Method for synthesis of zeolite from fly ash

A technology for synthesizing zeolite and fly ash, which is applied in the direction of crystalline aluminosilicate zeolite and solid waste removal, which can solve the problems of poor cracking effect and low utilization rate of fly ash resources, and achieve simple production process and shortened rubber The effect of shortening the time and simplifying the iron removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

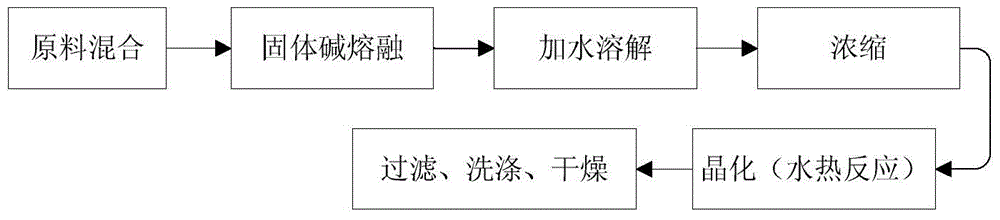

[0029] A kind of method for synthesizing zeolite from coal ash of the present embodiment comprises the steps:

[0030] Step 1: Mix the raw materials, take 20.00g of fly ash and 54.48g of NaOH (that is, the molar ratio of soda to ash is 3:1) and place them in a 100mL crucible, stir and mix evenly with a glass rod;

[0031] Step 2: Solid alkali melting, put the crucible containing fly ash and alkali in a muffle furnace for melting at 800°C for 1 hour, take it out and let it cool naturally, then crush it and perform mechanical ball milling until the particle size is less than 1 μm, and obtain melting Sample, weighing mass;

[0032] Step 3: Dissolve, take 5g of the molten sample and dissolve it in 100mL of deionized water (that is, the liquid-solid mass ratio is 20:1), stir and dissolve, filter and wash to obtain the extract;

[0033] Step 4: Concentrate, concentrate the extract to 40ml by rotary evaporation, that is, the liquid-solid mass ratio is 8:1, the gelation time is 20min...

Embodiment 2

[0037] This embodiment is a method for synthesizing zeolite from fly ash. The steps are the same as in Example 1, the difference is that the quality of NaOH in step 1 is 27.24g (that is, the molar ratio of soda to ash is 1.5:1), and in step 2, the zeolite is synthesized at 700°C. Melting for 3 hours, the hydrothermal reaction temperature in step 5 was 100°C, and the time was 24 hours.

Embodiment 3

[0039] This embodiment is a method for synthesizing zeolite from fly ash. The steps are the same as in Example 1, the difference is that the quality of NaOH in step 1 is 18.16g (that is, the molar ratio of soda to ash is 1:1), and in step 2, 500 ° C Melt for 2h, and the reaction time in step 5 is 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com