Patents

Literature

36results about How to "Reduce extrusion load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

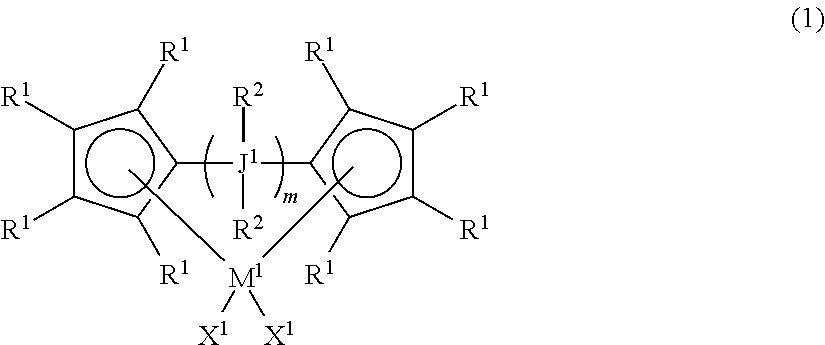

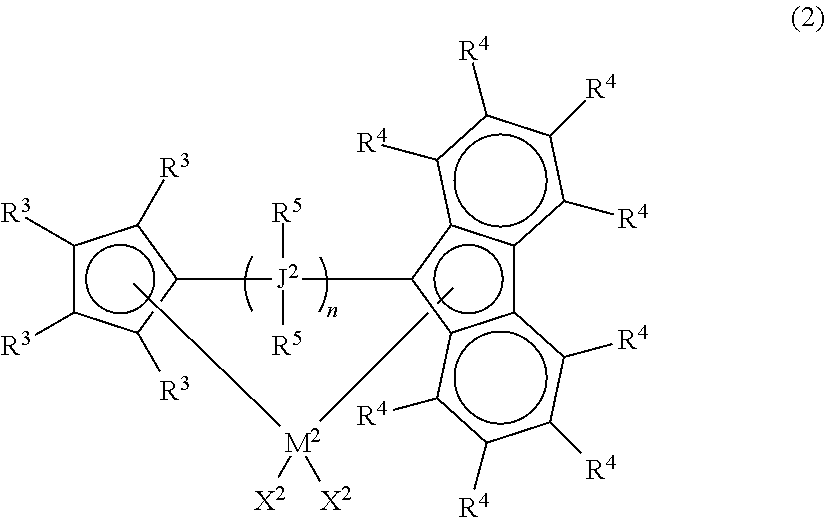

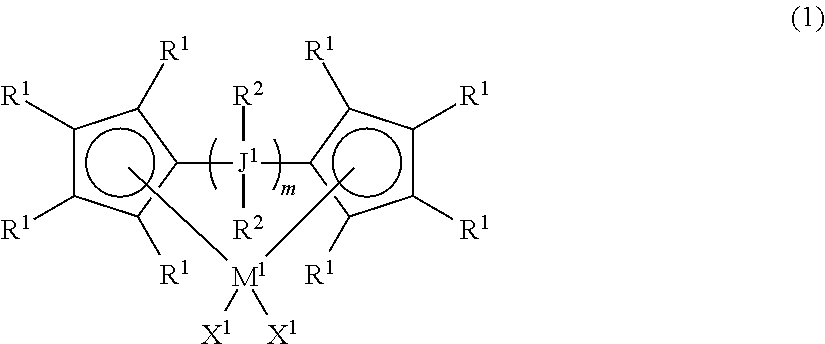

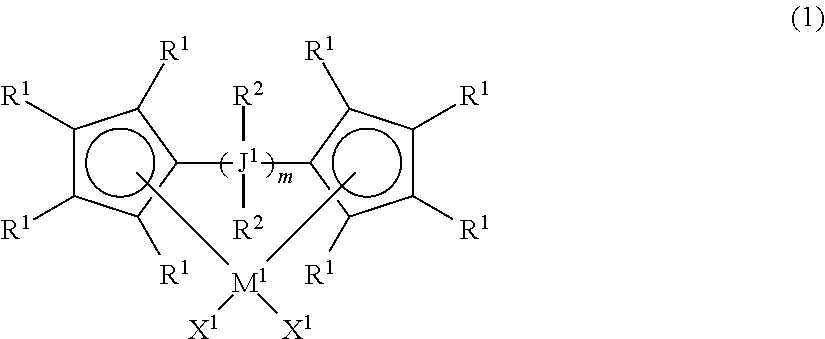

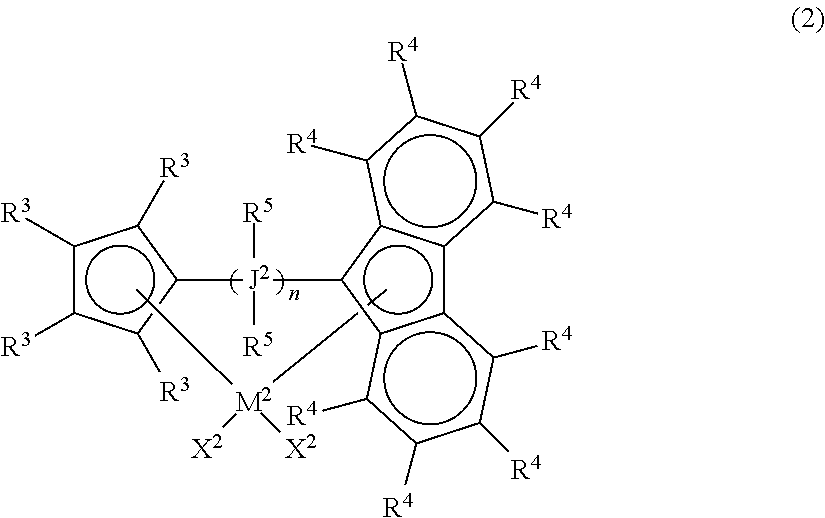

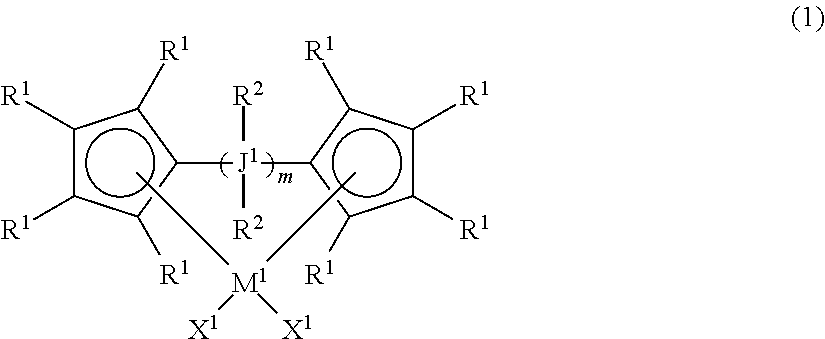

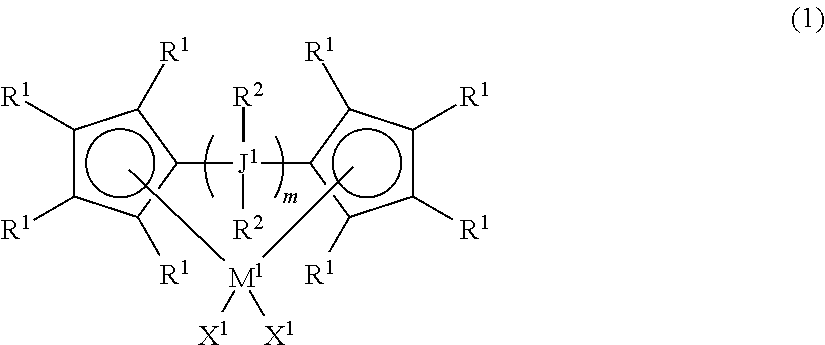

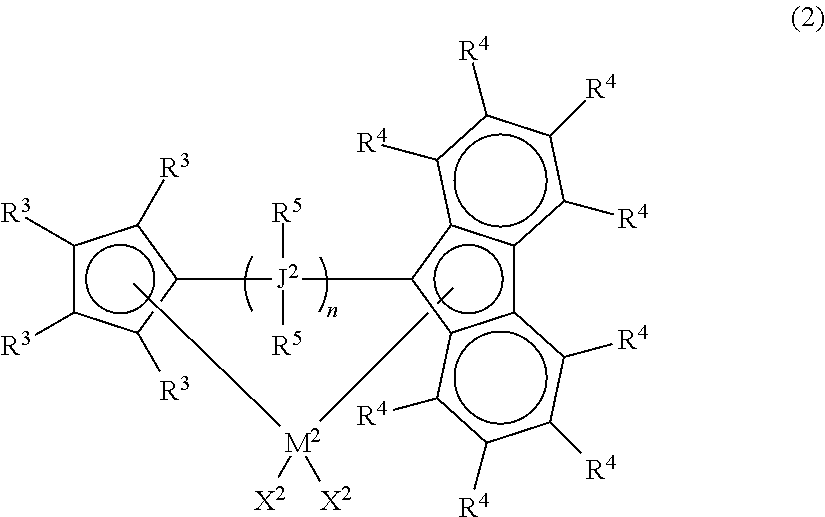

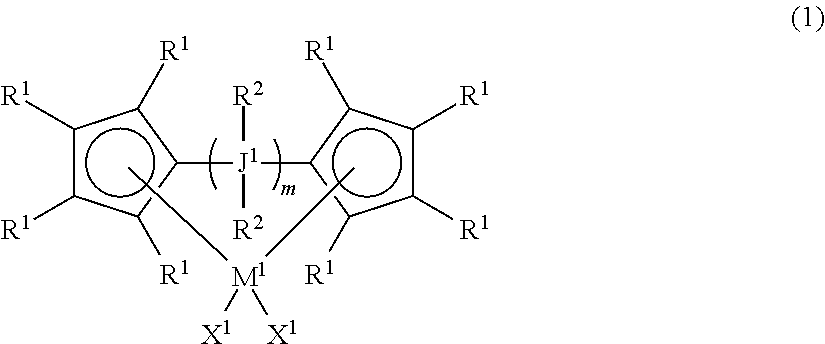

Ethylene-alpha-olefin copolymer, molded article, catalyst for copolymerization, and method for producing an ethylene-alpha-olefin copolymer

ActiveUS20120065346A1Low extrusion loadSuperior in take-up propertyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCarbon atomAlkene

An ethylene-α-olefin copolymer comprising monomer units derived from ethylene and monomer units derived from an α-olefin having 3 to 20 carbon atoms, having a density (d) of 860 to 950 kg / m3, having a melt flow rate (MFR) of 0.01 to 100 g / 10 min, having a bimodal molecular weight distribution, and having a single melting peak measured by a differential scanning calorimeter (DSC).

Owner:SUMITOMO CHEM CO LTD

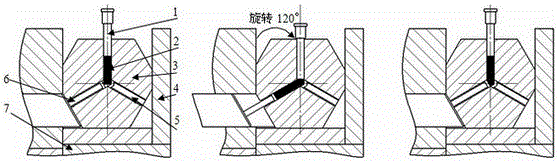

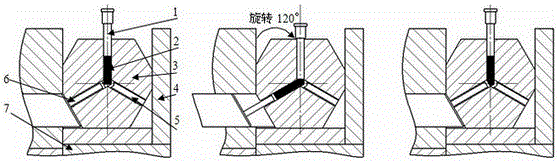

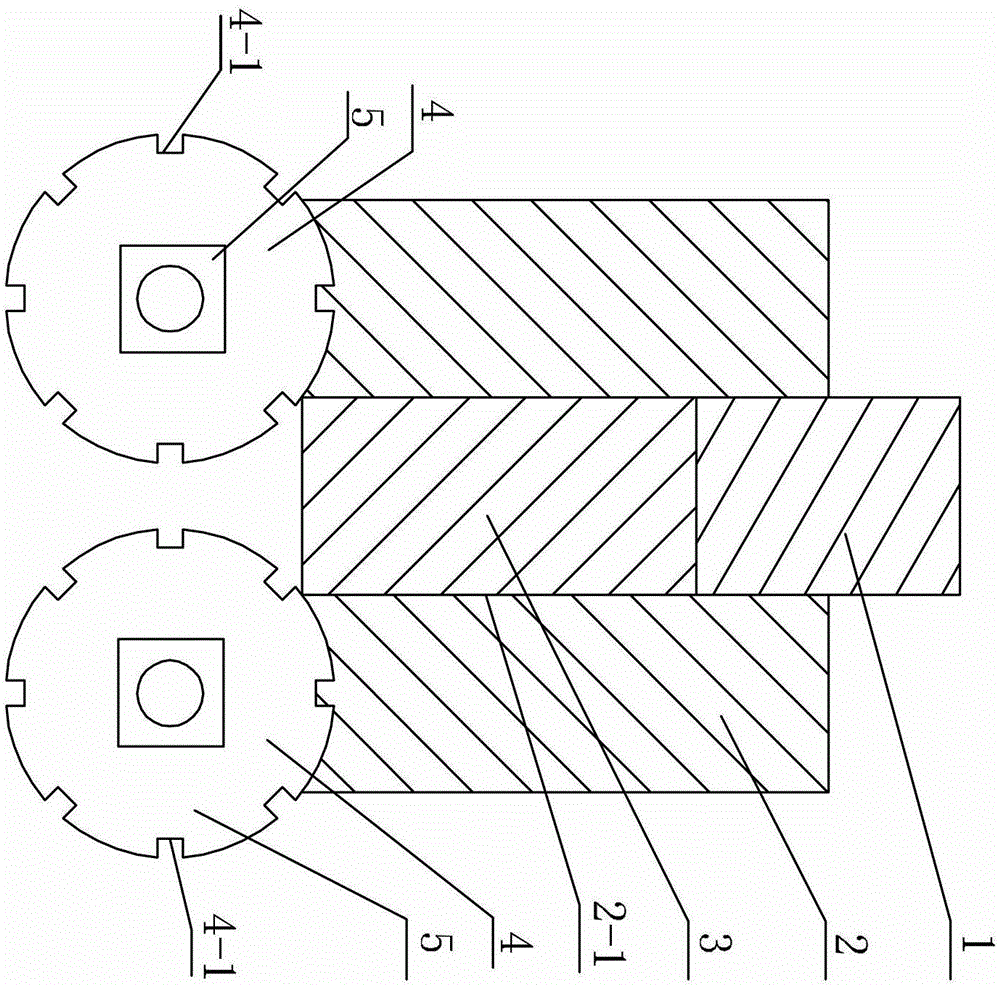

Method for preparing titanium alloy nano materials through warm extrusion of herringbone channel mold

The invention discloses a method for preparing titanium alloy nano materials through warm extrusion of a herringbone channel mold. The method is characterized in that through the herringbone central axis, the herringbone channel mold is rotated by 120 degrees, and then subsequent-pass extrusion is carried out; repeated plastic deformation of the titanium alloy nano materials can be achieved, and finally, large deformation is accumulated; the nano titanium alloy materials are obtained; in each pass extrusion process, the rotating direction of the herringbone mold is changed, and uniform severe plastic deformation of the titanium alloy can be achieved; and the grain size is uniform, and refined nano grains are equiaxed grains with large grain boundary angles, and the mechanical property of the blocky nano titanium alloy is further improved, and on the premise that the high density is ensured, the high strength and the good toughness are high.

Owner:福建省诺希科技园发展有限公司

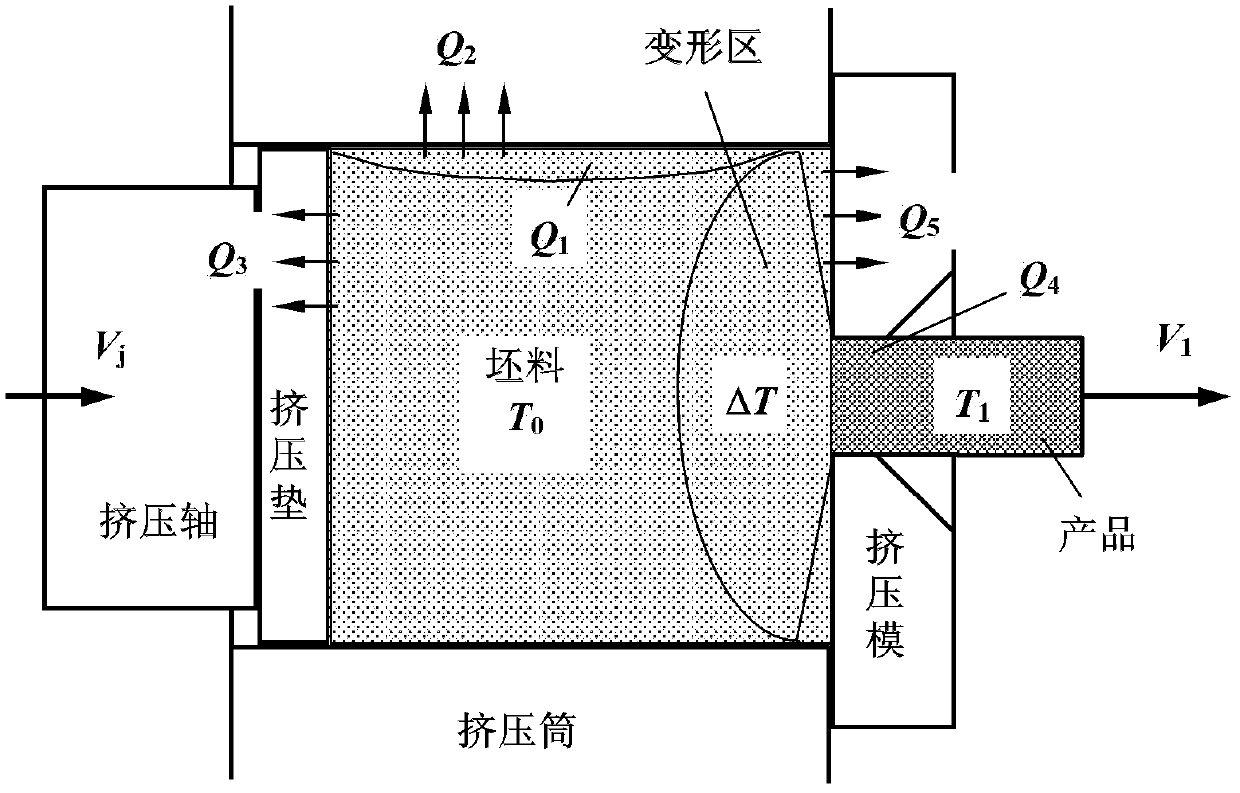

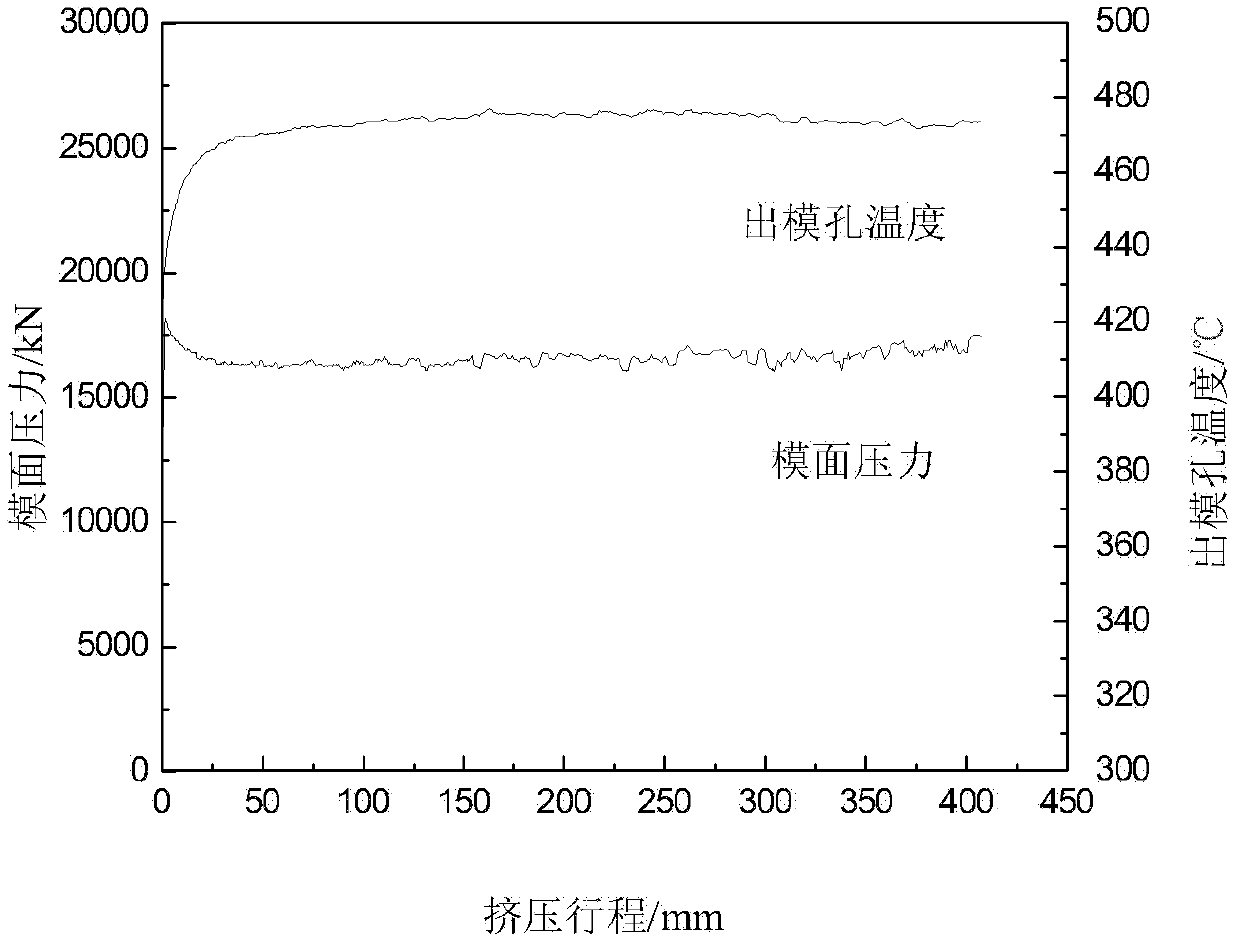

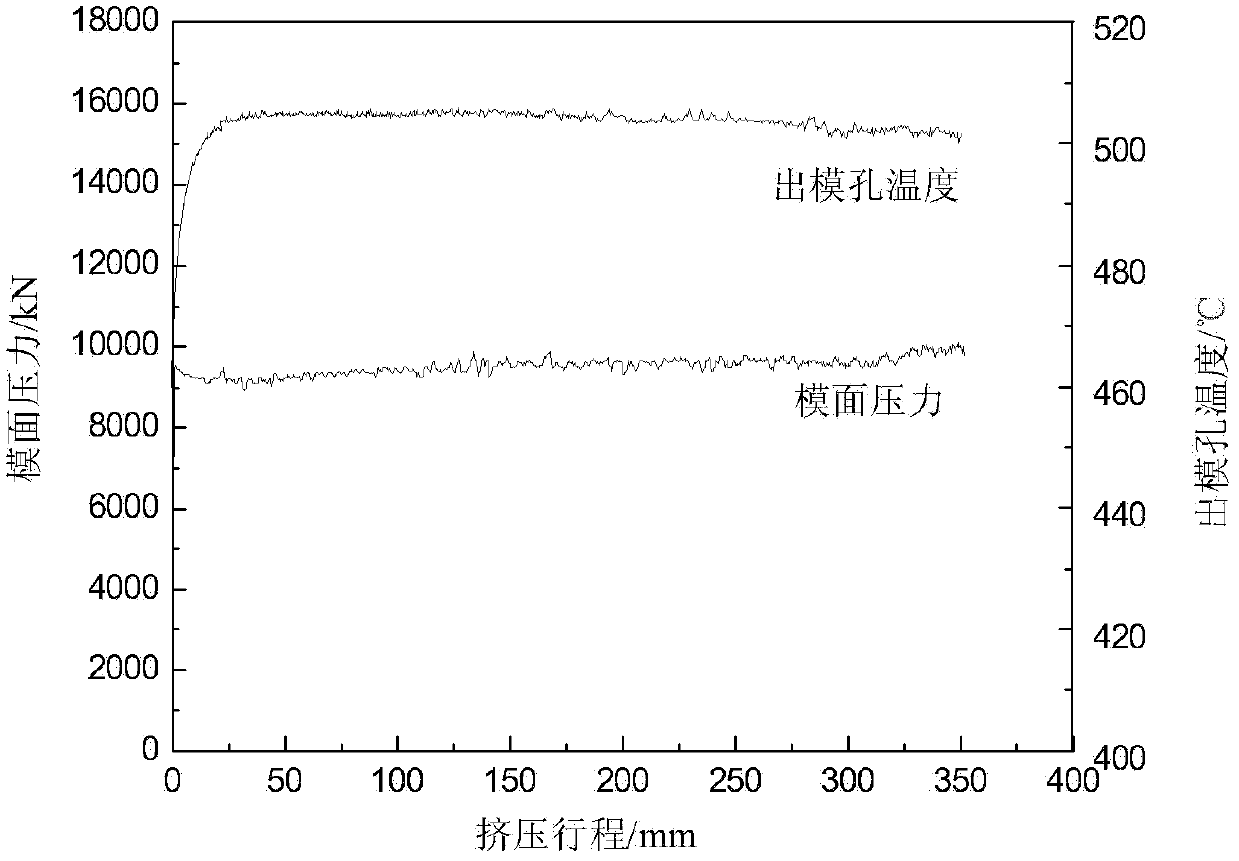

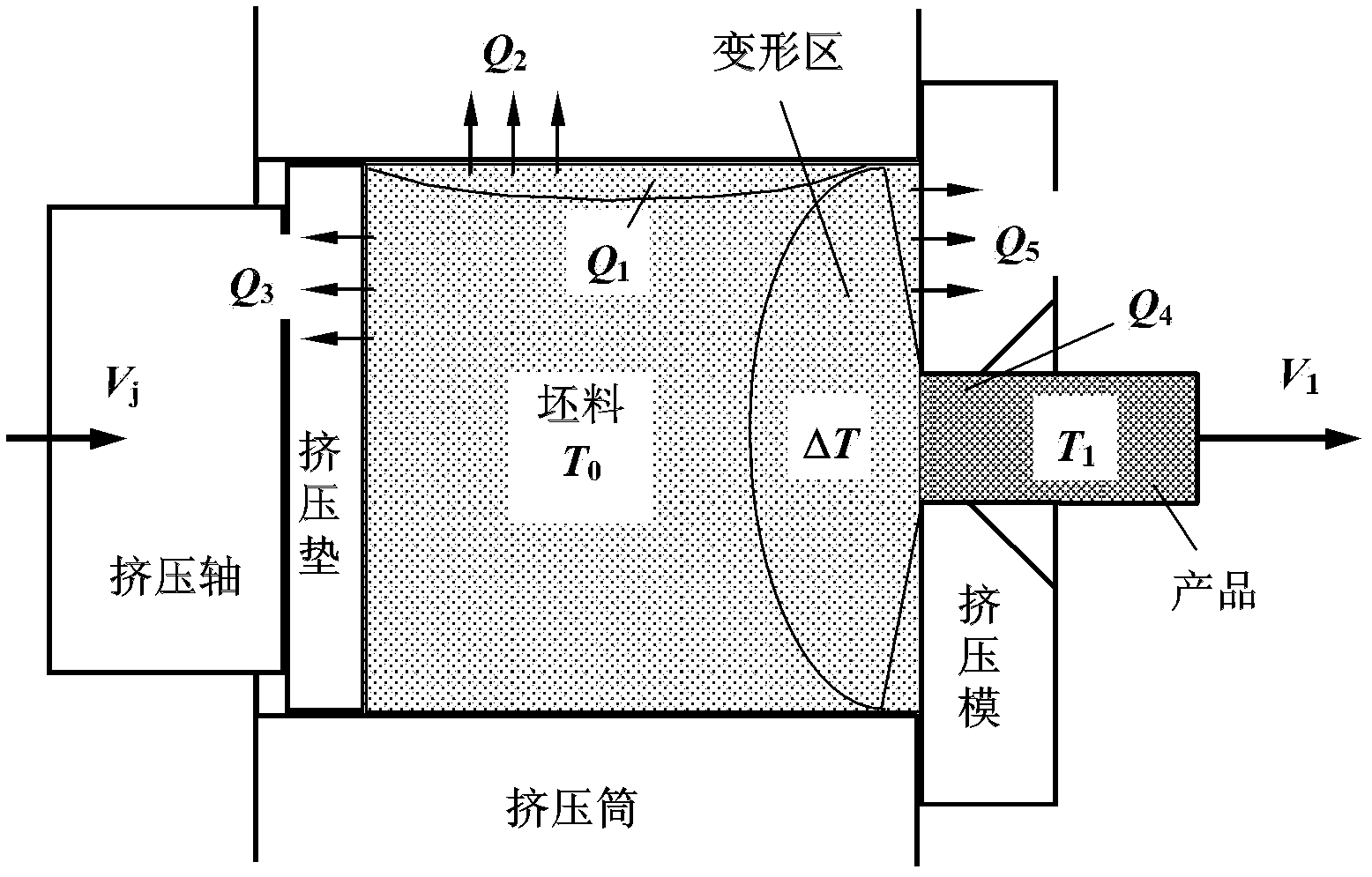

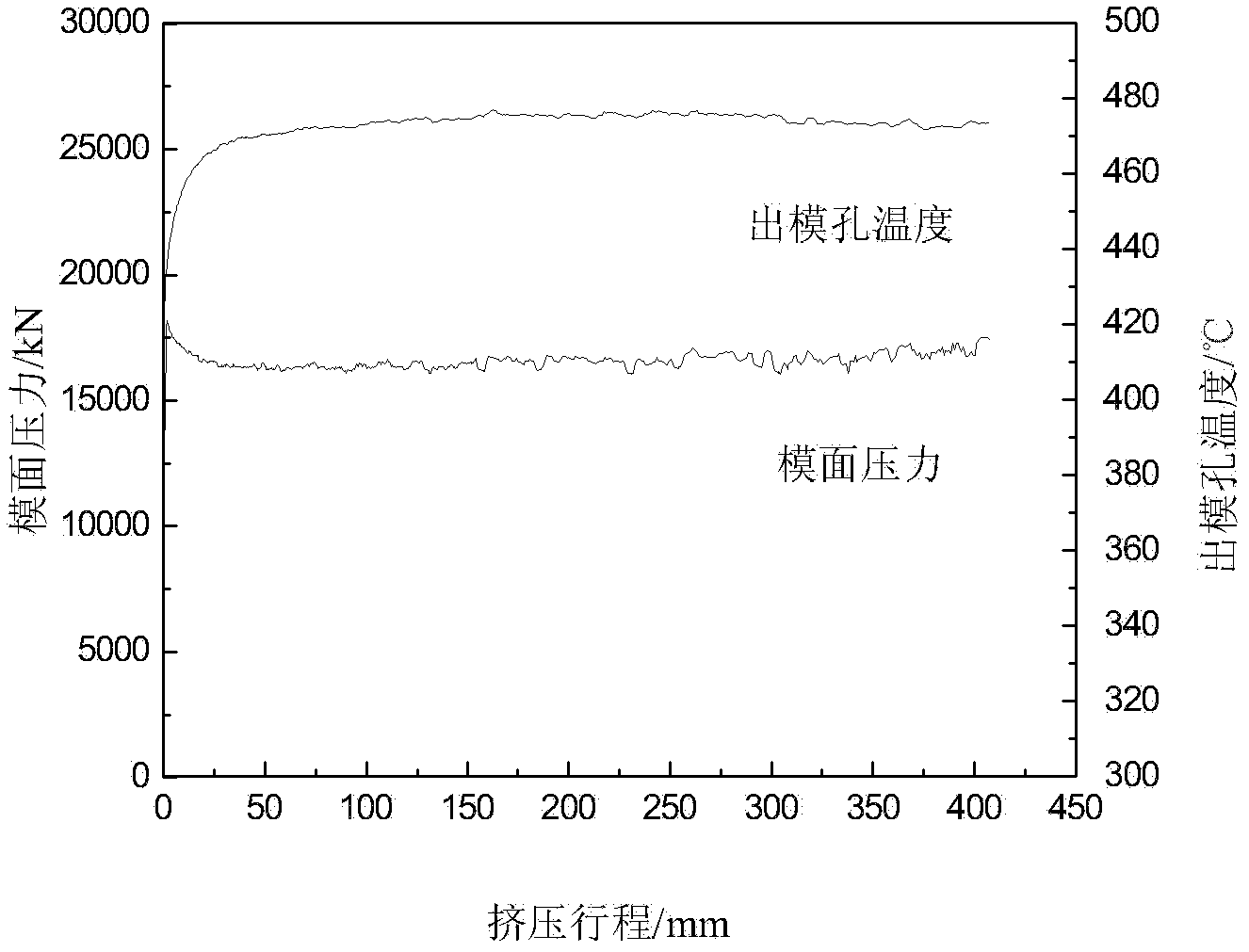

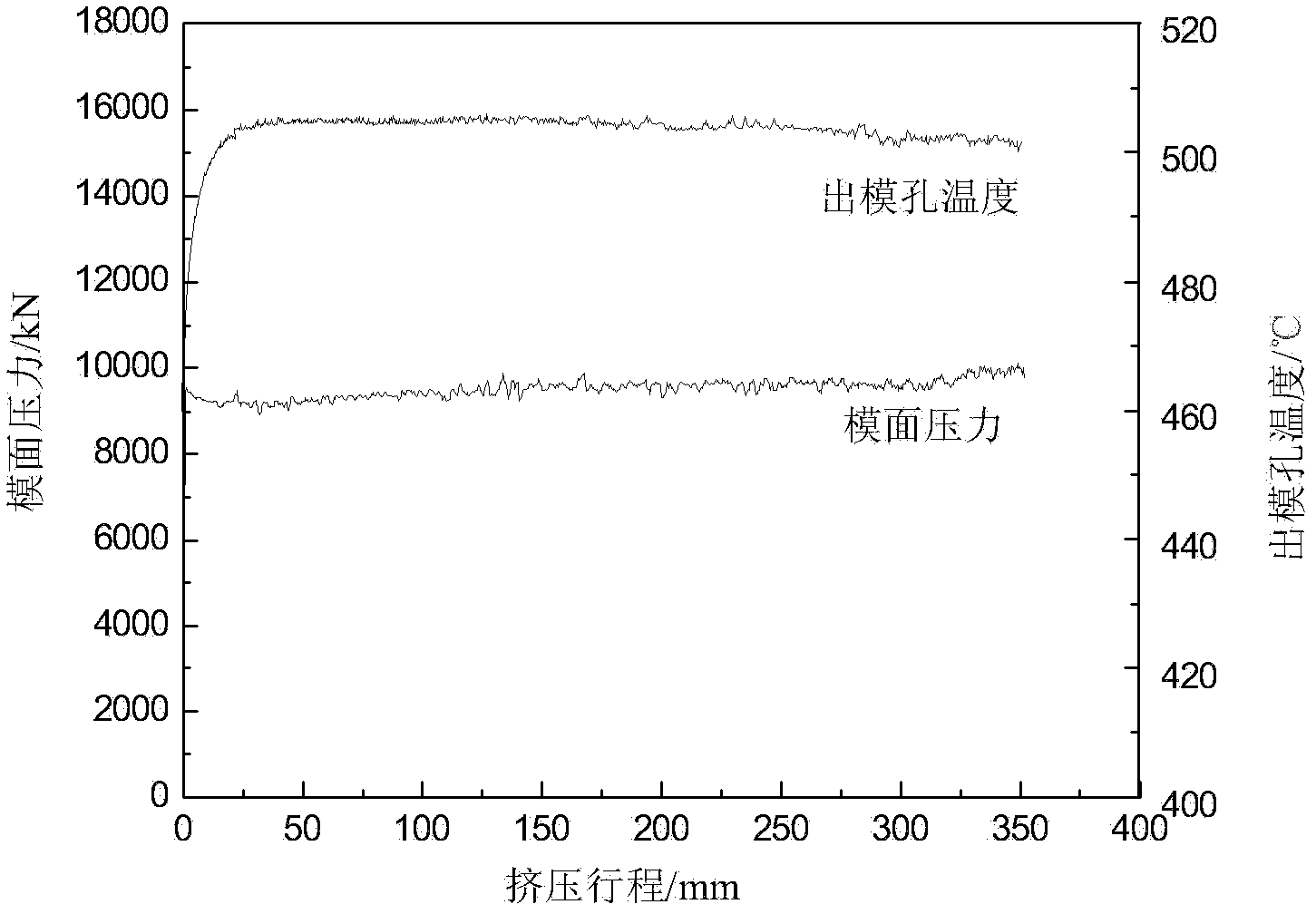

Method for realizing synthermal extrusion through technological parameter combination control

ActiveCN102601152AHigh precisionReduce extrusion loadExtrusion control devicesHeat flowStructure property

The invention relates to a method for realizing synthermal extrusion of an aluminium alloy material, which aims at obtaining a high-property extruded aluminium alloy product with a uniform structure property along the length direction. The method provided by the invention comprises the following steps: selecting an extruding device and computing the size of an extrusion billet according to a type and a specification of a target product; determining a maximum allowable temperature T1 and a heating temperature T0 of the billet of the extruded aluminium alloy product according to the production experience and the information data, so as to determine an allowable extrusion temperature rise deltaT; and determining an extrusion speed Vj and a heating temperature Tc of an extruding cylinder according to the extrusion flowing deformation characteristics and the balanced heat flow and temperature characteristics of metal. According to the invention, the technical parameters are utilized, so that the synthermal extrusion production can be realized under the uniform heating temperature of the billet and the constant extrusion speed, without reforming the existing extrusion production equipment or increasing any auxiliary equipment; uniform-speed and constant-pressure extrusion can be realized under the constant-temperature (synthermal extrusion) condition; and extrusion load can be reduced and energy consumption of the production can be reduced through reasonably matching the extrusion speed and the heating temperature of the billet.

Owner:UNIV OF SCI & TECH BEIJING

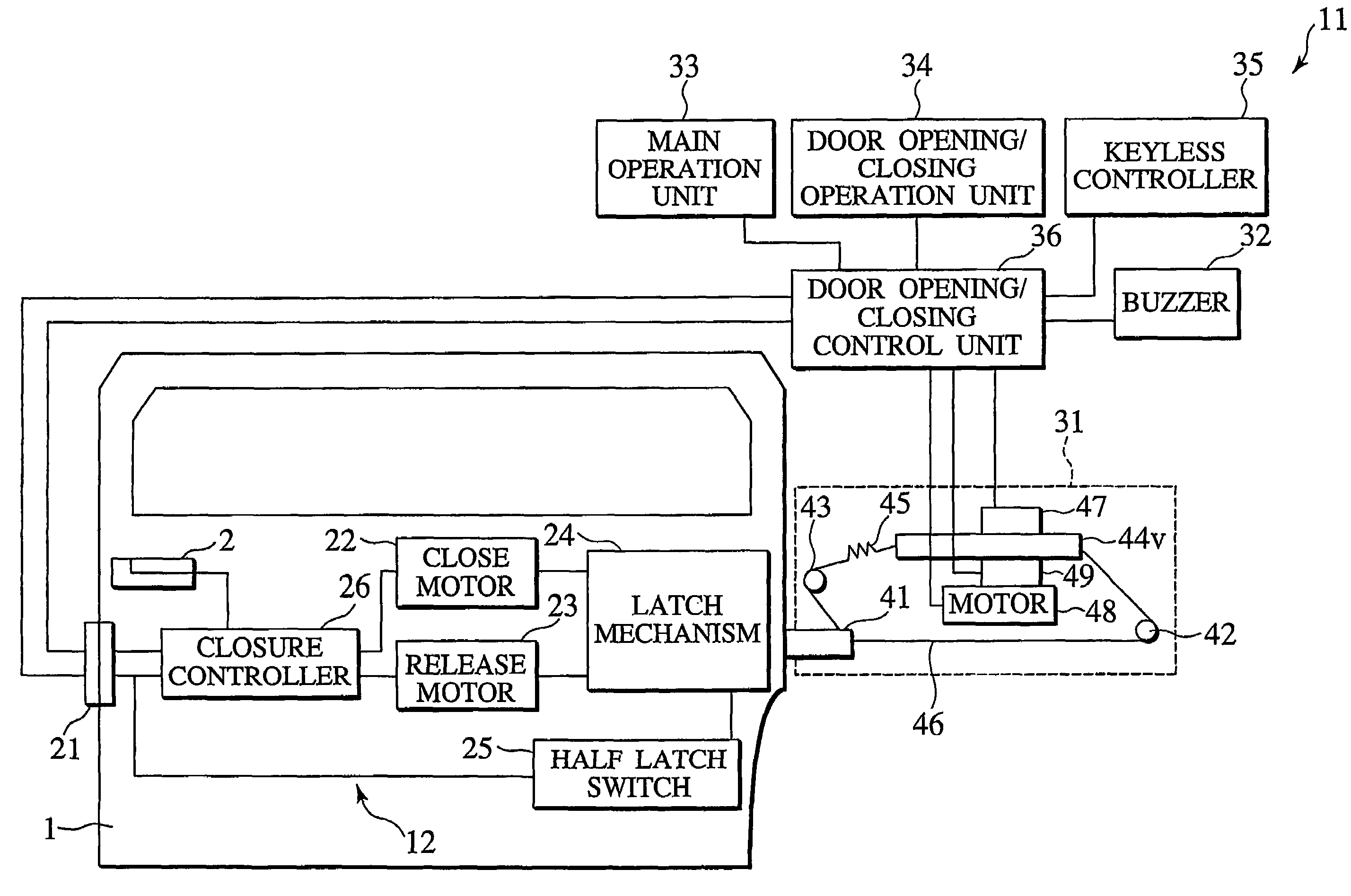

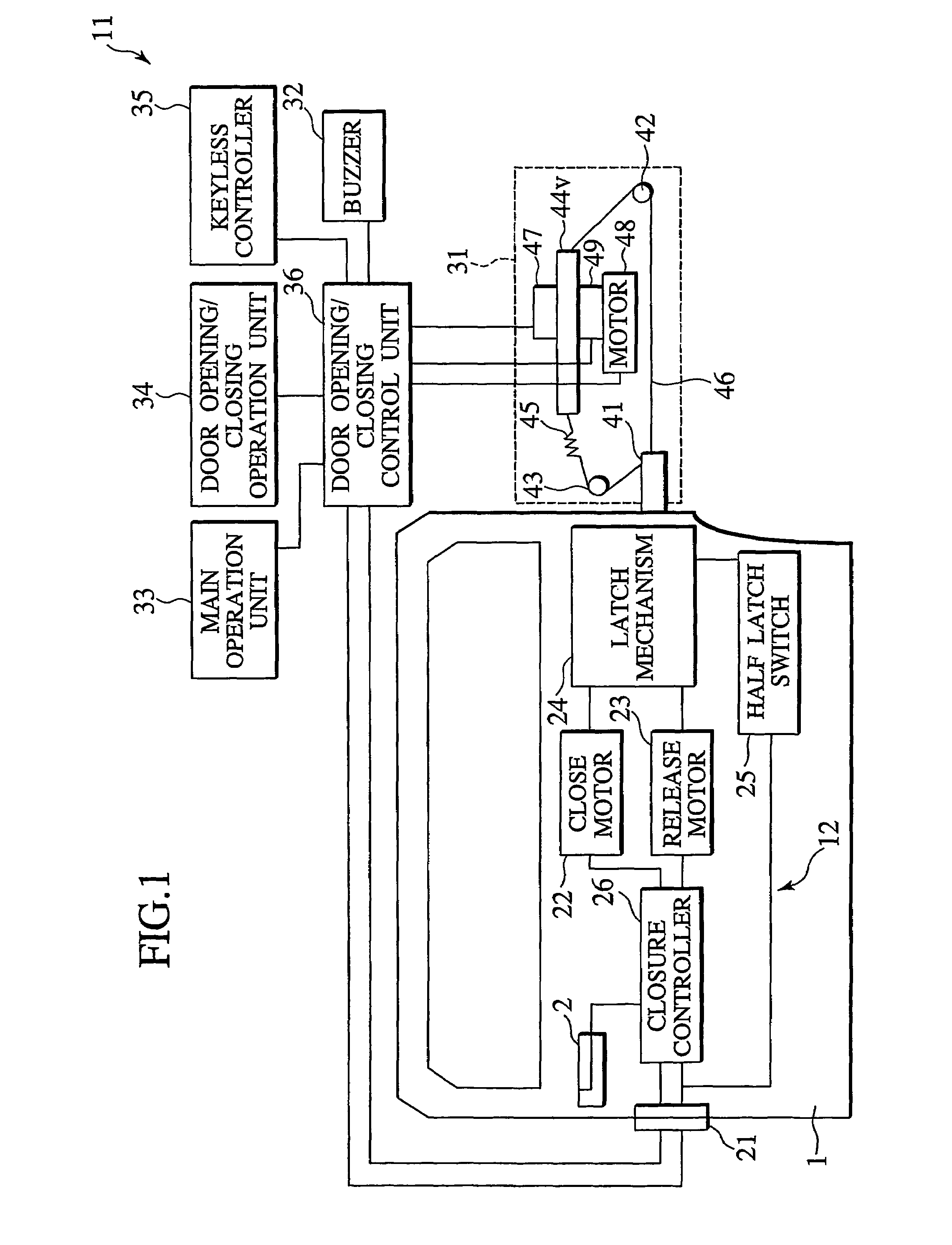

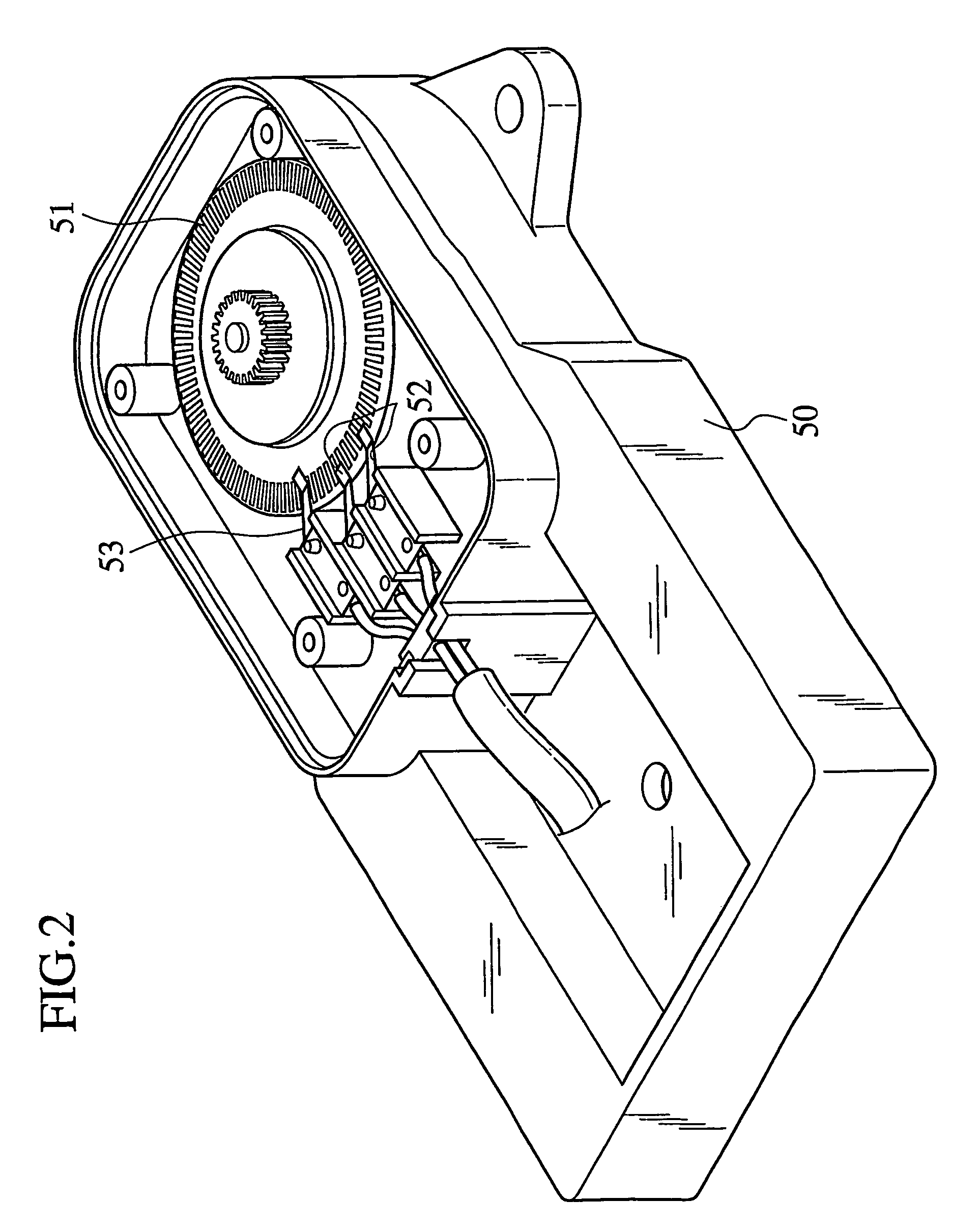

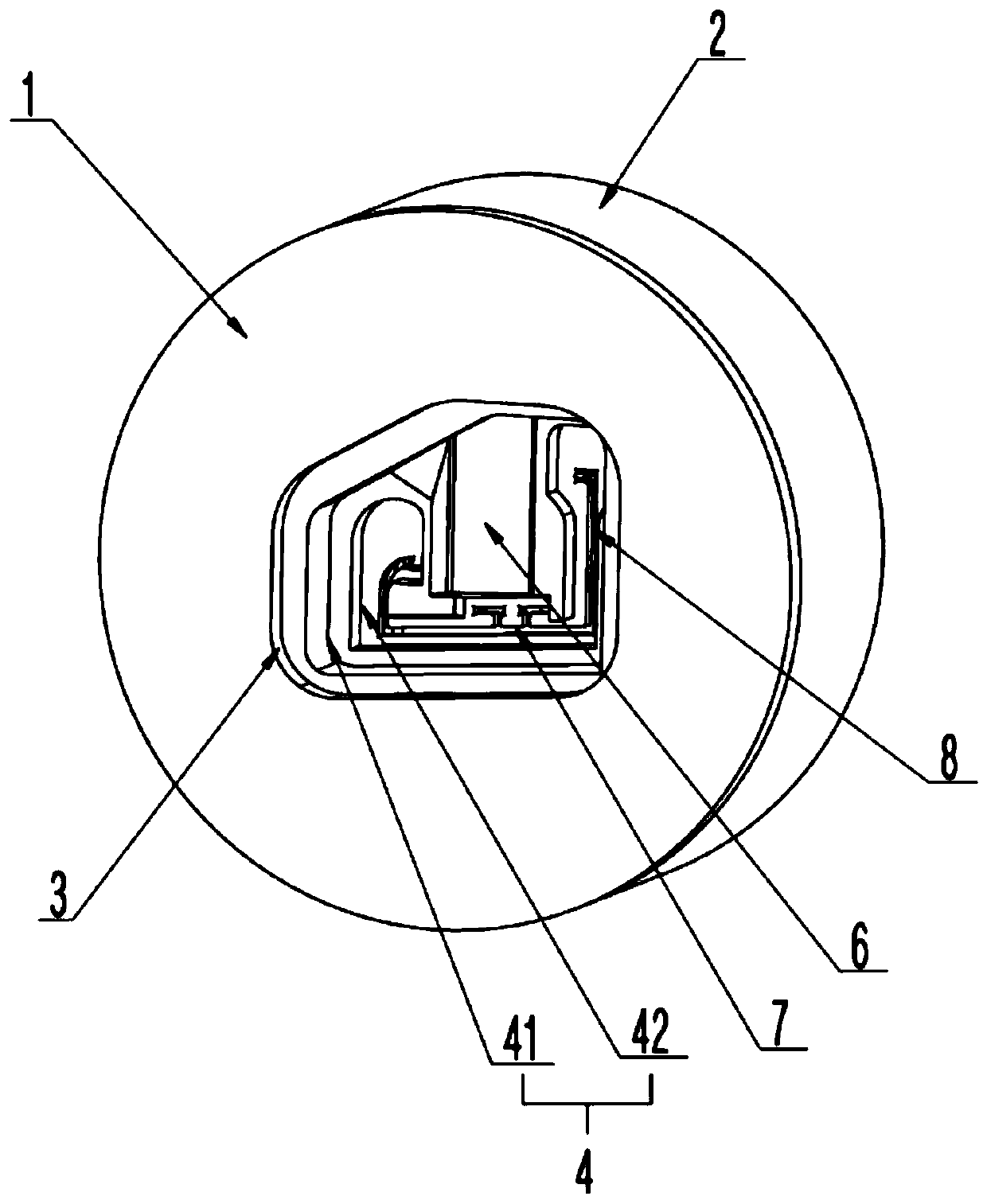

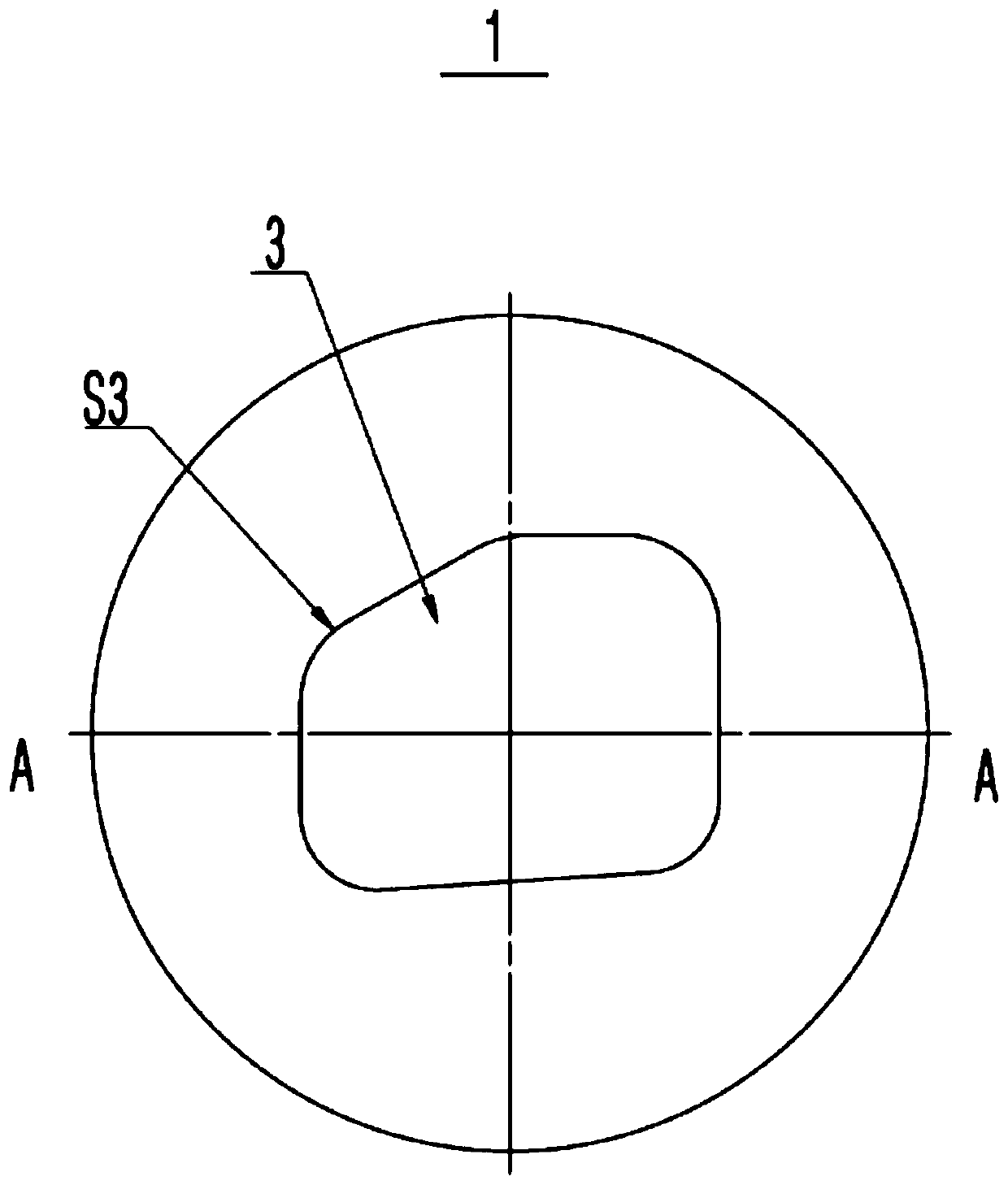

Control device for vehicular opening/closing body

ActiveUS7205734B2Reduce extrusion loadDC motor speed/torque controlEmergency protective circuit arrangementsElectric forceDrive motor

A control device for a vehicular opening / closing body is provided with a duty ratio calculator (78), which calculates a duty ratio when power supplied to a door drive motor (48) allowing an opening / closing body to open / close is subjected to duty control based on a result of adding first second multiplication values, the first multiplication value being obtained by multiplying a speed difference between a target opening / closing body speed and an actual opening / closing body speed by a negative proportional gain, and the second multiplication value being obtained by multiplying an integral value of the speed difference by an integral gain.

Owner:NISSAN MOTOR CO LTD

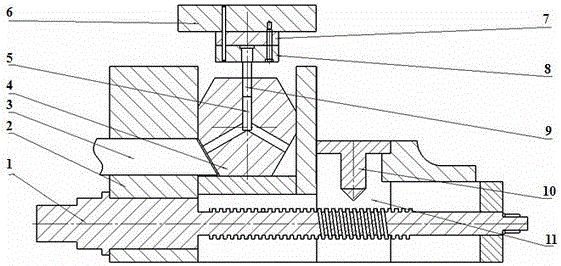

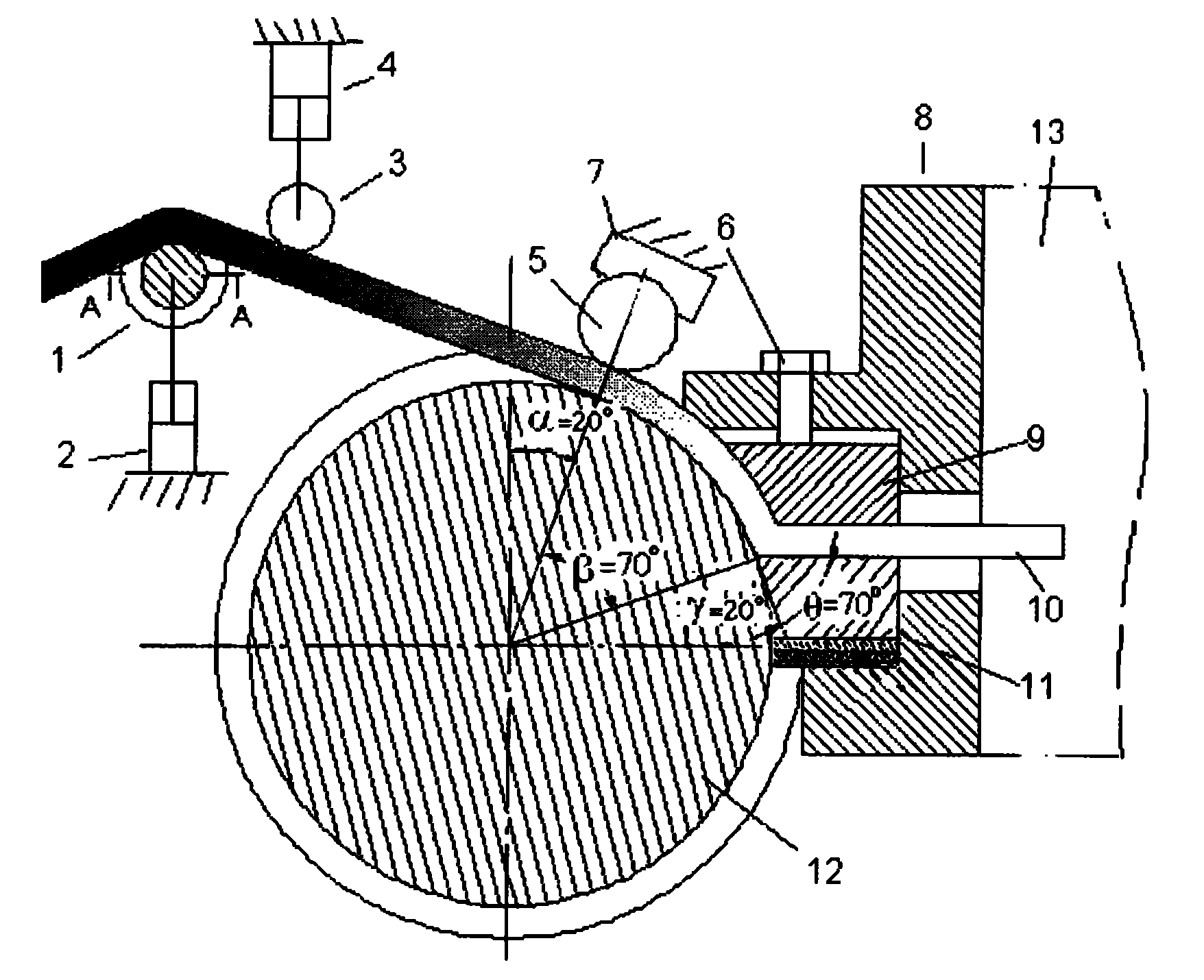

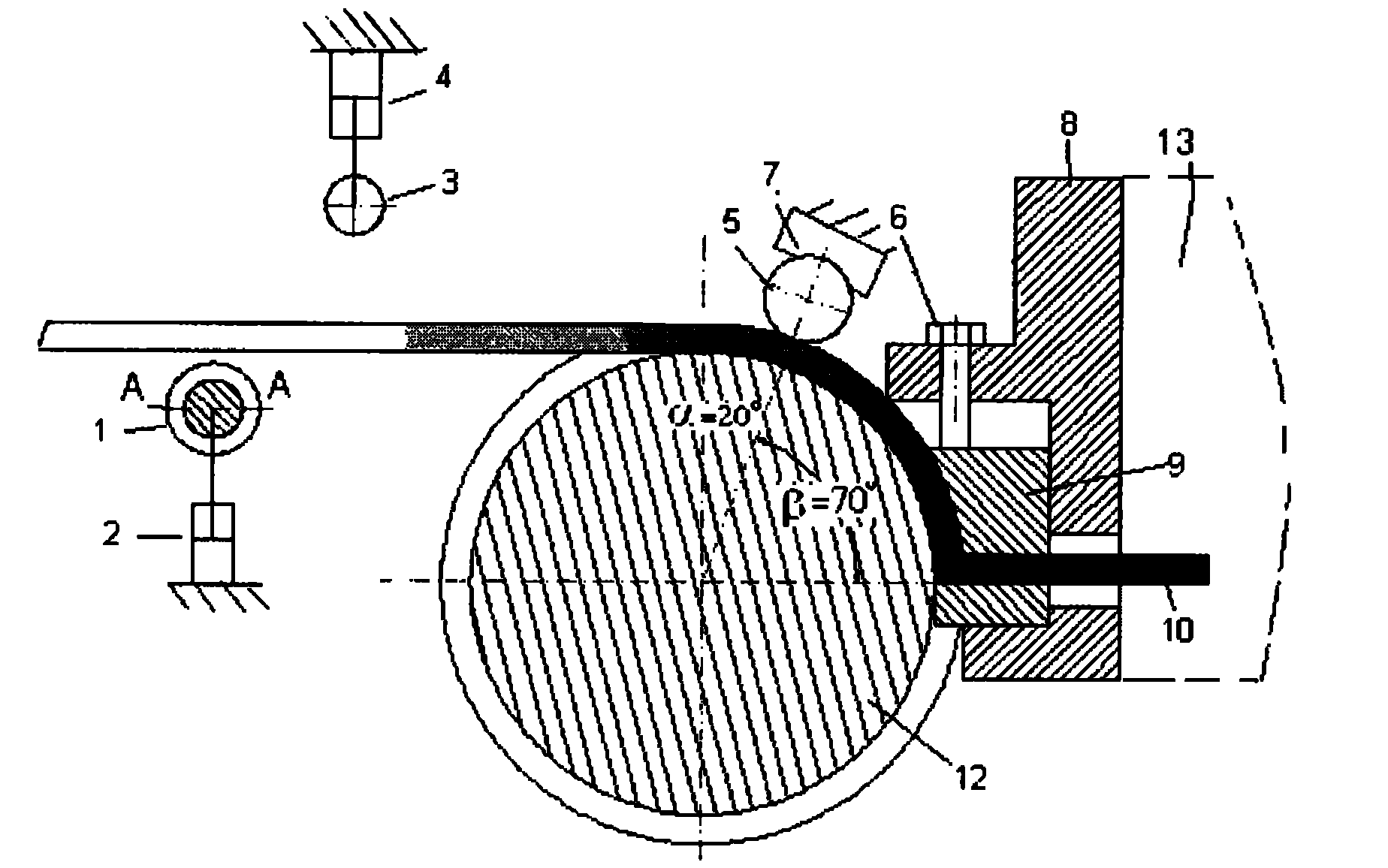

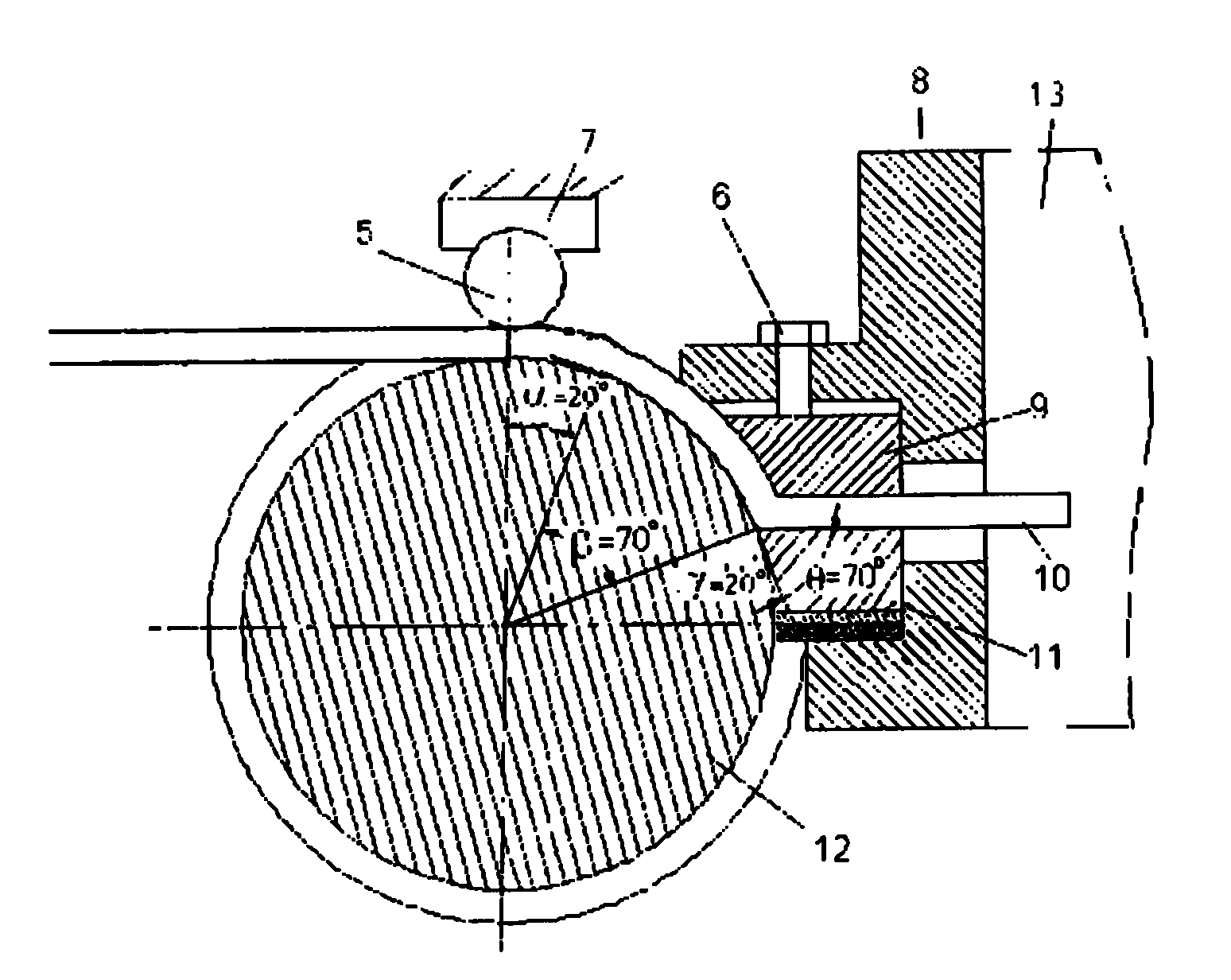

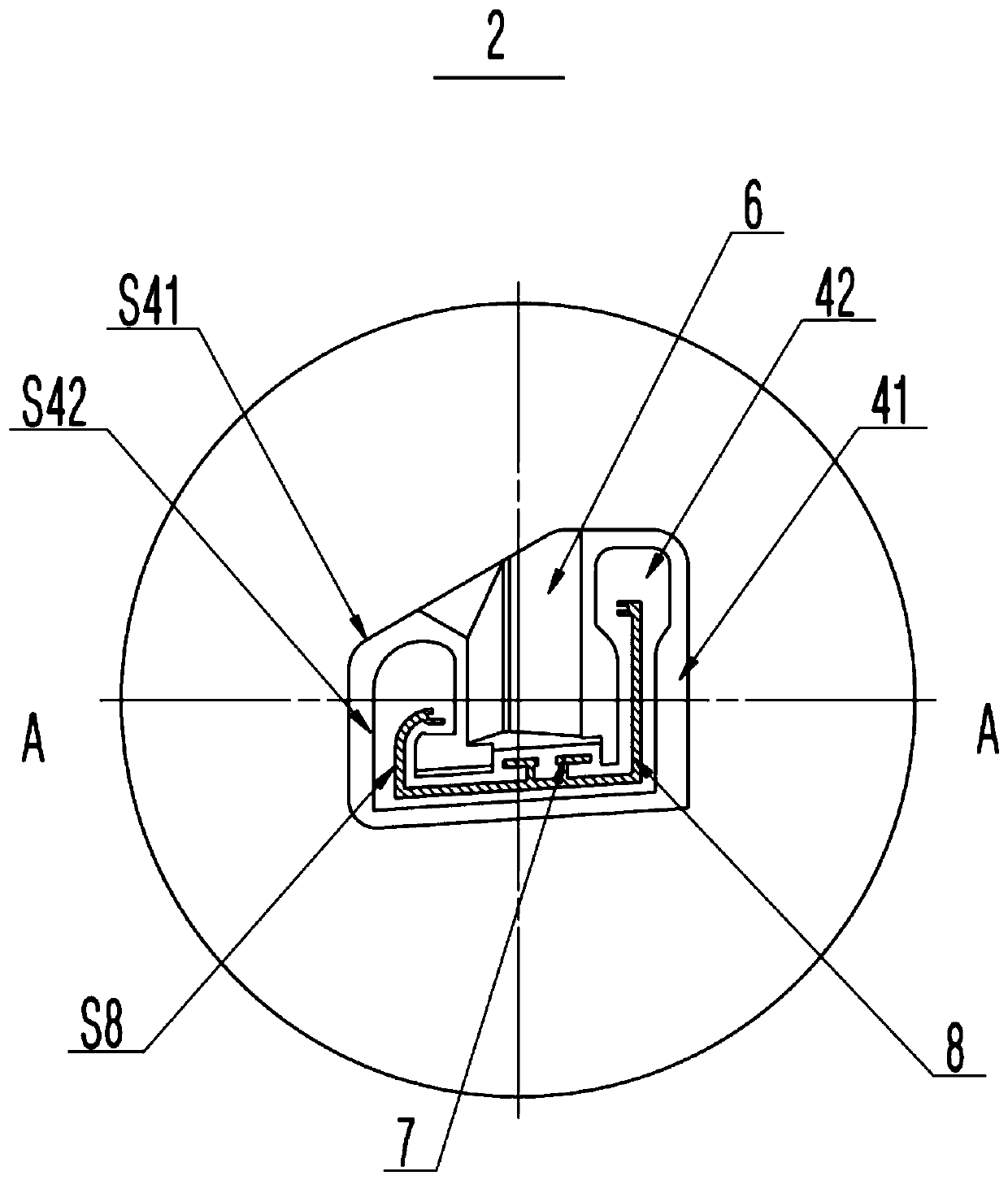

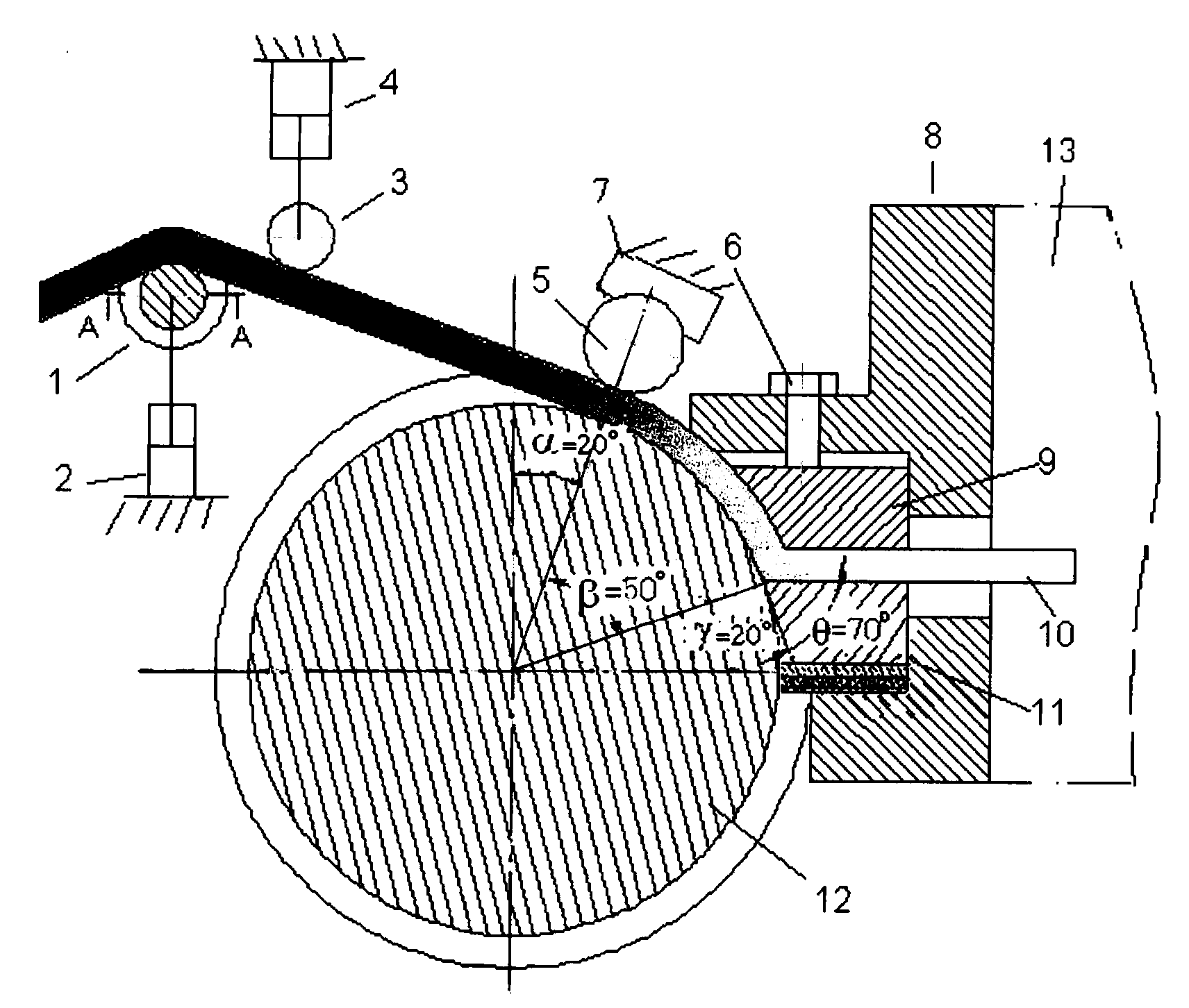

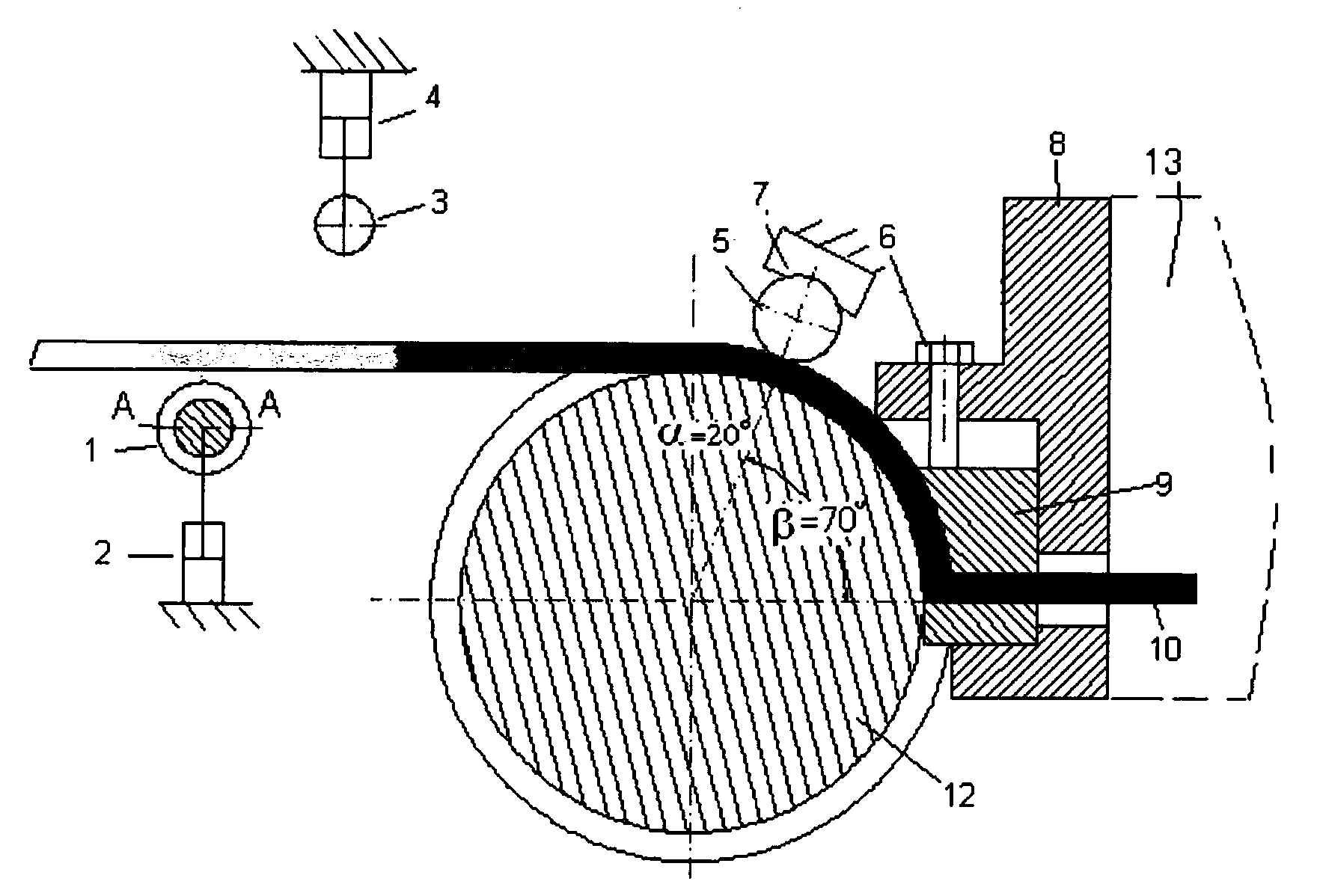

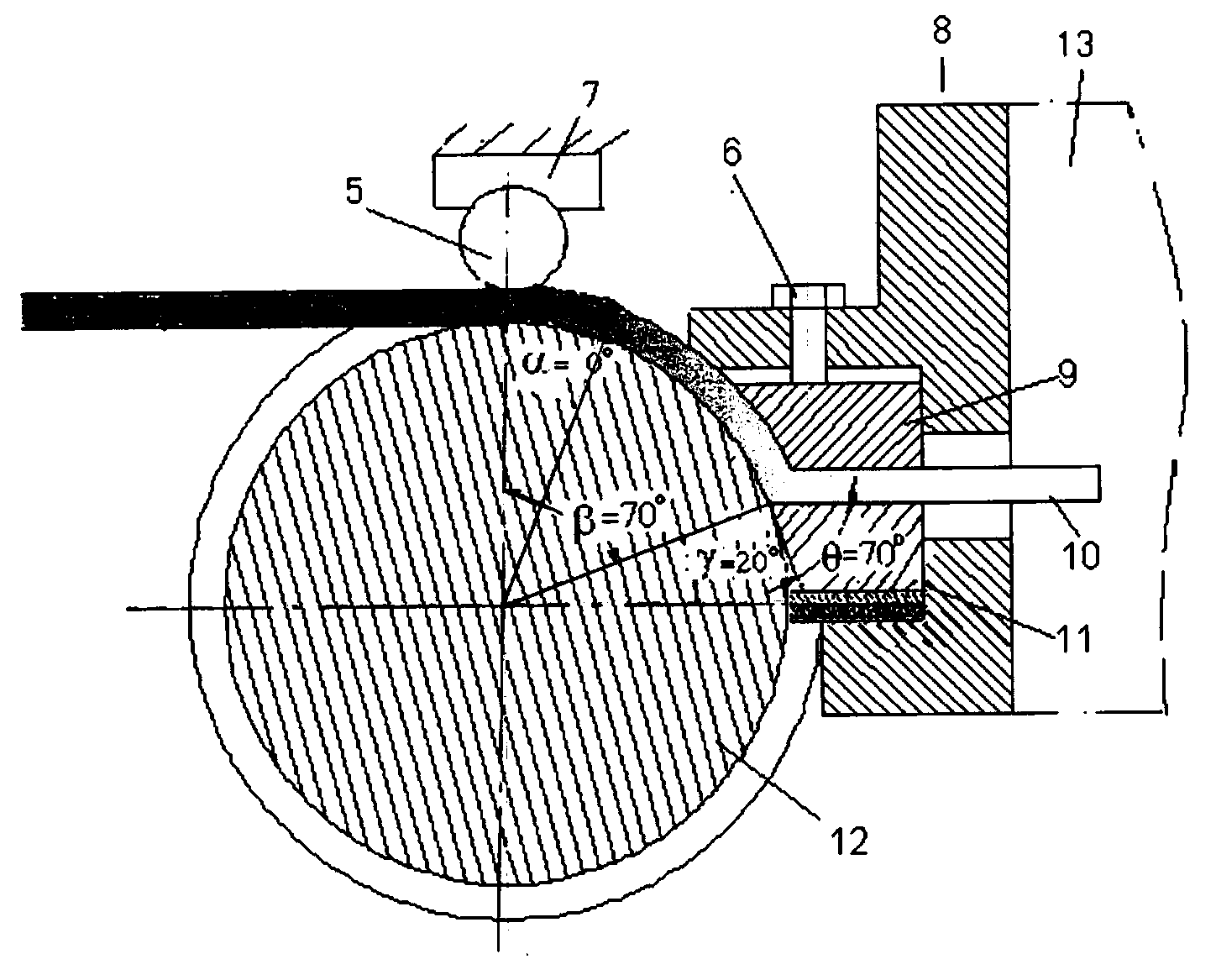

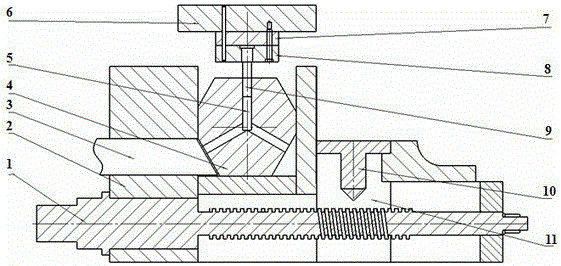

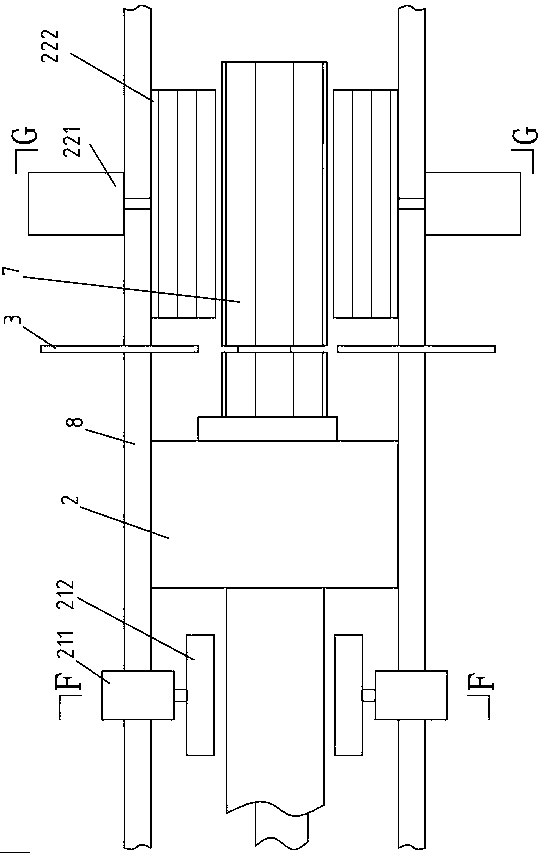

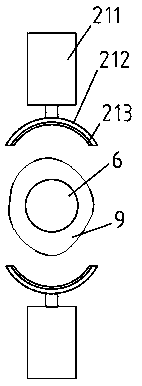

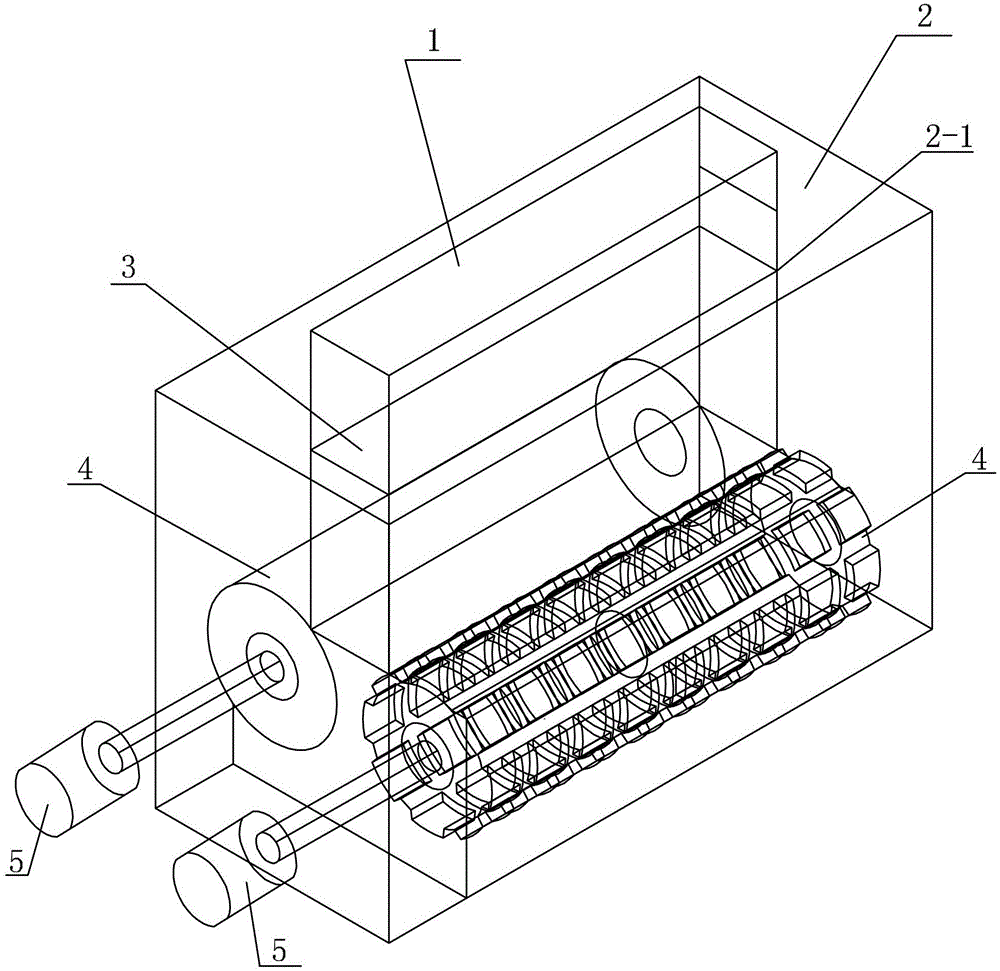

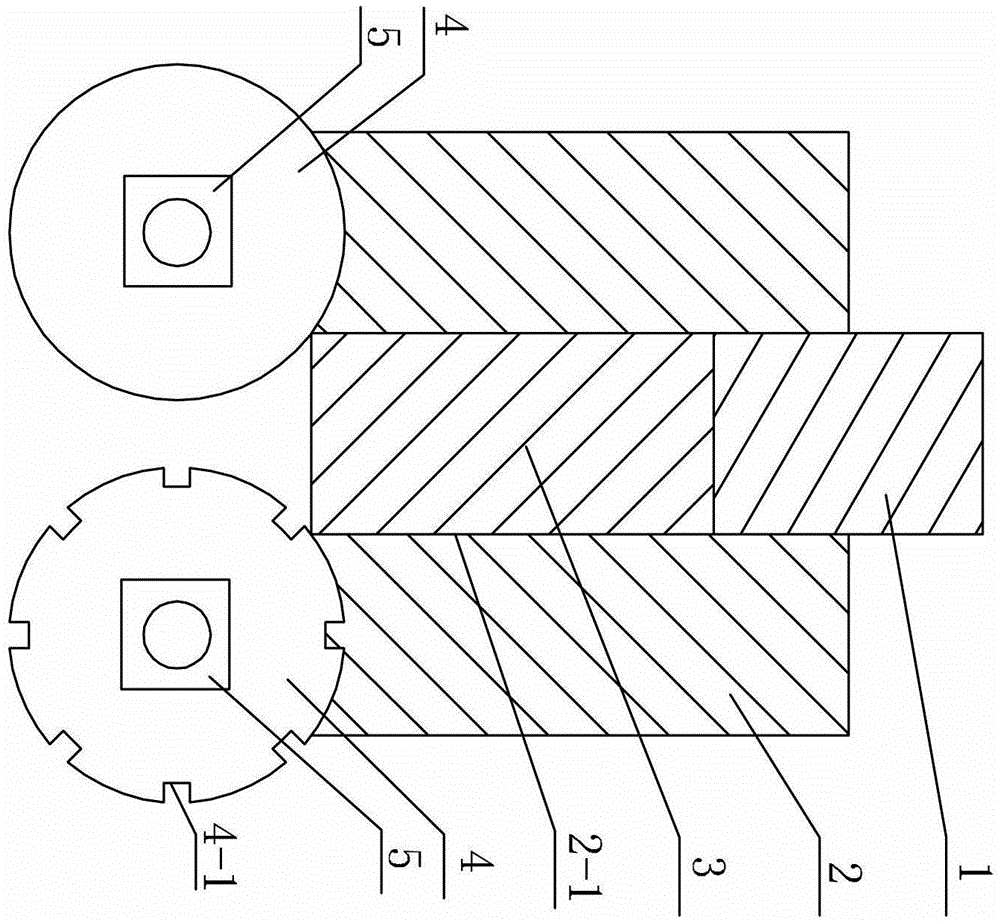

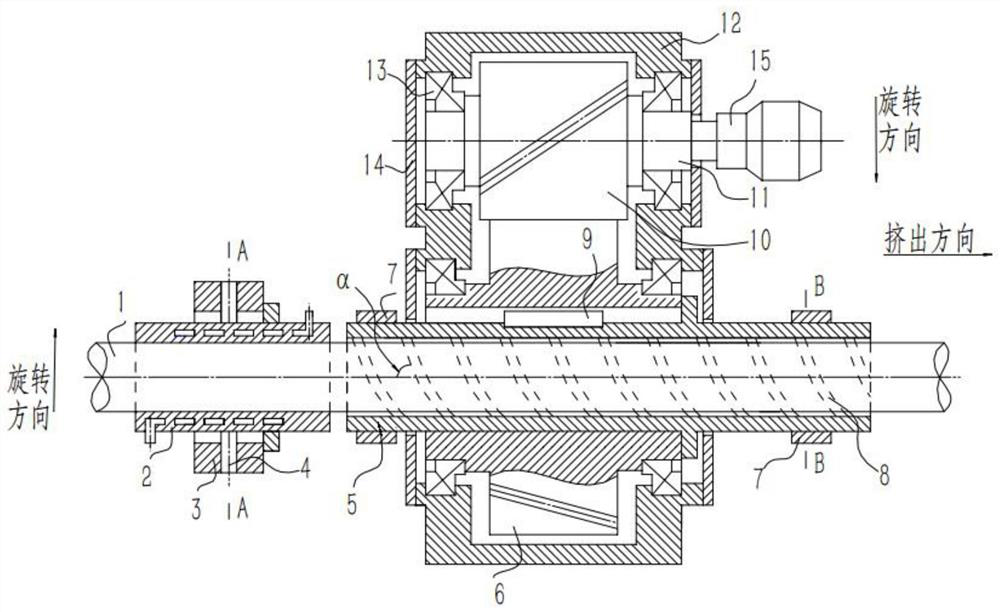

Extrusion device for shortening blank friction flow path

The invention relates to an extrusion device for shortening a blank friction flow path, which is suitable for continuous extrusion equipment. The extrusion device is characterized in that a blank friction flow path shortening device constituted by a wrap angle adjusting mechanism and an auxiliary blank gripping mechanism is arranged on a frame, and the wrap angle adjusting mechanism comprises a gripping wheel position adjusting component and an extrusion cavity position adjusting component; and the auxiliary blank gripping mechanism comprises a bending guide roller I, a bending guide roller oil cylinder I, a bending guide roller II and a bending guide roller oil cylinder II, so that the blank friction flow path can be shortened and the rotational angle of a blank can be reduced. According to the extrusion device disclosed by the invention, by adjusting the positions of a gripping wheel and an extrusion cavity, the blank flow path can be shortened, and the rotational angle of the blank can be reduced, so that the extrusion device can further reduce the extrusion load and deformation temperature of metal, not only save energy, but also prolong the service life of a tool and a mold; and particularly, the control of the deformation temperature can be realized by adjusting the blank flow path, which is very beneficial to preparation of high-performance nonferrous metal extruded products with fine-grained structures.

Owner:DALIAN JIAOTONG UNIVERSITY

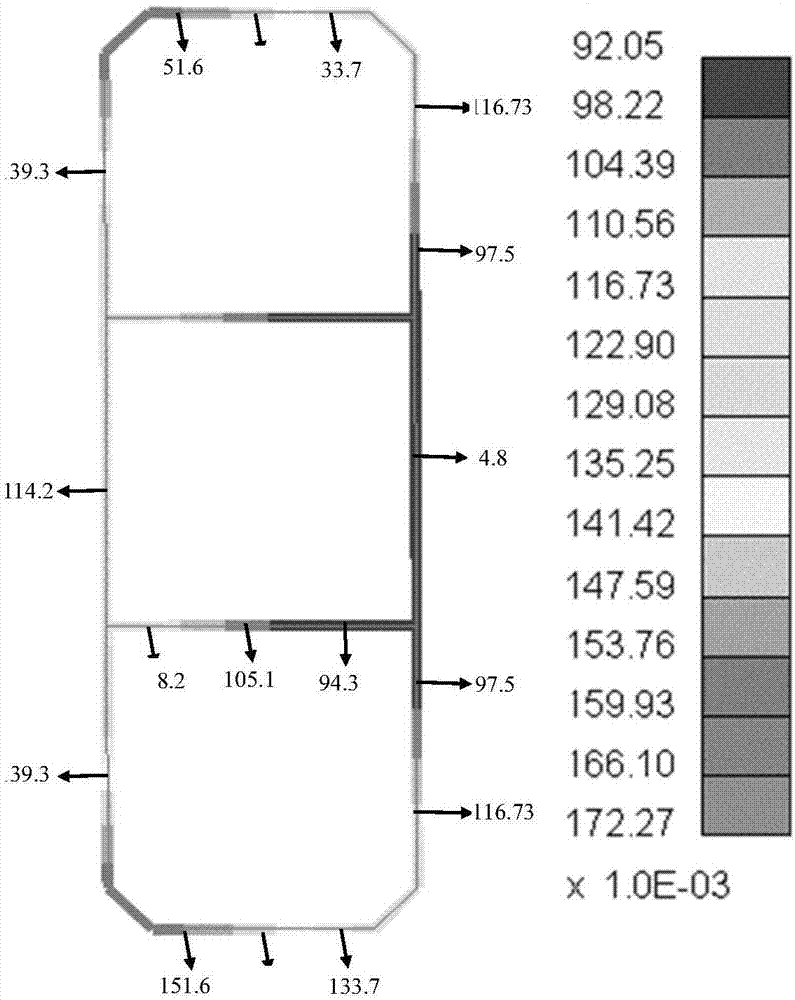

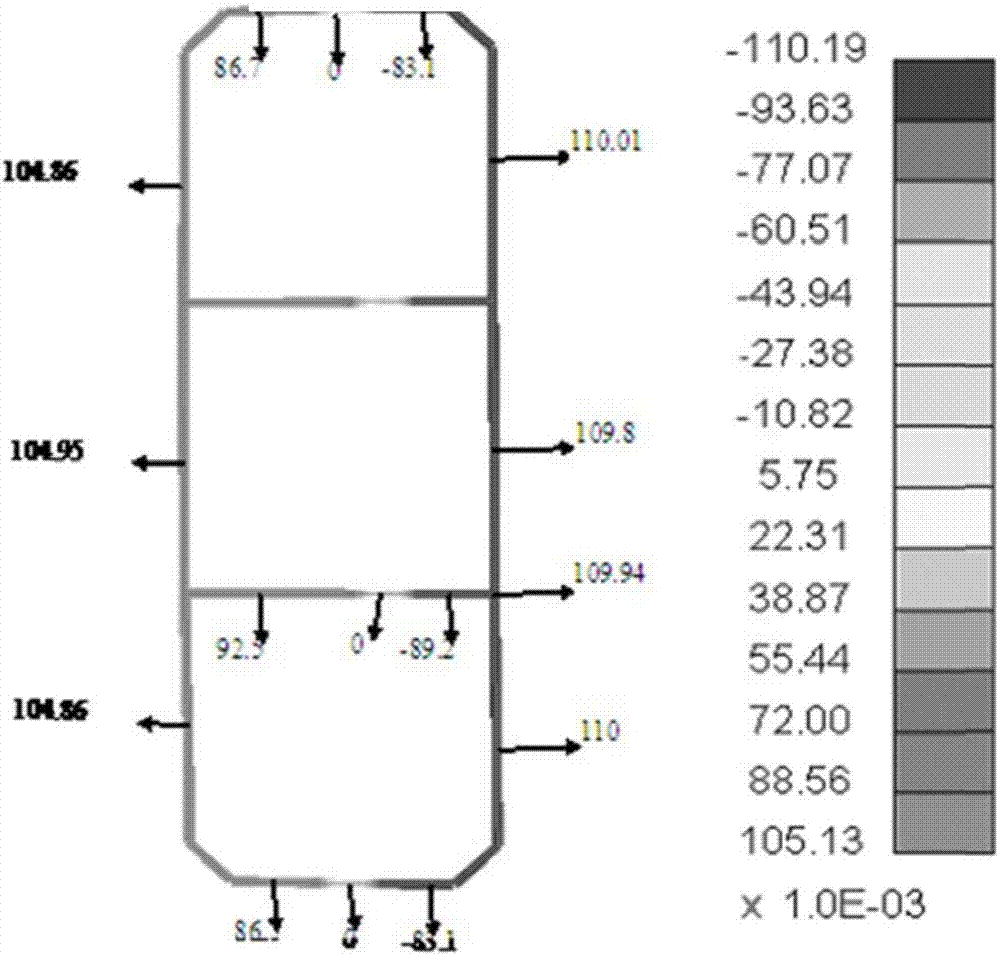

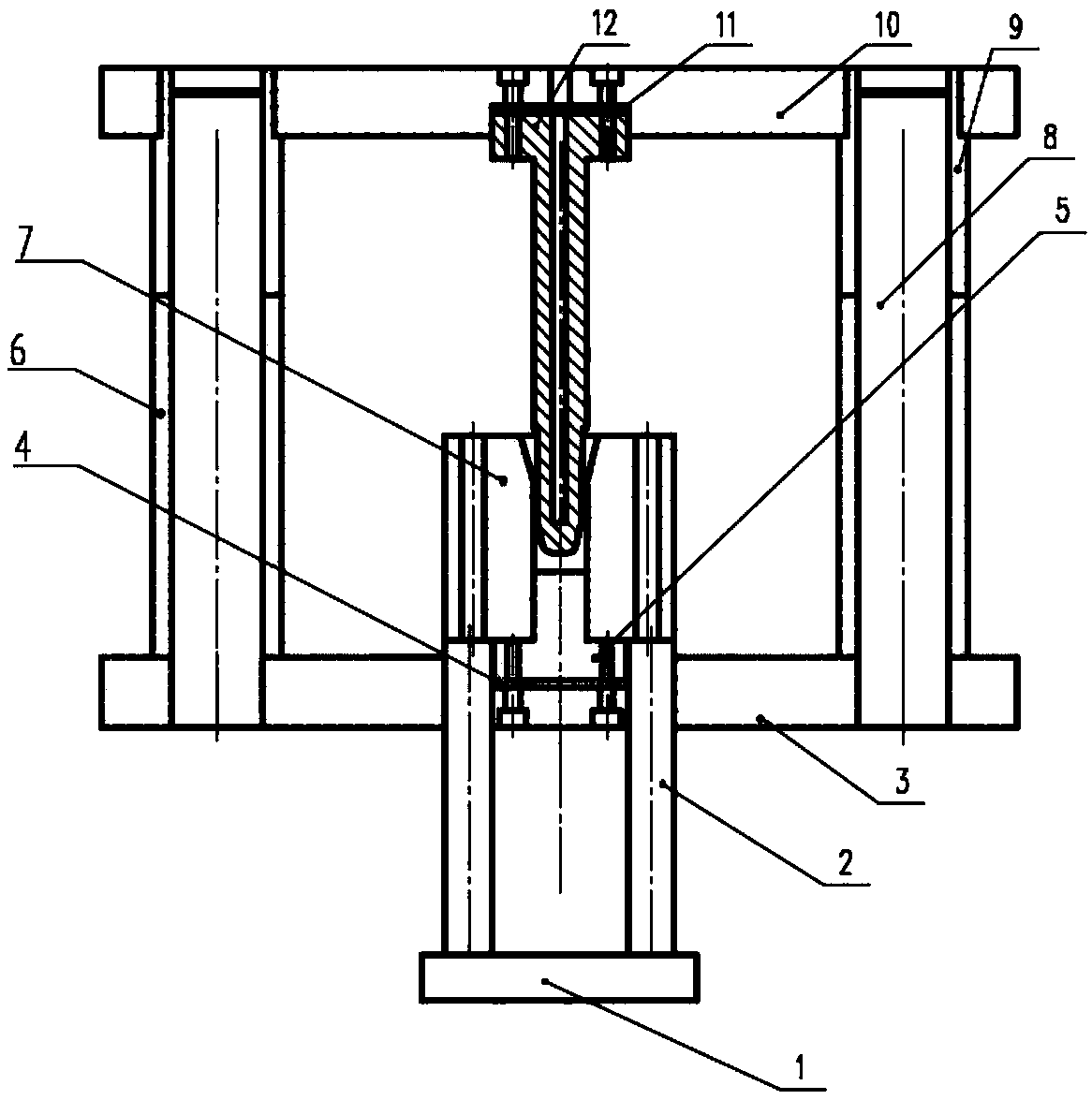

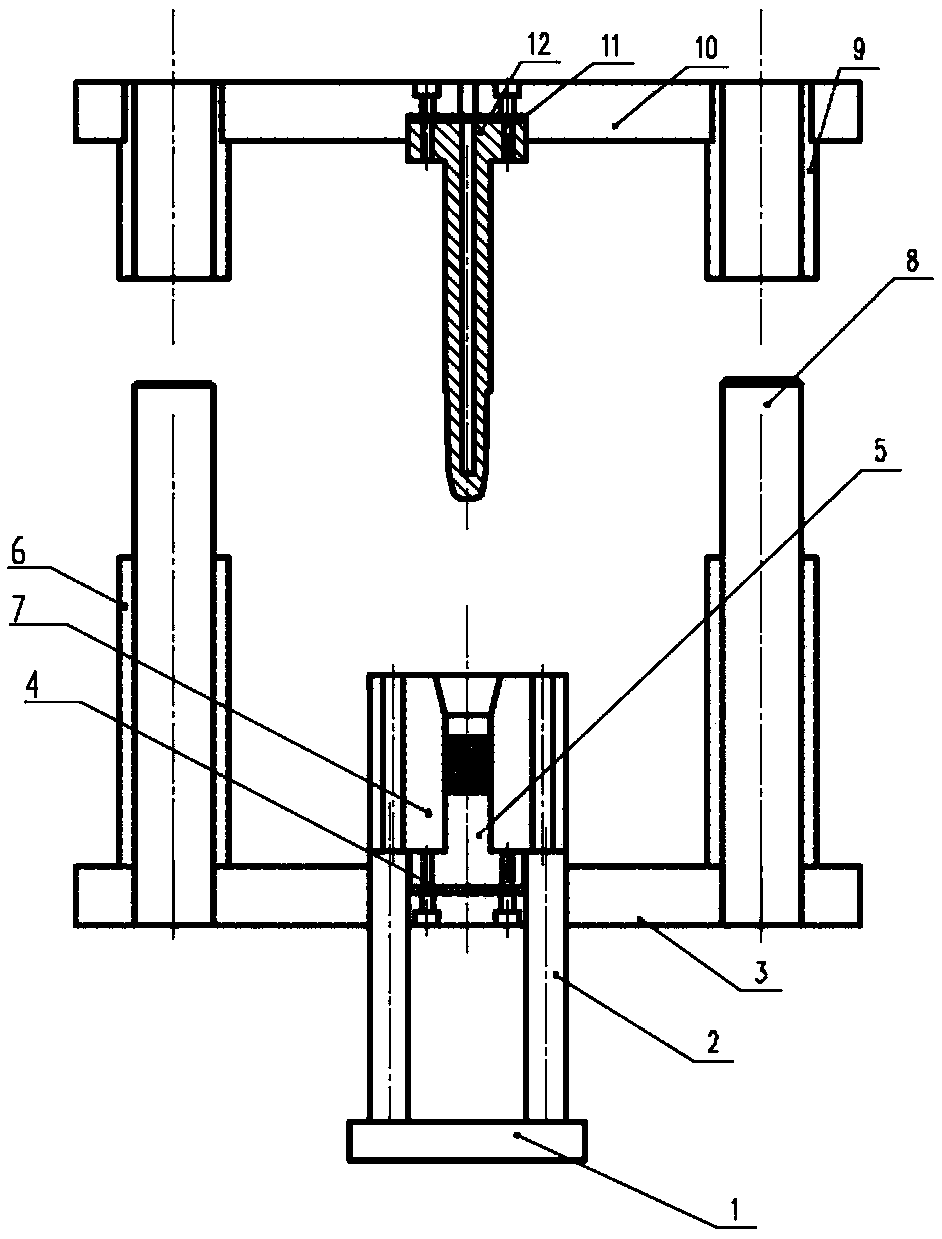

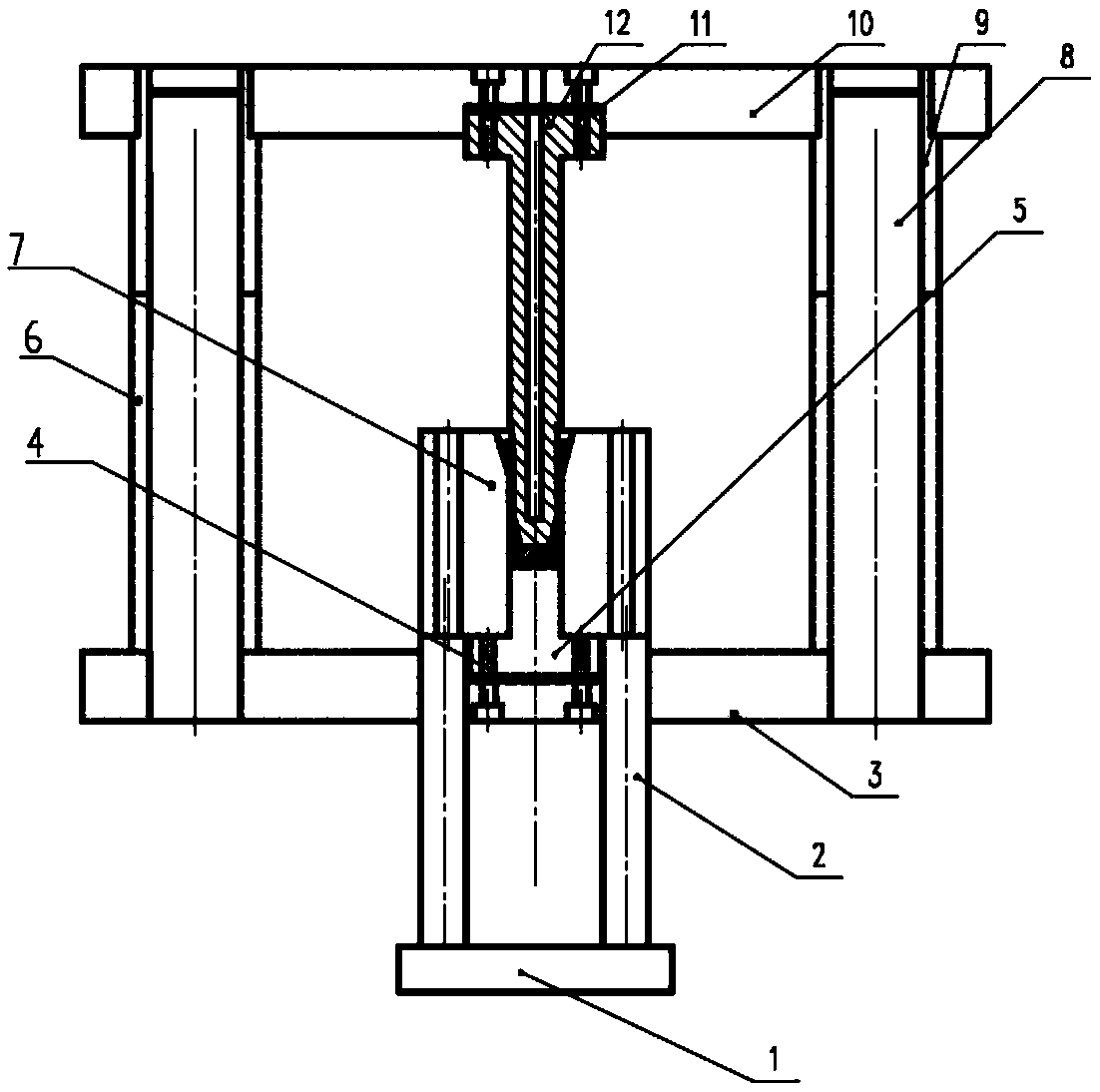

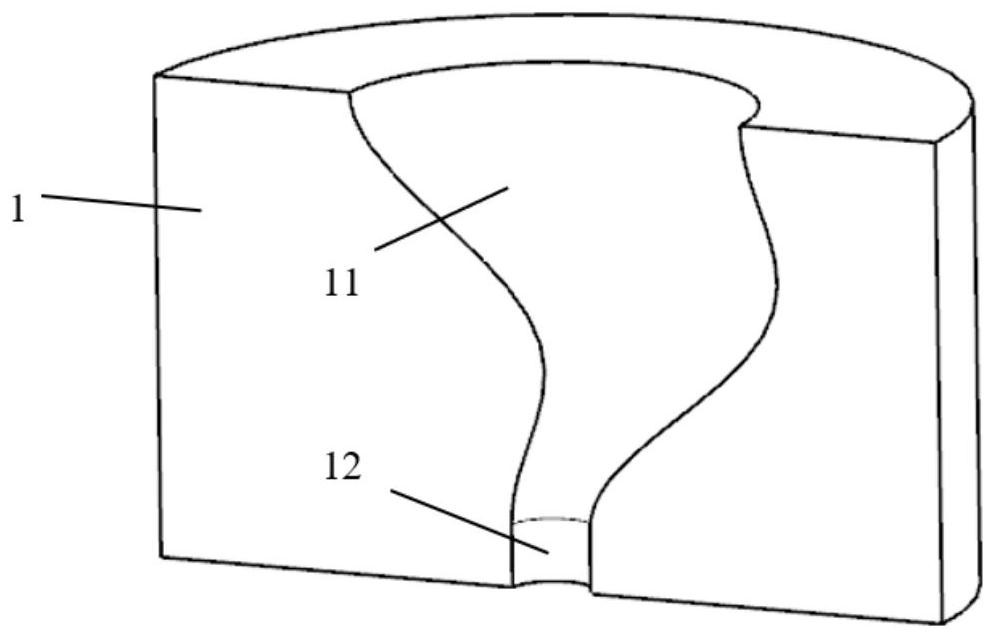

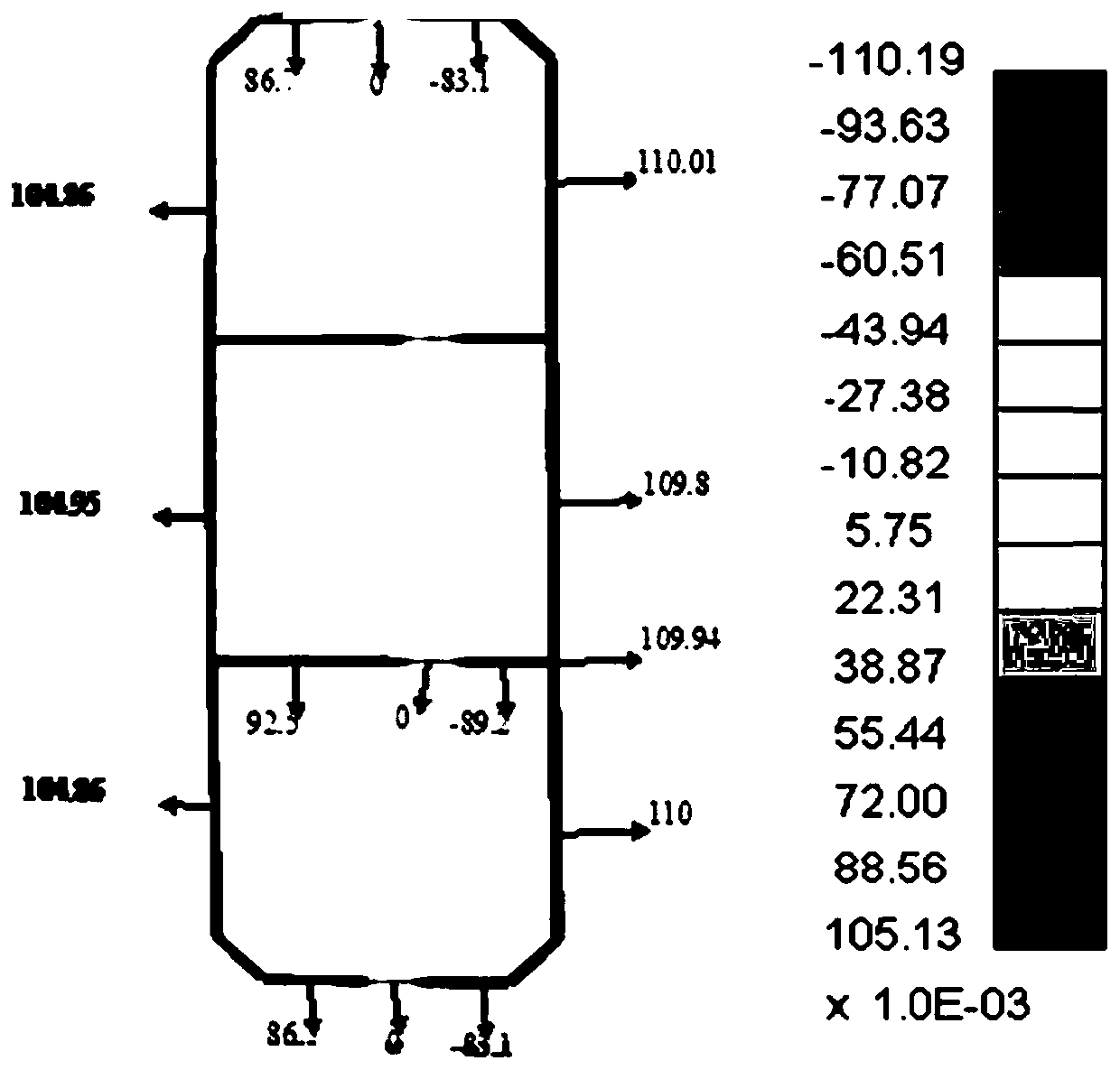

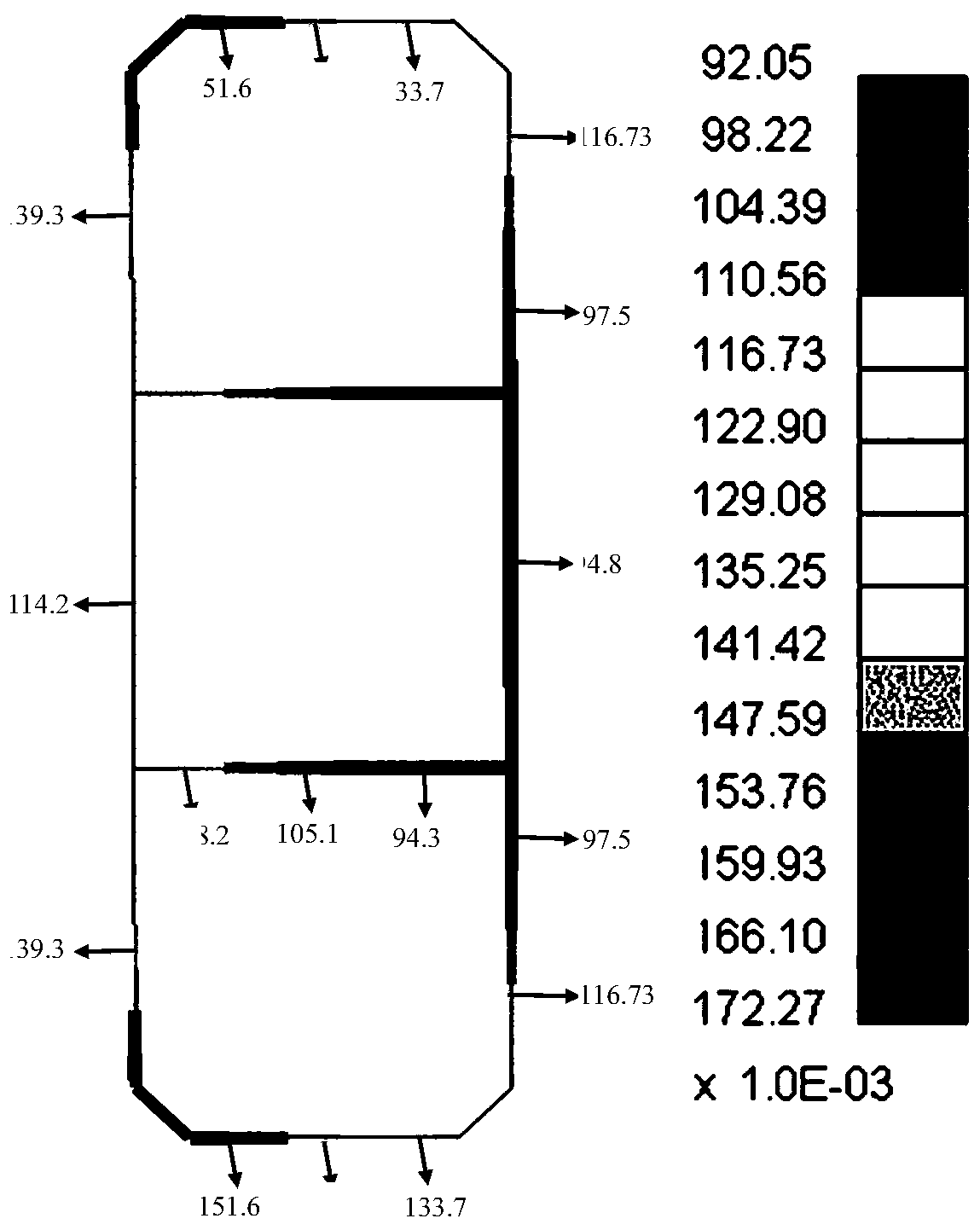

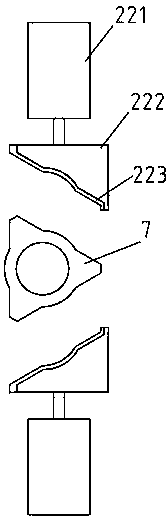

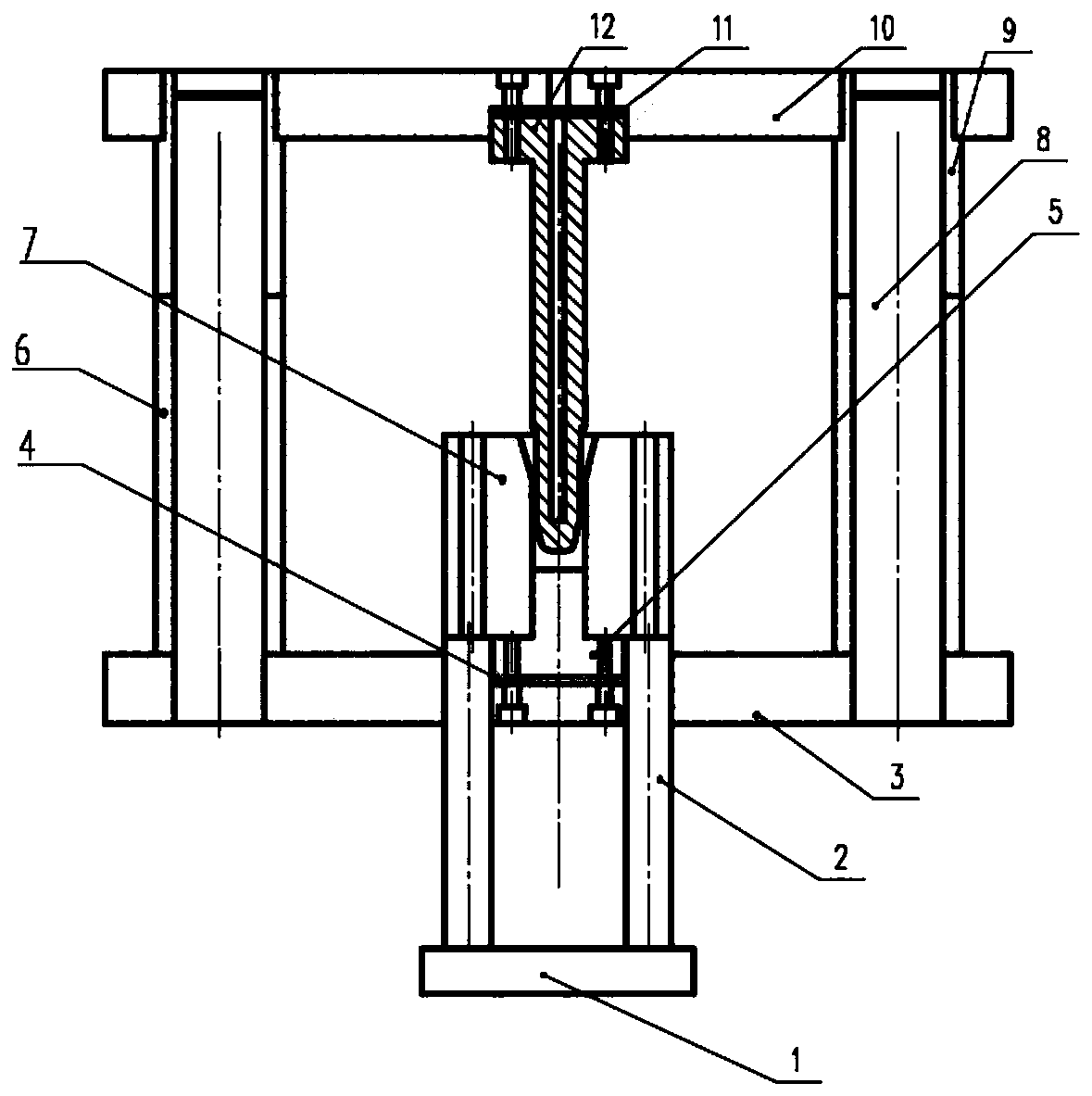

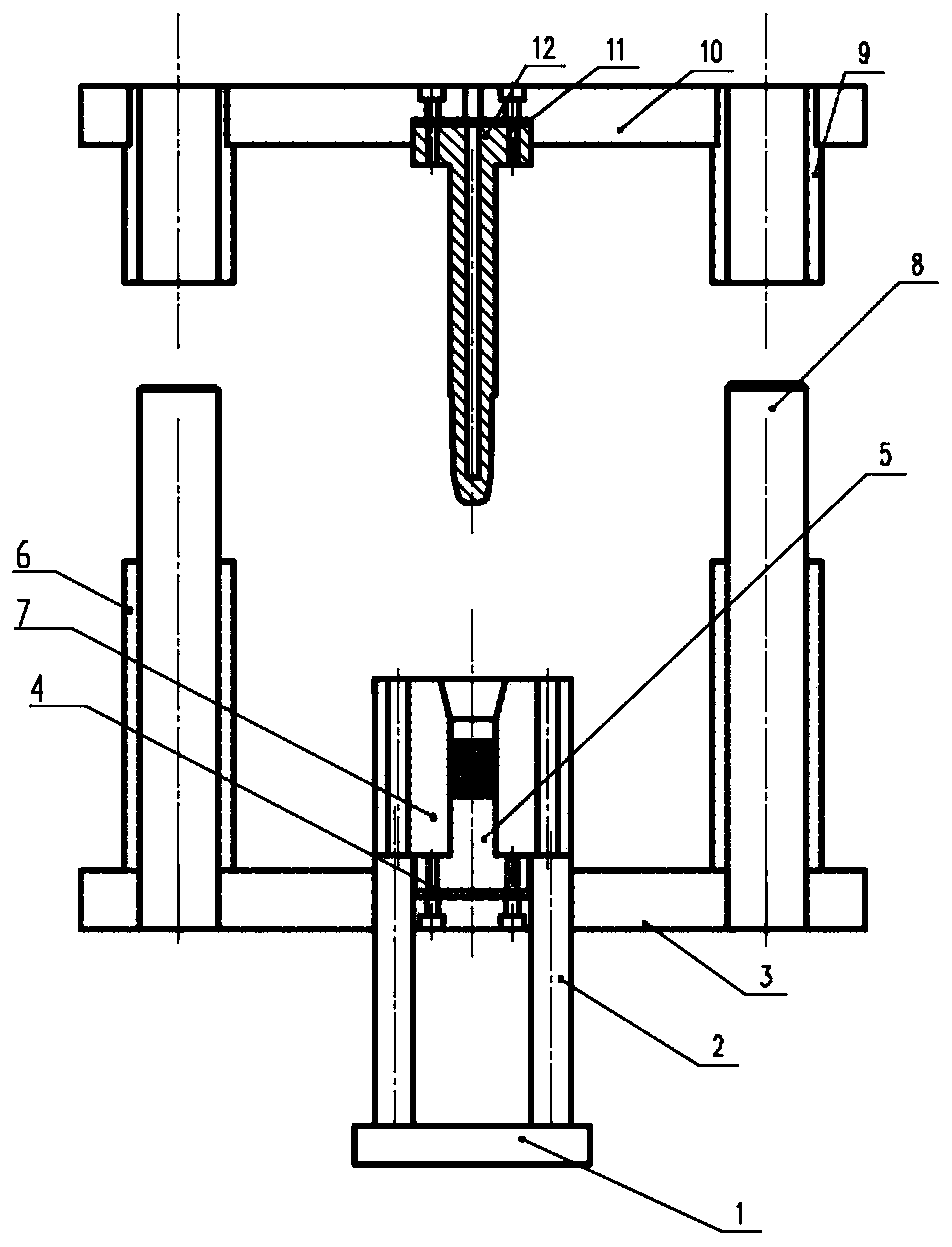

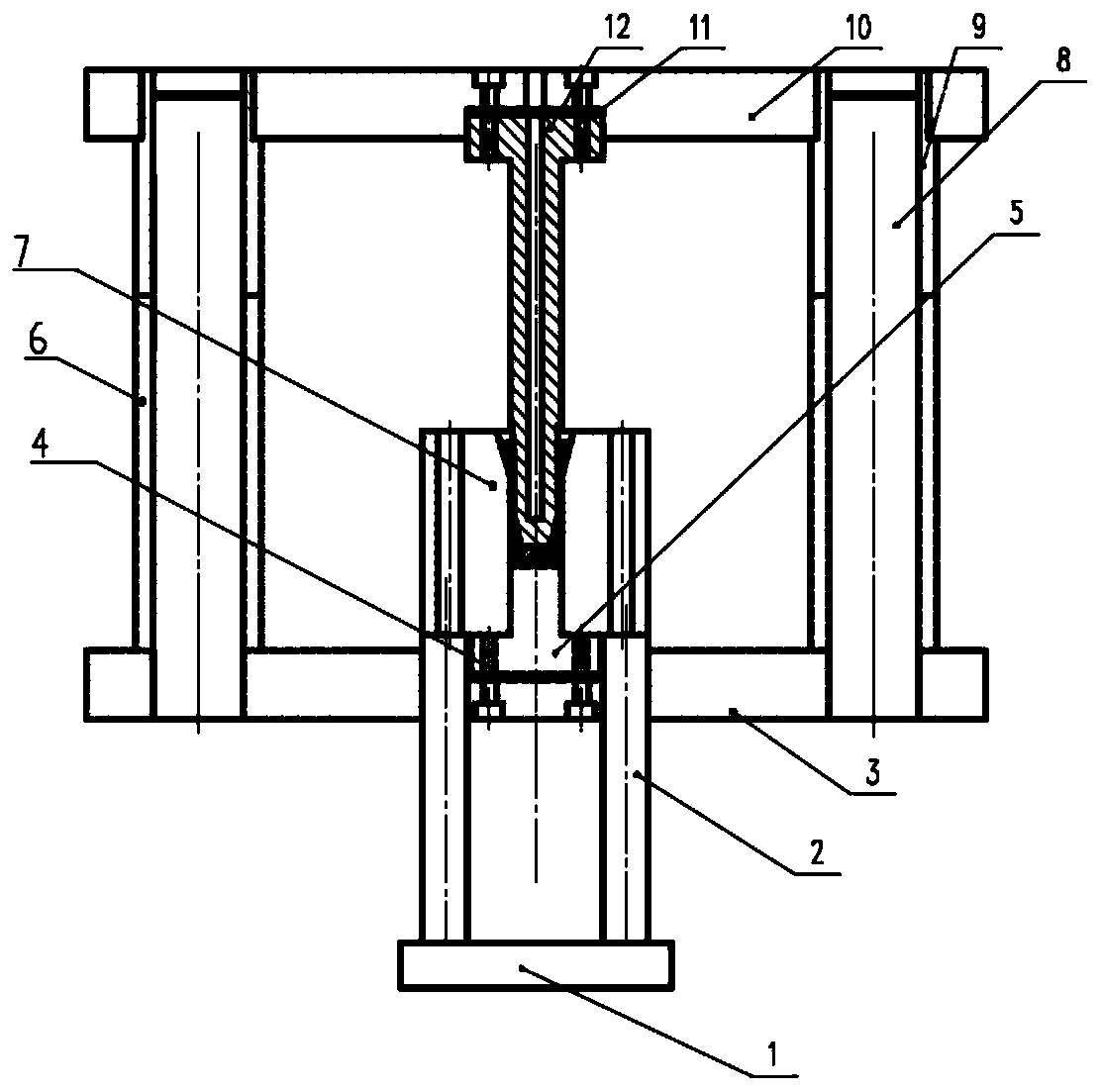

Metal alternative extrusion forming device and method

The invention relates to a metal alternative extrusion forming device and method and relates to a labor-saving extrusion forming device and method. The device and method solve the problems that according to an existing extrusion forming device and method, needed energy consumption is large, flowing uniformity is poor, and the material utilizing rate is low. According to the scheme of the device, an extrusion container is arranged on a base, a core die is arranged at the bottom of the extrusion container, blanks are arranged in the extrusion container and located above the core die, and one end of a first punch and one end of a second punch are arranged in the extrusion container and abut against the upper end faces of the blanks. According to the scheme of the method, the core die, the blanks, the first punch and the second punch are sequentially placed in the extrusion container; the second punch is fixed, the first punch moves downwards by the distance of L, and metal on the lower side of the first punch is extruded and deformed and is sequentially extruded and formed; then the first punch is fixed, the second punch moves downwards by the distance of 2L, and the blanks below the second punch are made to be extruded and formed. According to the acting sequence, the first punch and the second punch alternatively move downwards for loading till the blanks are totally extruded. The device and method are used for metal forming.

Owner:福建祥鑫股份有限公司

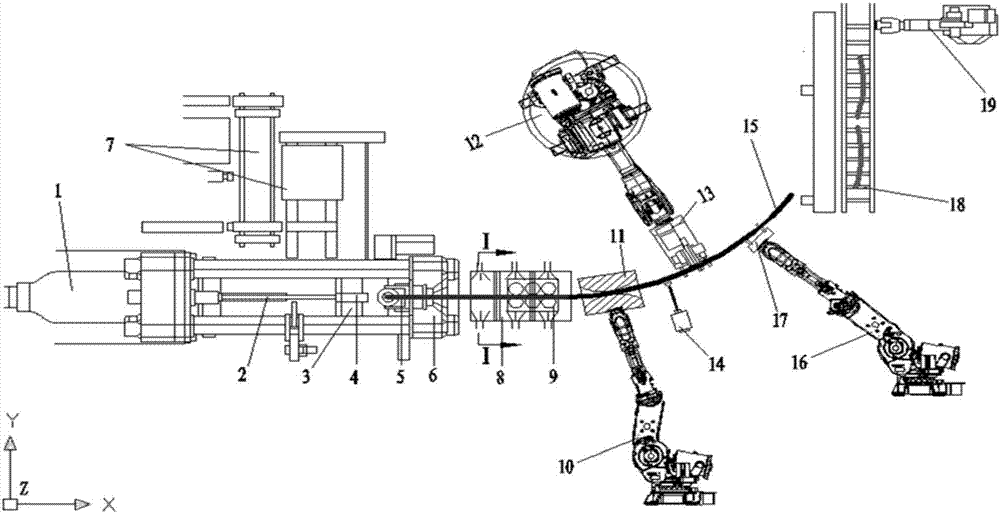

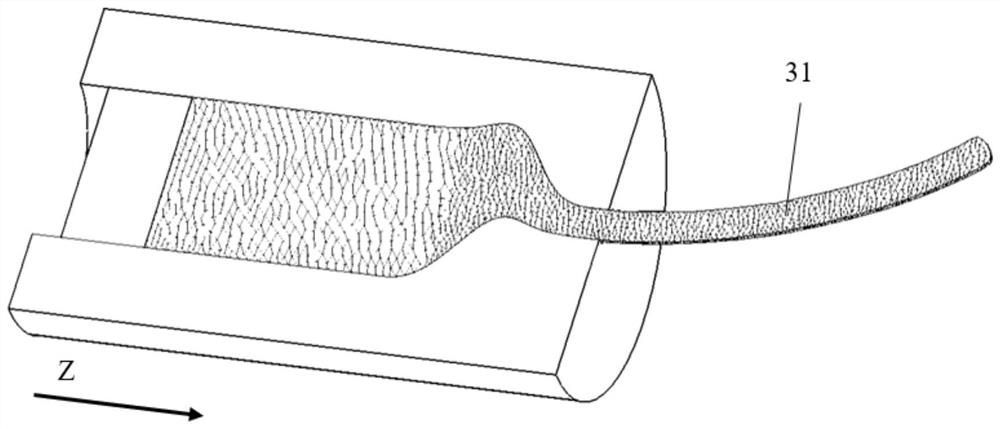

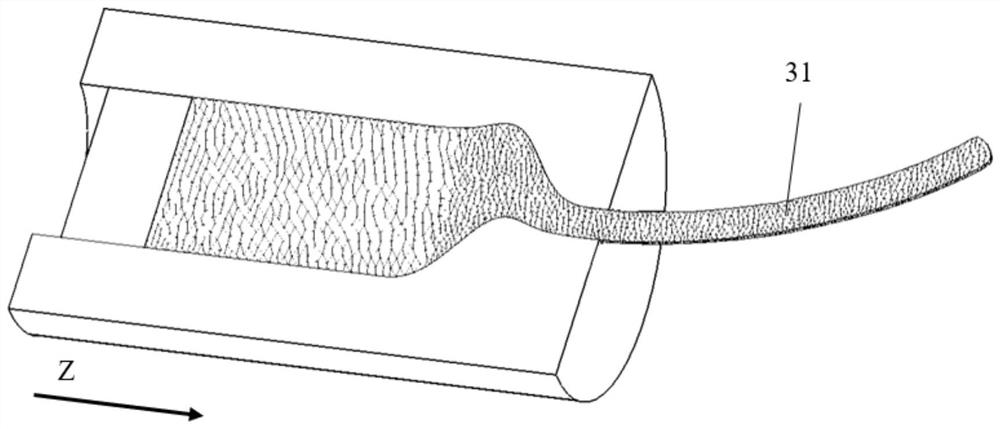

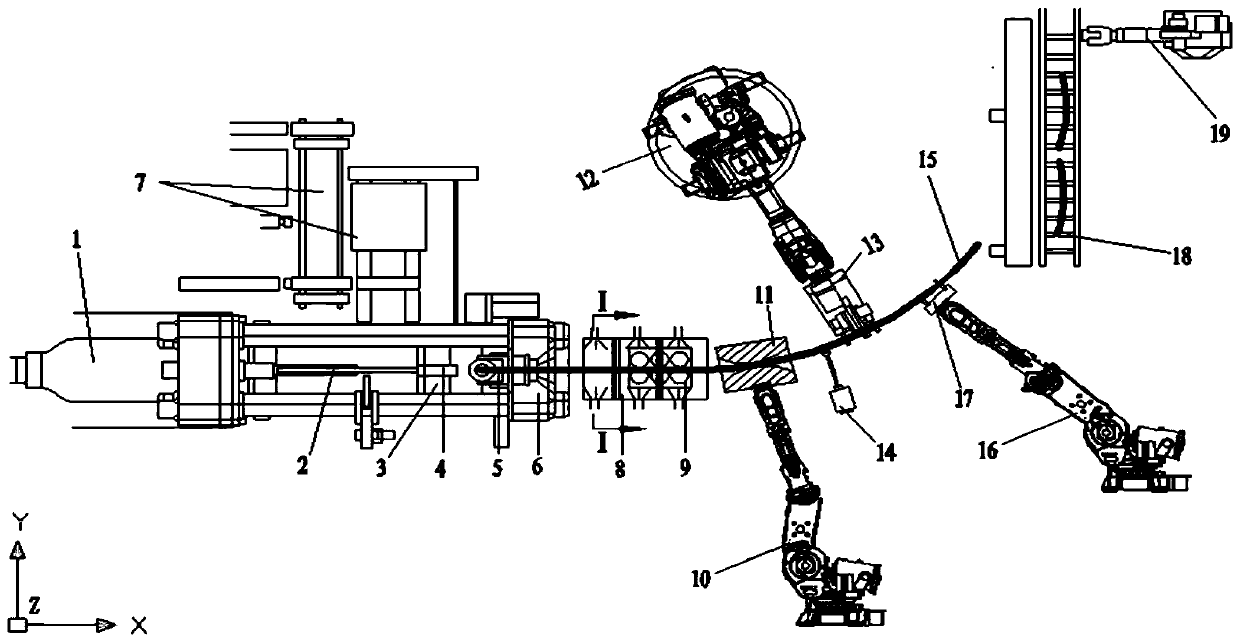

Three-dimensional variable-curvature sectional material online bending and forming device pulled by robot initiatively

ActiveCN107234443AOvercome rolling frictionReduce extrusion loadMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a three-dimensional variable-curvature sectional material online bending and forming device pulled by a robot initiatively. The three-dimensional variable-curvature sectional material online bending and forming device comprises a horizontal extruding machine, a quenching device, a guiding device, the initiatively-pulling robot, a cutting robot and a transfer robot; the quenching device is arranged on the outlet side of the horizontal extruding machine and is used for controlling the temperatures of all cross sections of an extruded sectional material; the guiding device is arranged in the quenching device and is used for straightening and positioning on the extruded sectional material; the initiatively-pulling robot is arranged on the discharging side of the quenching device and is used for pulling the extruded sectional material to achieve the three-dimensional variable curvature; the cutting robot is used for cutting the variable-curvature sectional material output by the initiatively-pulling robot; and the transfer robot is used for sending the cut variable-curvature sectional material output by the cutting robot into an extruding and conveying roller bed. By means of the three-dimensional variable-curvature sectional material online bending and forming device, the defects that by means of an existing extruding and bending integrated method, the required extruding load is high, the stress of the cross sections of the sectional material is uneven, and surface scratches are generated are overcome, bending and forming quality of a product is improved, and the material utilization rate is increased.

Owner:HUNAN UNIV +1

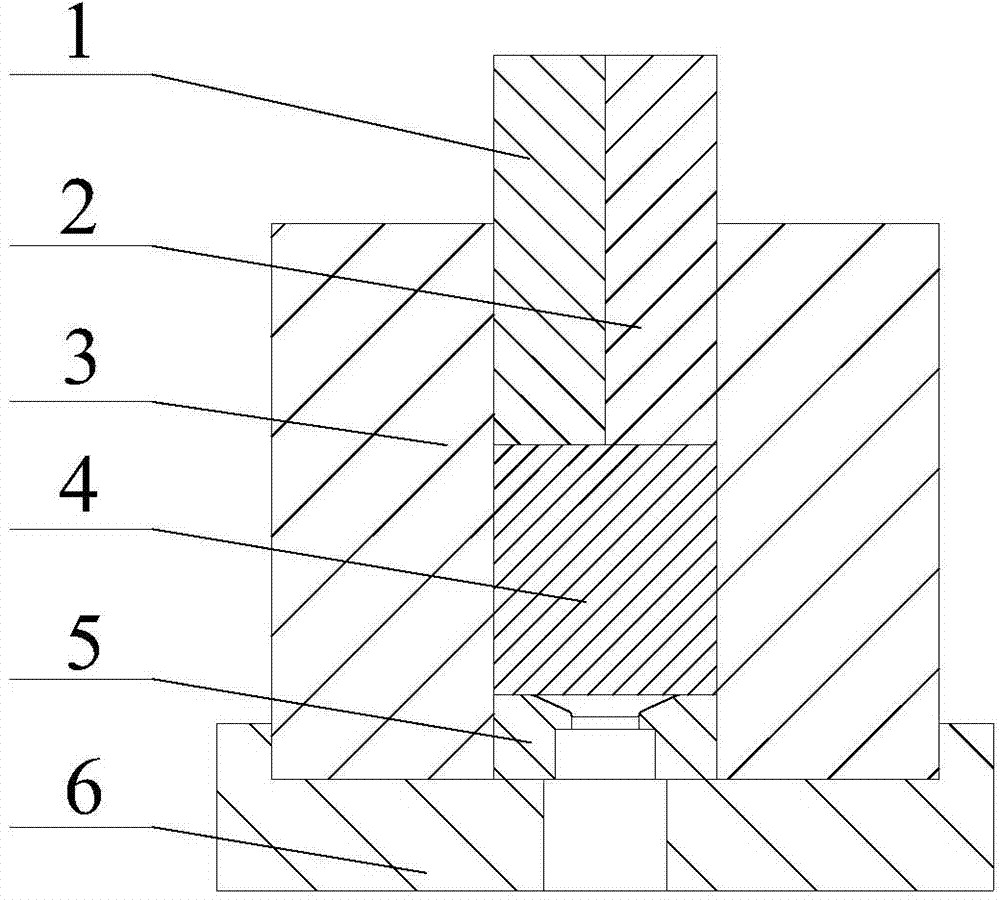

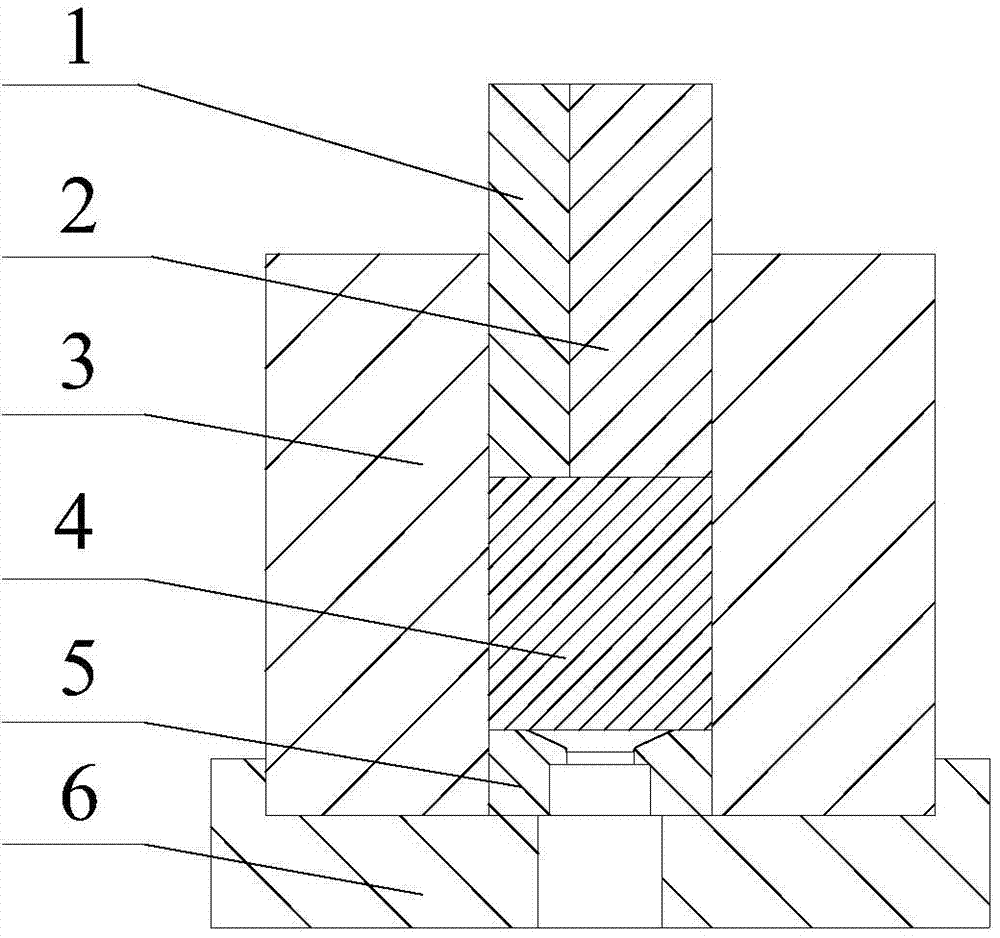

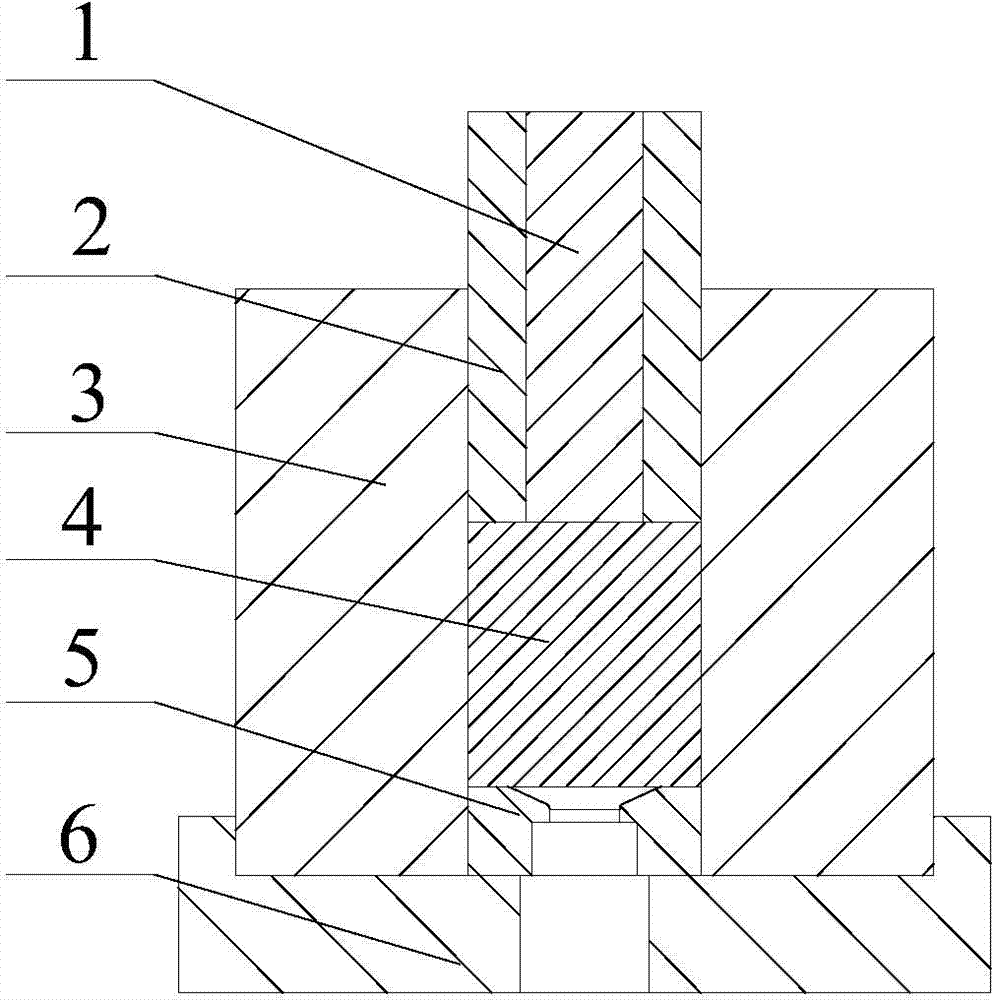

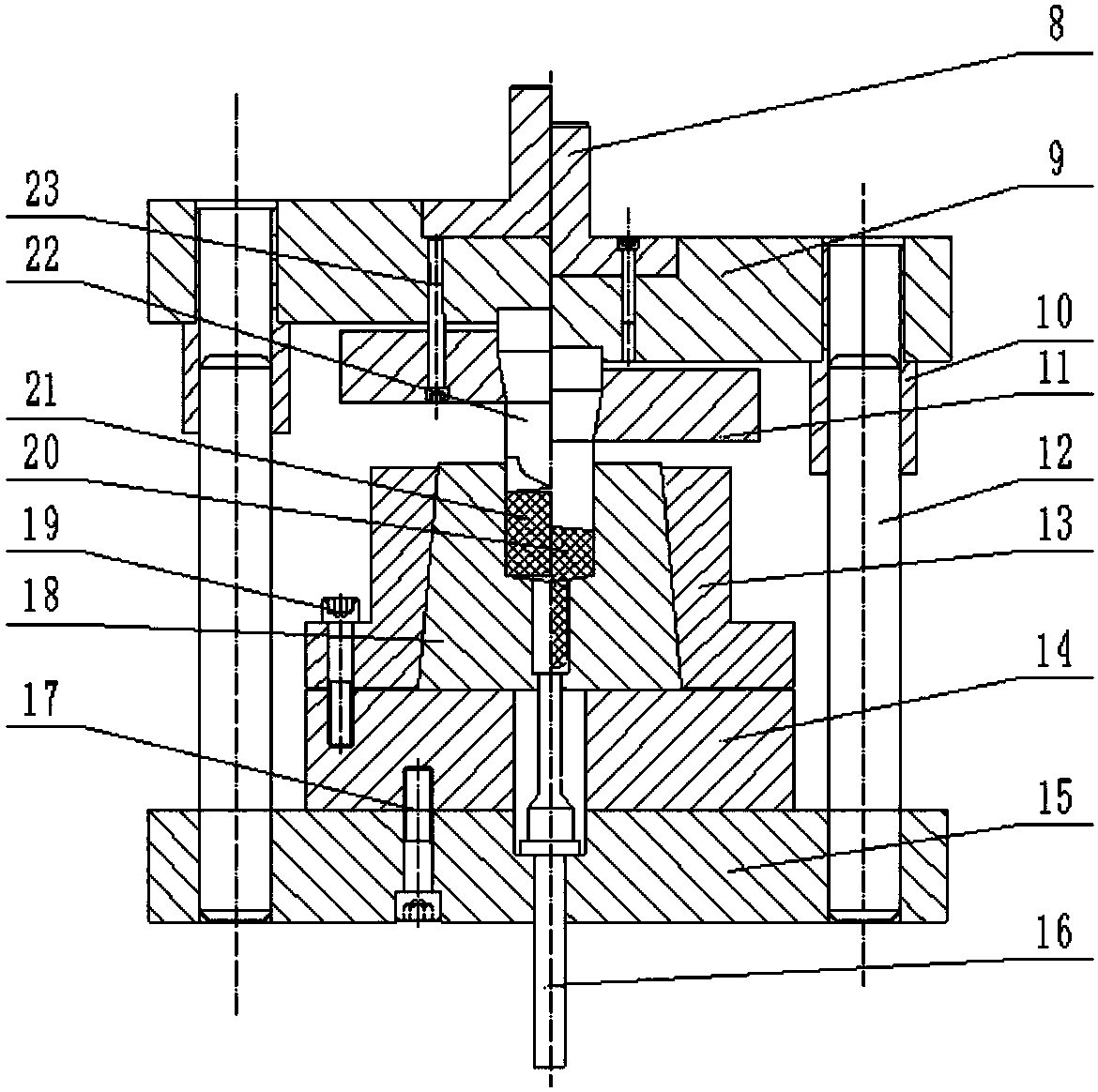

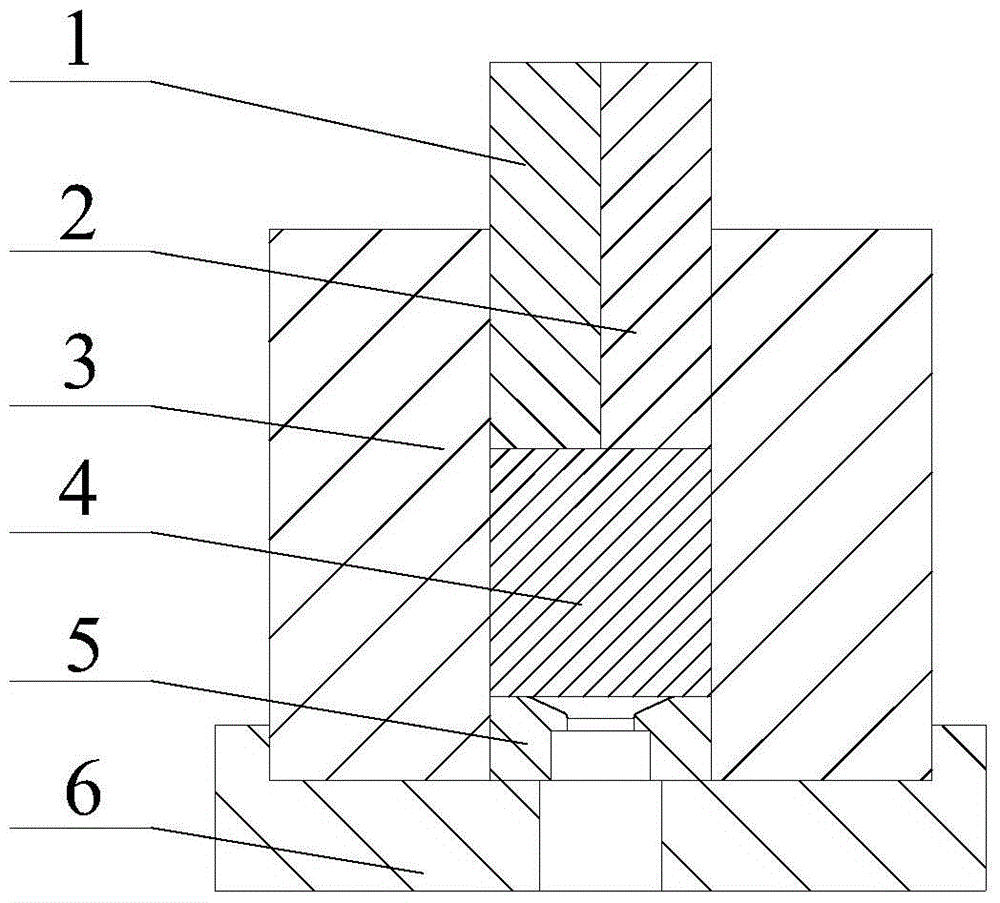

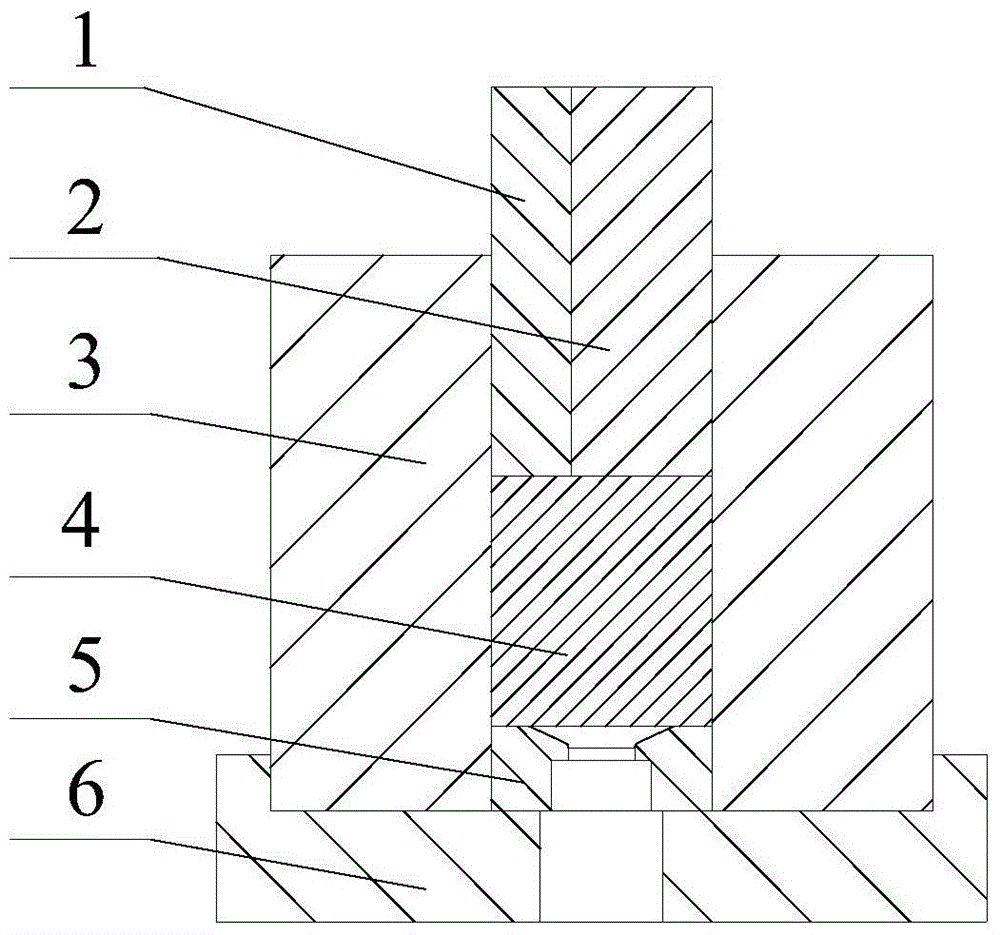

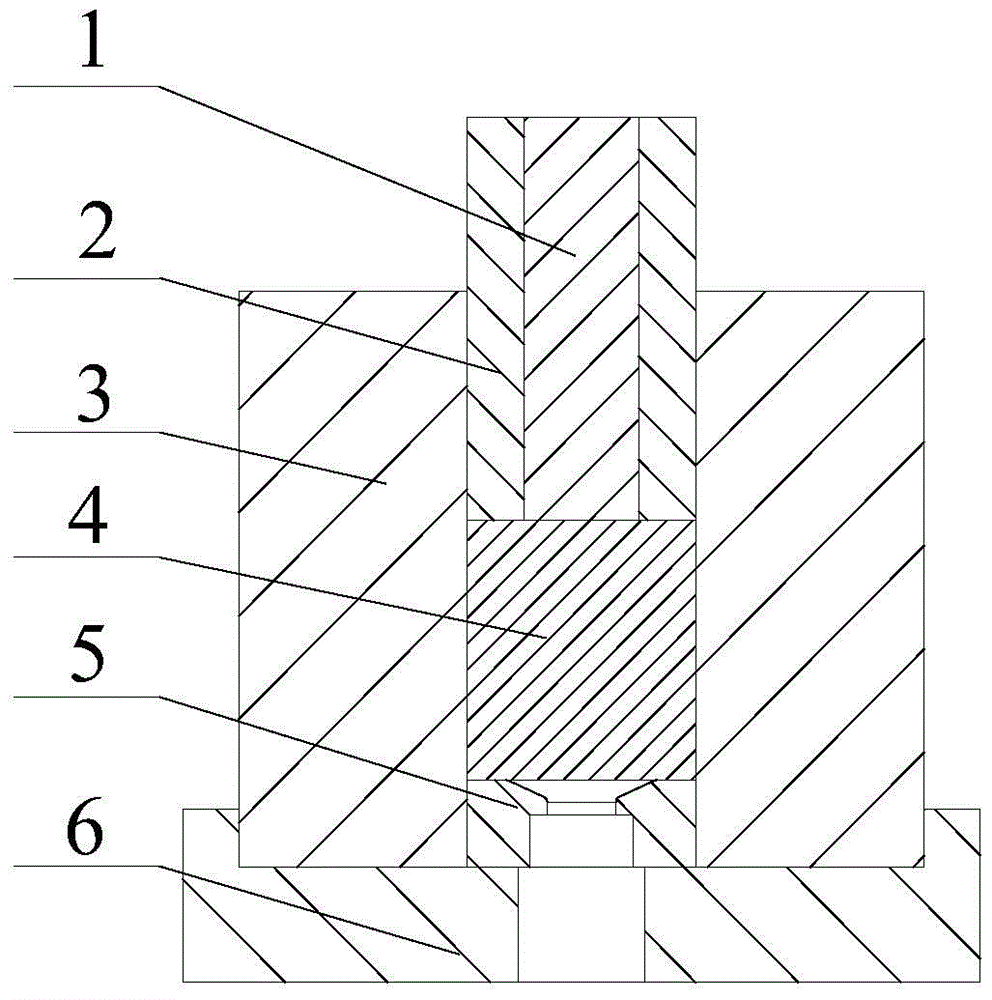

Small diameter thin wall deep blind hole part extrusion molding mold

ActiveCN109351799AReduce extrusion loadExtend your lifeExtrusion diesLongest DiameterLarge deformation

The invention discloses a small diameter thin wall deep blind hole part extrusion mold which combines extrusion and stretching working procedures into one mold and is applied to molding of small diameter thin wall blind hole parts with large deformation quantity, extrusion ratio and long diameter ratio. The small diameter thin wall deep blind hole part extrusion mold structurally comprises an upper mold plate, a lower mold plate, a lower mold core, guiding position-limiting components, a mold cavity with a heating function and a punch head, wherein a pull mold angle arranged inside the mold cavity makes materials be capable of flowing out of a deformation area in the reverse extrusion process to reduce the contact area with the mold, so that load of the mold in the reverse extrusion process is reduced, the key problem that the small-diameter punch head has short life in the extrusion process is solved, the mold cavity acts as a pull mold to be used in the ascending process, and the stretching materials are normalized to the standard size. According to the small diameter thin wall deep blind hole part extrusion mold, by means of the manner that a reverse extrusion mold and a stretching mold are combined into one mold, the molding efficiency of small diameter thin wall deep blind holes can be effectively improved, and the material use ratio is high; and meanwhile, produced products have low residual stress, the fabrication cost is low, the mold is convenient to maintain and operate, and the small diameter thin wall deep blind hole part extrusion mold has wide application value.

Owner:NANJING UNIV OF SCI & TECH

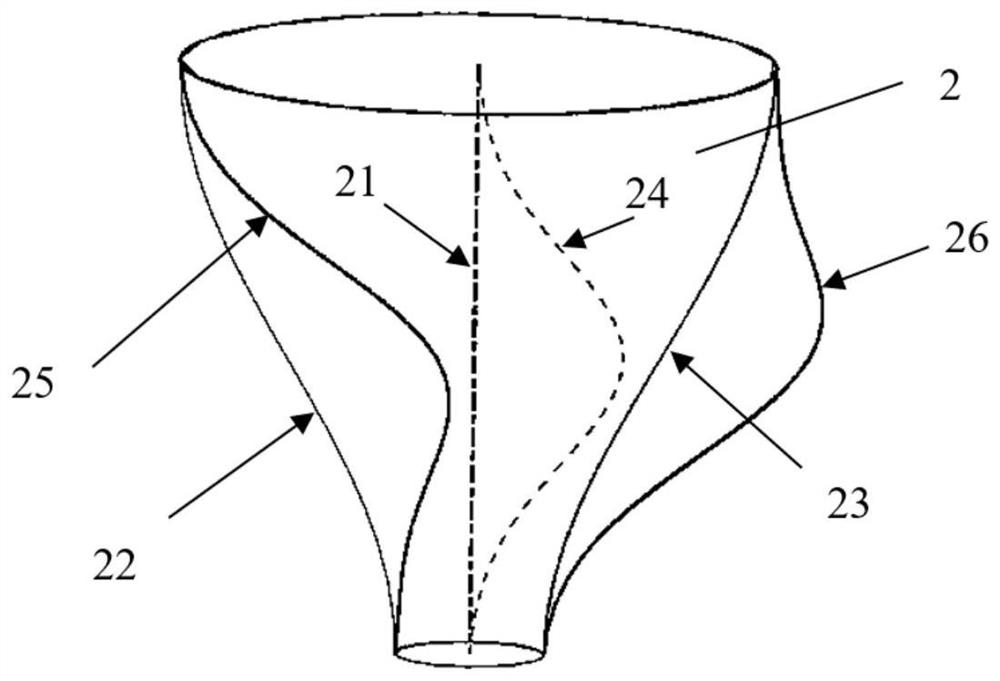

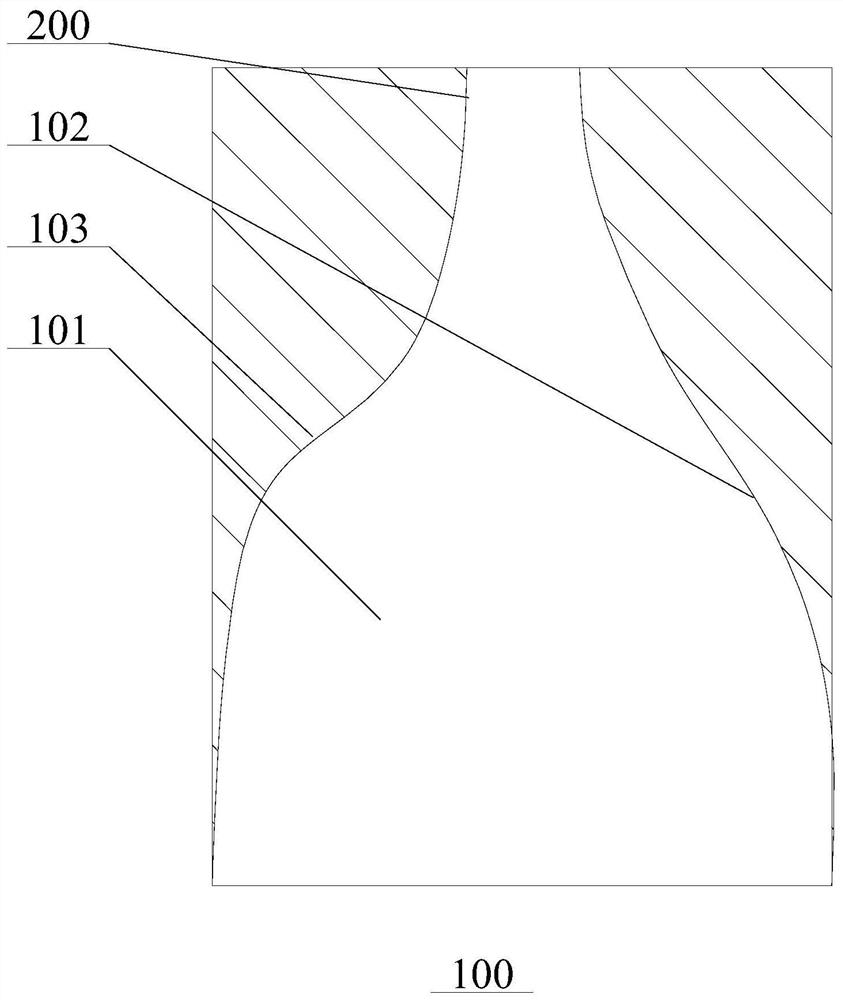

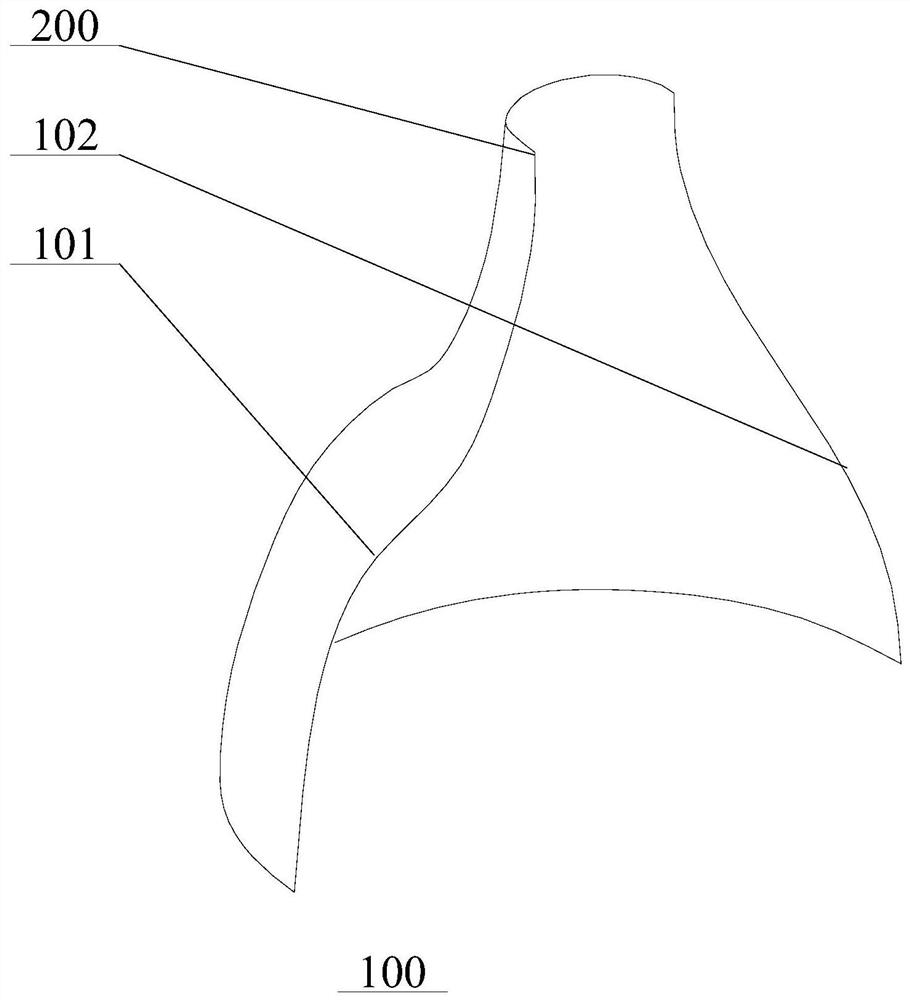

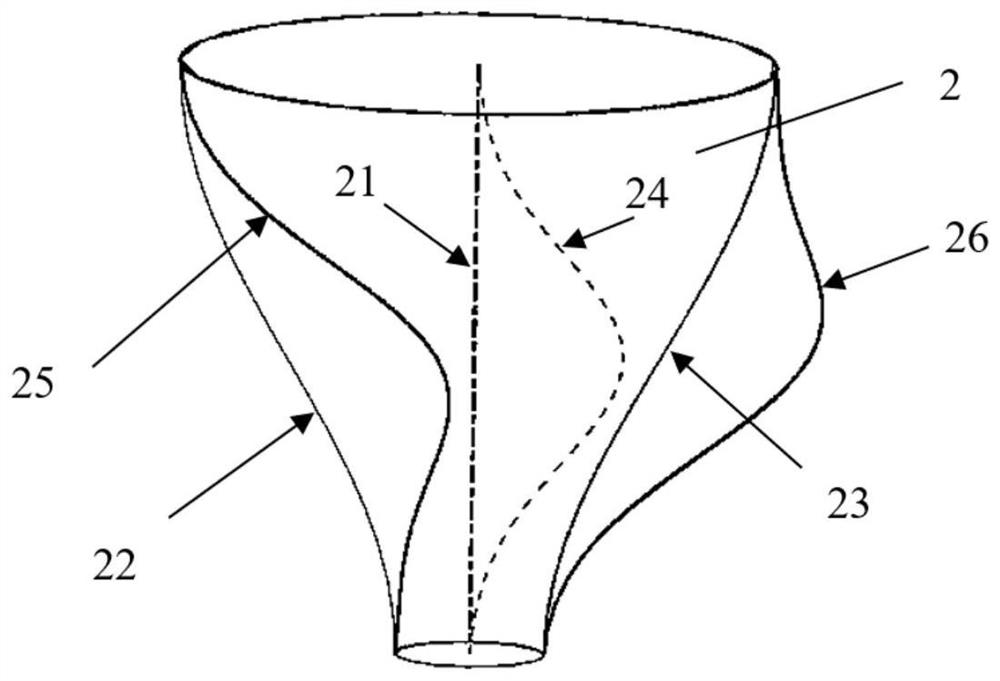

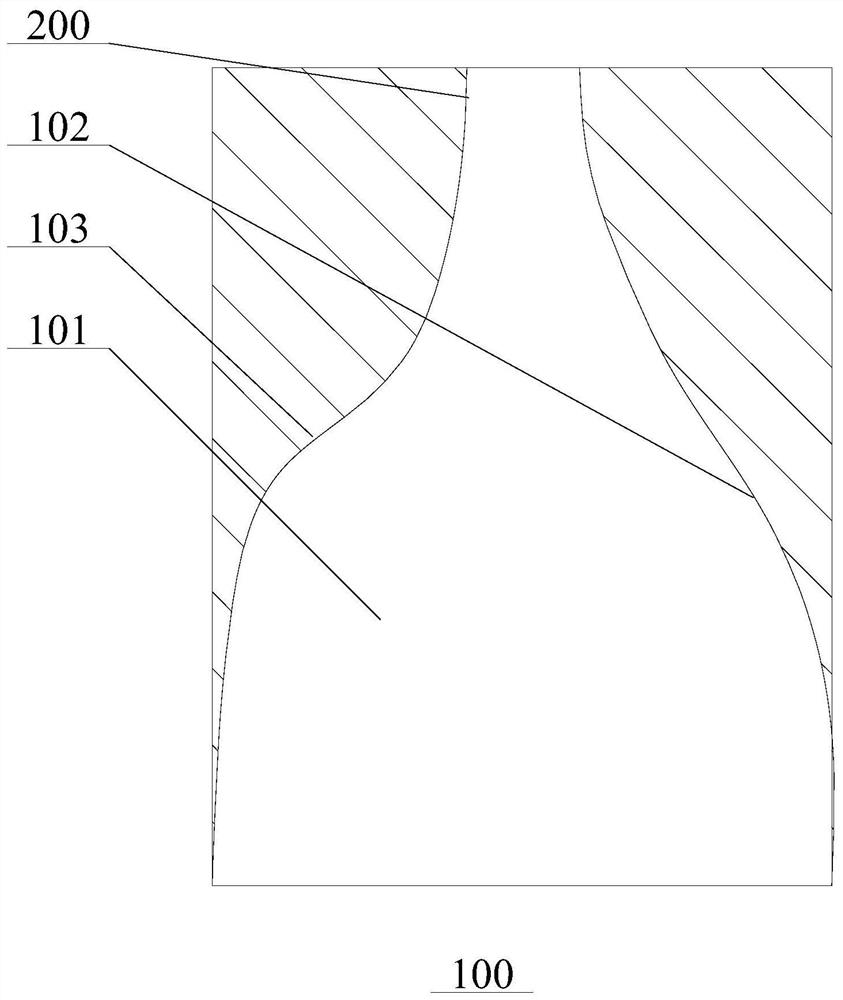

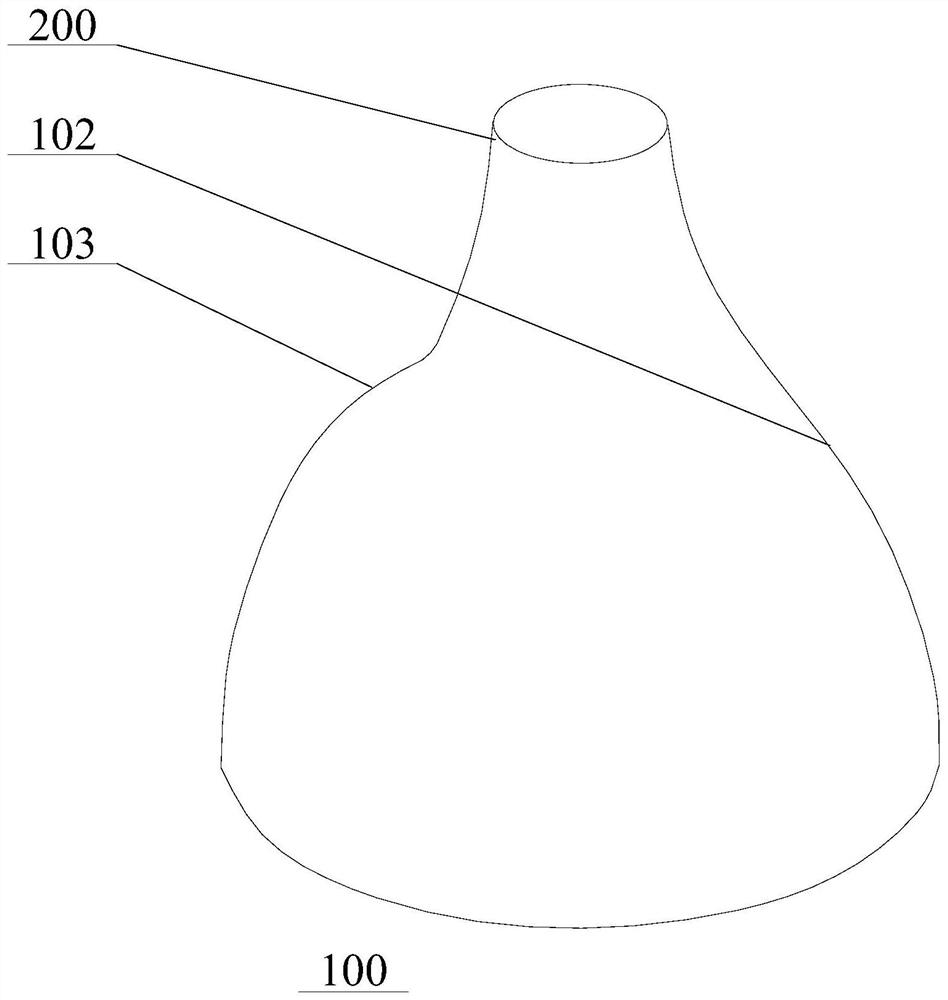

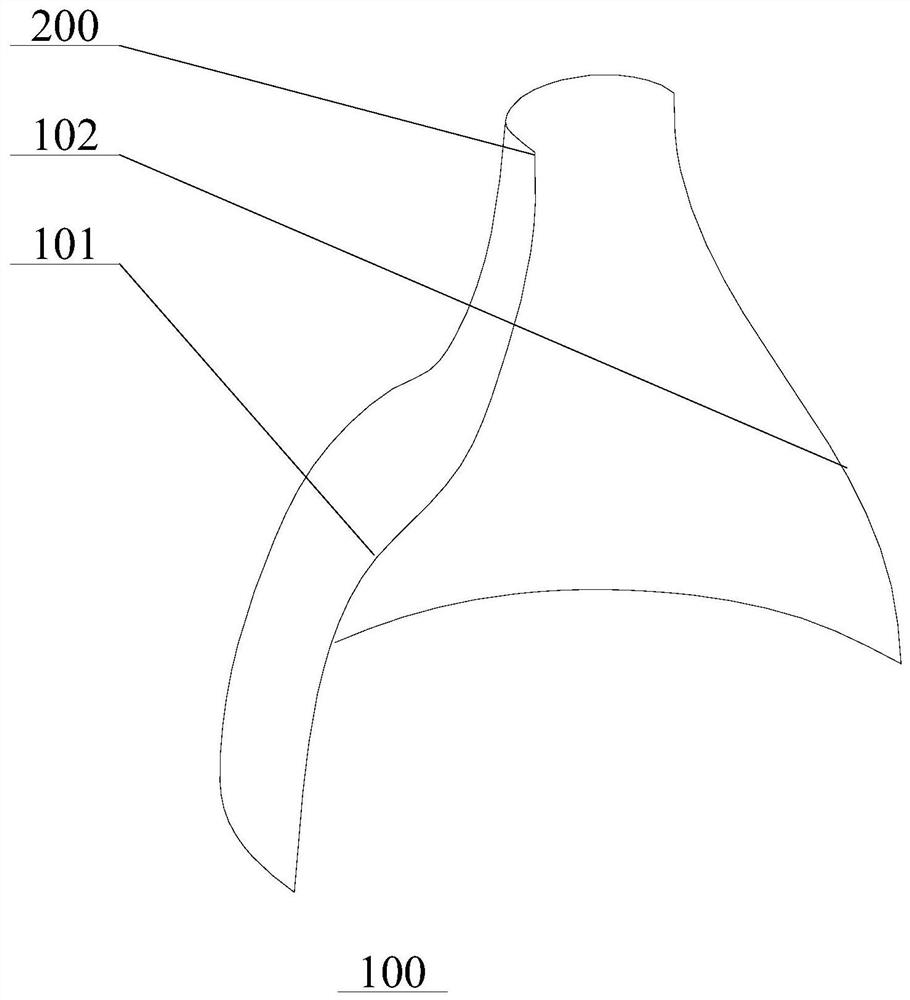

Variable-channel corner self-bending extrusion die and design, manufacturing and extrusion method thereof

ActiveCN111644478ASpeed up the flowReduce or eliminate section deformationExtrusion diesGeometric CADPhysicsEngineering

The invention provides a variable-channel corner self-bending extrusion die and a design, manufacturing and extrusion method thereof, and relates to the technical field of dies. The method comprises the following steps: 1, a symmetric streamlined extrusion die is designed based on a sine function; 2, a central axis of a die cavity of the symmetric streamlined extrusion die is distorted and deformed at a certain plane; 3, a cavity wall surface equation for the variable channel corner self-bending extrusion die is established; 4, a work strip structure is added behind the die cavity of the variable channel corner self-bending extrusion die; and 5, after metal flows through the variable channel corner self-bending extrusion die, the extrusion speed is controlled to be linearly distributed, sothat a bending part is directly extruded, the outer side surface of a profile is reduced or the cross-section deformation is avoided, and the flow of the metal in the extrusion process is smoother and the extrusion load becomes low; and he technical problems of rebound, wrinkling and cross-sectional deformation during bending processing of profile in the prior art is solved, and the technical problem of load during extrusion is solved.

Owner:SHANDONG UNIV OF TECH

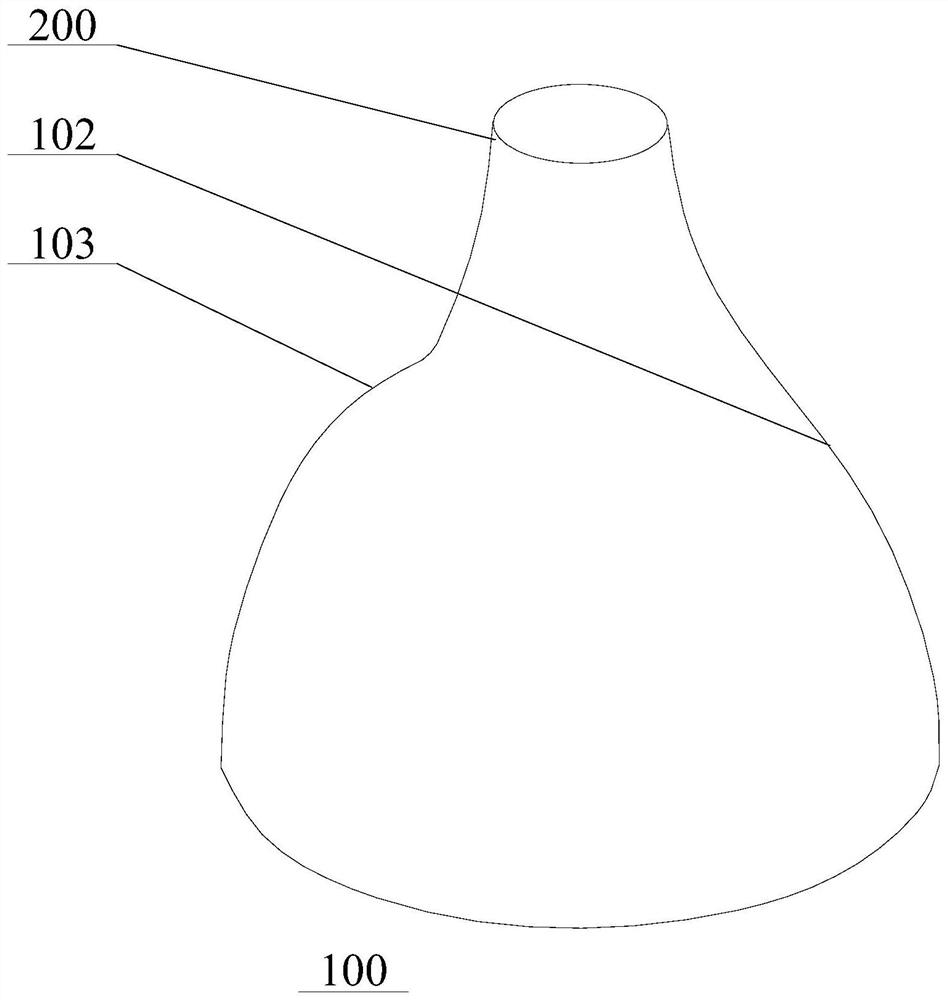

Sectional material self-bending forming extrusion die

The invention relates to a sectional material self-bending forming extrusion die, and relates to the technical field of dies. The sectional material self-bending forming extrusion die is used for solving the technical problem that the cross section deformation is easily caused when the outer side surface of a sectional material is subjected to large stress in the prior art. The sectional materialself-bending forming extrusion die comprises an upper die and a lower die connected to the upper die; and due to the fact that the area covered by an inner contour line of the upper half part of a flow guide cavity is larger than the area covered by the inner contour line of the lower half part of the flow guide cavity, and the area covered by an inner contour line of the upper half part of an extrusion cavity is larger than the area covered by the inner contour line of the lower half part of the extrusion cavity, the metal amounts flowing into the upper sides of the flow guide cavity and theextrusion cavity is more than those flowing into the lower sides correspondingly, so that a blank is pre-deformed firstly during extrusion, the extrusion load on the outer side surface of the sectional material can be reduced, and extrusion molding is facilitated.

Owner:SHANDONG UNIV OF TECH

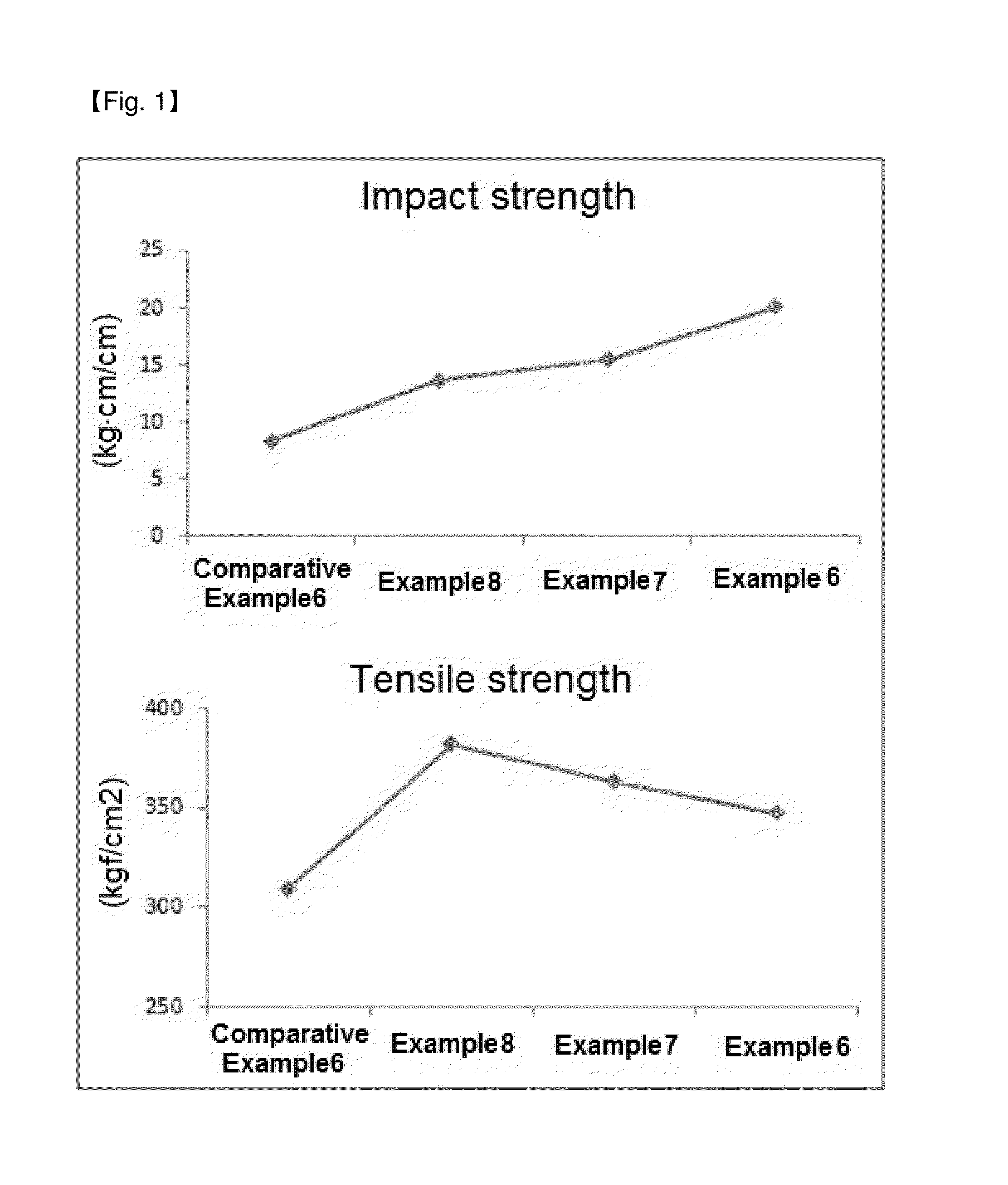

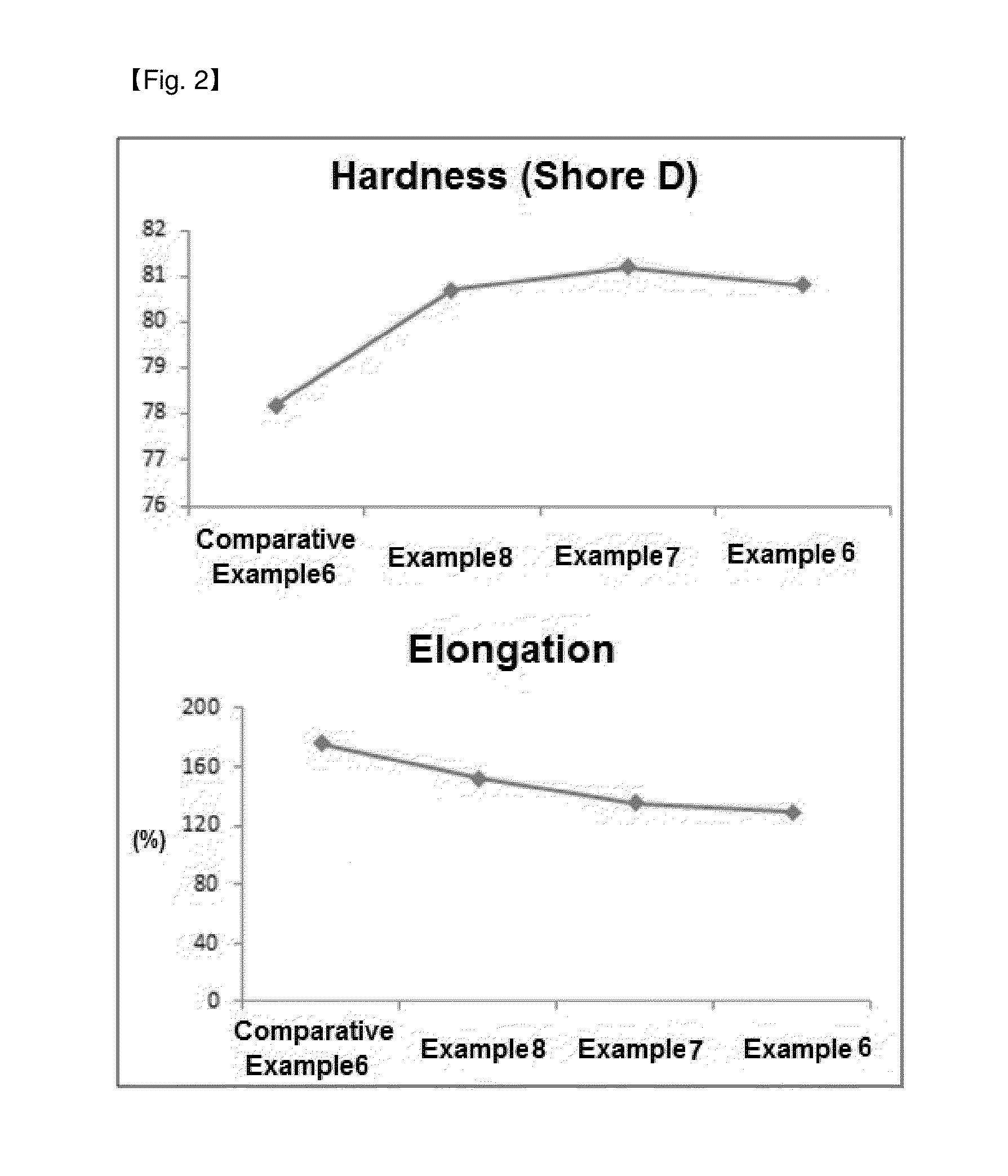

PVC-based compound composition

The present invention relates to a polyvinyl chloride (PVC)-based compound composition, and more specifically, to a PVC-based compound composition that uses a PVC-based copolymer having internal plasticity prepared by suspension polymerization together with a PVC resin, thereby increasing compatibility with the PVC resin to shorten the gelling time, lowering the load at the time of extrusion to increase production in the same process conditions, and partially showing an impact modifier substitution effect.

Owner:HANWHA CHEMICAL CORPORATION

Automobile clutch cold extruding production technology

The invention discloses an automobile clutch cold extruding production technology. The automobile clutch cold extruding production technology comprises the following steps that S1, a blank is selected; S2, the blank is washed, is subjected to sawing blanking and is cut; S3, annealing treatment is carried out; S4, the blank is subjected to phosphorization and saponification; S5, cold extrusion is carried out; and S6, and the workblank is subjected to finish machining. According to the automobile clutch cold extruding production technology, a special-shaped tooth disc hub positive extrusion technology is optimized, products qualified in quality can be produced, the tooth shape compactness and the abrasive resistance are improved, the extrusion load is reduced in the forming process of a special-shaped tooth clutch disc hub, the tooth shape and corner filling effect is good, the surface damage is avoided, and the product quality is improved.

Owner:来安县隆华摩擦材料有限公司

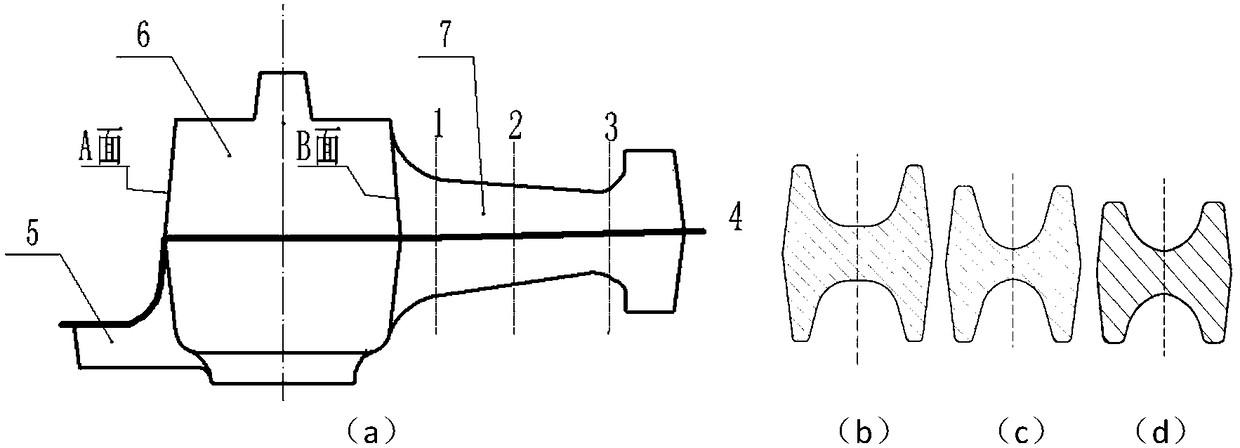

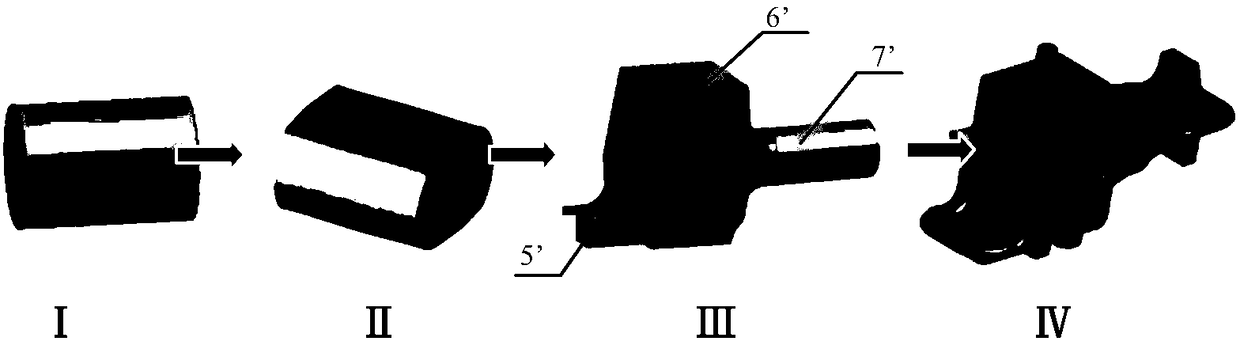

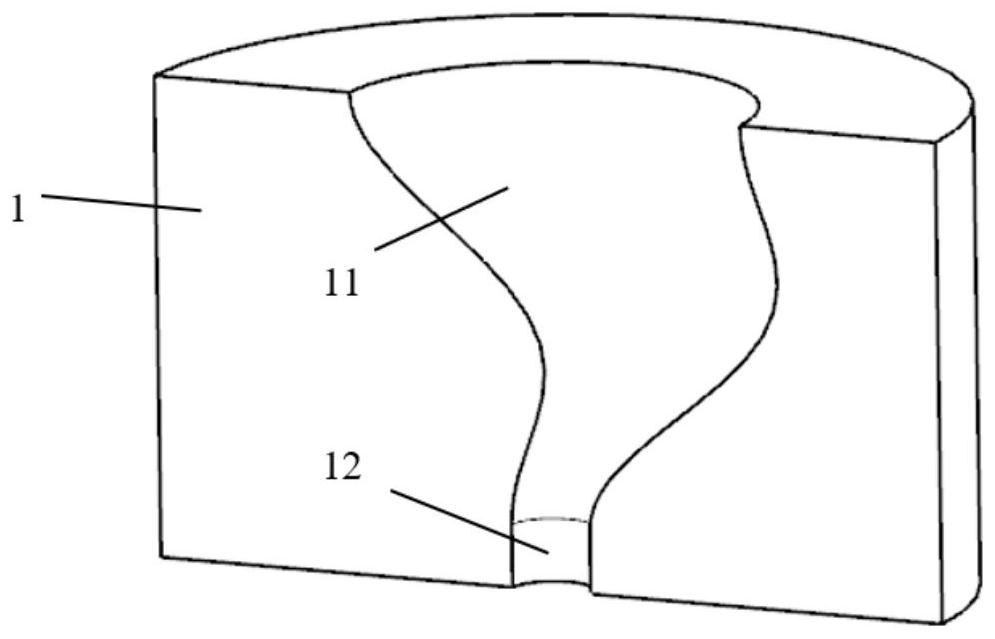

A kind of forging method of high-speed train axle box body

ActiveCN106734799BGood volume distributionEasy to shapeRailway componentsForging/hammering/pressing machinesBar stockManufacturing engineering

The invention discloses a forging method of a high-speed train axle box body. The forging method comprises the following steps that 1, blank blanking is conducted, wherein a blank is a cylindrical extrusion bar, and the blank with the set length is obtained through sawing blanking; 2, transverse flattening upsetting is conducted, wherein transverse flattening upsetting is conducted on the blank to obtain a prefabricated blank; 3 the prefabricated blank is extruded to obtain a pre-forging piece, wherein the pre-forging piece sequentially comprises an end corresponding to the shape of the axle box body, a middle and a rod portion in the length direction, and volume distribution of the pre-forging piece is matched with that of the axle box body; 4, final forging piece molding is conducted, wherein the pre-forging piece is placed in a final forging mold to be subjected to final forging, and a final forging piece is obtained. Volume distribution of the pre-forging piece is well matched with that of the final forging piece, an extrusion process is adopted in pre-forging piece molding, no flash is generated, the pre-forging piece is stably positioned in a final forging mold cavity, and therefore it can be guaranteed that the final forging piece is well molded.

Owner:SHANDONG UNIV +1

ETHYLENE-alpha-OLEFIN COPOLYMER AND MOLDED ARTICLE

An ethylene-α-olefin copolymer, wherein the ethylene-α-olefin copolymer has a density of 860 to 950 kg / m3 and a melt flow rate of 0.01 to 100 g / 10 min, wherein in a molecular weight curve measured by gel permeation chromatography, the molecular weight of the copolymer providing the highest peak exists within the range of 10,000 to 20,000, wherein the height of the peak at a molecular weight of 177,000 is 5 to 30% where the height of the highest peak is 100%, wherein a characteristic relaxation time of the copolymer satisfies a relation represented by formula (1), and wherein the ethylene-α-olefin copolymer exhibits more than one melt peak observed by a differential scanning calorimeter.40.2×MFR−0.606<τ<71.8×MFR−0.175 (1)

Owner:SUMITOMO CHEM CO LTD

Ethylene-.alpha.-olefin copolymer, molded article, catalyst for copolymerization, and method for producing an ethylene-.alpha.-olefin copolymer

ActiveUS8809462B2Reduce extrusion loadPromote absorptionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlpha-olefinAlkene

An ethylene-α-olefin copolymer comprising monomer units derived from ethylene and monomer units derived from an α-olefin having 3 to 20 carbon atoms, having a density (d) of 860 to 950 kg / m3, having a melt flow rate (MFR) of 0.01 to 100 g / 10 min, having a bimodal molecular weight distribution, and having a single melting peak measured by a differential scanning calorimeter (DSC).

Owner:SUMITOMO CHEM CO LTD

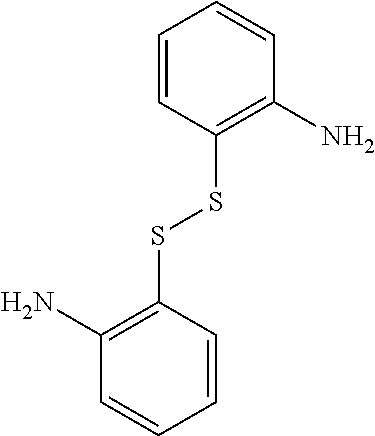

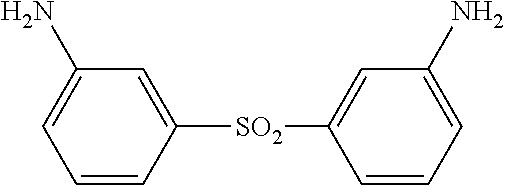

Thermoplastic elastomer composition

ActiveUS8536271B2Reduce extrusion loadWithout separate inflatable insertsWith separate inflatable insertsElastomerPolymer science

An object of the present invention is, in a thermoplastic elastomer composition in which a modified rubber is dispersed and filled in an ethylene-vinyl alcohol copolymer matrix in order to improve the low-temperature durability of the ethylene-vinyl alcohol copolymer, to reduce the extrusion load during extrusion molding thereof into a film without deteriorating the low-temperature durability. The present invention is a thermoplastic elastomer composition comprising an ethylene-vinyl alcohol copolymer (A) and a modified rubber (B) dispersed in the ethylene-vinyl alcohol copolymer (A), wherein the modified rubber (B) has an acid anhydride group or epoxy group and is dynamically cross-linked by a compound (C) having at least two amino groups. This thermoplastic elastomer composition can be suitably used in the production of an inner liner of a pneumatic tire.

Owner:THE YOKOHAMA RUBBER CO LTD

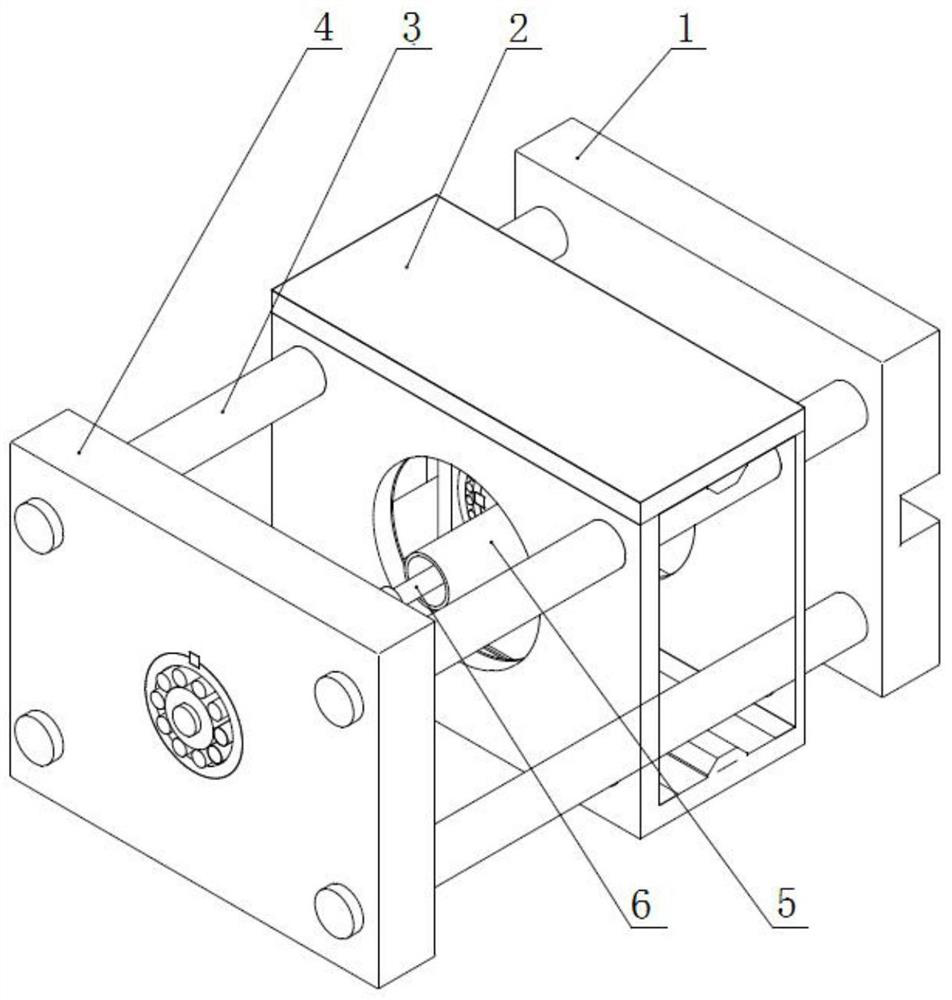

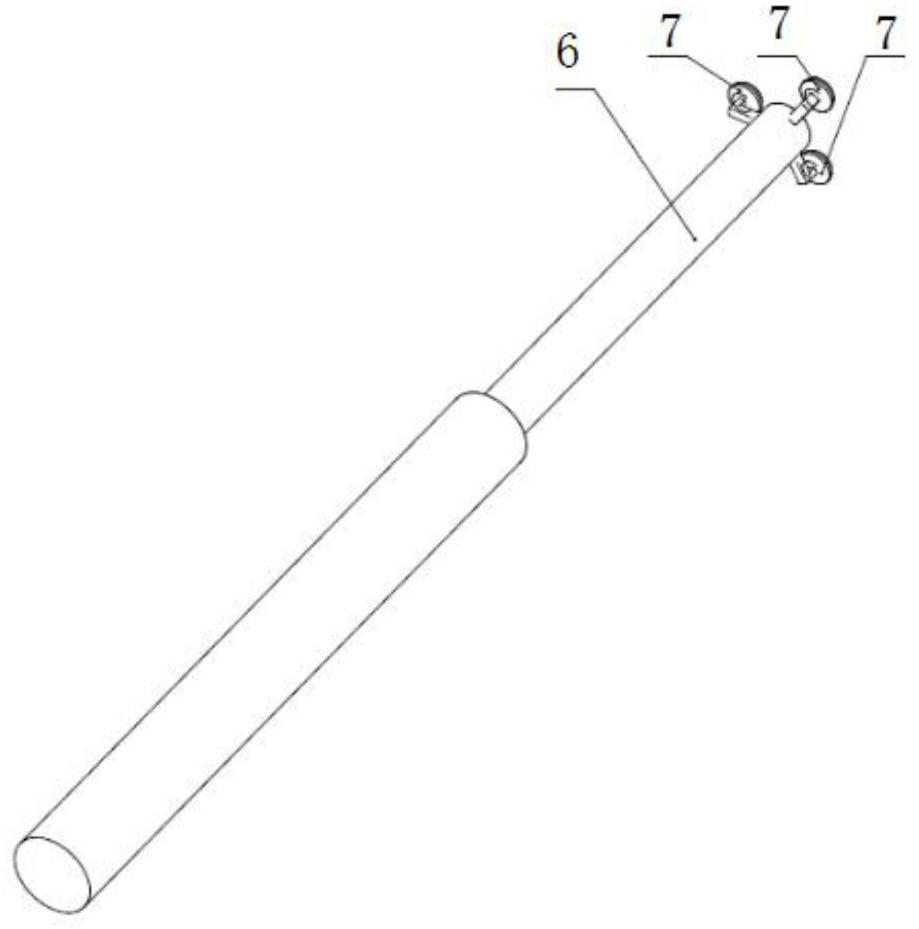

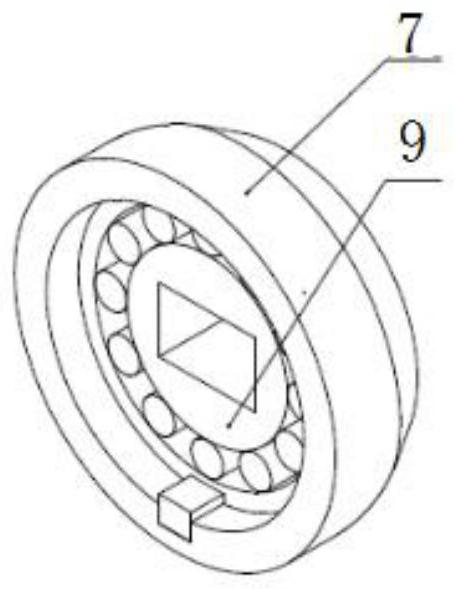

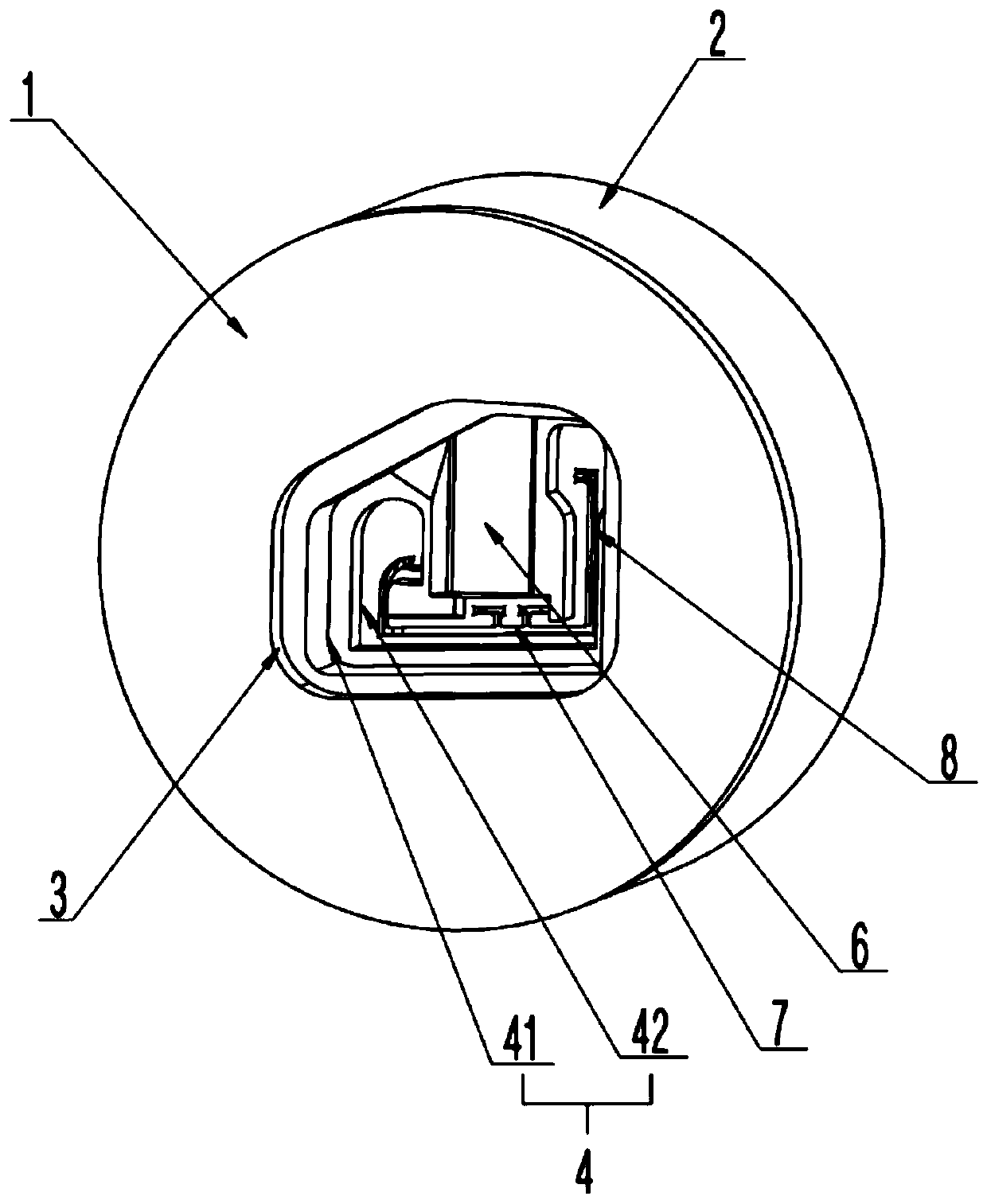

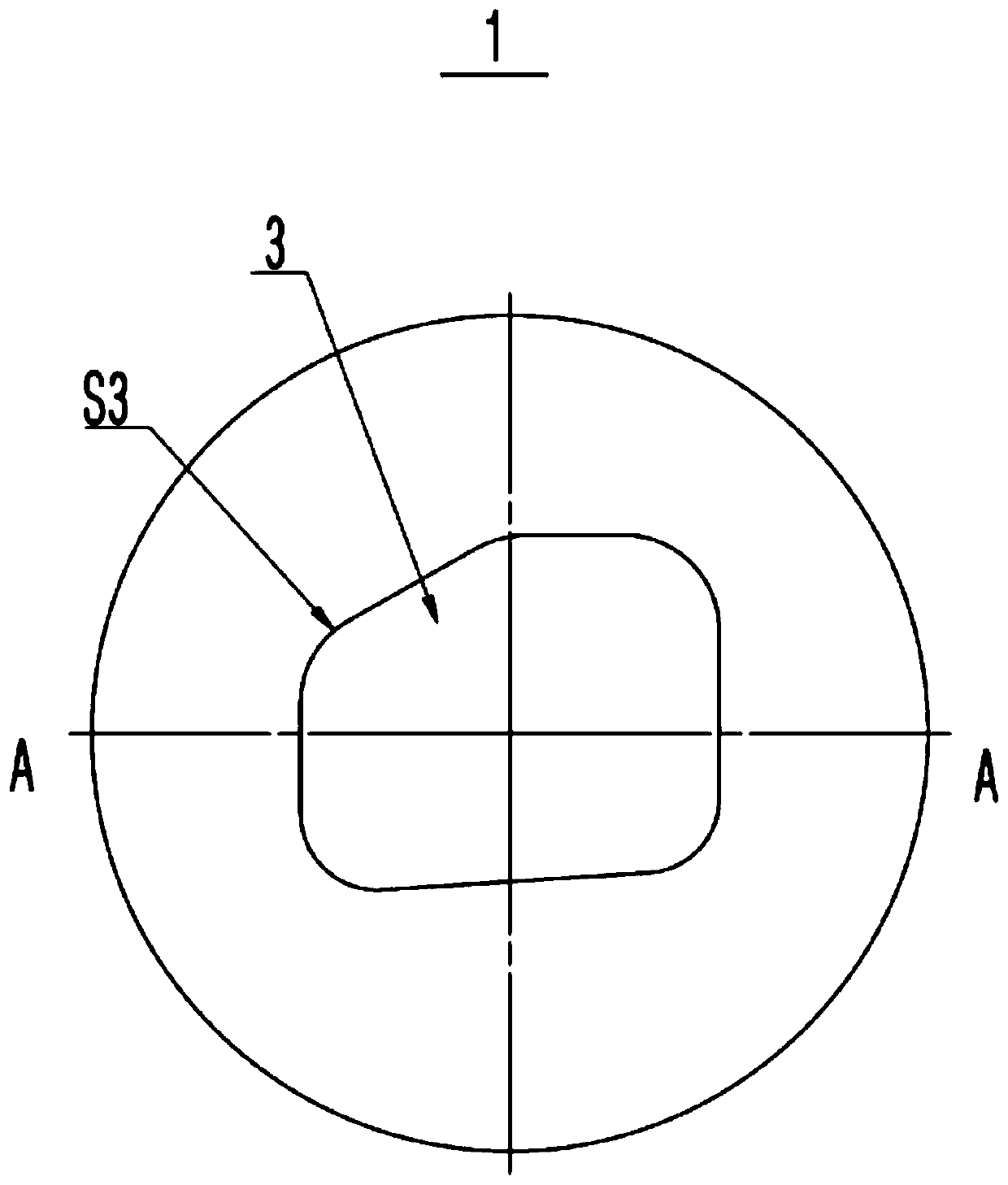

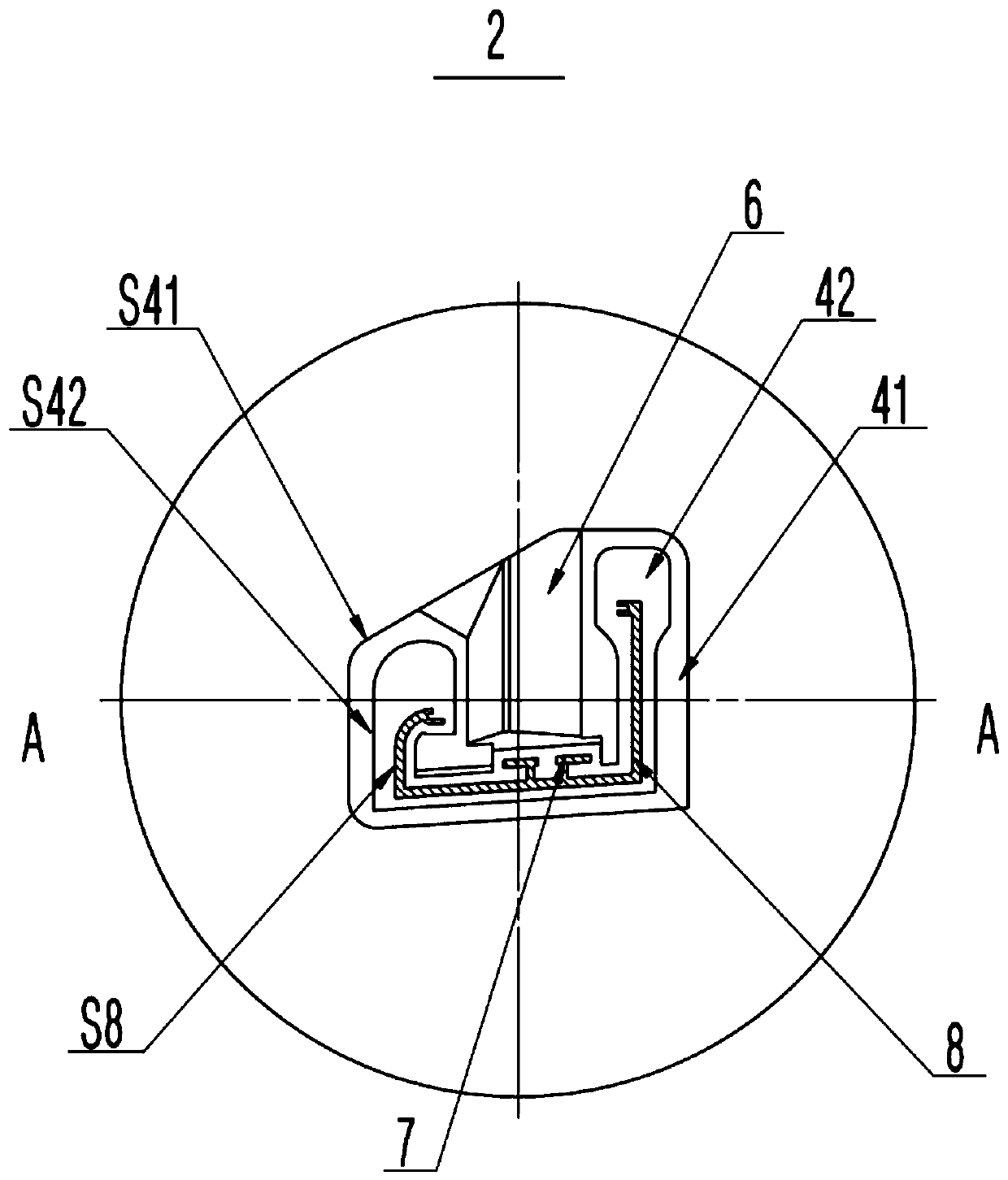

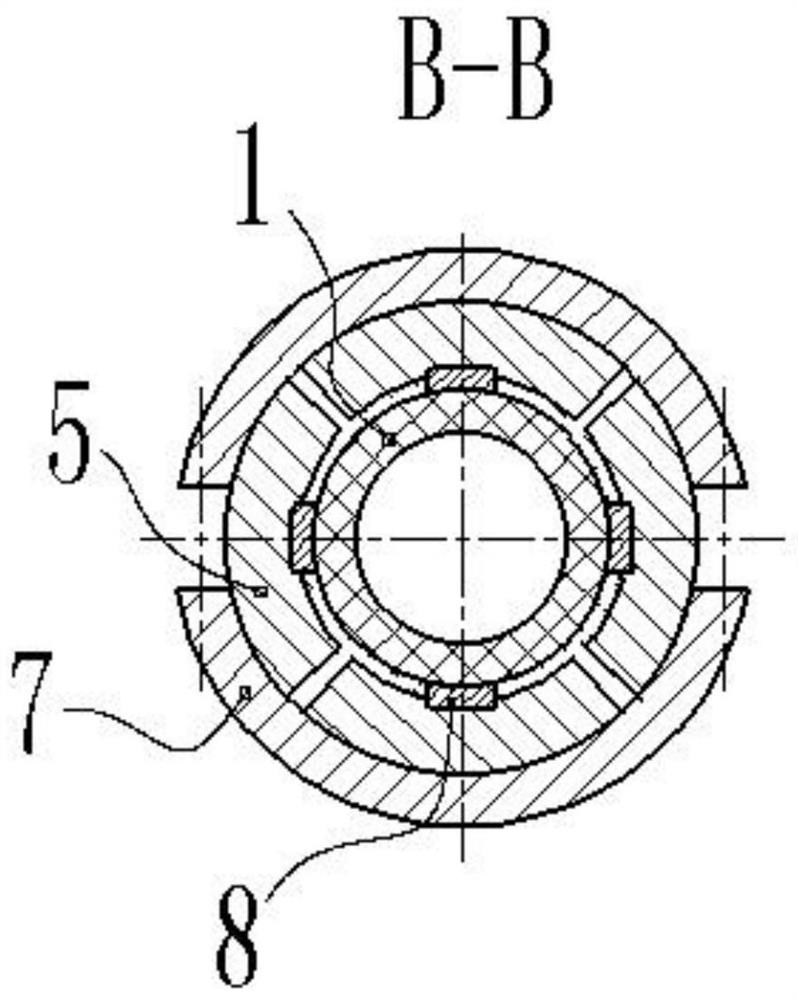

Internal rolling extrusion forming device and forming method for metal cylindrical parts

ActiveCN113042560BExtend your lifeReduce extrusion loadExtrusion mandrelsEngineeringMechanical engineering

Owner:安徽汉正轴承科技有限公司

Extrusion device for shortening blank friction flow path

InactiveCN102601143BFrictional flow path shortenedDecrease the rotation angle θNonferrous metalEngineering

The invention relates to an extrusion device for shortening a blank friction flow path, which is suitable for continuous extrusion equipment. The extrusion device is characterized in that a blank friction flow path shortening device constituted by a wrap angle adjusting mechanism and an auxiliary blank gripping mechanism is arranged on a frame, and the wrap angle adjusting mechanism comprises a gripping wheel position adjusting component and an extrusion cavity position adjusting component; and the auxiliary blank gripping mechanism comprises a bending guide roller I, a bending guide roller oil cylinder I, a bending guide roller II and a bending guide roller oil cylinder II, so that the blank friction flow path can be shortened and the rotational angle of a blank can be reduced. According to the extrusion device disclosed by the invention, by adjusting the positions of a gripping wheel and an extrusion cavity, the blank flow path can be shortened, and the rotational angle of the blank can be reduced, so that the extrusion device can further reduce the extrusion load and deformation temperature of metal, not only save energy, but also prolong the service life of a tool and a mold; and particularly, the control of the deformation temperature can be realized by adjusting the blank flow path, which is very beneficial to preparation of high-performance nonferrous metal extruded products with fine-grained structures.

Owner:DALIAN JIAOTONG UNIVERSITY

Streamline self-bending extrusion die and design method thereof

ActiveCN112948988AReduce local damageExtend your lifeGeometric CADDesign optimisation/simulationDesign methodsControl curve

The invention provides a streamline self-bending extrusion die and a design method thereof, and relates to the technical field of dies, and the design method comprises the following steps: designing a boundary control curve on one side of the cross section of a die cavity based on a sine function; designing boundary control curves on the two sides of the section of the die cavity to be asymmetric; performing smooth transition based on the boundary control curves on the two sides to obtain a curved surface control function of the mold cavity; arranging a working belt structure is behind a die cavity of the extrusion die, wherein the wall surface of the working belt structure is parallel to the extrusion direction; by means of the streamline die cavity of the extrusion die, non-uniform flowing can occur in the material extrusion process, then a self-bending extrusion profile is obtained, flowing of the streamline die cavity is closer to a real material flowing path, the streamline adaptive die can reduce extrusion loads, and local damage to the die is reduced; the technical problems of resilience, wrinkling and section deformation during bending processing of the profile in the prior art are relieved, and the technical problem of load reduction during extrusion is solved.

Owner:SHANDONG UNIV OF TECH

Variable channel corner self-bending extrusion die and its design, manufacture and extrusion method

ActiveCN111644478BSpeed up the flowReduce or eliminate section deformationExtrusion diesGeometric CADEngineeringMechanical engineering

The invention provides a self-bending extrusion die with variable channel angle and its design, manufacture and extrusion method, and relates to the technical field of moulds, including the following steps: designing a symmetrical streamlined extrusion die based on a sine function; a symmetrical streamlined extrusion die The central axis of the mold cavity is twisted and deformed on a certain plane; the cavity wall equation of the variable channel angle self-bending extrusion mold is established; a working belt structure is added behind the cavity of the variable channel angle self-bending extrusion mold; the metal flows through the variable channel angle self-bending extrusion mold. After the channel corner is bent from the extrusion die, the extrusion speed is controlled to be linearly distributed, so that the curved parts are directly extruded, so the profile is not subject to lateral moment, so that the outer surface of the profile is reduced or the cross-sectional deformation is eliminated, and the metal is extruded during the extrusion process. The flow in the mold is smoother than the traditional stepped extrusion die, and the extrusion load becomes lower; it alleviates the technical problems of springback, wrinkling, and cross-sectional deformation during the bending process of the profile in the prior art and reduces the load during extrusion technical issues.

Owner:SHANDONG UNIV OF TECH

Metal alternate extrusion forming device and method

The invention relates to a metal alternative extrusion forming device and method and relates to a labor-saving extrusion forming device and method. The device and method solve the problems that according to an existing extrusion forming device and method, needed energy consumption is large, flowing uniformity is poor, and the material utilizing rate is low. According to the scheme of the device, an extrusion container is arranged on a base, a core die is arranged at the bottom of the extrusion container, blanks are arranged in the extrusion container and located above the core die, and one end of a first punch and one end of a second punch are arranged in the extrusion container and abut against the upper end faces of the blanks. According to the scheme of the method, the core die, the blanks, the first punch and the second punch are sequentially placed in the extrusion container; the second punch is fixed, the first punch moves downwards by the distance of L, and metal on the lower side of the first punch is extruded and deformed and is sequentially extruded and formed; then the first punch is fixed, the second punch moves downwards by the distance of 2L, and the blanks below the second punch are made to be extruded and formed. According to the acting sequence, the first punch and the second punch alternatively move downwards for loading till the blanks are totally extruded. The device and method are used for metal forming.

Owner:福建祥鑫股份有限公司

On-line Bending Device for Three-Dimensional Variable Curvature Profiles Actively Pulled by Robot

ActiveCN107234443BOvercome rolling frictionReduce extrusion loadMetal-working feeding devicesOther manufacturing equipments/toolsMachineRobot

The invention discloses a three-dimensional variable-curvature sectional material online bending and forming device pulled by a robot initiatively. The three-dimensional variable-curvature sectional material online bending and forming device comprises a horizontal extruding machine, a quenching device, a guiding device, the initiatively-pulling robot, a cutting robot and a transfer robot; the quenching device is arranged on the outlet side of the horizontal extruding machine and is used for controlling the temperatures of all cross sections of an extruded sectional material; the guiding device is arranged in the quenching device and is used for straightening and positioning on the extruded sectional material; the initiatively-pulling robot is arranged on the discharging side of the quenching device and is used for pulling the extruded sectional material to achieve the three-dimensional variable curvature; the cutting robot is used for cutting the variable-curvature sectional material output by the initiatively-pulling robot; and the transfer robot is used for sending the cut variable-curvature sectional material output by the cutting robot into an extruding and conveying roller bed. By means of the three-dimensional variable-curvature sectional material online bending and forming device, the defects that by means of an existing extruding and bending integrated method, the required extruding load is high, the stress of the cross sections of the sectional material is uneven, and surface scratches are generated are overcome, bending and forming quality of a product is improved, and the material utilization rate is increased.

Owner:HUNAN UNIV +1

Streamlined self-bending extrusion die and its design method

ActiveCN112948988BReduce local damageExtend your lifeGeometric CADDesign optimisation/simulationEngineeringDesign methods

The invention provides a streamlined self-bending extrusion die and a design method thereof, relating to the technical field of dies, comprising the following steps: designing the boundary control curve on one side of the die cavity section based on a sine function; designing the boundary control on both sides of the die cavity cross section The curve is asymmetrical; based on the boundary control curves on both sides, a smooth transition is made to obtain the surface control function of the cavity; a working belt structure is added behind the cavity of the extrusion die, and the wall surface of the working belt structure is parallel to the extrusion direction; The streamlined cavity of the compression mold can make the material flow unevenly during the extrusion process and then obtain the self-bending extrusion profile. The flow of the streamlined cavity is closer to the real material flow path, and the streamlined adaptable mold can reduce the extrusion load, The local damage of the mold is reduced; the technical problems of springback, wrinkling and section deformation during the bending process of the profile in the prior art are alleviated, and the technical problems of reducing the load during extrusion are alleviated.

Owner:SHANDONG UNIV OF TECH

Method for preparing titanium alloy nanomaterials by warm extrusion of herringbone channel die

ActiveCN105154800BGuaranteed dimensional accuracyGuaranteed shape accuracyTitanium alloyMechanical property

The invention discloses a method for preparing titanium alloy nano materials through warm extrusion of a herringbone channel mold. The method is characterized in that through the herringbone central axis, the herringbone channel mold is rotated by 120 degrees, and then subsequent-pass extrusion is carried out; repeated plastic deformation of the titanium alloy nano materials can be achieved, and finally, large deformation is accumulated; the nano titanium alloy materials are obtained; in each pass extrusion process, the rotating direction of the herringbone mold is changed, and uniform severe plastic deformation of the titanium alloy can be achieved; and the grain size is uniform, and refined nano grains are equiaxed grains with large grain boundary angles, and the mechanical property of the blocky nano titanium alloy is further improved, and on the premise that the high density is ensured, the high strength and the good toughness are high.

Owner:福建省诺希科技园发展有限公司

Profile self-bending forming extrusion die

The invention relates to a sectional material self-bending forming extrusion die, and relates to the technical field of dies. The sectional material self-bending forming extrusion die is used for solving the technical problem that the cross section deformation is easily caused when the outer side surface of a sectional material is subjected to large stress in the prior art. The sectional materialself-bending forming extrusion die comprises an upper die and a lower die connected to the upper die; and due to the fact that the area covered by an inner contour line of the upper half part of a flow guide cavity is larger than the area covered by the inner contour line of the lower half part of the flow guide cavity, and the area covered by an inner contour line of the upper half part of an extrusion cavity is larger than the area covered by the inner contour line of the lower half part of the extrusion cavity, the metal amounts flowing into the upper sides of the flow guide cavity and theextrusion cavity is more than those flowing into the lower sides correspondingly, so that a blank is pre-deformed firstly during extrusion, the extrusion load on the outer side surface of the sectional material can be reduced, and extrusion molding is facilitated.

Owner:SHANDONG UNIV OF TECH

Method for realizing synthermal extrusion through technological parameter combination control

ActiveCN102601152BHigh precisionReduce extrusion loadExtrusion control devicesHeat flowStructure property

The invention relates to a method for realizing synthermal extrusion of an aluminium alloy material, which aims at obtaining a high-property extruded aluminium alloy product with a uniform structure property along the length direction. The method provided by the invention comprises the following steps: selecting an extruding device and computing the size of an extrusion billet according to a type and a specification of a target product; determining a maximum allowable temperature T1 and a heating temperature T0 of the billet of the extruded aluminium alloy product according to the production experience and the information data, so as to determine an allowable extrusion temperature rise deltaT; and determining an extrusion speed Vj and a heating temperature Tc of an extruding cylinder according to the extrusion flowing deformation characteristics and the balanced heat flow and temperature characteristics of metal. According to the invention, the technical parameters are utilized, so that the synthermal extrusion production can be realized under the uniform heating temperature of the billet and the constant extrusion speed, without reforming the existing extrusion production equipment or increasing any auxiliary equipment; uniform-speed and constant-pressure extrusion can be realized under the constant-temperature (synthermal extrusion) condition; and extrusion load can be reduced and energy consumption of the production can be reduced through reasonably matching the extrusion speed and the heating temperature of the billet.

Owner:UNIV OF SCI & TECH BEIJING

Conveying structure used for triangular magnesium pipe sintering equipment

PendingCN109051715ASo as not to damageReduce extrusion loadCeramic shaping apparatusEmulsificationInverted triangleMagnesium

The invention discloses a conveying structure used for triangular magnesium pipe sintering equipment. First telescopic air cylinders arranged symmetrically on guide rails on the two sides drive circular-arc-shaped first conveying clamps to synchronously clamp a doughy irregular mixture, the circular-arc-shaped inner surfaces extrude the doughy irregular mixture into a partially regular mixture, and the extruding load of an extruder can be decreased; and after a moist triangular magnesium pipe with the inverted triangle shaped section, extruding formed by the extruder, is cut into triangular magnesium pipe sections, second telescopic air cylinders on the two sides drive second conveying clamps to clamp the triangular magnesium pipe sections through slope surfaces adapting to the two side surfaces of the triangular magnesium pipe in shape, size and angle, so that the triangular magnesium pipe sections are conveyed to a subsequent dryer, first flexible pads and second flexible pads do notscrape or damage the surfaces of the triangular magnesium pipe sections which are not fixing formed yet, the supporting and clamping effect is good, and conveying is stable and reliable.

Owner:镇江裕太防爆电加热器有限公司

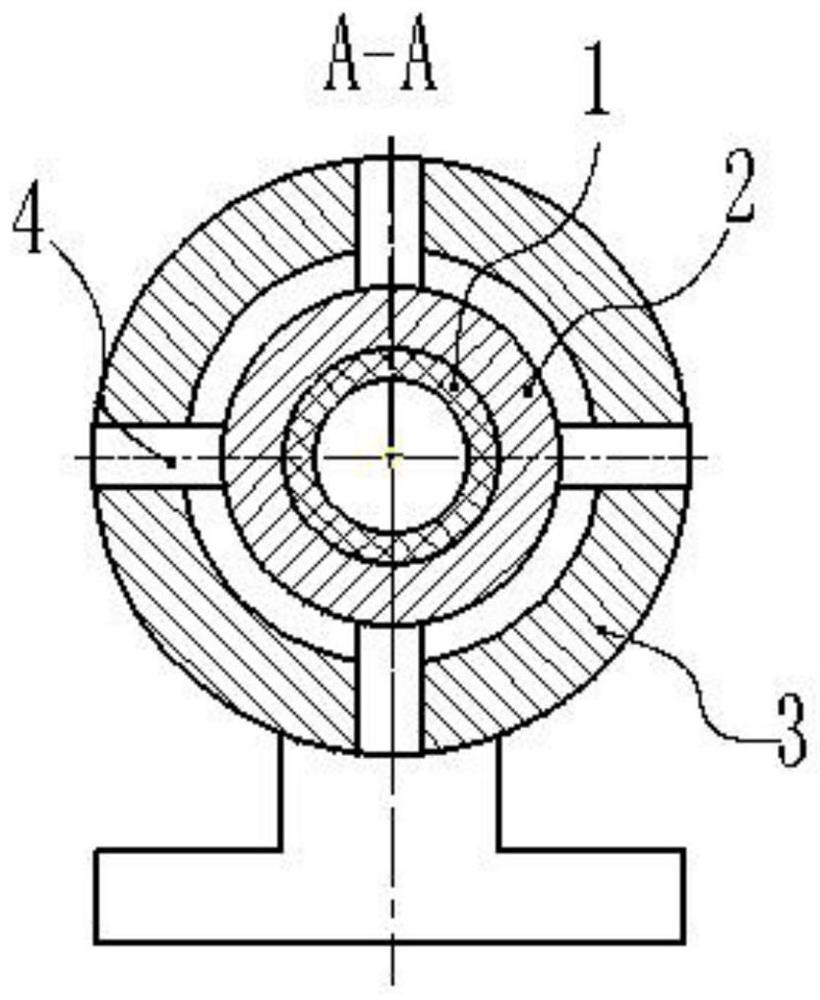

The overall wall plate is crowded and composite forming devices and methods

ActiveCN103192266BIncrease profitEasy extrusionRollsOther manufacturing equipments/toolsRoll formingPeening

An extruding and rolling composite forming device and an extruding and rolling composite forming method of an integral panel skin with ribs belong to processing forming devices and processing forming methods of the integral panel skin with the ribs, and aim at solving the problems that the manufacturing cycle is long, the material utilization rate is low and the forming accuracy is hard to guarantee when an existing integral panel skin with ribs utilizes roll forming and bending forming and the problems that special equipment is needed and the cost is high when peen forming and creep age forming are utilized. The extruding and rolling composite forming device of the integral panel skin with the ribs includes a punch, an extruding container, two cylindrical rollers and two driving mechanisms, wherein two sides of the lower end of a chamber is provided with the two cylindrical rollers, the axes of the two cylindrical rollers are on the same plane, the horizontal distance of the centers of the section circles of the two cylindrical rollers to the vertical center line of the chamber is the same, the side surface on the outer periphery of at least one of the two cylindrical rollers is provided with a plurality of grooves, and each of the cylindrical rollers is connected with one driving mechanism capable of driving the roller to rotate. The extruding and rolling composite forming device and the extruding and rolling composite forming method of the integral panel skin with ribs are applicable to the forming of the integral panel skin with ribs.

Owner:福建祥鑫股份有限公司

A kind of rotating pipe shaping pulling device and method thereof

The invention discloses a rotating pipe shaping and pulling device and method, and relates to the field of pipe production equipment. The device comprises a pulling sleeve arranged on a rotating pipein a sleeving manner; the two ends of the pulling sleeve are sleeved with hooping devices; a key groove is formed in the outer wall of the pulling sleeve; the key groove is fixedly connected with a rotating wheel through a key; the rotating wheel meshes with a driving wheel; one end of the driving wheel is connected with a motor through a driving shaft; the rotating wheel and the driving wheel arearranged on a transmission box body through bearings; the pulling sleeve penetrates through the rotating wheel and the transmission box body; friction blocks are evenly arranged on the inner wall ofthe pulling sleeve; and the friction blocks make contact with the outer wall of the rotating pipe. With the adoption of the shaping and pulling method of the rotating pipe shaping and pulling device,spiral pulling of the pipe in the axial direction is realized, and the pulling efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

An Extrusion Die for Small Diameter Thin Wall Deep Blind Hole Parts

ActiveCN109351799BReduce extrusion loadExtend your lifeExtrusion diesLongest DiameterLarge deformation

The invention discloses a small diameter thin wall deep blind hole part extrusion mold which combines extrusion and stretching working procedures into one mold and is applied to molding of small diameter thin wall blind hole parts with large deformation quantity, extrusion ratio and long diameter ratio. The small diameter thin wall deep blind hole part extrusion mold structurally comprises an upper mold plate, a lower mold plate, a lower mold core, guiding position-limiting components, a mold cavity with a heating function and a punch head, wherein a pull mold angle arranged inside the mold cavity makes materials be capable of flowing out of a deformation area in the reverse extrusion process to reduce the contact area with the mold, so that load of the mold in the reverse extrusion process is reduced, the key problem that the small-diameter punch head has short life in the extrusion process is solved, the mold cavity acts as a pull mold to be used in the ascending process, and the stretching materials are normalized to the standard size. According to the small diameter thin wall deep blind hole part extrusion mold, by means of the manner that a reverse extrusion mold and a stretching mold are combined into one mold, the molding efficiency of small diameter thin wall deep blind holes can be effectively improved, and the material use ratio is high; and meanwhile, produced products have low residual stress, the fabrication cost is low, the mold is convenient to maintain and operate, and the small diameter thin wall deep blind hole part extrusion mold has wide application value.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com