Patents

Literature

49results about How to "Shorten gel time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

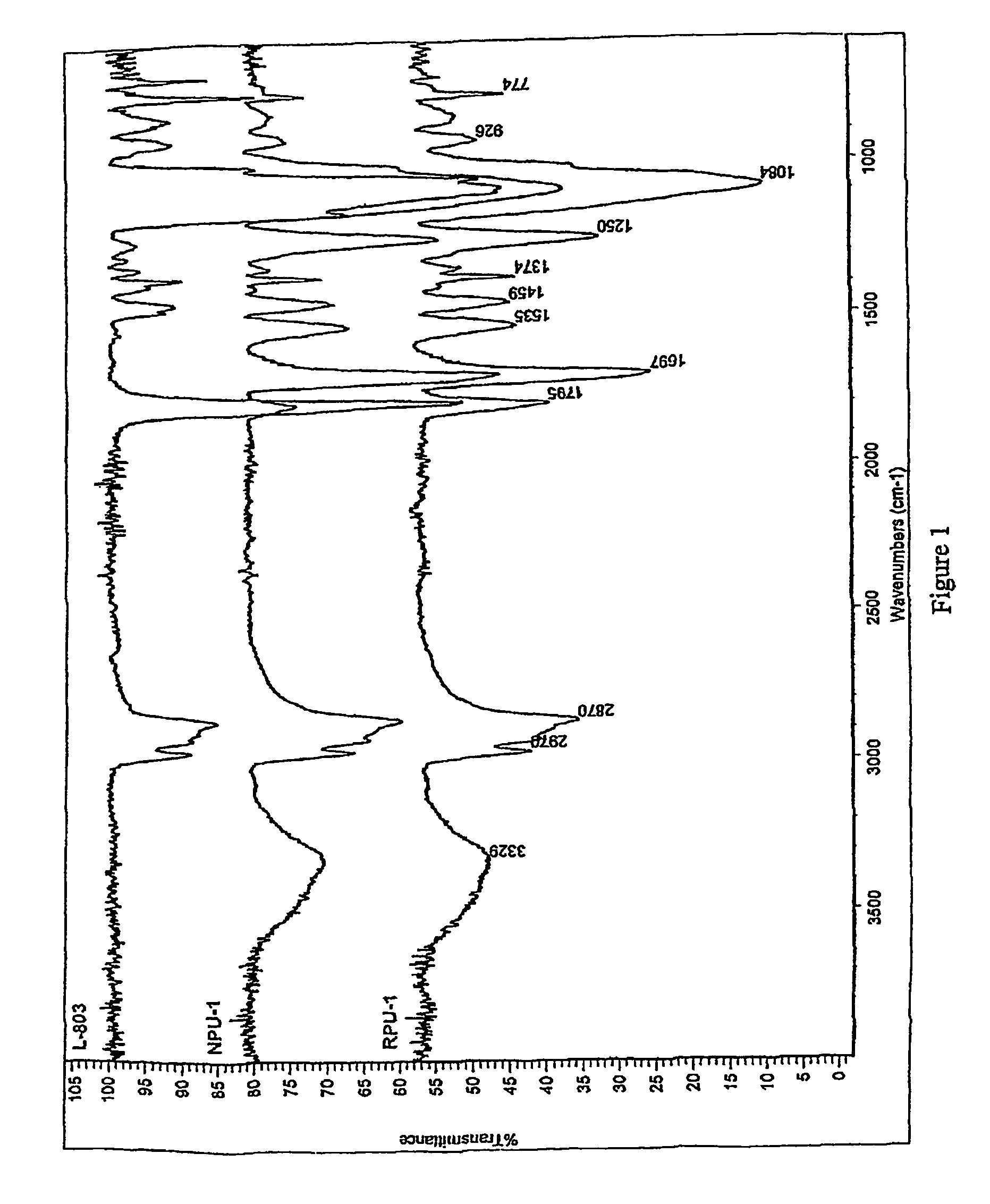

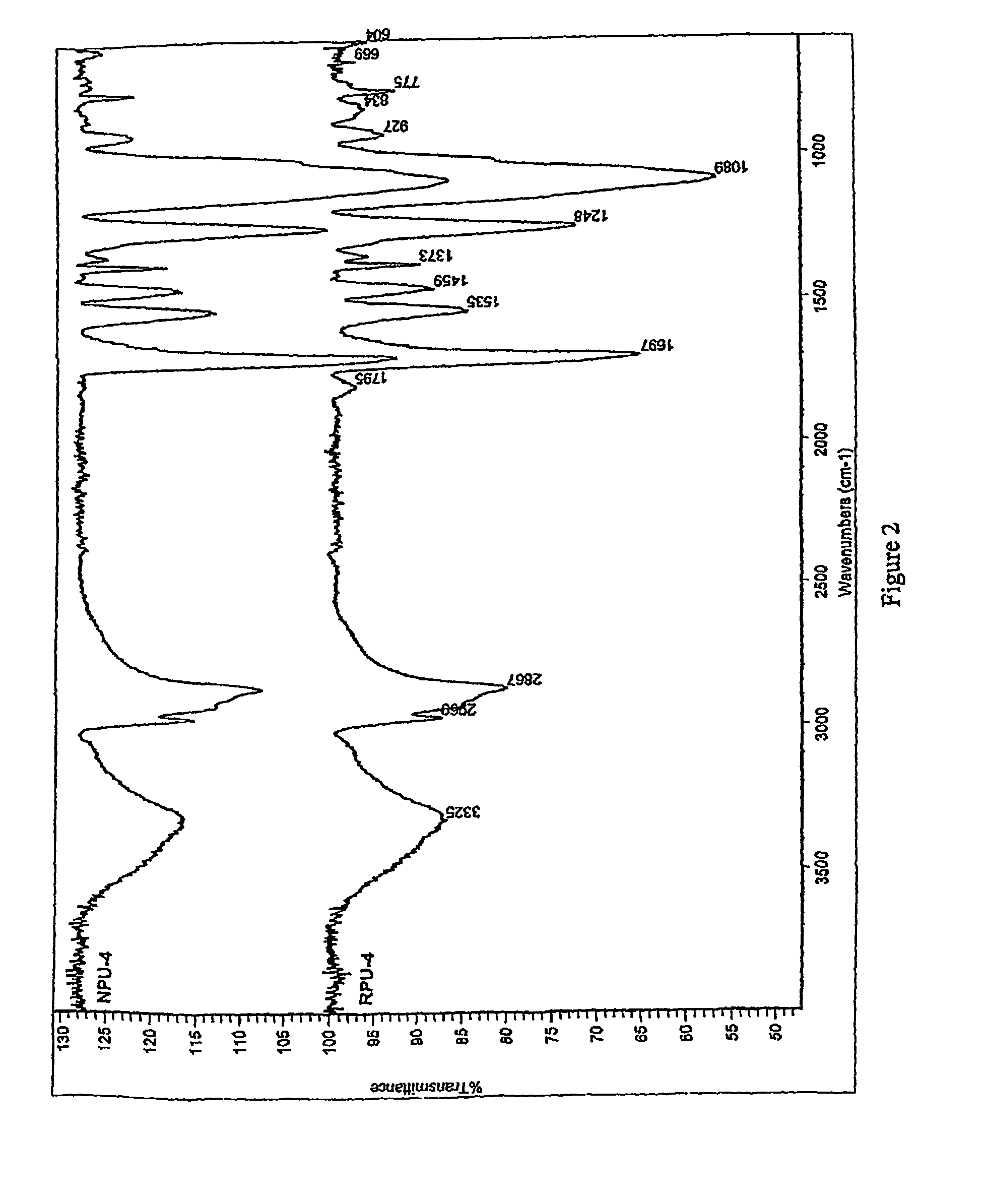

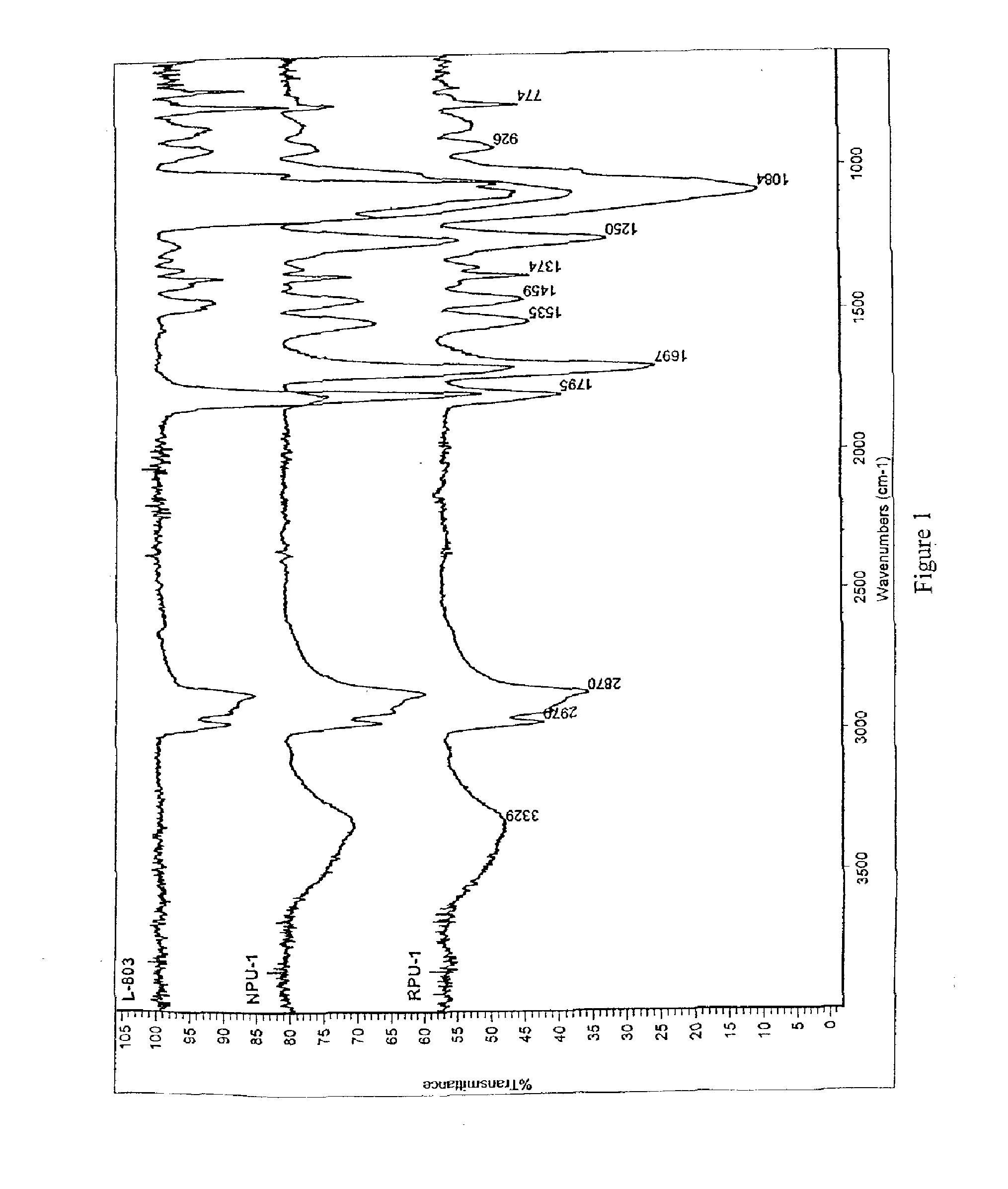

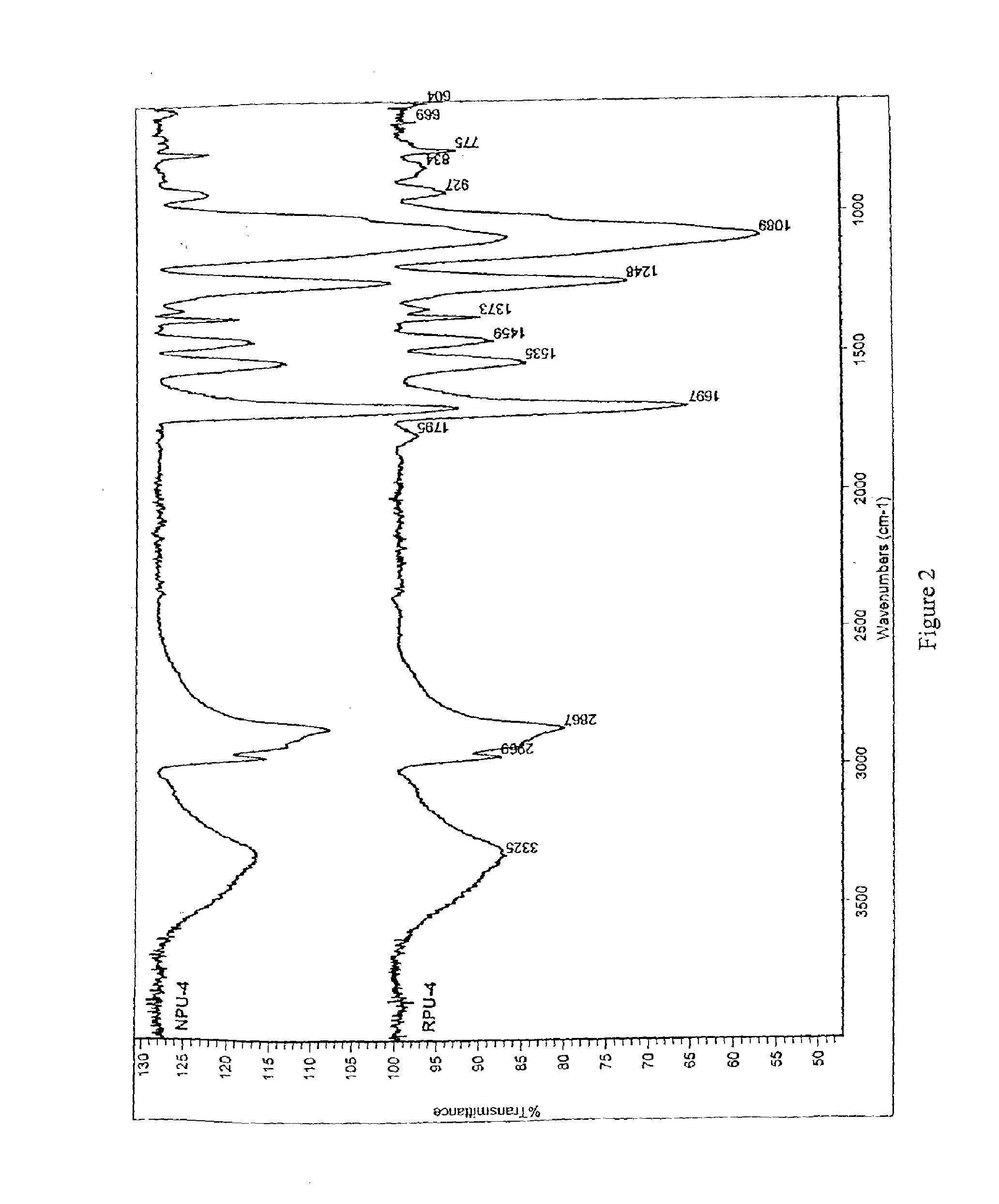

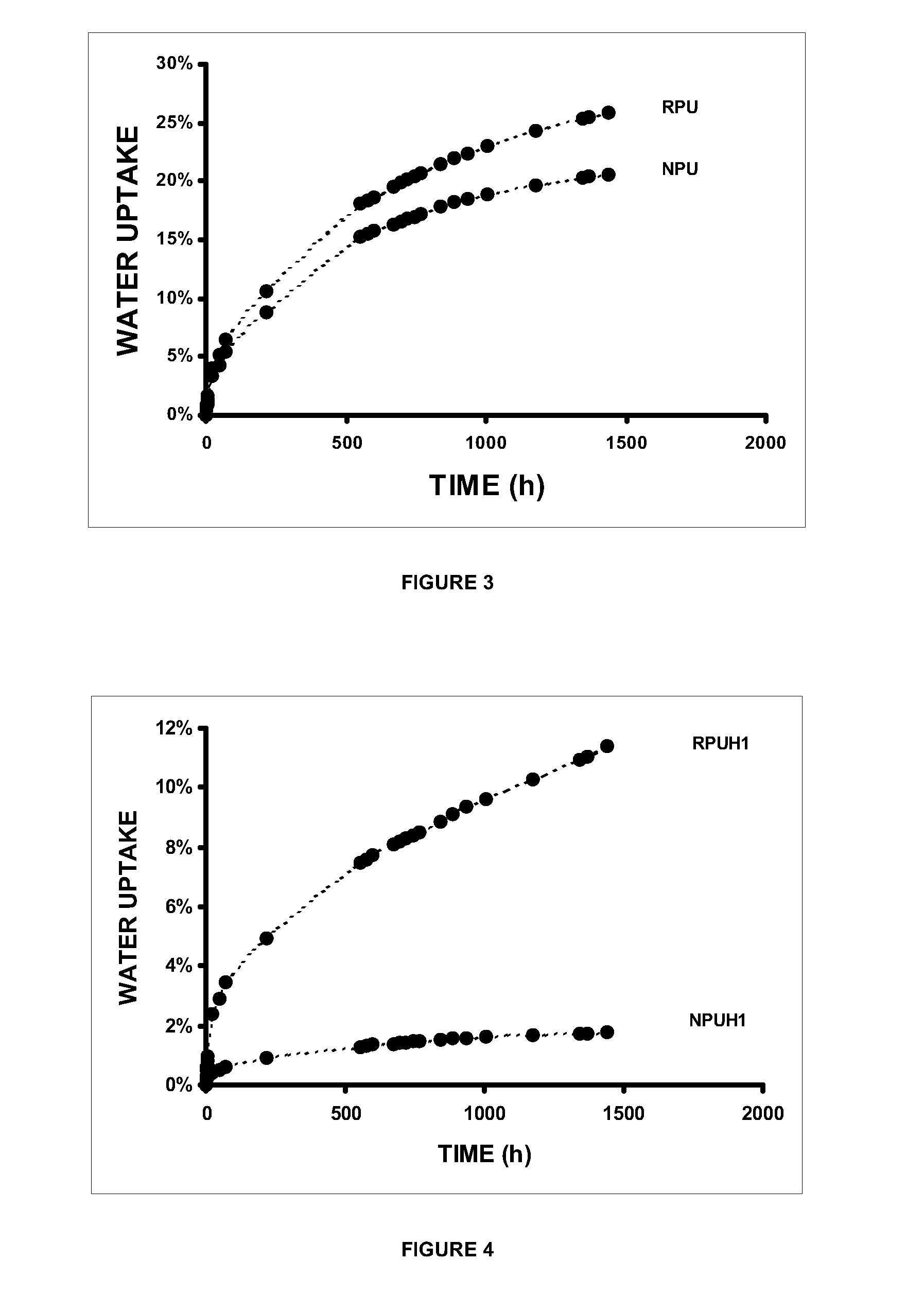

Nanocomposites based on polyurethane or polyurethane-epoxy hybrid resins prepared avoiding isocyanates

ActiveUS20070135588A1Beneficial physicochemical and mechanical propertyAvoid damageMaterial nanotechnologySynthetic resin layered productsNanometreAspect ratio

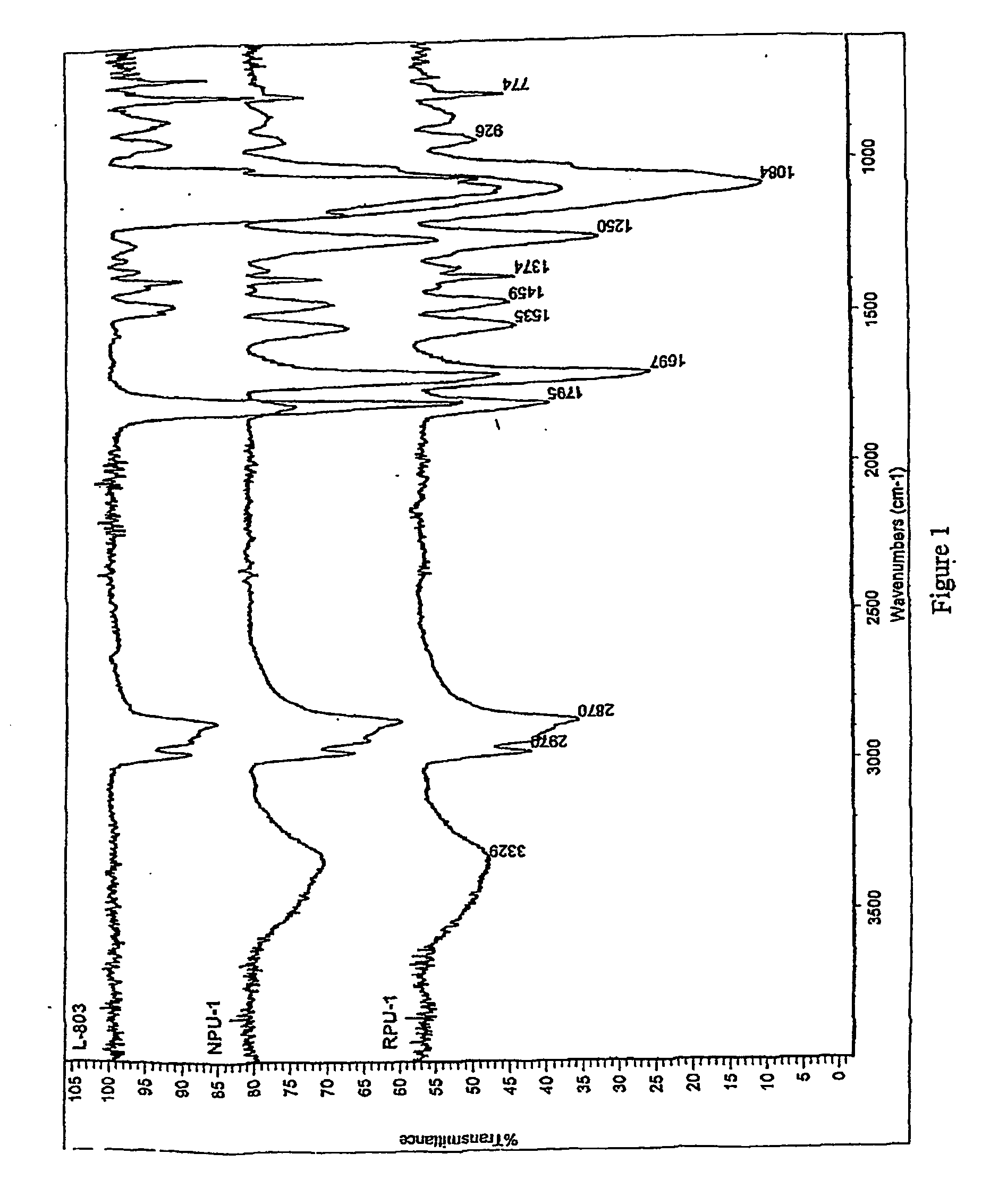

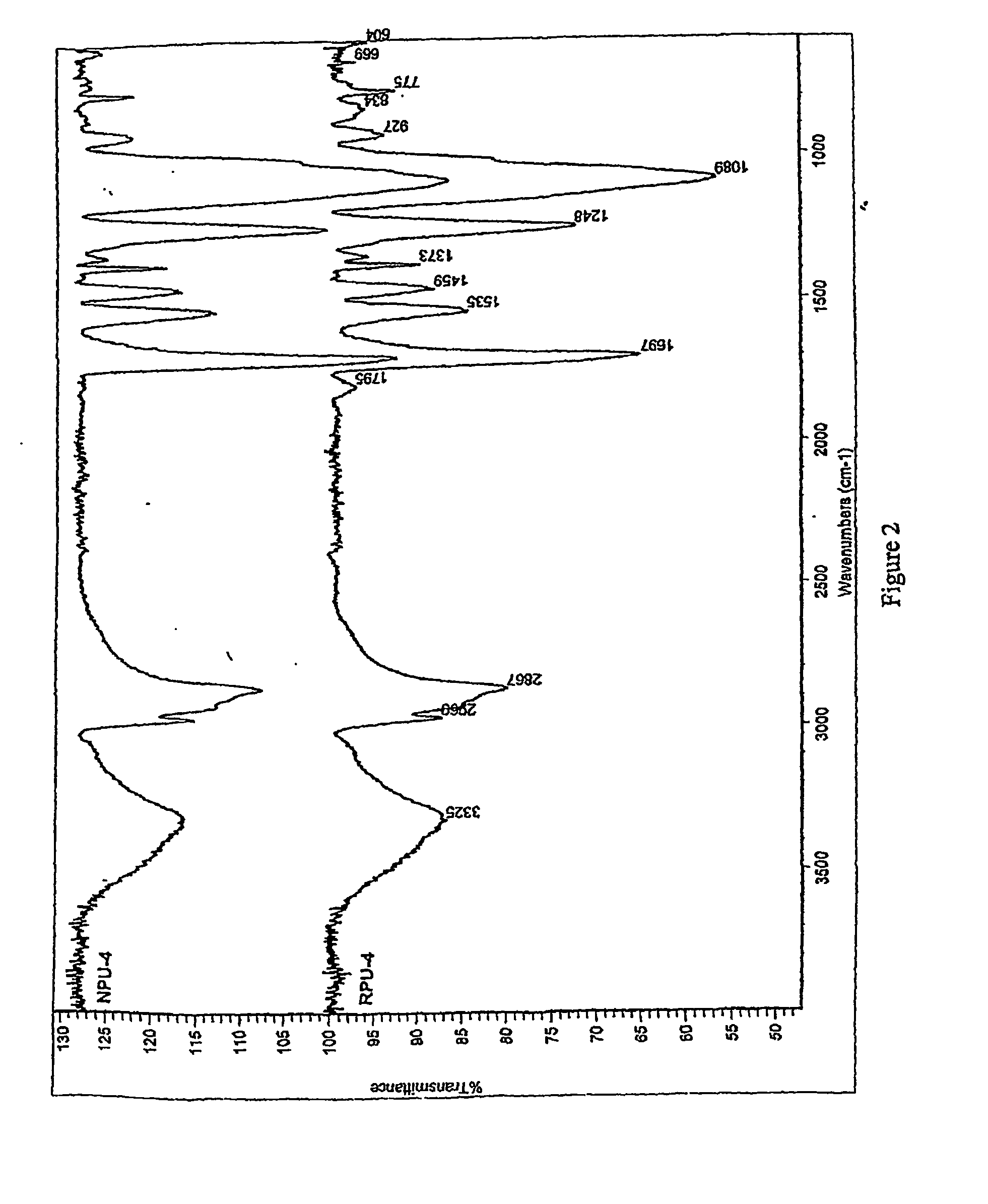

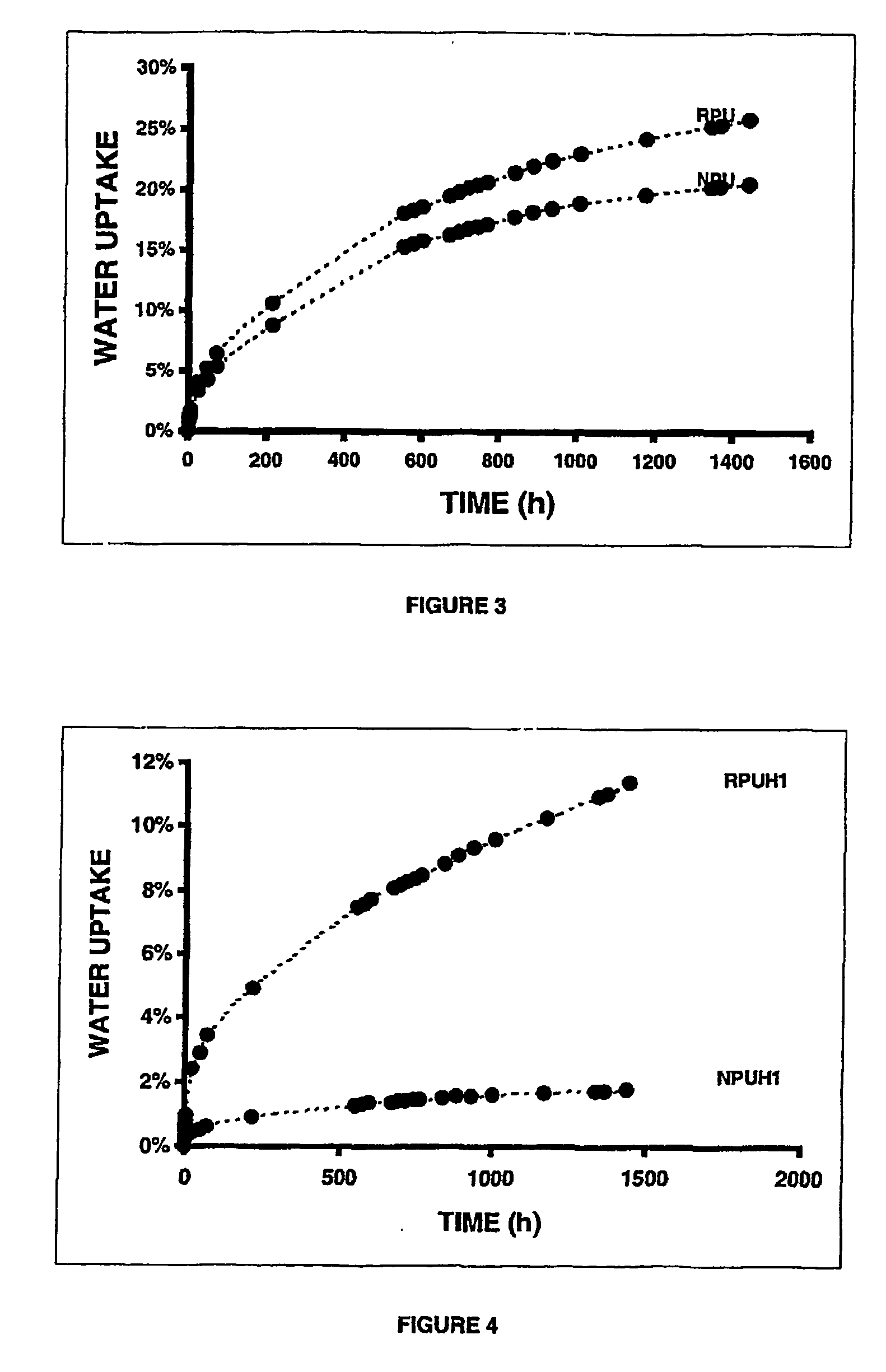

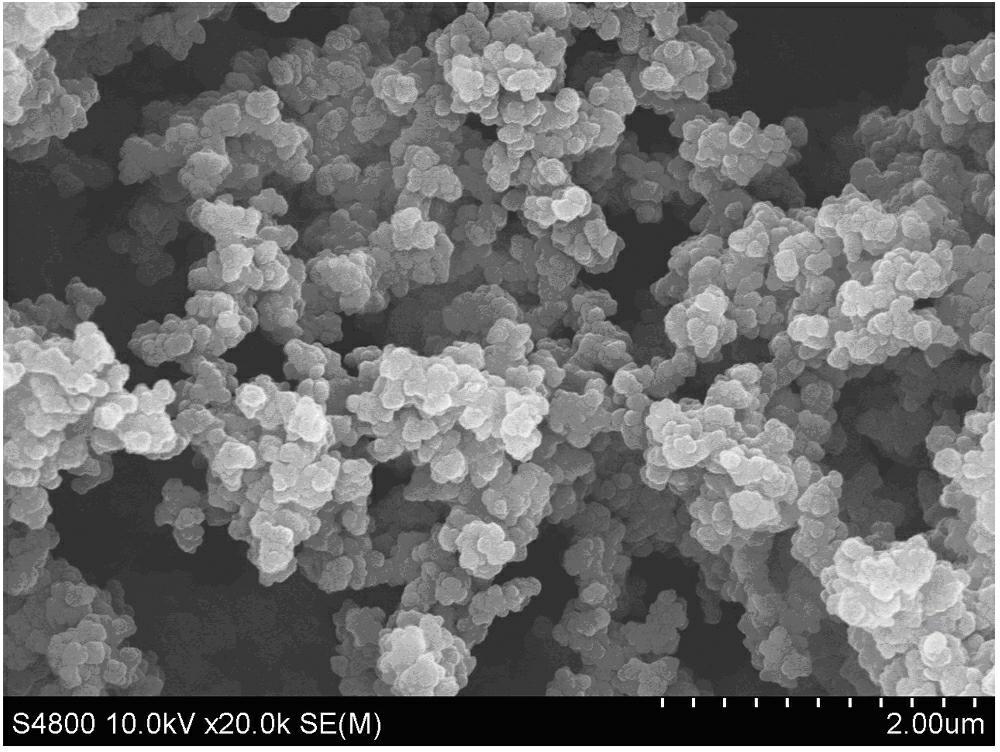

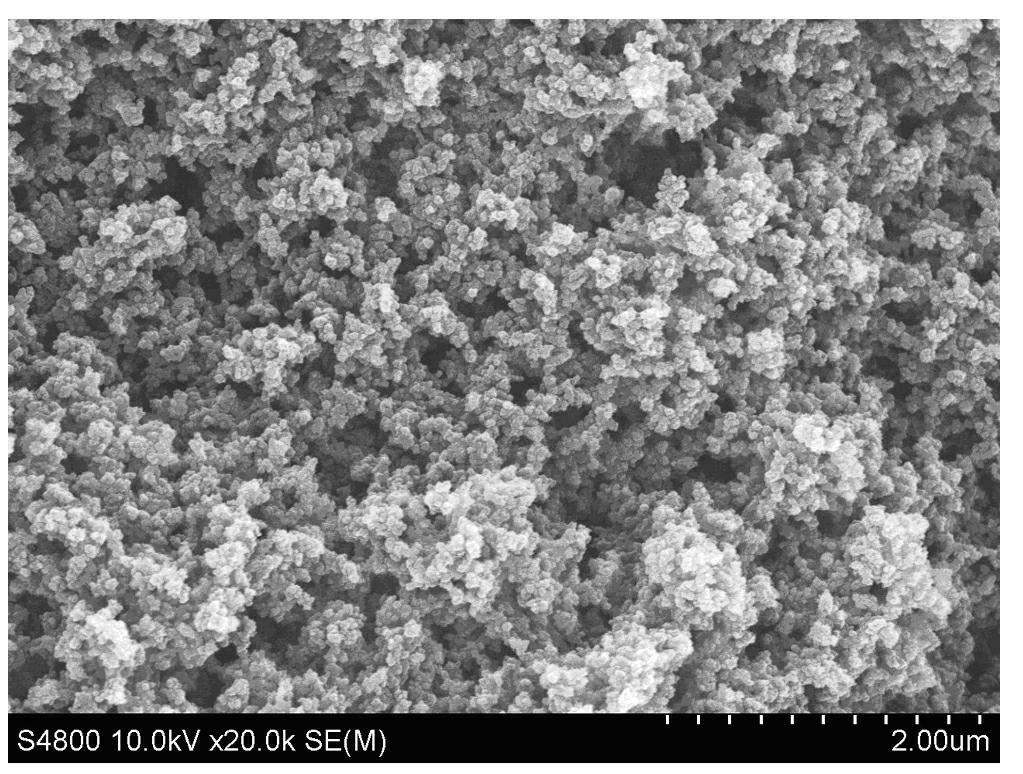

A fast curable non-isocyanate-based polyurethane- and polyurethane-epoxy network nanocomposite polymeric compositions are derived upon crosslinking a mixture comprising of natural or modified nano-clay [ionic phyllosilicate] with platelet thickness in the scale of A (˜1 nm) and aspect ratio (length / thickness) higher than 10 (nm)] preferably natural or modified montmorillonite with either a monomer(s) or oligomer(s) bearing at least one cyclocarbonate group or a mixture of the latter with an epoxy resin, with a hardener, which is a monomer or oligomer or mixtures therefrom, bearing primary and / or secondary amino groups. The use of the nanoclays reduces the gel time and increases the adhesion of the cured polyurethane and polyurethane / epoxy hybrid and also reduces its water absorption.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Elastomeric urethane composition

An elastomeric urethane composition includes the reaction product of a resin composition, including a polyol, and an isocyanate. The resin composition and the isocyanate are reacted, in the presence of a first and a second catalyst, to form a polyurethane elastomer. The first catalyst includes a metal selected from the group of iron, titanium, zirconium and hafnium. The second catalyst includes an amine. The elastomeric urethane composition may be used in a method of making an article. The method includes reacting the resin composition and the isocyanate to form the elastomeric urethane composition, applying the elastomeric urethane composition to a mold cavity, and allowing the elastomeric urethane composition to cure to form a first layer. The method also includes applying a urethane composition, different from the elastomeric urethane composition, to the mold to form a second layer, curing the article in the mold, and de-molding the article from the mold.

Owner:BASF CORP

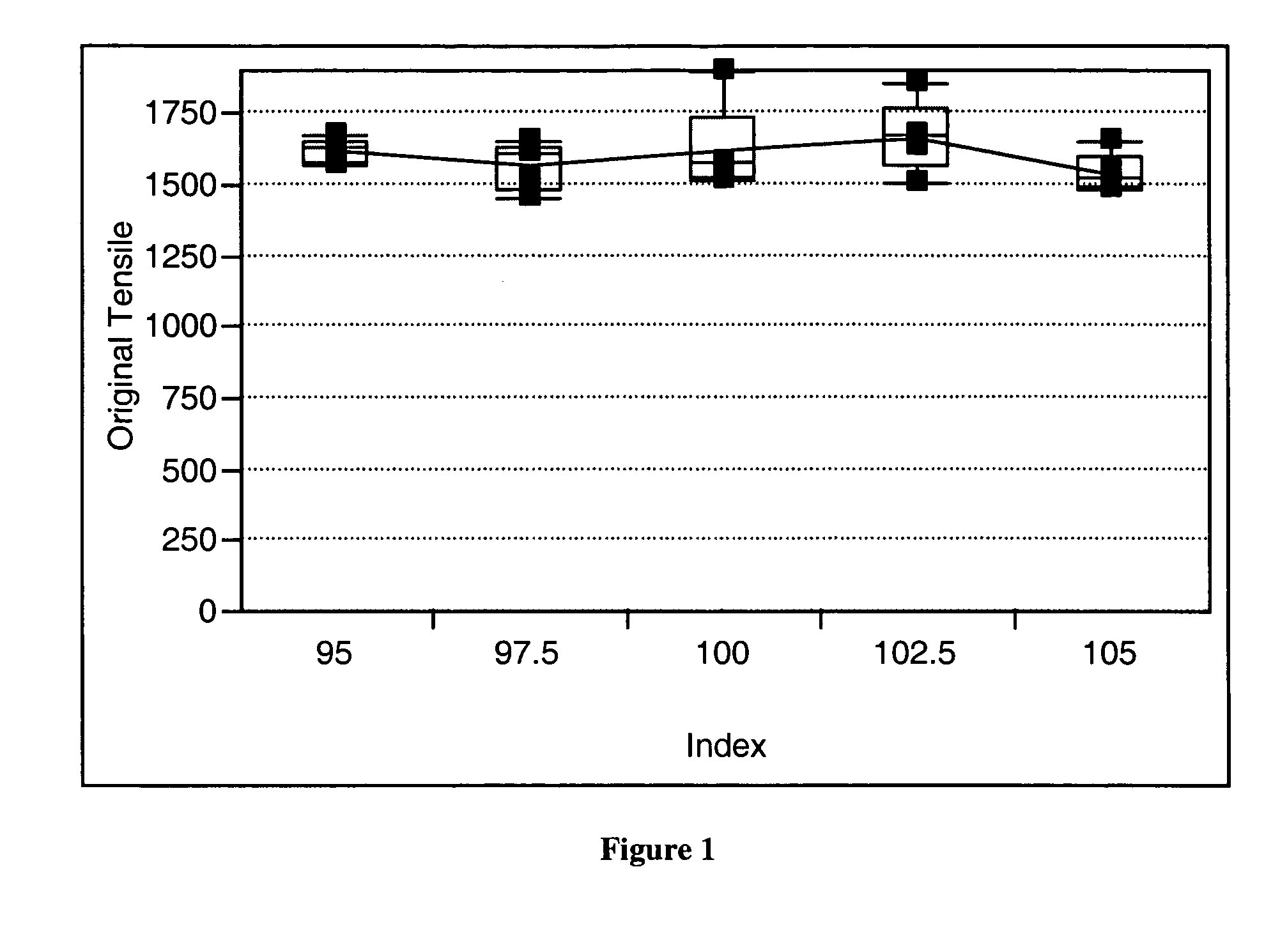

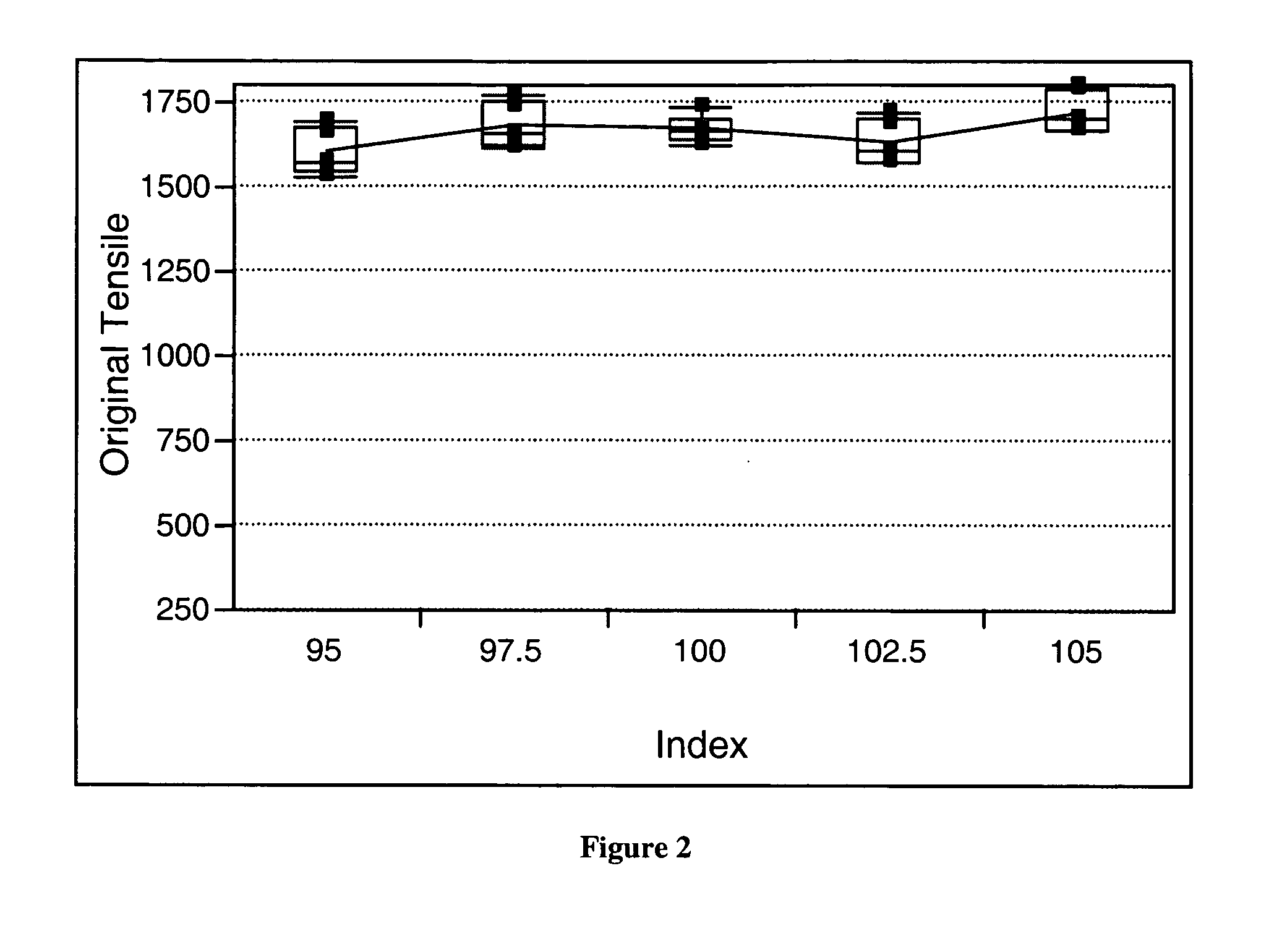

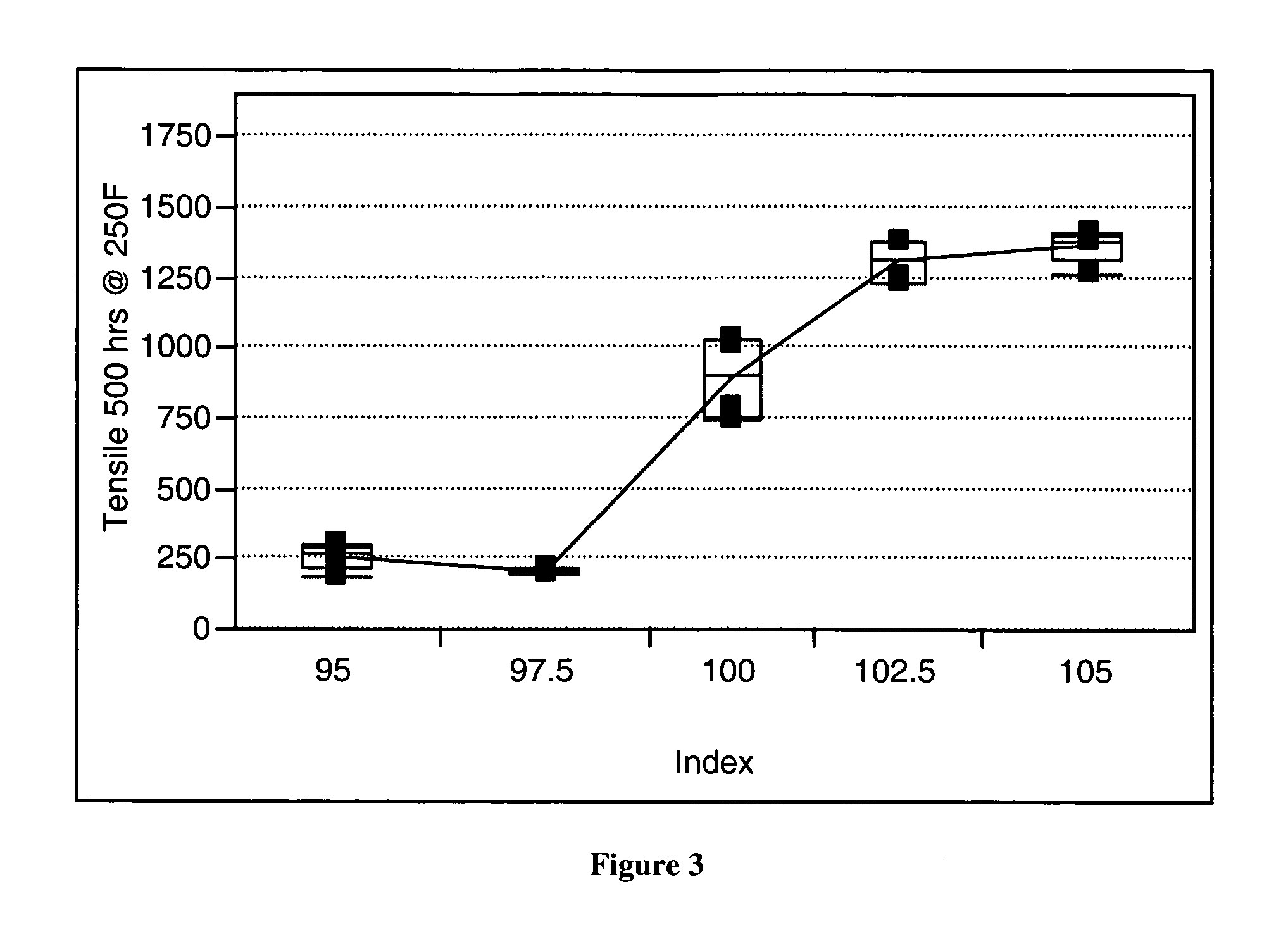

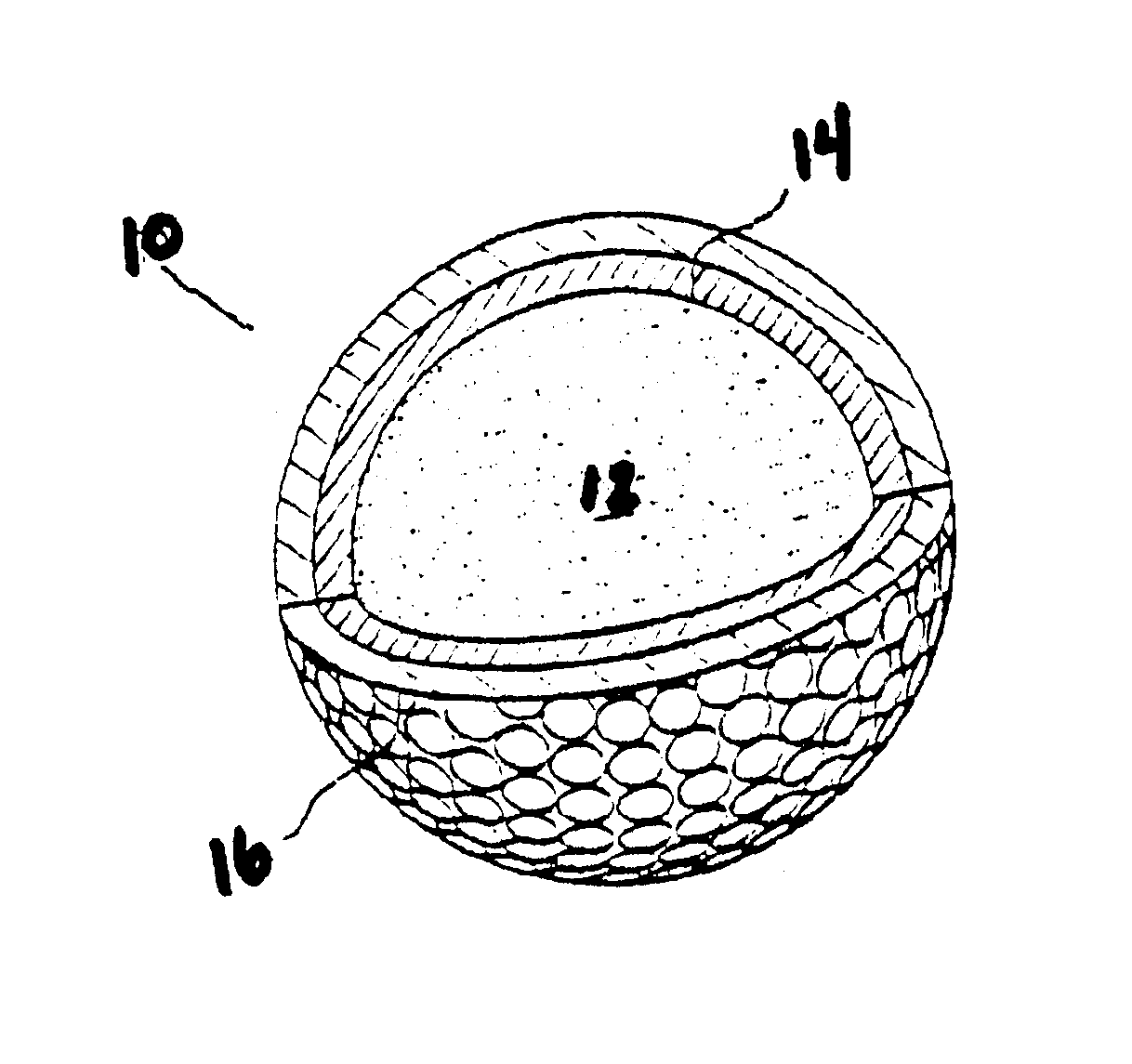

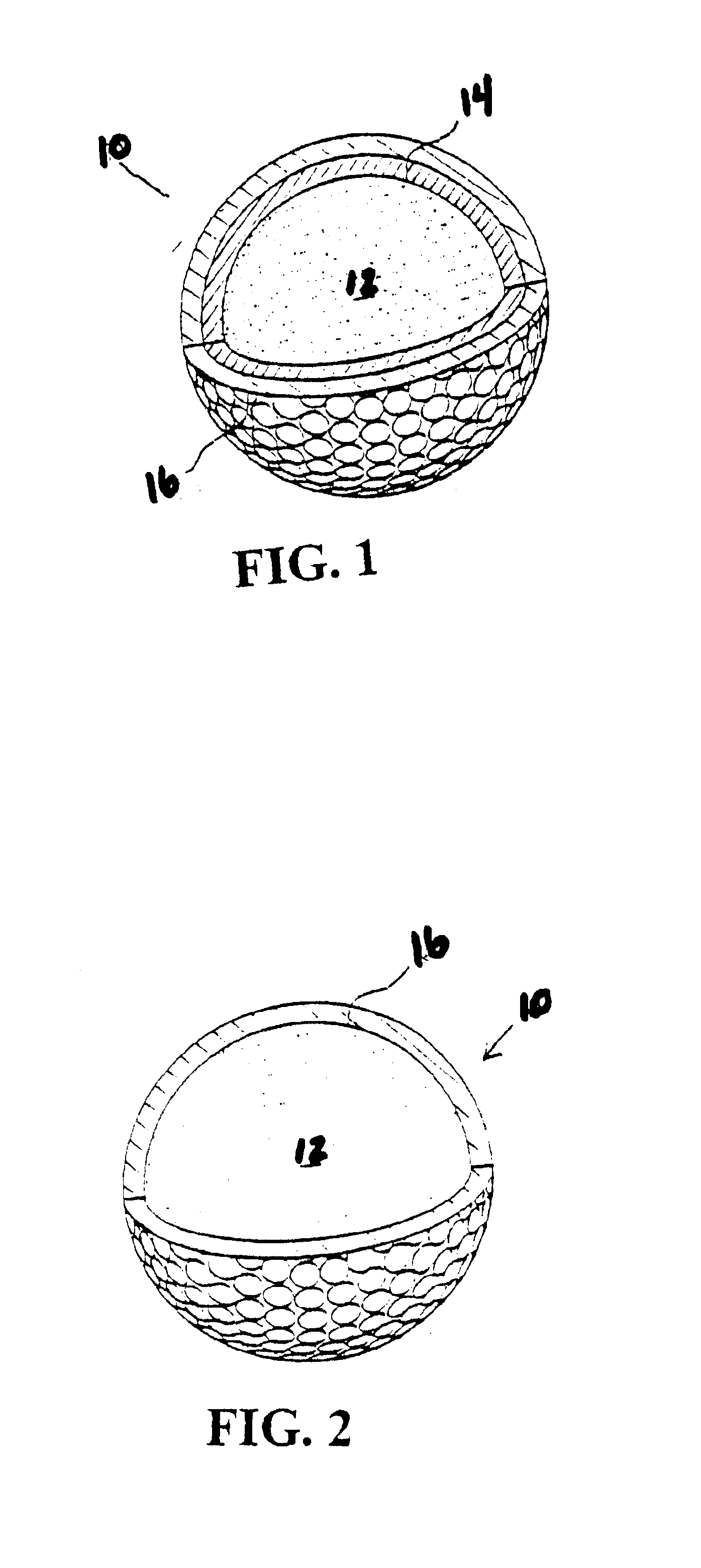

Thermosetting polyurethane material for a golf ball cover

A prepolymer blend for a thermosetting polyurethane material that allows for control of the reaction time is disclosed herein. The prepolymer blend is preferably composed of a polyurethane prepolymer and dimethyl methylphosphonate. The thermosetting polyurethane is preferably utilized as a cover for a golf ball. The cover is preferably formed over a core and boundary layer.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Casting compound based on thermosetting epoxy resins

InactiveUS6852415B2Improve curing speedShorten gel timePlastic/resin/waxes insulatorsNon-macromolecular adhesive additivesEpoxyProduct base

The curable casting compound comprises an epoxy resin having at least one aminoglycidyl group in the molecule, a curative, and a fluorosurfactant. In the manufacture of products based on this casting compound, the shaping and curing operation can be shortened considerably.

Owner:ABB RES LTD

Preparation method of phenolic resin base carbon aerogel

InactiveCN102423668ALow priceOmit the replacement stepColloidal chemistry detailsSupercritical dryingHigh pressure

A preparation method of a phenolic resin base carbon aerogel comprises steps of: (1) preparing a phenolic resin solution with a content of 10-50wt%; (2) gelling and ageing under high temperature and high pressure; (3) carrying out supercritical drying and discharging to obtain an organic aerogel; (4) cracking, carbonizing and discharging to obtain the aerogel. The preparation method of the carbon aerogel of the invention has the following three advantages: 1) a sodium carbonate catalyst does not need to be added in the first step, and the carbon aerogel has high purity and does not contain metal ion impurity; 2) the raw material phenolic resin is cheap; 3) a total process time is shortened that the organic aerogel can be obtained in one day and that the carbon aerogel can be obtained in two days.

Owner:NAT UNIV OF DEFENSE TECH

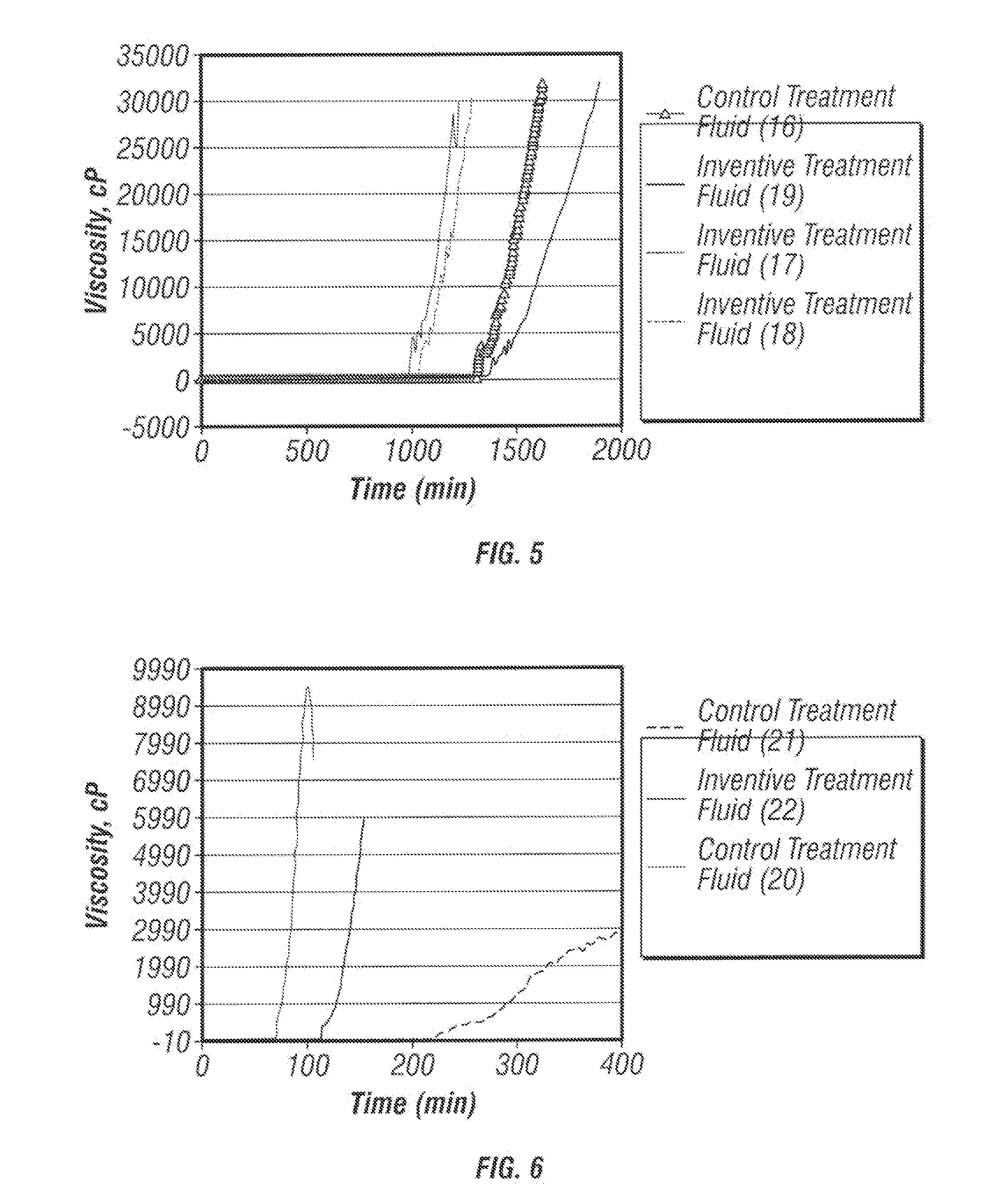

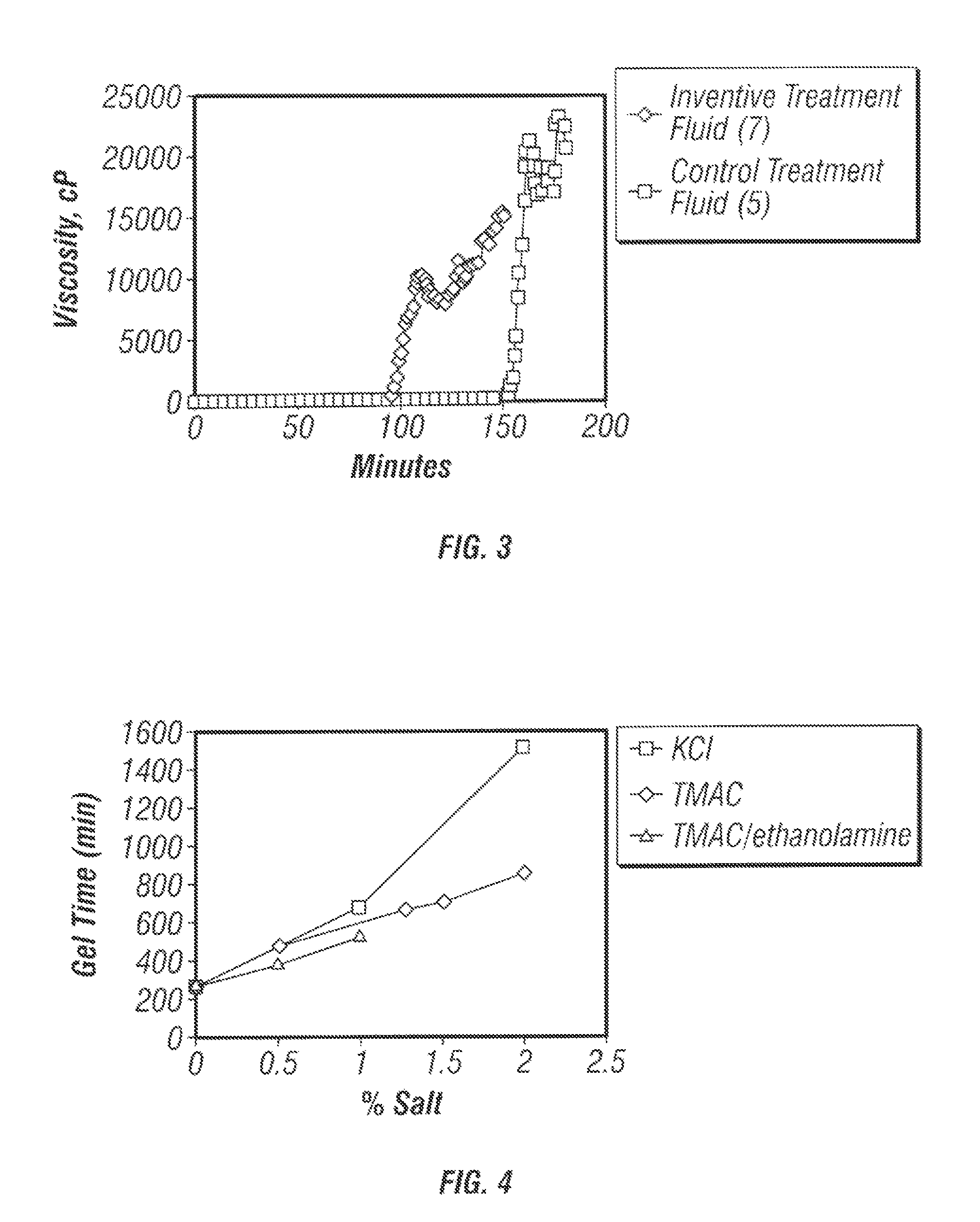

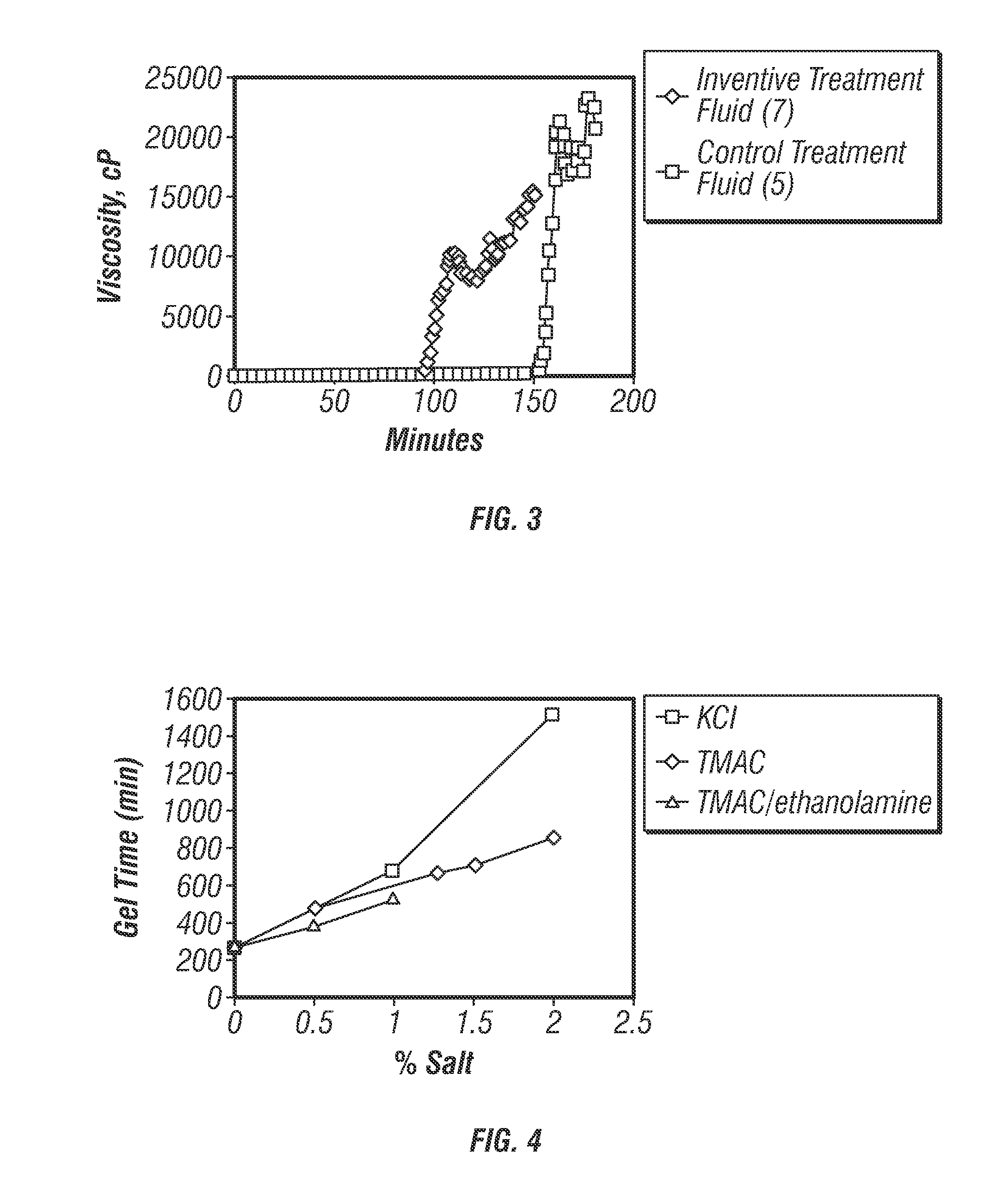

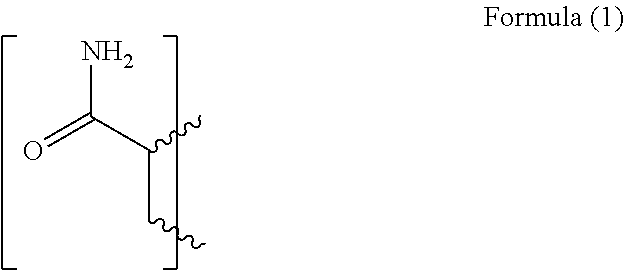

Gellable Treatment Fluids Comprising Amino Group Gel-Time Modifiers and Methods for Use Thereof

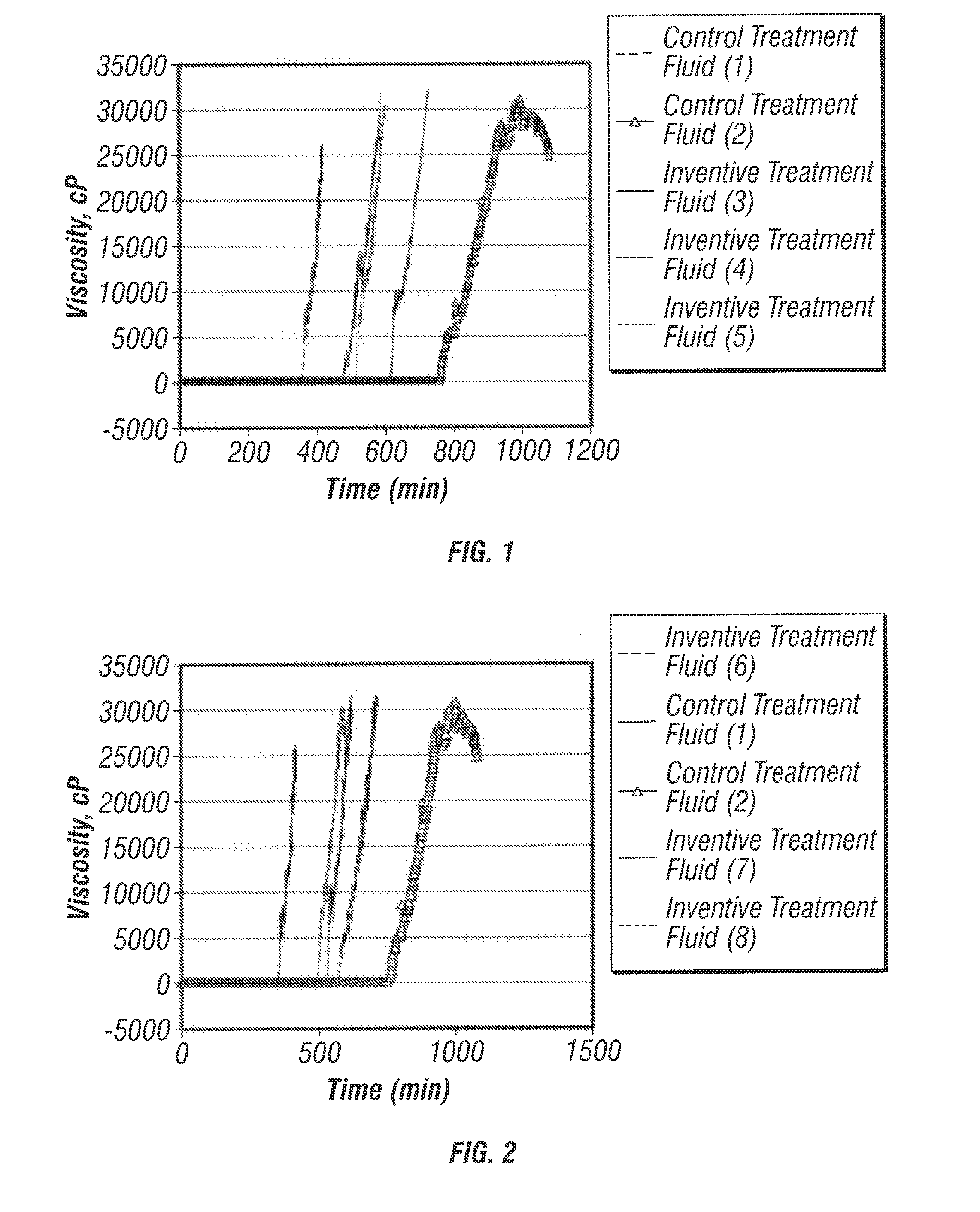

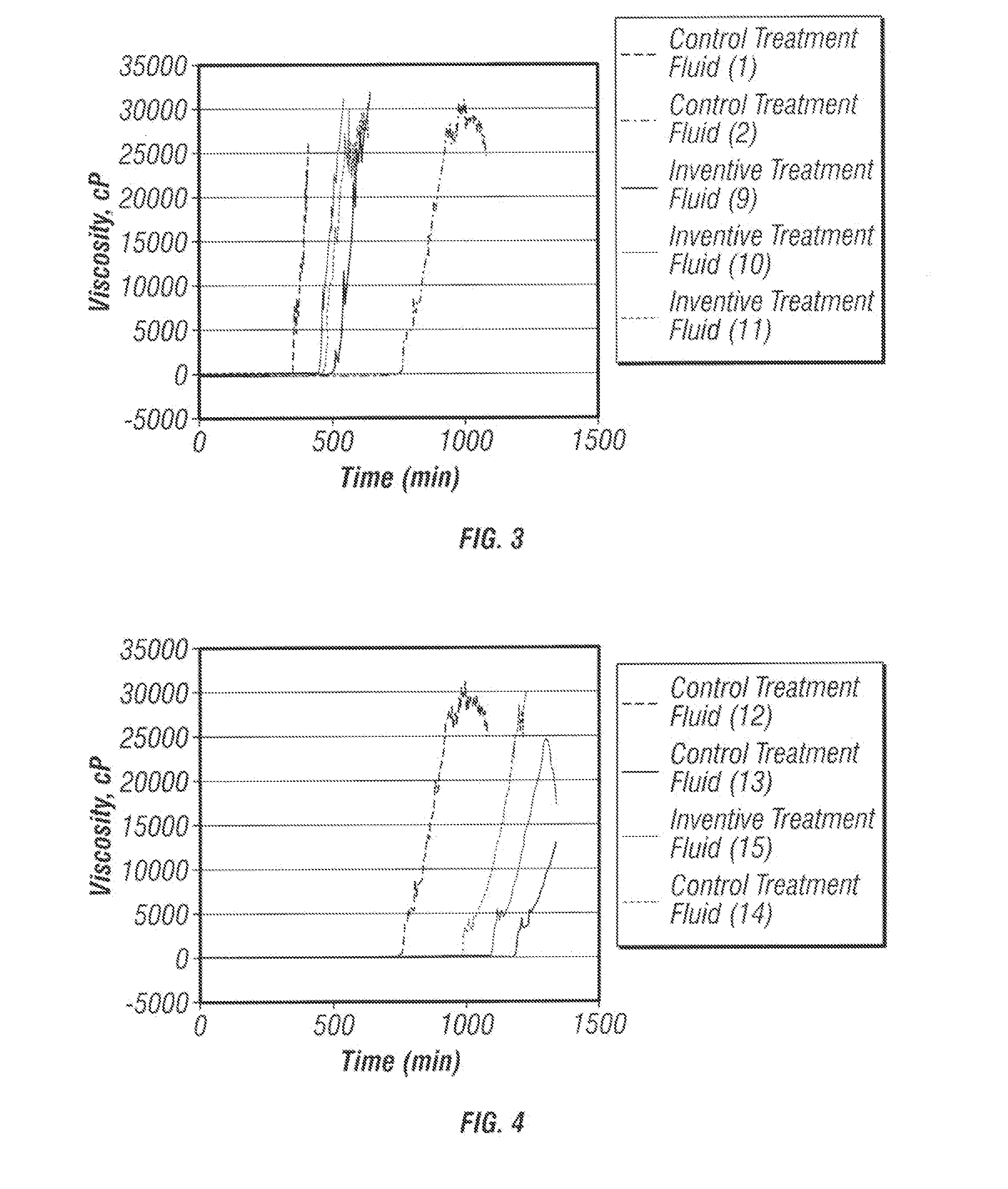

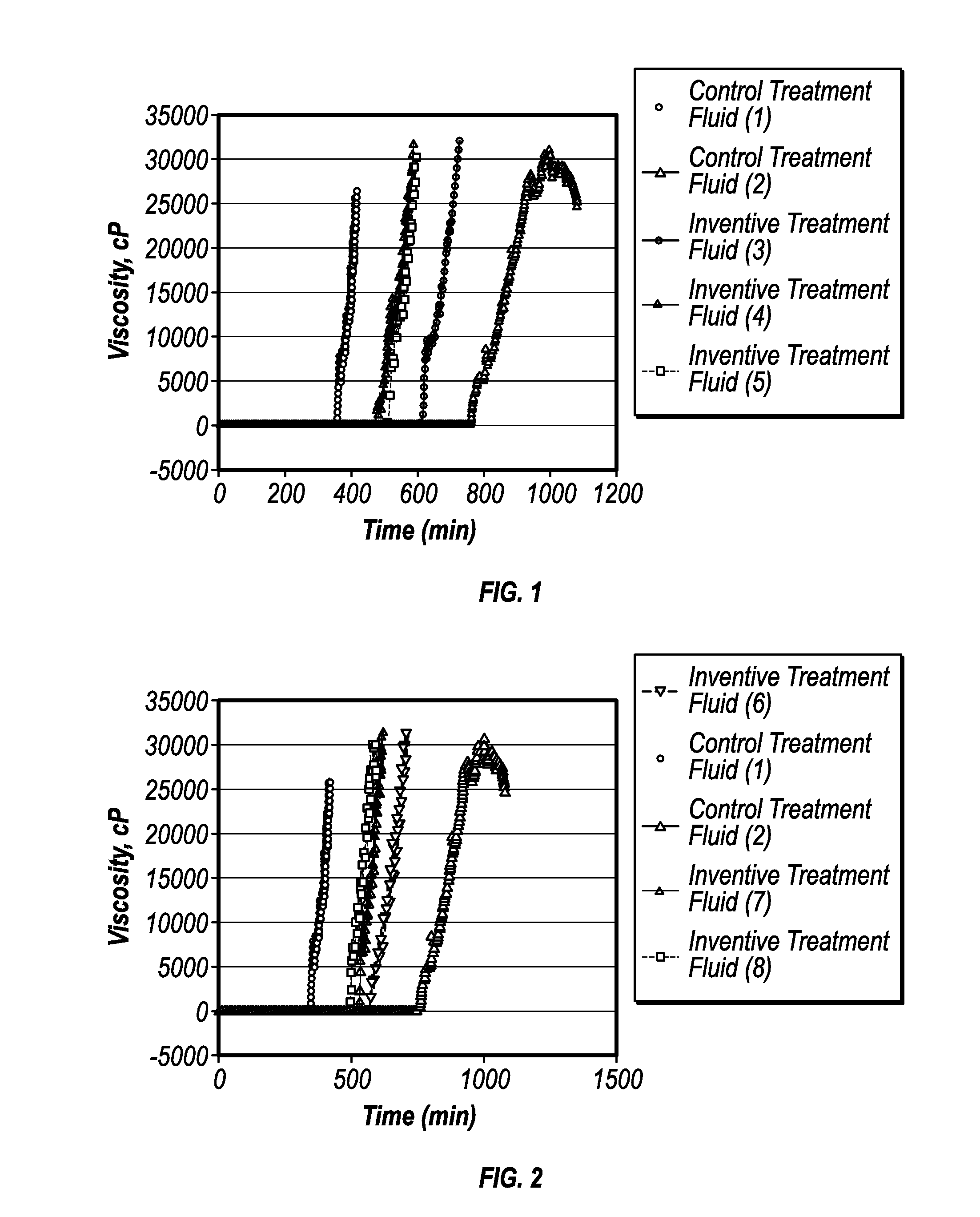

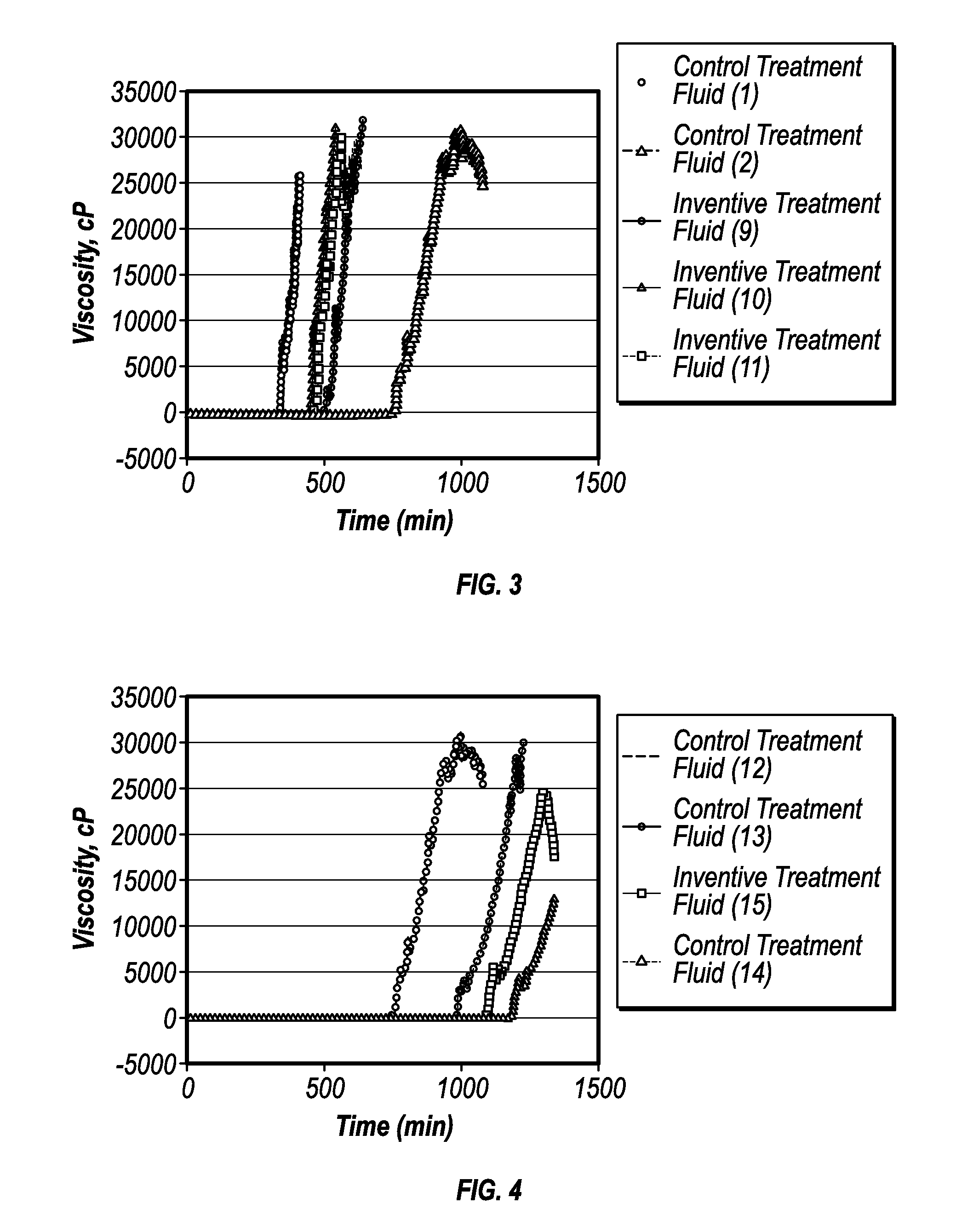

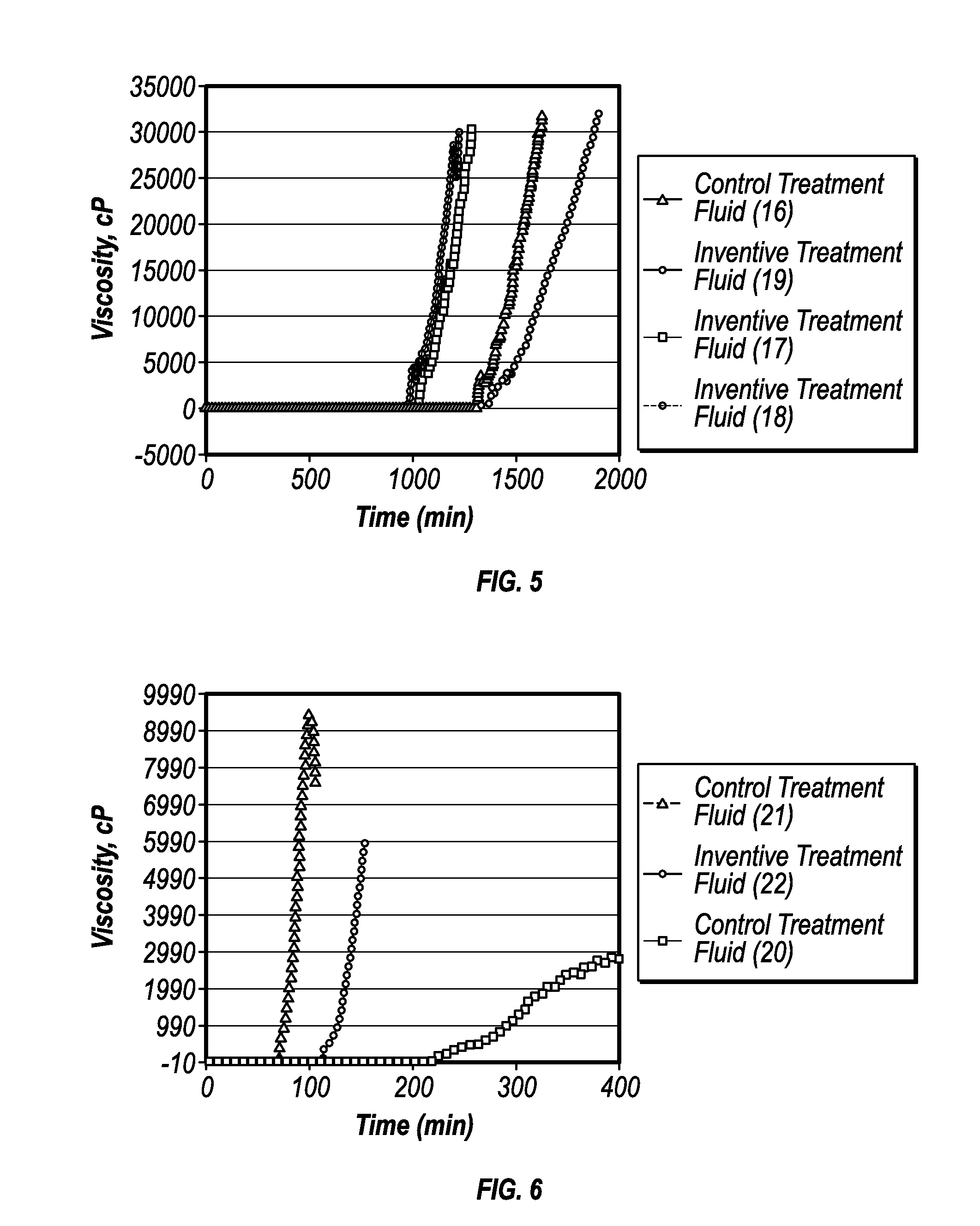

Methods for reducing the amount of water produced from a subterranean formation can include the use of a gellable treatment fluid that comprises a gel-time modifier comprising at least one amino group. The gellable treatment fluids can comprise an aqueous base fluid, a base polymer comprising an acrylamide monomer unit, an organic crosslinking agent, and a get-time modifier comprising at least one amino group.

Owner:HALLIBURTON ENERGY SERVICES INC

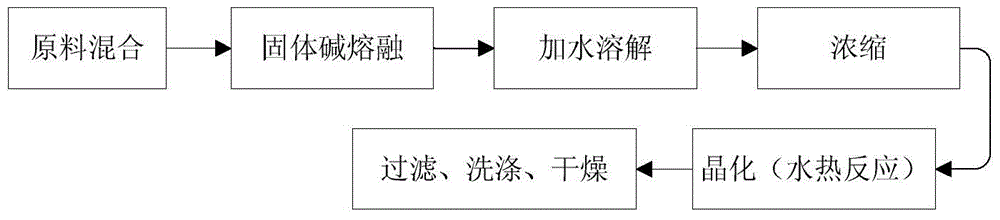

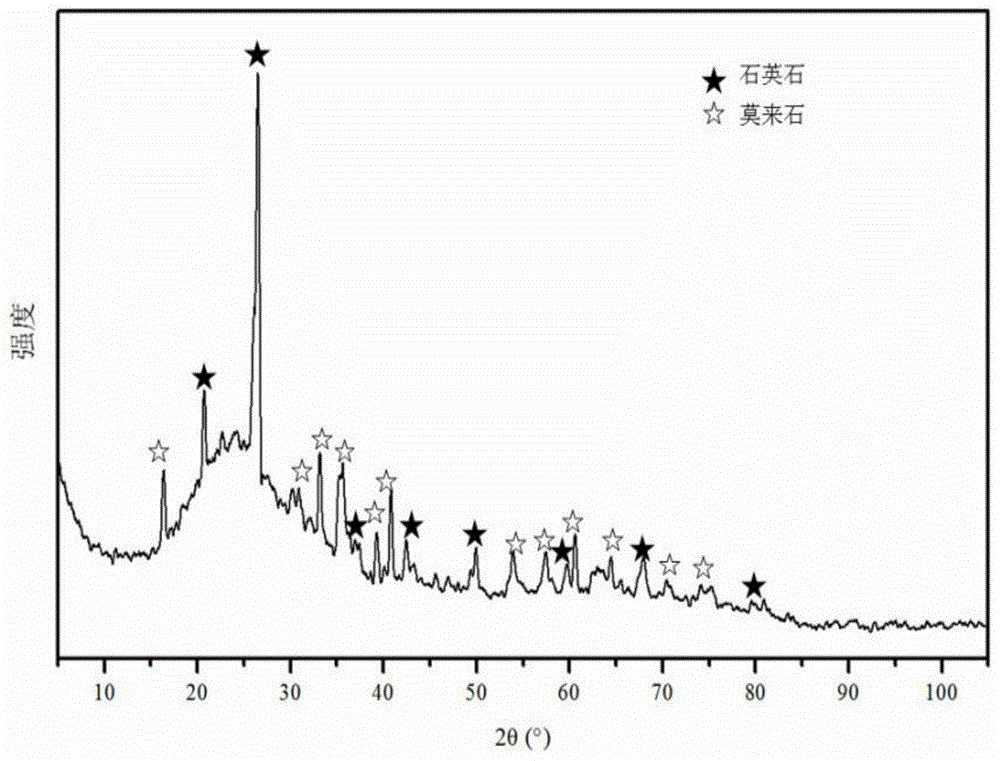

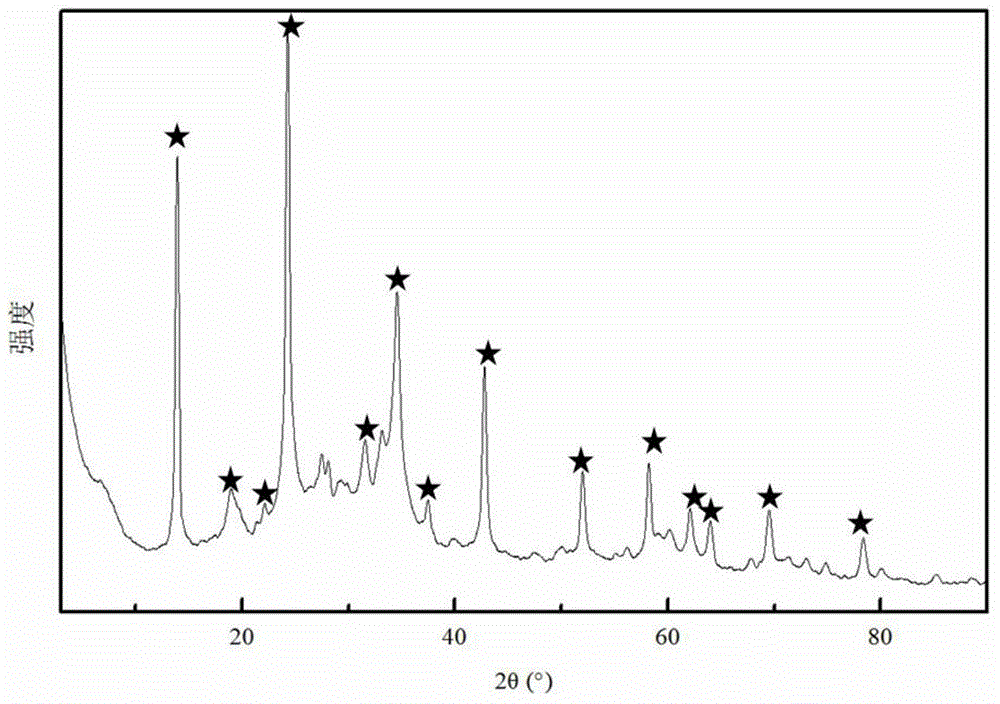

Method for synthesis of zeolite from fly ash

ActiveCN104402017ALow costShorten gel timeSolid waste disposalCrystalline aluminosilicate zeolitesResource utilizationCrucible

A method for synthesis of zeolite from fly ash comprises the following steps: putting the fly ash and alkali ash in accordance with the molar ratio of 1:1 to 4:1 into a crucible, mixing evenly, putting into a muffle furnace for melting at 500-900 DEG C for 0.5-4H, taking out, naturally cooling, crushing to obtain a molten sample; taking 2.5-10g of the molten sample to dissolve in 100ml of deionized water, stirring for dissolving, filtering and washing to obtain extract; rotatably evaporating the extract to concentrate to 40ml, gelling for 20-40min; putting in a 50ml hydrothermal reaction kettle, sealing, putting into the muffle furnace at the temperature of 100 to 120 DEG C for 12-48h, performing hydrothermal reaction; cooling to room temperature, filtering by suction, washing and drying to obtain a zeolite crystal sample; the method improves the quality and yield of zeolite, reduces cost, simplifies the technical process, and provides a new way for high grade resource utilization of industrial solid waste fly ash.

Owner:TSINGHUA UNIV

Accelerated curing of epoxy gelcoats

InactiveUS20030130481A1Reduced room temperature gel timeDecrease room temperature gelling timePretreated surfacesCoatingsVitrificationAccelerated curing

Aqueous solutions of inorganic nitrate salts are used to accelerate the gelling of epoxy gelcoat resins without adversely affecting the glass transition temperature of the finally cured gelcoat. The aqueous accelerants may be used to accelerate gelling of gelcoats that are formed during initial fabrication of composite parts. The aqueous acclerants are also useful for shortening the gel time of gelcoats that are intended for use in repairing damaged structures.

Owner:HEXCEL COMPOSITES LTD (GB)

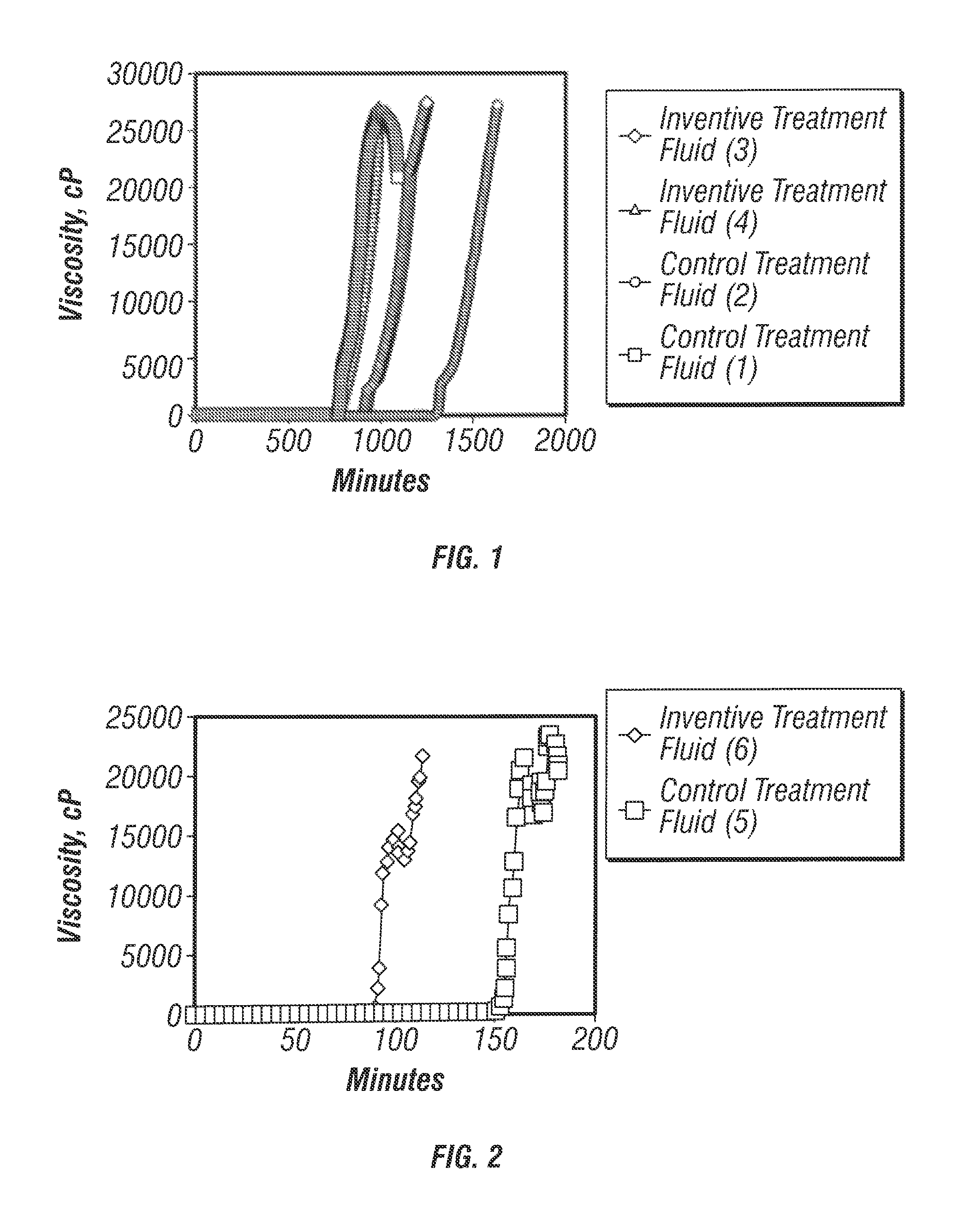

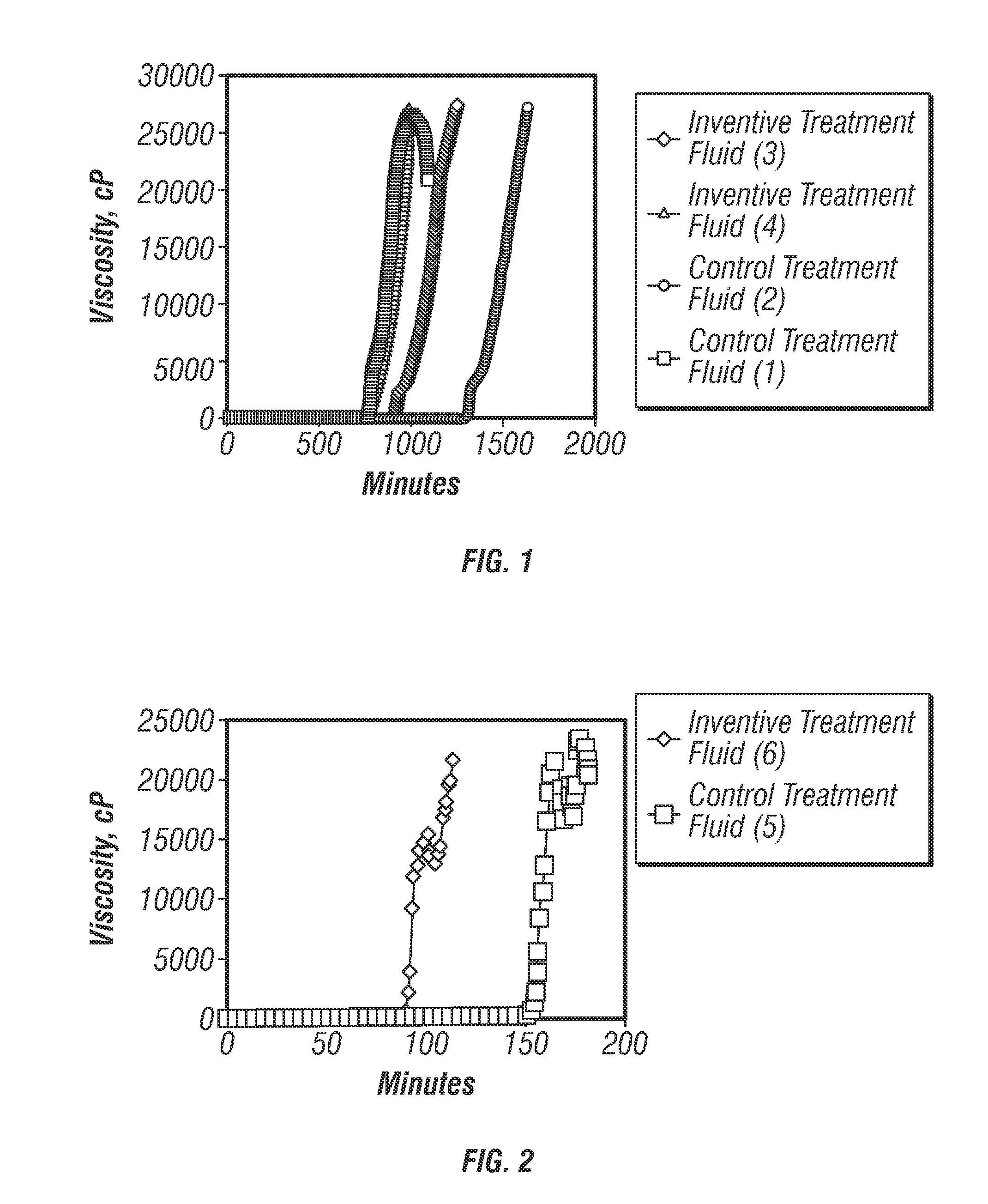

Gellable treatment fluids comprising quaternary ammonium salt gel-time modifiers and methods for use thereof

Owner:HALLIBURTON ENERGY SERVICES INC

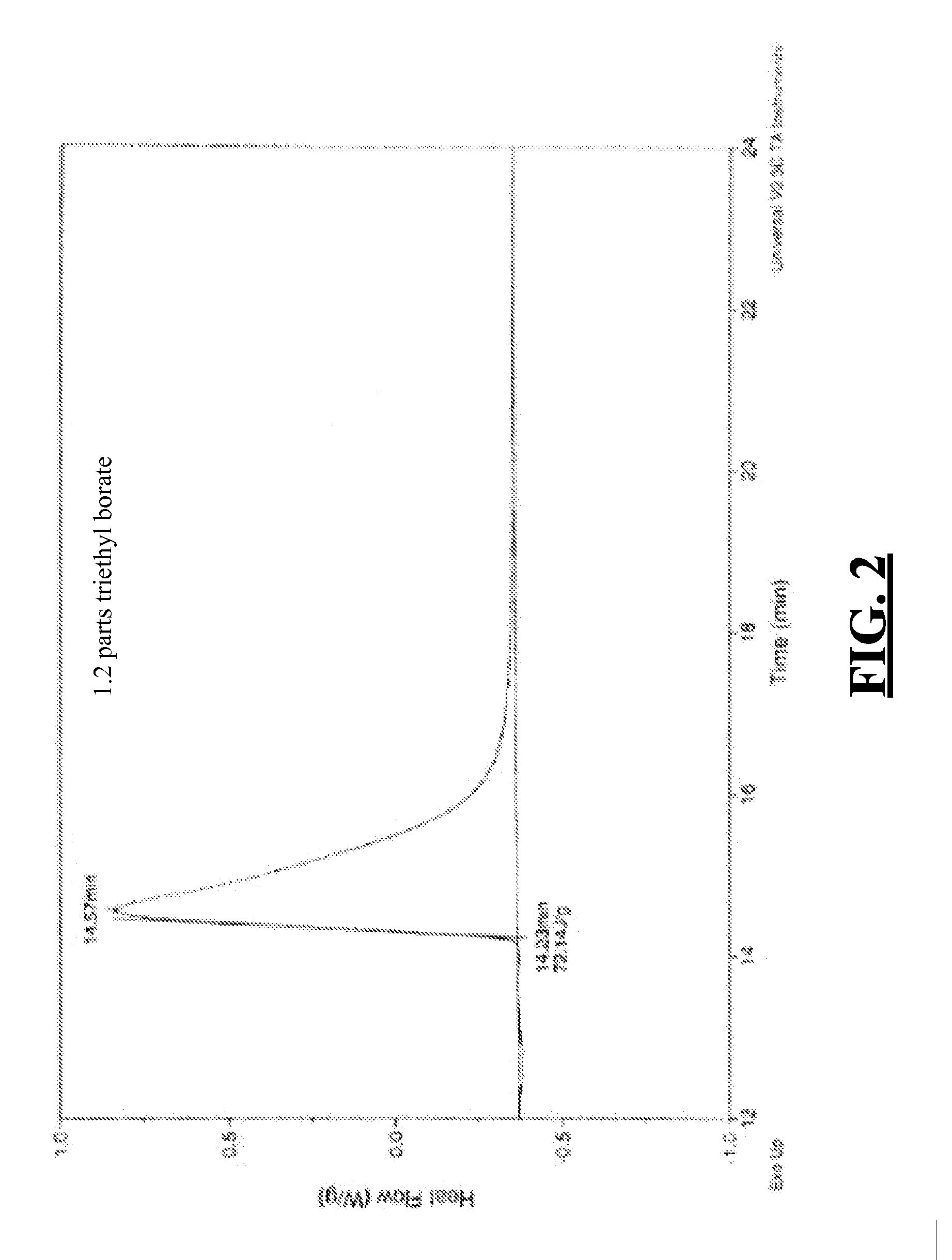

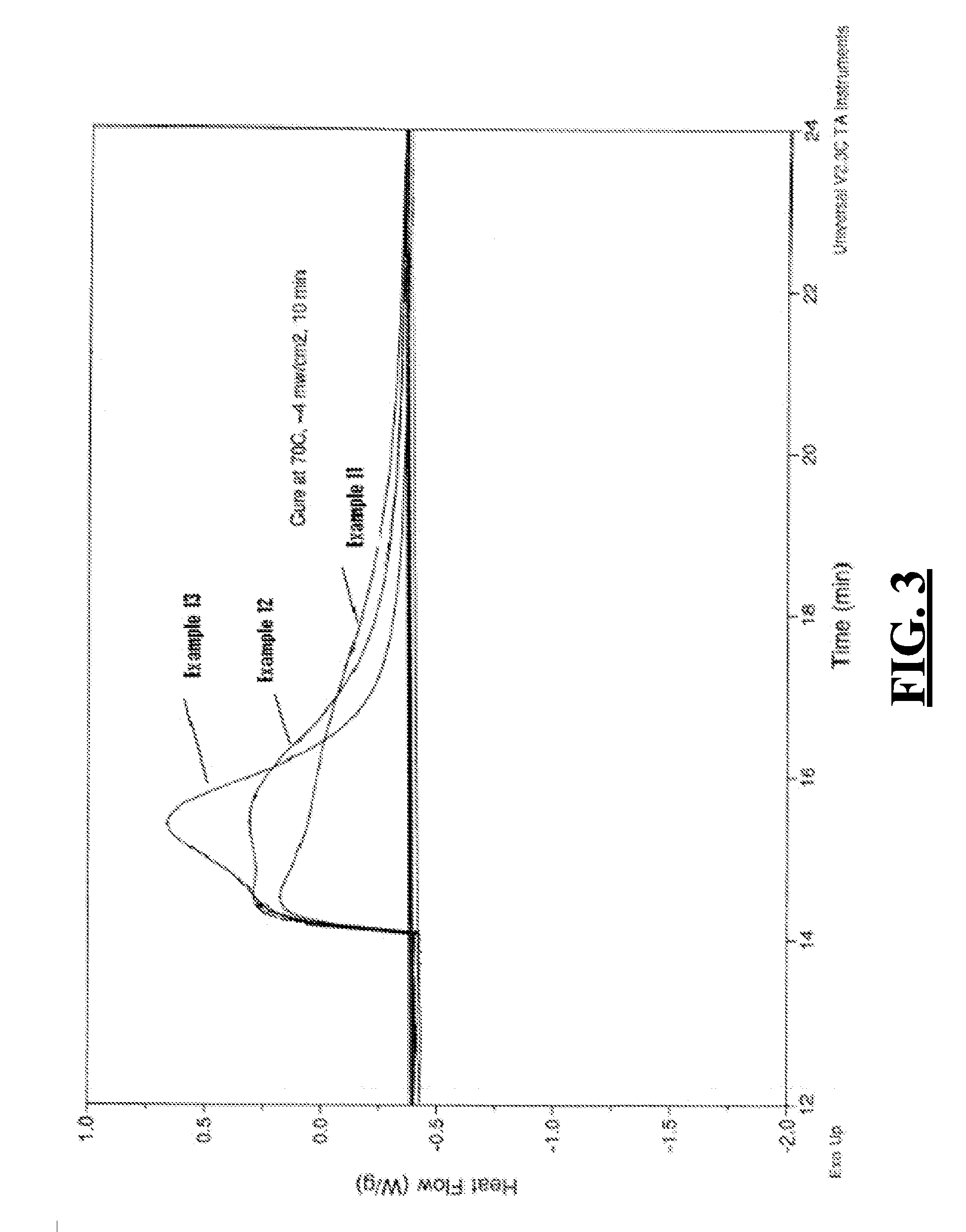

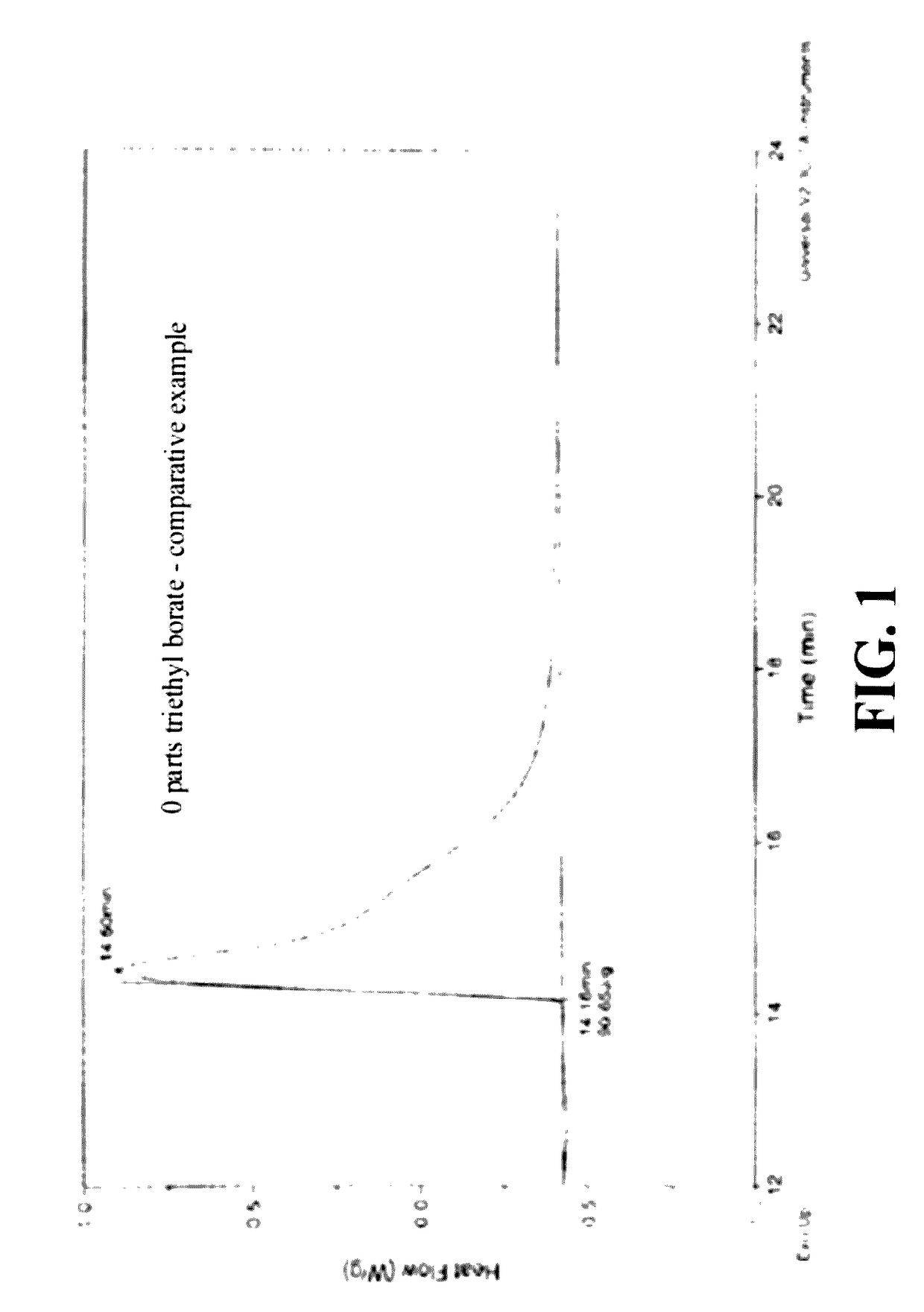

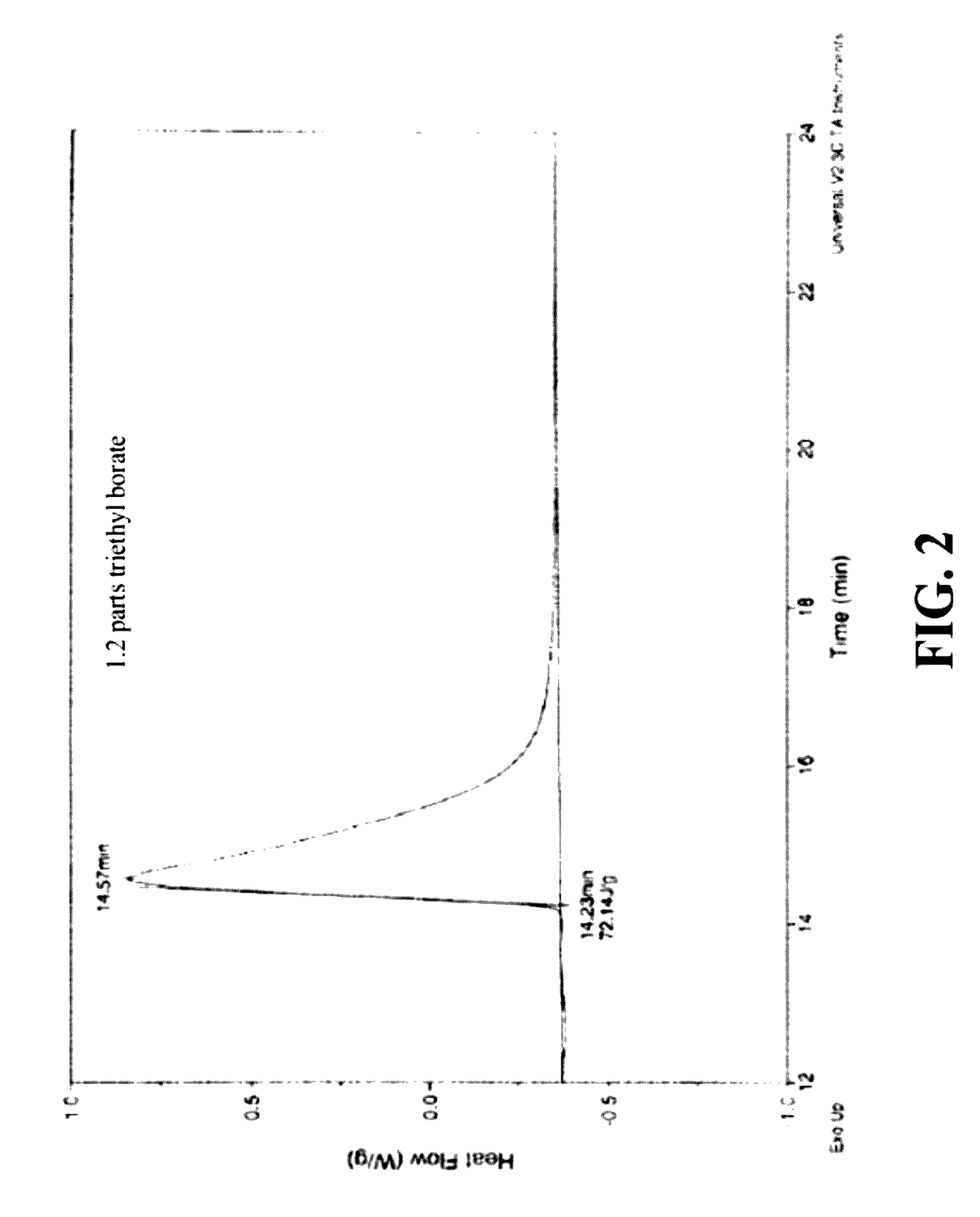

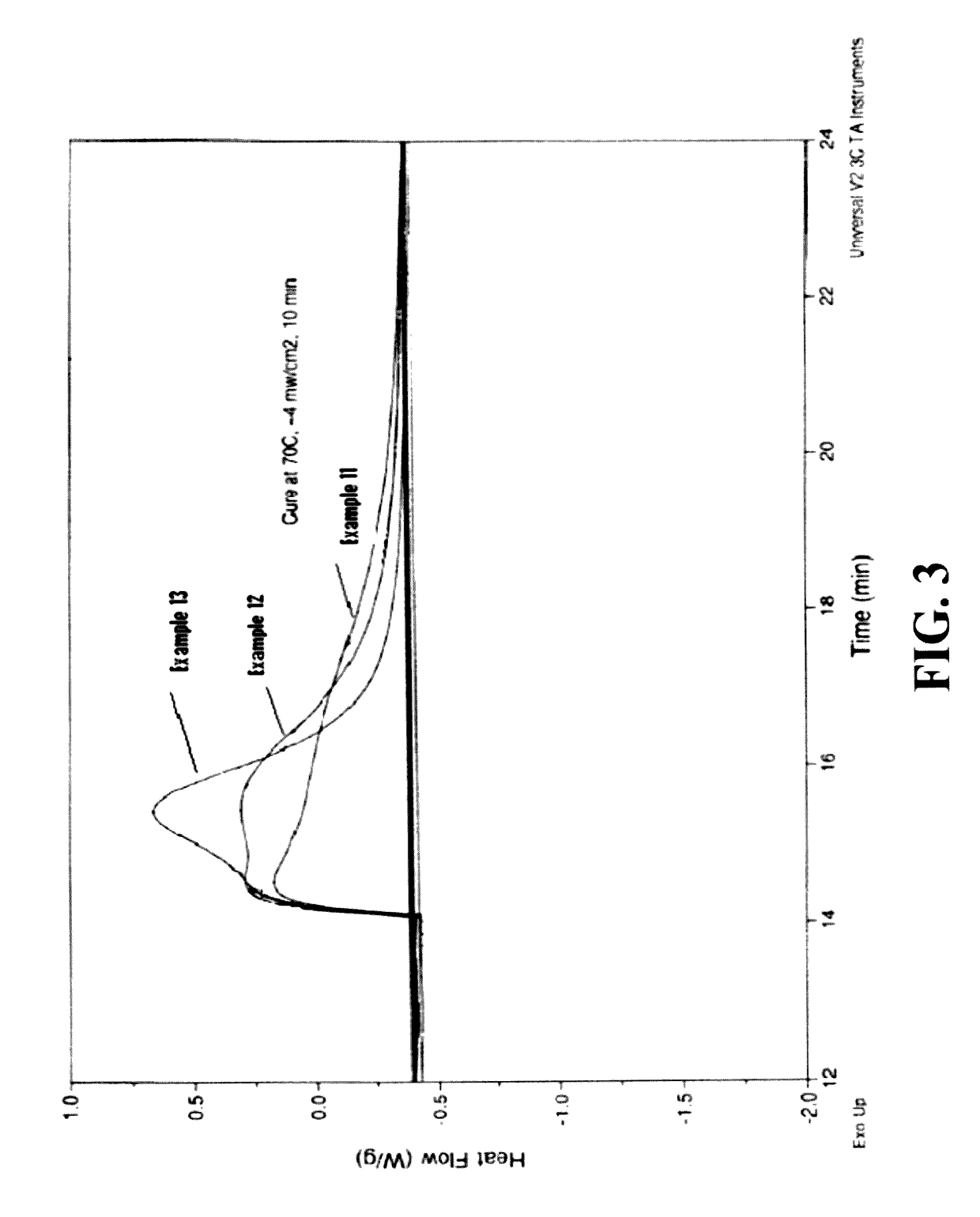

Silicone hydrogel reactive mixtures comprising borates

ActiveUS20120115980A1Reduced gel timeIncrease viscosity of mixtureOptical elementsSilicone hydrogelChemistry

Disclosed in this specification is a method for forming a silicone hydrogel material that is useful for forming contact lens materials. The method includes using an effective amount of a borate additive to reduce the gel time of the silicone hydrogel reactive mixture and / or enhance the optical properties of the resulting cured material.

Owner:JOHNSON & JOHNSON VISION CARE INC

Nanocomposites based on polyurethane or polyurethane-epoxy hybrid resins prepared avoiding isocyanates

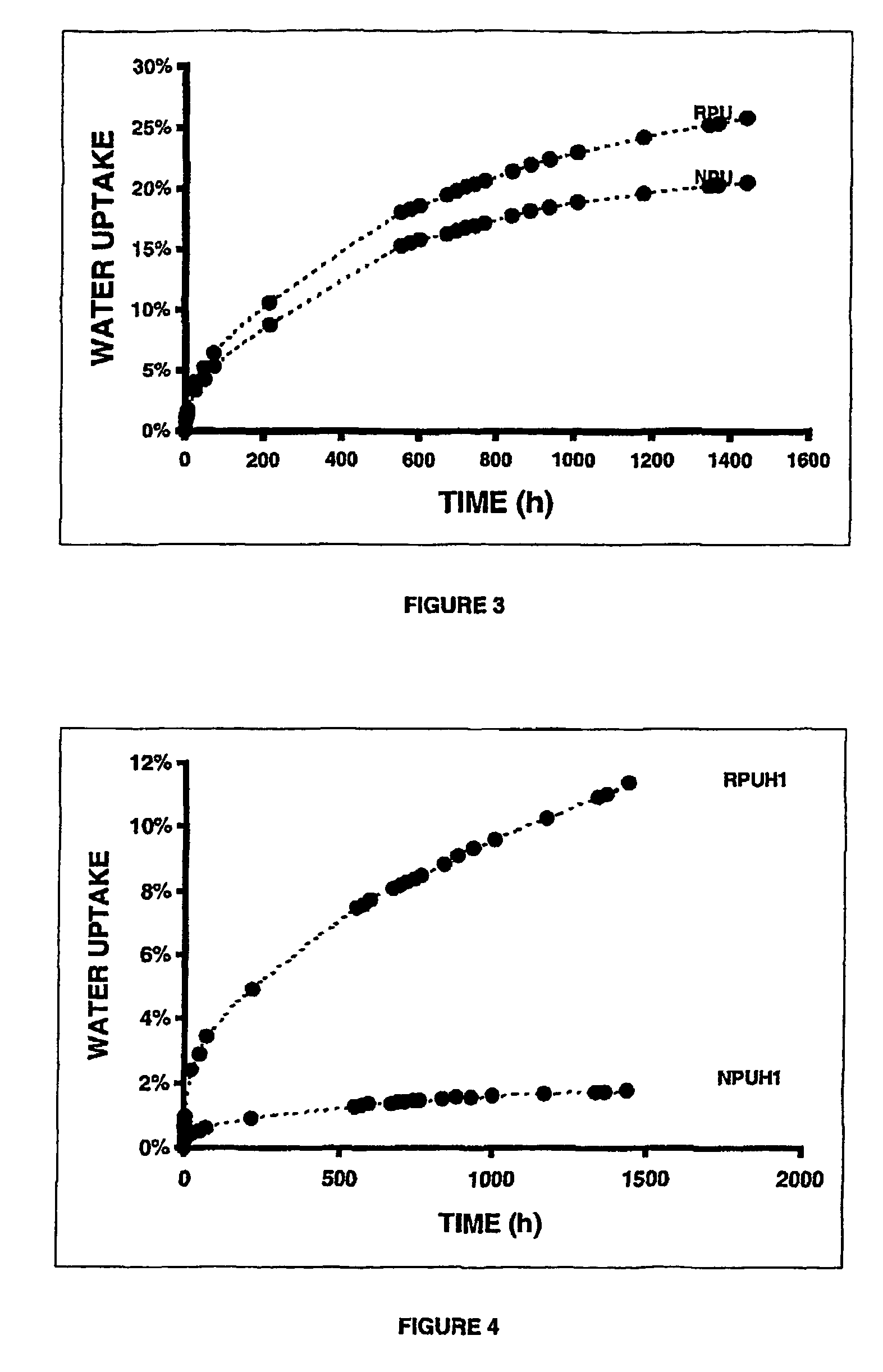

A fast curable non-isocyanate-based polyurethane- and polyurethane-epoxy network nanocomposite polymeric compositions are derived upon crosslinking a mixture comprising of natural or modified nano-clay [ionic phyllosilicate] with platelet thickness in the scale of A (˜1 nm) and aspect ratio (length / thickness) higher than 10 (nm)] preferably natural or modified montmorillonite with either a monomer(s) or oligomer(s) bearing at least one cyclocarbonate group or a mixture of the latter with an epoxy resin, with a hardener, which is a monomer or oligomer or mixtures therefrom, bearing primary and / or secondary amino groups. The use of the nanoclays reduces the gel time and increases the adhesion of the cured polyurethane and polyurethane / epoxy hybrid and also reduces its water absorption.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Gellable treatment fluids comprising amino group gel-time modifiers and methods for use thereof

Methods for reducing the amount of water produced from a subterranean formation can include the use of a gellable treatment fluid that comprises a gel-time modifier comprising at least one amino group. The gellable treatment fluids can comprise an aqueous base fluid, a base polymer comprising an acrylamide monomer unit, an organic crosslinking agent, and a get-time modifier comprising at least one amino group.

Owner:HALLIBURTON ENERGY SERVICES INC

Cyanate/microcapsule resin system and preparation method thereof

The invention discloses a cyanate / microcapsule resin system and a preparation method thereof. The preparation method is as follows: calculated by weight, 100 parts of cyanate (CE) is heated at 80-100 DEG C to melt, organotin microcapsule coated with 0.125-5 parts of polyurea formaldehyde is filled in CE resin; and by utilizing the controlled-release function of the polyurea formaldehyde used as the microcapsule wall material to the organotin compound used as the microcapsule core catalyst, the CE curing reaction temperature and reaction rate can be adjusted. After being cured, the obtained CE / microcapsule resin system has good mechanical properties; and the resin system can be used to prepare high-performance composites used in aviation and aerospace, electronic elements and the like.

Owner:SUZHOU UNIV

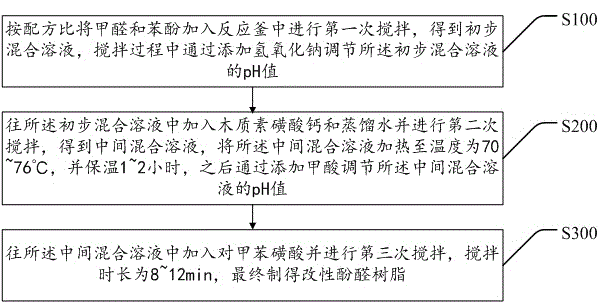

Modified phenol formaldehyde resin, backing plate and preparation method thereof

ActiveCN106279584AReduce warpageHigh hardnessLayered product treatmentSynthetic resin layered productsThermal compressionHardness

The invention discloses a modified phenol formaldehyde resin, a backing plate and a preparation method thereof. The backing plate is prepared by hot compression of paper in the modified phenol formaldehyde resin through a gum dipping process, wherein toluenesulfonic acid is added in the modified phenol formaldehyde resin, so that the colloidizing time is effectively shortened, thus increasing the production efficiency; calcium lignosulfonate added in the resin is beneficial to reducing warpage of the backing plate, and effectively improves the hardness, density, smoothness and drilling precision of the backing plate; and meanwhile, the backing plate provided by the invention can also effectively solve the problem of high needle breakage rate in IC (integrated circuit) packaging substrate drilling.

Owner:HUNAN LIUXIN ELECTRONICS NEW MATERIAL

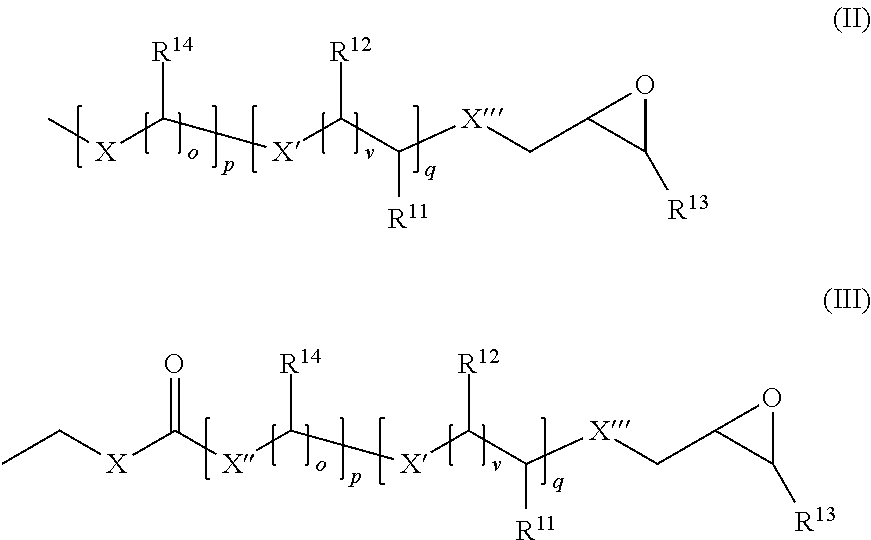

Non-Isocyanate-Based Polyurethane and Hybrid Polyurethane-Epoxy Nanocomposite Polymer Compositions

ActiveUS20120149842A1Maintain good propertiesHigh strengthMaterial nanotechnologySemiconductor/solid-state device manufacturingEpoxyOligomer

A fast curable non-isocyanate-based polyurethane- and polyurethane-epoxy network nanocomposite polymeric compositions are derived upon crosslinking a mixture comprising of natural or modified nano-clay [ionic phyllosilicate] with platelet thickness in the scale of Å (˜1 nm) and aspect ratio (length / thickness) higher than 10 (nm)] preferably natural or modified montmorillonite with either a monomer(s) or oligomer(s) bearing at least one cyclocarbonate group or a mixture of the latter with an epoxy resin, with a hardener, which is a monomer or oligomer or mixtures therefrom, bearing primary and / or secondary amino groups. The use of the nanoclays reduces the gel time and increases the adhesion of the cured polyurethane and polyurethane / epoxy hybrid and also reduces its water absorption.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Pad plate for hole drilling and preparation method thereof

ActiveCN106183318AShorten gel timeReduce warpageSynthetic resin layered productsVegetable material additionPulp and paper industryProcess time

The invention discloses a pad plate for hole drilling and a preparation method thereof. The method comprises the following steps of preparing modified urea resin; soaking paper into the modified urea resin to prepare glue soaking paper under the conditions that the temperature is 200 to 230 DEG C and the drilling speed is 20 to 25m / min; laminating a plurality of pieces of glue soaking paper; performing pressing for 90 to 120min under the conditions that the temperature is 110 to 140 DEG C and the pressure is 4 to 6MPa to obtain the pad plate. The pad plate provided by the invention is prepared from the modified urea resin and paper by using a glue soaking process through hot pressing. The pad plate has the advantages that the gelatination time of the modified urea resin is shortened; the preparation process time can be effectively improved; the production efficiency is improved; in addition, the modified urea resin is favorable for reducing the plate tilting; meanwhile, the hole plugging and needle fracturing due to adhesion of drill hole cut chips onto the needle is avoided; the material cost is reduced to a certain degree. The plate uses the urea resin system; the uniformity of the plate and the drill hole quality can be ensured through the thermoset resin features and good bonding performance.

Owner:HUNAN LIUXIN ELECTRONICS NEW MATERIAL

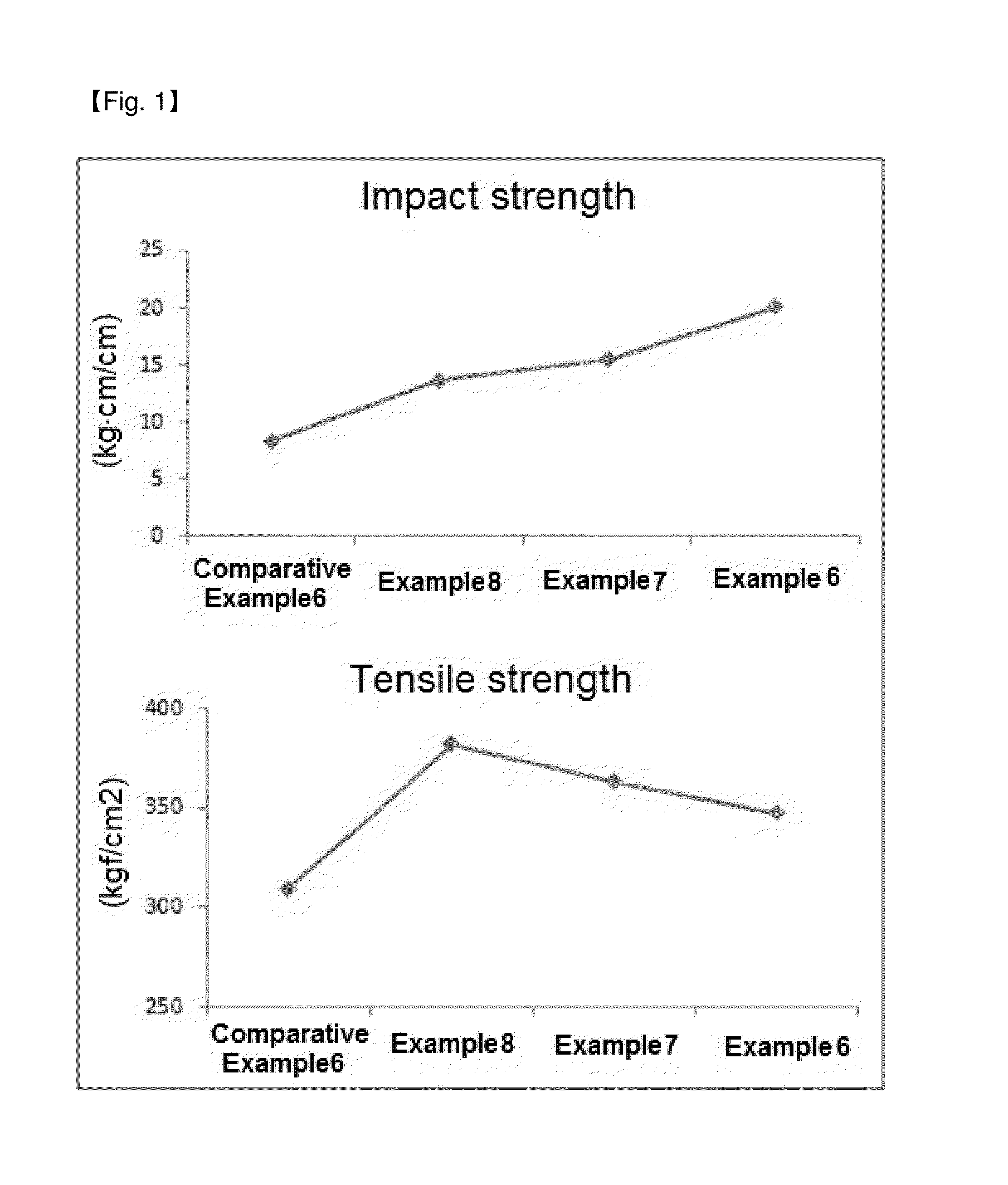

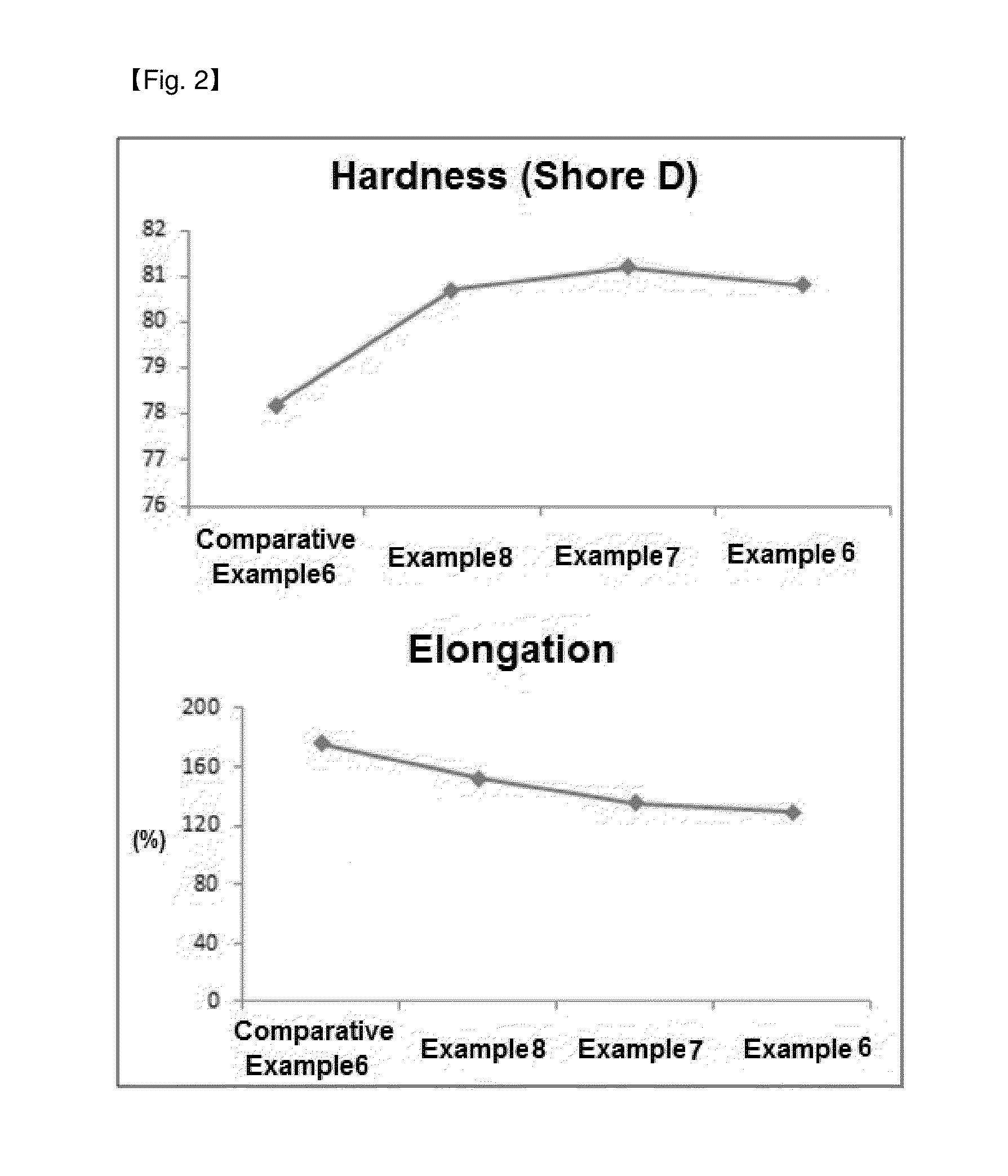

PVC-based compound composition

The present invention relates to a polyvinyl chloride (PVC)-based compound composition, and more specifically, to a PVC-based compound composition that uses a PVC-based copolymer having internal plasticity prepared by suspension polymerization together with a PVC resin, thereby increasing compatibility with the PVC resin to shorten the gelling time, lowering the load at the time of extrusion to increase production in the same process conditions, and partially showing an impact modifier substitution effect.

Owner:HANWHA CHEMICAL CORPORATION

Silicone hydrogel reactive mixtures comprising borates

Disclosed in this specification is a method for forming a silicone hydrogel material that is useful for forming contact lens materials. The method includes using an effective amount of a borate additive to reduce the gel time of the silicone hydrogel reactive mixture and / or enhance the optical properties of the resulting cured material.

Owner:JOHNSON & JOHNSON VISION CARE INC

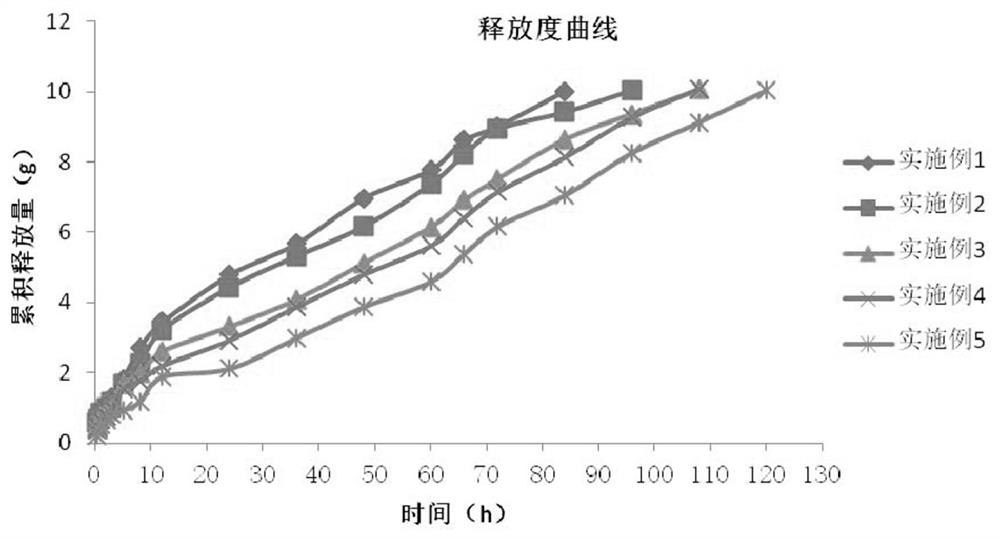

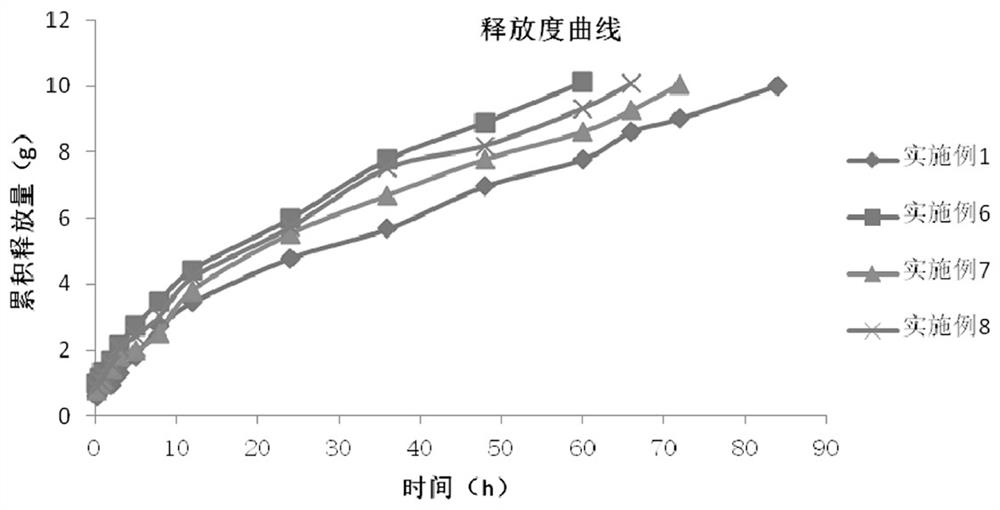

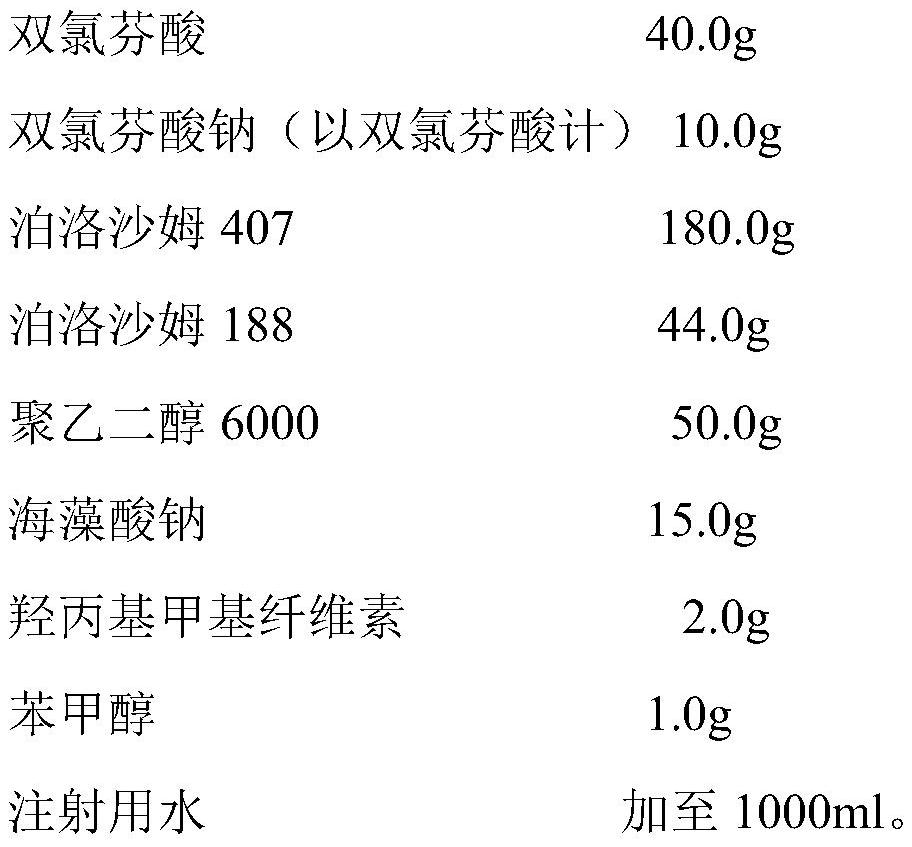

Novel diclofenac injection and preparation method thereof

ActiveCN112516081AImprove securityGood biocompatibilityOrganic active ingredientsAntipyreticPolythylene glycolPolymer

The invention belongs to the technical field of pharmaceutical preparations for animals, and discloses a novel diclofenac injection and a preparation method thereof. The diclofenac injection comprisesdiclofenac existing in a dispersed form, diclofenac sodium dissolved in a system, a temperature-sensitive in-situ gel matrix, polyethylene glycol, sodium alginate, a polymer retardant and water for injection, wherein the temperature-sensitive in-situ gel matrix consists of poloxamer 407 and poloxamer 188. The diclofenac injection specifically comprises the following components in percentage by mass of 2-18 percent of the diclofenac, 0-8 percent of the diclofenac sodium, 10-25 percent of the poloxamer 407, 0.1-16 percent of the poloxamer 188, 0.1-7 percent of polyethylene glycol, 0.02-5 percent of sodium alginate, 0.01-5 percent of the polymer retardant, 0.001-2 percent of a bacteriostatic agent and the balance of the water for injection. According to the diclofenac injection disclosed bythe invention, the gelling temperature is 31-35 DEG C, the gelling time is within 15 seconds, the diclofenac injection exists in a liquid state at room temperature, and a gel storage can be quickly formed at an injection part during intramuscular injection or subcutaneous injection administration.

Owner:ZHENGZHOU BARY ANIMAL PHARMA

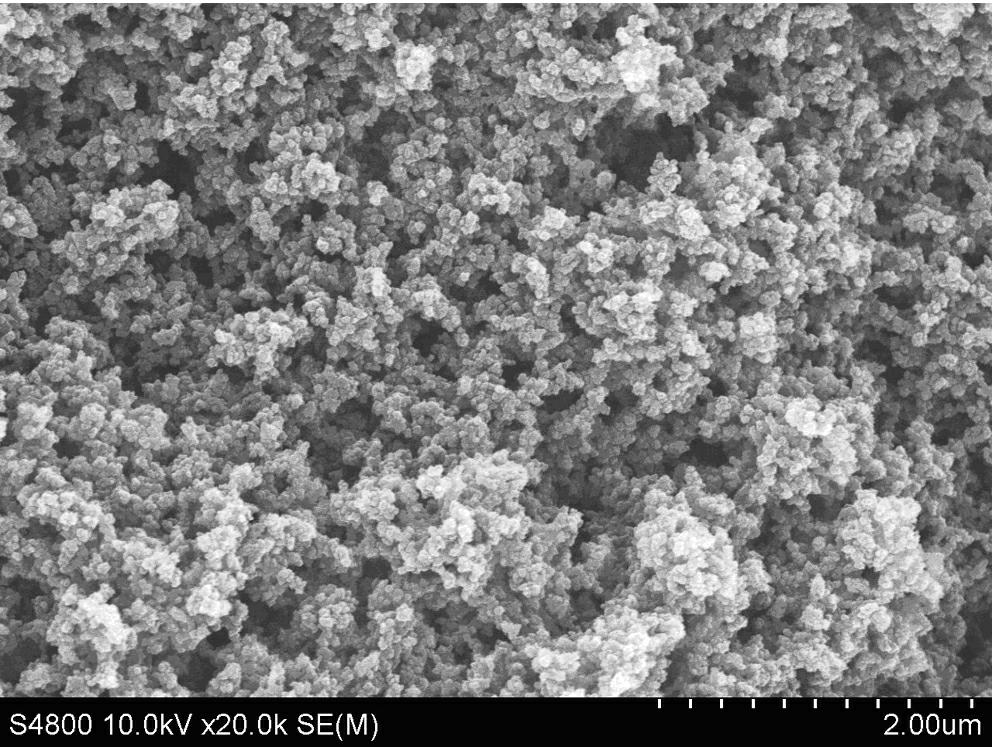

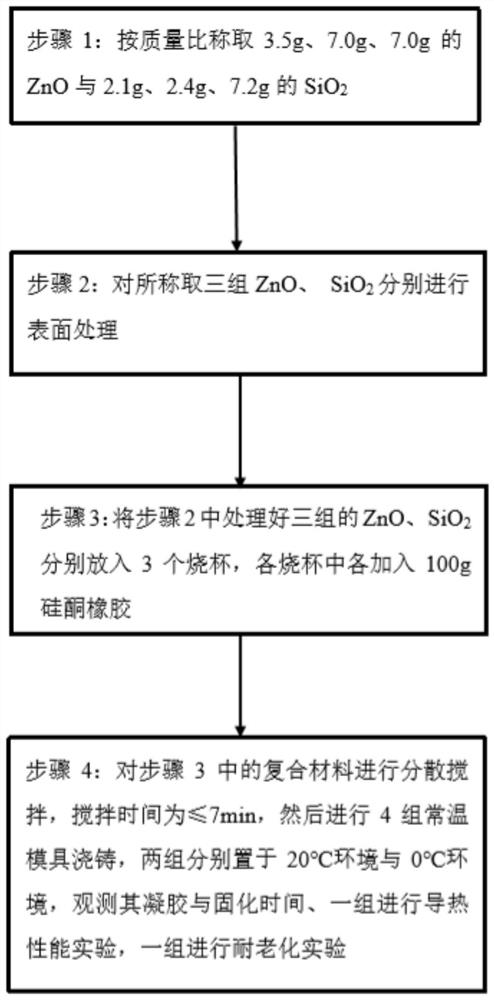

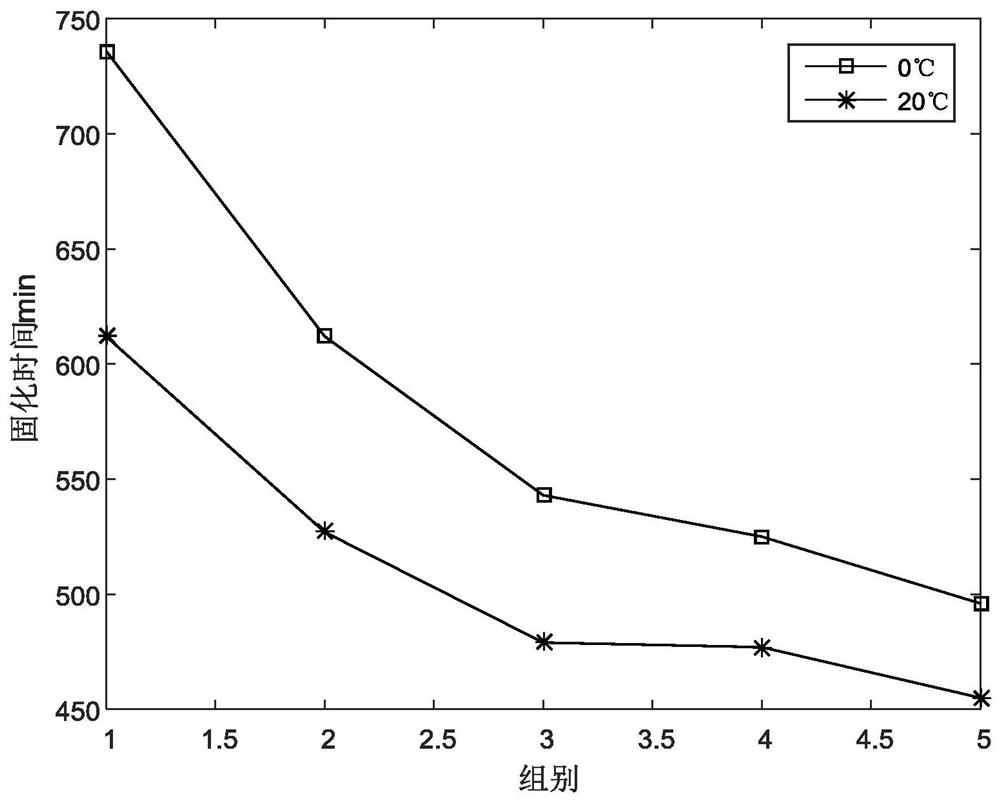

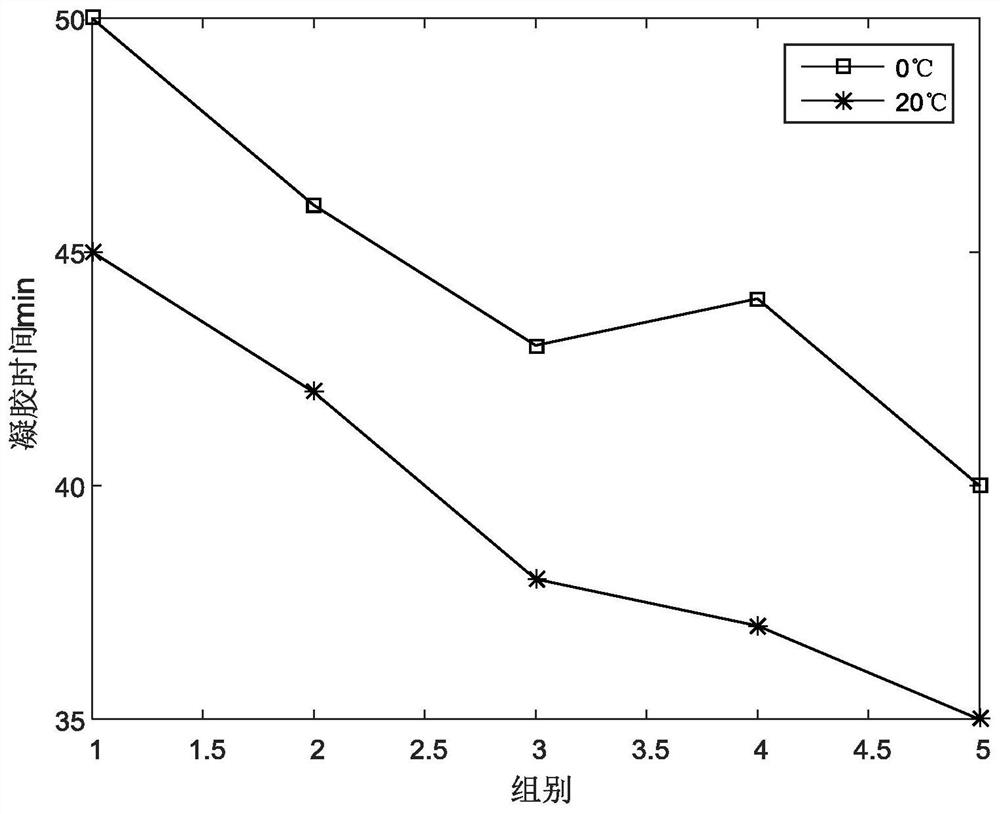

Nanometer modified rapid prototyping polymer insulating material and preparation method thereof

ActiveCN113292859AImprove thermal conductivityImprove aging resistanceCoatingsRubber materialPolymer science

The invention aims to provide a nanometer modified rapid prototyping polymer insulating material. The nanometer modified rapid prototyping polymer insulating material specifically comprises the following components in percentage by mass: silicone rubber, nano-zinc oxide and nano-silicon dioxide. According to the invention, 2.4%-7% by mass of the nano-zinc oxide and 1.2%-7.2% by mass of the nano-silicon dioxide are added into the silicone rubber, so while the insulating property of a silicone rubber material is maintained, the gelation and curing temperature conditions of the silicone rubber material are improved, the gelation and curing time of the silicone rubber material is shortened, and the heat-conducting property and the aging resistance of the insulating material are enhanced. The invention also provides a preparation method of the nanometer modified rapid prototyping polymer insulating material.

Owner:陕西能源研究院有限公司

Elastomeric composition

An elastomeric composition includes a reaction product of an isocyanate component and a resin component comprising a polyol and a polyetheramine in the presence of a first catalyst comprising a metal and a second catalyst comprising an amine. An elastomeric system and a method of making an elastomer are provided. The method includes providing the isocyanate component and the resin component, combining the resin component and the isocyanate component in the presence of the first and second catalysts to form an elastomeric composition, applying the elastomeric composition to a mold having a mold cavity, curing the elastomeric composition to form the elastomer, and demolding the elastomer from the mold cavity. An article including a first layer formed from the elastomeric composition emits less than 100 μg / g of volatile organic compounds over 0.5 hour at 90° C.

Owner:BASF CORP

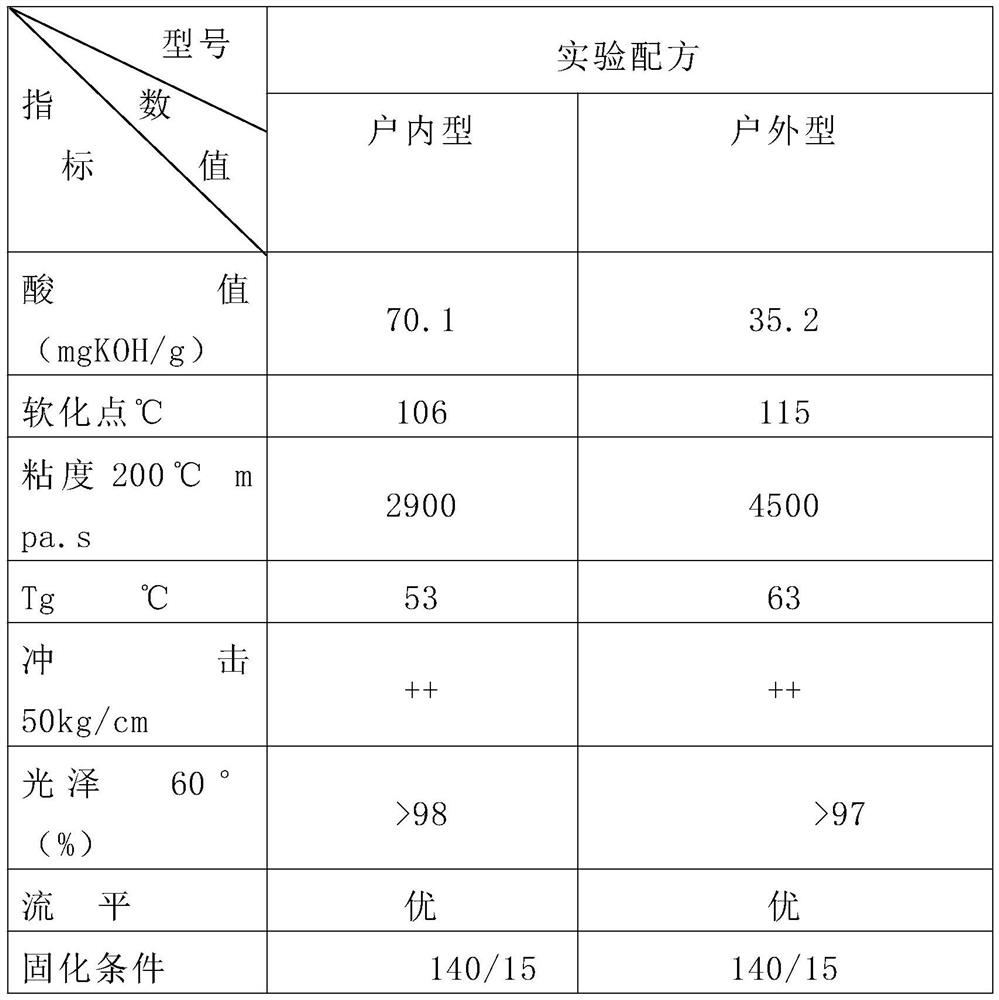

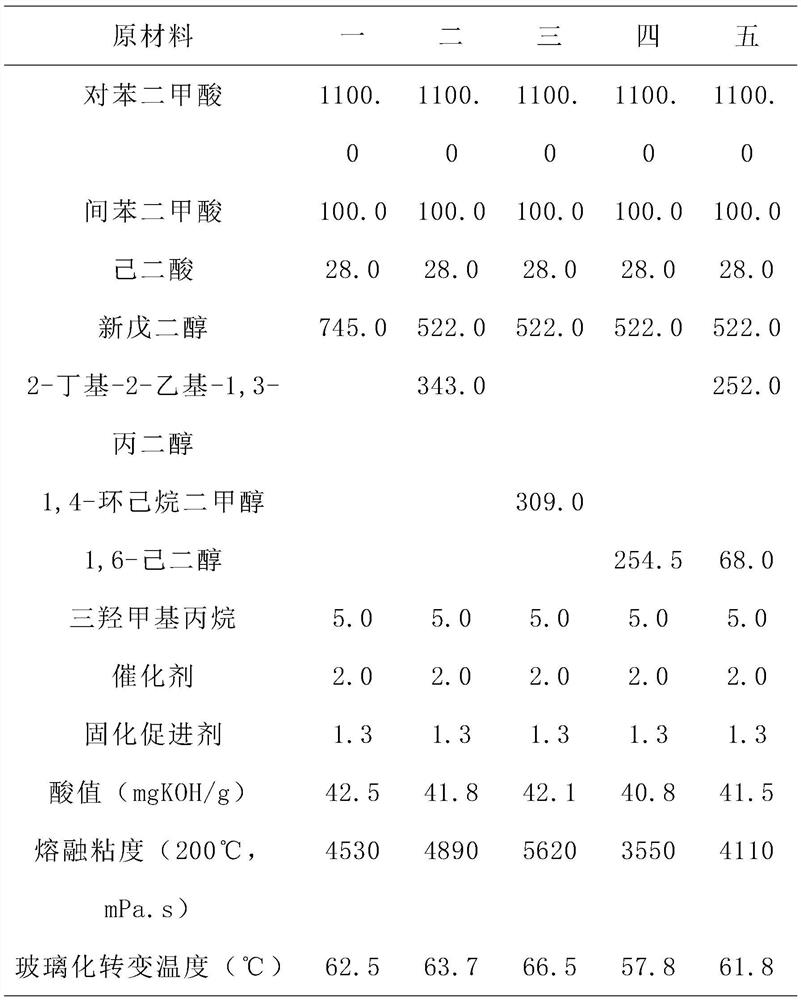

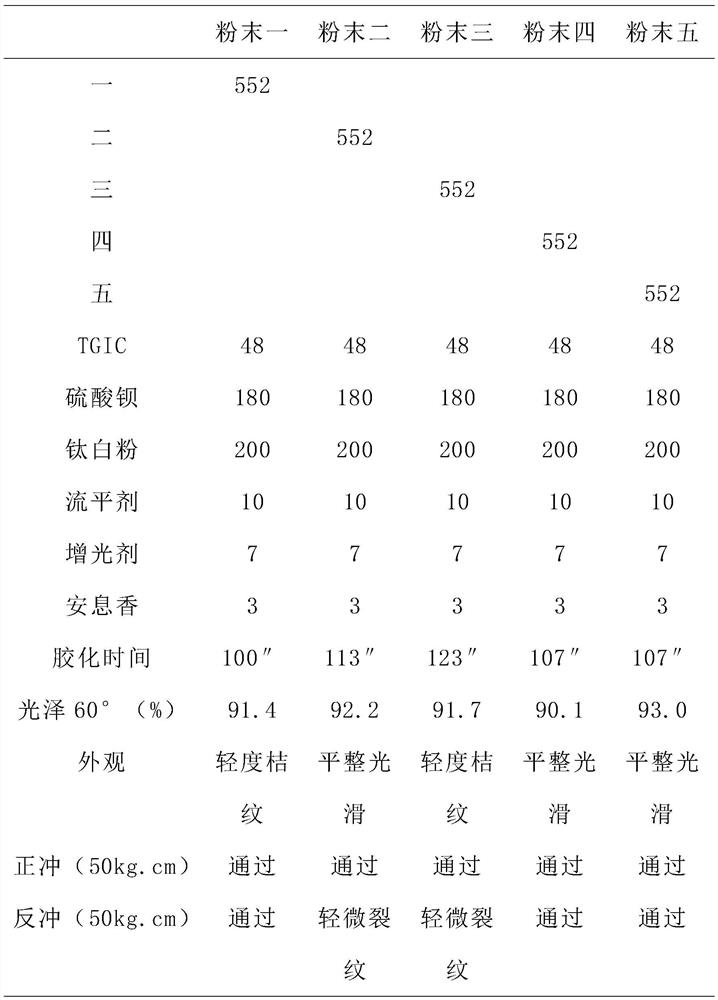

Special high-performance carboxyl-terminated polyester resin for powder coating and synthesis method thereof

InactiveCN111748082AIdeal sampleImprove performancePowdery paintsEpoxy resin coatingsPolymer scienceLow temperature curing

The invention discloses special high-performance carboxyl-terminated polyester resin for a powder coating and a synthesis method thereof. The invention solves the problems that in the prior art, the outdoor powder coating, which is prepared by taking TGIC as a curing agent, has the curing condition of 200 DEG C * 10 minutes or above, and the curing condition of the indoor powder coating taking theepoxy resin as the curing agent is 180 DEG C * 10 minutes, wherein the excessive high curing temperature may cause serious waste of energy resources and long baking time, and further causes long production period and increase on equipment and manpower cost. In the invention, the polyester resin monomer for preparing the powder coating is improved and optimized, so that the polyester resin with good stability, the powder coating can be cured at a relatively low temperature, and the application range of the powder coating can be expanded through low-temperature curing; meanwhile, the processingefficiency can be improved, the production cost is greatly reduced, and the problem that the powder coating synthesized through traditional polyester resin is prone to causing a large amount of energy waste is solved.

Owner:ANHUI MEIJIA NEW MATERIAL

Dental composition

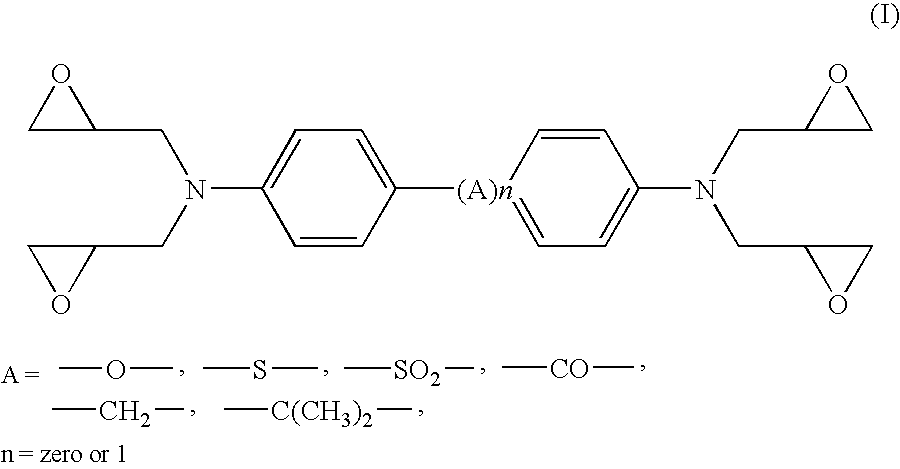

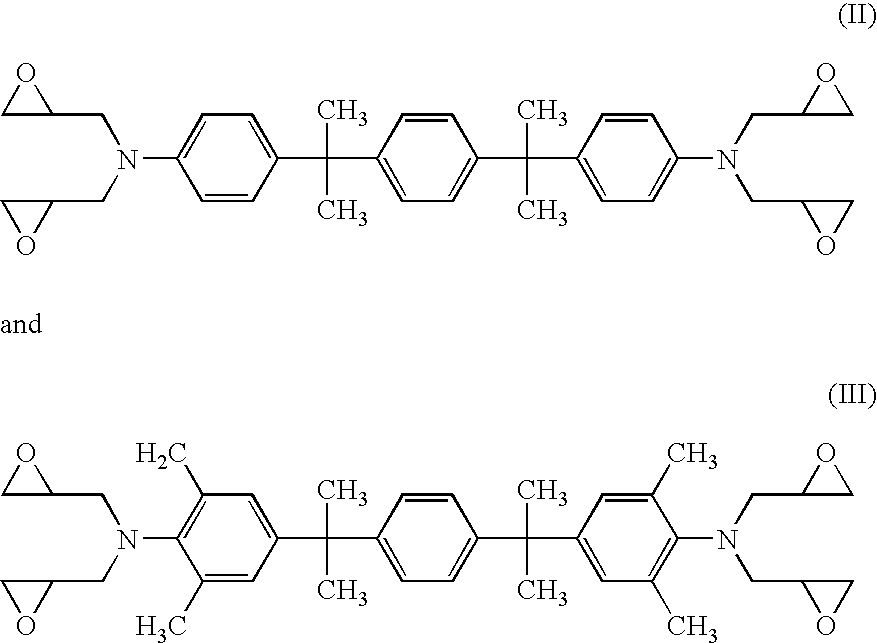

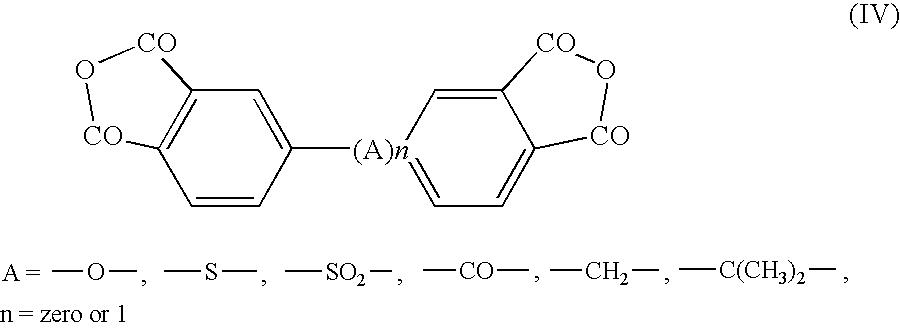

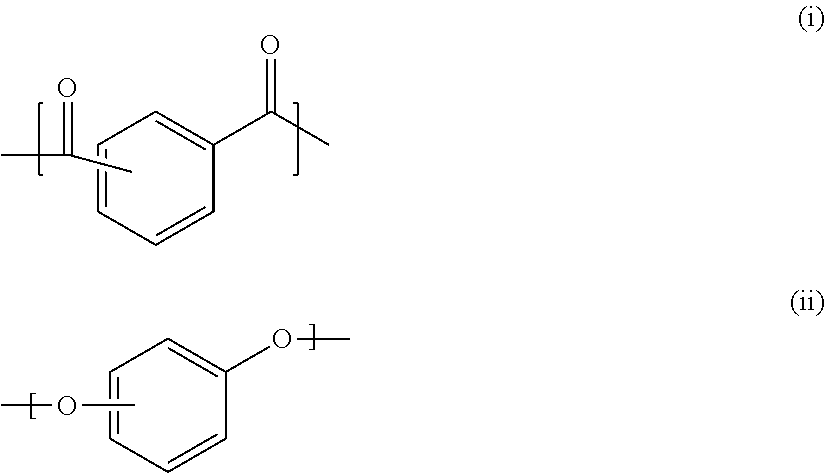

InactiveUS10278901B2Shorten gel timeImprove sealingImpression capsOrganic chemistryParticulatesCarboxylic acid

Dental composition comprising(a) at least two di- or polyepoxides having 2 to 5 epoxide groups and having a molecular weight of from 200 to 700 Da, or a macromonomeric reaction product obtainable by reacting the diepoxide with a dicarboxylic acid in a molar ratio [diepoxide] / [dicarboxylic acid] of at least 2;(b) one or more primary monoamines and / or disecondary diamines;(c) optionally one or more aliphatic polyamines;(d) a particulate filler,wherein the molar ratio of epoxide groups in component (a) to the N—H bonds in component (b) and (c) [epoxide(a)] / [N—H(b),(c)] is in the range of from 0.9 to 1.1;wherein the di- or polyepoxide having 2 to 5 epoxide groups is a compound of the following formula (I):A(BZm)n (I)whereinA represents an n-valent organic moiety optionally having 1 to 10 heteroatoms selected from oxygen atoms and sulfur atoms; andB represents an m+1-valent organic moiety,Z is an epoxide group which may have a substituent,m which are independent from each other represent an integer of at least 1; andn is an integer of from 1 to 5;wherein the m are selected so that 2 to 5 epoxide groups are present;wherein the composition does not contain any 2,2-bis-(4-hydroxyphenyl)-propane, or 2,2-bis-(4-hydroxyphenyl)-methane.

Owner:DENTSPLY SIRONA INC

Gellable treatment fluids comprising quaternary ammonium salt gel-time modifiers and methods for use thereof

Methods for reducing the amount of water produced from a subterranean formation can include the use of a gellable treatment fluid that comprises a quaternary ammonium salt as a gel-time modifier. The gellable treatment fluids can comprise an aqueous base fluid, a base polymer comprising an acrylamide monomer unit, an organic crosslinking agent, and a gel-time modifier comprising a quaternary ammonium salt.

Owner:HALLIBURTON ENERGY SERVICES INC

Production process capable of improving powder coating production yield

ActiveCN107722799ALow viscosityEasy to wasteAnti-corrosive paintsPowdery paintsPolyester resinWater cooling

The invention discloses a production process capable of improving the powder coating production yield. The process comprises the following steps: 1, preparing and mixing materials to obtain a coatingmixture which is prepared from the following components in parts by weight: 25-35 parts of high-viscosity polyester resin, 25-35 parts of low-viscosity polyester resin, 3-3.5 parts of a curing agent T105, 12-14 parts of titanium dioxide, 0.4-0.6 part of carbon black, 0.08-0.1 part of pigment green, 0.1-0.3 part of ferrite yellow, 0.8-1 part of a flatting agent, 0.2-0.4 part of a defoaming agent, 0.04-0.06 part of a catalyst, 0.5-0.6 part of nano-metal oxide particles and 20-23 parts of filler; 2, extruding to obtain an extruded material; 3, cooling and pressing the extruded material to obtaina coating sheet, and cooling by adopting a water-cooling mode; and 4, grinding the coating sheet, and controlling the grinding particle size to be 37-41mu m. The production process has the characteristics of improving the powder coating yield, improving the product production efficiency and reducing the production cost.

Owner:浙江旗创科技集团有限公司

Unsaturated polyester resin accelerant as well as preparation method and application thereof

ActiveCN114249864AThe highest exothermic peak is moderateImprove curing effectSolid waste managementPolymer scienceCobalt octoate

The invention belongs to the technical field of accelerators, and particularly relates to an unsaturated polyester resin accelerator as well as a preparation method and application thereof. The unsaturated polyester resin accelerant is prepared from the following raw materials in percentage by mass: 69 to 89.5 percent of methanol, 0.5 to 1 percent of copper acetate, 5 to 10 percent of cobalt iso-octoate and 5 to 20 percent of water. The invention also provides a preparation method of the unsaturated polyester resin accelerator, which comprises the following steps: mixing methanol, copper acetate, cobalt iso-octoate and water, and stirring for 30-60 minutes to obtain the unsaturated polyester resin accelerator. The accelerator product system is stable, the layering phenomenon cannot occur after long-time standing, and the problem of layering of an existing accelerator system is solved. A resin product prepared from the accelerator is good in curing effect and high in hardness, and the phenomenon that the resin is sticky to hands and becomes soft is avoided. The unsaturated polyester resin accelerator can shorten the gelling time and improve the production efficiency, the highest exothermic peak temperature in the resin curing process is similar to that of commercially available products, the curing effect is ideal, and the unsaturated polyester resin accelerator can replace existing products.

Owner:GUANGDONG MEIHENG NEW MATERIAL TECH CO LTD

Method for preparing Al/CuO nano energetic material based on alkaline catalysis sol-gel method

InactiveCN110028372ASolve the problem that the gel condition is difficult to controlSolving Dispersion ProblemsExplosive working-up apparatusDispersityDodecylsulfonic acid

The invention discloses a method for preparing an Al / CuO nano energetic material based on an alkaline catalysis sol-gel method. According to the method, the Al / CuO nano energetic material is preparedby adopting a sol-gel method in a weakly alkaline environment and by taking urea as an alkaline catalyst and sodium dodecyl sulfate as a surfactant, wherein the pH value of the weakly alkaline environment is 7-9. The problem that the gel condition of an Al / CuO system is difficult to control is solved, the gel time is shortened, sedimentation of nAl in CuO gel is avoided, and the problem that the nanometer energetic material is prone to sedimentation and poor in dispersity after mixing is solved.

Owner:ZHONGBEI UNIV

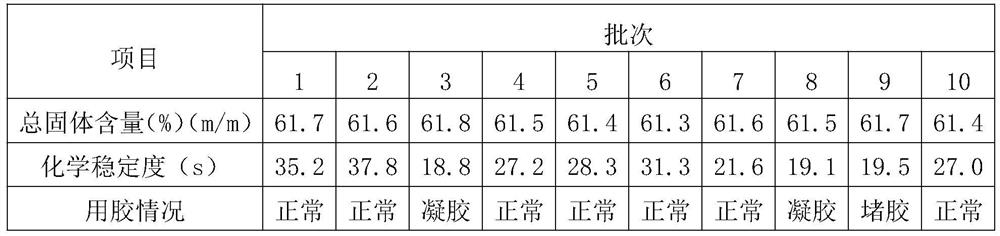

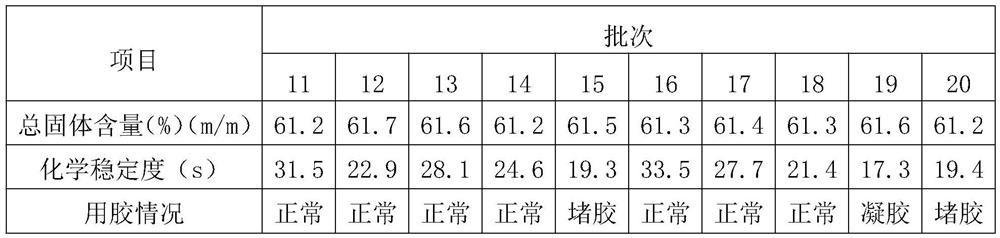

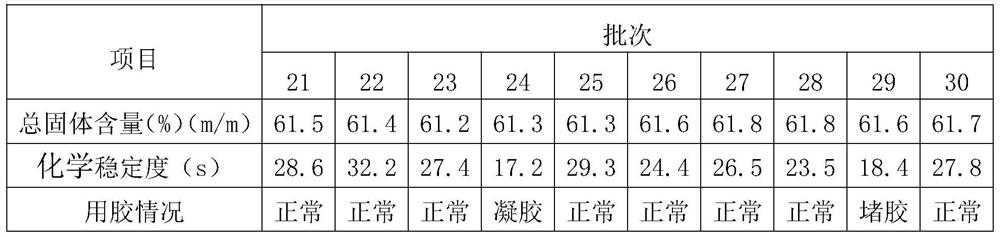

Method for testing chemical stability of latex and application of method

ActiveCN113063933ACheck chemical stabilityGuaranteed accuracyMaterial testing goodsPlant fibreLatex rubber

The invention discloses a method for testing the chemical stability of latex and application of the method. According to the testing method, an ammonium sulfate solution and latex are mixed and stirred, timing is started, timing is stopped when gel appears through stirring, and the chemical stability of the latex is judged according to the deadline. The method is applied to plant fiber product production to detect whether the chemical stability of latex is qualified or not. The method overcomes the defect that the chemical stability of the latex cannot be judged according to the current standard, and the latex which is tested to be qualified by the method does not have the phenomena of latex blocking and gelling when being used for producing plant fiber products.

Owner:GUIZHOU DAZIRAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com