Recycling processing treatment system for steelmaking processing waste steel slag

A steel slag recovery and treatment system technology, applied in grain processing, solid waste removal, etc., can solve the problems of low efficiency of steel slag jaw crusher, easy work-related injuries of jaw crusher, increased safety hazards, etc., to save electricity and oil resources , avoid the effect of lowering the efficiency of jaw crushing and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

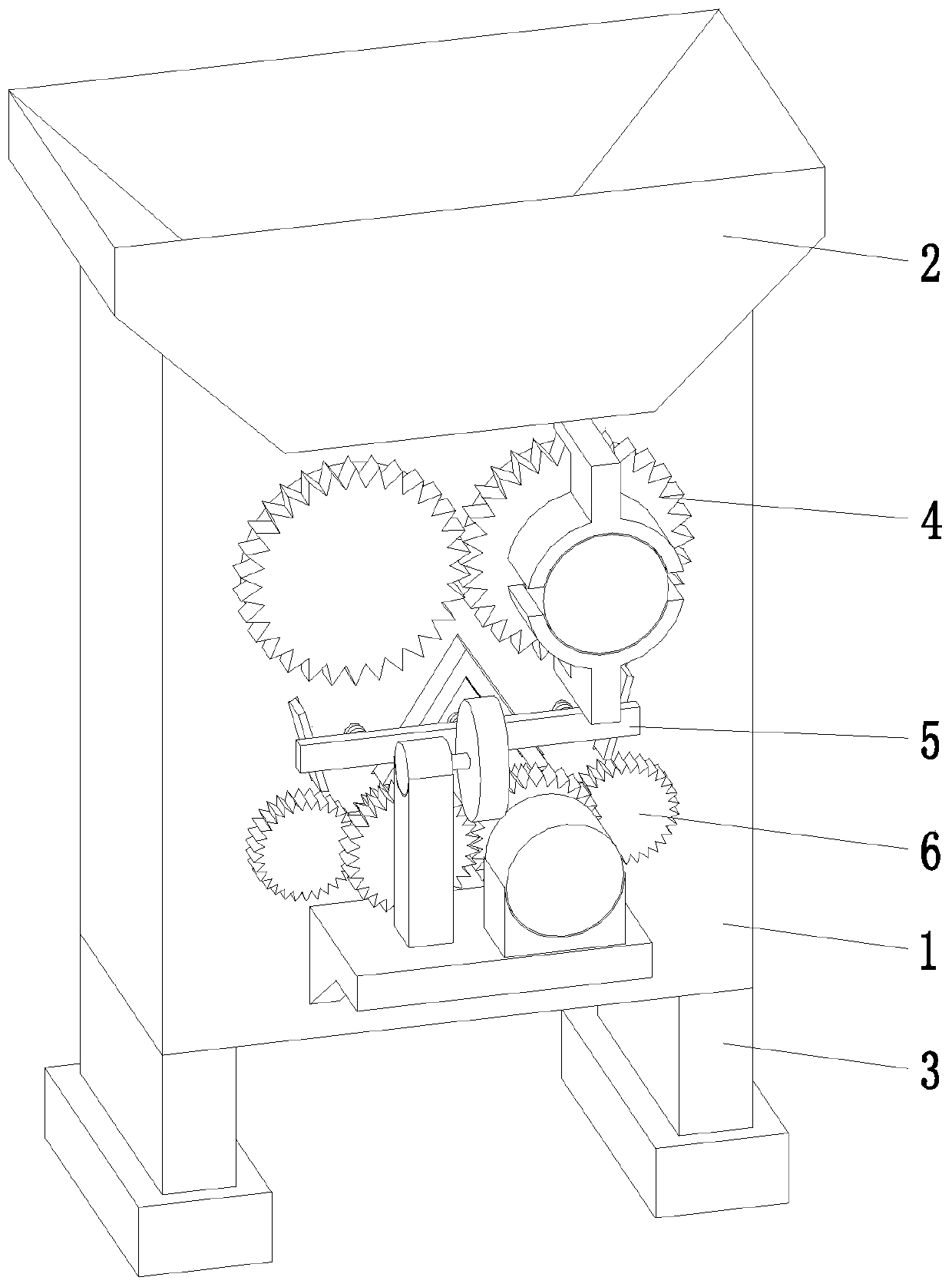

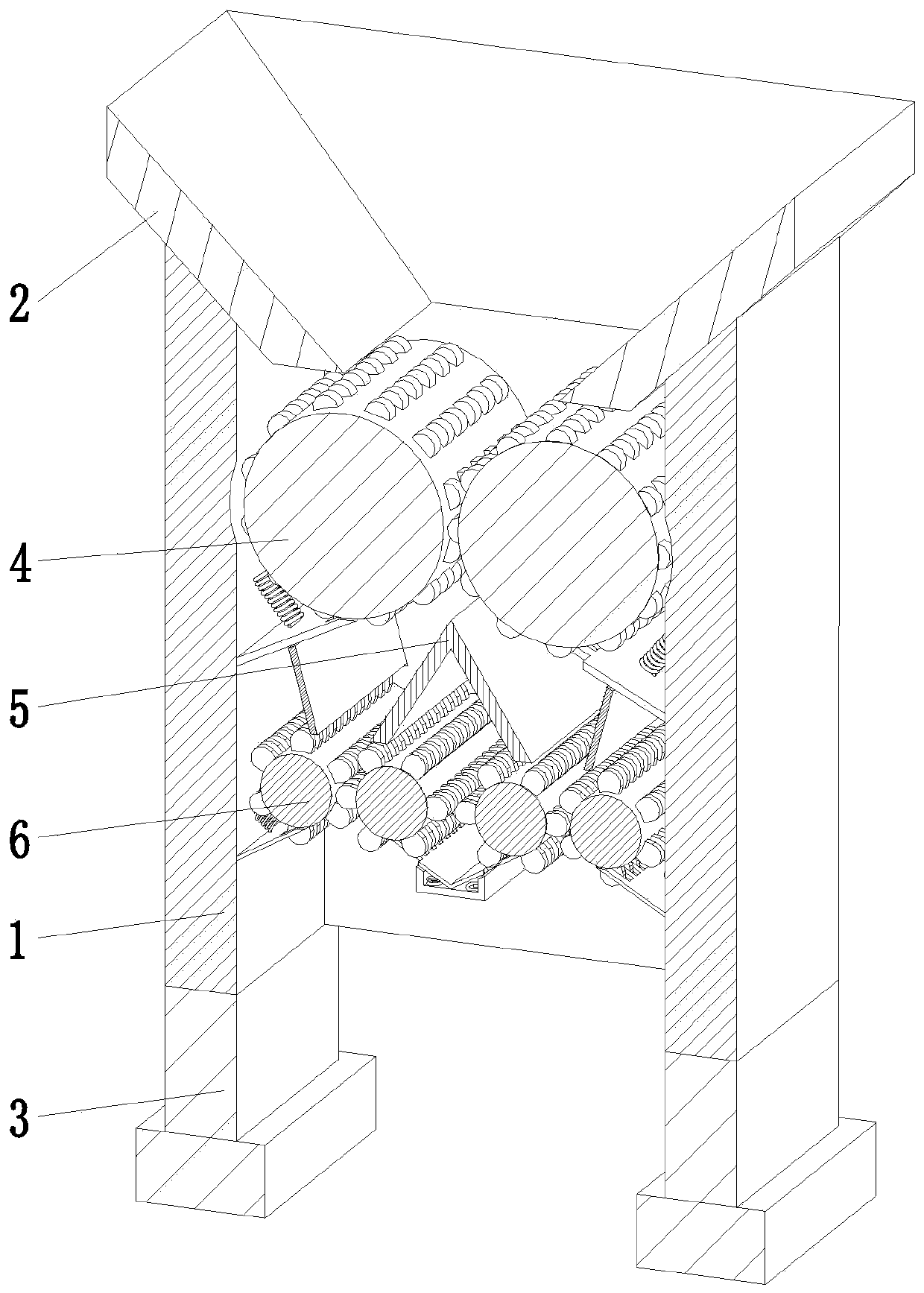

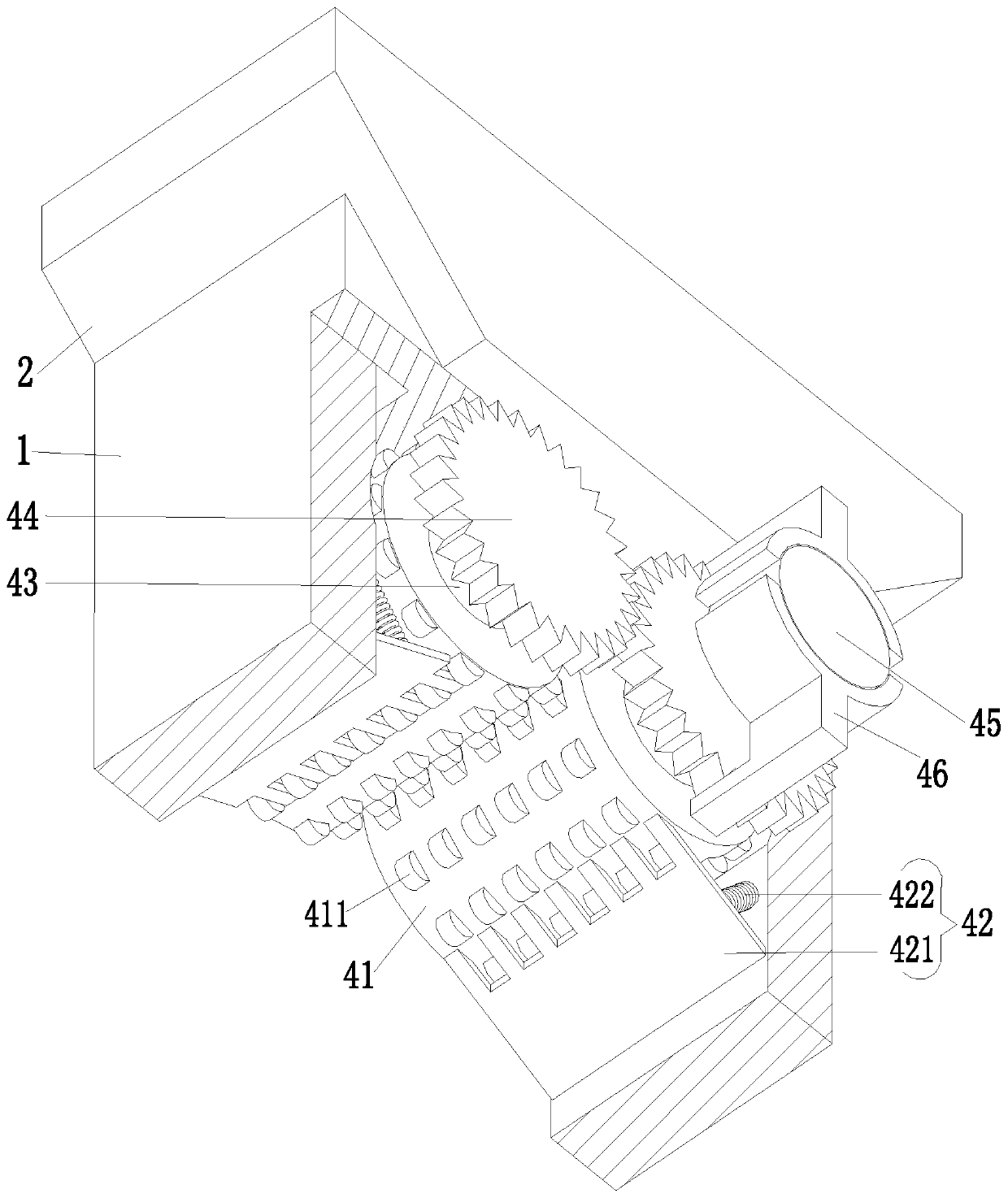

[0026] Such as Figure 1 to Figure 5 As shown, a steelmaking processing waste steel slag recycling and processing system includes a housing 1, a guide frame 2, a support plate 3, a first crushing mechanism 4, a shaking mechanism 5 and a second crushing mechanism 6, the casing 1 is a back-shaped structure with upper and lower ends open. The front end of housing 1 is provided with circular through holes, installation through holes and installation shaft holes in sequence from top to bottom, and the installation through holes are arranged symmetrically front and rear. The flow frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com