Scraping method of main bearing shell of ball mill

A technology of main bearing bush and ball mill, which is applied in the field of mechanical repair and inspection equipment, can solve the problems of long maintenance time, low success rate, oil film damage, etc., and achieve the effect of reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

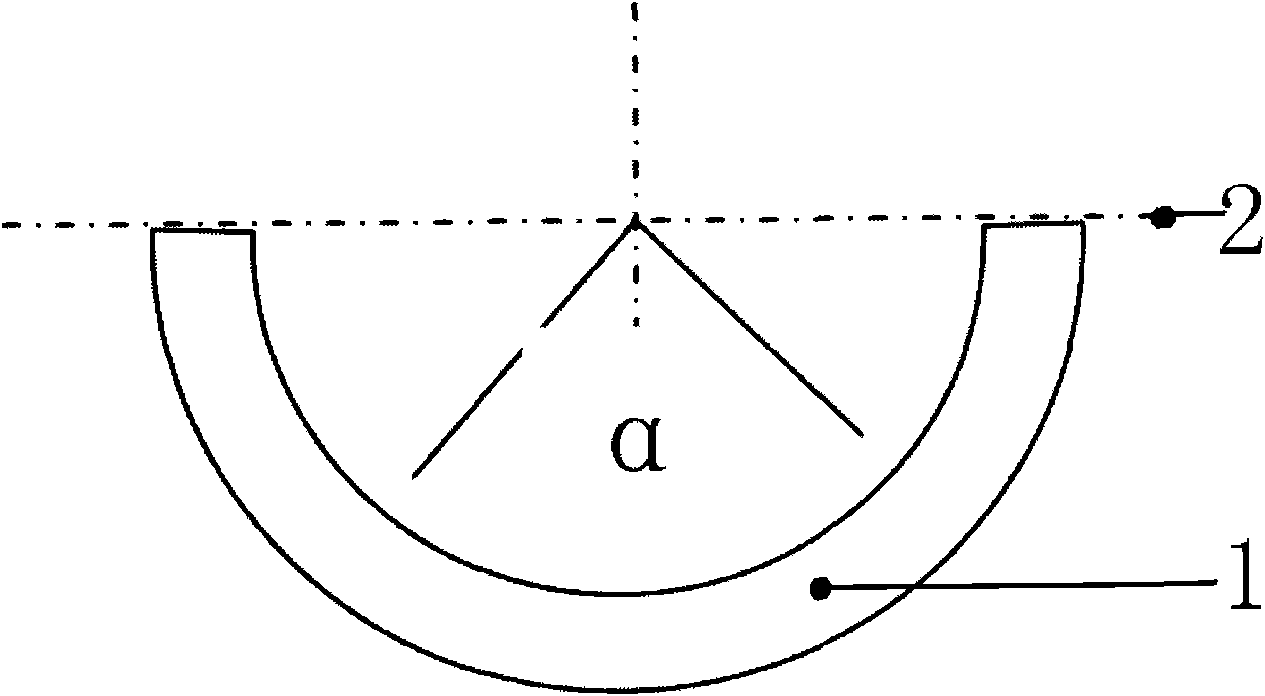

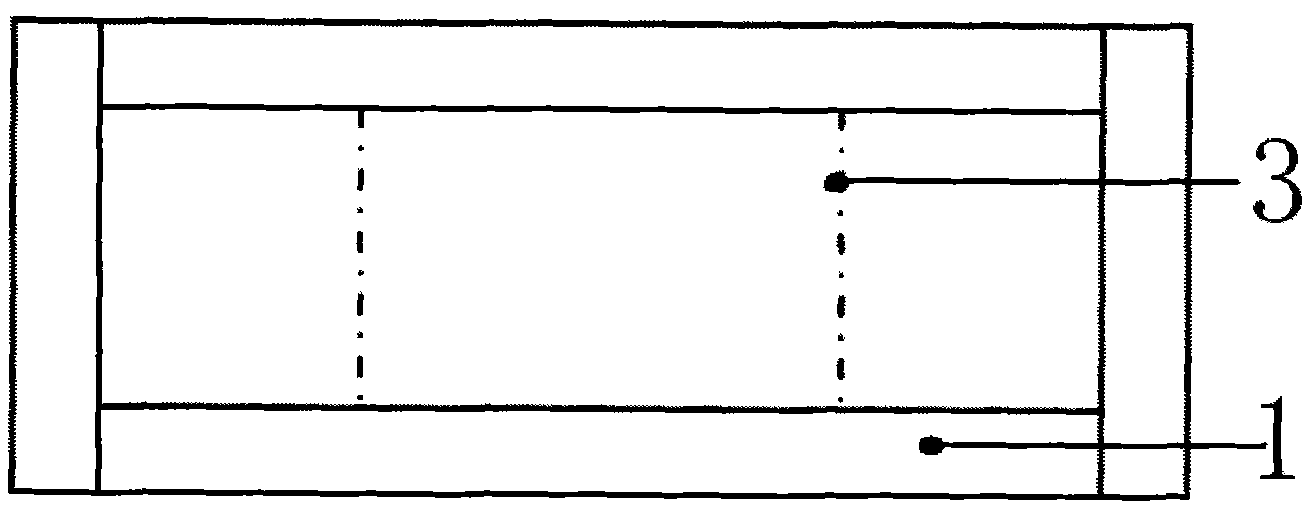

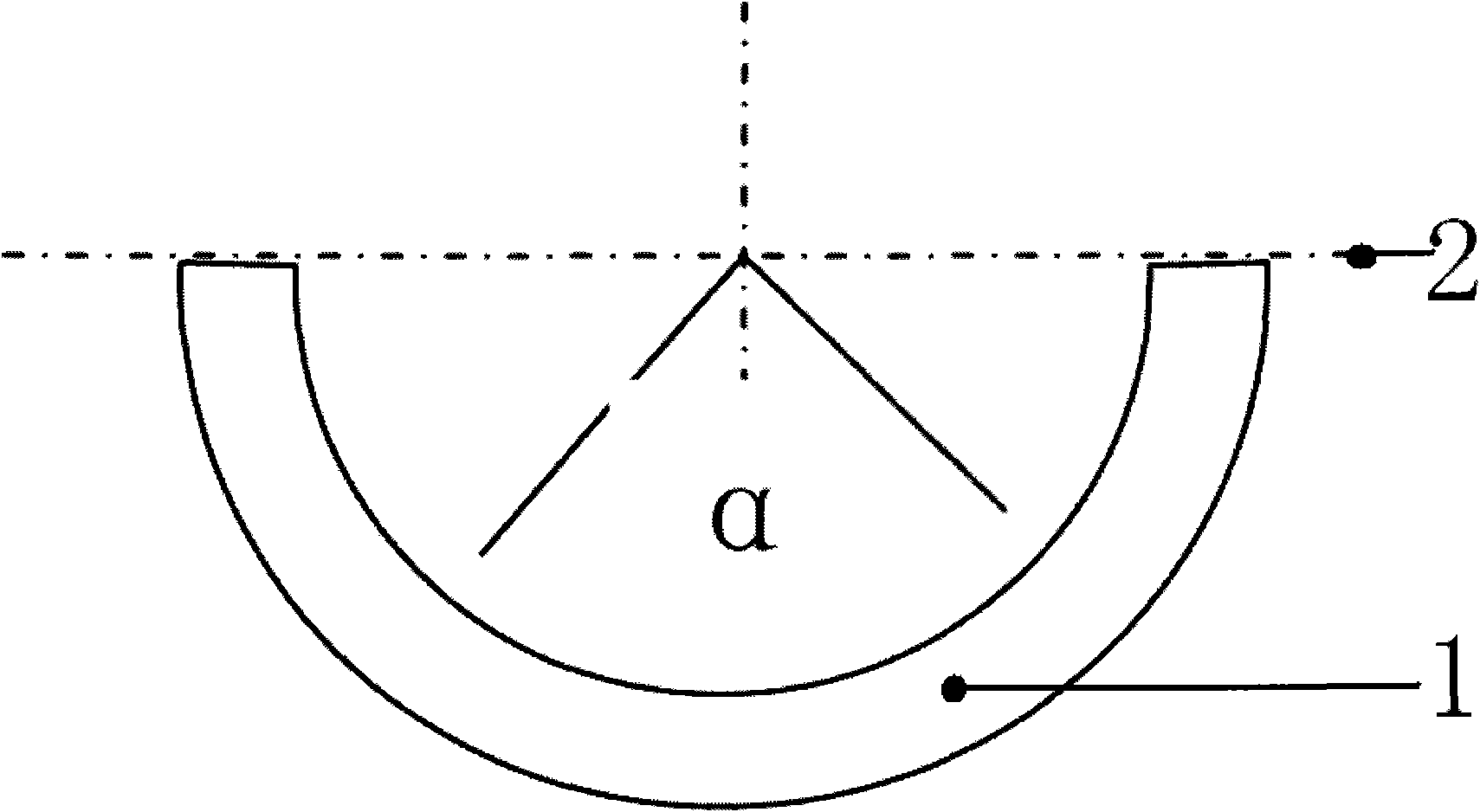

[0030] attached Figure 1-2 The middle marks respectively represent: main bearing 1, split surface 2, boundary line 3, and contact angle α.

[0031] This scraping method is mainly suitable for sliding bearings made of Babbitt alloy or copper casting, see attached Figure 1-2 , the method of scraping and grinding the main bearing bush of the ball mill is as follows:

[0032] Preparation

[0033] Sand the hollow shaft with 120-200 grit sandpaper until the finish reaches above. If there is no condition for accurate measurement on-site inspection, hand touch and visual inspection can be used. The measurement standard is: the tactile sense of the hand should be similar to that of a mirror when touched by the hand; Then clean the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com