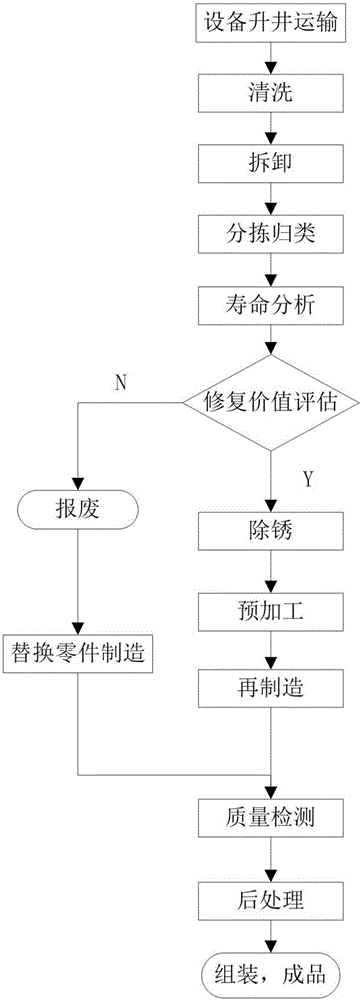

Mine waste machine repair process

A mine and machinery technology, which is applied in the field of mine waste machinery repair technology, can solve the problems of sprocket tooth wear and chain failure, achieve cost reduction, reduce repair and maintenance costs, and improve service life and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Taking the most widely used hydraulic support column in coal mine machinery as an example, the repair process of the present invention includes the following steps:

[0024] ⑴Cleaning and sorting

[0025] First, the mine machinery and equipment to be repaired will be transported to the raw material yard for unified storage, and then the stored mine machinery and equipment to be repaired will be transported to the cleaning and sorting workshop according to the order of demand, and then the mechanical equipment will be washed with a high-pressure water gun to remove the oily sludge on the surface. Use the CZ-1-45 single pillar dismantling machine for disassembly, cleaning and sorting. The sorted parts are ultrasonically cleaned with a special cleaning solution under ultrasonic treatment conditions, and then washed with warm water at 60°C, and finally Use a 24 cubic meter air compressor to generate hot compressed air to dry the parts, and use the recycling device to recycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com