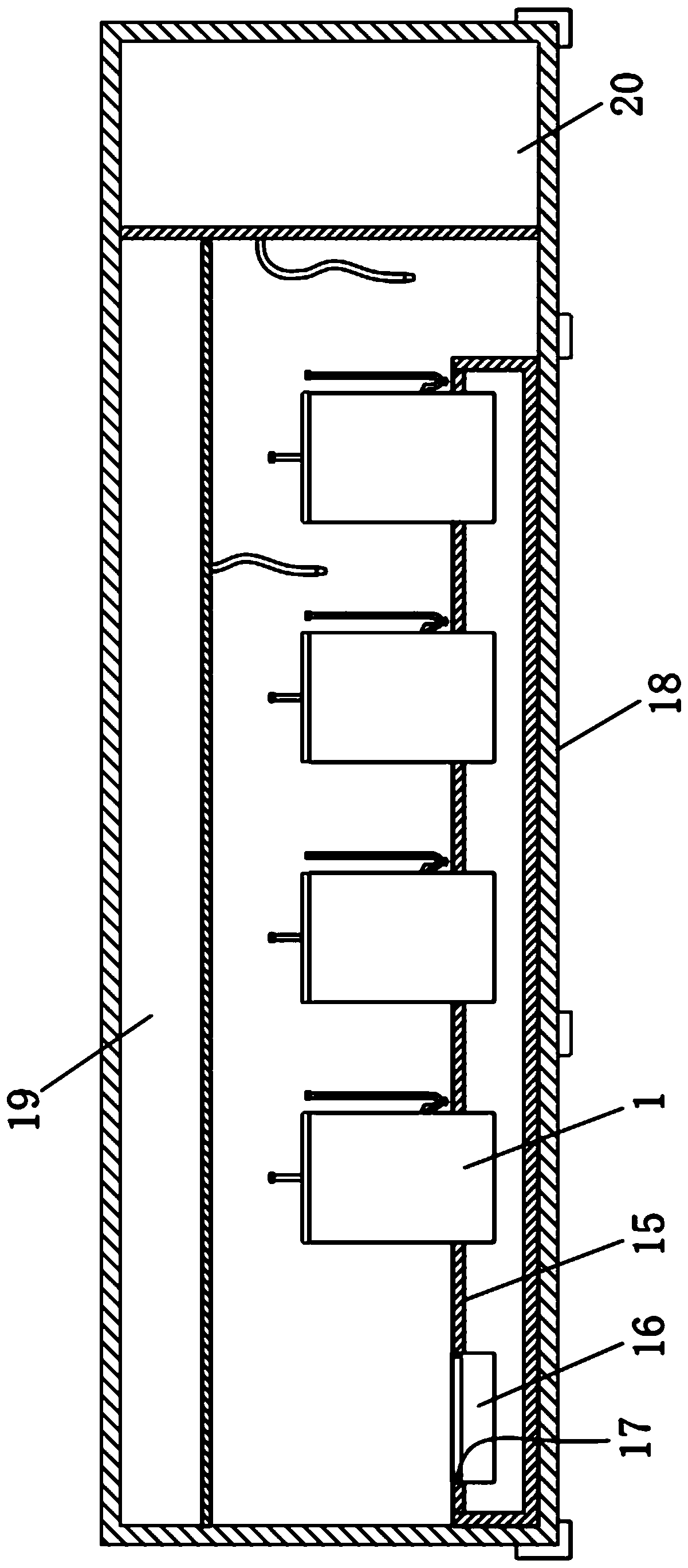

Multifunctional incubator

PendingCN108795713AImprove the heating effectAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

The invention discloses a multifunctional incubator, which comprises a box body, a heating plate, thermal conduction columns, moving pieces, a connecting plate, a working table, a vibration device anda culture dish, wherein the heating plate is arranged inside the box body; a driving mechanism is arranged on the box body; the multiple thermal conduction columns are vertically arranged at the bottom of the heating plate; two groups of moving pieces are respectively arranged on the inner walls of two sides of the box body in a sliding manner, and move up and down in the vertical direction; theconnecting plate comprises first connecting pieces arranged in the transverse direction and second connecting pieces arranged in the longitudinal direction; multiple groups of first connecting piecesare arranged in parallel; two groups of second connecting pieces are respectively arranged on the two groups of moving pieces; multiple connecting columns are downwards vertically arranged on the first connecting pieces; blind holes are formed in the connecting columns; the working table is arranged at the bottom of the box body; the culture dish is placed on the working table. According to the multifunctional incubator disclosed by the invention, the culture dish is heated quickly and uniformly; the culture quality and the culture effect of microorganisms are improved; equipment is used conveniently and sanitarily.

Owner:安徽省佳逸环保科技有限公司

Kit for culturing mesenchymal stem cells and culturing method

ActiveCN106190837ANo differentiationGuarantee the quality of trainingCulture processSkeletal/connective tissue cellsMesenchymal stem cellCell survival rate

The invention provides a kit for culturing mesenchymal stem cells and a culturing method. The kit comprises a kit body and a kit cover hinged to the kit body; a partition plate is transversely arranged in the kit body, the kit body is internally divided into a reagent storage box and a tool box, the tool box is internally provided with a drawing box, the reagent storage box is internally provided with multiple reagent bottles which contain an umbilical cord preservation solution, a culture solution, additives, growth factors I, growth factors II, digestive juice, a cleaning solution and a culture-medium. The kit is simple in structure and is specially used for culturing the mesenchymal stem cells, the culturing efficiency of the mesenchymal stem cells is improved, more mesenchymal stem cells can be cultured in large quantities, demands of people can be met, and the economic cost is reduced; meanwhile, reagent formulas of the reagents in the kit are reasonable and effective, the nutritional requirements of mesenchymal stem cell growth can be met, value added growth of the mesenchymal stem cells is effectively promoted, and the cell survival rate is increased.

Owner:BEIJING YULONG SHENGSHI BIOTECH CO LTD

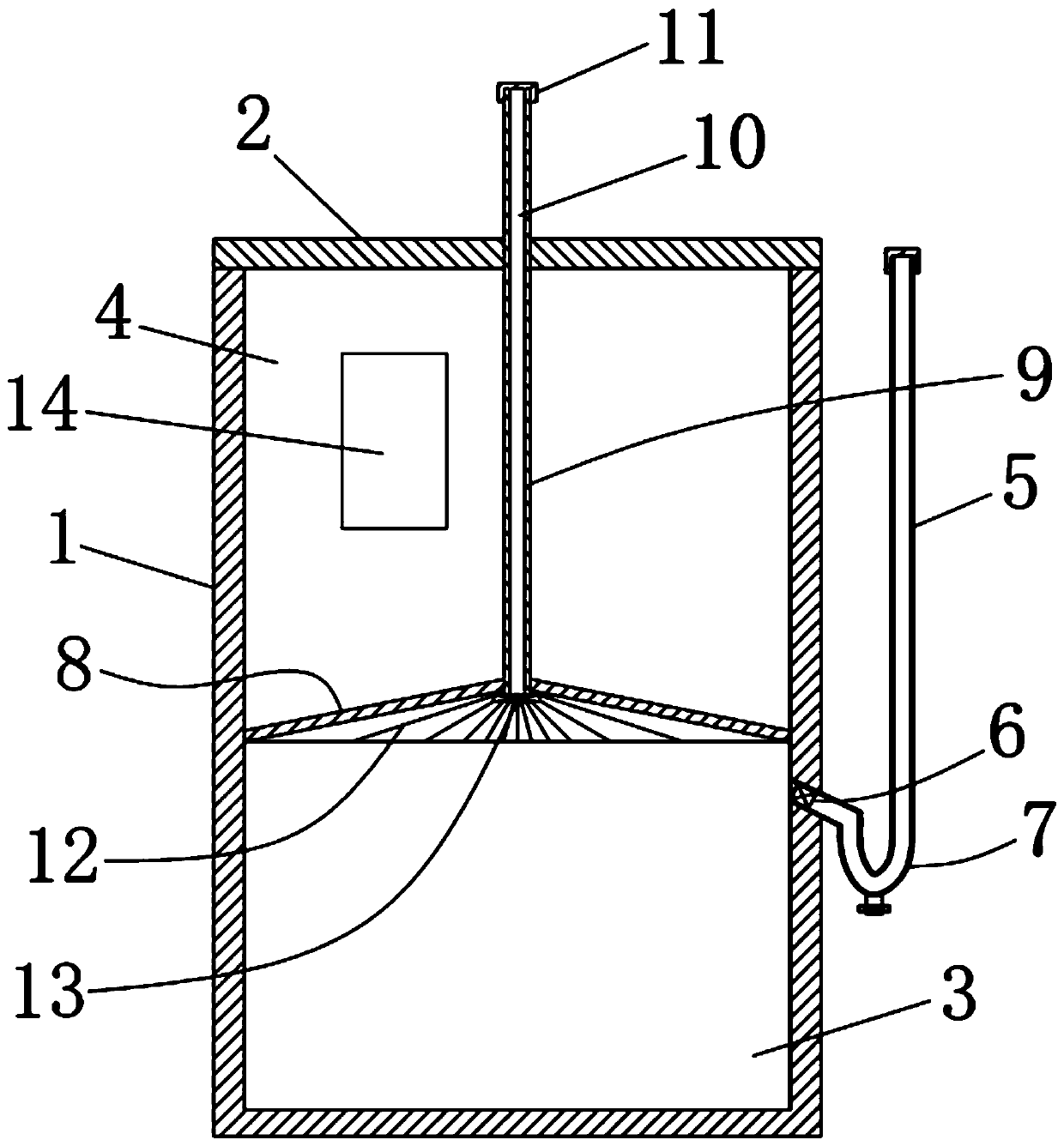

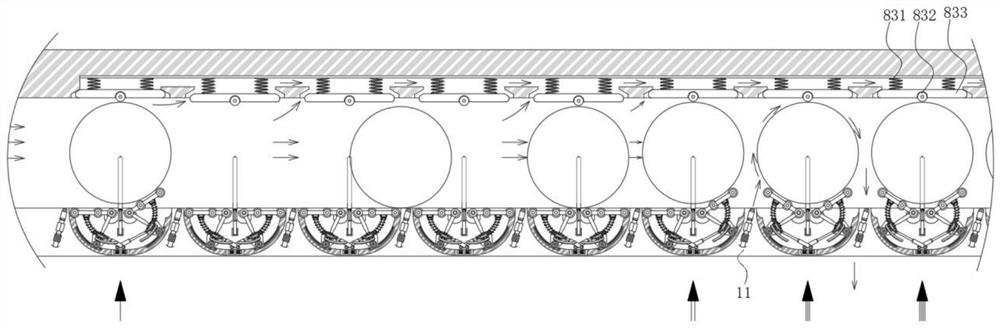

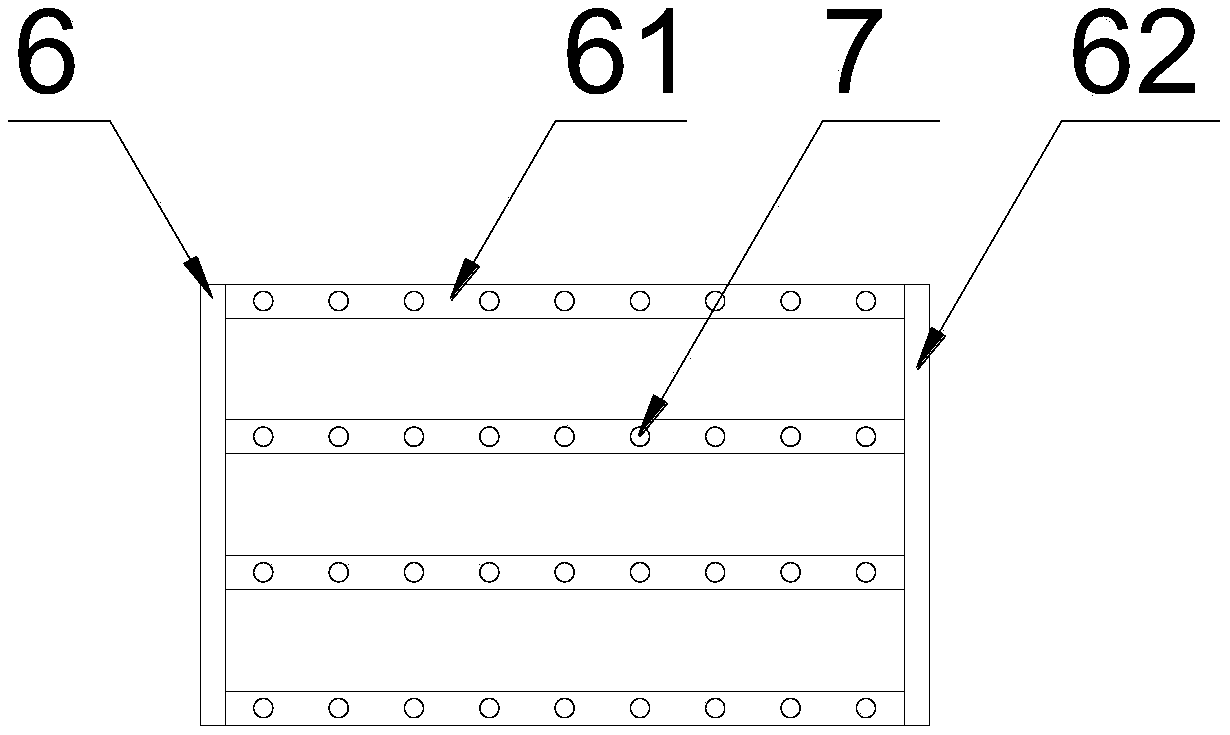

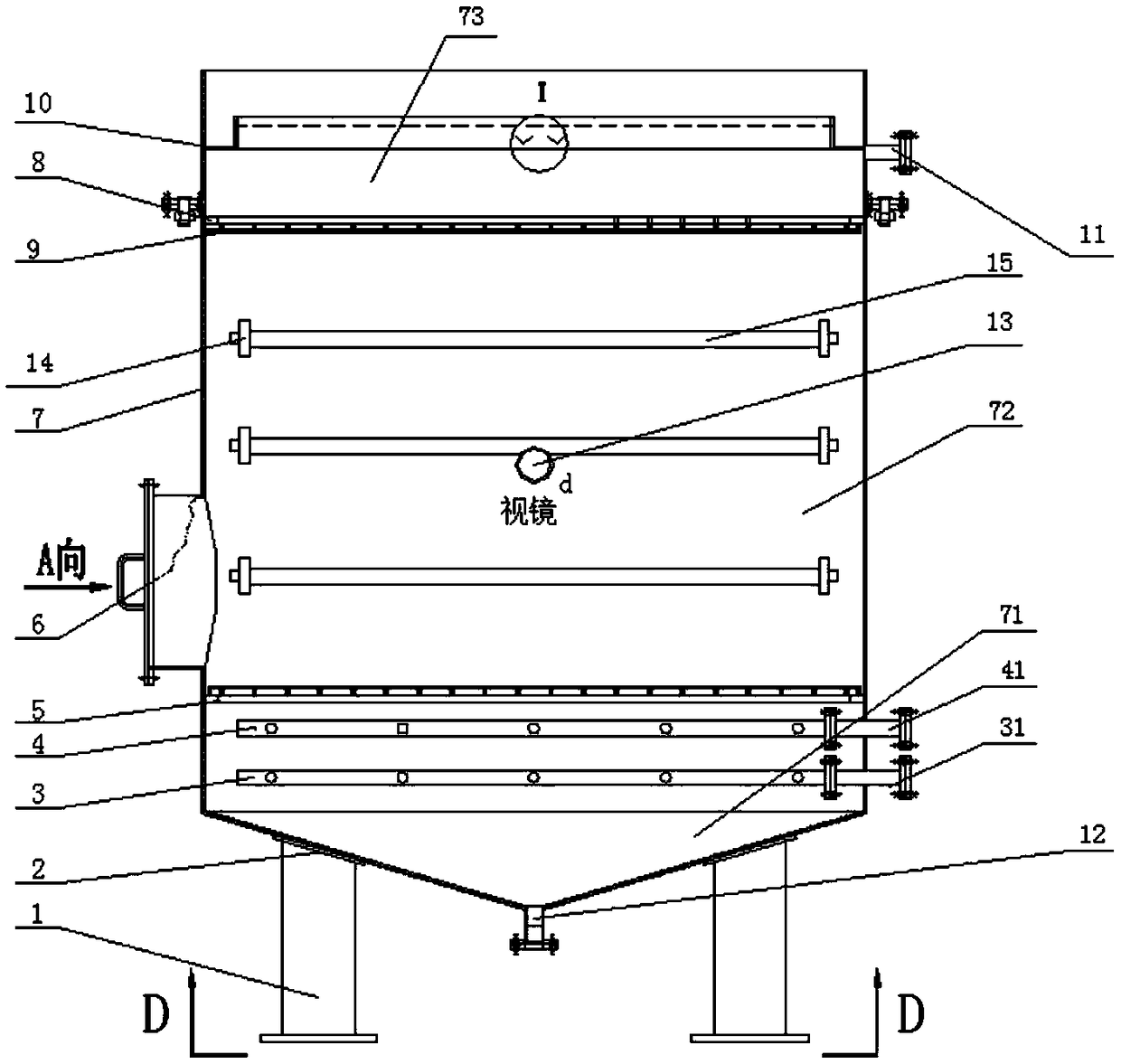

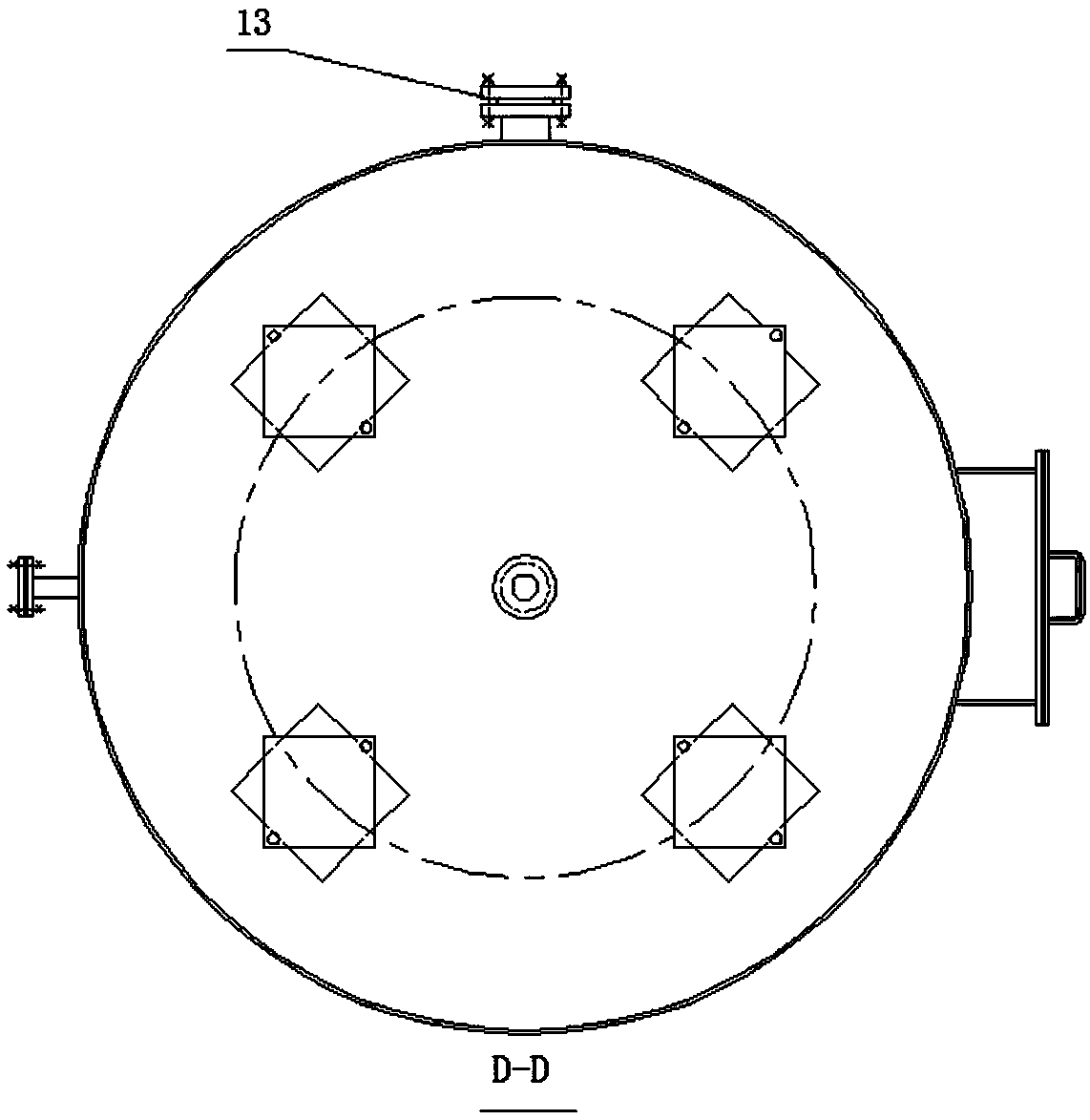

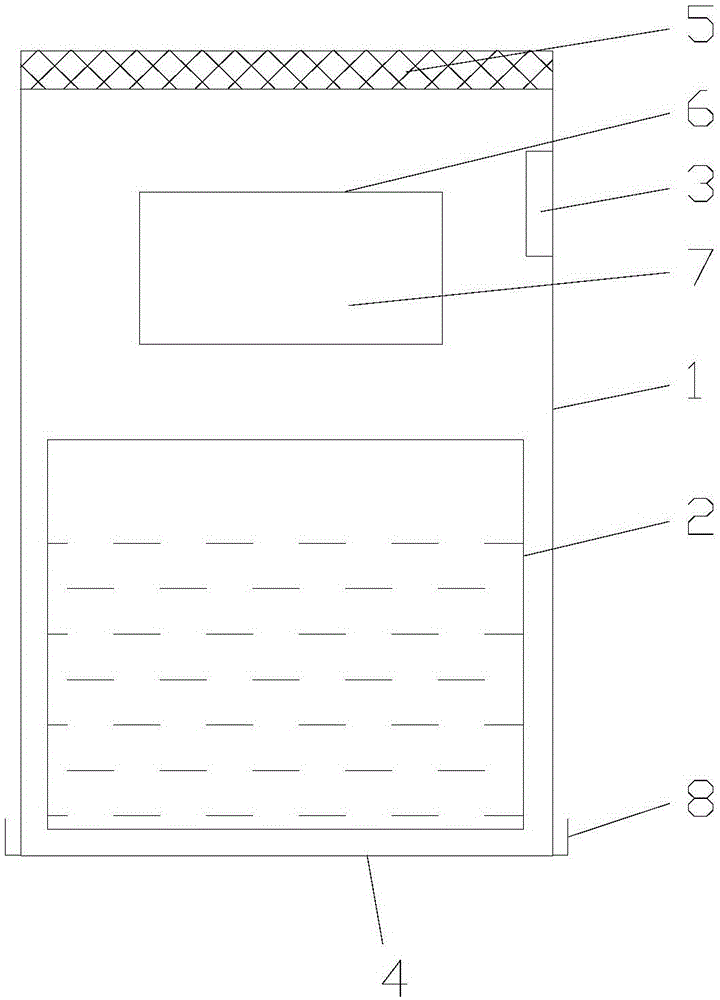

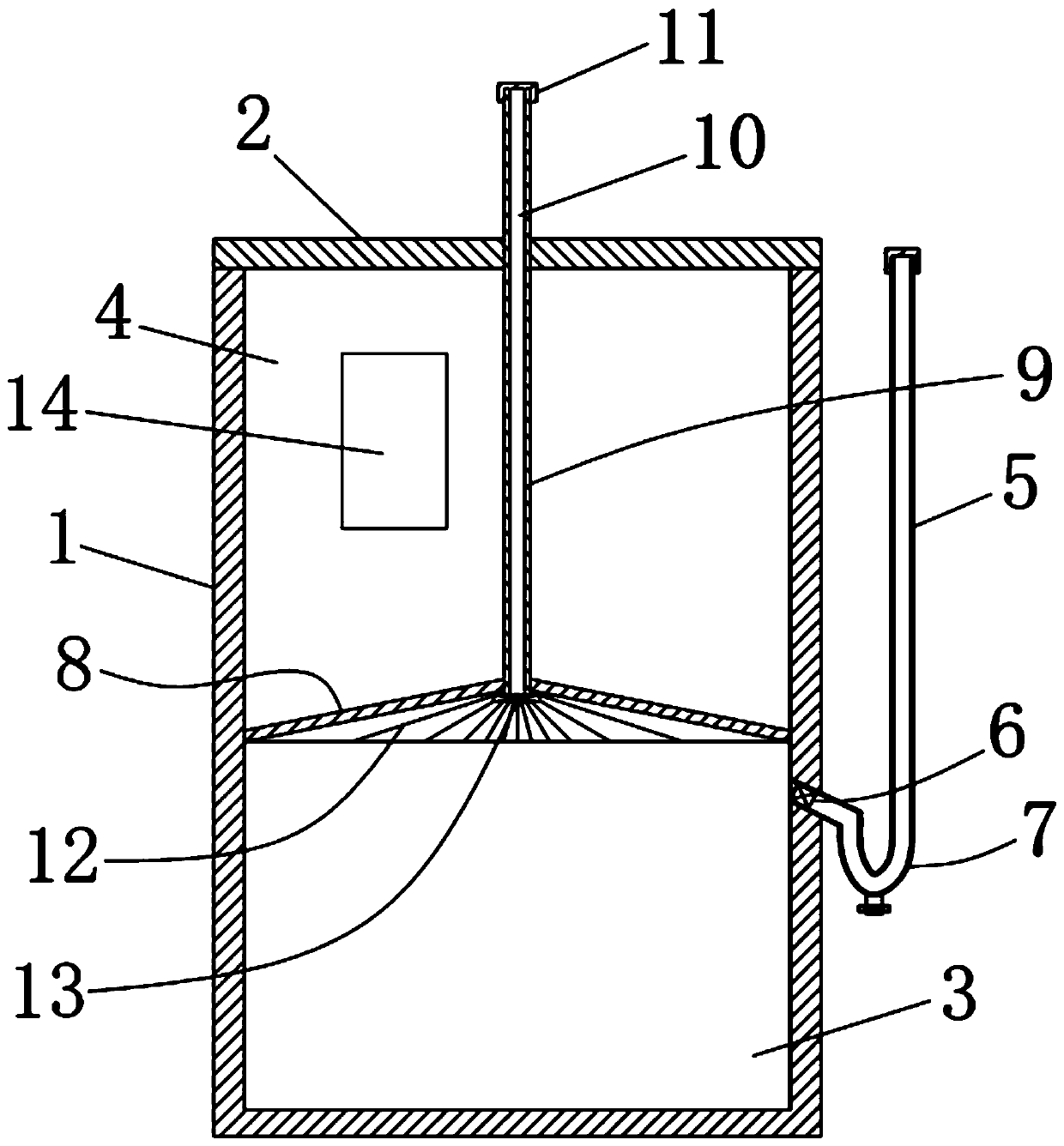

Photoreactor for efficient photosynthetic cultivation of spirulina

InactiveCN109439522AGuarantee the quality of trainingEasy to install and disassembleBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSpirodela

The invention discloses a photoreactor for efficient photosynthetic cultivation of spirulina. The photoreactor comprises support feet, a barrel and a barrel cover. The barrel is of tubular structure having an upward opening; the support feet are arranged at the lower periphery of the barrel through mounting pads; connection wing plates are connected to the periphery of the open end of the barrel and are integrated to the open end of the barrel; the open end of the barrel is provided with the barrel cover via a connection flange; the barrel cover is in convex type and is internally provided with an overflow weir; one side of the cover is provided with an overflow port. The photoreactor herein is convenient to maintain and wash at the premise that spirulina cultivation quality is guaranteed;therefore, it is effectively avoided that non-uniform distribution of nutrients in algae easily leads to non-uniform lighting for algae in deep and shallow tiers of the photoreactor, which causes optical damage and optical hunger.

Owner:XIAMEN CANCO BIOTECH CO LTD

Enterprise training management method

InactiveCN113129183AGuarantee the quality of trainingTo achieve the effect of useData processing applicationsSubcutaneous biometric featuresBusiness enterpriseData management

The invention discloses an enterprise training management method. The method comprises the following steps that 1, a training teacher uploads a teaching file to a data management system through a training teacher end or carries out online live broadcasting on the teaching file; step 2, a training student downloads a teaching file from the data management system through the training student terminal or watches the teaching file online; and step 3, when the training student browses the teaching file through the training student terminal, continuous concentration detection and continuous identity verification need to be carried out through identity verification equipment. According to the enterprise training management method provided by the invention, during network remote teaching, the use effect of supervising the learning state of the trained student is achieved, so that the enterprise training quality can be conveniently guaranteed.

Owner:深圳市凯博百通信息技术有限公司

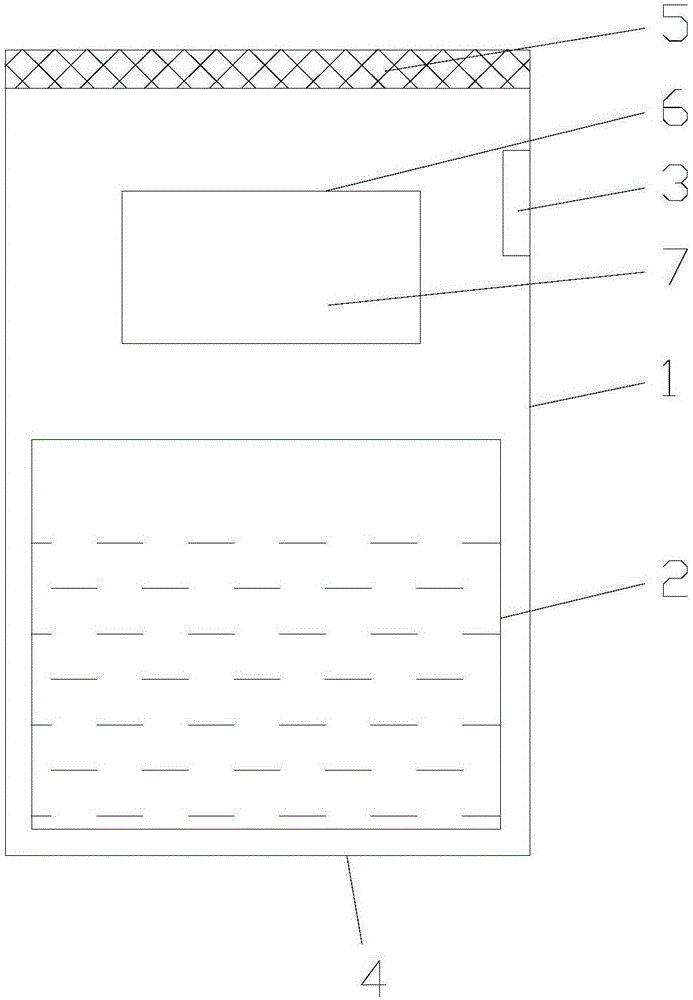

Edible fungus culture barrel with good service performance

The invention discloses an edible fungus culture barrel with good service performance, comprising an outer barrel, an inner barrel and a carbon dioxide absorbing device; the outer barrel is provided with a bottom plate and an upper cover, and both the bottom plate and the upper cover are releasably mounted at the outer barrel; the inner barrel is disposed in the outer barrel and is lower than the same; the carbon dioxide absorbing device is fixed to the inner wall of the upper end of the outer barrel, and the sidewall of the outer barrel is provided with a view port correspondingly above the inner barrel. The edible fungus culture barrel with good service performance facilitates the placement and removal of the inner barrel and is convenient to use and operate; it is convenient to observe the growth condition of Agrocybe cylindracea through the view port, and culture quality of Agrocybe cylindracea can be guaranteed.

Owner:KAIXIAN LVTONG PLANTING COOP

Culturing device for culturing edible mushroom

The invention discloses a culturing device for culturing edible mushroom. The culturing device comprises an outer cylinder, an inner cylinder, a carbon dioxide absorption device and a fixing bolt, wherein the outer cylinder is provided with a base plate and an upper cover which are both detachably installed on the outer cylinder; the inner cylinder is placed in the outer cylinder, and is lower than the same; the carbon dioxide absorption device is fixed on the inner wall of the upper end of the outer cylinder, and a viewing port is formed in the side wall, corresponding to the upper side of the inner cylinder, of the outer cylinder; the fixing bolt passes through the side wall of the outer cylinder and is pressed against the outer wall of the inner cylinder for connecting and fixing the outer cylinder with the inner cylinder; a flange radially protruding outwards is arranged at the outer end of the inner cylinder, and the fixing bolt is tightly fit with the top surface of the flange. According to the culturing device, the inner cylinder is convenient to put in and take out, and utilization and operation are facilitated; the outer cylinder and the inner cylinder are fixed by the fixing bolt and the flange arranged at the lower end of the inner cylinder, so that structural stability is good, and utilization and transportation are facilitated; furthermore, a growing condition of agrocybe cylindracea can be conveniently observed via the viewing port, thus being beneficial to ensuing culturing quality of the agrocybe cylindracea.

Owner:KAIXIAN LVTONG PLANTING COOP

Observation-convenient agrocybe cylindracea culturing device

InactiveCN106538228AGuarantee the quality of trainingEasy to observeHorticultureCo2 absorptionEngineering

The invention discloses an observation-convenient agrocybe cylindracea culturing device. The observation-convenient agrocybe cylindracea culturing device comprises an outer barrel, an inner barrel and a carbon dioxide absorbing device. The outer barrel is provided with a bottom plate and an upper lid; the inner barrel is arranged inside the outer barrel and is lower than the outer barrel; the carbon dioxide absorbing device is fixed onto the inner wall of the upper end of the outer barrel; the side wall of the outer barrel is provided with an observation window corresponding to the top of the inner barrel. According to the observation-convenient agrocybe cylindracea culturing device, a user can conveniently observe the growth status of agrocybe cylindracea, so that the cultivation quality of agrocybe cylindracea can be ensured.

Owner:KAIXIAN LVTONG PLANTING COOP

A kind of cultivation method for microorganism cultivation

ActiveCN110862943BReduce deathReduce riskBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The present invention relates to the technical field of microorganism cultivation, in particular to a cultivation method for microorganism cultivation. After obtaining microorganism strains, the strains are cultivated in a microorganism cultivation system, and then the microorganism cultivation system cultivated with microorganism strains is transported to On-site use, and then the microorganisms in the culture system are taken out for on-site use. The microbial culture system of the present application directly avoids the steps of preservation and recovery of microorganisms in the traditional way, so that the cost of preservation and recovery is firstly avoided, and more importantly, the death and recovery of microorganisms caused in the traditional preservation and recovery processes are avoided. The risk of variation, and with the method of this application, since the microbial strains are cultivated, they are directly entered into the cultivation system for microbial cultivation, which reduces the risk of microbial variation.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

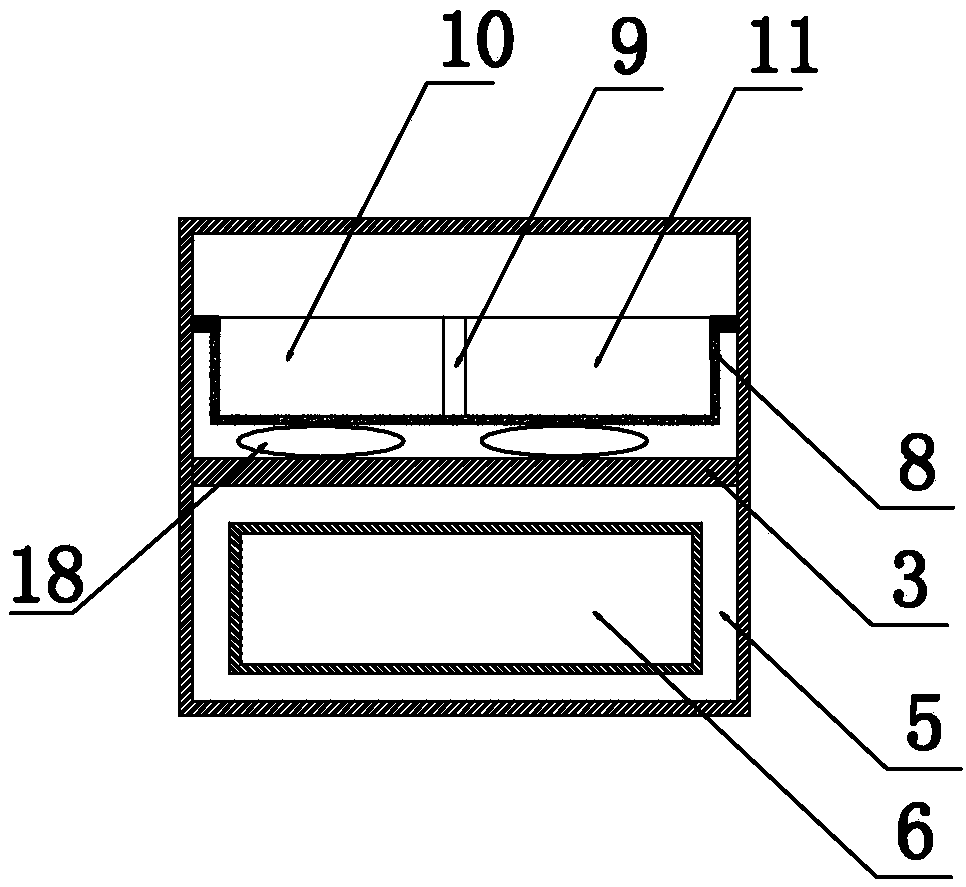

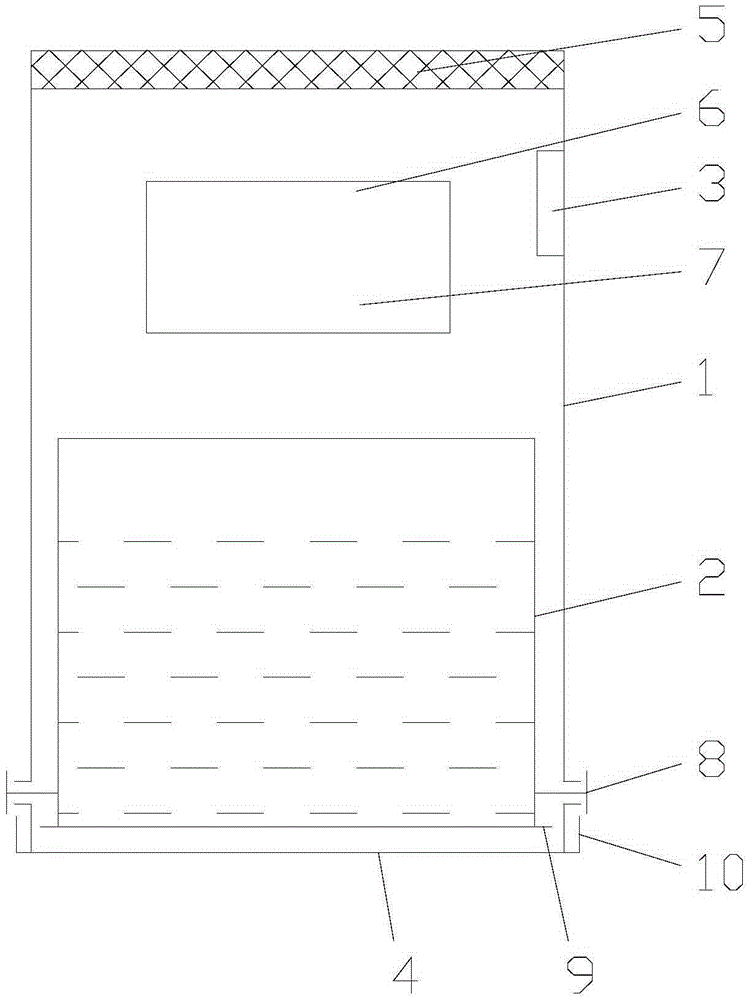

Culture cylinder, culture system and culture method for microbial culture

PendingCN110878252AReduce deathReduce riskBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention relates to the technical field of microbial culture, specifically to a culture cylinder, a culture system and a culture method for microbial culture. The culture cylinder includes a cylinder body with a closed lower end and an open upper end and a cover body matched with the open upper end of the cylinder body. The inner space of the cylinder body is divided into a culture matrix cavity and a gas cavity from bottom to top. The culture matrix cavity is used for accommodating a culture medium suitable for microbial growth, and the gas cavity is used for accommodating a suitable gassuitable for microbial growth. A gas replacement device is also arranged in the cylinder body, and the gas replacement device is used for replacing a gas in the gas cavity with a new suitable gas. The culture cylinder of the invention reduces the risk of death, variation or contamination during the growth, development and reproduction of microbes, and also ensures a good development speed of microbes and saves culture time.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

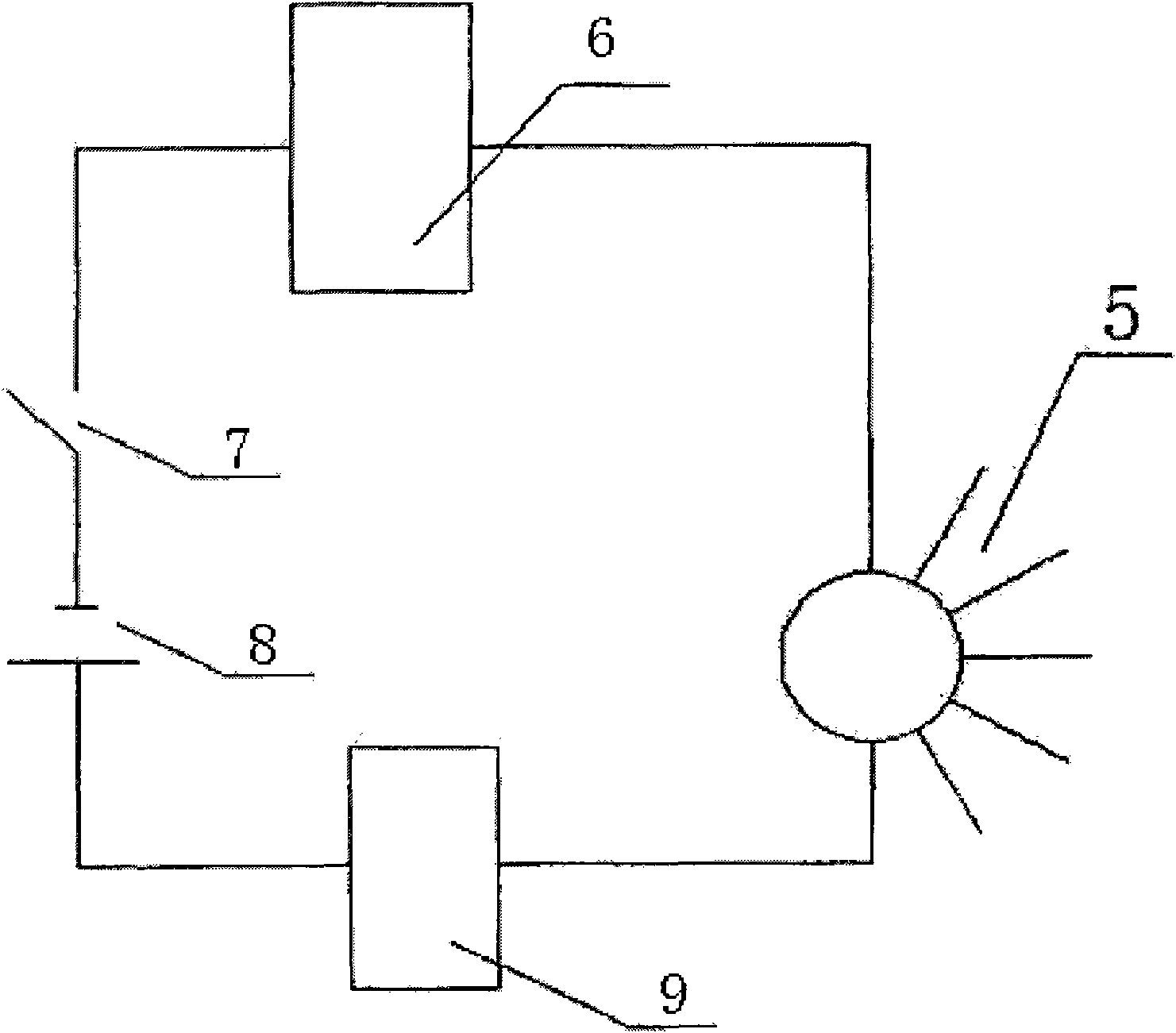

Driving test training voice broadcaster

InactiveCN103177556AReduce labor intensitySimple structureNon-electrical signal transmission systemsKey pressingMicrocomputer

The invention relates to a driving test training voice broadcaster. The driving test training voice broadcaster comprises an infrared emitting circuit and an infrared receiving circuit, wherein the infrared emitting circuit comprises a first power supply, a plurality of parallel switches, a first single chip microcomputer and an infrared emitter, and the infrared receiving circuit comprises an infrared receiver, a second single chip microcomputer, a switch, a second power supply and a voice broadcasting module; the infrared emitting circuit is arranged on a handheld remote controller, the plurality of parallel switches are in one-to-one correspondence to keys on the handheld remote controller; the infrared receiving circuit is arranged on a trainer vehicle; when the voice broadcaster is in use, the switch in the infrared receiving circuit is closed, the infrared receiving circuit begins to work, the switch in the plurality of parallel switches corresponding to the key is closed by pressing down one key on the handheld remote controller, through the treatment of the first single chip microcomputer, the infrared emitter is controlled to emit a corresponding infrared signal, and after the infrared receiver receives the infrared signal emitted by the infrared emitter, the signal is treated by the second single chip microcomputer so as to control the voice broadcasting module to broadcast the corresponding voice.

Owner:JIANGNAN UNIV

Gas replacing device for microbial culture cylinder, and culture cylinder

PendingCN111218397AReduce deathReduce riskBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobial culture techniqueMechanical engineering

The invention relates to the technical field of microbial culture, and in particular to a gas replacing device for a microbial culture cylinder, and the culture cylinder. The gas replacing device comprises a replacing component and a gas discharging component, wherein the gas discharging component is used for making communication between a gas cavity of the culture cylinder and an external space of a cylinder body of the culture cylinder; the replacing component is used for pushing gas in the gas cavity to discharge the gas in the gas cavity out of the cylinder body through the gas dischargingcomponent; the gas discharging component comprises a communicating pipe; one end of the communicating pipe communicates with the gas cavity; the other end of the communicating pipe passes through thecylinder body and communicates with the external space of the cylinder body; the communicating pipe is also provided with a one-way conducting device; and the one-way conducting device is arranged atone end, close to the gas cavity, of the communicating pipe. According to the gas replacing device disclosed by the invention, the replacing component and the gas exhaust component are separated, sothat inlet gas is prevented from being polluted by exhaust remains.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com