Pneumatic oil injection system for crossheading wheel type crusher

A crusher, pneumatic technology, applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of inability to meet the needs of use, high labor intensity, low reliability, etc., to improve safety and reliability, low labor intensity. , The effect of high oil injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

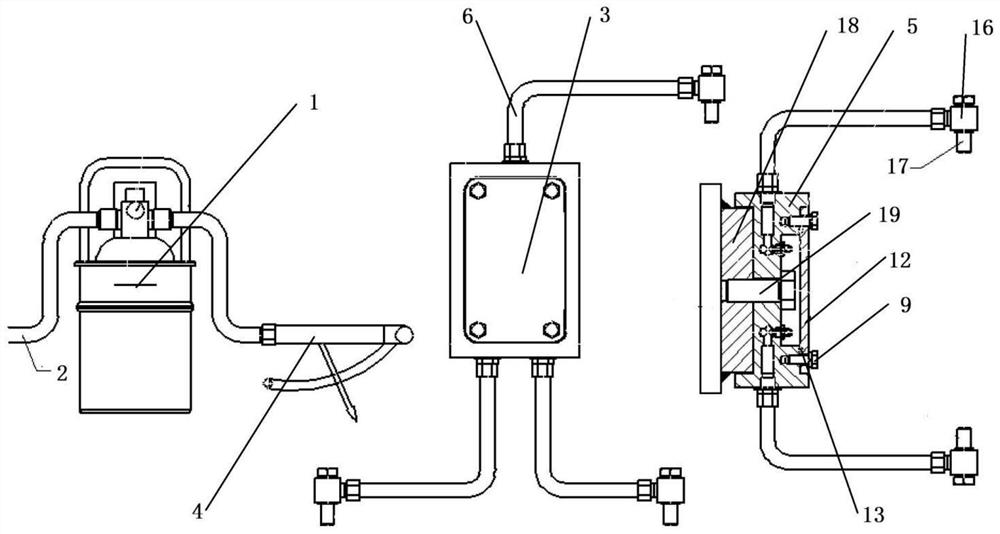

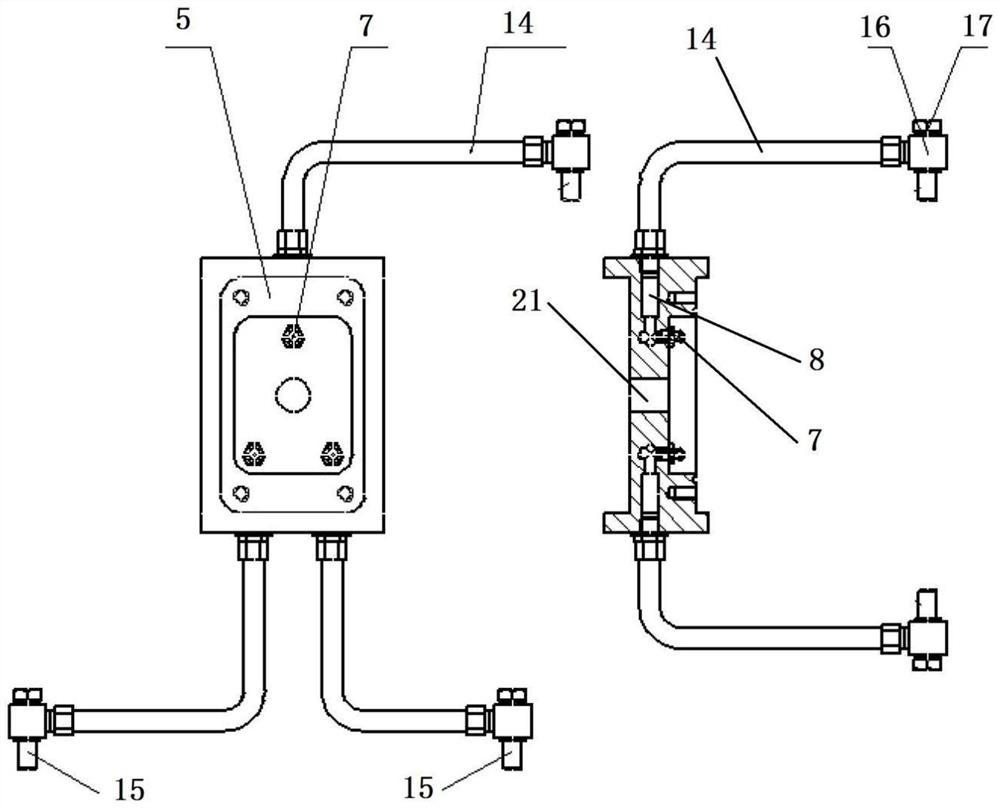

[0026] Such as Figure 1 to Figure 4 As shown, a pneumatic oil injection system for a down-trough wheel crusher includes a pneumatic oil injection pump 1, an air pipe 2 and an oil distribution system 3, and the oil distribution system 3 includes an oil distribution plate 5, a pipeline system 6 and The oil cup 7 and the oil distribution plate 5 are provided with an oil injection passage 8 .

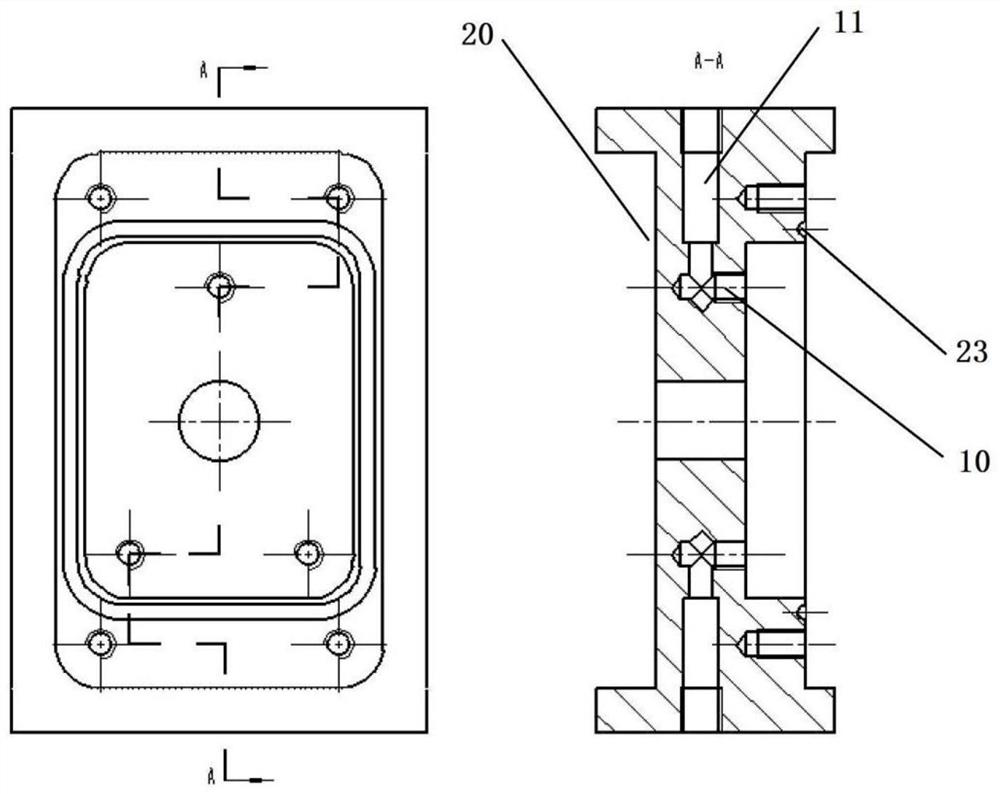

[0027] There are three oil injection passages 8, and different oil injection passages are independent of each other. Each oil injection passage 8 includes a horizontal pipeline 10 and a vertical passage 11 communicating with each other. The vertical passage 11 communicates with the outer surface of the oil distribution plate 5, and the horizontal passage 10 communicates with the front end surface of the oil distribution plate 5 , and the oil cup 7 communicating with the horizontal passage 10 is arranged on the front end surface of the oil distribution plate 5 .

[0028] The pipeline syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com