Vehicle Delay Type Height Valve Automatic Oil Filling Machine

A technology of height valve and oil injection machine, which is applied in the direction of engine components, engine lubrication, mechanical equipment, etc., can solve the problems of silicone oil overflow, limited improvement of production efficiency, low efficiency, etc., and achieve convenient disassembly and cleaning, and convenient and quick mastering , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

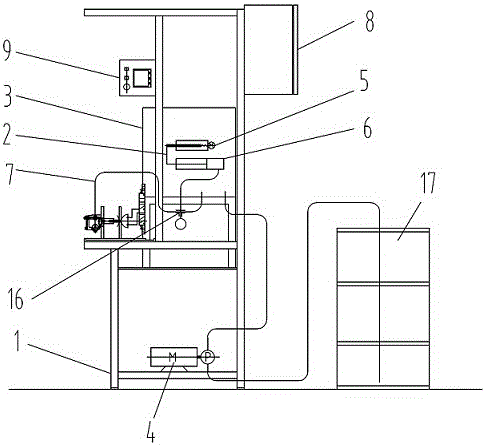

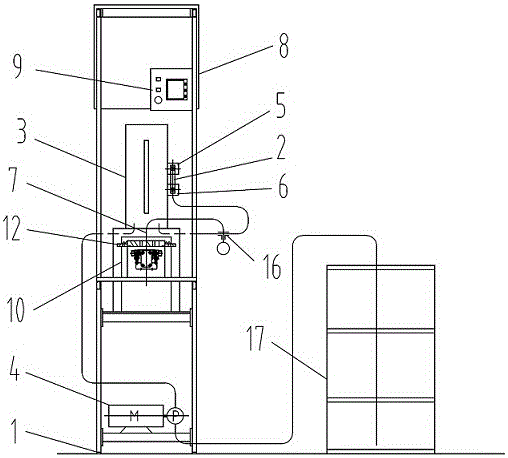

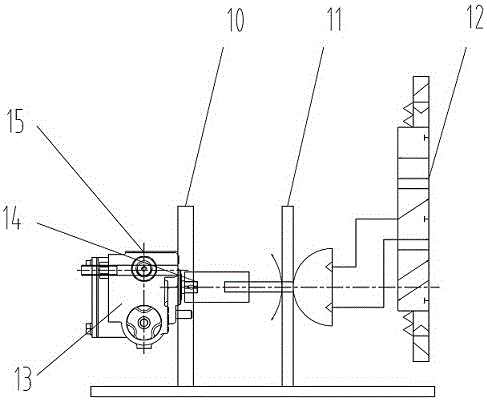

[0026] The invention discloses a vehicle delay type height valve automatic oiling machine. Such as figure 1 and figure 2 As shown, the vehicle delay type height valve at least includes an oil chamber 13, a center shaft 14 inserted into the oil chamber 13 that can swing left and right, and an oil injection hole 15 arranged on the oil chamber housing. . The central axis 14 is perpendicular to the axial space of the oil injection hole 15 .

[0027] The automatic oil filling machine includes a frame 1, an oil storage tank 3 and a swing assembly arranged on the frame 1, an oil injection assembly is fixed on the outer wall of the oil storage tank 3, and the vehicle delay type height valve is fixed on on the swing assembly.

[0028] Specifically, such as figure 2 As shown, the swing assembly includes a positioning frame 10 for fixing the vehicle delay height valve, a swing cylinder 11 spaced apart from the positioning frame 10, and a cylinder shaft for driving the swing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com