The overall wall plate is crowded and composite forming devices and methods

A technology of integral wall and composite forming, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of difficult to guarantee forming accuracy, low material utilization rate, long manufacturing cycle, etc., and achieve forming accuracy guarantee, manufacturing technology The effect of maturity and improved material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

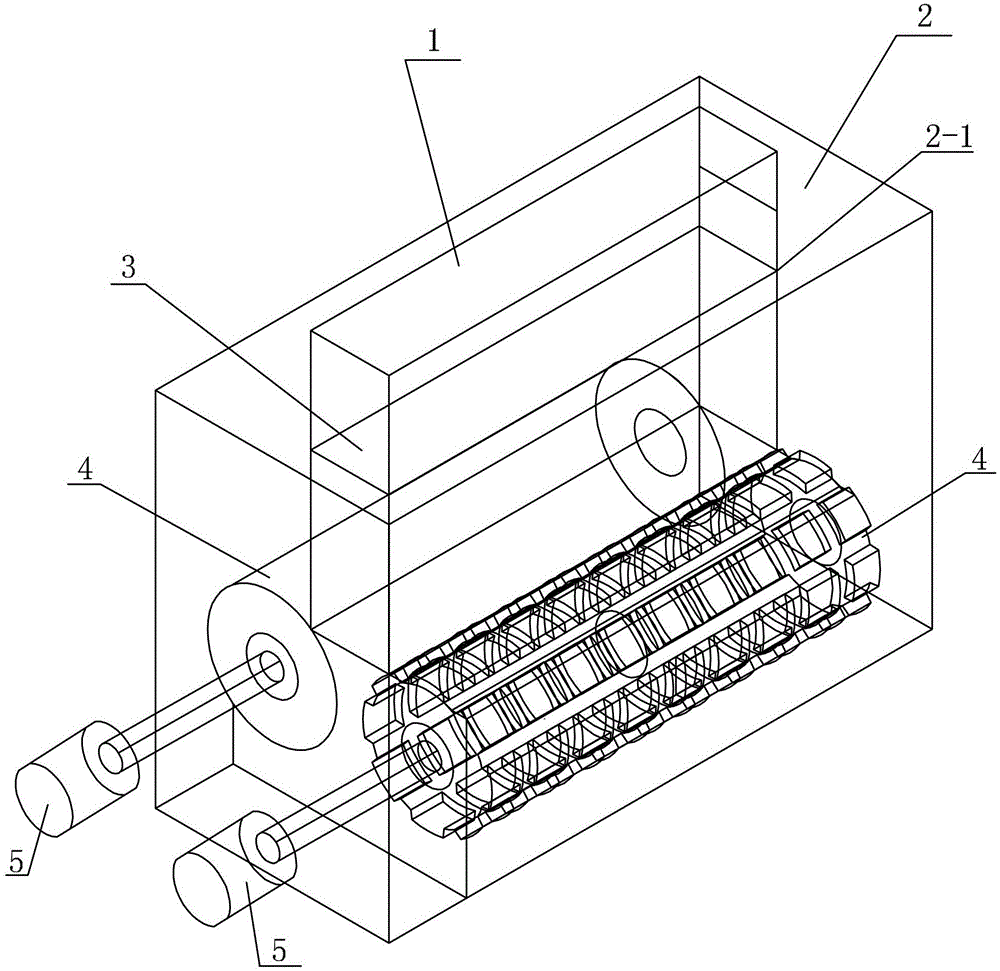

[0014] Specific implementation mode one: combine Figure 1 ~ Figure 3This embodiment is described. A ribbed integral wall panel extrusion-rolling composite forming device in this embodiment includes a punch 1, an extrusion cylinder 2, two cylindrical rolls 4 and two driving mechanisms 5. The extrusion cylinder 2 It is a square structure, the upper and lower ends of the hollow cavity 2-1 of the extrusion cylinder 2 are open ends, two cylindrical rolls 4 are arranged on both sides of the lower end of the hollow cavity 2-1, and the outer circumferences of the two cylindrical rolls 4 The side is close to the lower end surface of the extrusion cylinder 2, the axes of the two cylindrical rolls 4 are on the same plane, and the horizontal distances from the centers of the cross-sectional circles of the two cylindrical rolls 4 to the vertical centerline of the hollow cavity 2-1 are equal , at least one of the two cylindrical rolls 4 is provided with a plurality of grooves 4-1 on the ou...

specific Embodiment approach 2

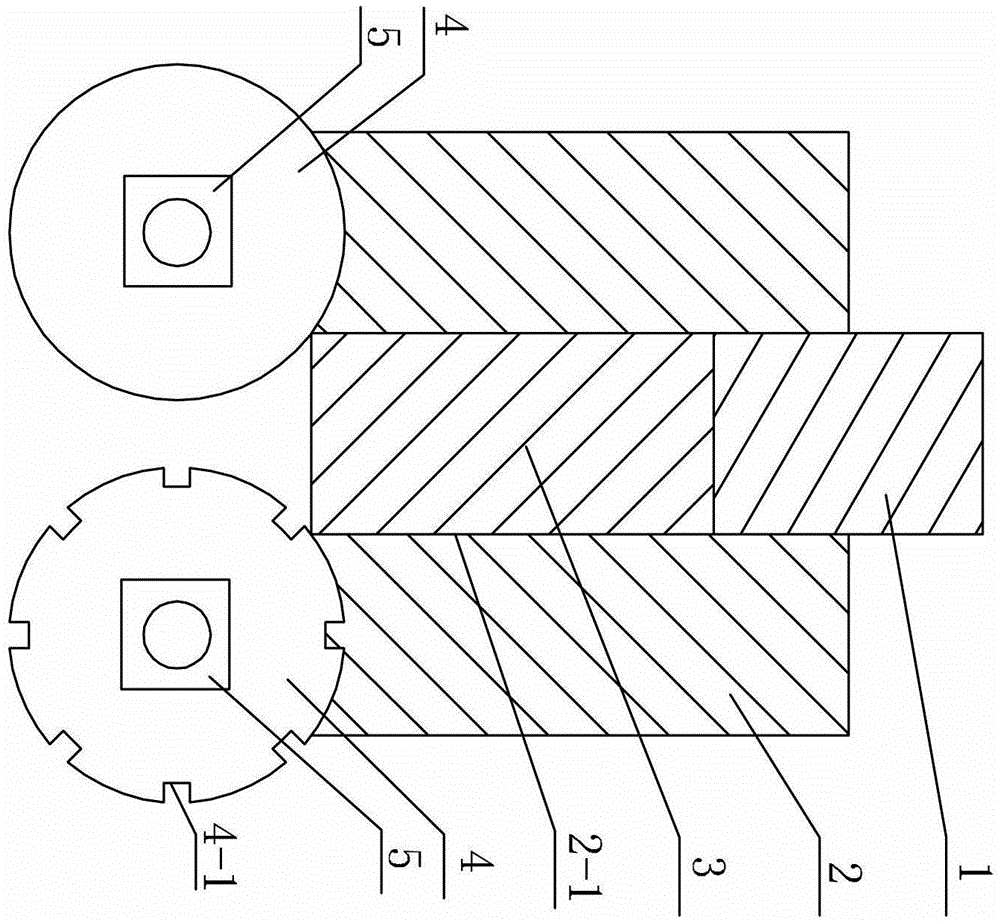

[0016] Specific implementation mode two: combination figure 2 To illustrate this embodiment, a plurality of grooves 4-1 are provided on the outer circumferential side of one of the two cylindrical rollers 4 of this embodiment, each groove 4-1 is a rectangular groove, The length direction of the groove 4-1 is consistent with the axial direction of the cylindrical roll 4 or perpendicular or at a certain angle. Such setting can meet the forming requirements of integral wall panels with ribs in different shapes. Others are the same as in the first embodiment.

specific Embodiment approach 3

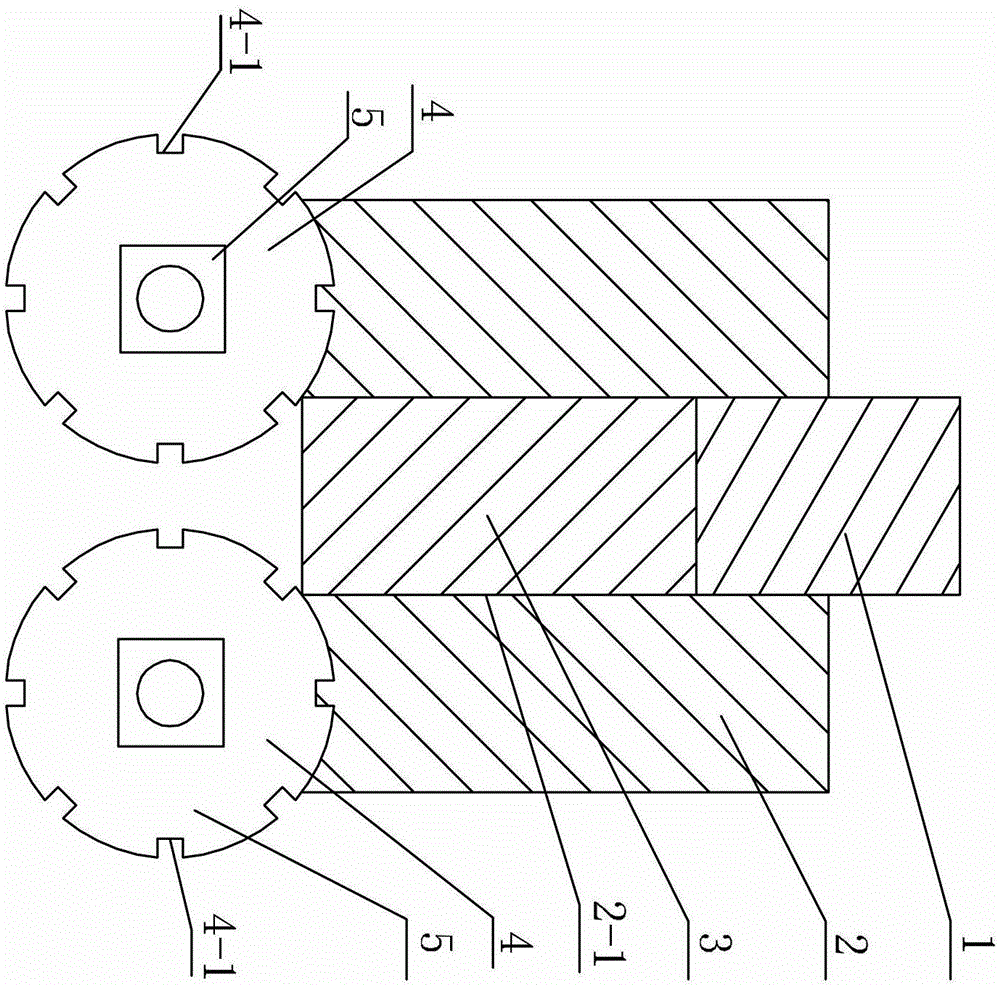

[0017] Specific implementation mode three: combination image 3 To describe this embodiment, a plurality of grooves 4-1 are provided on the outer peripheral sides of the two cylindrical rolls 4 of this embodiment. Such setting can meet the forming requirements of integral wall panels with ribs in different shapes. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com