Weighing pressure sensor with high oil injection efficiency and oil injection method

A pressure sensor, high-efficiency technology, applied in fluid pressure measurement by changing ohmic resistance, measuring fluid pressure, instruments, etc., can solve the problem of easy tearing and damage at right angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

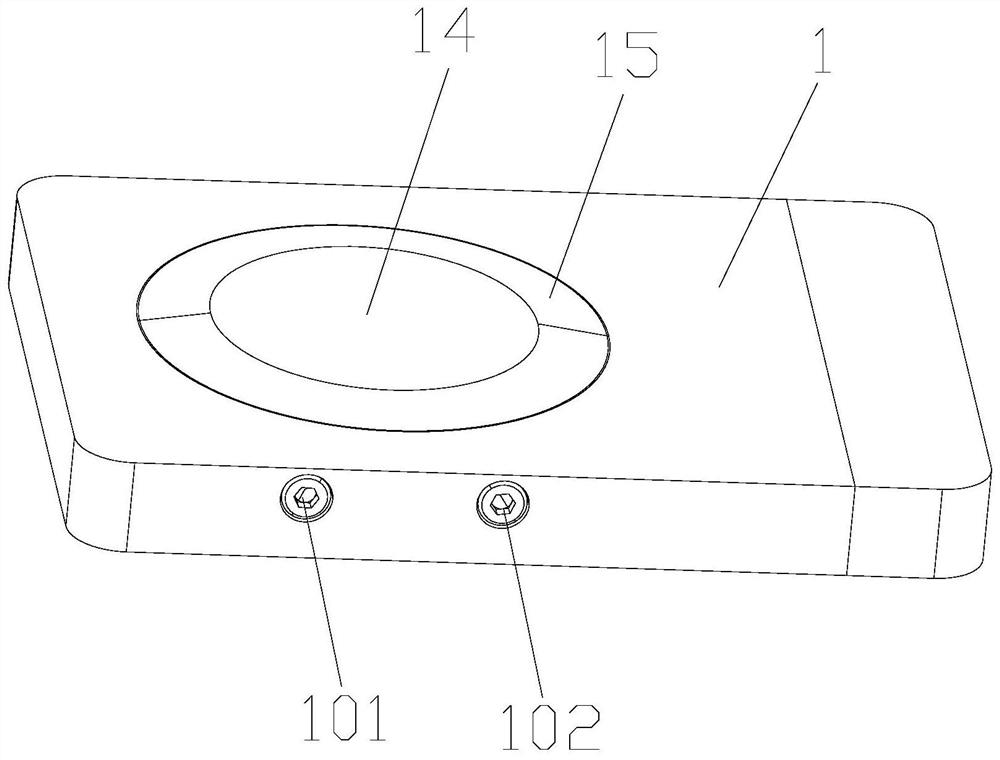

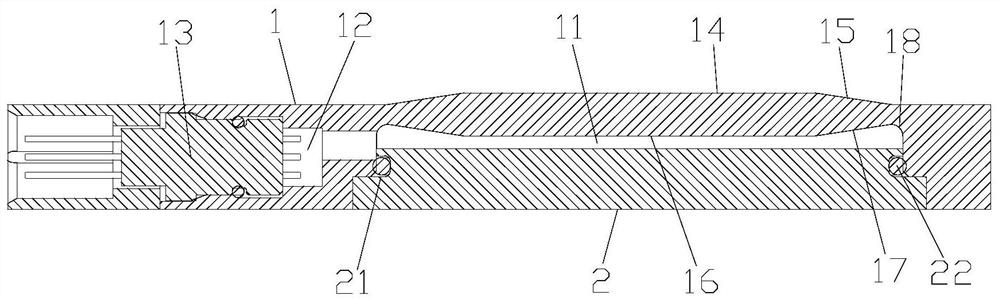

[0027] Such as figure 1 and figure 2 As shown, a weighing pressure sensor with high oil injection efficiency provided by the present invention includes: a housing 1, which has a cavity 11 inside, and the cavity 11 is filled with liquid, and the liquid can be Silicone oil, and one side of the housing 1 is provided with an opening communicating with the cavity 11, and the size of the opening matches the size of the cavity, and the opening is provided with a bottom cover 2 for sealing the cavity, so One side of the housing 1 is provided with a first through hole 12 communicating with the cavity 11, and a connector 13 is arranged in the first through hole 12, and the connector not only serves the purpose of sealing the first through hole, but also At the same time, the cavity end of the connector 13 is provided with a diffused silicon sensor, and the cavity wall on the side of the housing 1 opposite to the bottom cover 2 has an outward first protrusion 14 and an inward first pro...

Embodiment 2

[0036] Such as figure 1 and figure 2As shown, a weighing pressure sensor with high oil injection efficiency provided by the present invention includes: a housing 1, which has a cavity 11 inside, and the cavity 11 is filled with liquid, and the liquid can be Silicone oil, and one side of the housing 1 is provided with an opening communicating with the cavity 11, and the size of the opening matches the size of the cavity, and the opening is provided with a bottom cover 2 for sealing the cavity, so The edge of the bottom cover 2 is provided with a step structure 21, and correspondingly, the edge of the opening is also provided with a step structure on the housing that matches the step structure 21, and the bottom cover 2 is interference fit with the housing 1 One side of the housing 1 is provided with a first through hole 12 communicating with the cavity 11, and a connector 13 is arranged in the first through hole 12, and the connector not only serves to seal the first through ...

Embodiment 3

[0047] The present invention also provides an oil injection method, including the weighing pressure sensor with high oil injection efficiency described in any one of the above embodiments, and the oil injection method for oil injection to the weighing pressure sensor with high oil injection efficiency includes the following steps:

[0048] The vacuuming equipment is connected to the vacuum hole, and the oiling equipment is connected to the oiling hole;

[0049] Vacuuming equipment vacuumizes the cavity;

[0050] The oil injection device injects oil into the cavity.

[0051] The conventional cavity oiling method is to put a lot of pre-oiling equipment into a vacuum tank, which contains pre-filled oil, and then vacuumize the vacuum tank, and gradually fill the equipment cavity with oil as the vacuum degree increases. Though this kind method can carry out oiling to a lot of equipments at one time, efficiency is extremely low, and each oiling time varies from several hours to mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com