Patents

Literature

306results about How to "Economical efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

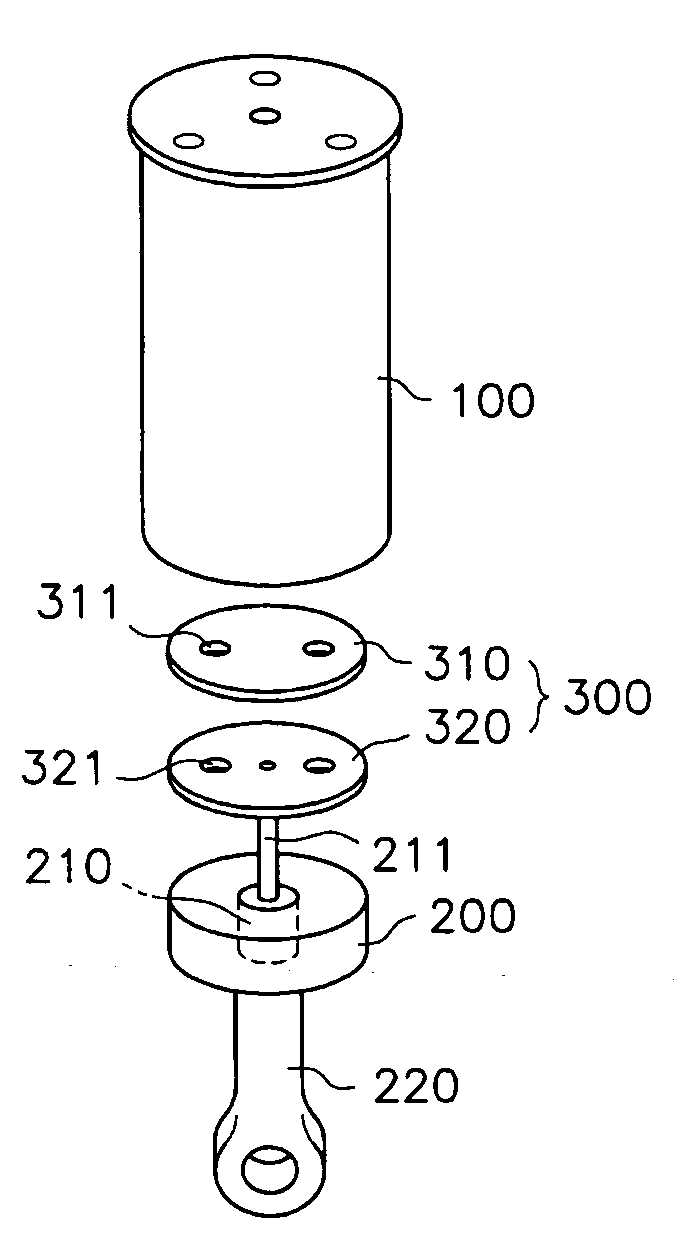

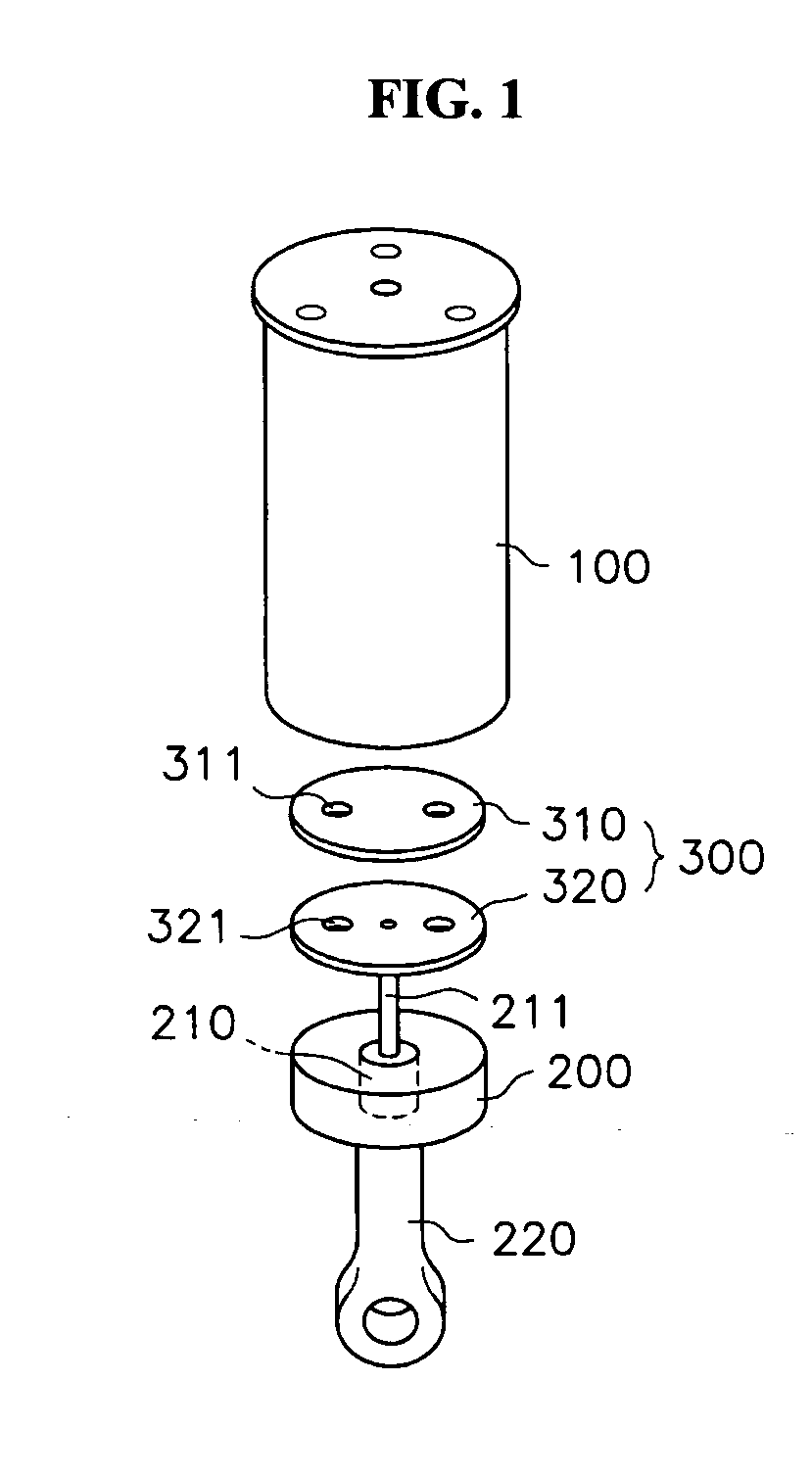

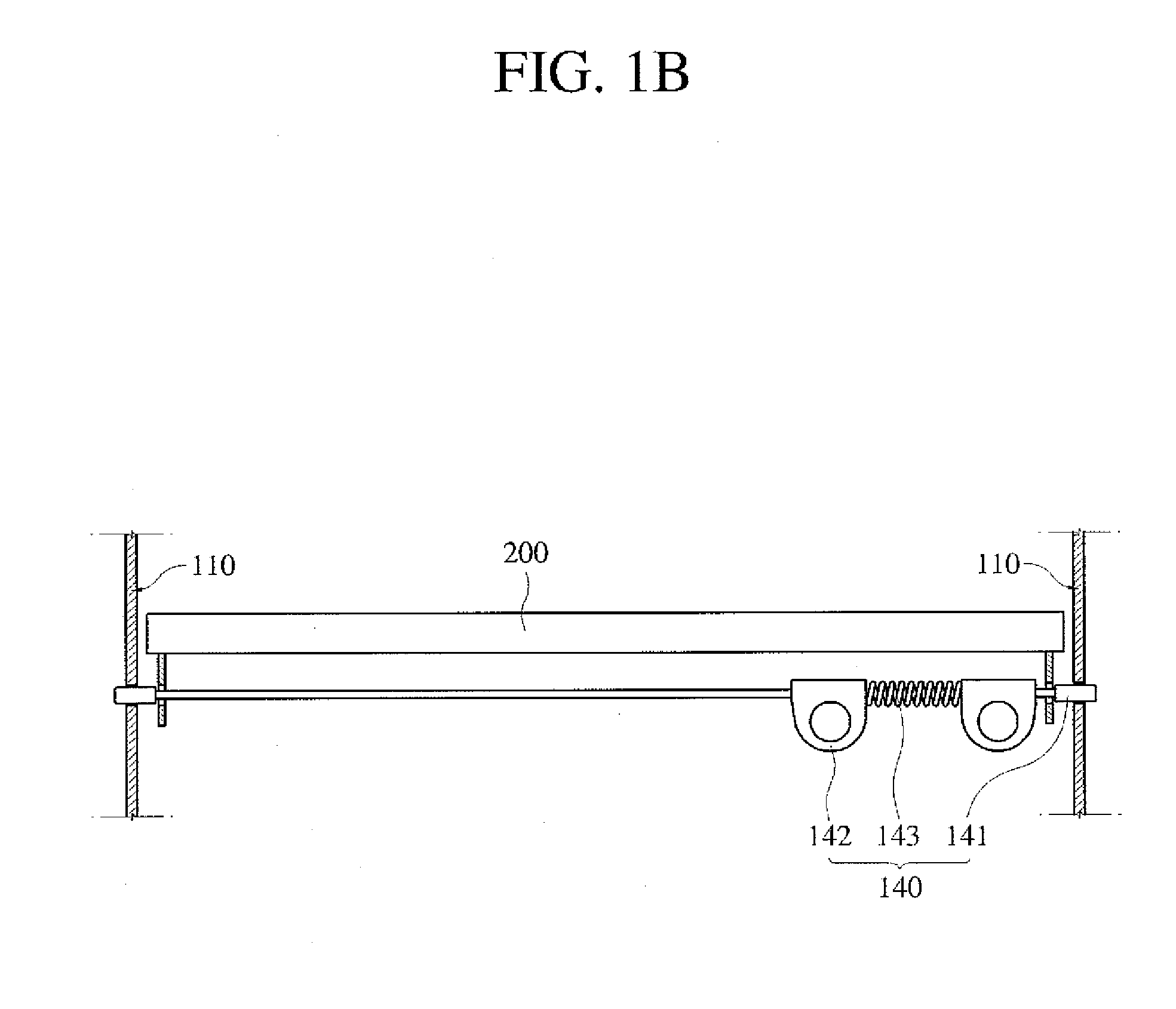

Integrated suspension system for vehicle

InactiveUS20060049013A1Easy to controlMaximize productivitySpringsLiquid based dampersCircular discDrive shaft

An integrated suspension system includes a cylinder that hermetically contains gas therein and is fixed to a vehicle body; a piston that has a motor at an upper portion thereof, is configured to support a road wheel and is guided within the cylinder to move vertically; a disk unit including a second disk that has a plurality of passage holes formed there through and a bottom surface coupled to a driving shaft of the motor to rotate while moving vertically integrally along with the piston, and a first disk that has a plurality of passage holes and is stacked on and connected via a hinge to the center of a top surface of the second disk to move vertically within the cylinder integrally along with the second disk without any rotation; and a control unit that controls an opening degree established through overlap of the passage holes formed in the first and second disks by changing power supplied to the motor to control a rotational angle of the second disk.

Owner:HYUNDAI MOBIS CO LTD

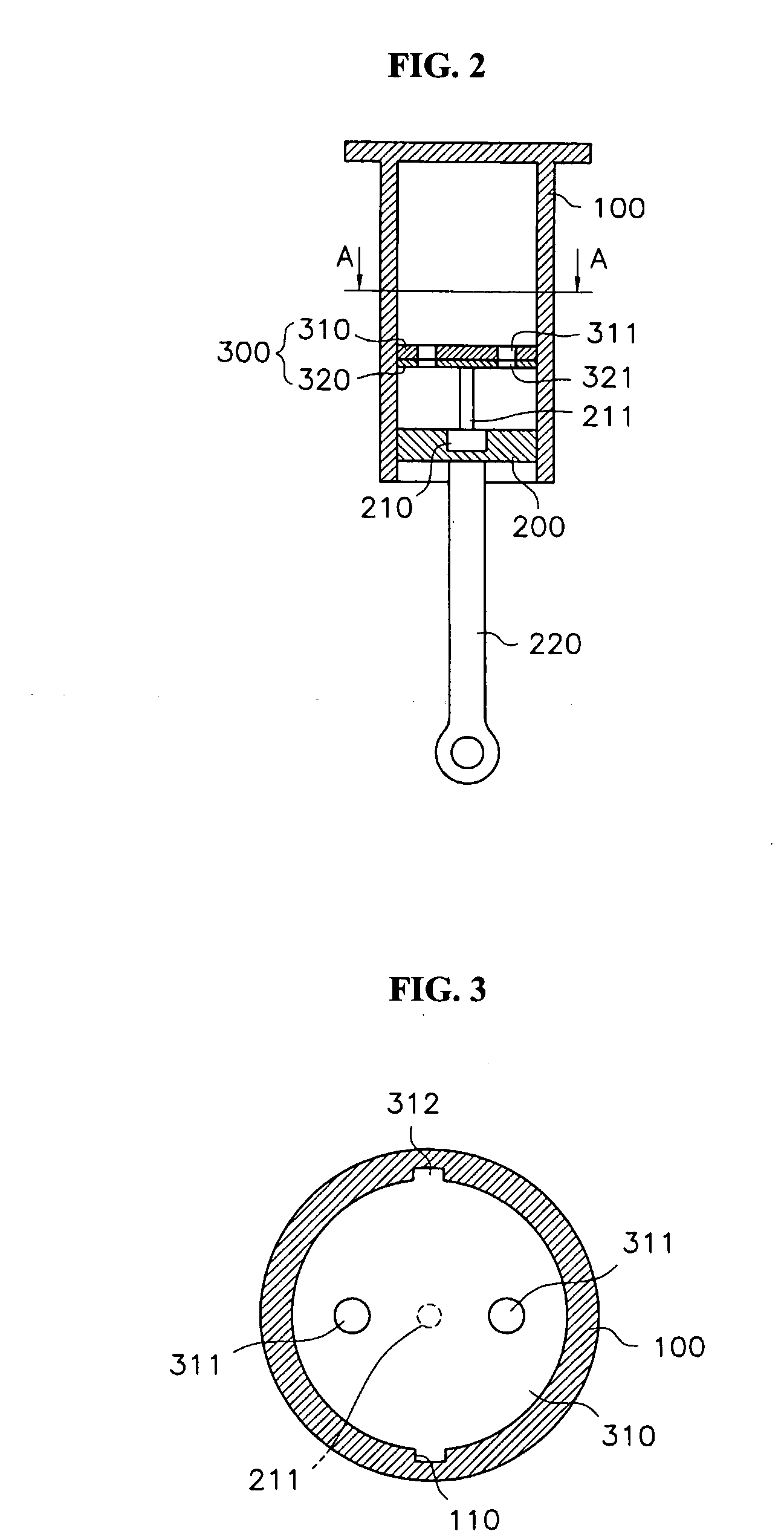

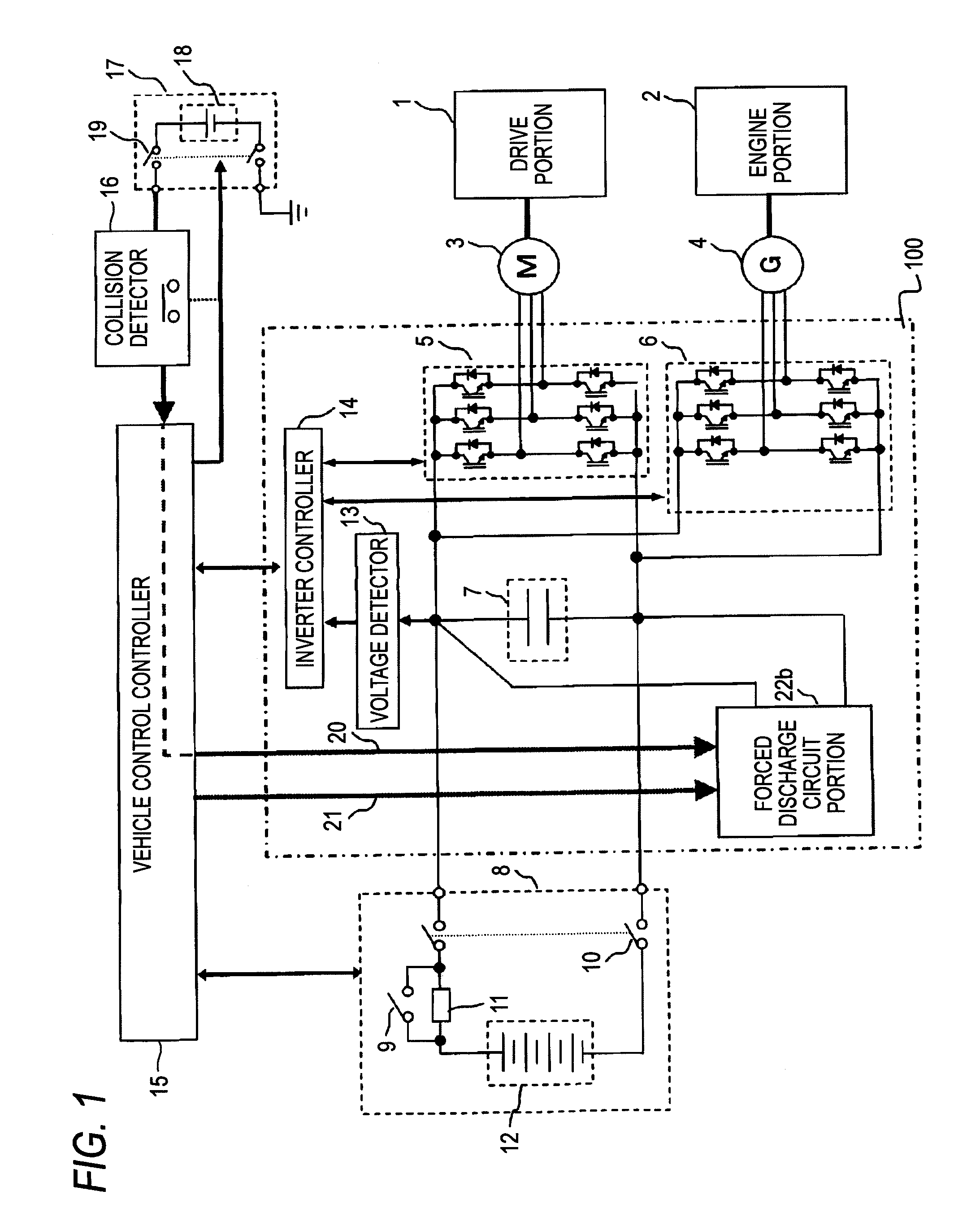

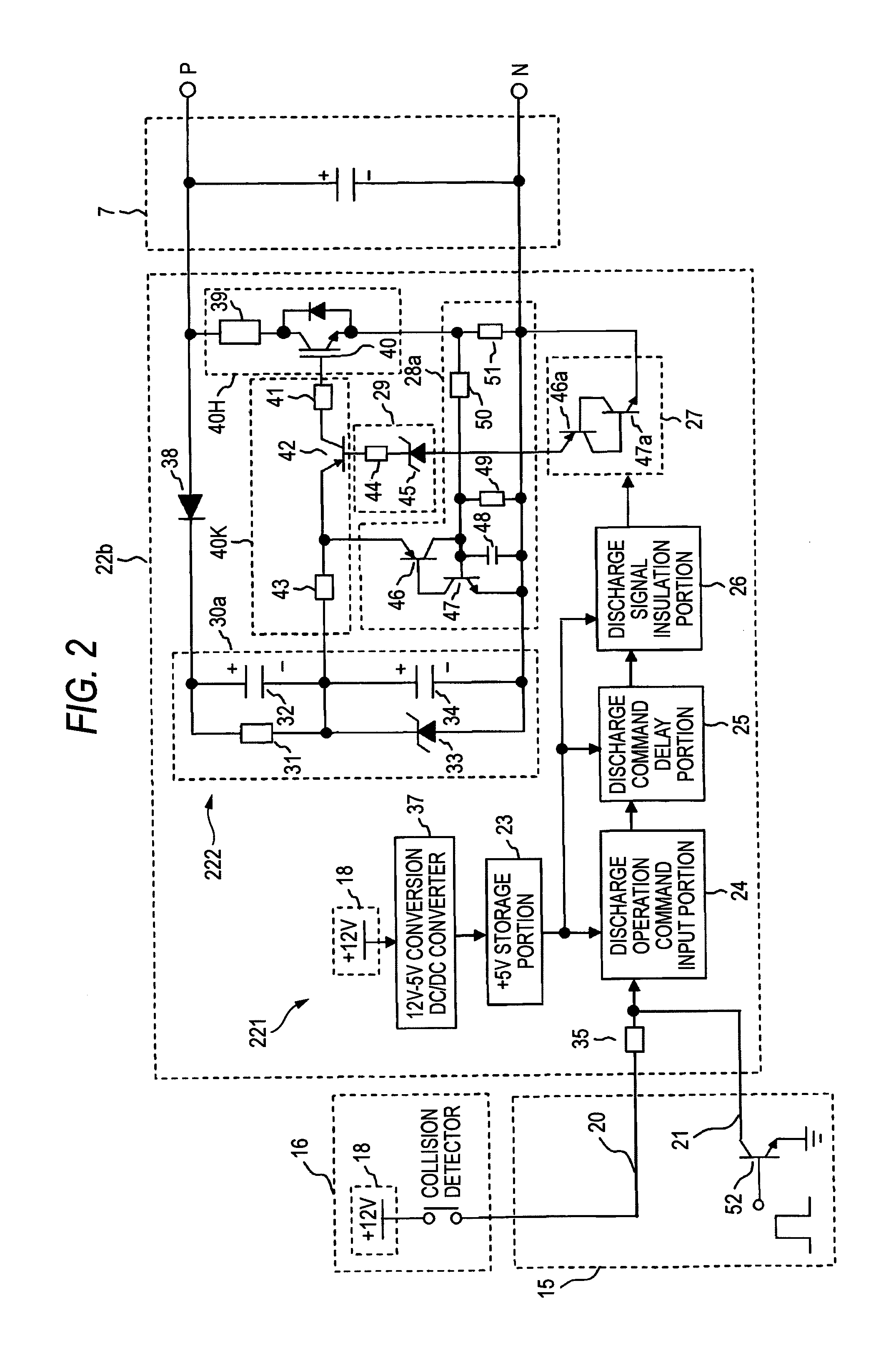

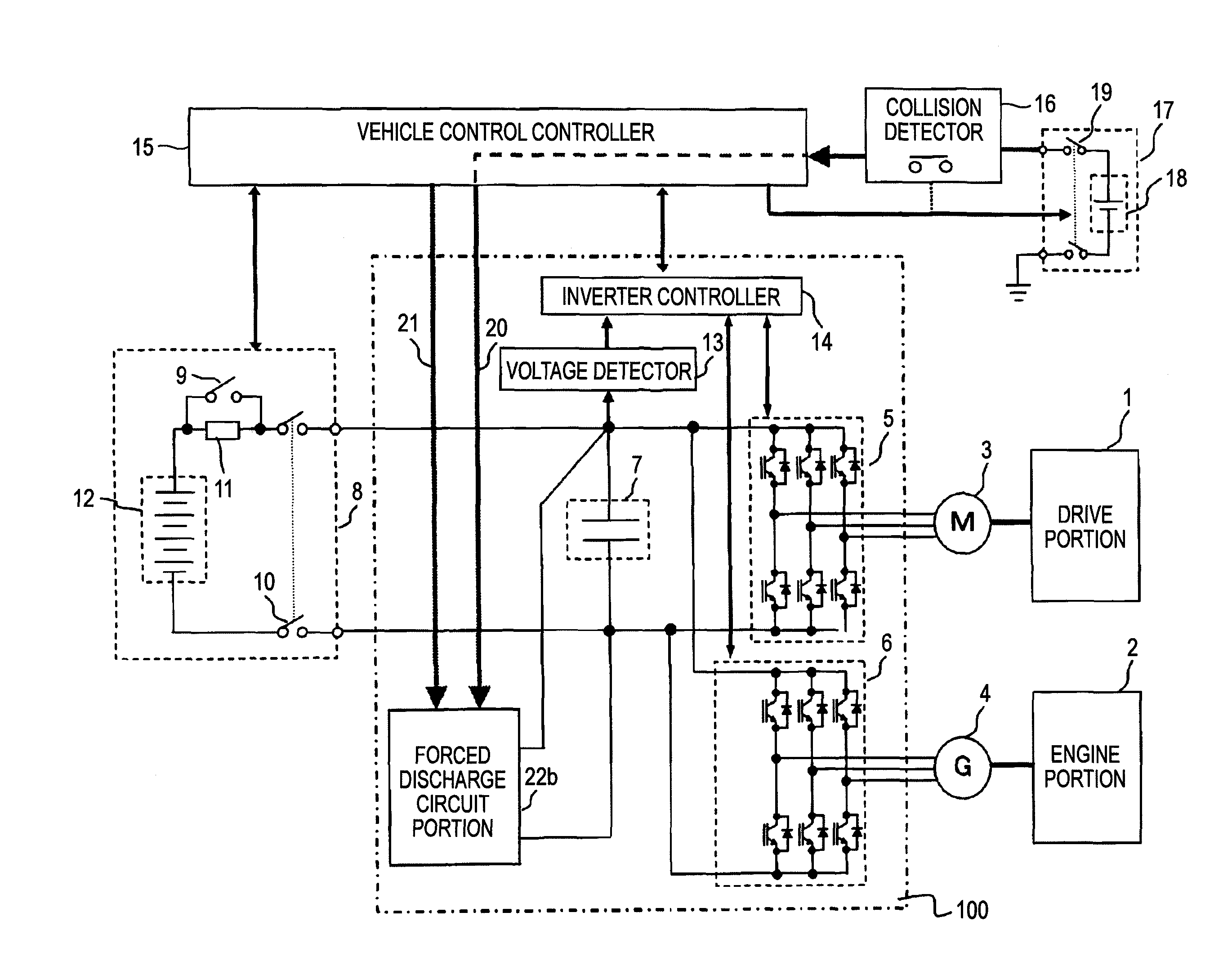

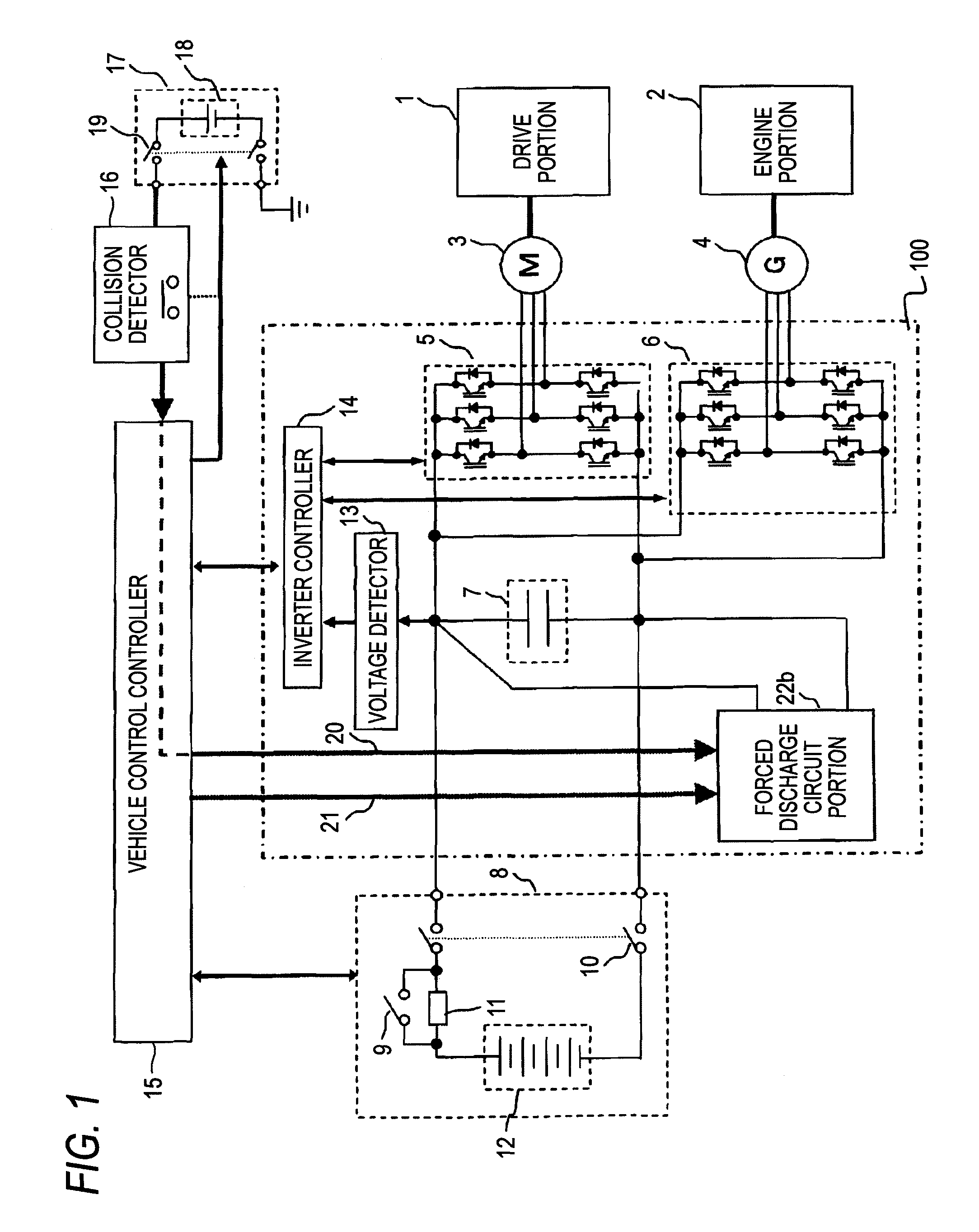

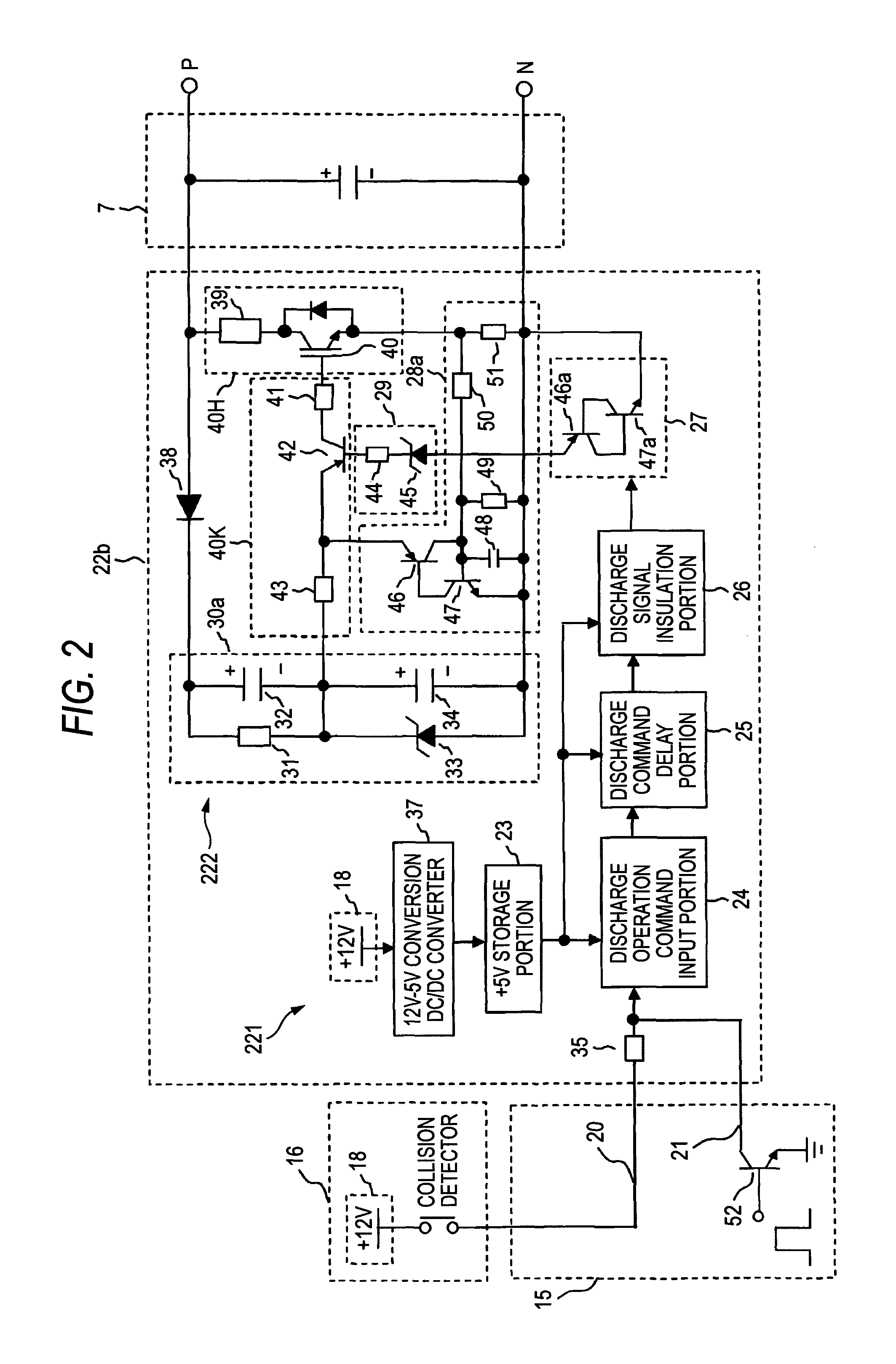

Electric vehicle inverter apparatus and protection method therefor

InactiveUS20100214055A1Improve design flexibilityIncrease flexibilityBatteries circuit arrangementsElectric devicesElectrical batteryHigh voltage battery

In an electric vehicle inverter apparatus 100, a vehicle control controller 15 detects a switch open signal output from a collision detector 16 when the collision detector 16 is caused by a collision between electric vehicles to operate. Then, an inverter main circuit connection switch 10 of a high-voltage battery unit 8 is put into an open state. Thus, the direct-current power supply from a high-voltage battery 12 to a DC bus portion is interrupted. In addition, electric charges charged into a main circuit capacitor 7 are discharged by a forced discharge circuit portion 22b.

Owner:YASKAWA DENKI KK +1

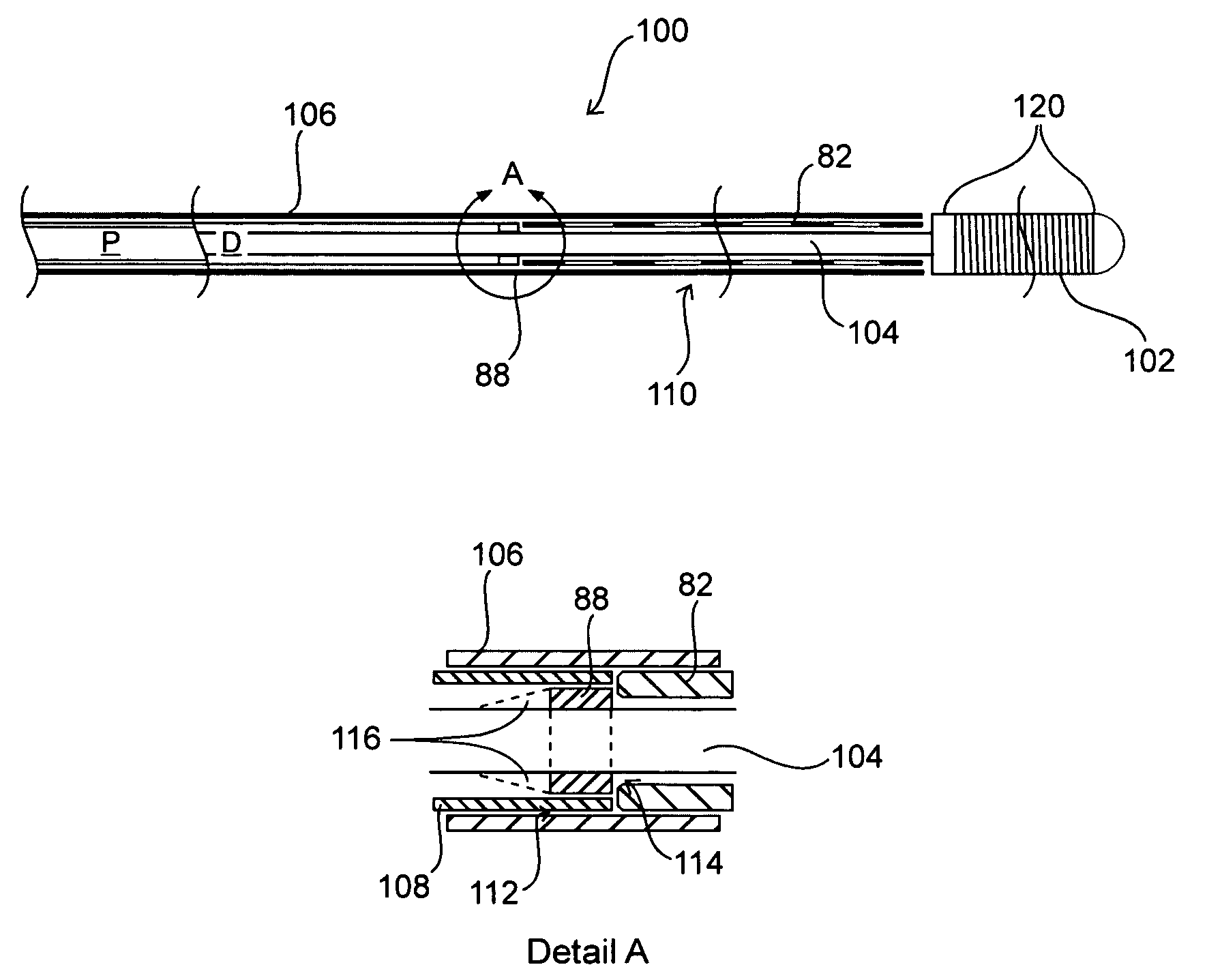

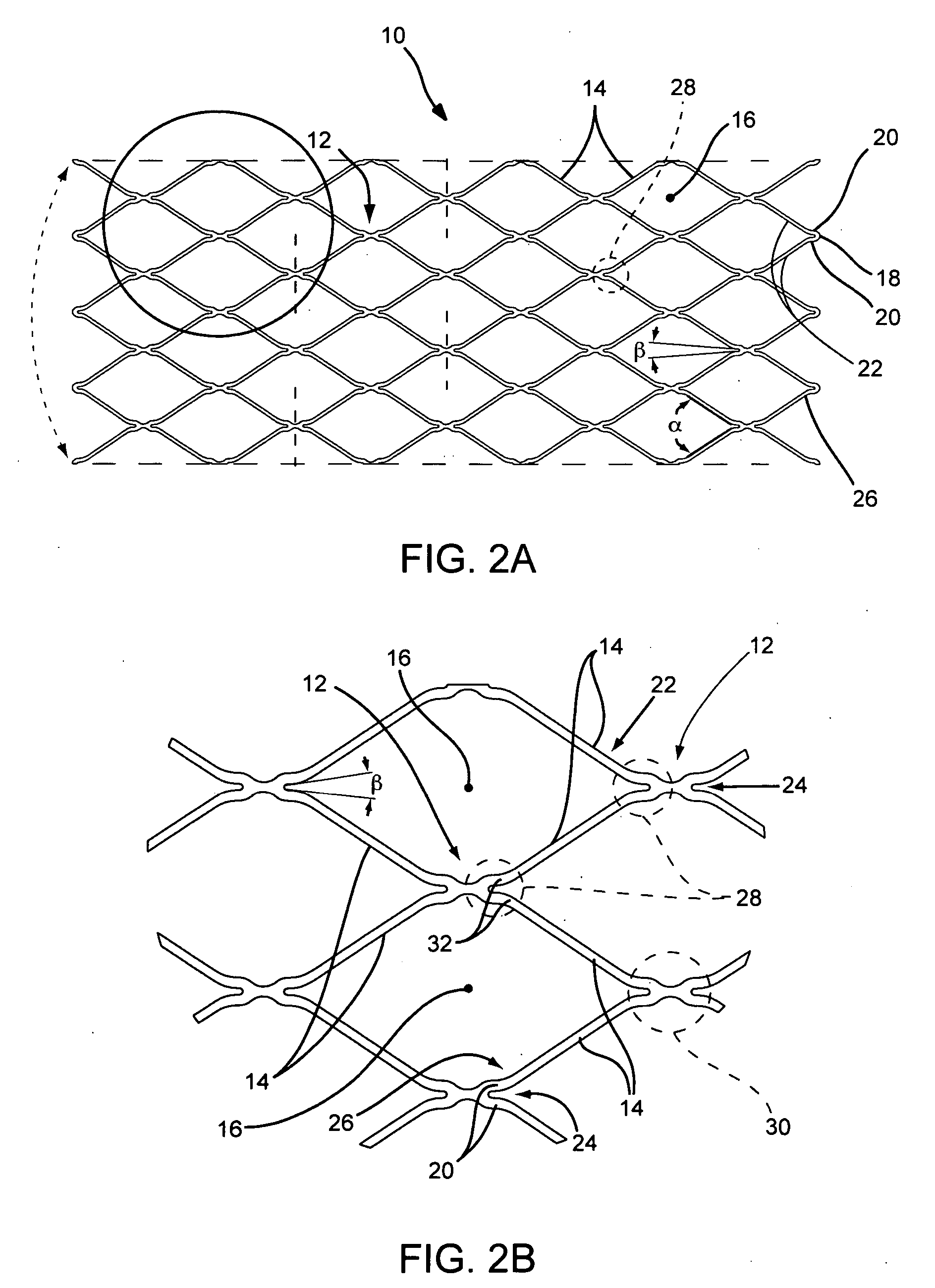

Stent delivery and guidewire systems

InactiveUS20070027522A1Saving surgical stepImproving patient careStentsBlood vesselsProsthesisBody organs

Medical device and methods for delivery or implantation of prostheses within hollow body organs and vessels or other luminal anatomy are disclosed. The subject technologies may be used in the treatment of atherosclerosis in stenting procedures.

Owner:BIOSENSORS INT GROUP

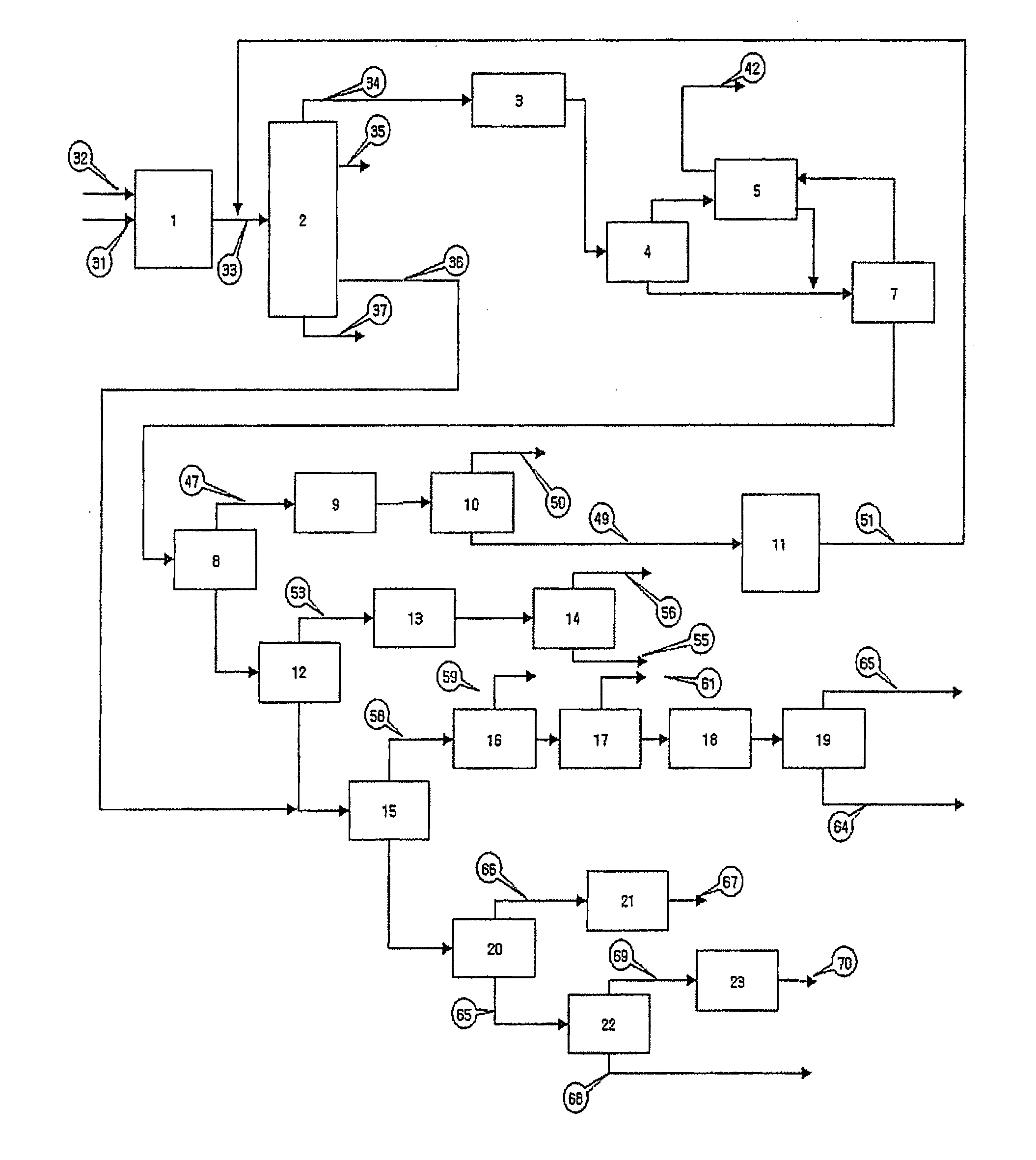

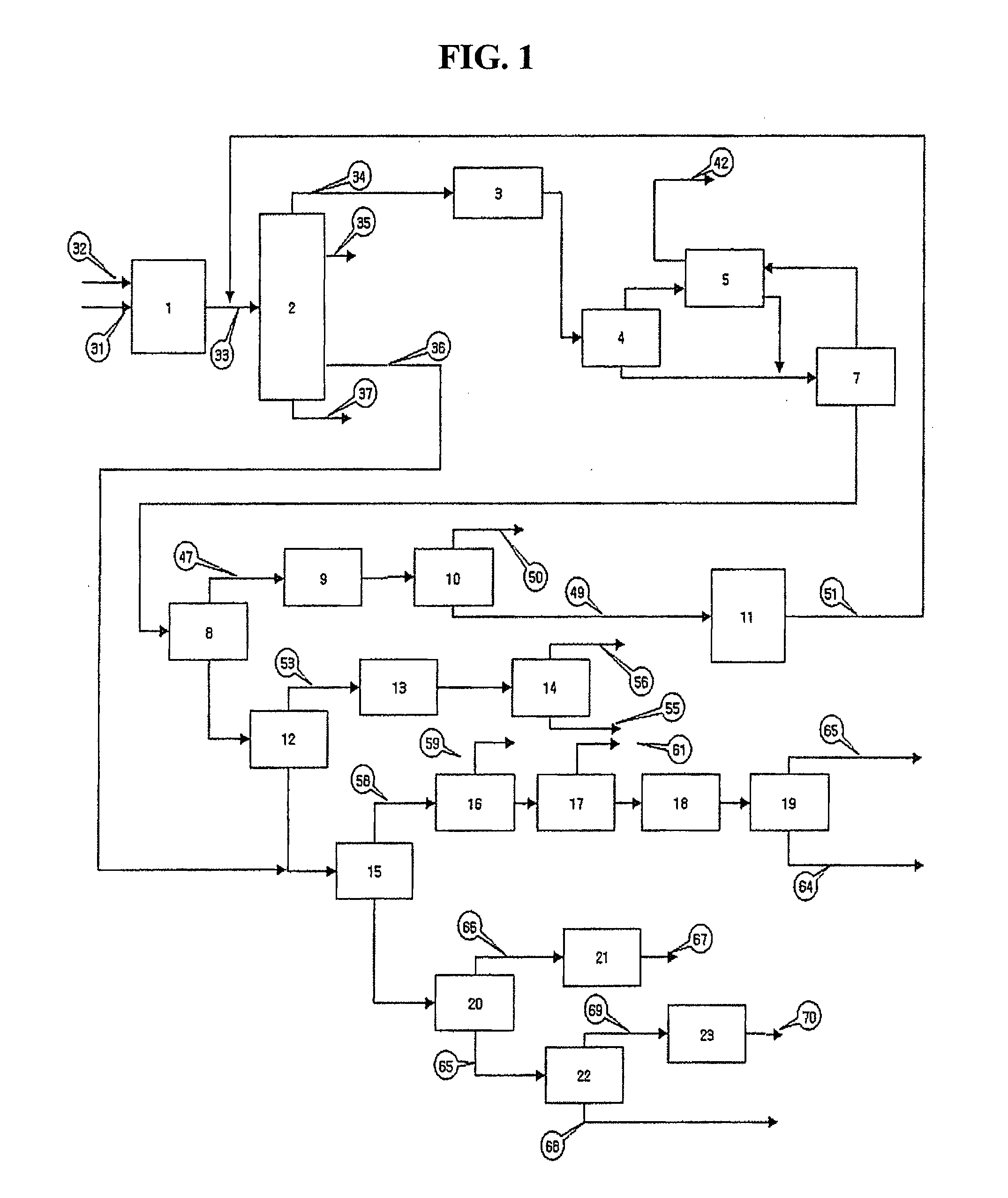

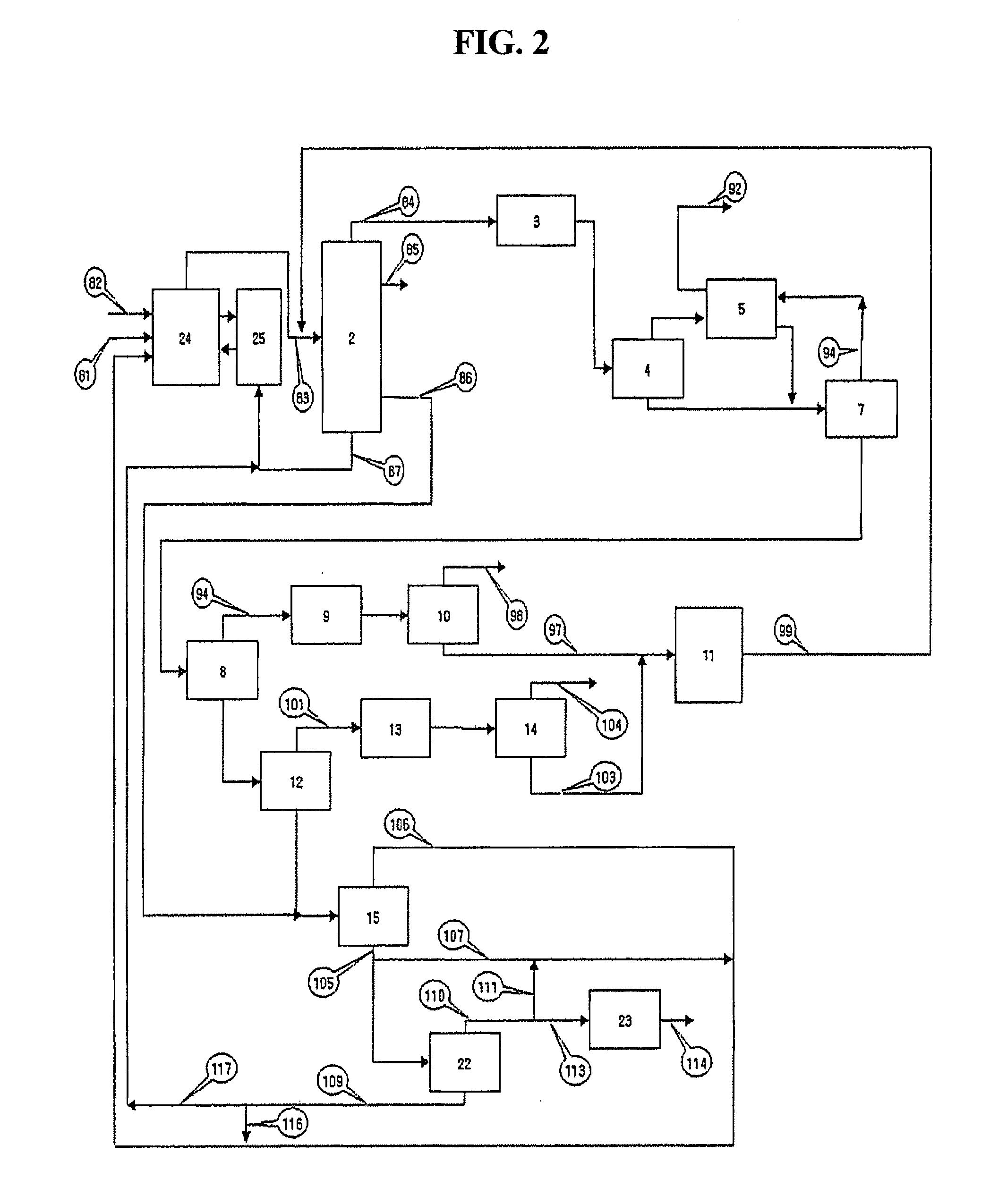

Process for increasing production of light olefins from hydrocarbon feedstock in catalytic cracking

ActiveUS20070083071A1Increase productionEconomical efficiencyTreatment with plural serial cracking stages onlyCatalytic crackingProduction ratePhotochemistry

Disclosed is a process for increasing production of light olefinic hydrocarbons from hydrocarbon feedstock by catalytic cracking. In the process, an effective separation process structure and recycle method of light olefins are used not only to increase the productivity and efficiency of an overall process, thus effectively increasing the production of light olefins, but also to simplify the overall process.

Owner:SK INNOVATION CO LTD

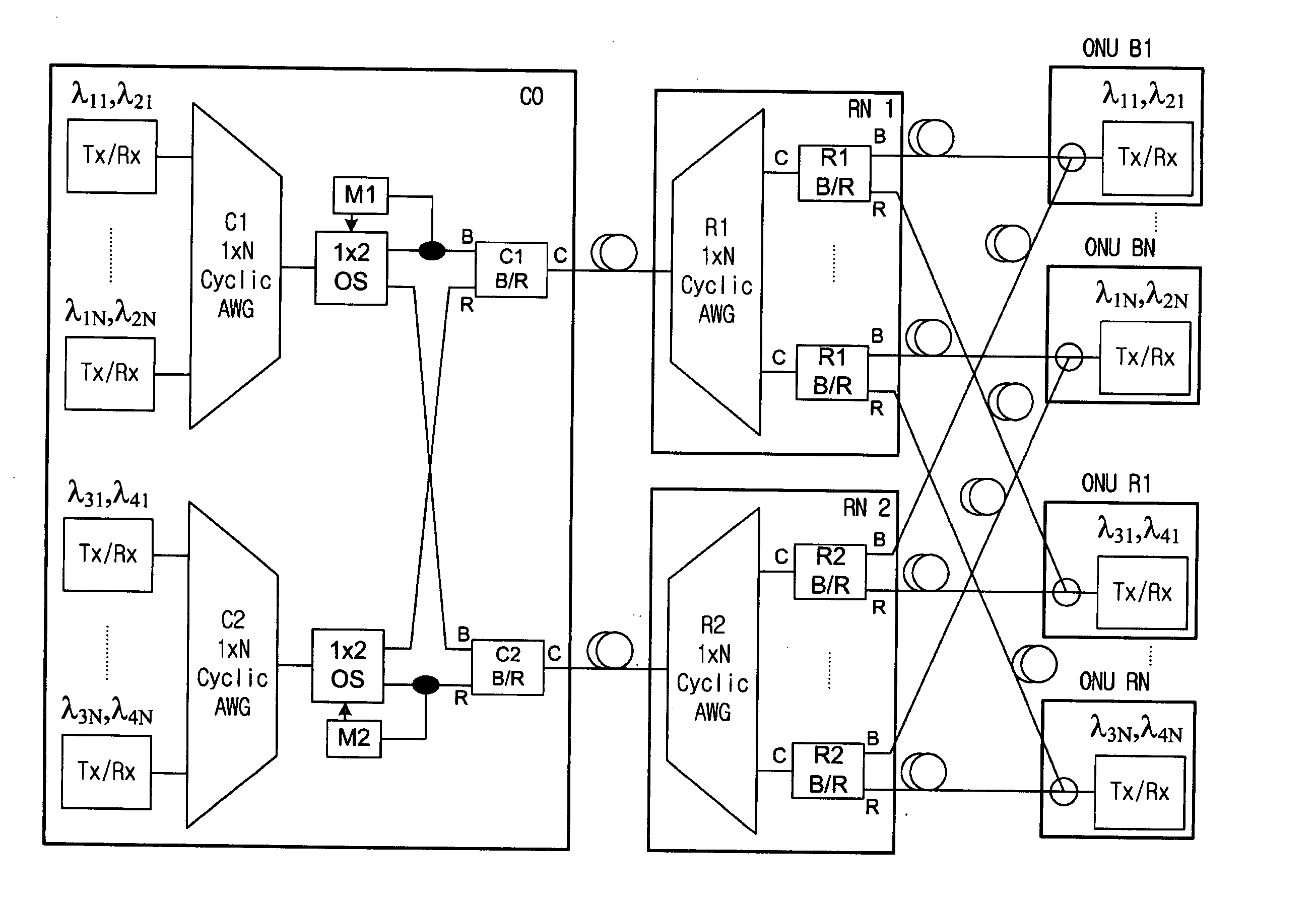

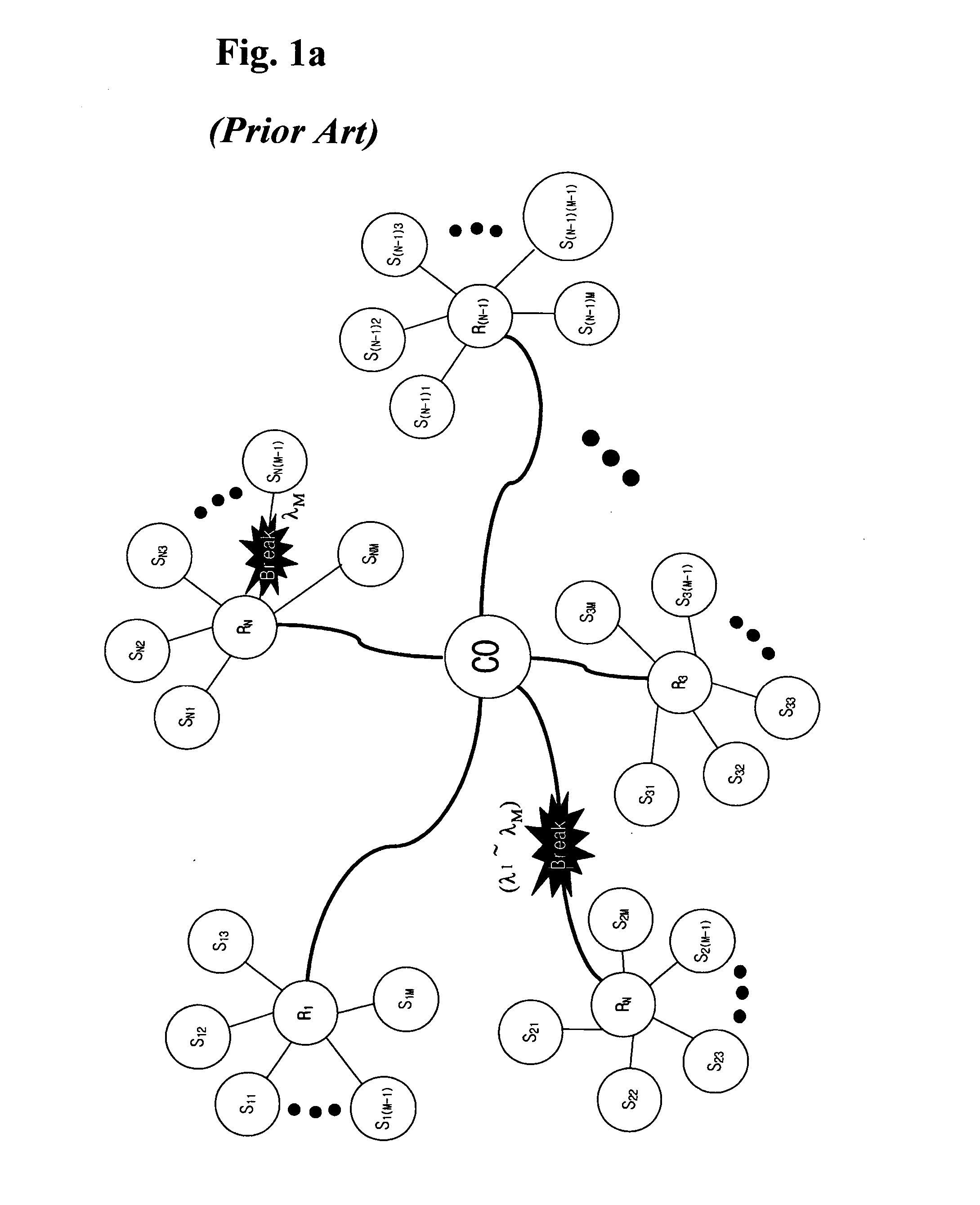

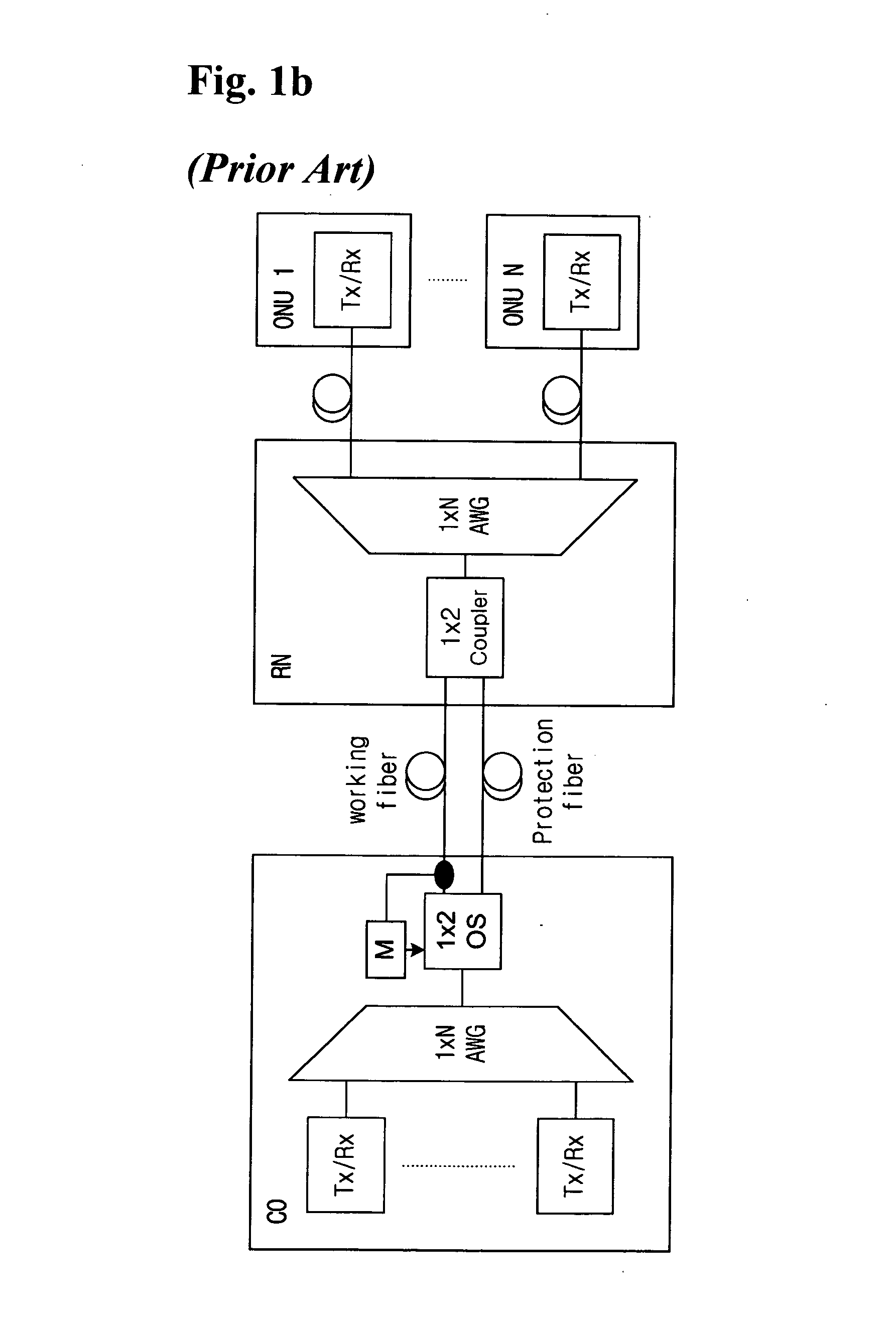

Communication recovering system for wavelength division multiplexed passive optical network

ActiveUS20060104638A1Enhance economical efficiencyMargin is maximizedLaser detailsOptical multiplexTransceiverNetwork structure

A communication recovering system for a wavelength division multiplexed passive optical network (WDM PON). The communication recovering system can recover fault of optical fibers between the central office and the remote nodes without additional optical fibers by grouping two remote nodes and employing an AWG having periodic transmission characteristics, and can also simply and rapidly recover such a fault with minimal optical loss using an AWG of 2×N structure and an On-Off optical switch, although protection optical fibers are additionally installed therein. The system can rapidly recover fault of optical fibers between a local office and optical network units, 1:N manner, using 2×2 optical switches, which are installed to each of the optical network units, a reserved transmitter and receiver, and a transceiver. The communication recovering system has advantages in that it can simplify network structure, be cost-effectively implemented, reduce optical loss, and rapidly perform protection of optical fiber fault.

Owner:KOREA ADVANCED INST OF SCI & TECH

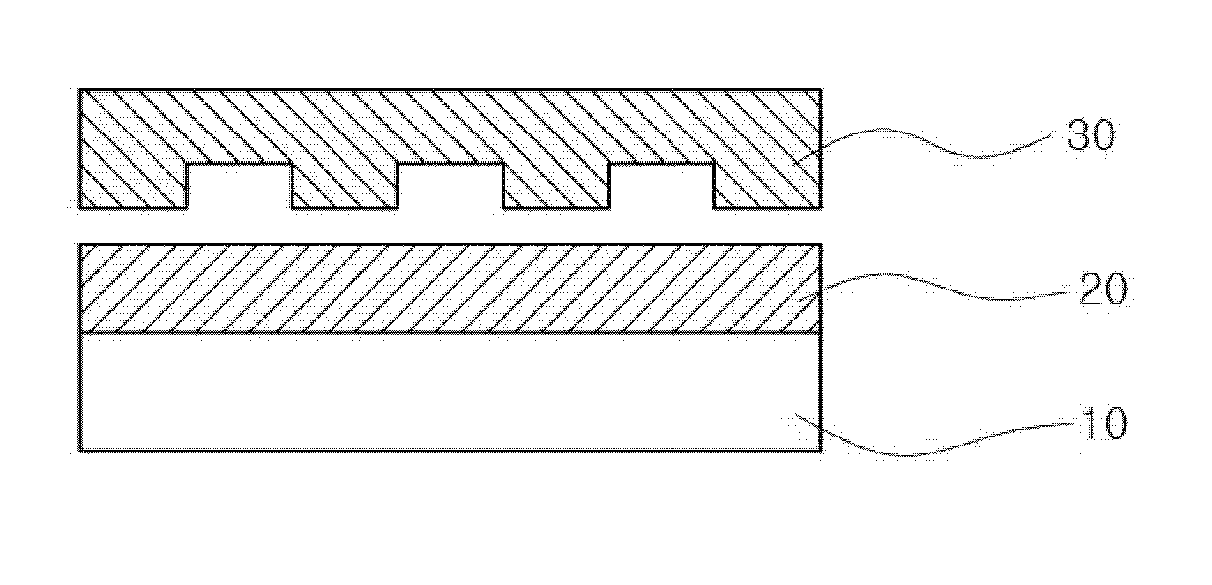

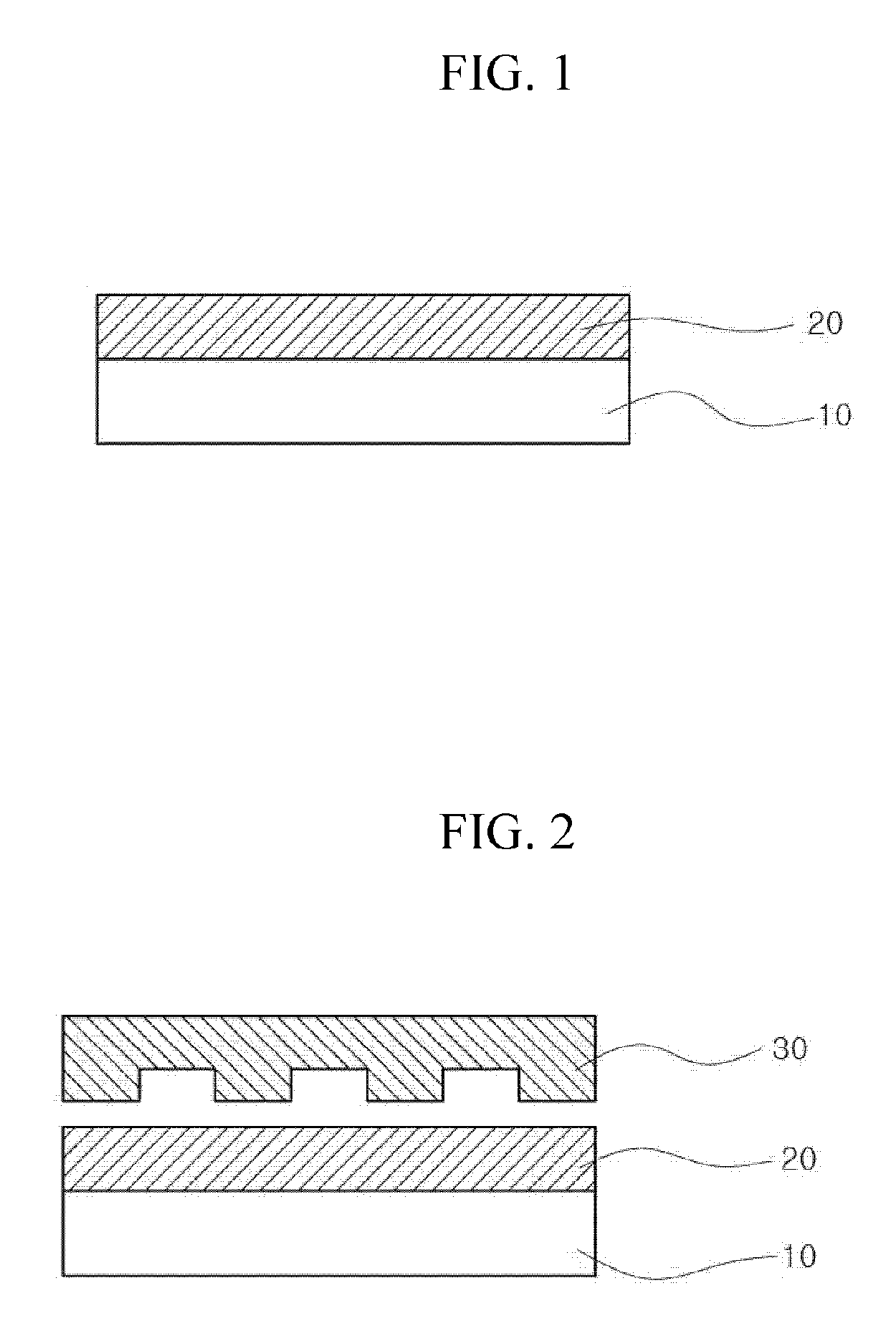

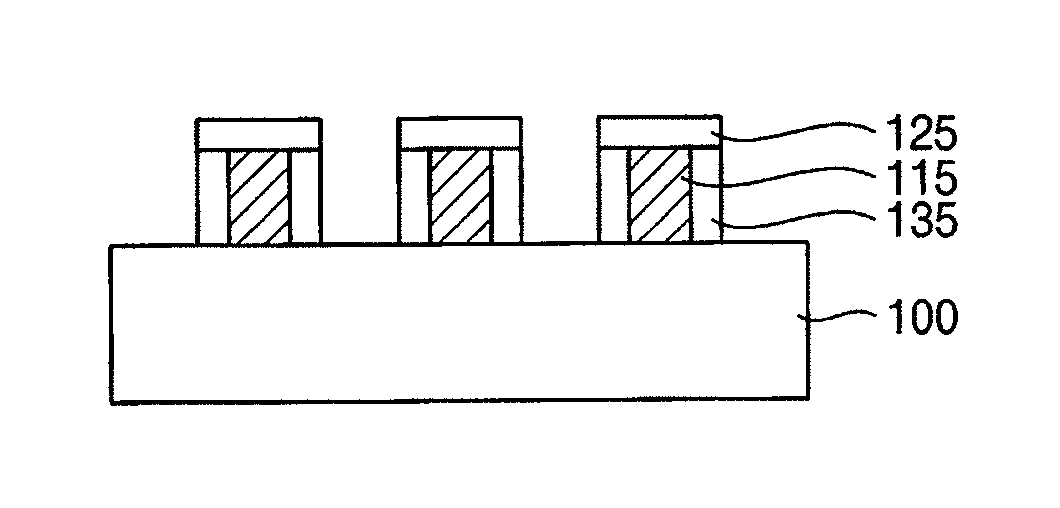

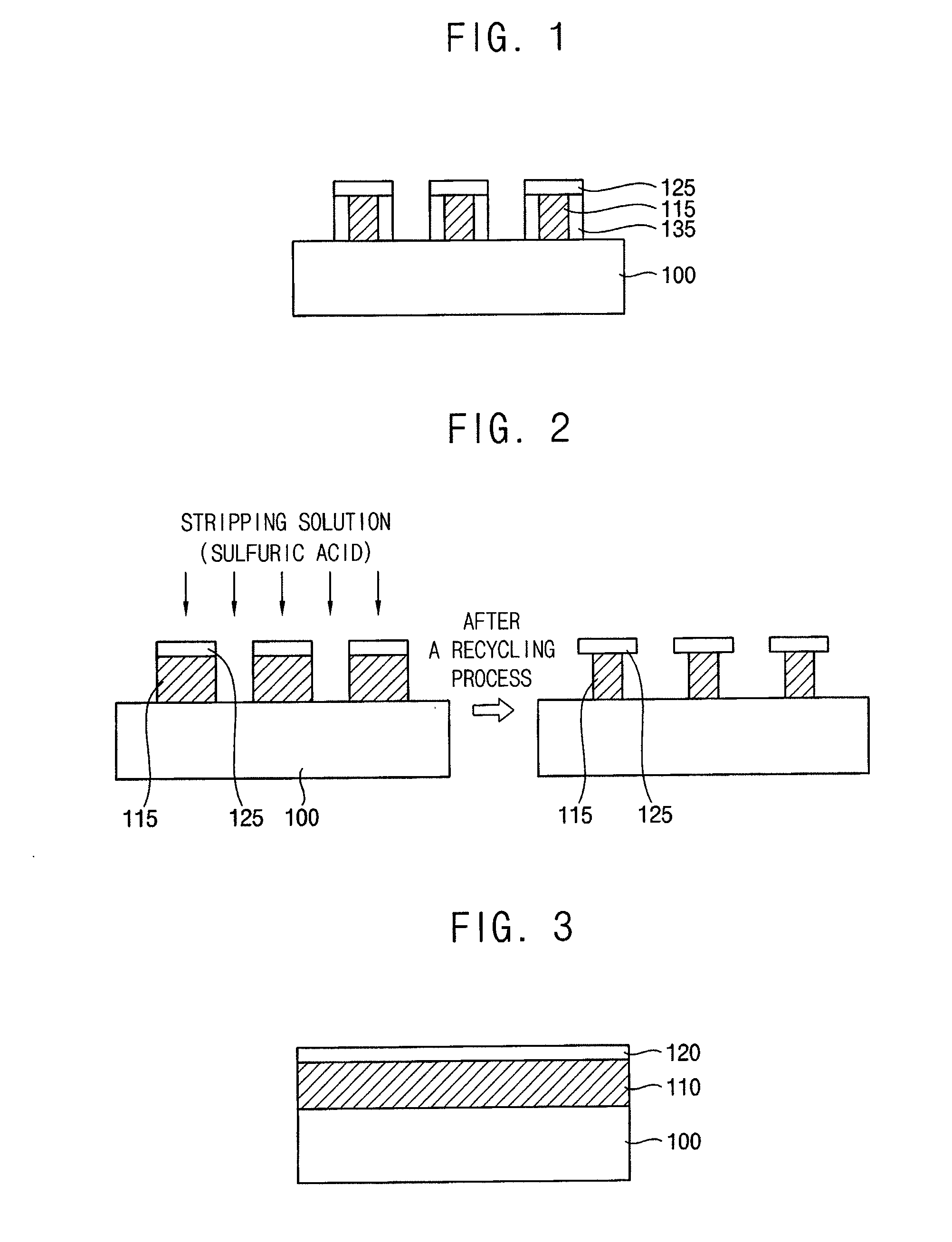

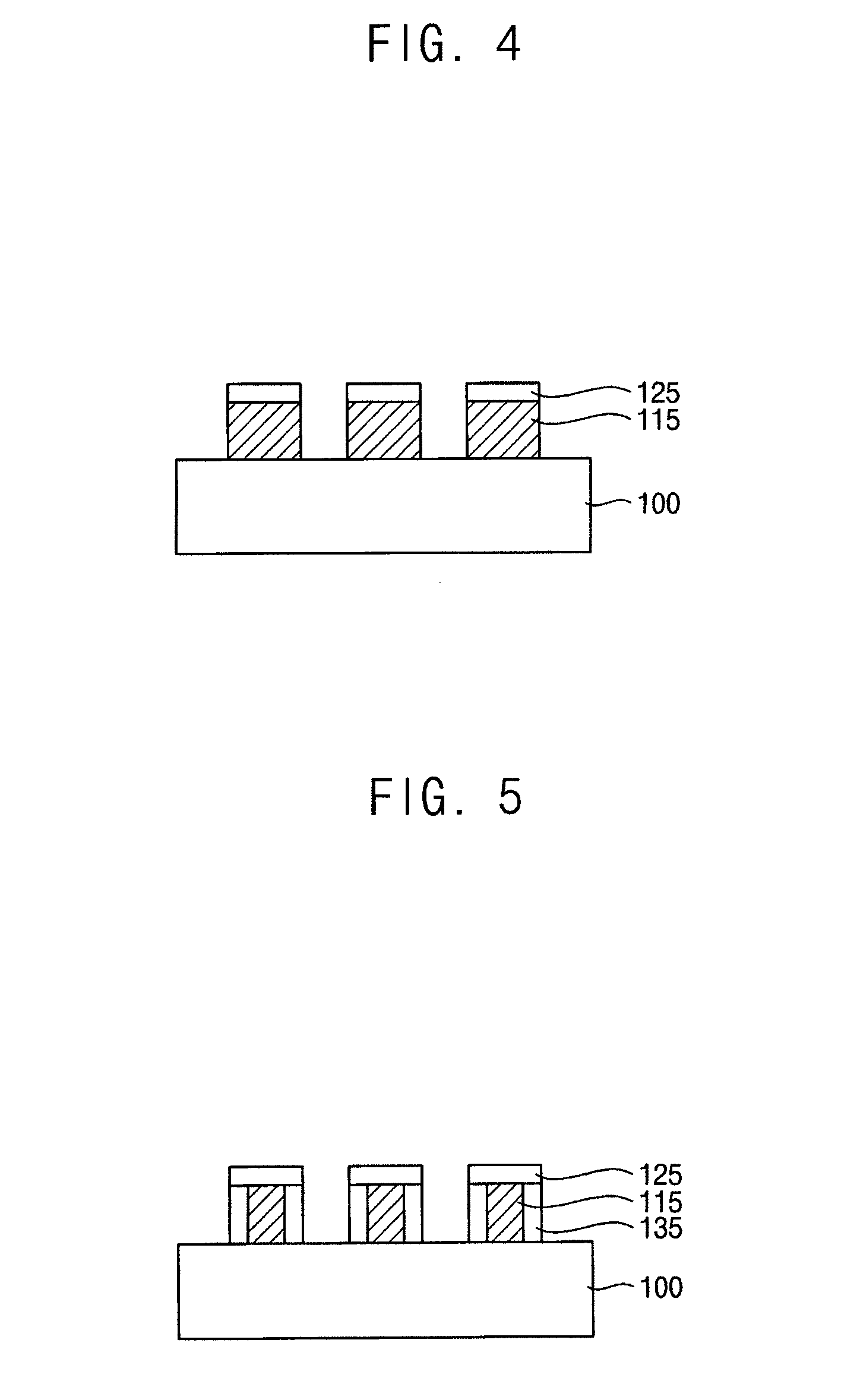

Method for forming nanostructure having high aspect ratio and method for forming nanopattern using the same

InactiveUS20080000871A1Simple and economical processHigh aspect ratioDecorative surface effectsIndividual molecule manipulationPolymer scienceCarbon nanotube

Provided is a method of forming a nanostructure having a nano-sized diameter and a high aspect ratio through a simple and economical process. To form the nanostructure, a polymer thin film is formed on a substrate and a mold is brought to contact the polymer thin film. Then, a polymer patterning is formed to contact the background surface of an engraved part of the mold, and then the polymer pattern is extended out by removing the mold out of the polymer thin film. The nanostructure forming method of the present research can reproduce diverse cilia optimized in the natural world. Also, it can be used to develop new materials with an ultra-hydrophobic property or a high adhesiveness. Further, it can be applied to a nanopattern forming process for miniaturizing electronic devices and to various ultra-precise industrial technologies together with carbon nanotube, which stands in the highlight recently.

Owner:SEOUL NAT UNIV R&DB FOUND

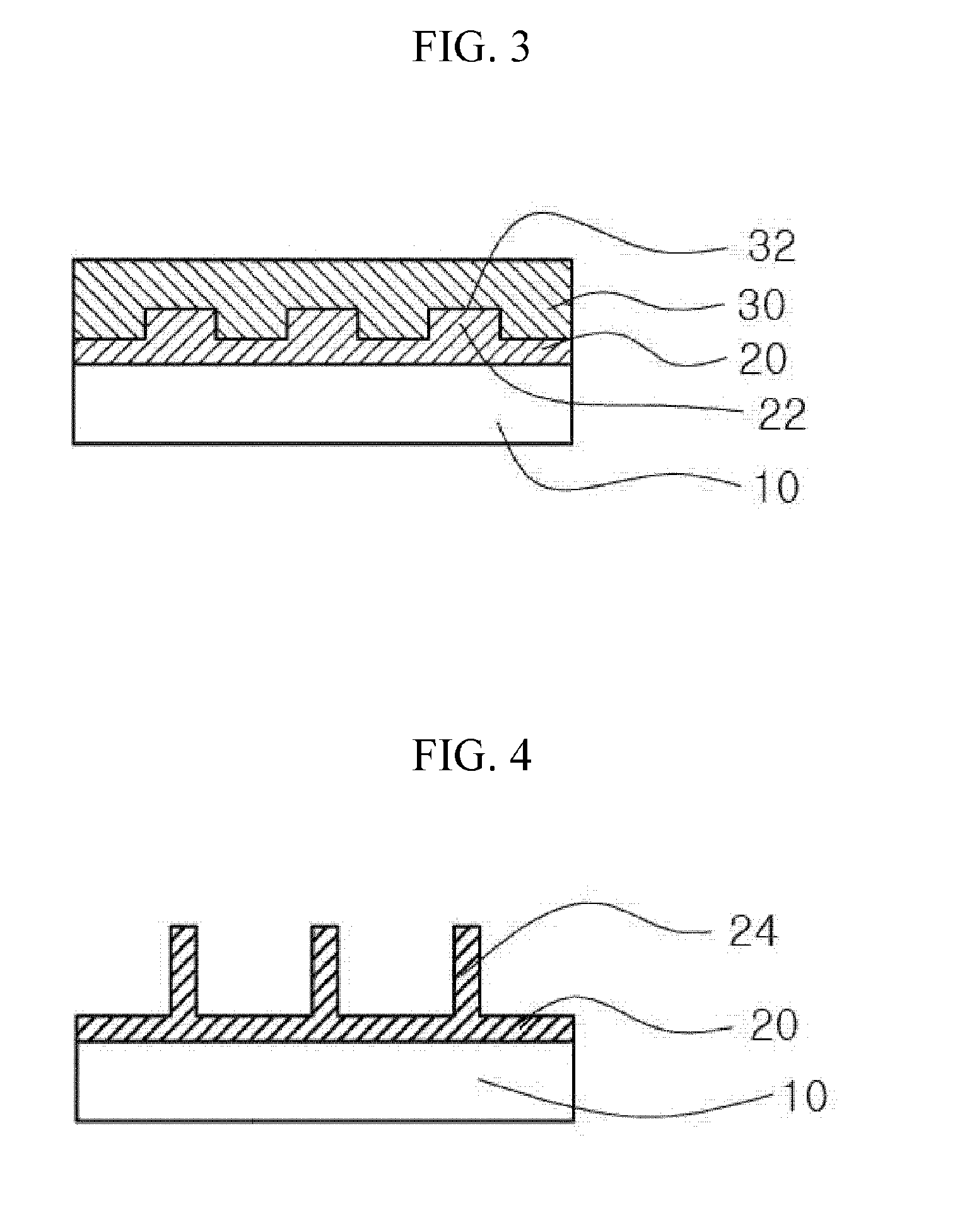

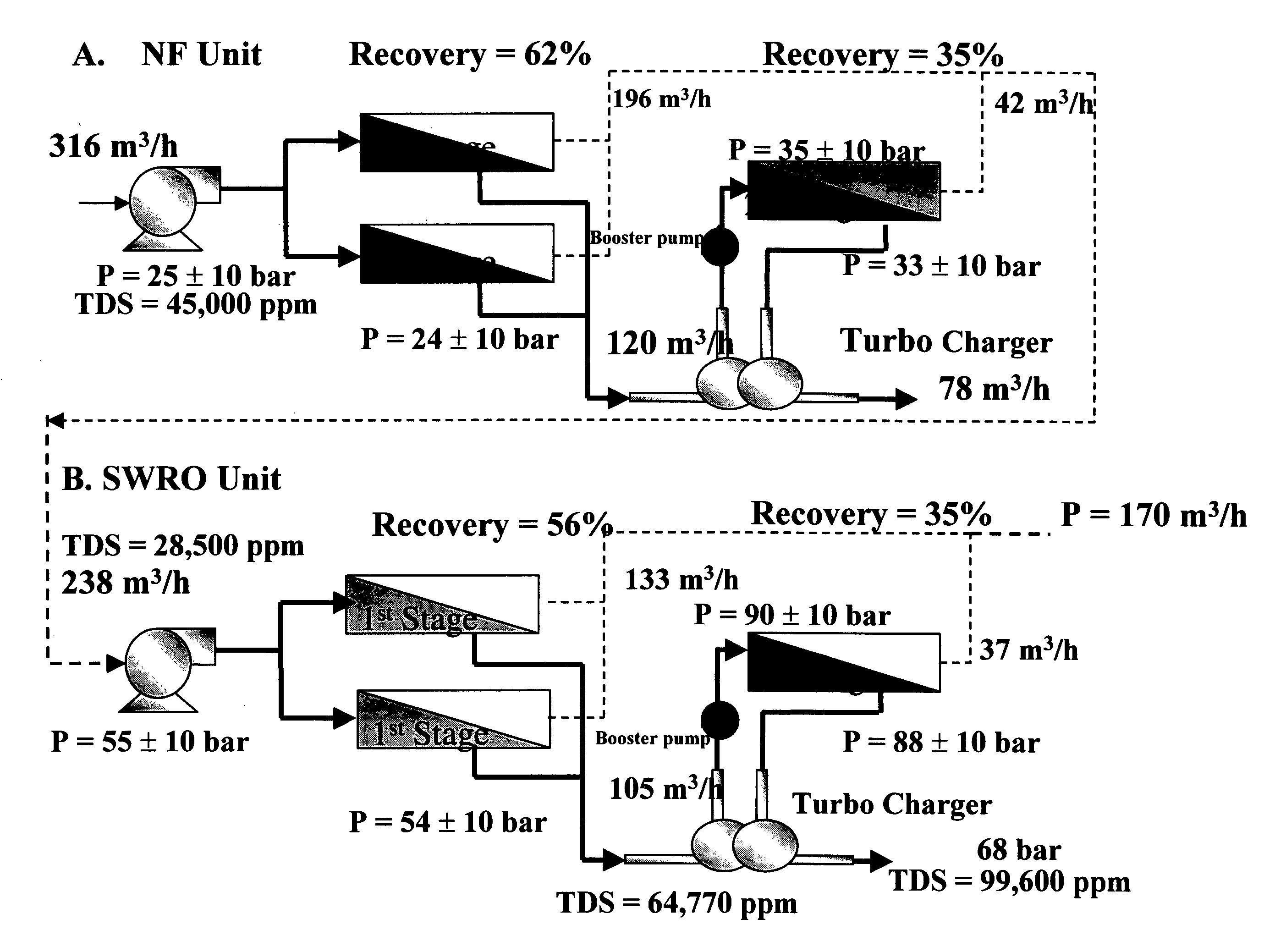

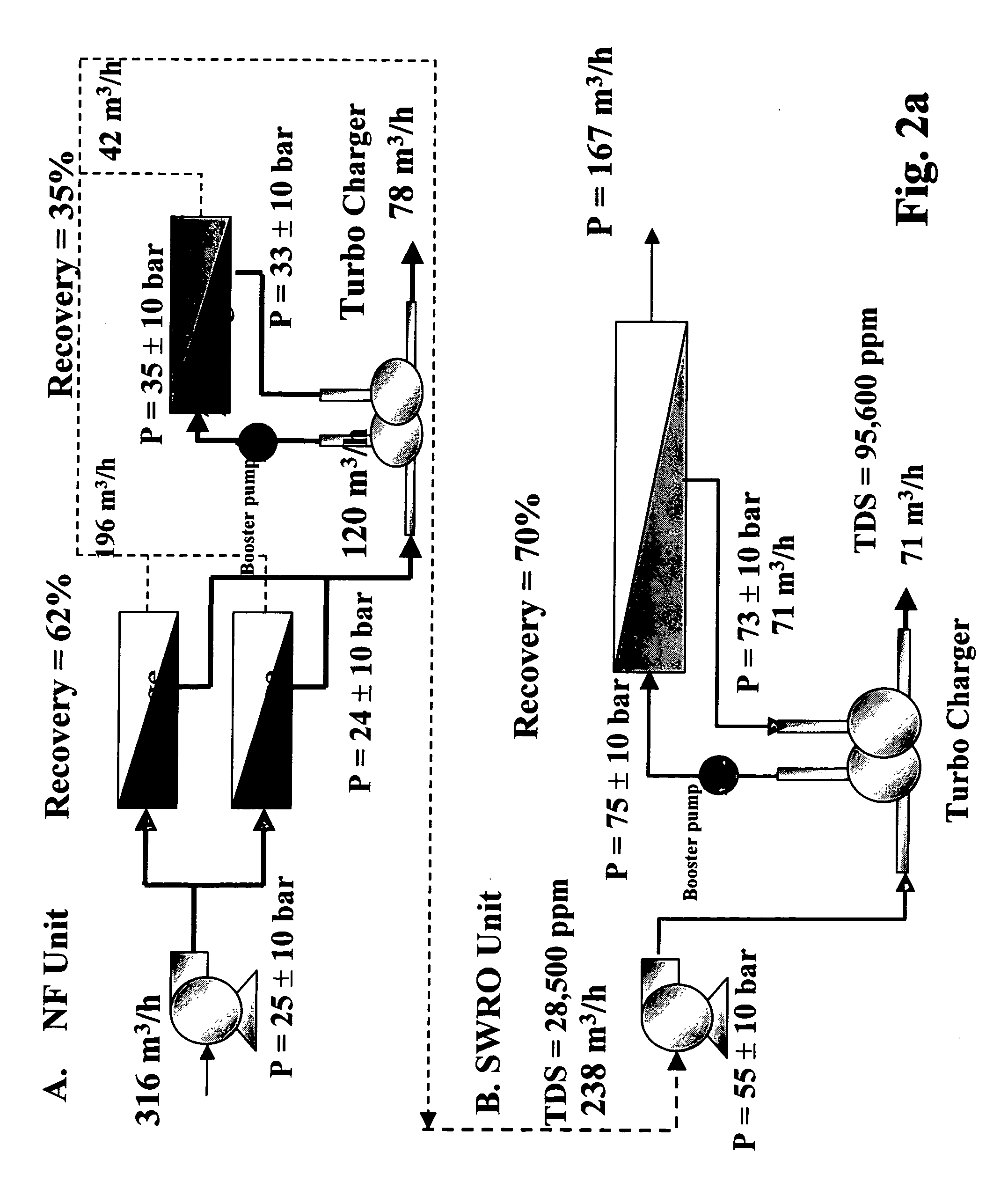

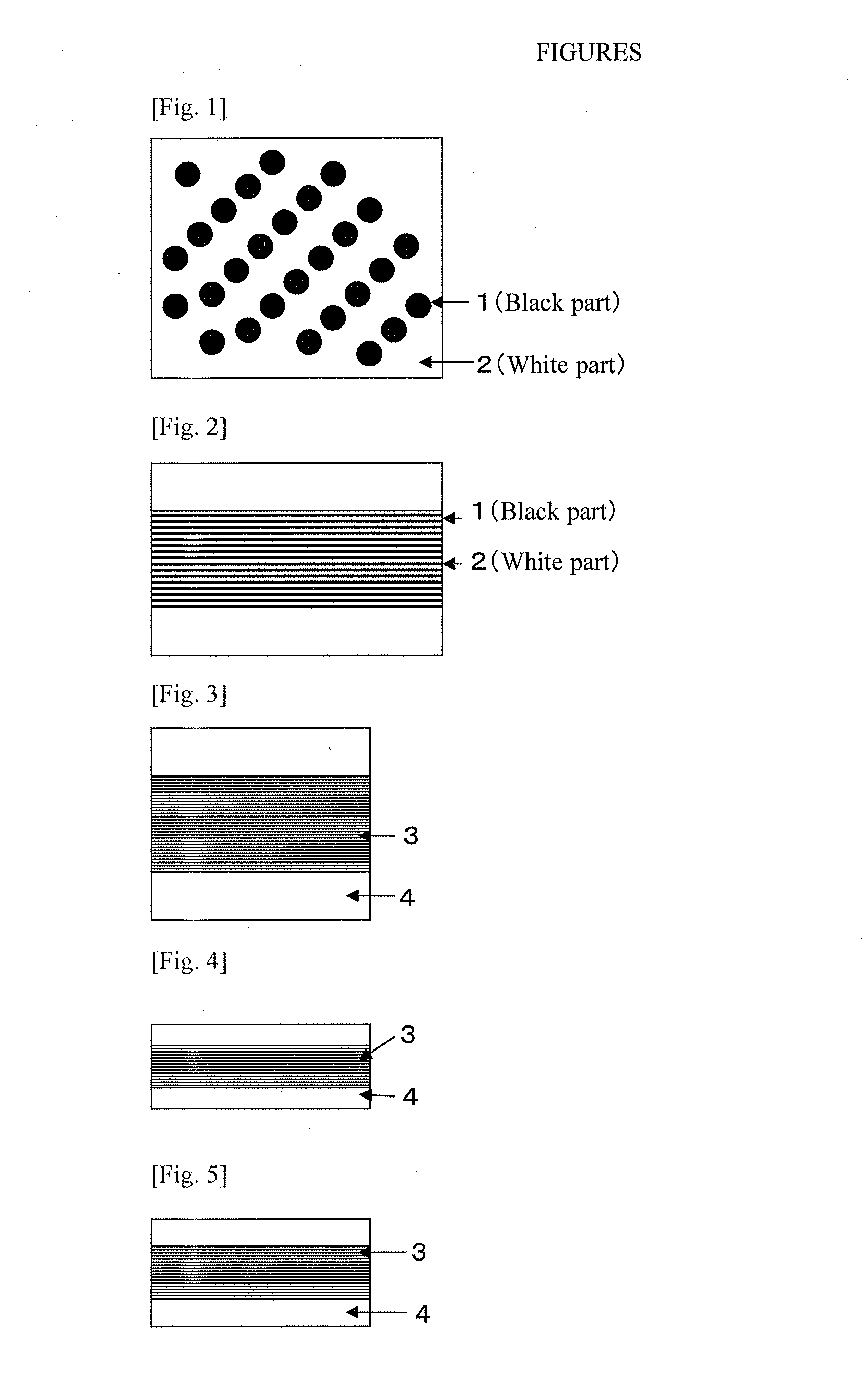

Fully integrated NF-thermal seawater desalination process and equipment

InactiveUS20060157410A1High yieldEffectively and efficiently dealGeneral water supply conservationReverse osmosisDistillationEngineering

An optimal thermal seawater desalination process is disclosed, which combines two or more substantially different water pretreatment processes in a unique manner and in a special configuration, hereto unknown to prior desalination arts, to produce a high yield of high quality fresh water, including potable water. In this process a two stage NF membrane pretreatment unit (NF2) with an energy recovery turbo charger (TC) device in between the stages or equipped with an energy recovery pressure exchanger (PX) is synergistically combined with at least one thermal desalination unit to form a dual hybrid of NF2-Thermal (FIG. 4 ), or alternatively the two stage NF2 unit is synergistically combined with a two stage SWRO unit (SWRO2) with an energy recovery TC in between the stages or combined with one stage SWRO (SWRO1) equipped with an energy recovery TC or PX system and the reject from the SWRO2 or SWRO1 unit is made make-up to a thermal unit to form a tri-hybrid of NF2-SWRO2 reject-Thermal (FIG. 5 ). In both the cases of di- or trihybrids the thermal unit is equivalent to a multistage flash distillation (MSFD) or multieffect distillation (MED) or vapor compression distillation (VCD) or thermal reheat (RH) evaporator. Typically a process of this invention using the two stage NF2 initial pretreatment step will perform a semi-desalination step by reducing feed TDS by about 35 to 50%, but most important, especially to the thermal seawater desalination process, it removes the water recovery limiting, scale forming hardness ions of Ca++ and Mg++ by better than 80% and their covalent anions of sulfate to better than 95% and bicarbonate to about 65%. The removal of scale forming hardness ions, especially SO4=, and bicarbonates allowed for the operation of thermal unit in the above hybrids at top brine temperature (TBT) much greater than its present TBT limit by the singular conventional process of 120° C. for MSFD and operation of MED or VCD or RH unit at TBT much higher than their present TBT limit of 65-70° C., with many advantages gained by this process over prior art sweater desalination processes. The process of this invention exceeds all prior thermal seawater desalination arts in efficiency, including water yield, product water recovery ratio and unit water cost as well as in energy consumption per unit product which is equivalent or less than other efficient prior art seawater thermal desalination processes. By this process, an NF product recovery ratio of 75 and 80% or better is achieved from the high salinity Gulf sea (TDS≈45,000 ppm) and about an equal product recovery ratio is also obtained from the SWRO or thermal unit when it is operated on NF product for a total water recovery ratio in excess of 52% for seawater

Owner:SALINE WATER CONVERSION CORP SWCC

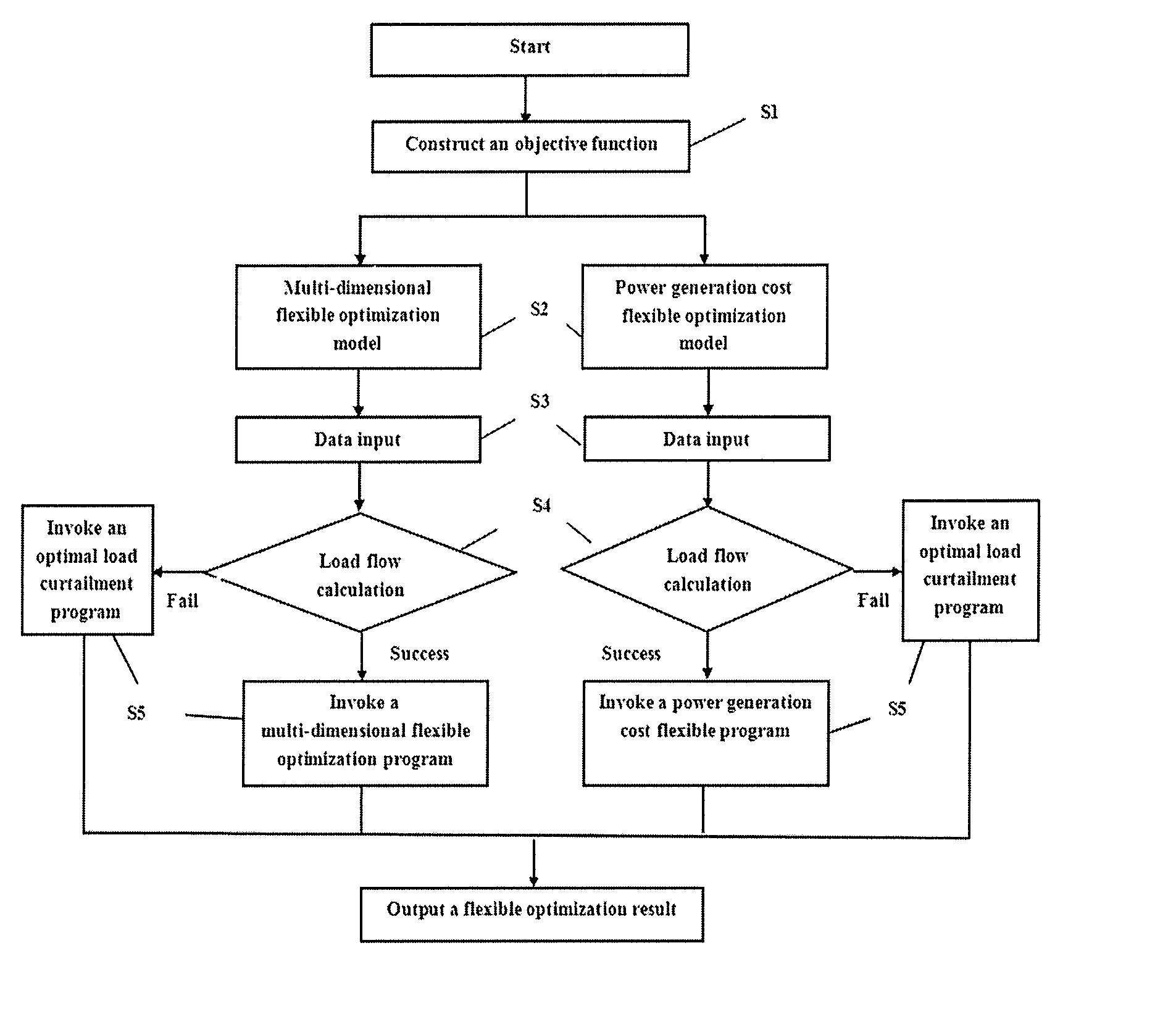

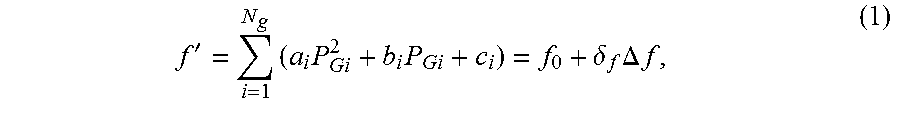

Method for optimizing the flexible constraints of an electric power system

ActiveUS20150355655A1Economical efficiencyImprove safety and reliabilityMechanical power/torque controlLevel controlTraffic volumeDynamo

A method for optimizing the flexible constraints of an electric power system includes a step S1 of expressing the total power generation cost of the electric power system by using the sum of quadratic functions of active power outputs of all generator sets in the system and constructing an objective function, a step S2 of selecting a multi-dimensional flexible optimization model or a flexible power generation cost optimization model according to the practical situation of the electric power system and the practical purpose of optimization, a step S3 of determining the operating conditions of the electric power system, and a step S4 of carrying out load flow calculation.

Owner:SHANGHAI JIAO TONG UNIV

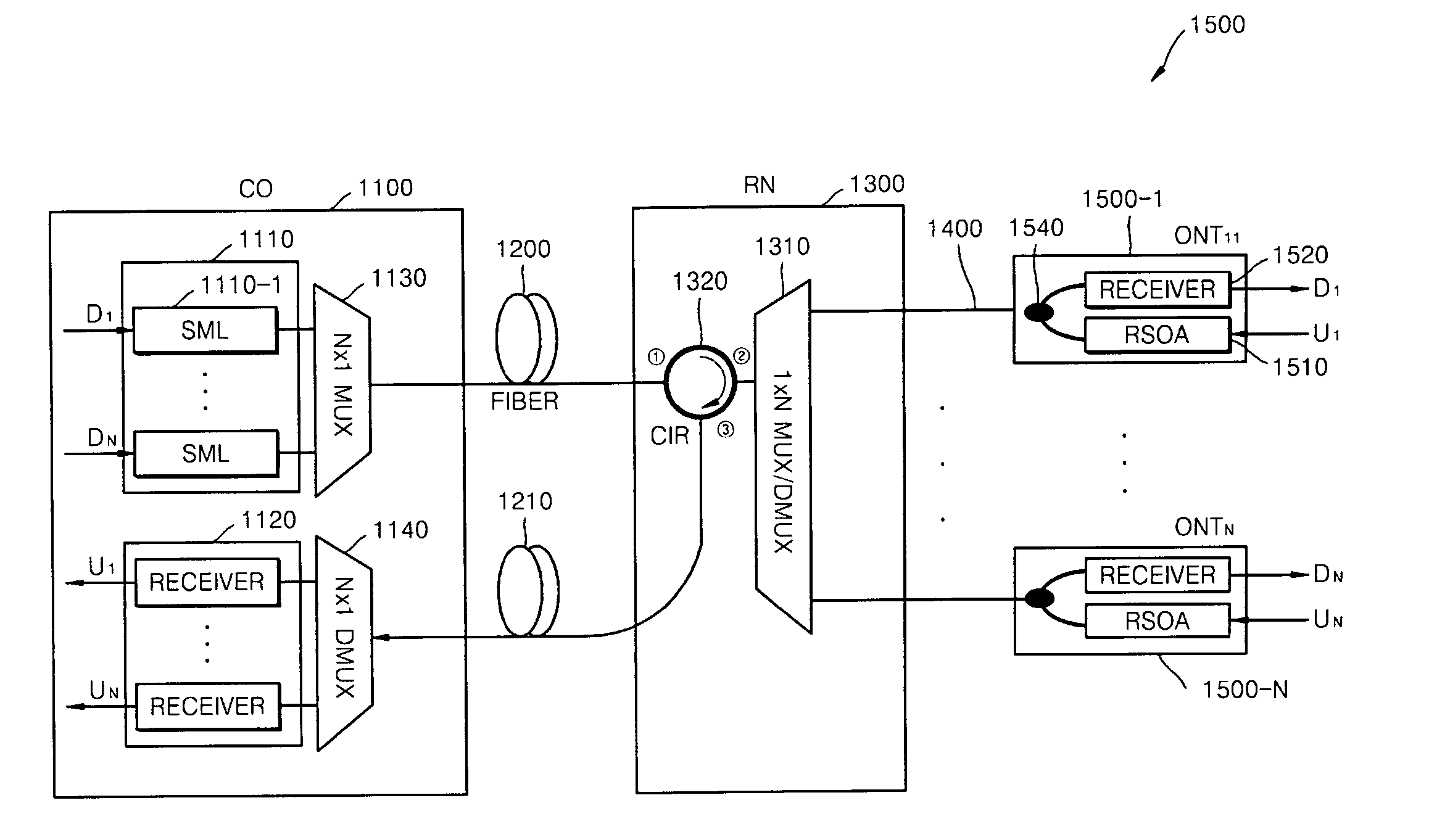

Reflective semiconductor optical amplifier (RSOA), RSOA module having the same, and passive optical network using the same

InactiveUS20070133990A1Reduce light lossImproving polarization dependencyLaser detailsLaser active region structureAudio power amplifierOptical power

A Reflective Semiconductor Optical Amplifier (RSOA) for compensating for light loss in an optical link, an RSOA module for improving polarization dependency using the RSOA, and a Passive Optical Network (PON) for increasing economical efficiency and practical use of a bandwidth using the RSOA are provided. The PON includes a central office comprising a plurality of optic sources transmitting a downstream signal and a plurality of first receivers receiving an upstream signal; at least one optical network terminal (ONT) including a second receiver receiving the downstream signal and an RSOA which receives the downstream signal, remodulates the downstream signal into the upstream signal, and transmits the upstream signal in loopback mode; and a remote node interfacing the central office with the ONT. The upstream signal and the downstream signal are transmitted between the remote node and the ONT via a single optical fiber. The remote node includes an optical power splitter at its port connected to the ONT.

Owner:ELECTRONICS & TELECOMM RES INST

Process of hydrotreating heavy hydrocarbon oil

ActiveUS7651605B2Increase deactivation rateImprove throughputCoke ovensHydrocarbon distillationReaction temperatureHeavy crude oil

When a heavy fuel oil with a sulfur content of 1 percent by mass or lower is produced from a feedstock consisting of a heavy hydrocarbon oil derived from a heavy crude oil having an API degree of 30 or less and containing sulfur and metal components in amounts larger than those of ordinary crude oil, the conventional processes requires higher reaction temperature and was accompanied with a remarkably enhanced deactivation rate of the catalyst which results in a remarkable shortened lifetime thereof. Therefore, it is regarded as substantially impossible to treat the feedstock. However, the present invention makes it possible to produce a low sulfur heavy fuel oil with a sulfur content of 1 percent by mass or less by hydrotreating a mix oil of 100 parts by volume of a heavy hydrocarbon oil derived from a heavy crude oil with an API degree of 30 or less and 30 to 1000 parts by volume of a heavy hydrocarbon oil derived from a light crude oil with an API degree of 35 or greater, without lowering the degree of demetallization while retarding the deactivation rate of the catalyst.

Owner:NIPPON OIL CORP

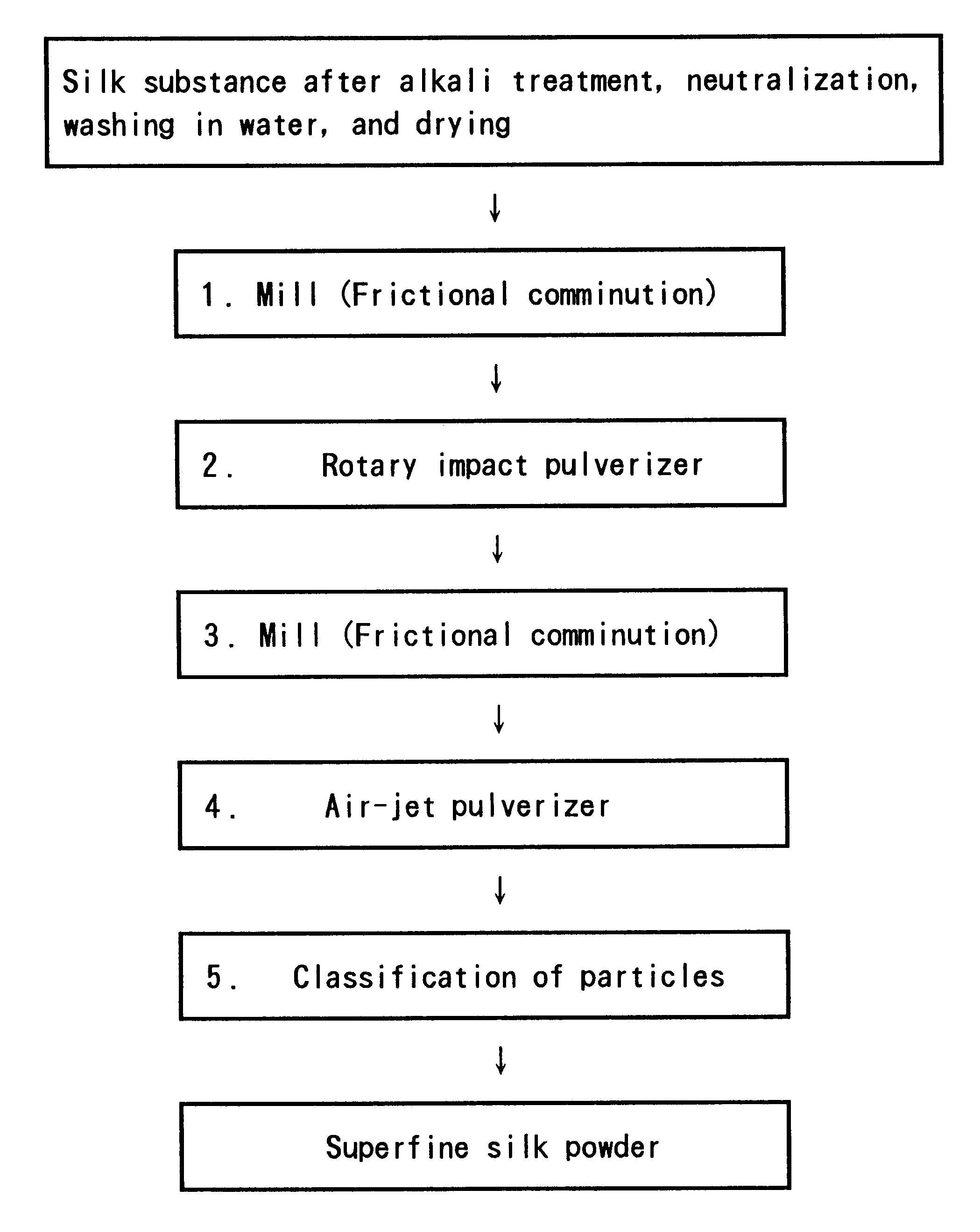

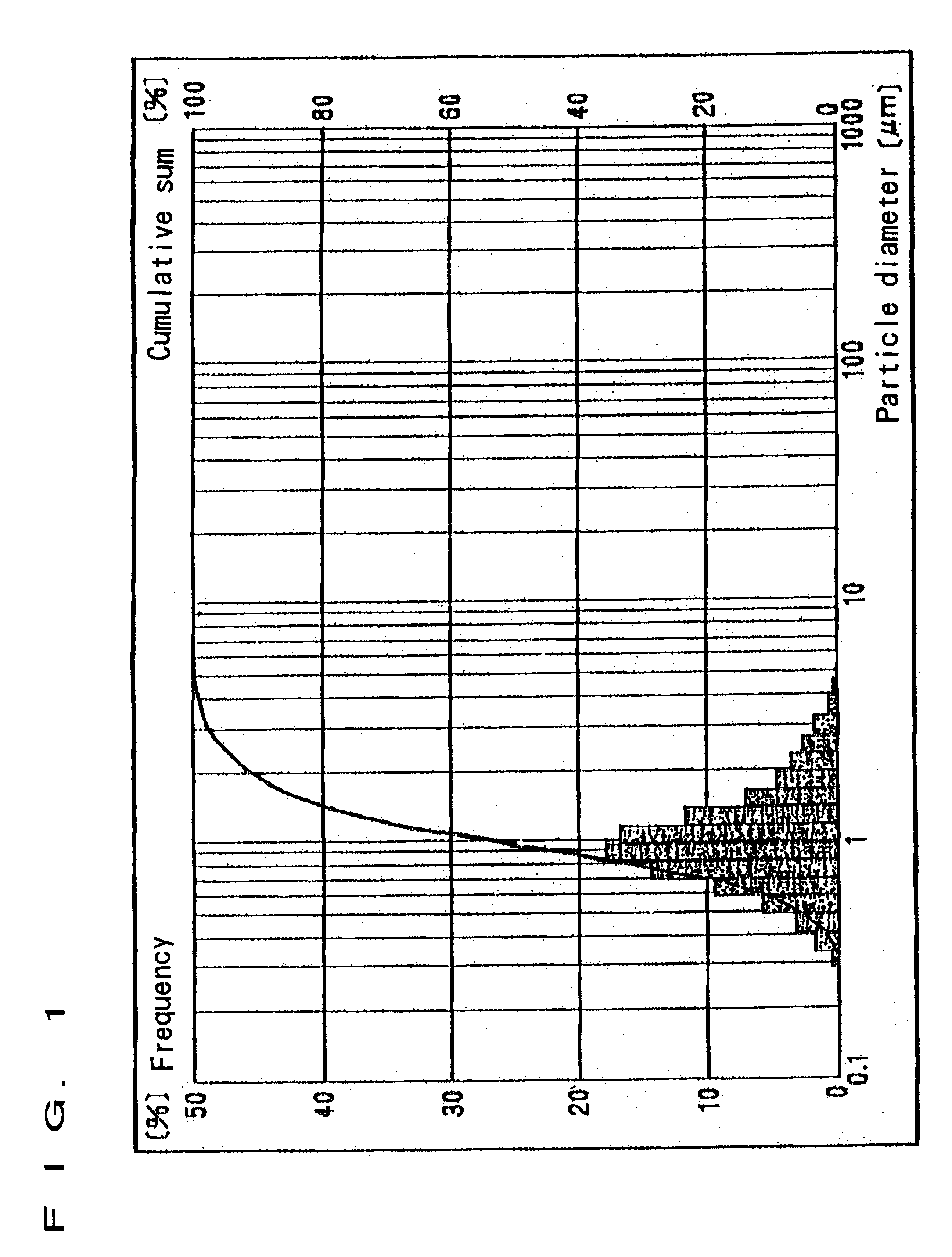

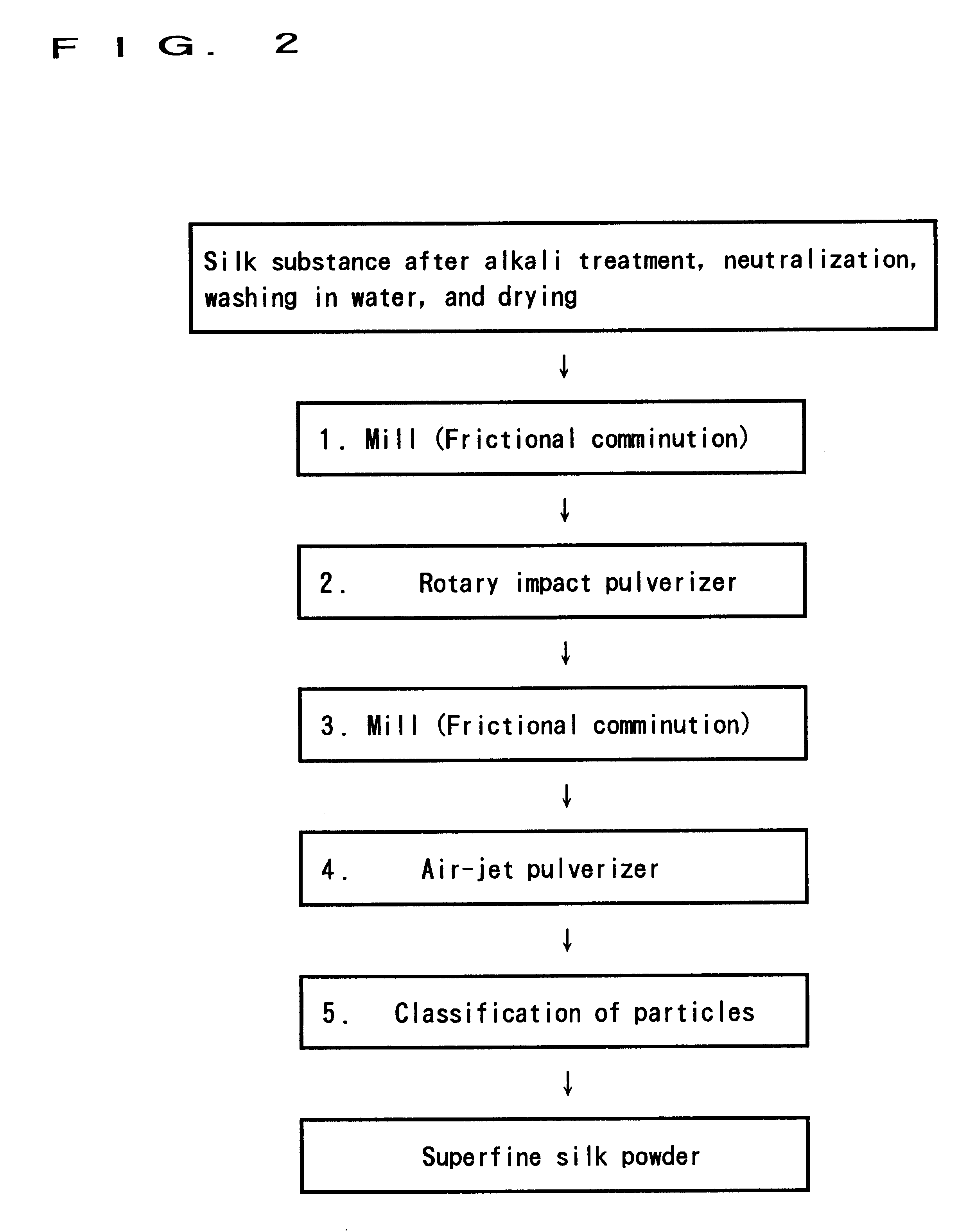

Method for manufacturing crystalline superfine silk powder

The main theme of the invention is to provide a method for manufacturing industrially, by mechanically comminuting silk yarn, crystalline silk fibroin powder below 3 mum in an average particle diameter, which can be used for various applications. A silk substance such as cocoon filament, silk yarn, or raw silk is brought into an alkali aqueous solution under a pressure of 1 through 5 atmospheric pressure at temperatures from 100° C. through 150° C. to reduce the tensile strength of the silk substance to around 0.02 g / d or less. Thereafter, the resultant silk substance is subjected to dealkalization and drying. Subsequently, the resultant dried silk substance is comminuted into powder below 3 mum in an average particle diameter. Thus, the crystalline silk fibroin powder below 3 mum in an average particle diameter is manufactured.

Owner:JAPAN AS REPRESENTED BY DIRECTOR GENERAL OF NAT INST OF SERICULTURAL & ENTOMOLIGICAL SCI MINIST OF AGRI FORESTRY & FISHERIES +1

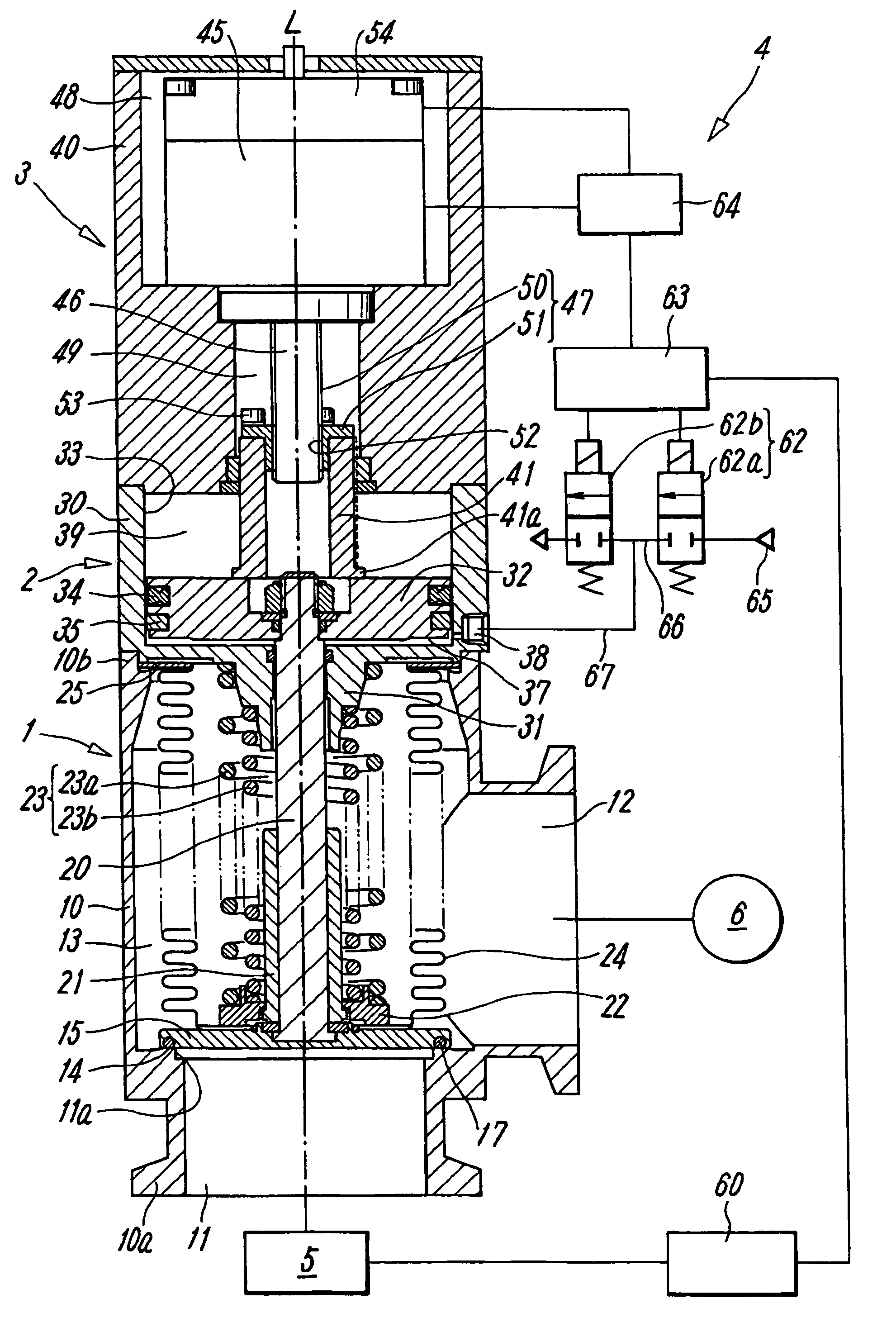

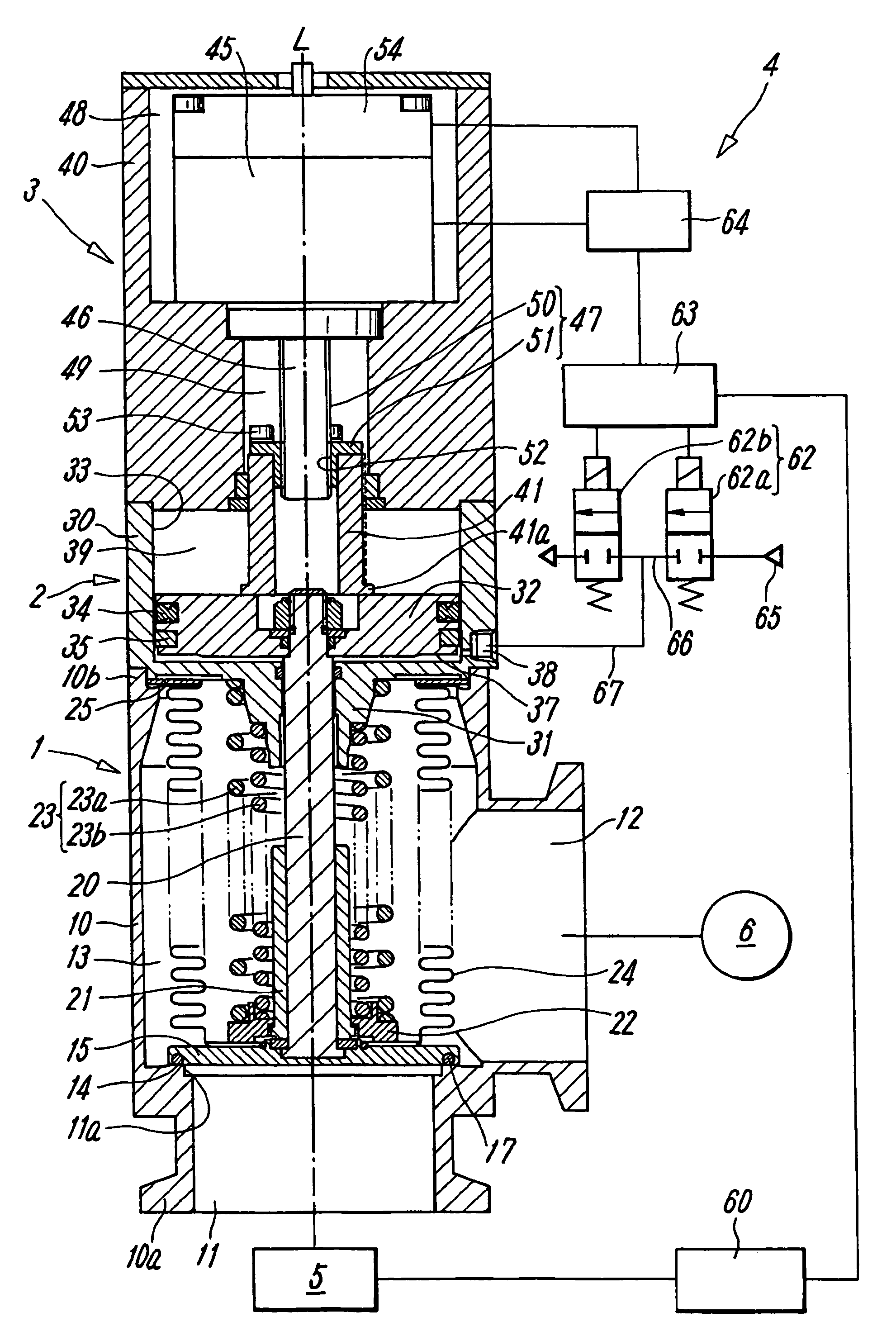

Vacuum regulating valve

ActiveUS7117886B2Quickly and accurately regulatedHighly controllableOperating means/releasing devices for valvesFluid pressure control using electric meansMotor controllerControllability

A vacuum regulating valve has high controllability, wherein the opening of a valving member can be quickly and accurately controlled by using a small and inexpensive electric motor. In accordance with a signal indicative of a pressure set value and a pressure signal from the pressure sensor, the main controller in the valve control section outputs a signal for setting the opening of the valving member to a motor controller that controls the electric motor, and performs control to cause a pilot fluid to be supplied to a pressure receiving chamber of the piston, thereby causing the piston to move to the position of abutment with the stopper.

Owner:SMC CORP

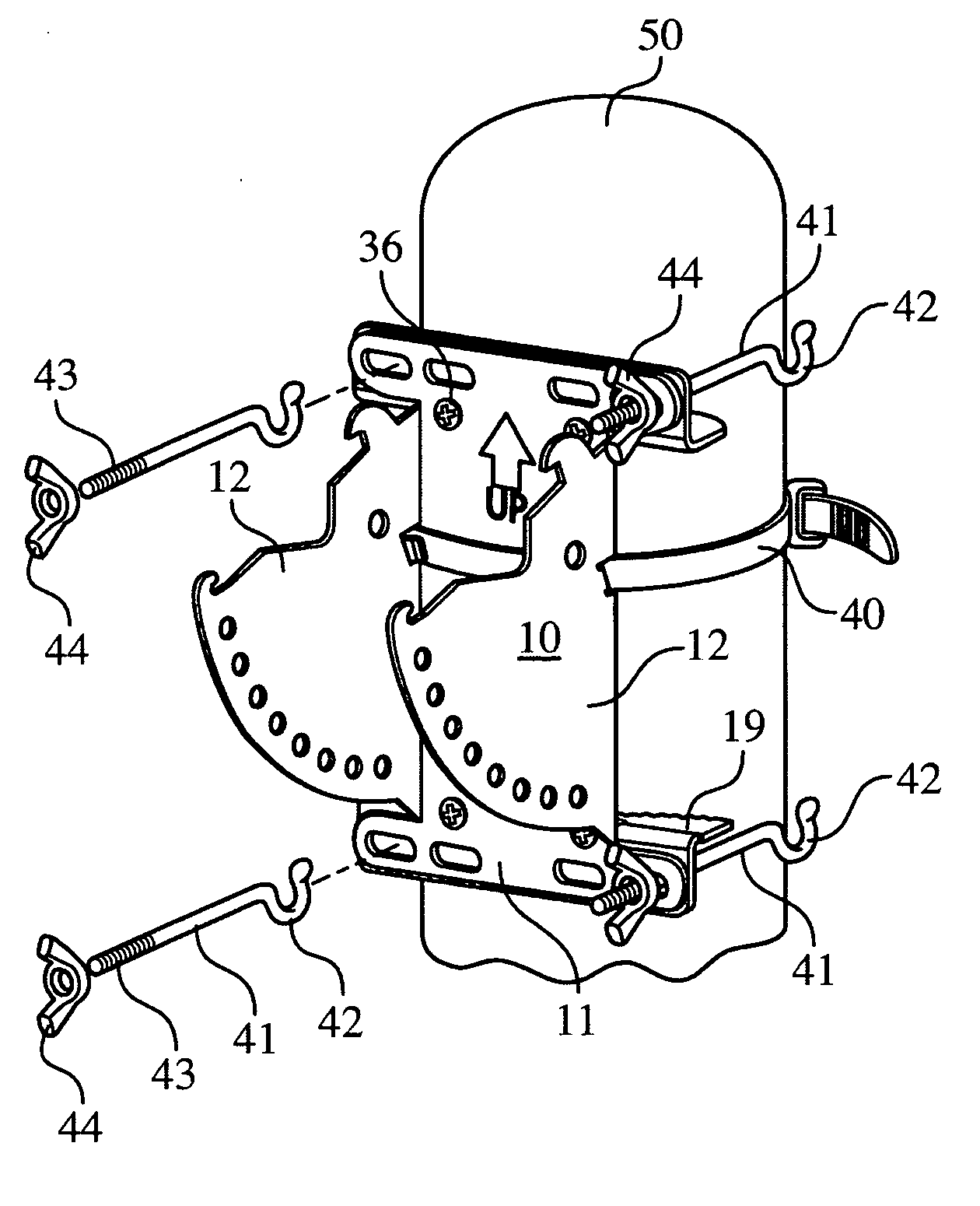

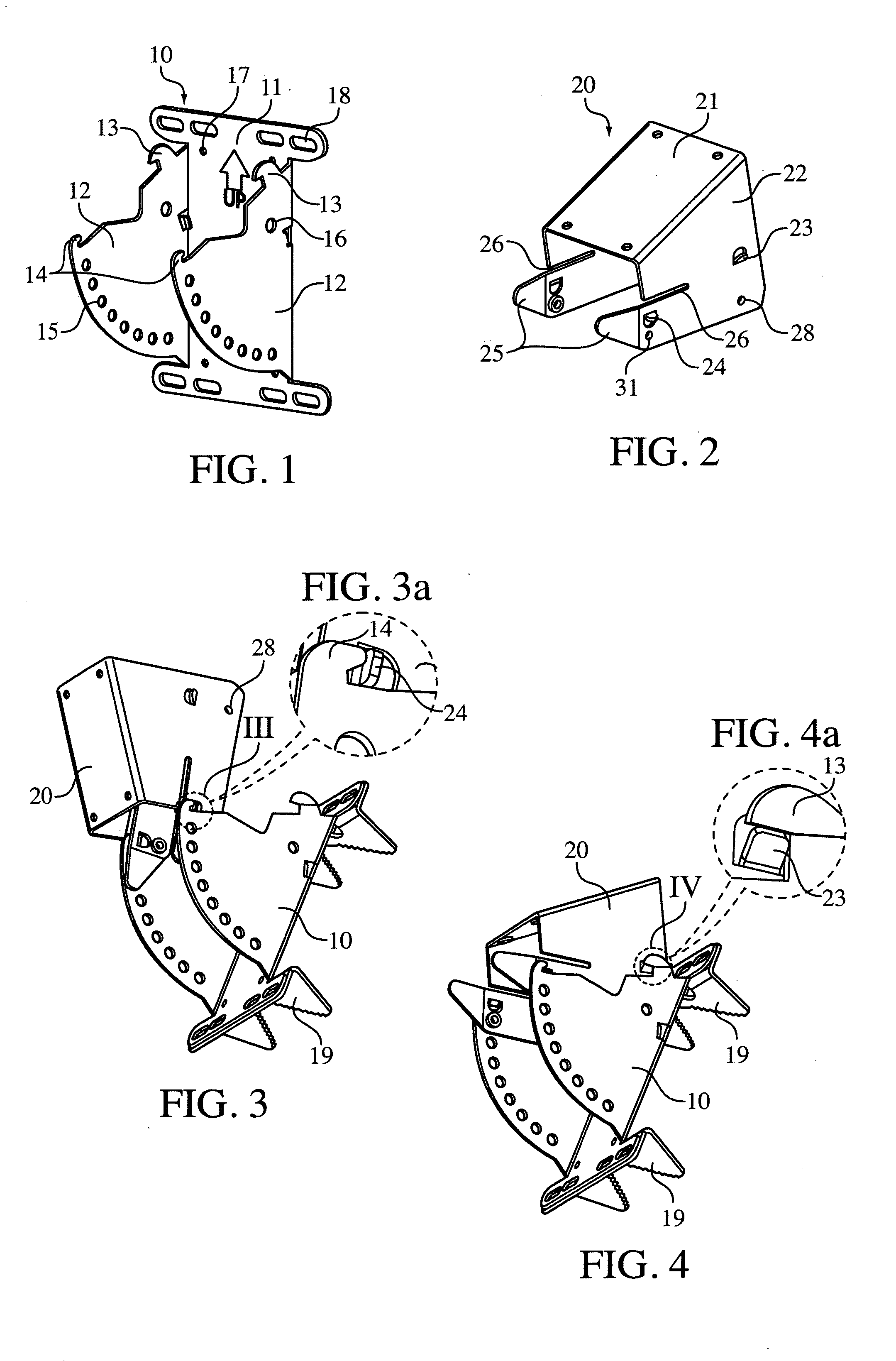

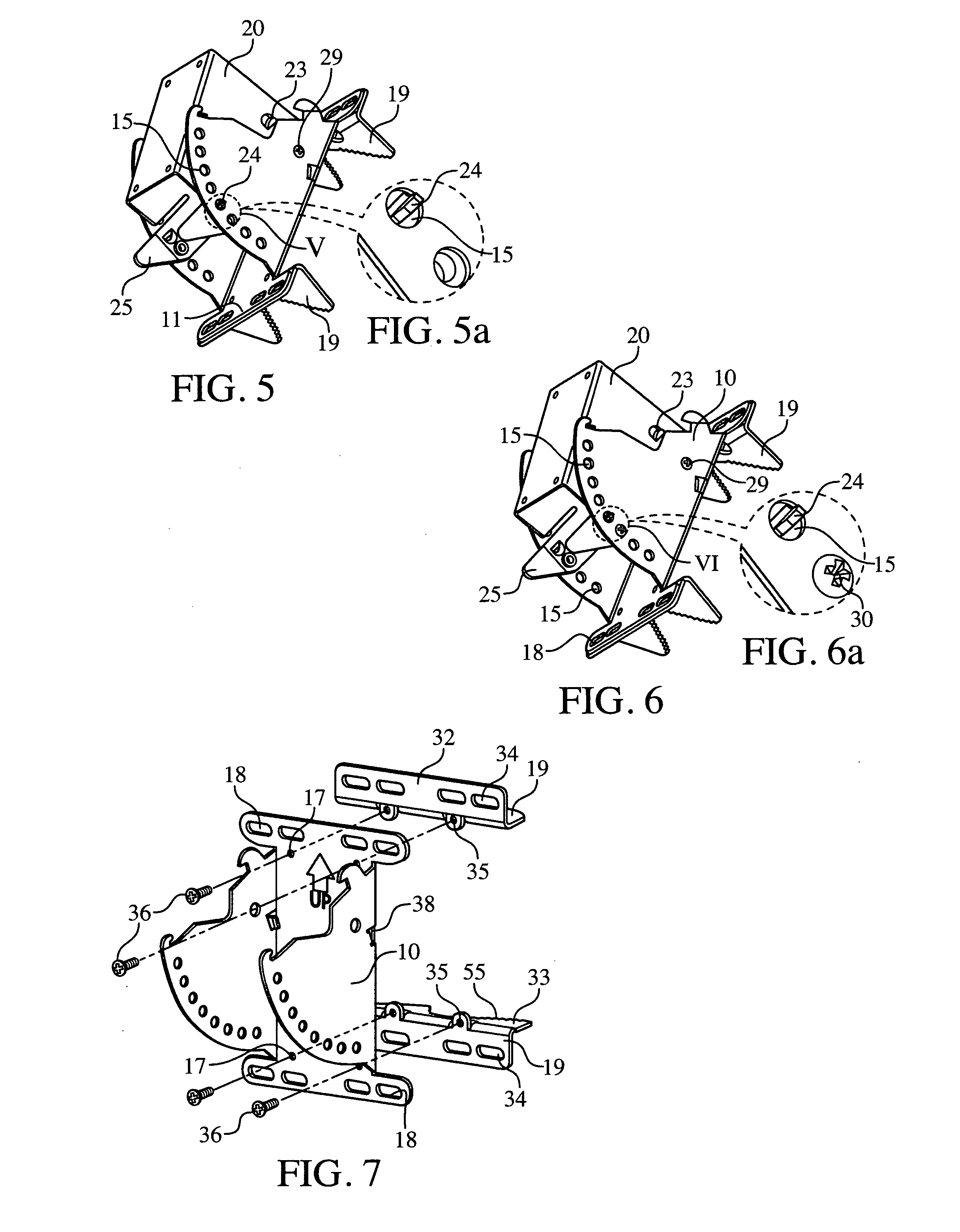

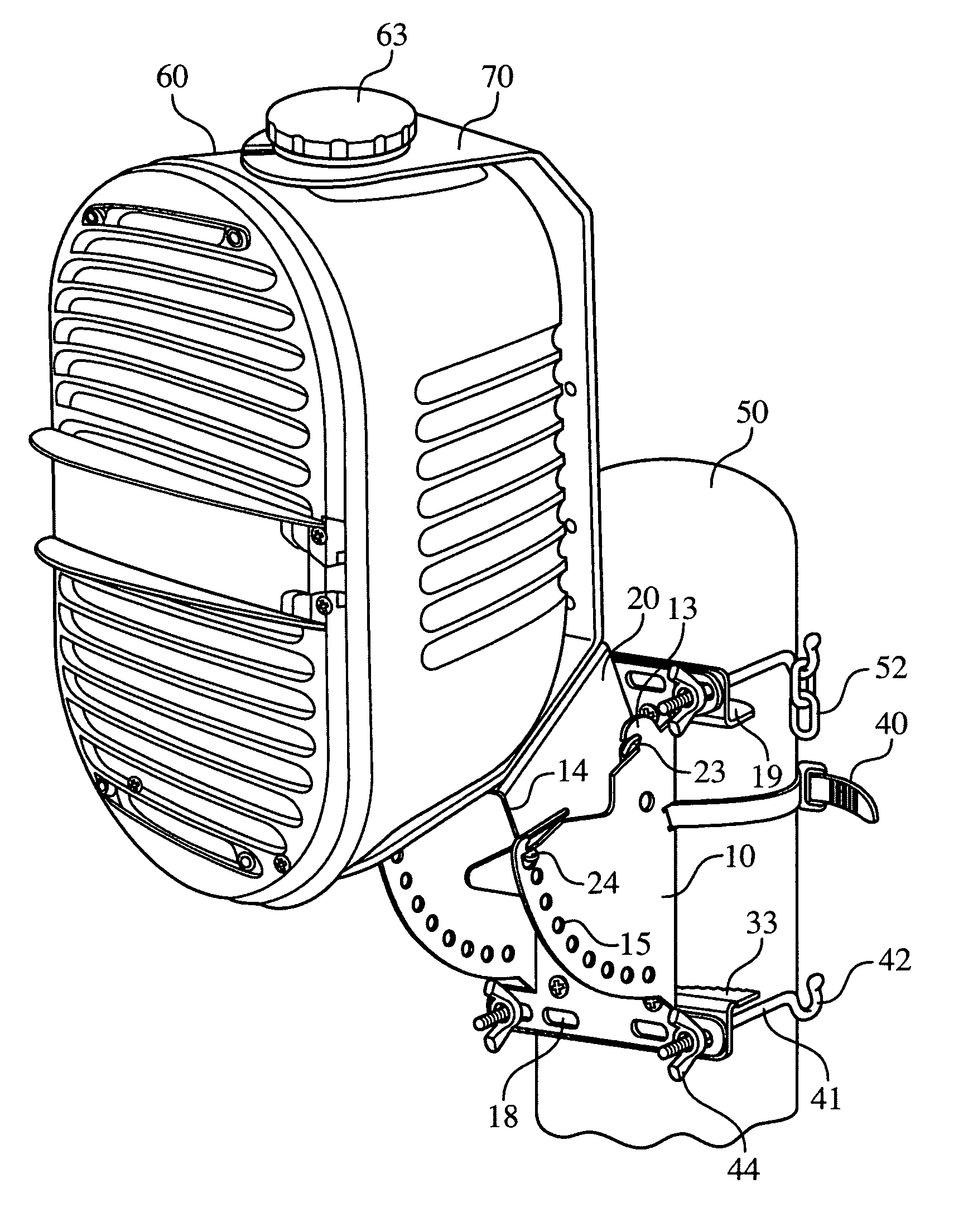

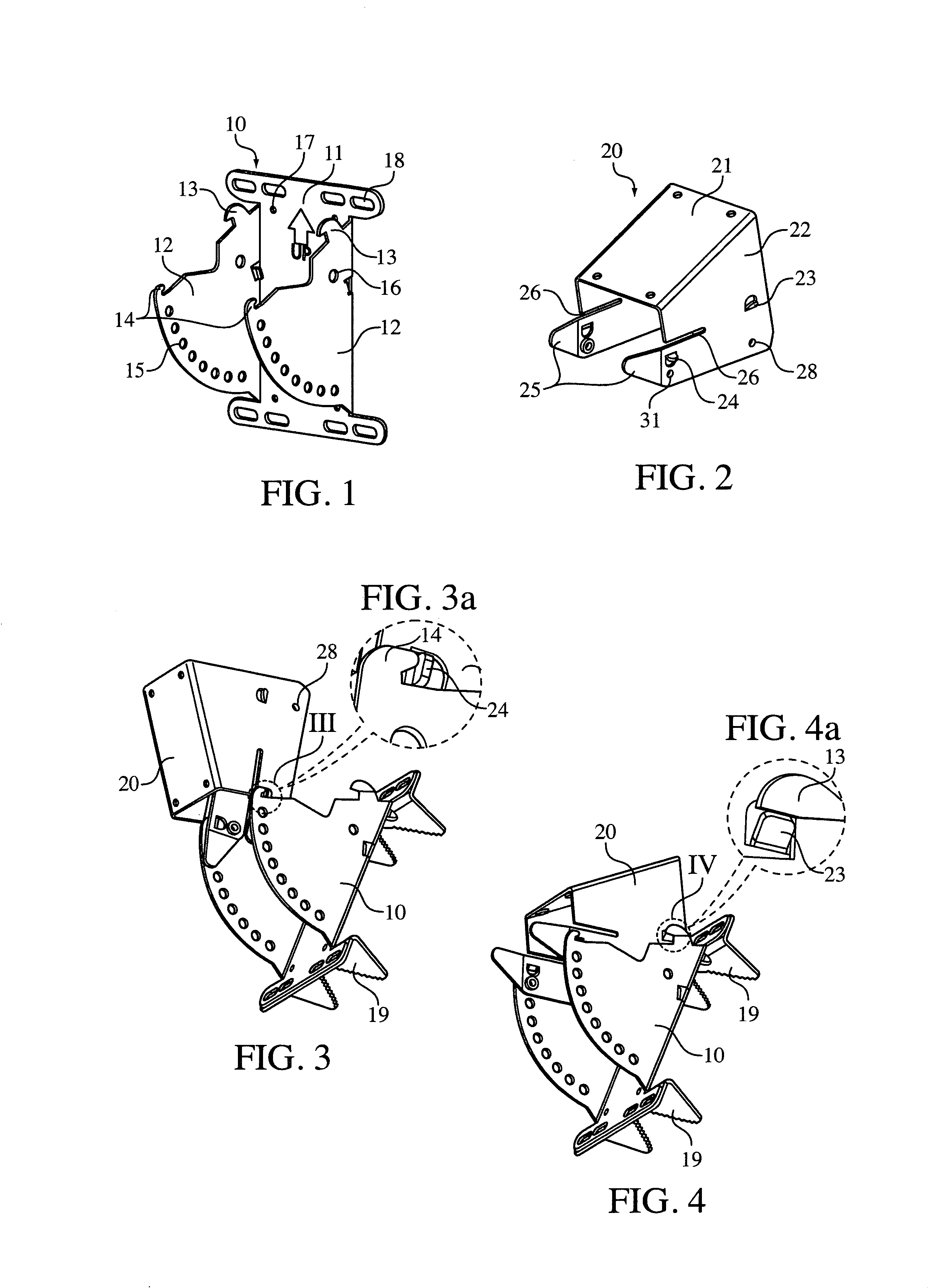

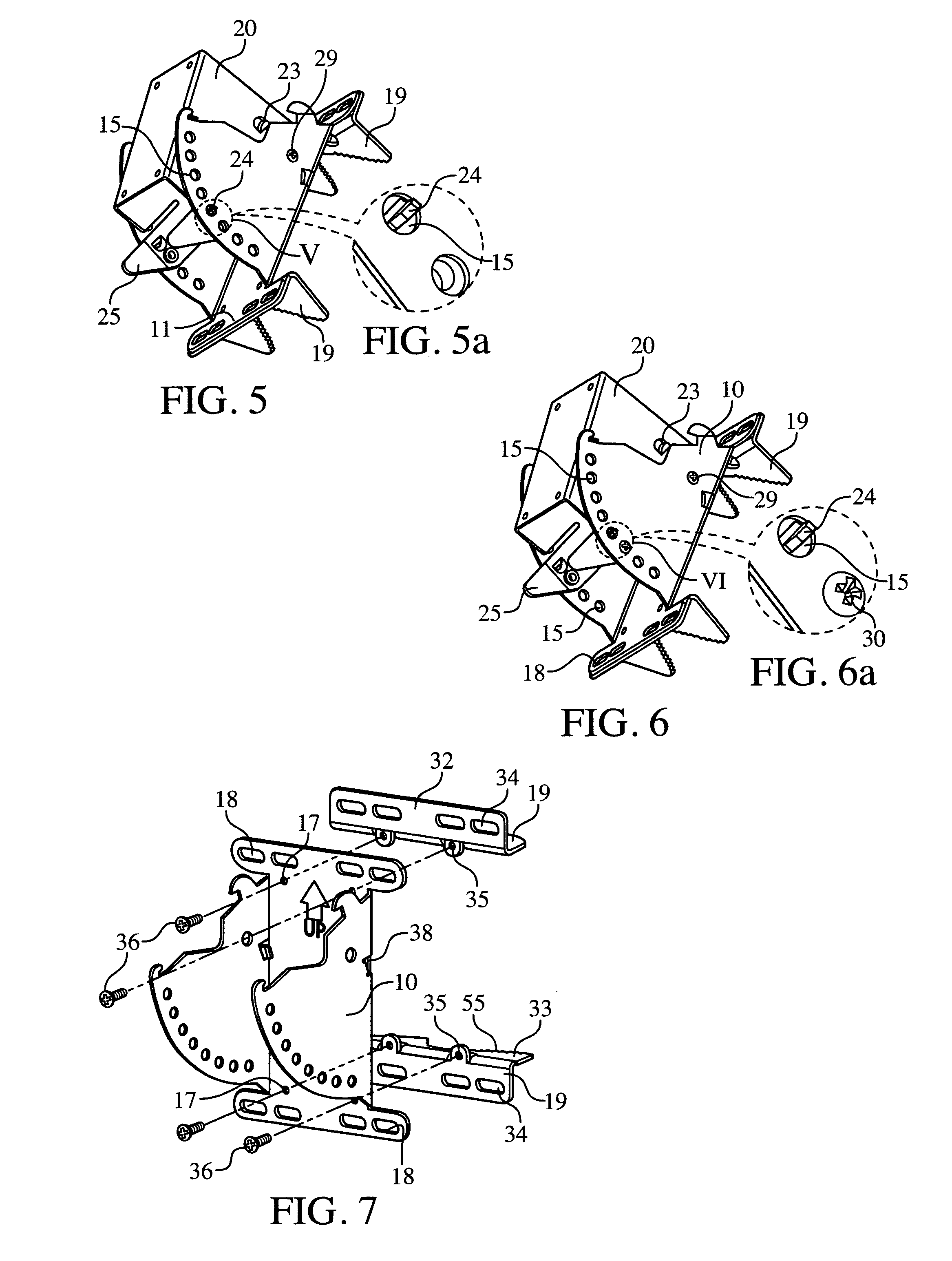

Mounting bracket

ActiveUS20100314514A1Simple wayEasy to aimCandle holdersLighting support devicesControl theoryPermanent Mount

A mounting bracket assembly has a stationary bracket to be mounted on a pole or other surface, and an adjustable bracket to be attached to the object to be mounted. The adjustable bracket is then positioned on the stationary bracket to mount the object on the surface or pole. The adjustable bracket is first mounted on the stationary bracket in a preliminary mounting position using integrated hooks and latches, and then can be easily adjusted to a permanent mounting position and secured with screws.

Owner:BOGEN COMM

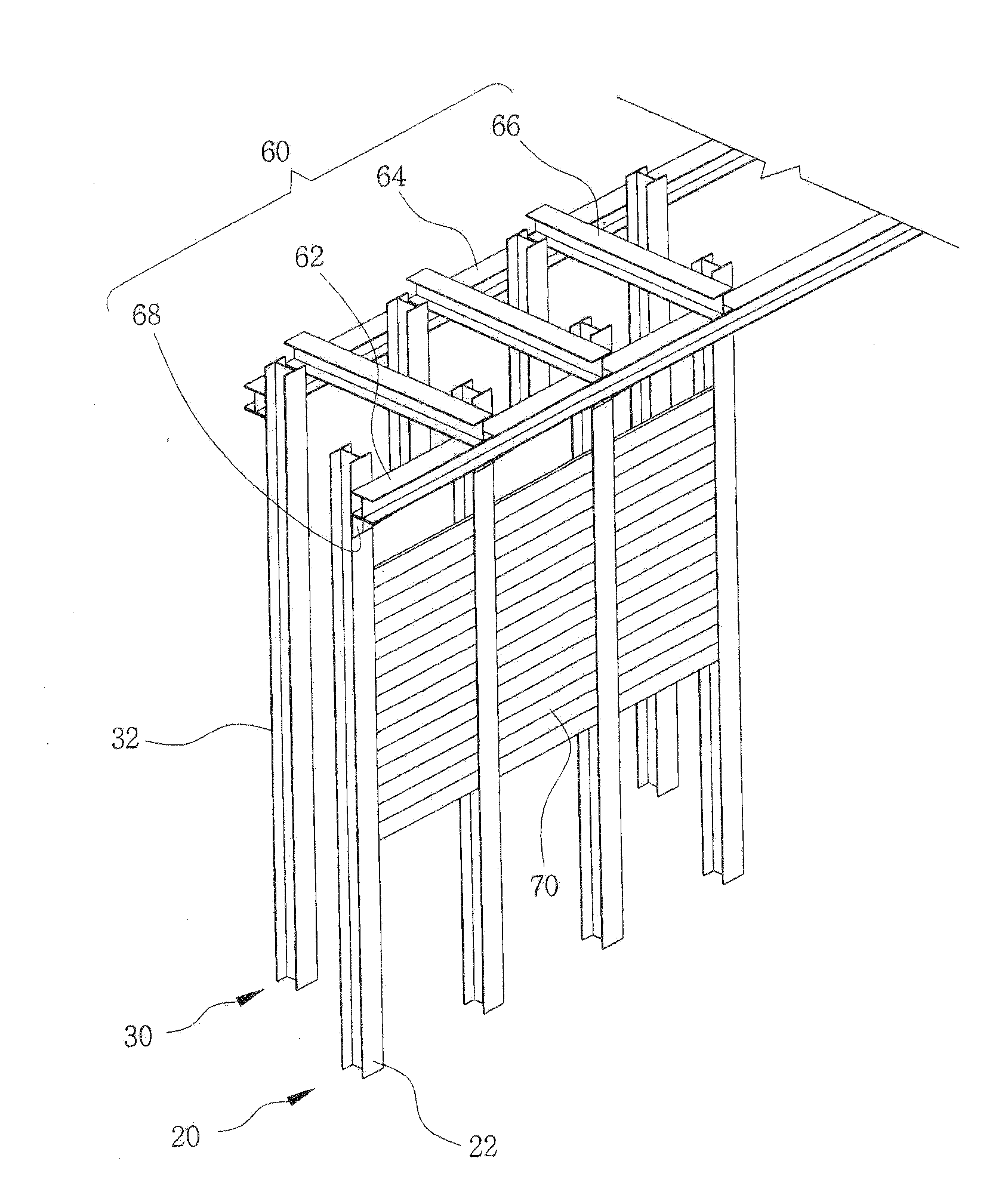

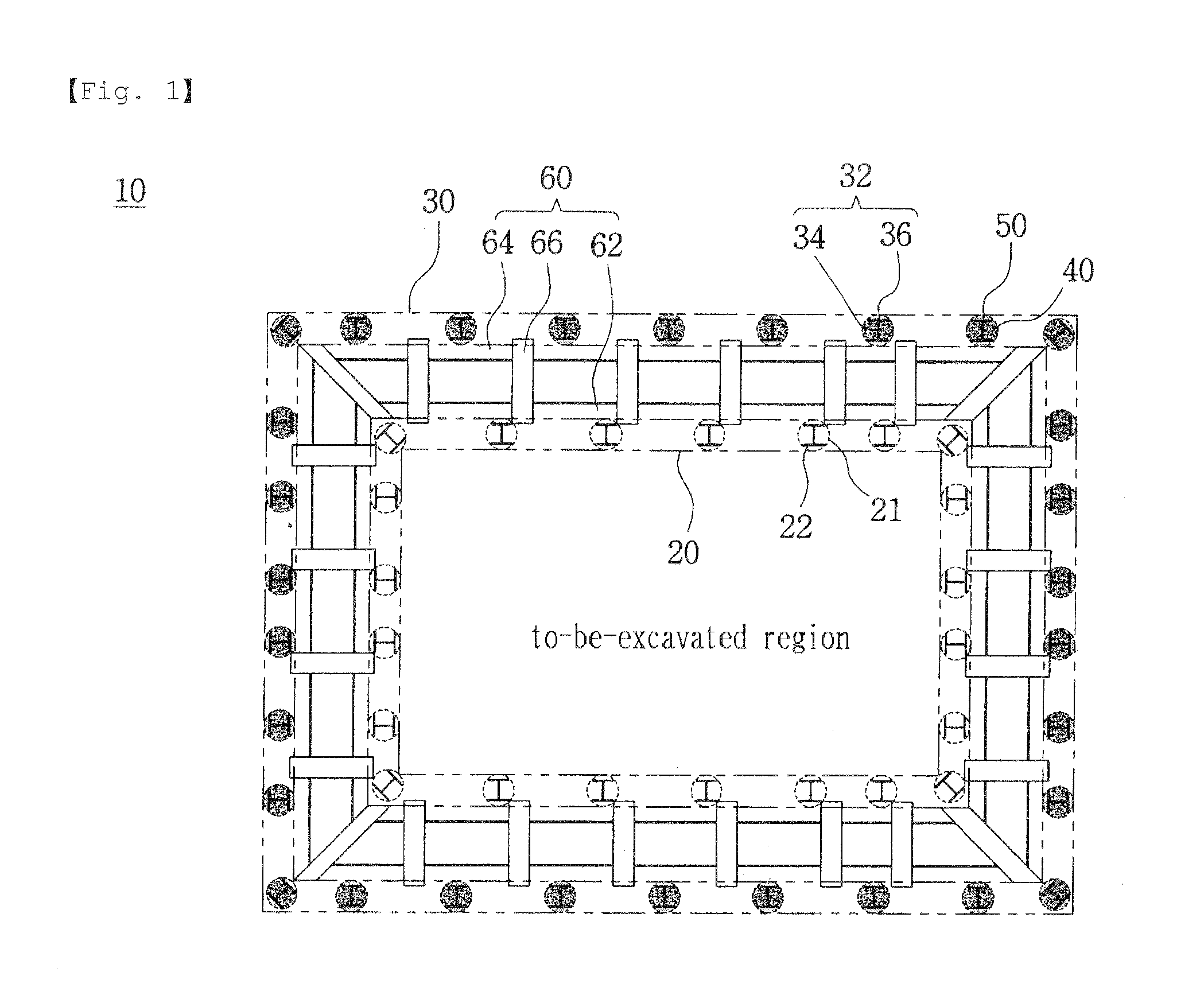

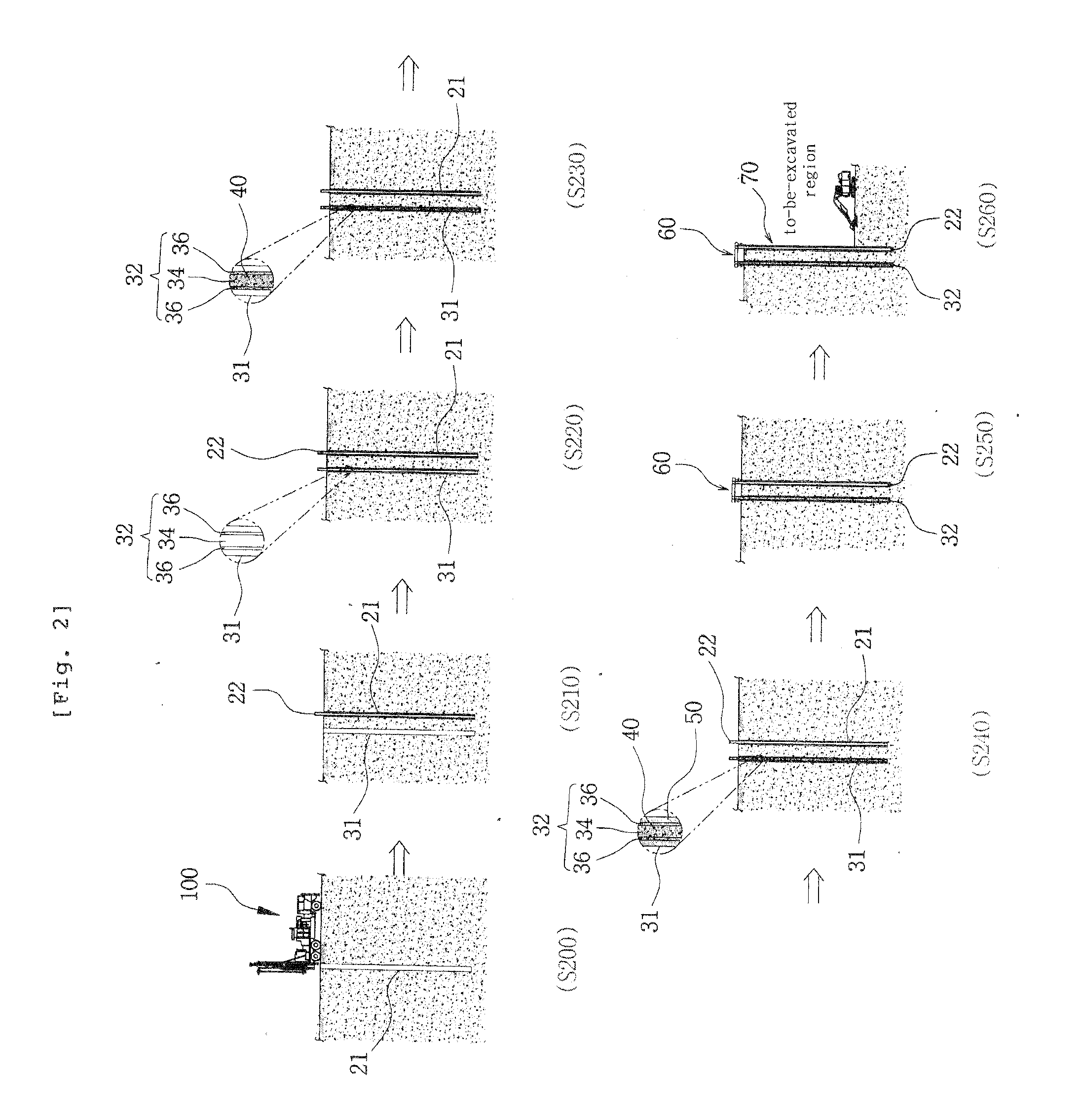

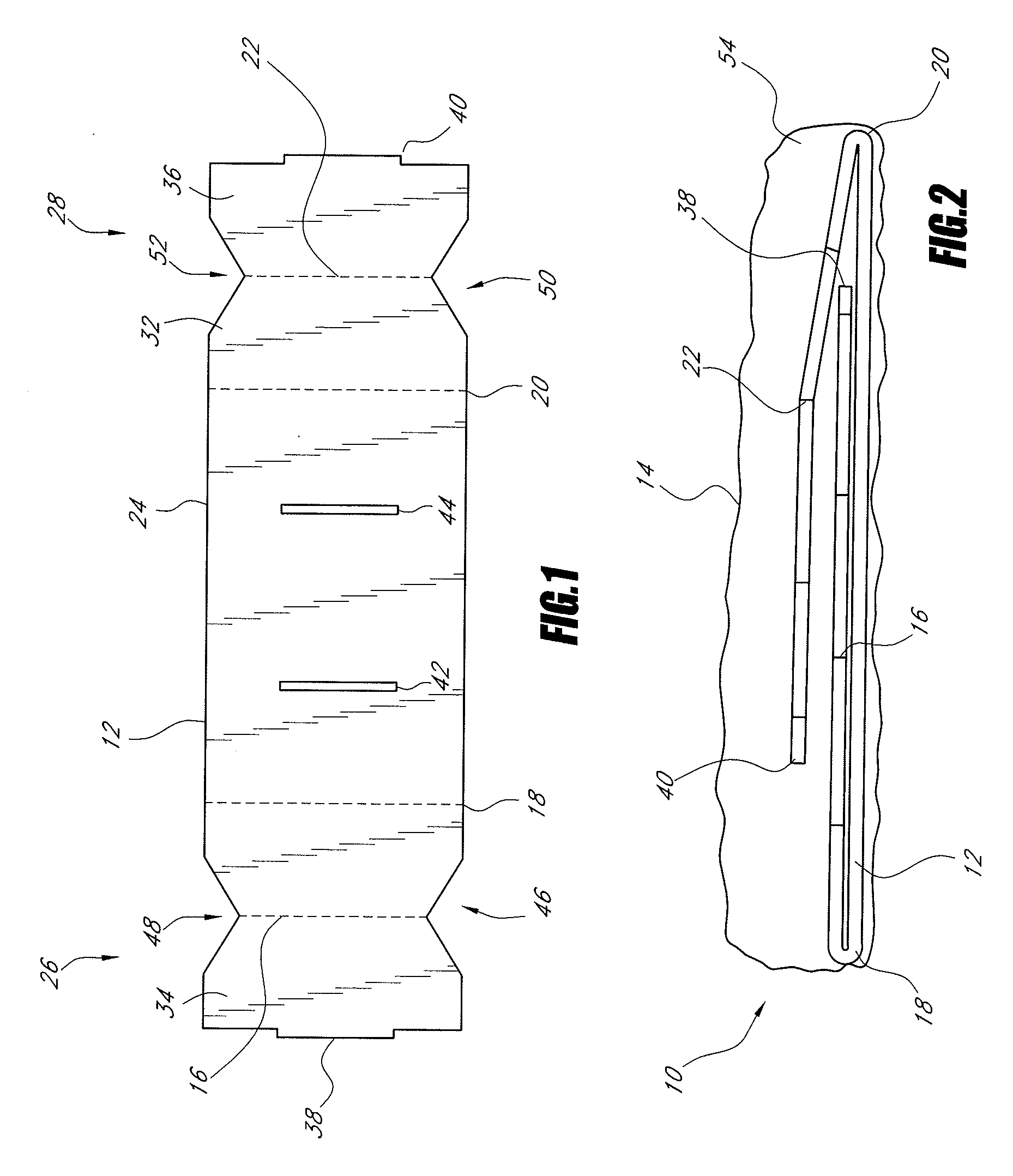

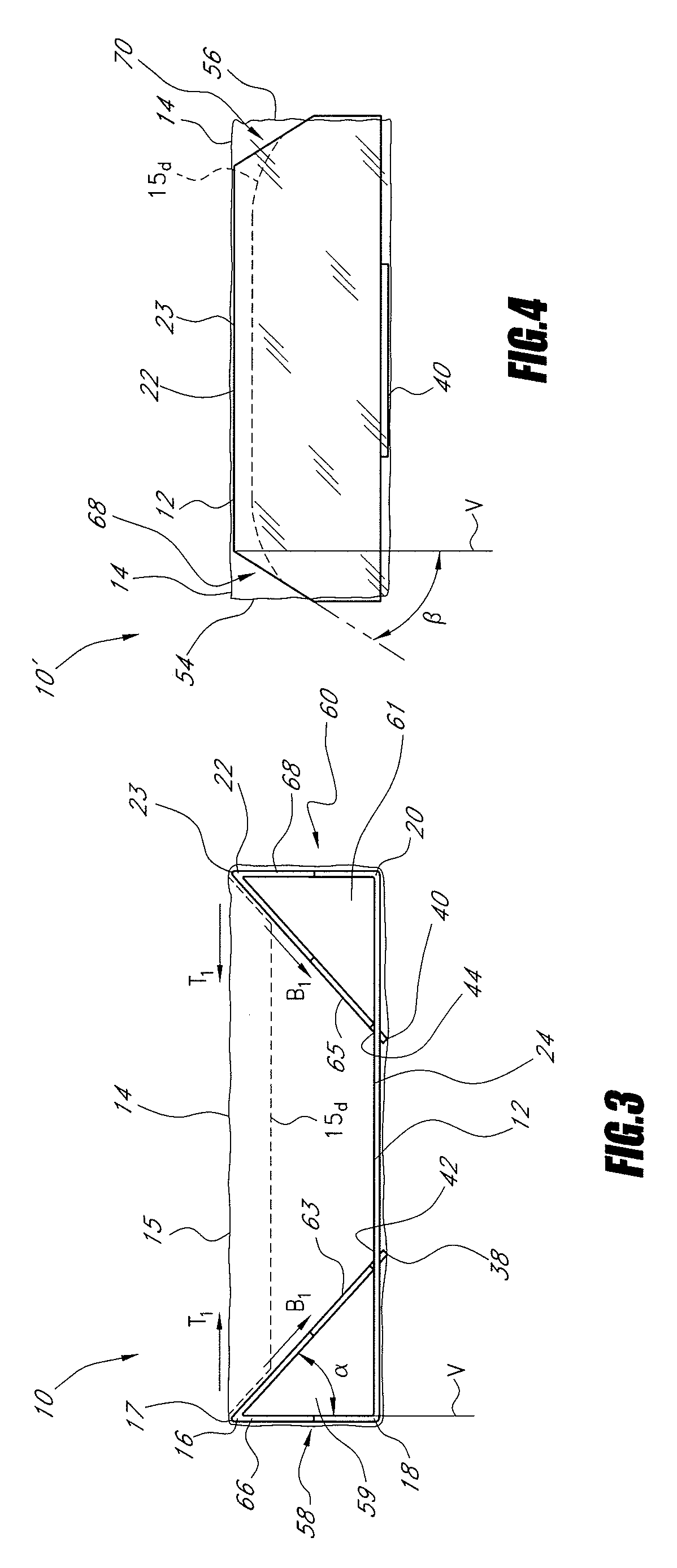

Method for constructing a chair-type, self-supported earth retaining wall

InactiveUS20110142550A1Low construction costShorten the construction periodArtificial islandsExcavationsRetaining wallOuter space

The present invention provides a method for constructing a chair-type, self-supported earth retaining wall used for retaining external forces such as earth pressure prior to an excavation. The method of the present invention forms a first column of piles having a plurality of piles arranged along the circumference of the region to be excavated. Subsequently, the method comprises forming a second column of piles having a plurality of piles by consecutively perforating a plurality of holes by a predetermined spacing at predetermined positions outwardly from the first column of piles, along the circumference of the region to be excavated, inserting H-beams into the respective holes, filling left and right spaces of the webs of the H-beams with soil, and filling the outer spaces of the flanges of the H-beams with a flowable stiffening material. The method subsequently comprises interconnecting the first column of piles and the second column of piles by a connection member. The first column of piles and the second column of piles are formed along the circumference of the region to be excavated, with an outward spacing, and connected to each other by the connection member.The present invention provides a method for constructing a chair-type, self-supported earth retaining wall used for supporting external forces such as earth pressure prior to an excavation. The method of the present invention comprises forming a first pile array 20 having a plurality of piles 22 arranged along a circumference of an region to be excavated. Subsequently, the method comprises forming a second pile array 30 having a plurality of piles arranged along a circumference of the to-be-excavated region by consecutively drilling a plurality of boreholes 31 at predetermined intervals at predetermined positions outwardly spaced apart from the first pile array, inserting H-beams into the respective boreholes, filling left and right spaces of webs 34 of the H-beams 32 with soil 40, and filling the outer spaces of flanges 36 of the H-beams with a flowable hardening material 50. The method subsequently comprises fixedly interconnecting the first pile array and the second pile array using a connection member. The first pile array and the second pile array are formed in such a fashion as to be outwardly spaced apart from each other along the circumferences of the to-be-excavated region, and are connected to each other by the connection member to construct an underground earth retaining wall.

Owner:KOLON CONSTR CO LTD

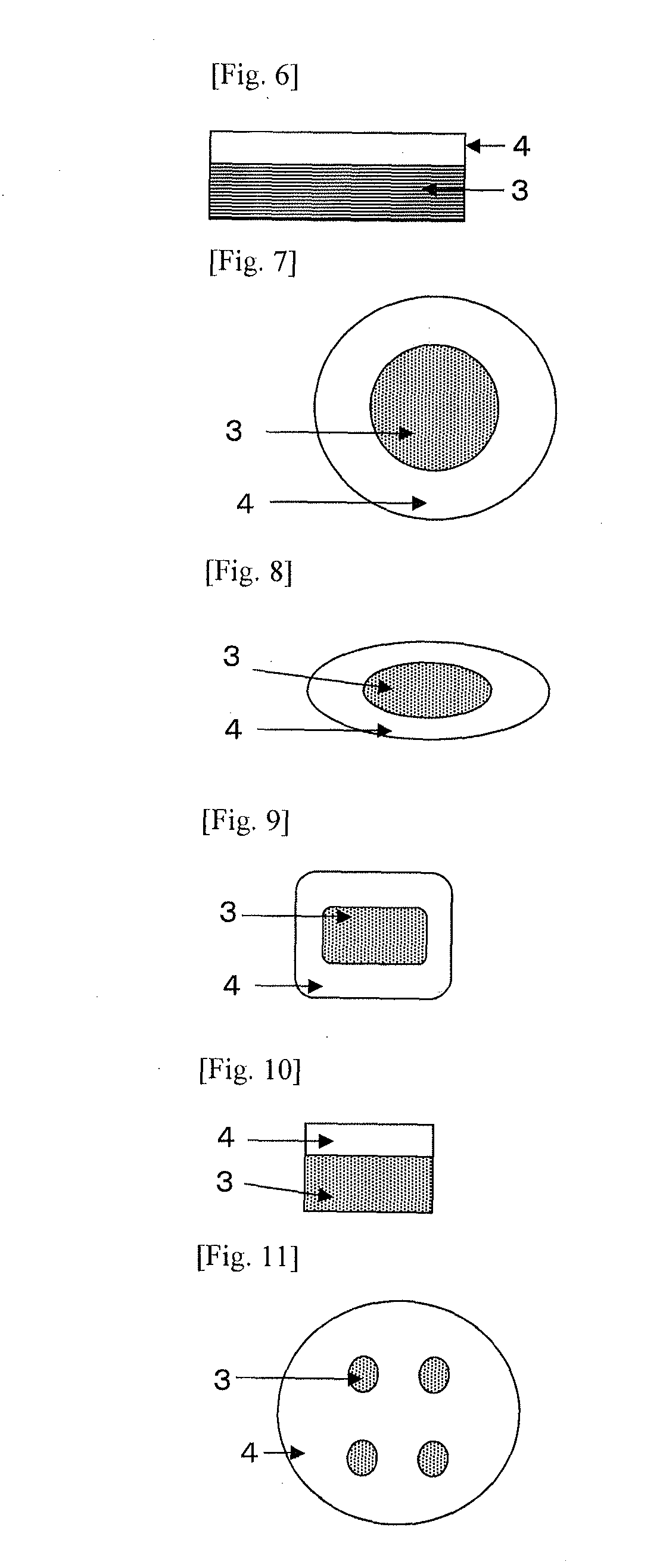

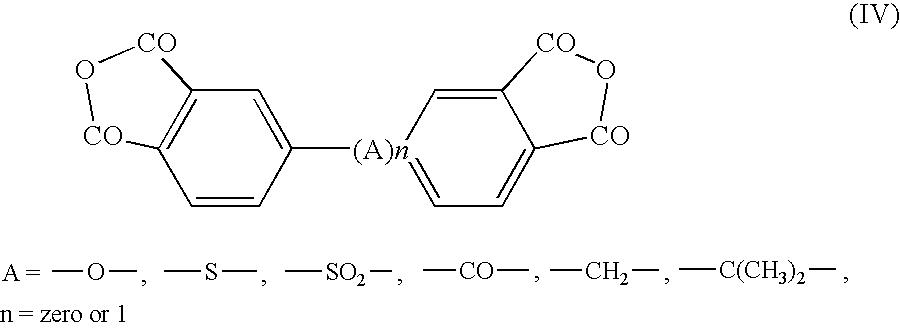

Molding material, prepreg, fiber-reinforced composite material, fiber-reinforced composite material laminate, and process for production of fiber-reinforced molding base material

InactiveUS20130295806A1Economical efficiencyEconomical productivityPretreated surfacesWoven fabricsProduction rateFiber-reinforced composite

A molding material is provided including a composite having 1 to 50 wt % of (A) a bundle of continuous reinforcing fibers and 0.1 to 40 wt % of (B) a polyarylene sulfide prepolymer or (B′) a polyarylene sulfide; and 10 to 98.9 wt % of (C) a thermoplastic resin adhered to the composite; wherein the composite further has (D) a zero-valent transition metal compound or (E) a low-valent iron compound in an amount of 0.001 to 20 mol % based on the amount of sulfur atoms contained in the component (B) or (B′). A prepreg and a method of producing a fiber-reinforced molding base material is also provided. By using the molding material according to the present invention which exhibits excellent economic efficiency and productivity, a molded article having excellent mechanical characteristics can be easily produced.

Owner:TORAY IND INC

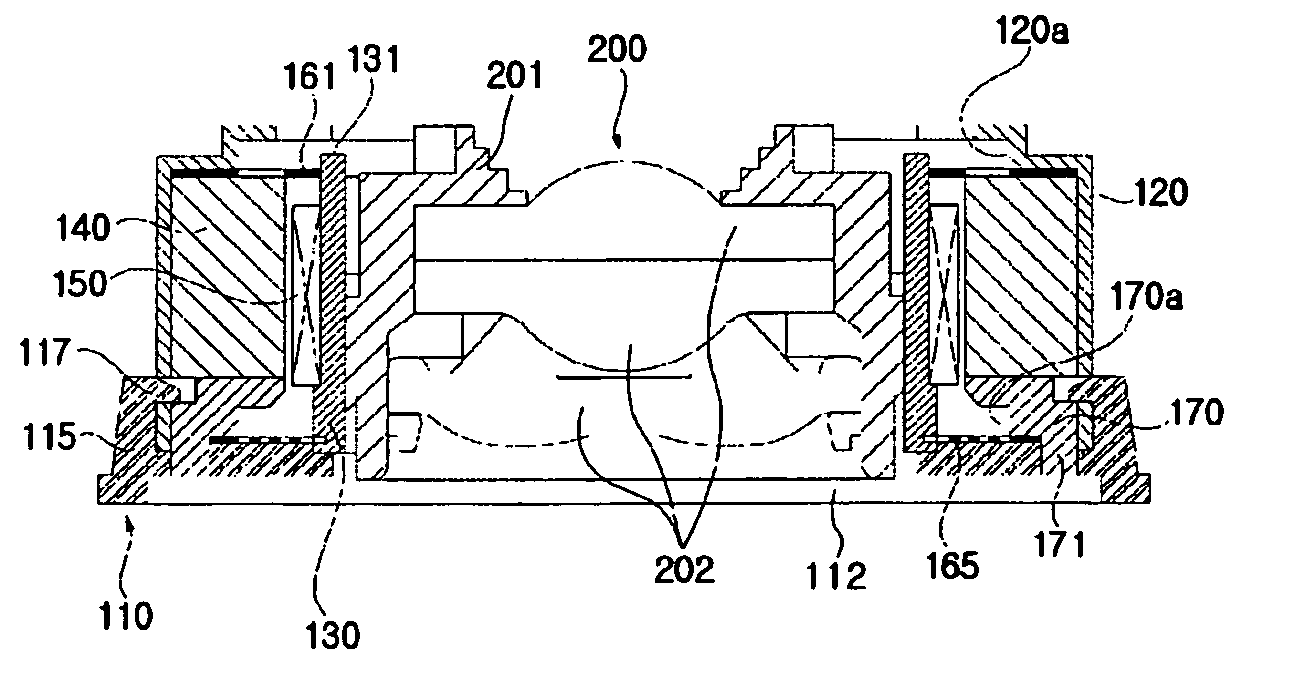

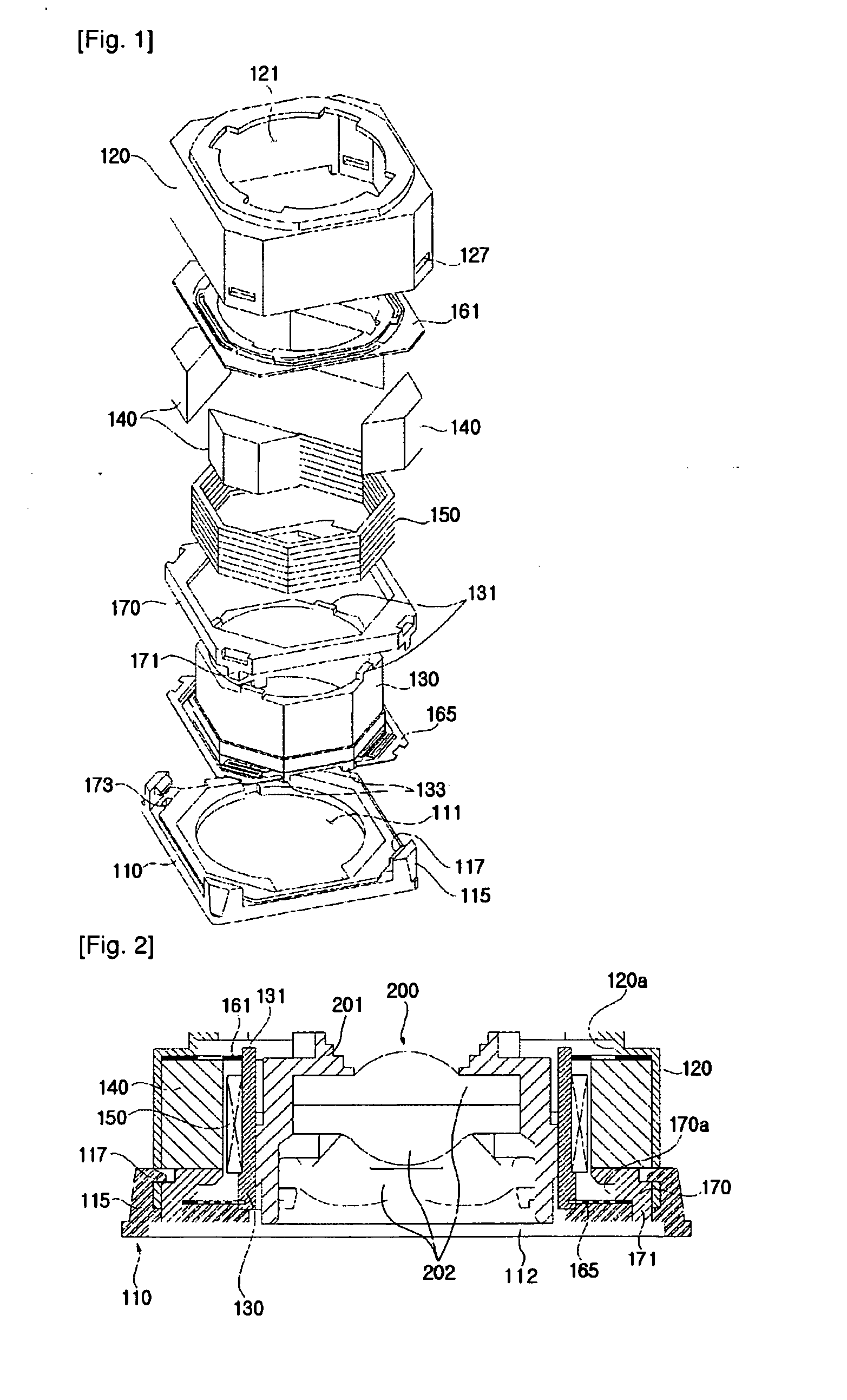

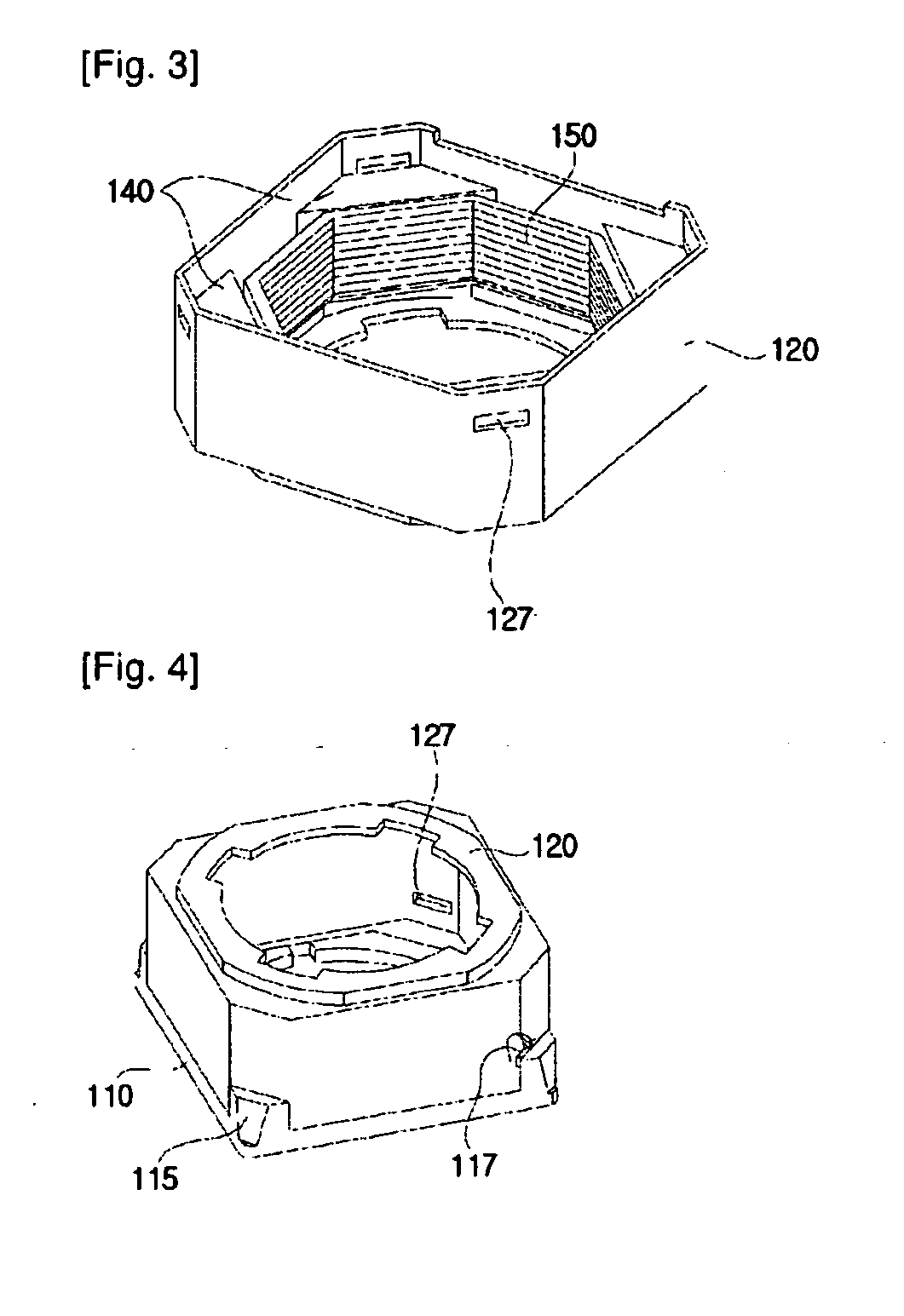

Lens driving apparatus

ActiveUS20090237815A1Reduce the number of partsSimplify the assembly processProjector focusing arrangementCamera focusing arrangementCamera lensBobbin

Disclosed is a lens driving apparatus. The lens driving apparatus comprises a base, a yoke coupled to the base, having an upper surface formed with a hole, a closed side surface, and an opened bottom surface, a bobbin movably installed in an inner portion of the yoke, a lens module coupled to the bobbin to go in and out the hole according to movement of the bobbin, a magnet fixed to an inner portion of the yoke, a coil fixed to an outer portion of the bobbin while facing the magnets, and springs coupled to the bobbin to provide restoration force to the bobbin.

Owner:LG INNOTEK CO LTD

Electric vehicle inverter apparatus and protection method therefor

InactiveUS8612073B2Avoid it happening againImprove reliabilityBatteries circuit arrangementsElectric devicesHigh voltage batteryElectric vehicle

In an electric vehicle inverter apparatus 100, a vehicle control controller 15 detects a switch open signal output from a collision detector 16 when the collision detector 16 is caused by a collision between electric vehicles to operate. Then, an inverter main circuit connection switch 10 of a high-voltage battery unit 8 is put into an open state. Thus, the direct-current power supply from a high-voltage battery 12 to a DC bus portion is interrupted. In addition, electric charges charged into a main circuit capacitor 7 are discharged by a forced discharge circuit portion 22b.

Owner:YASKAWA DENKI KK +1

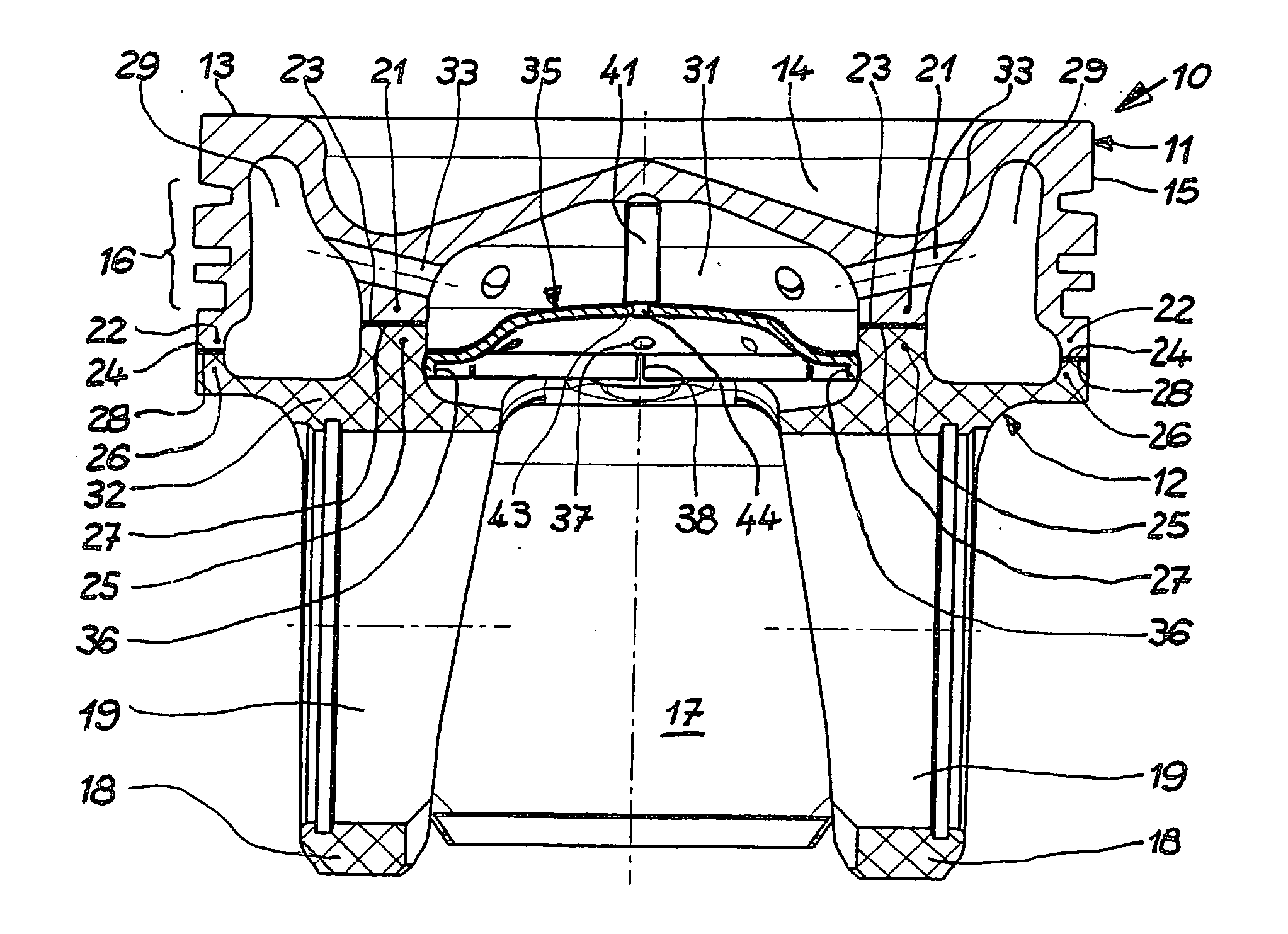

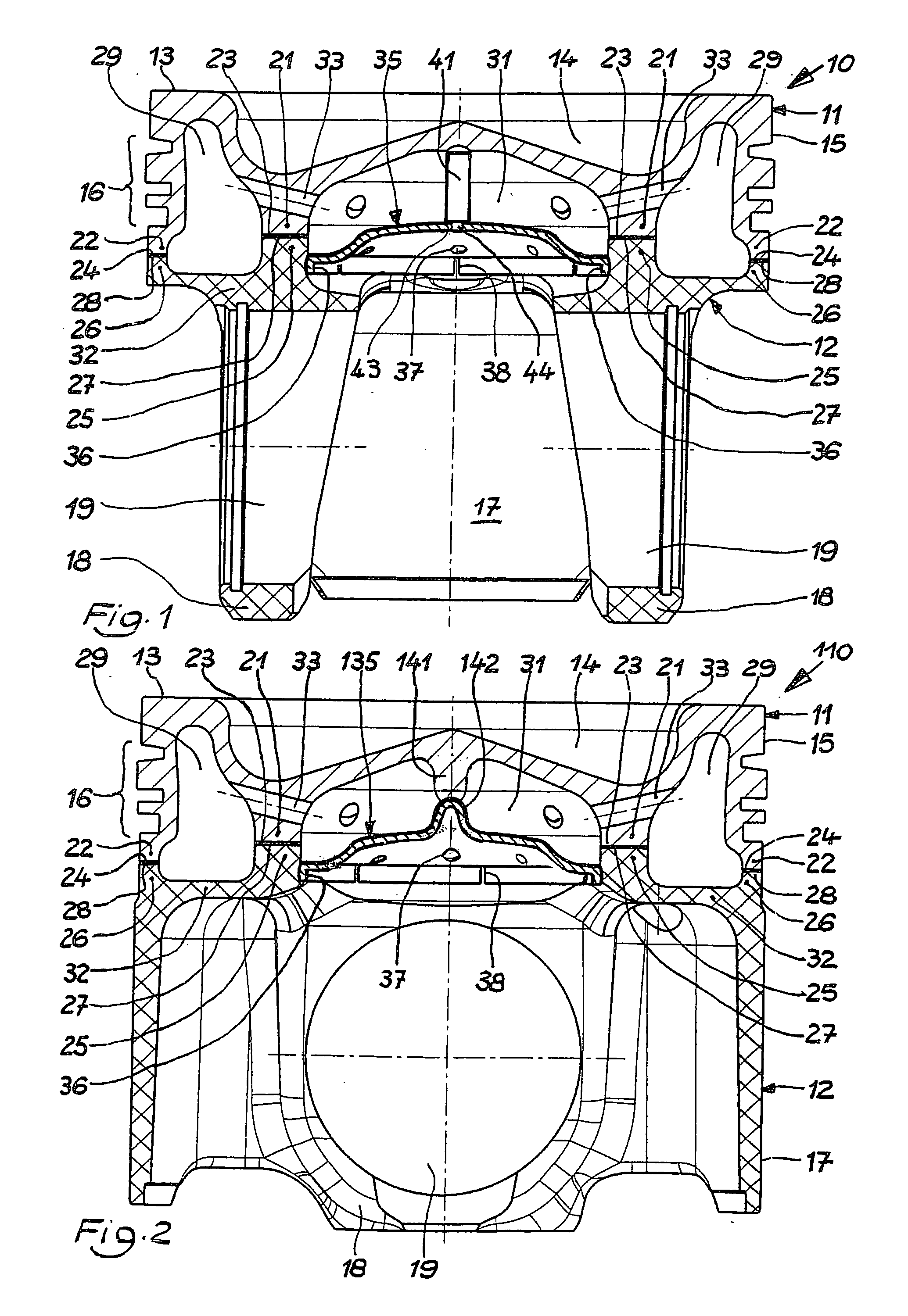

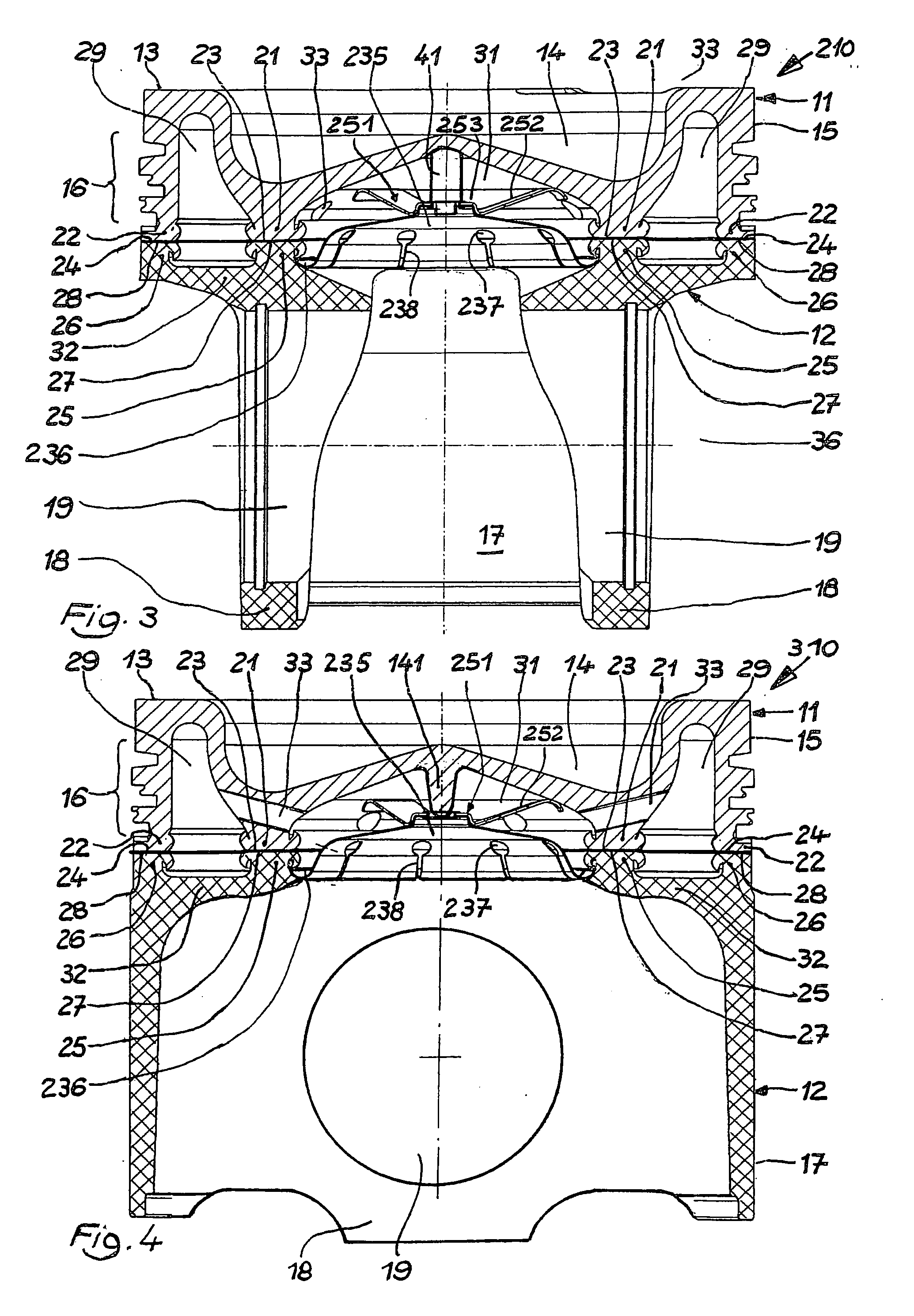

Multi-part piston for an internal combustion engine and method for its production

InactiveUS20100108001A1Easy to produceImprove cooling effectLiquid coolingAir coolingExternal combustion engineInternal combustion engine

A multi-part piston for an internal combustion engine has an upper piston part having a piston crown, and a lower piston part having pin boss supports and pin bosses connected with them. The upper piston part and lower piston part each have an inner and an outer support element, which delimit an outer circumferential cooling channel. The inner support elements delimit a cavity that is open toward the pin bosses, and the cavity is provided with a separate cooling oil collector that has at least one cooling oil opening. In a method for producing a piston, the upper and lower piston parts are manufactured, the cooling oil collector is inserted into one of the upper and lower piston parts in a region of the cavity, and the upper and lower piston parts are connected together at their support elements.

Owner:MAHLE INT GMBH

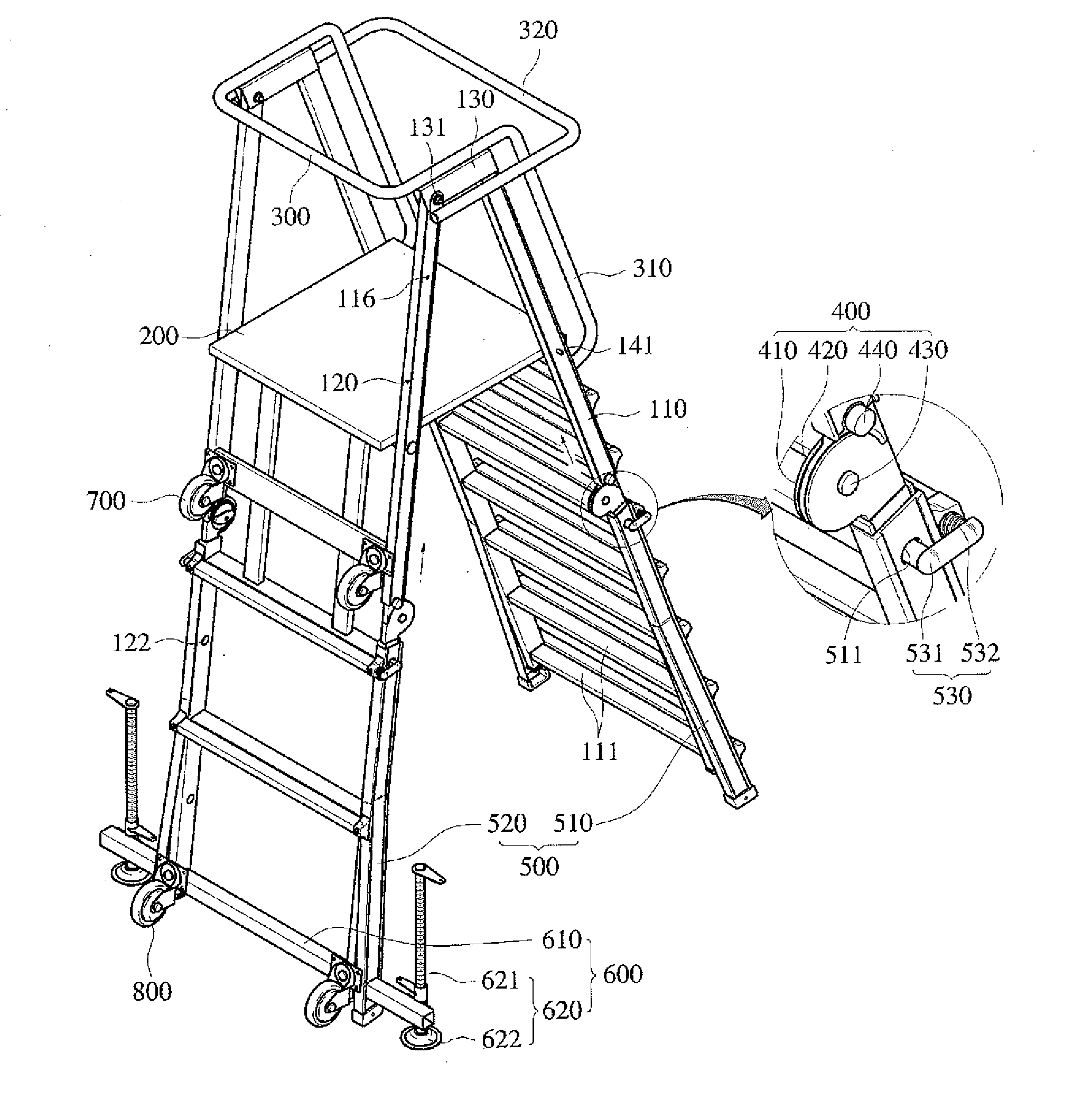

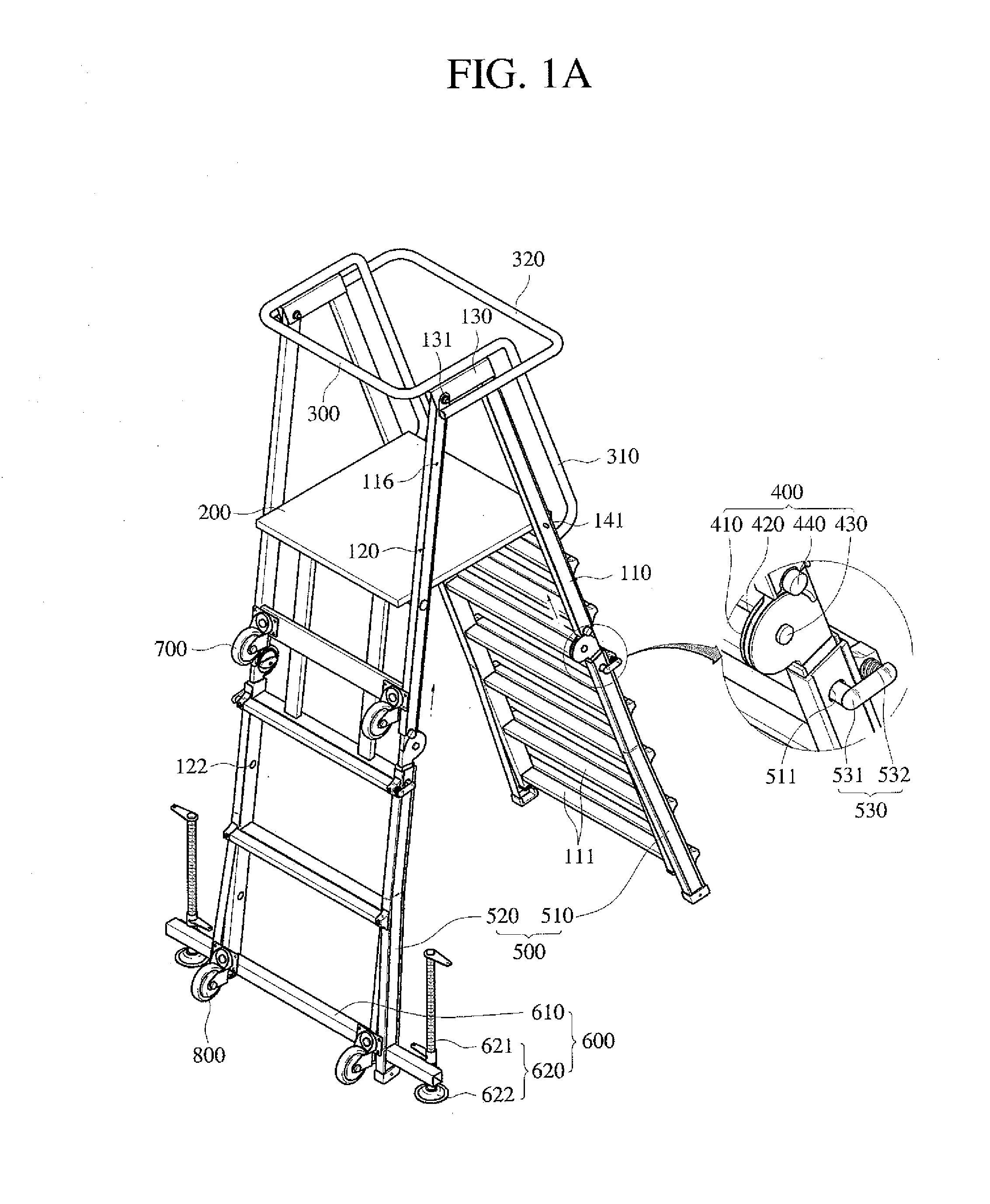

Ladder equipped with safety bar

InactiveUS20110011674A1Maximize efficiencyEconomical efficiencyLaddersEngineeringMechanical engineering

Owner:KIM E E

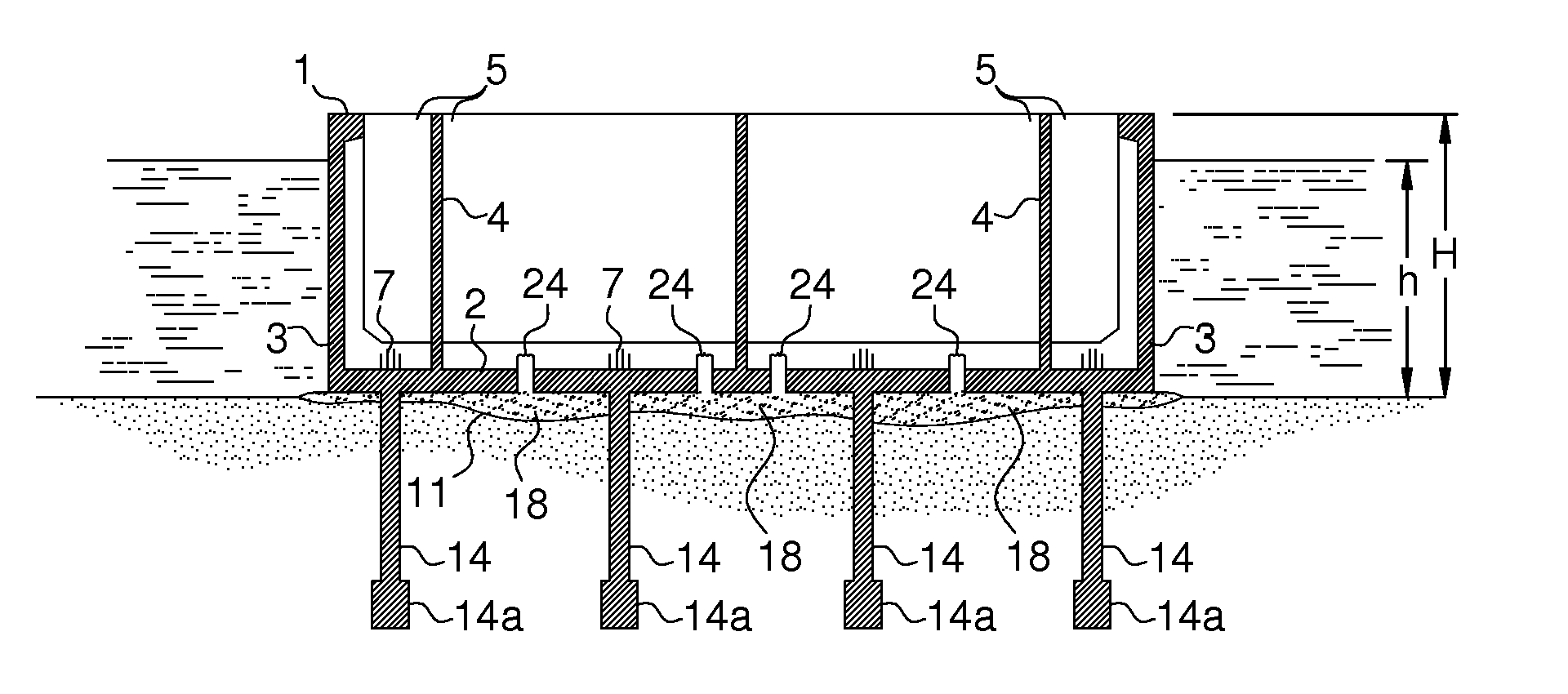

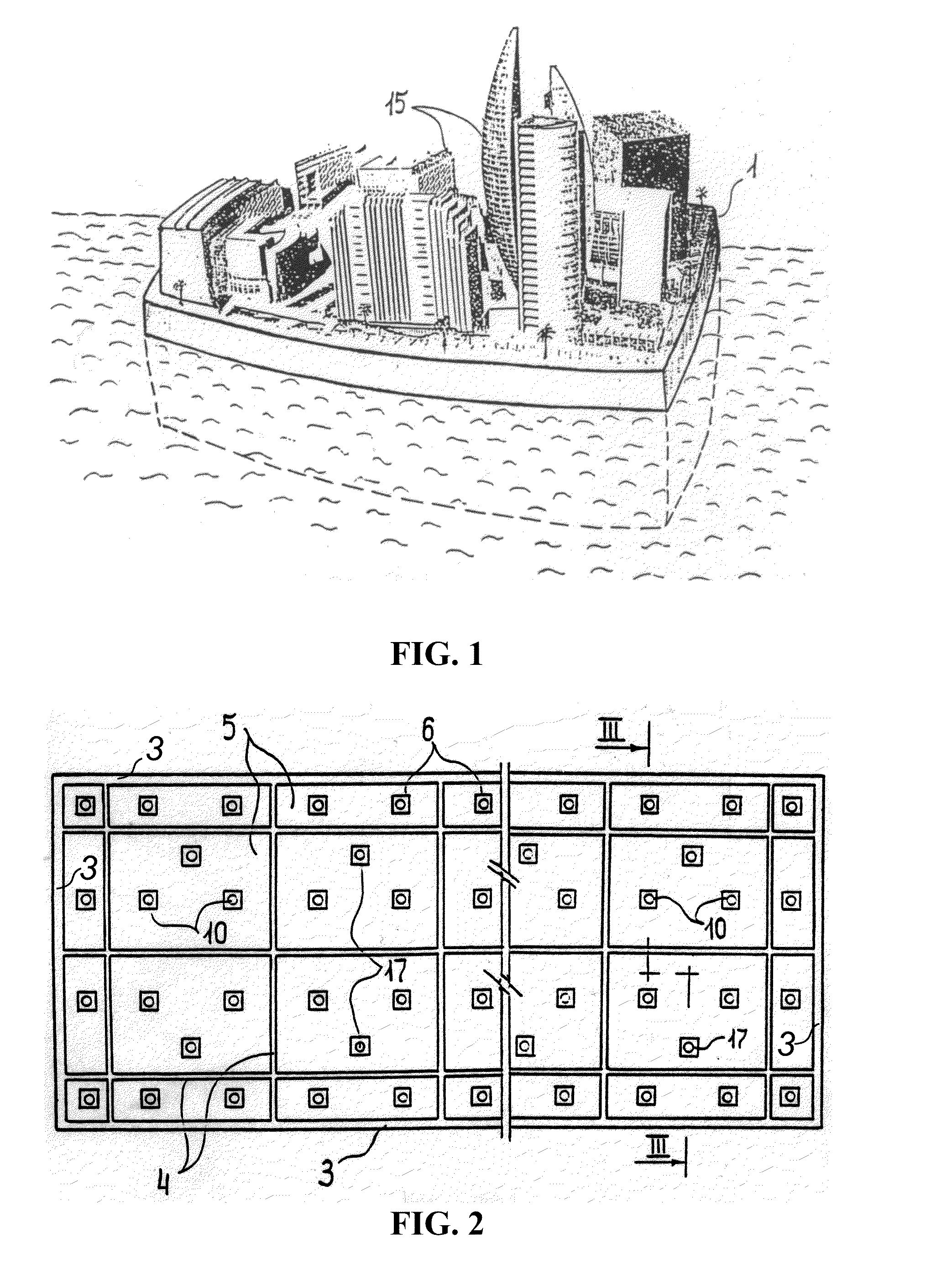

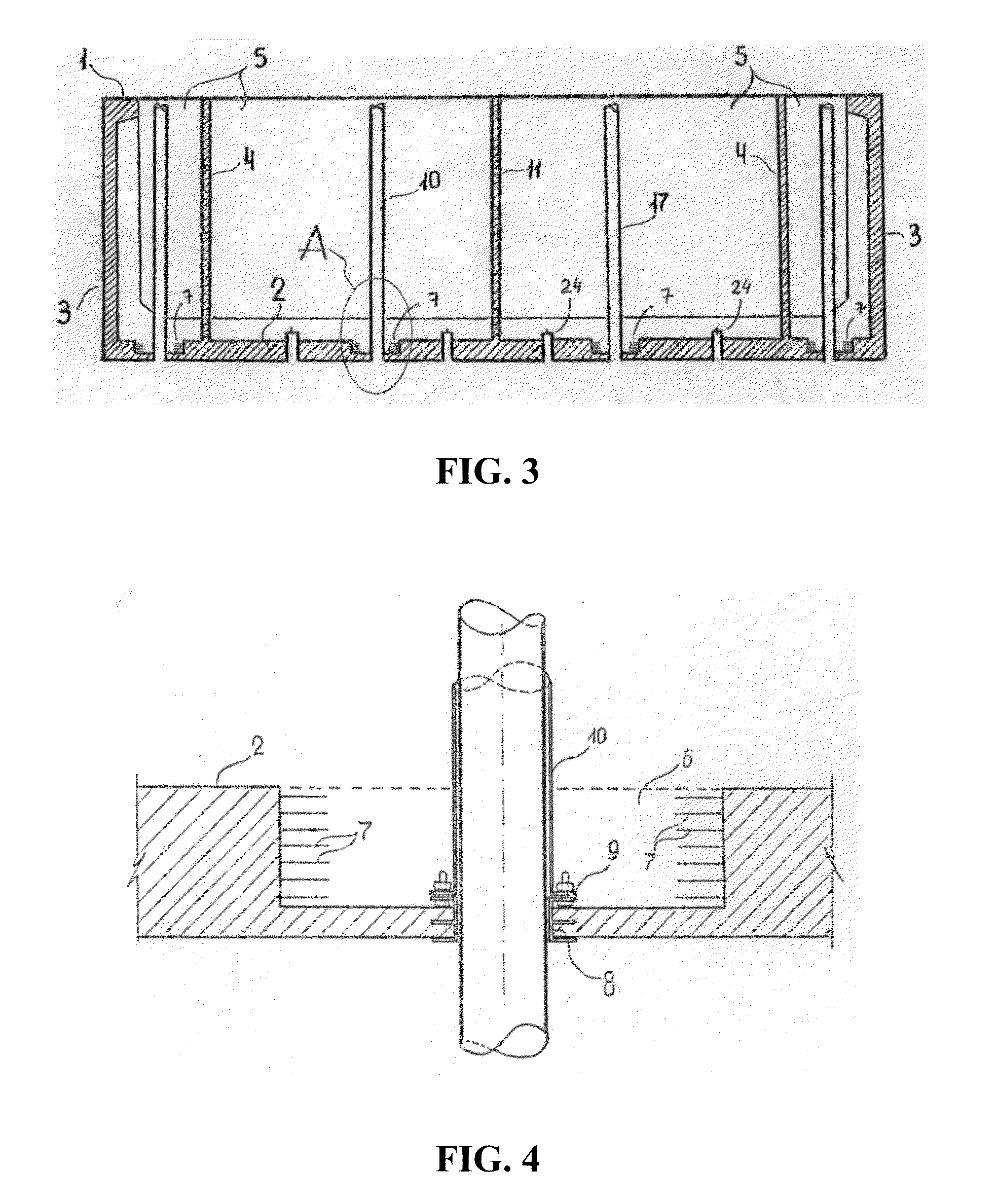

Method of erecting a building structure in a water basin

InactiveUS20090324341A1Economic efficiency be increaseEconomical efficiencyCaissonsStructural engineering

Owner:TECHNION RES & DEV FOUND LTD

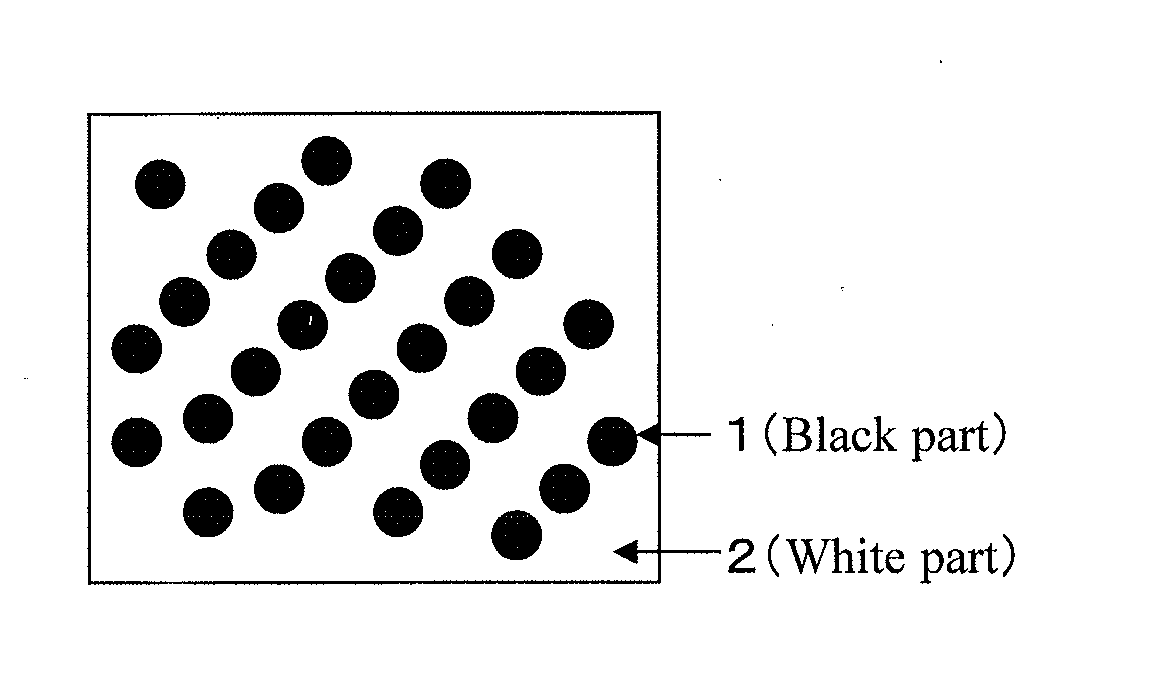

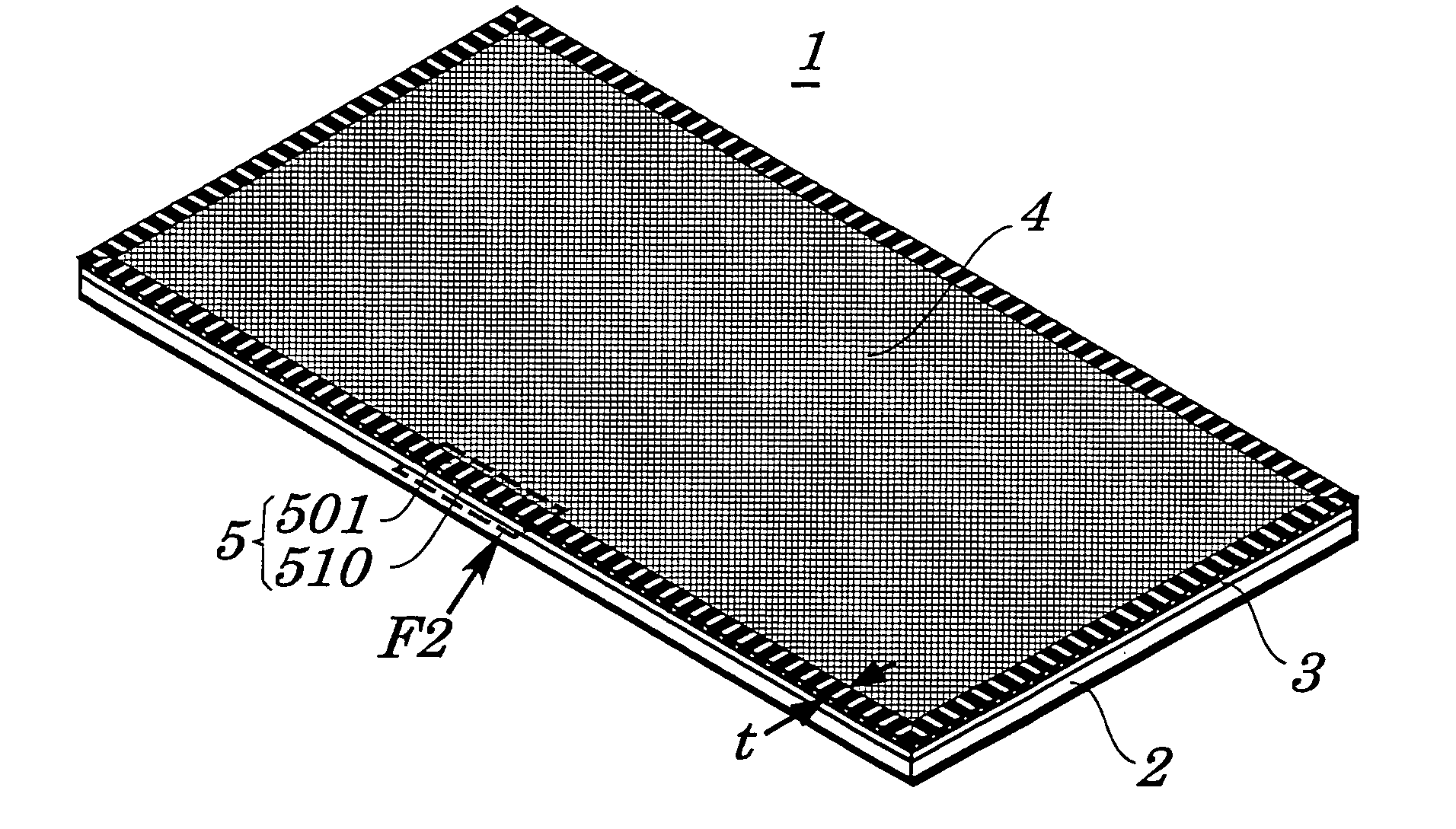

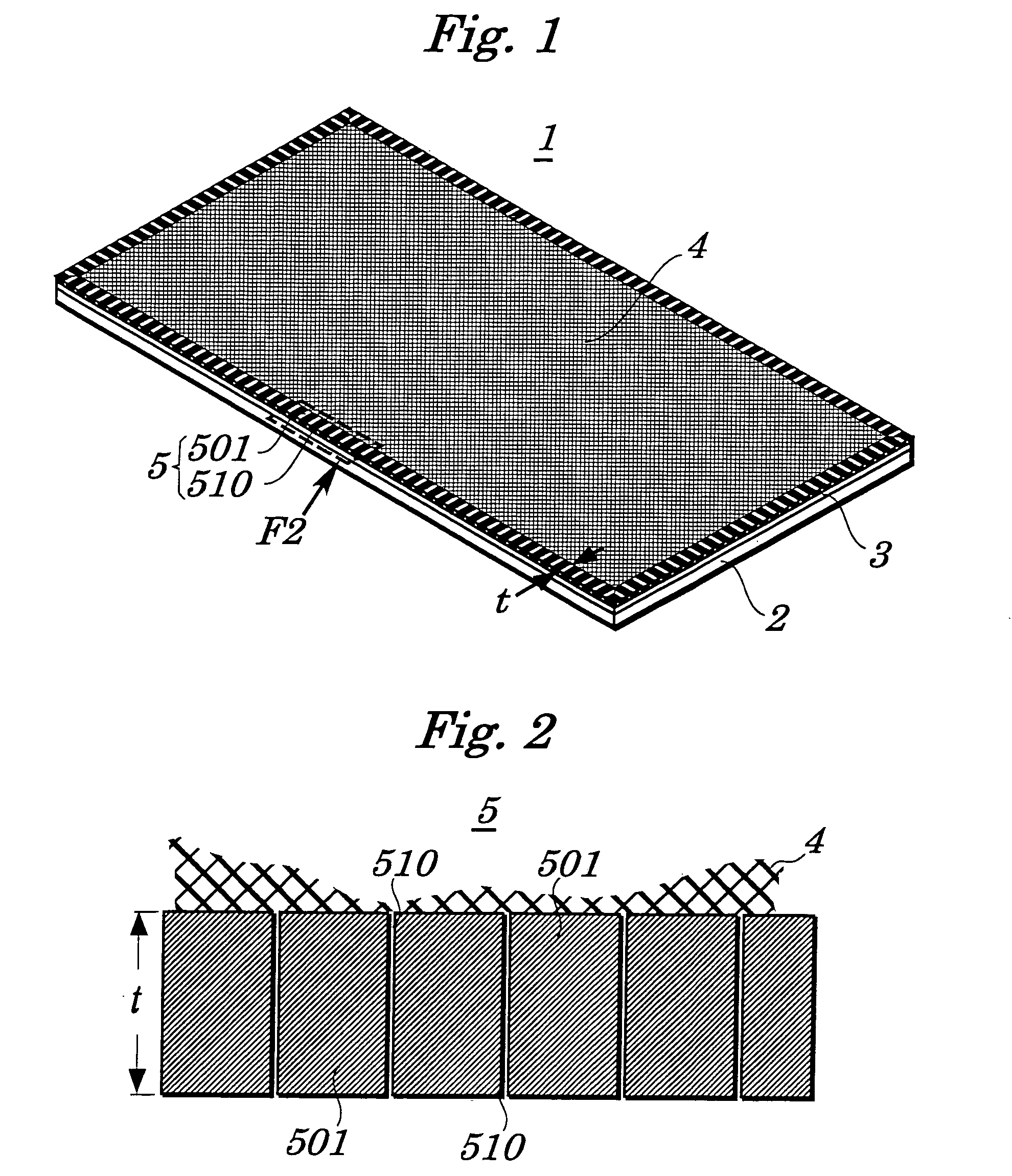

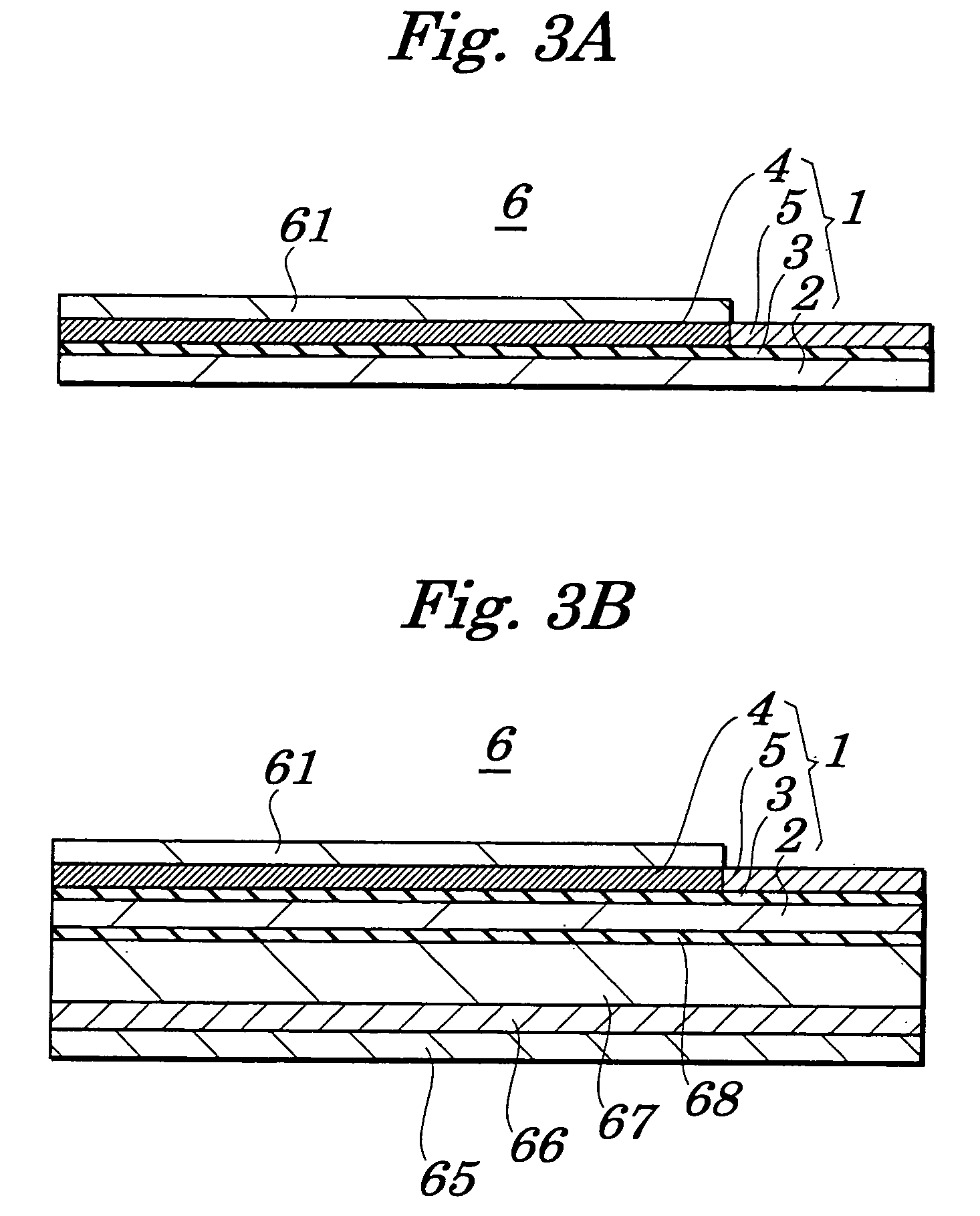

Electromagnetic shield film, electromagnetic shield unit and display

InactiveUS20040074655A1Easy to thinAvoid creasesTelevision system detailsMagnetic/electric field screeningElectrical conductorAdhesive

An electromagnetic wave shield film (1) comprises a transparent base (2), a conductor (4) positioned on the transparent base (2) via an adhesive (3) and having a mesh geometric pattern, and an earth portion (5) arranged around the conductor (4) and including conductive regions (501) which absorb electromagnetic waves, and non-conductive regions (510) which prevent the earth portion (5) from being creased.

Owner:HITACHI CHEM CO LTD

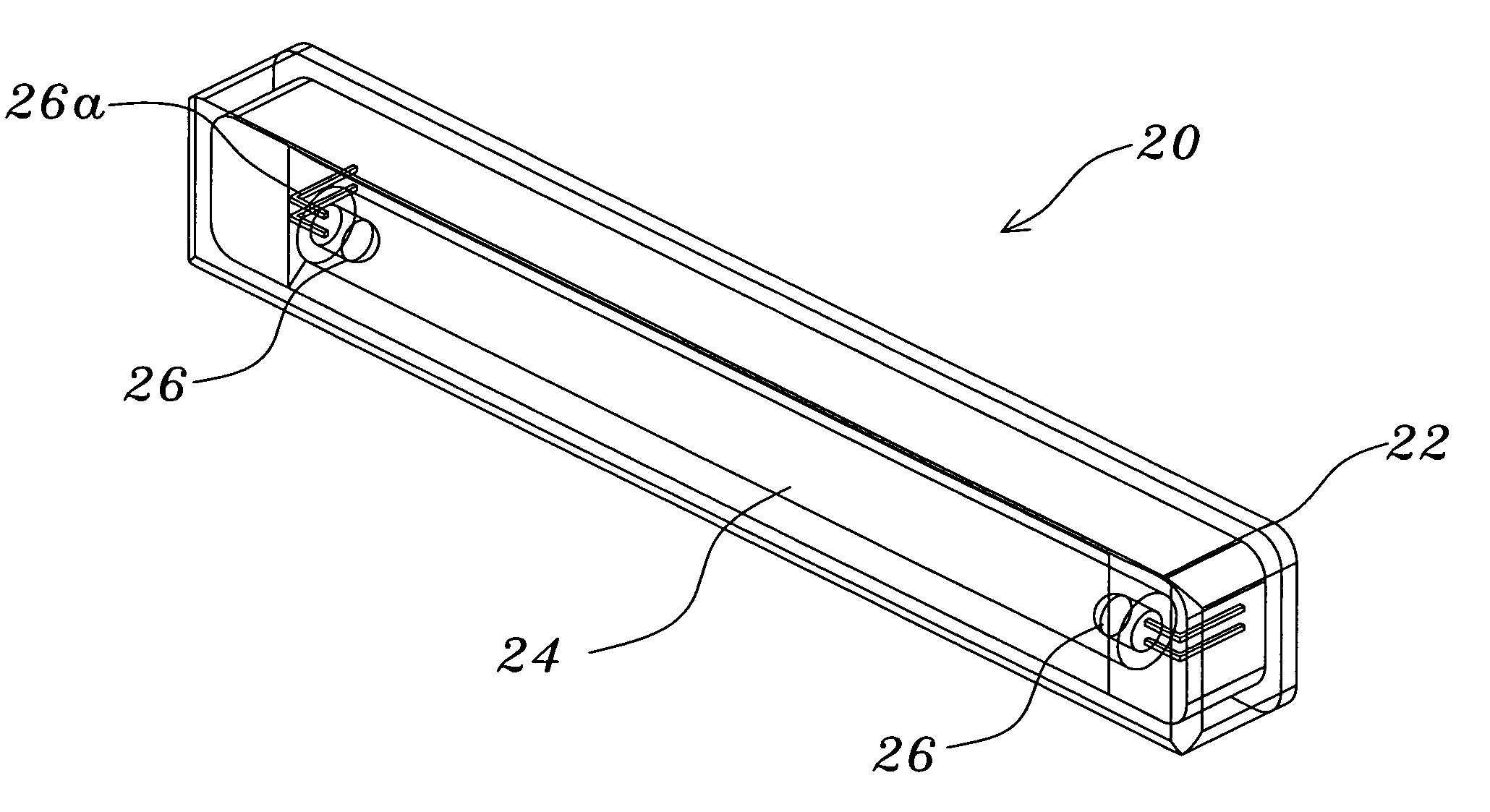

Structure for a center high mounted stop lamp

InactiveUS20090027914A1Reduce the numberReduce power consumptionMechanical apparatusFibre light guidesLight pipeLight guide

The present invention discloses a structure for a center high mounted stop lamp, which comprises: a light pipe, a housing and LEDs. The light pipe has an inorganic light guide coating on a lateral side thereof and has LEDs at both ends thereof. The housing covers the light pipe and has a light reflection layer. The light reflection layer is arranged around the light pipe and behind the inorganic light guide coating. The light emitted by LEDs is scattered by the light pipe and reflected by the inorganic light guide coating. Thus, the light pipe can uniformly emit light. Further, the light emitted by the light pipe is concentrated and reflected out by the light reflection layer. Thereby, the present invention can decrease the number of required LEDs, save power, prolong the service life of LEDs and promote economic efficiency.

Owner:WU CHIA YEH

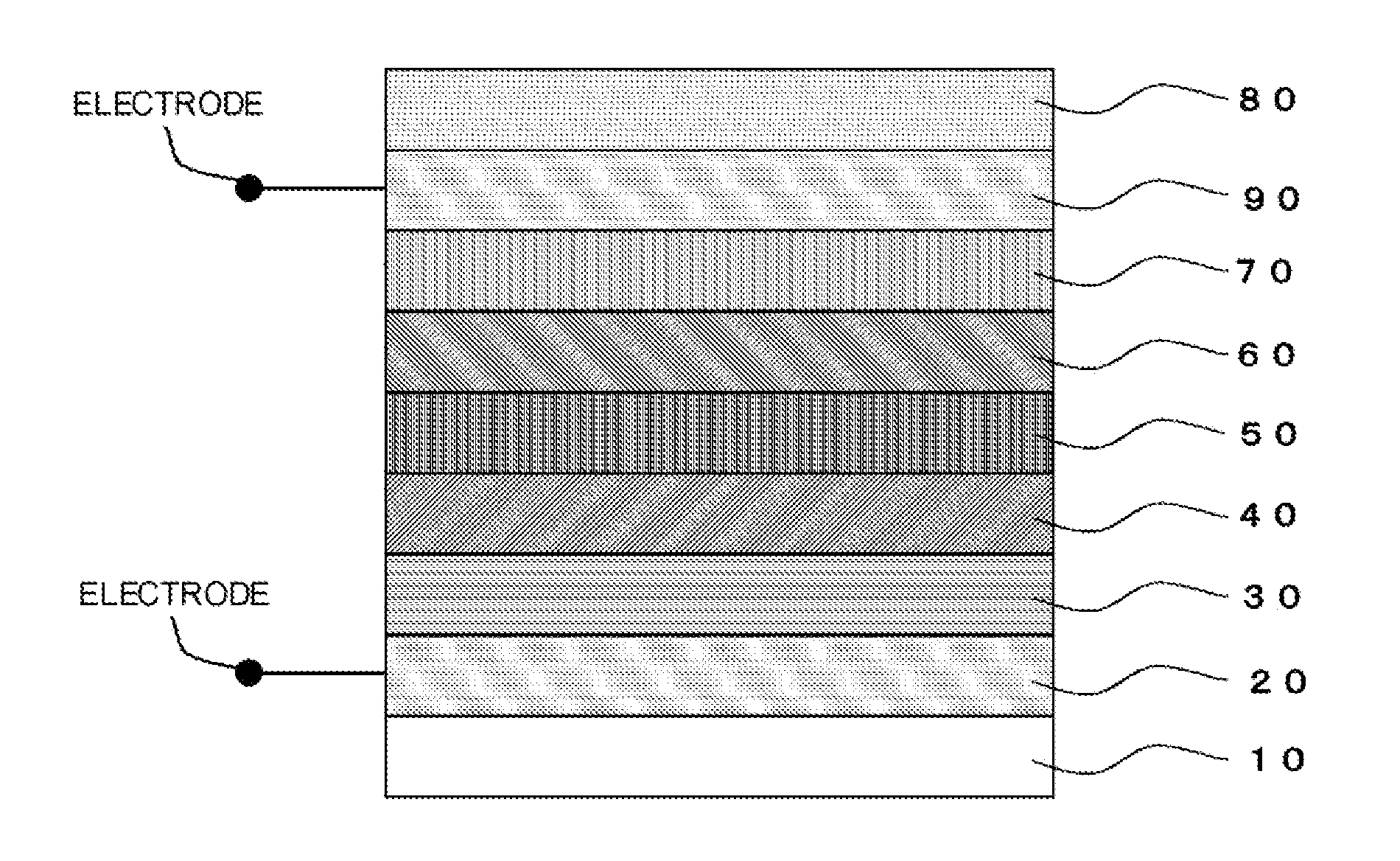

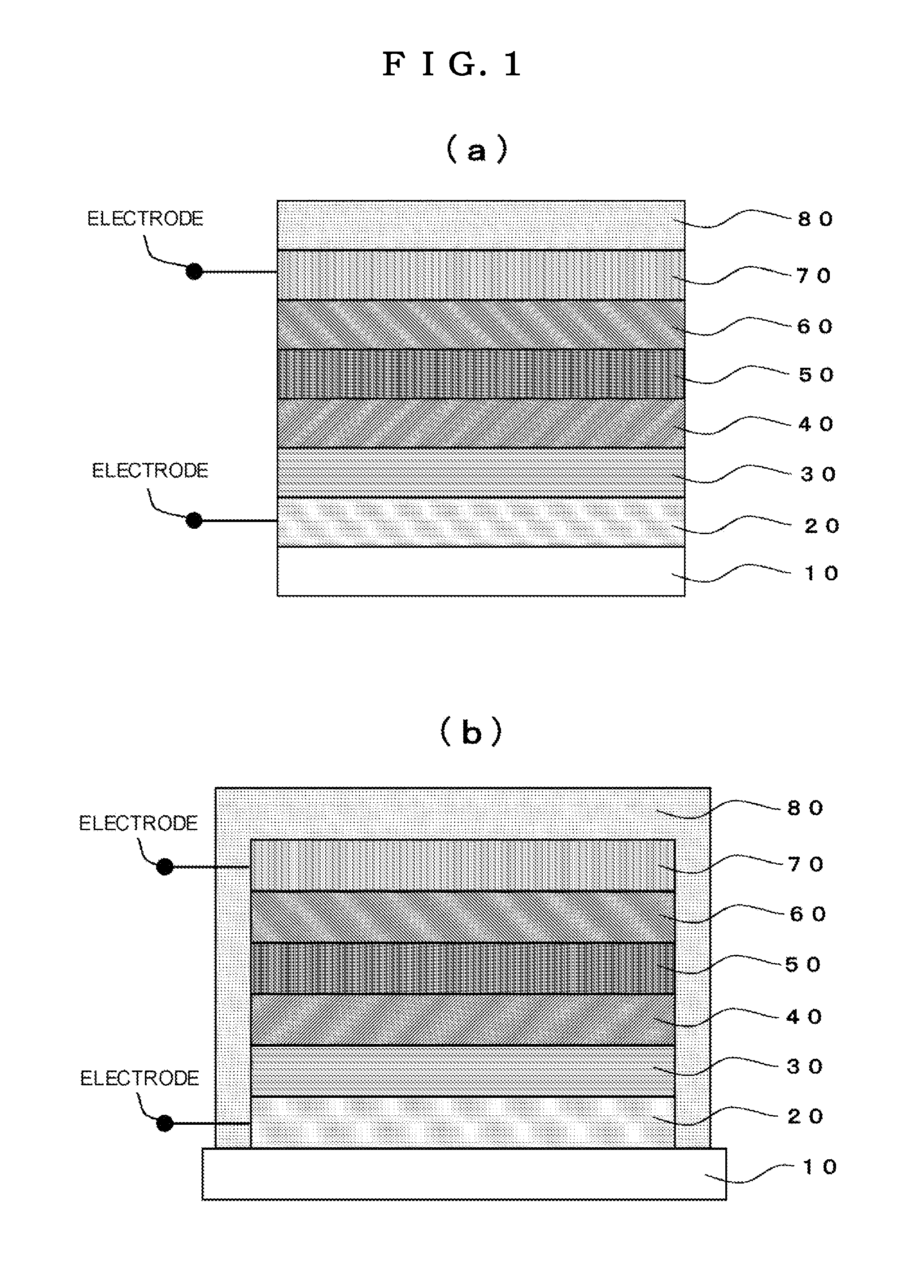

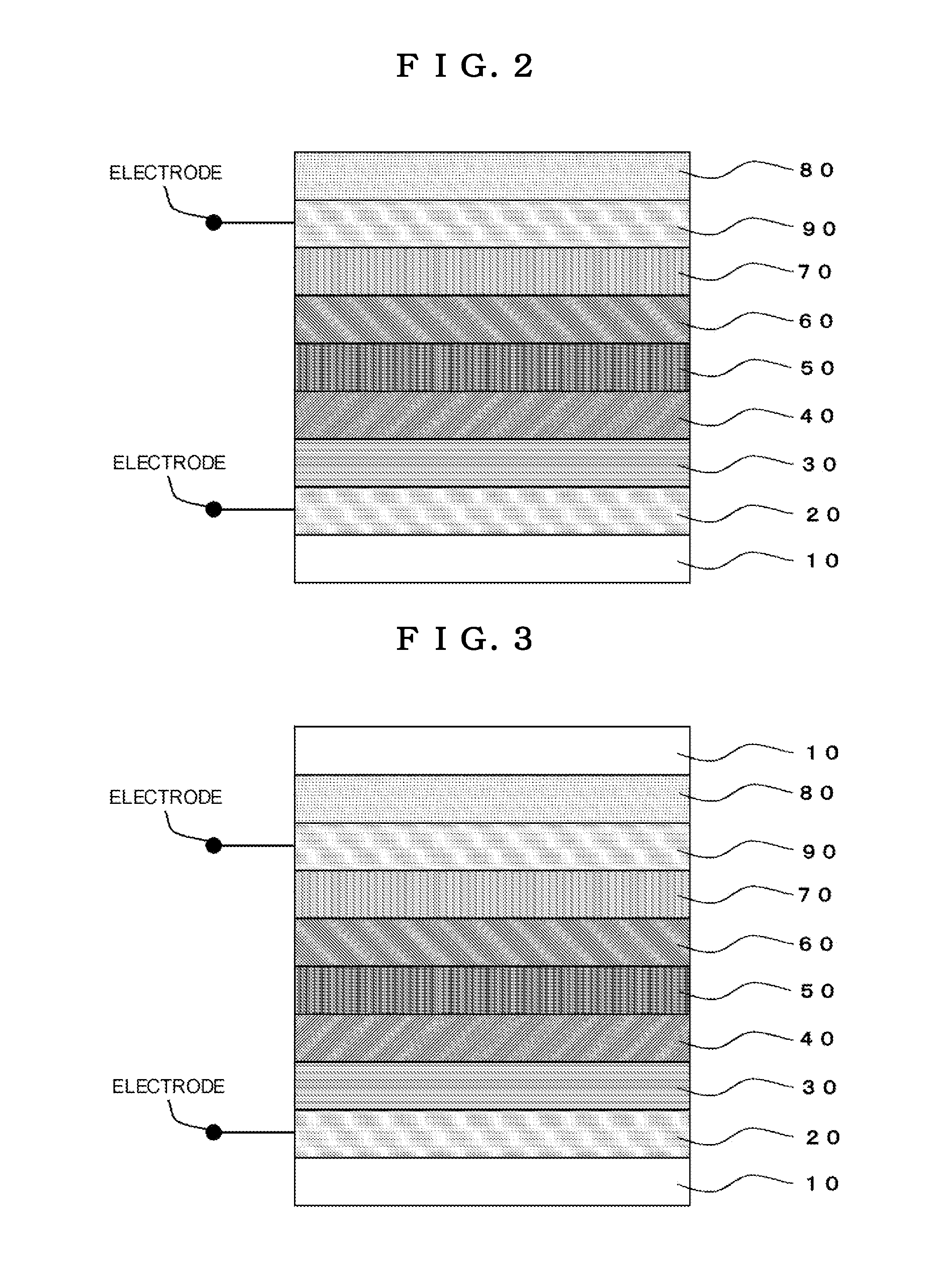

All-solid-state reflective dimming electrochromic element sealed with protective layer, and dimming member comprising the same

InactiveUS20130010347A1Dimming propertyIncrease the areaLight protection screensCoatingsAll solid stateTransparent conducting film

An all-solid-state reflective dimming electrochromic element having a multilayer film formed on a transparent substrate, which is characterized in that the multilayer film has a multilayer structure comprising at least a transparent conductive film layer, an ion storage layer, a solid electrolyte layer, a buffer layer, a catalyst layer, a reflective dimming layer, and a protective layer formed on the transparent substrate, and which is sealed with the protective layer, and a dimming member comprising the same are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

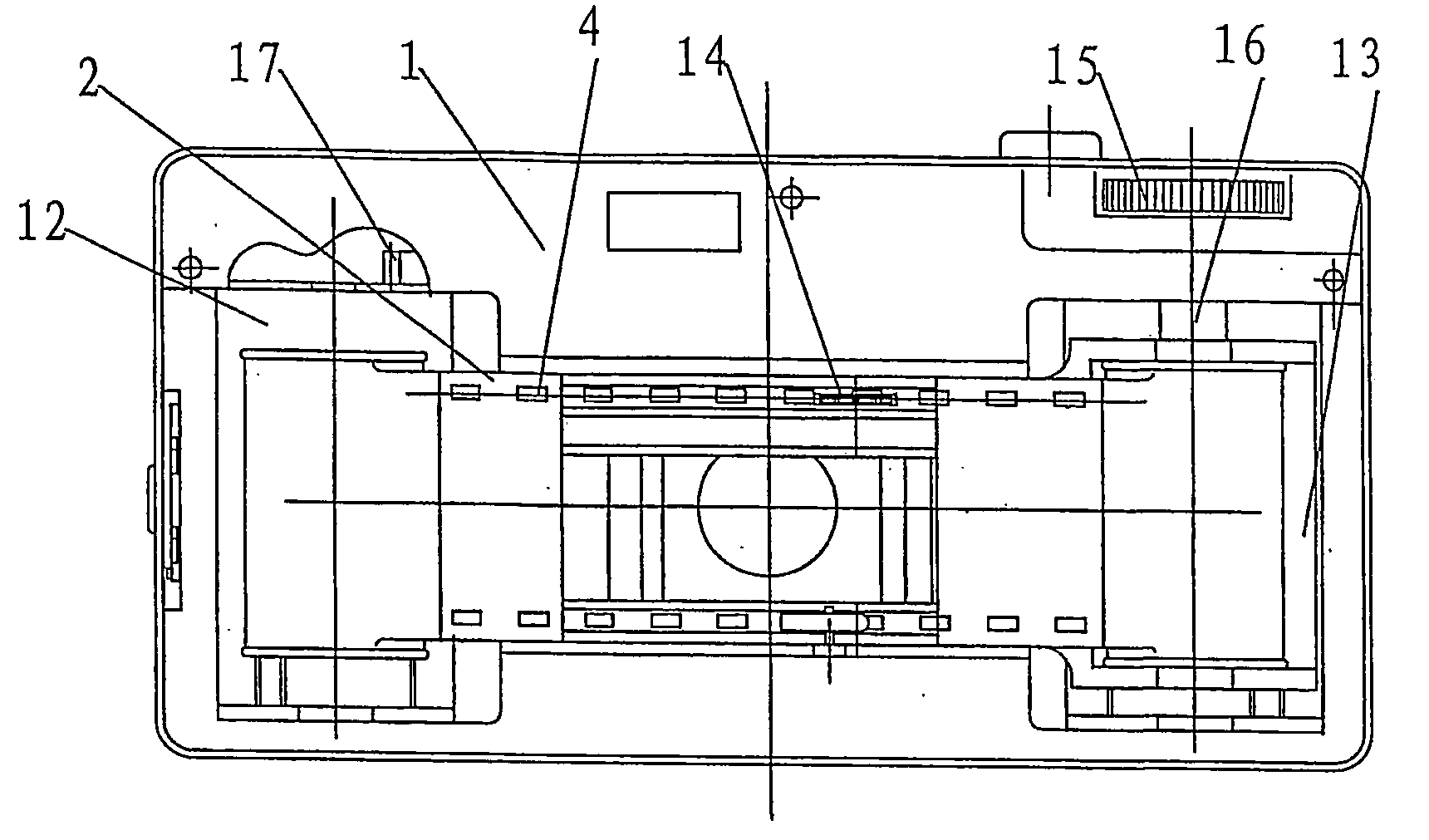

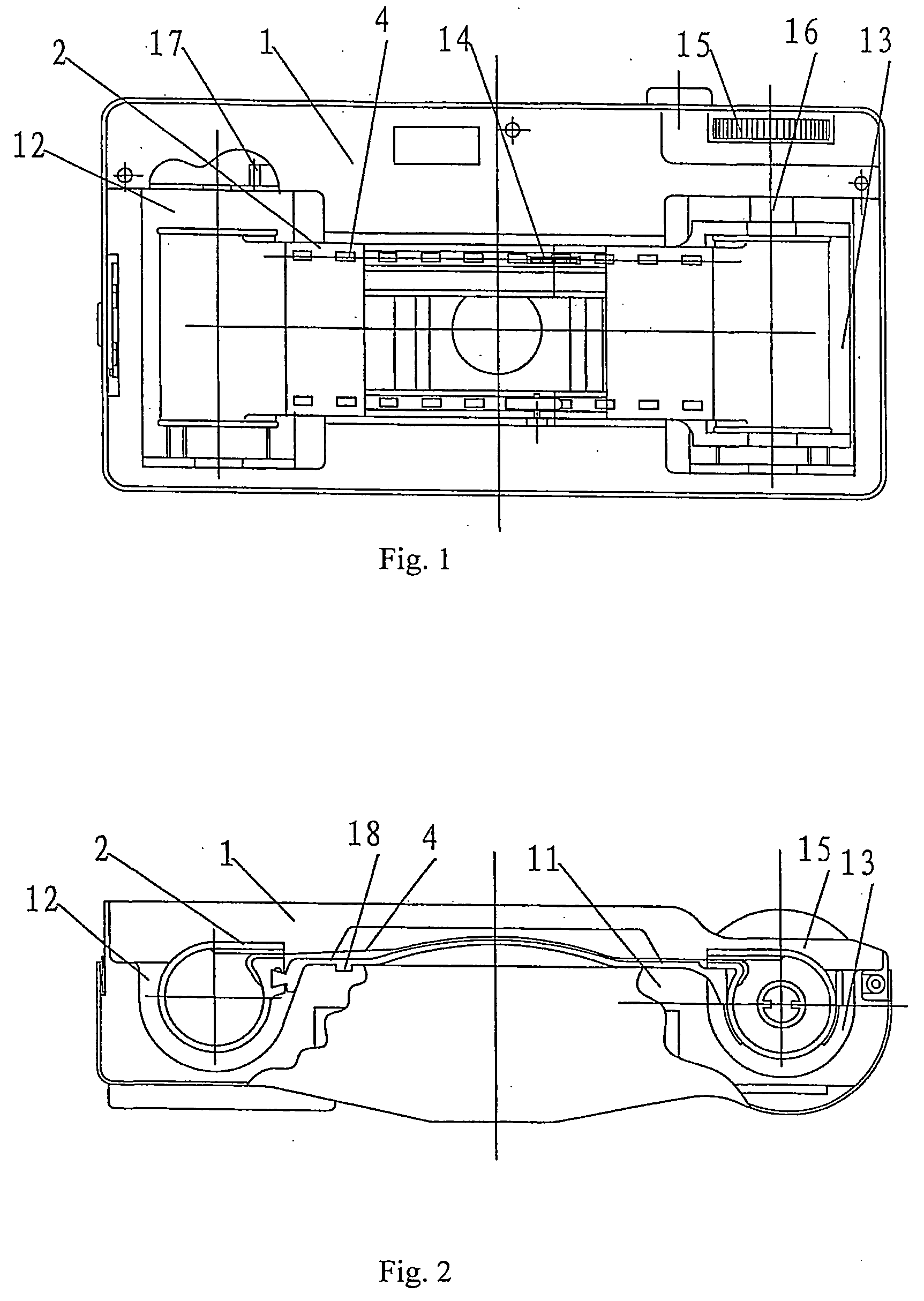

Imaging system for producing double exposure composite images and application thereof

InactiveUS20040151489A1Low applicabilityImprove adaptabilityCamerasPhotographyLatent imageFixed frame

The invention discloses an imaging system for producing double exposure composite images and application method therefor. This system includes a cartridge-clip camera and a cartridge-clip film. The cartridge-clip camera can achieve a conversion between a full-frame transmission and a half-frame transmission by a fixed-frame wheel, and can also provide a single-sheet-film card. The film may be a kind of information medium, on which there are various pre-exposed picture-and-word information latent images. When the cartridge-clip camera uses the cartridge-clip film, it can employ a positioning means for locating to make the cartridge clip provided with the film to be conveniently and accurately located in the cartridge-clip camera, and can produce accurately located double exposure composite images, thereby overcoming the drawback of known art, using conveniently and avoiding waste. In the use of the imaging system, the invention can independent package and sale the film,

Owner:ZHOU XIANFENG +1

Photomasks and methods of manufacturing the same

ActiveUS20120148944A1Economical efficiencyReliability economicalMaterial nanotechnologyNanoinformaticsOptoelectronicsPhotomask

Owner:SAMSUNG ELECTRONICS CO LTD

Mounting bracket

ActiveUS7883065B2Simple wayEasy to aimCandle holdersLighting support devicesControl theoryPermanent Mount

Owner:BOGEN COMM

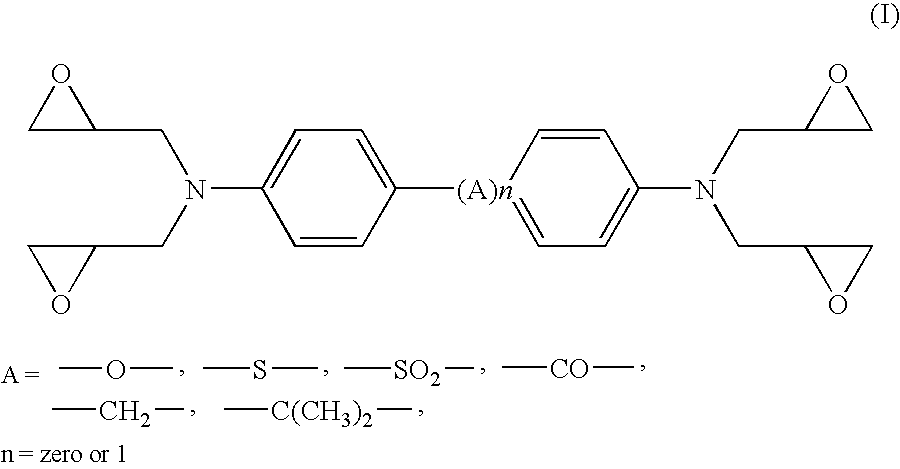

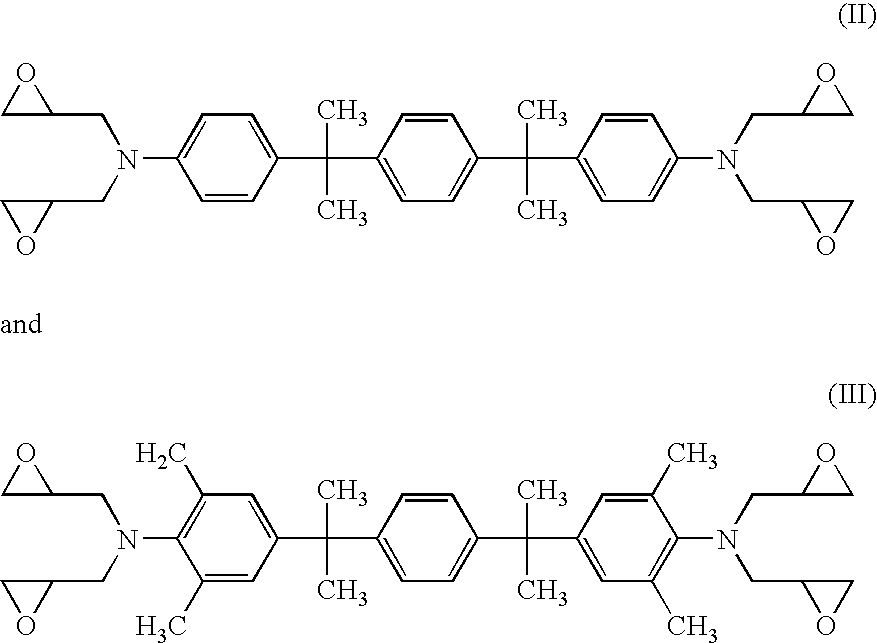

Casting compound based on thermosetting epoxy resins

InactiveUS6852415B2Improve curing speedShorten gel timePlastic/resin/waxes insulatorsNon-macromolecular adhesive additivesEpoxyProduct base

The curable casting compound comprises an epoxy resin having at least one aminoglycidyl group in the molecule, a curative, and a fluorosurfactant. In the manufacture of products based on this casting compound, the shaping and curing operation can be shortened considerably.

Owner:ABB RES LTD

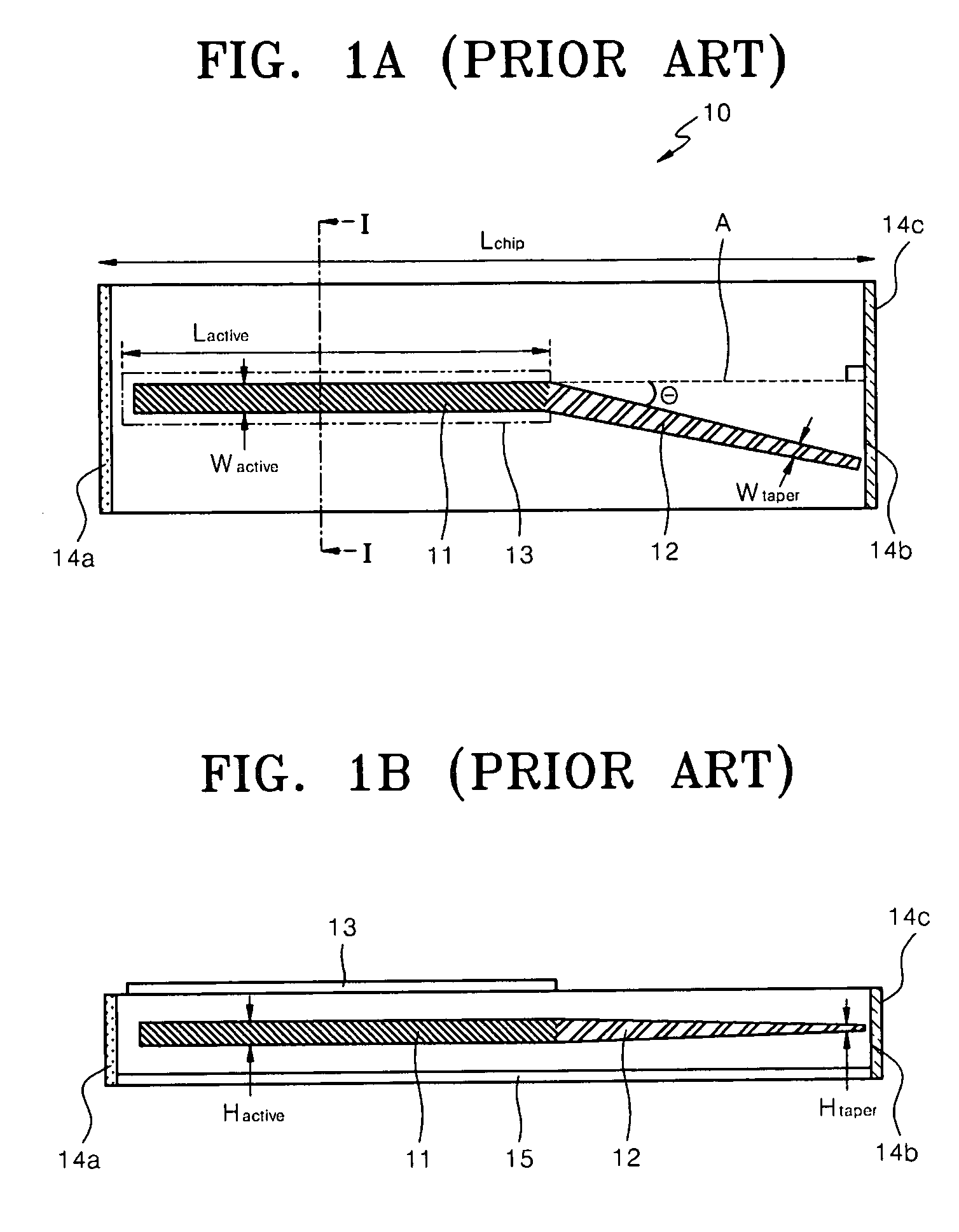

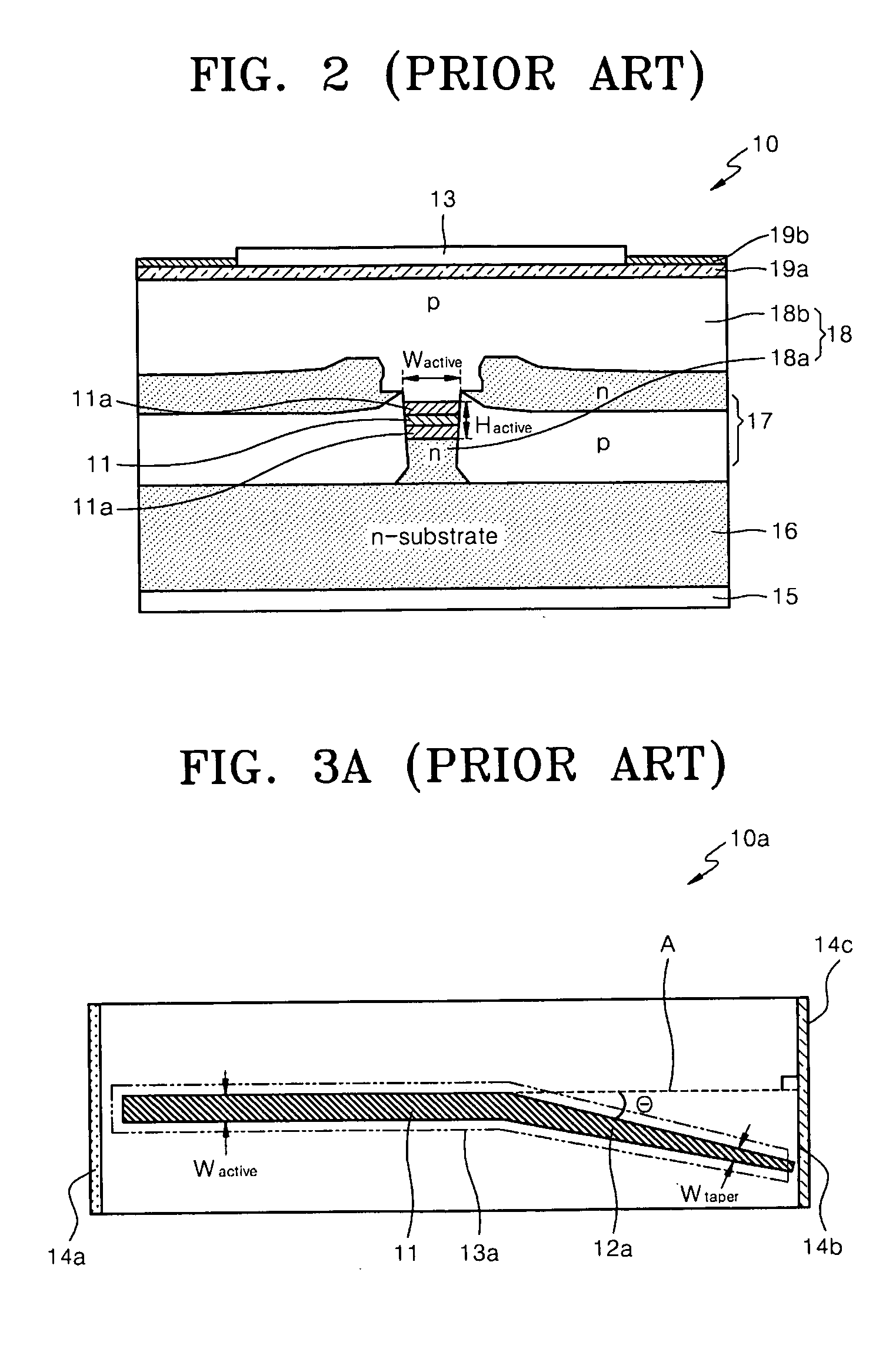

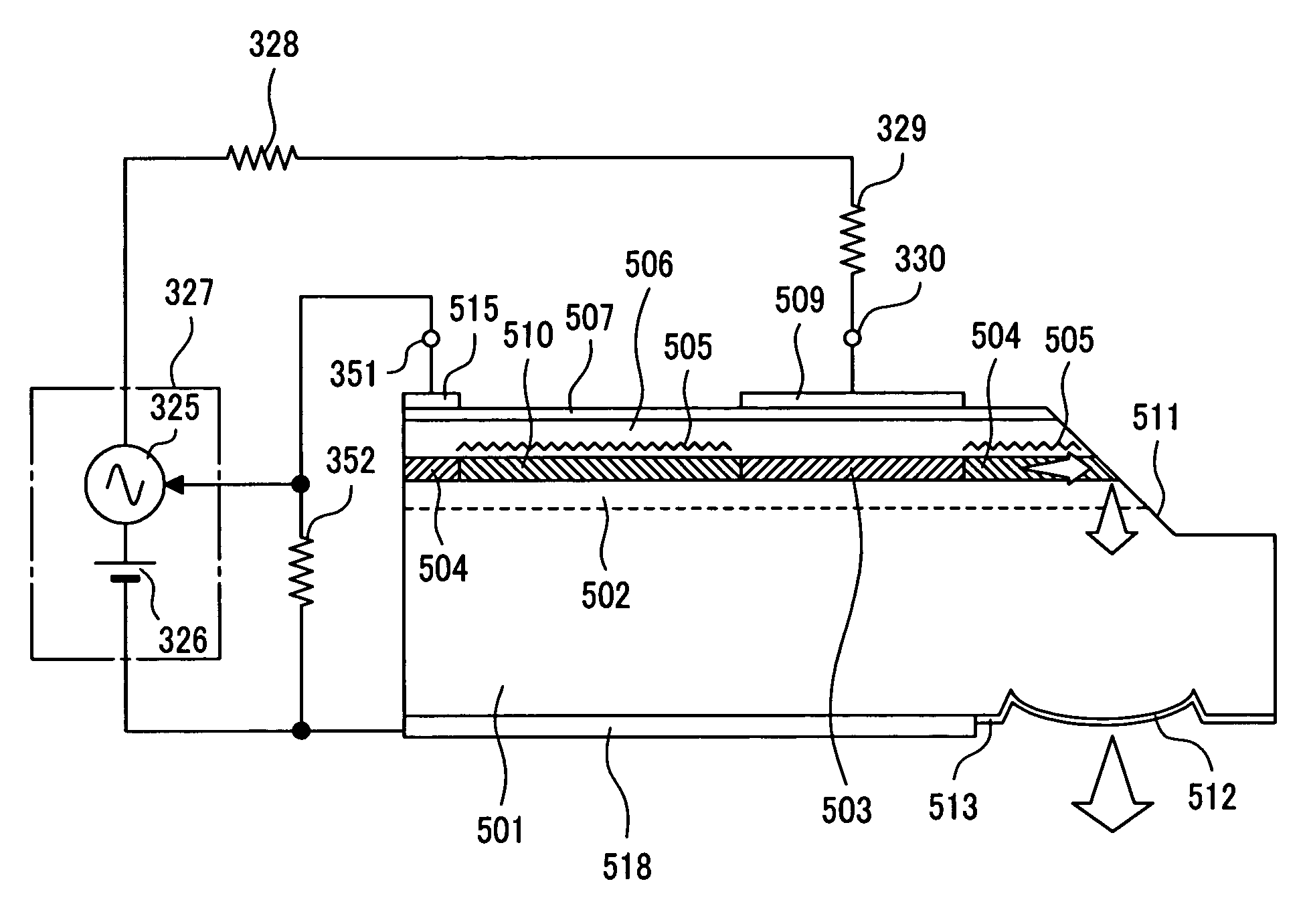

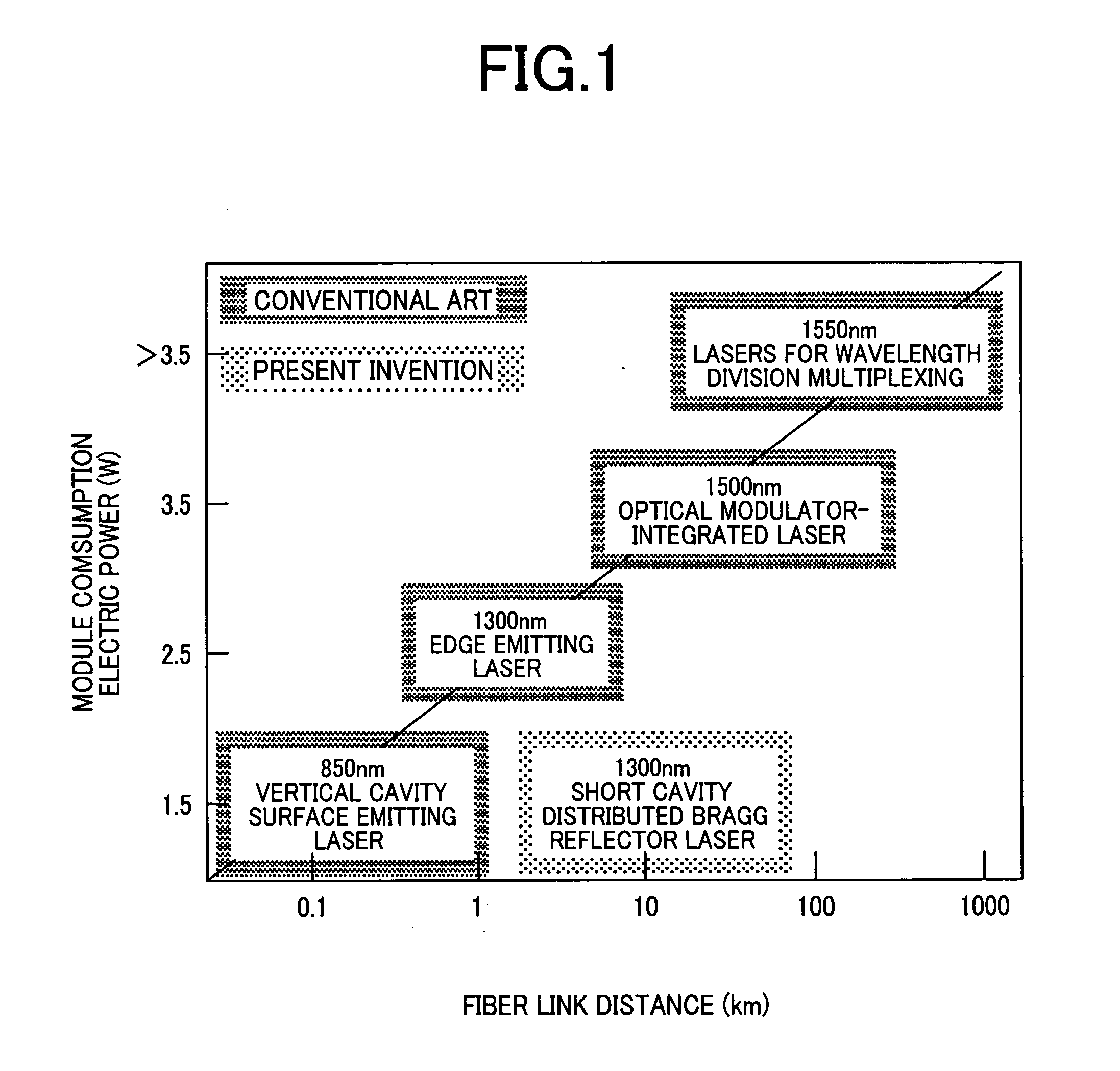

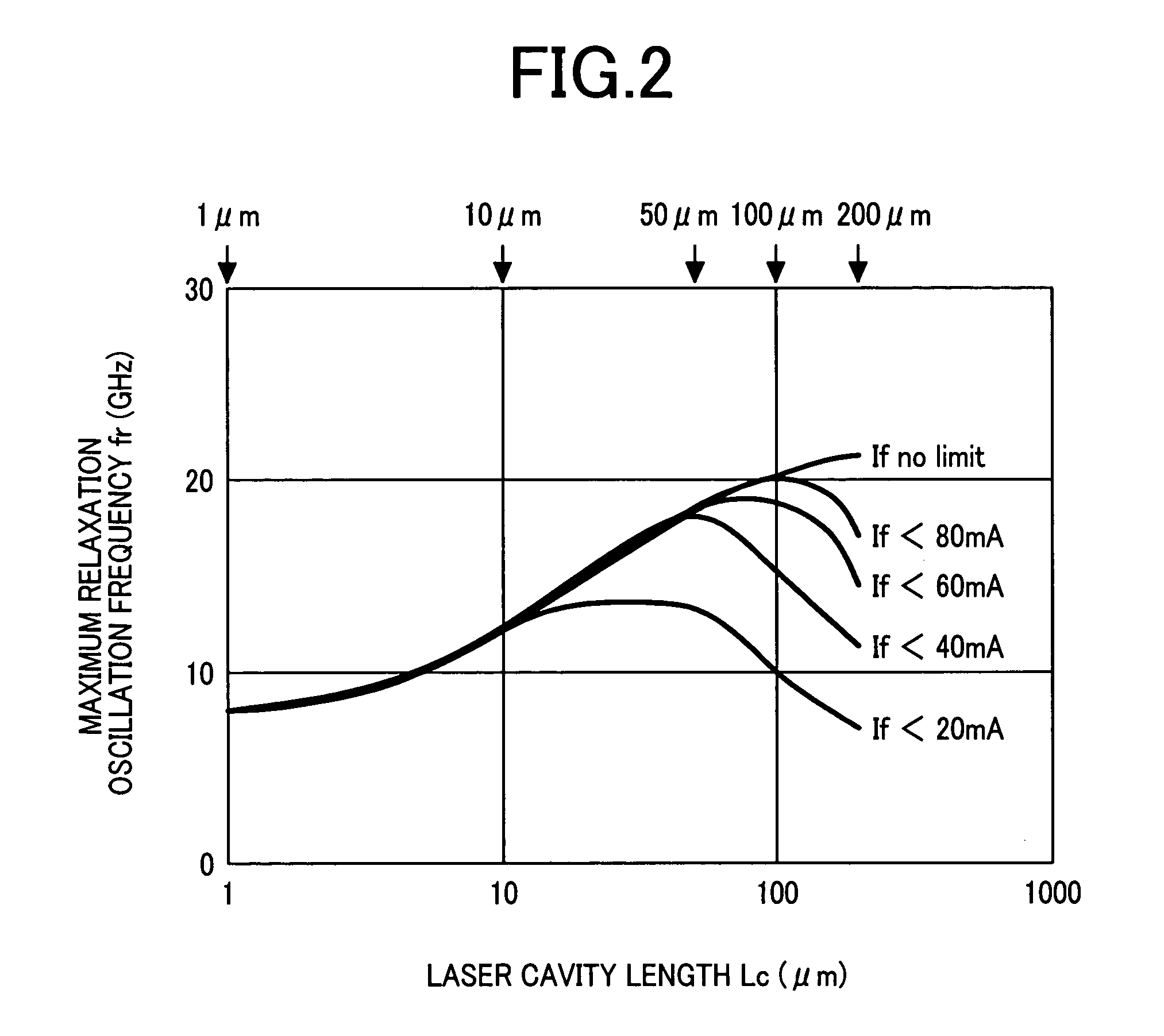

Optical semiconductor device and optical module using thereof

ActiveUS20060291516A1Economic efficiency is excellentLess power consumptionOptical resonator shape and constructionSemiconductor lasersOptical ModuleDistributed Bragg reflector laser

The invention aims at realizing a 1300-nm-band direct modulation laser, having a single lateral mode, in which a chip light power of several milliwatts and a low current operation are simultaneously realized. Also, the invention aims at realizing a laser light source excellent in economy as well by realizing output characteristics of a vertical cavity surface light emitting laser. A distributed Bragg reflector laser is constructed in the form of a semiconductor laser having a multilayer structure formed on a predetermined semiconductor substrate. The multilayer structure includes an active region for emitting a laser beam, and a distributed Bragg reflector layer. A length of the active region falls within the range of 10 to 100 μm, and a laser light beam is generated in accordance with ON / OFF of current injection to the active region.

Owner:LUMENTUM JAPAN INC

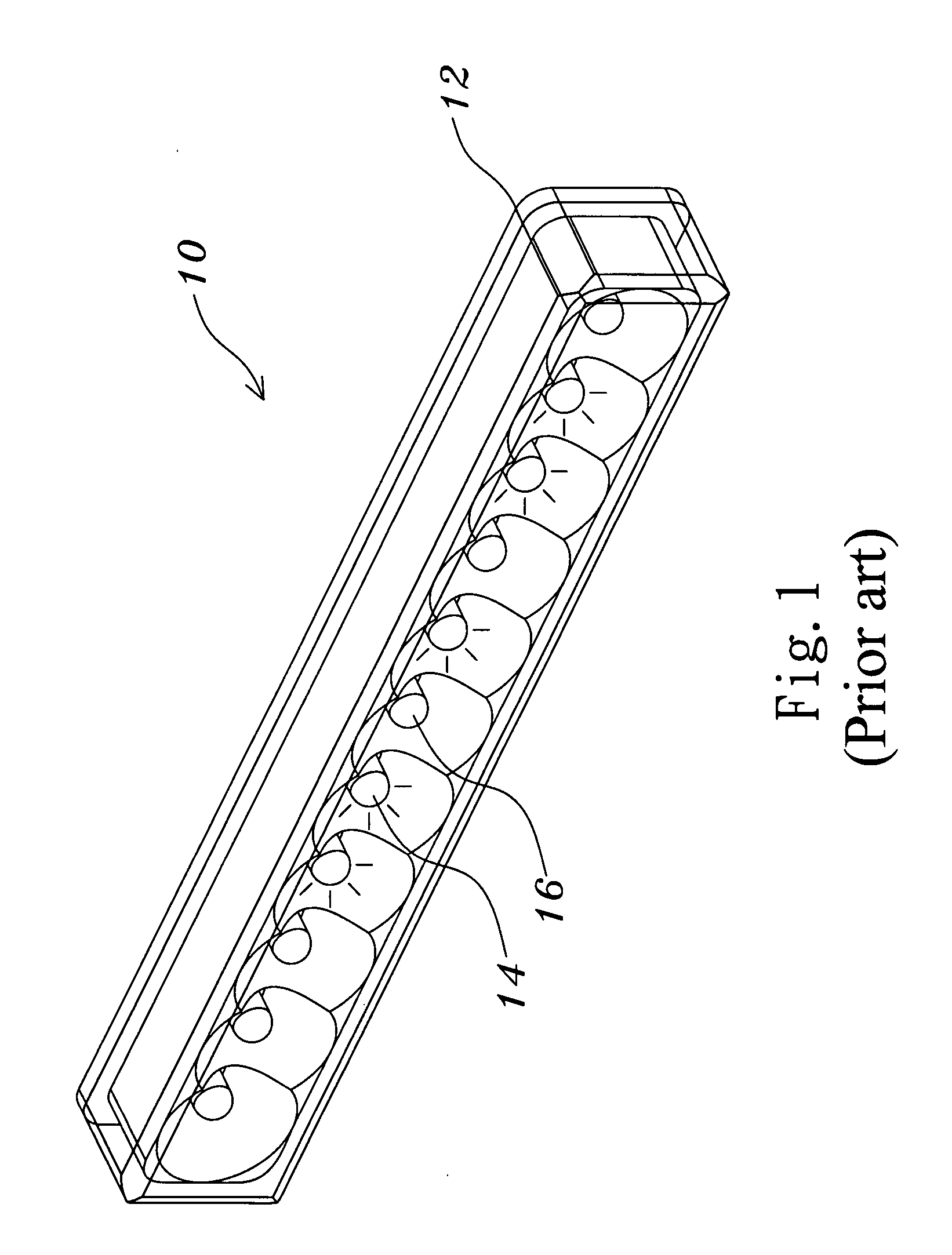

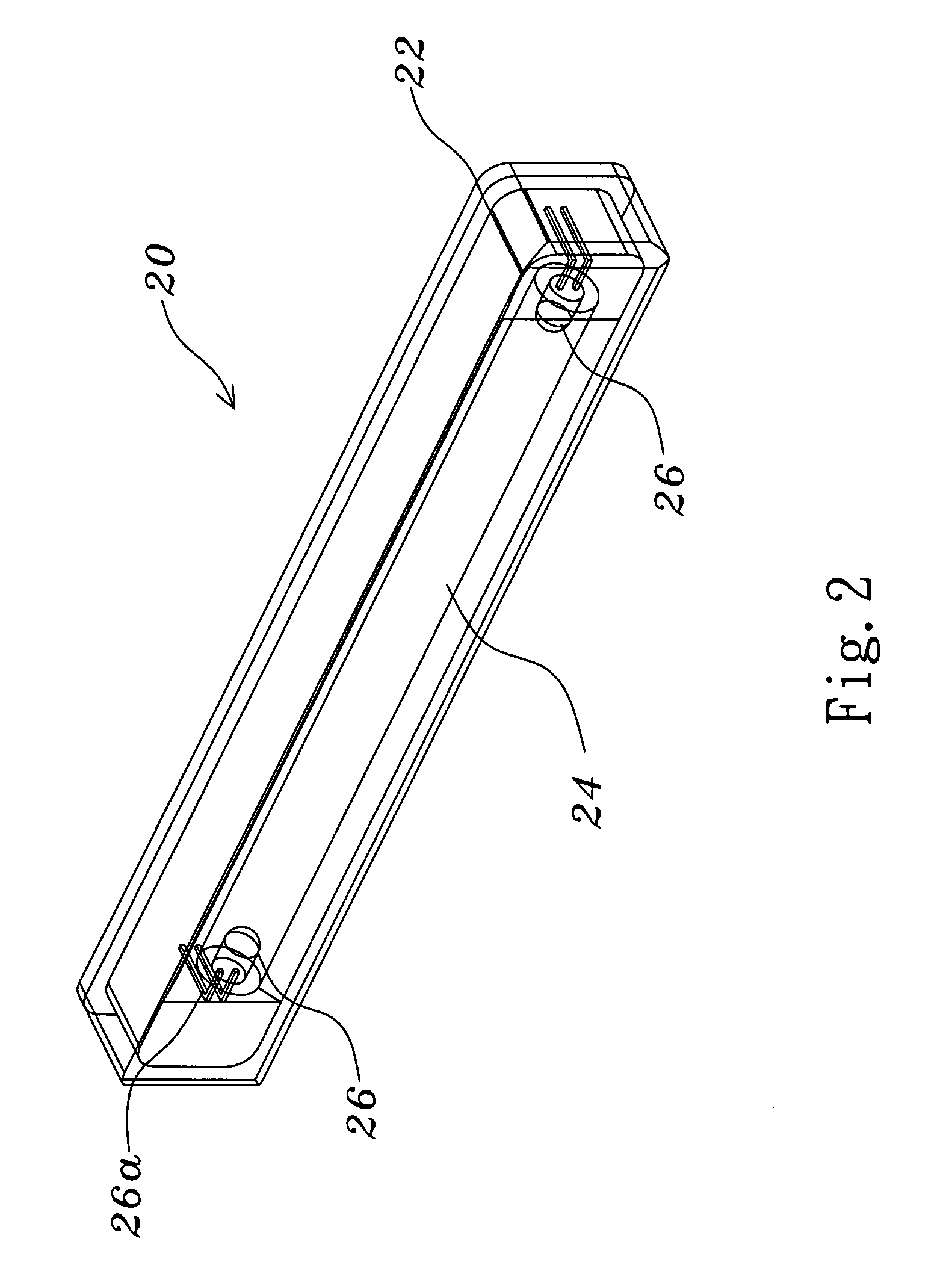

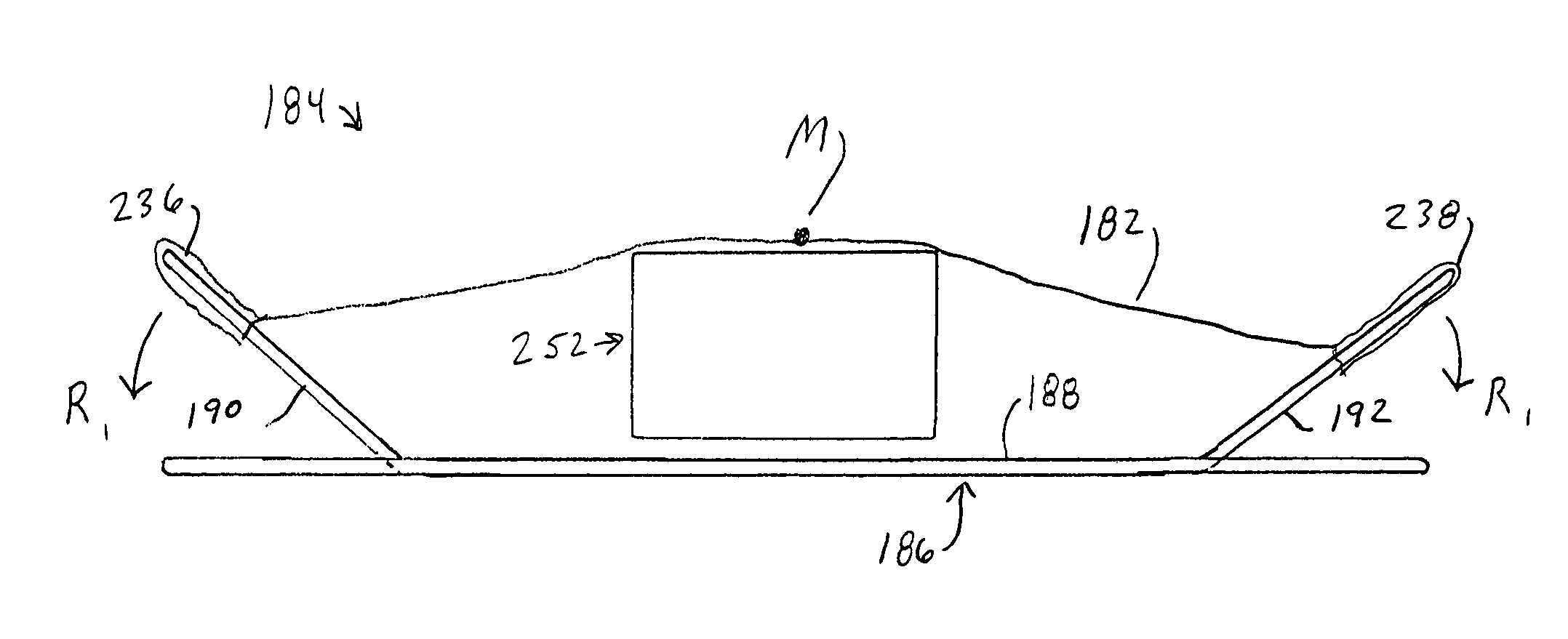

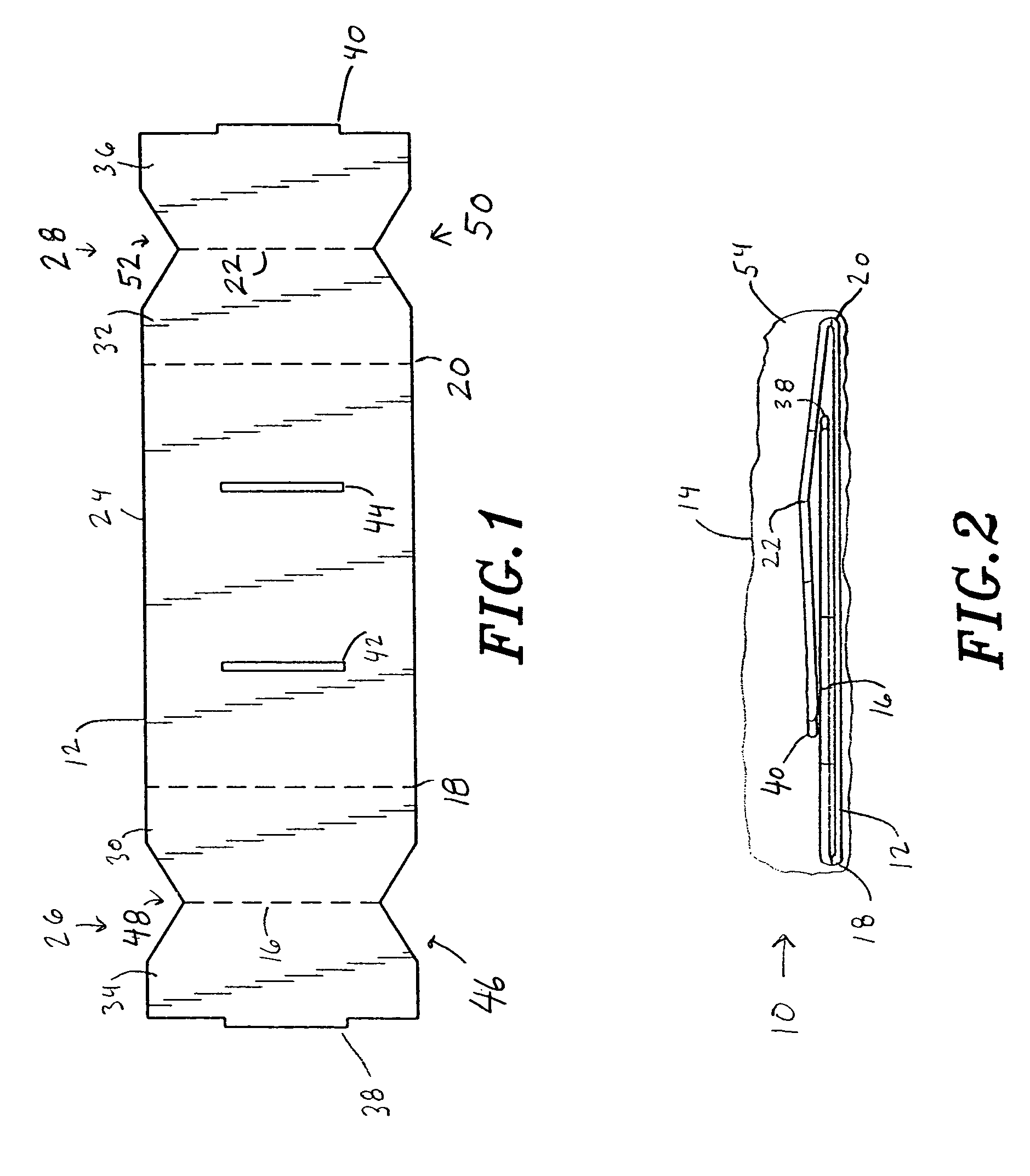

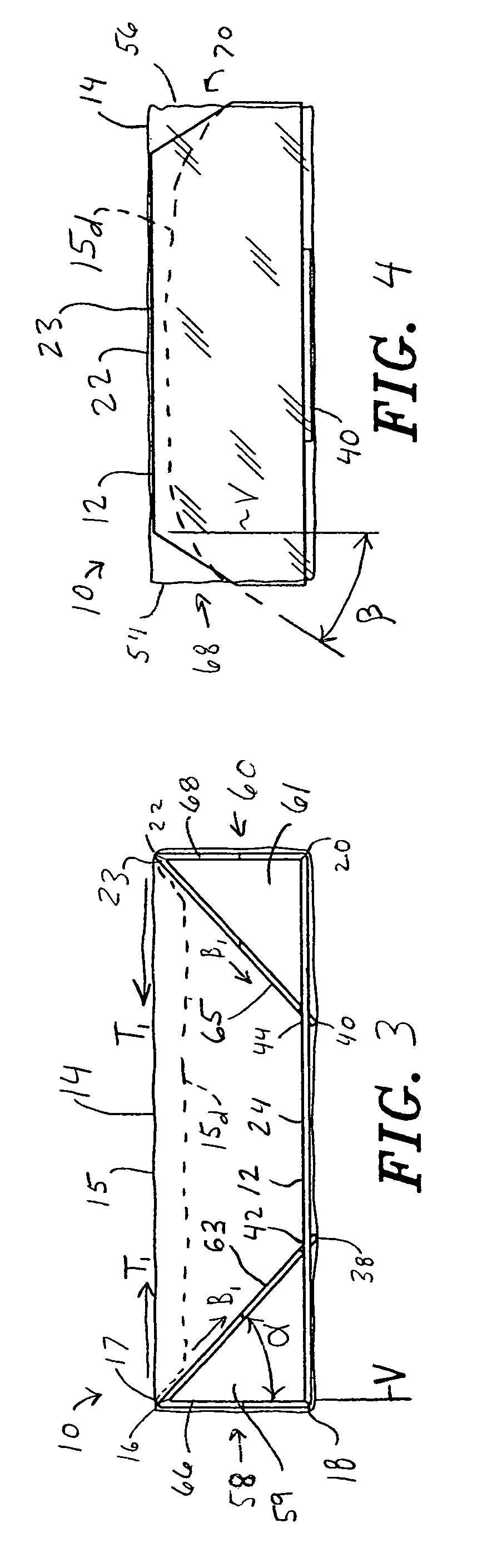

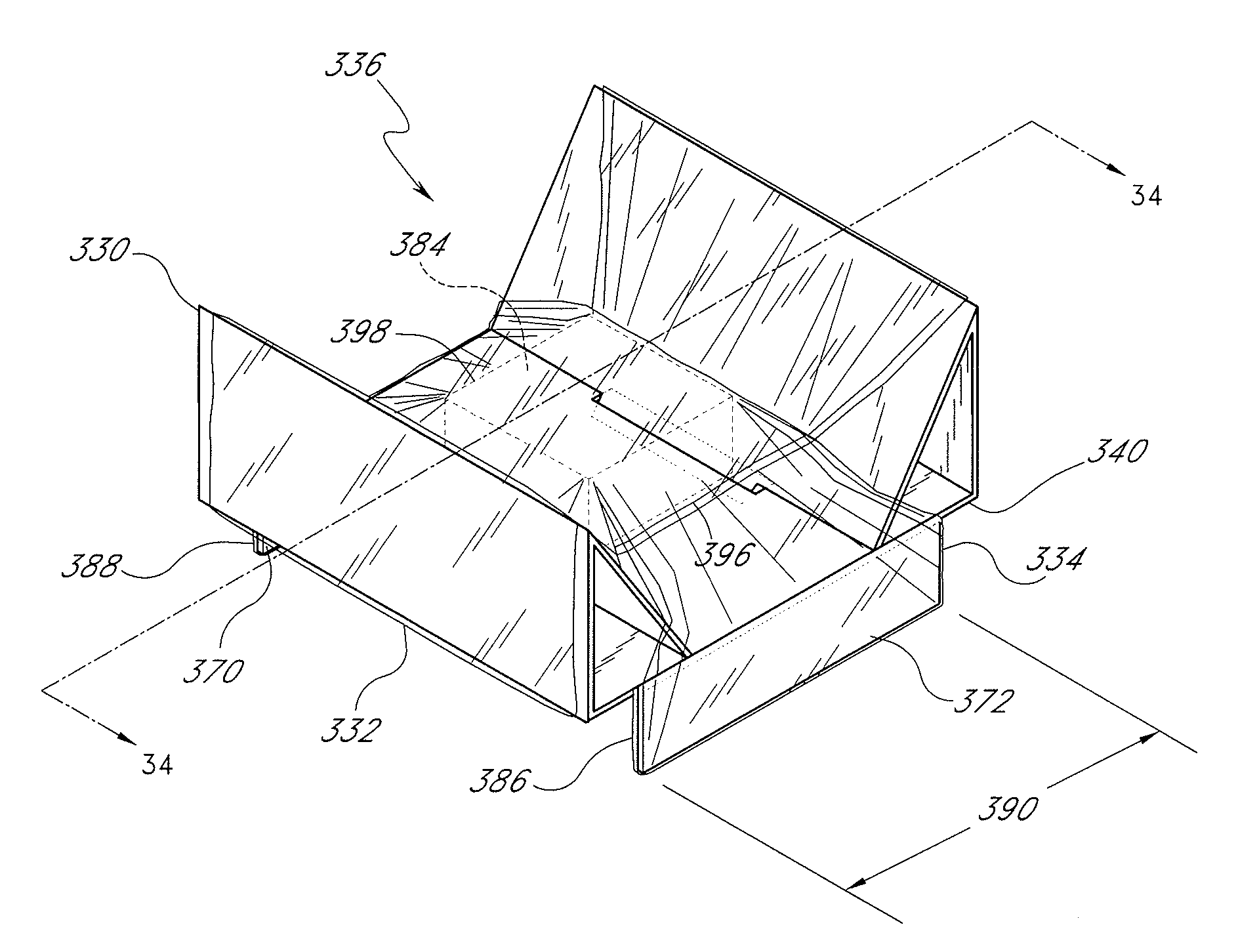

Suspension packaging assembly

InactiveUS7731032B2Reduce manufacturing costEasy to assembleContainers to prevent mechanical damageRigid containersMechanical engineering

A packaging assembly includes a frame member and a retention member which is not permanently affixed to the frame member. The frame member can include a variety of features which allow the retention member to be tightened around an article to be packaged and thus protected from shocks and impacts during transport, display, and / or retail use. The retention member can be formed as a sleeve or with pockets for engaging the frame member.

Owner:CLEARPAK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com