Gearbox oil filler

A technology of transmission oil and filler, which is applied in the direction of lubricating oil container, lubricating oil input, engine lubrication, etc., and can solve the problems of long filling time, long time and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

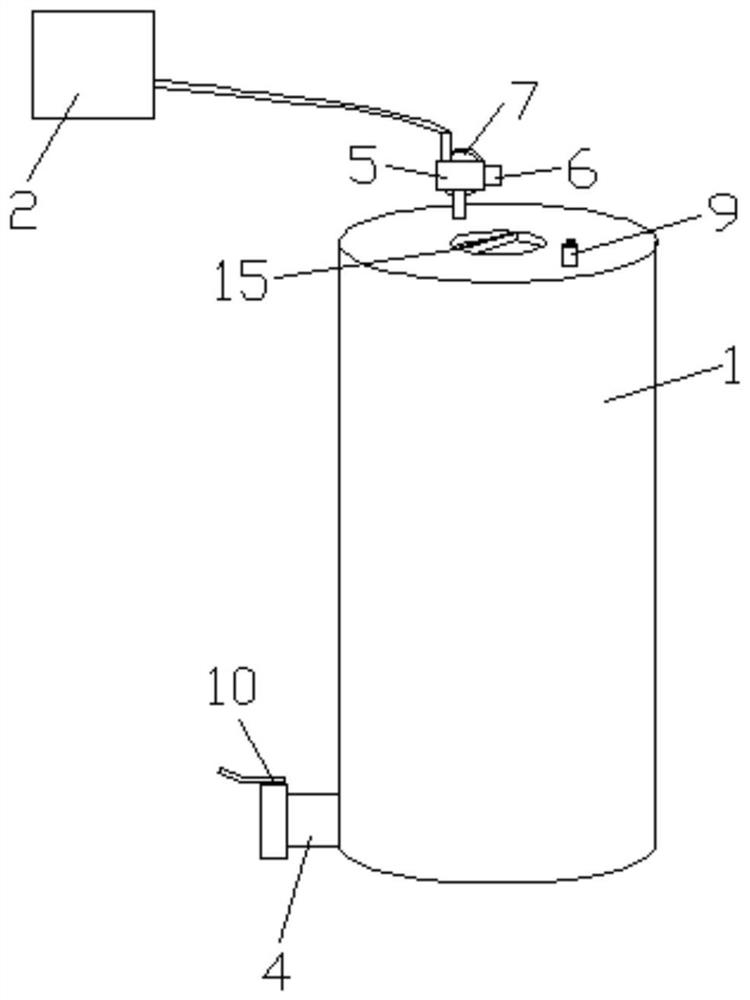

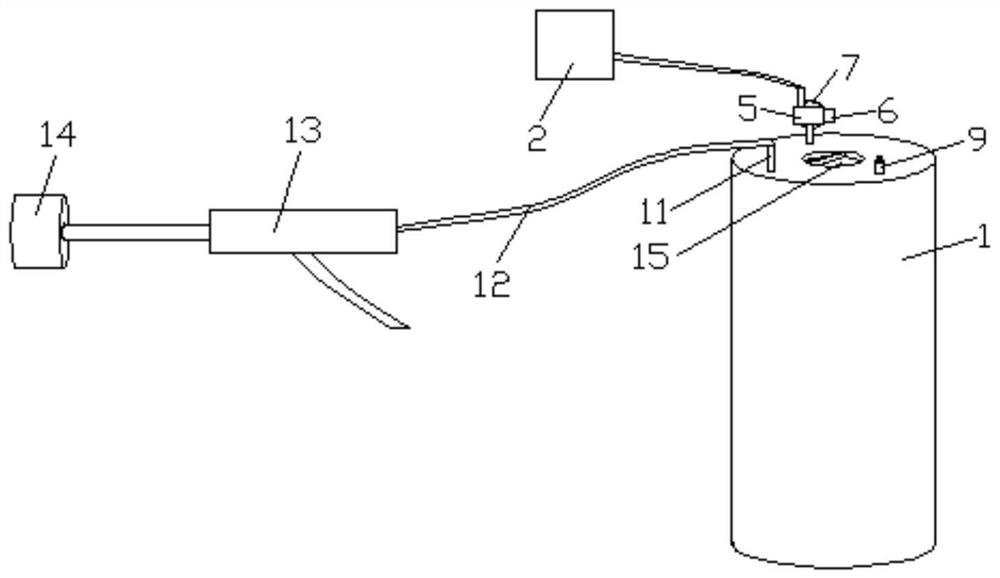

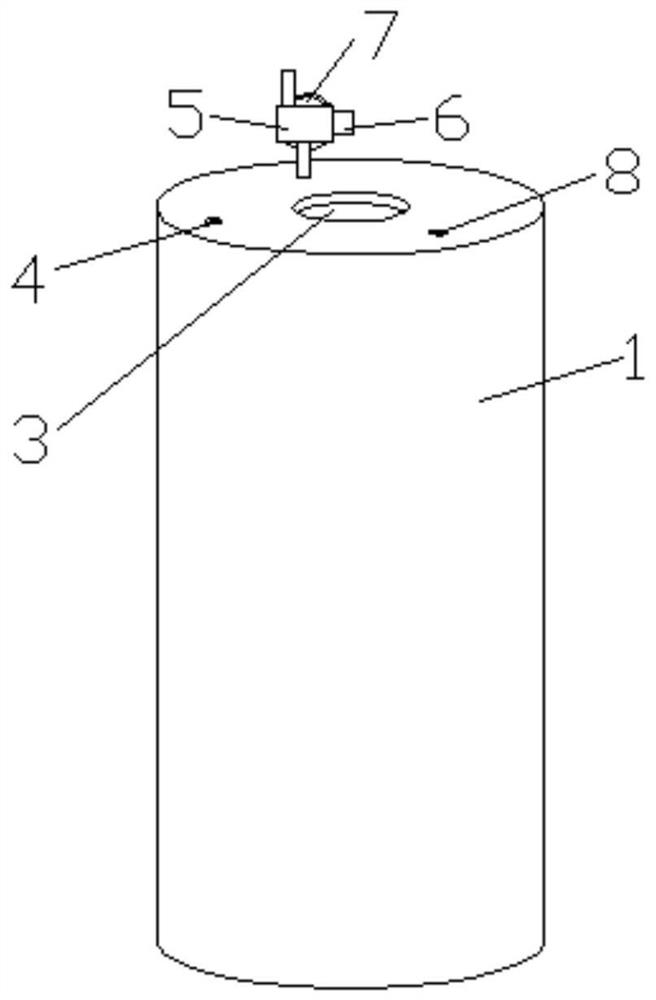

[0036] On the basis of the above structure, in this embodiment, the top of the oil storage tank 1 is also provided with a gas injection port that penetrates inside and outside, and a regulating valve 5 is fixedly installed at the gas injection port, usually by welding; the air intake on the regulating valve 5 The port communicates with the gas injection device 2 through a pipeline, and its gas outlet communicates with the gas injection port. When in use, the gas injection device 2 and the oil storage tank 1 can be quickly connected or disconnected through the regulating valve 5, which is easy to operate and saves time and effort.

Embodiment 2

[0038] On the basis of Embodiment 1, in this embodiment, a knob 6 for adjusting the opening degree is installed on the regulating valve 5, and the opening degree of the regulating valve 5 can be adjusted according to the demand through the knob 6, so as to adjust the gas injection volume, adjust Convenient, save time and effort.

[0039] The regulating valve 5 mentioned above adopts the prior art, and the cooperation method between the knob 6 and the regulating valve 5 is also the prior art, so its structure and principle will not be repeated here.

Embodiment 3

[0041] On the basis of Embodiment 1, in this embodiment, a pressure gauge 7 for measuring the internal pressure of the oil storage tank 1 is installed on the regulating valve 5 through bolts. The pressure gauge 7 communicates with the inside of the regulating valve 5, that is, it is always connected with the storage The interior of the oil tank 1 communicates. During use, the pressure in the oil storage tank 1 is monitored in real time by the pressure gauge 7, which is convenient for staff to observe the pressure in the oil storage tank 1, so as to deal with it in time when the pressure in the oil storage tank 1 is too high, which is safe and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com