A processing system for recycling and reusing steel slag, a steelmaking processing waste

A steel slag recycling and processing system technology, applied in grain processing, solid waste removal, etc., can solve problems such as waste of electricity and oil resources, jamming, and low efficiency of steel slag crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in conjunction with specific illustrations. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict.

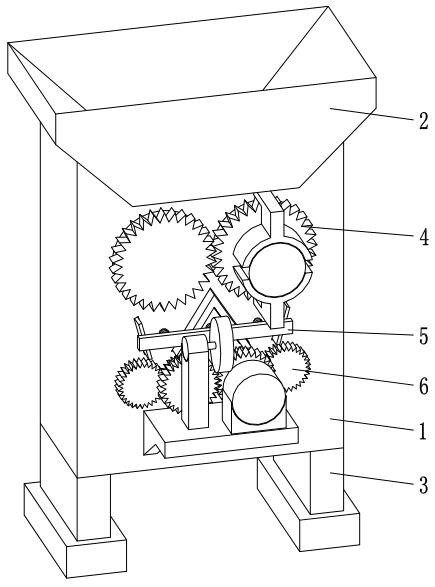

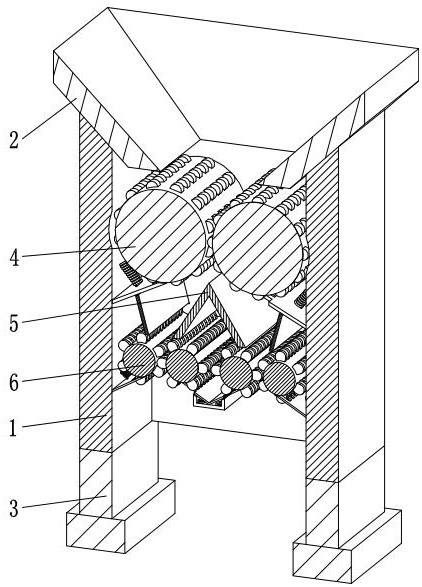

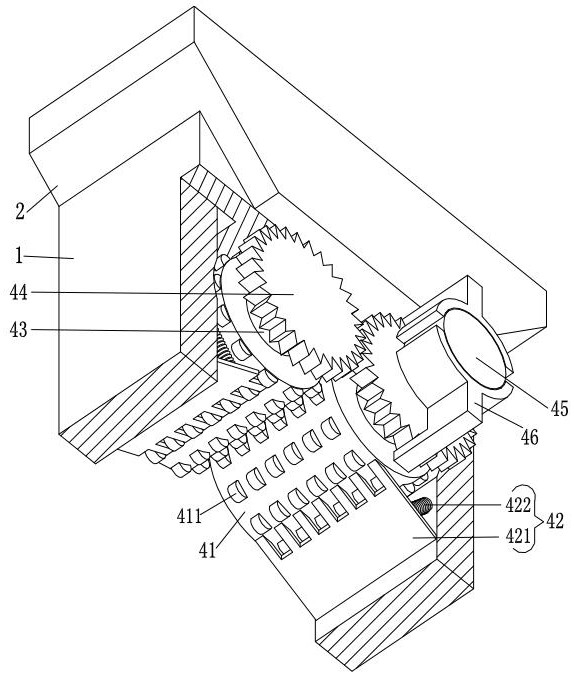

[0026]Such asFigure 1 to 5As shown, a steel scrap processing waste steel slag recovery re-use processing processing system includes a housing 1, a guide frame 2, a support plate 3, a first crusher 4, a jitter mechanism 5, and a second crushing mechanism 6, a housing 1 For the back and lower end opening, the front end of the housing 1 is sequentially opened from top to bottom, mounts the through hole, and the mounting shaft hole, and the mounting through hole is the front and rear symmetry setting, the upper end of the housing 1 is installed Flow frame 2, the upper side of the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com