Method for realizing synthermal extrusion through technological parameter combination control

An isothermal extrusion and comprehensive control technology, applied in the field of warm extrusion, can solve problems such as difficult to achieve uniformity of performance, narrow adjustable range of speed, and low extrusion speed of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

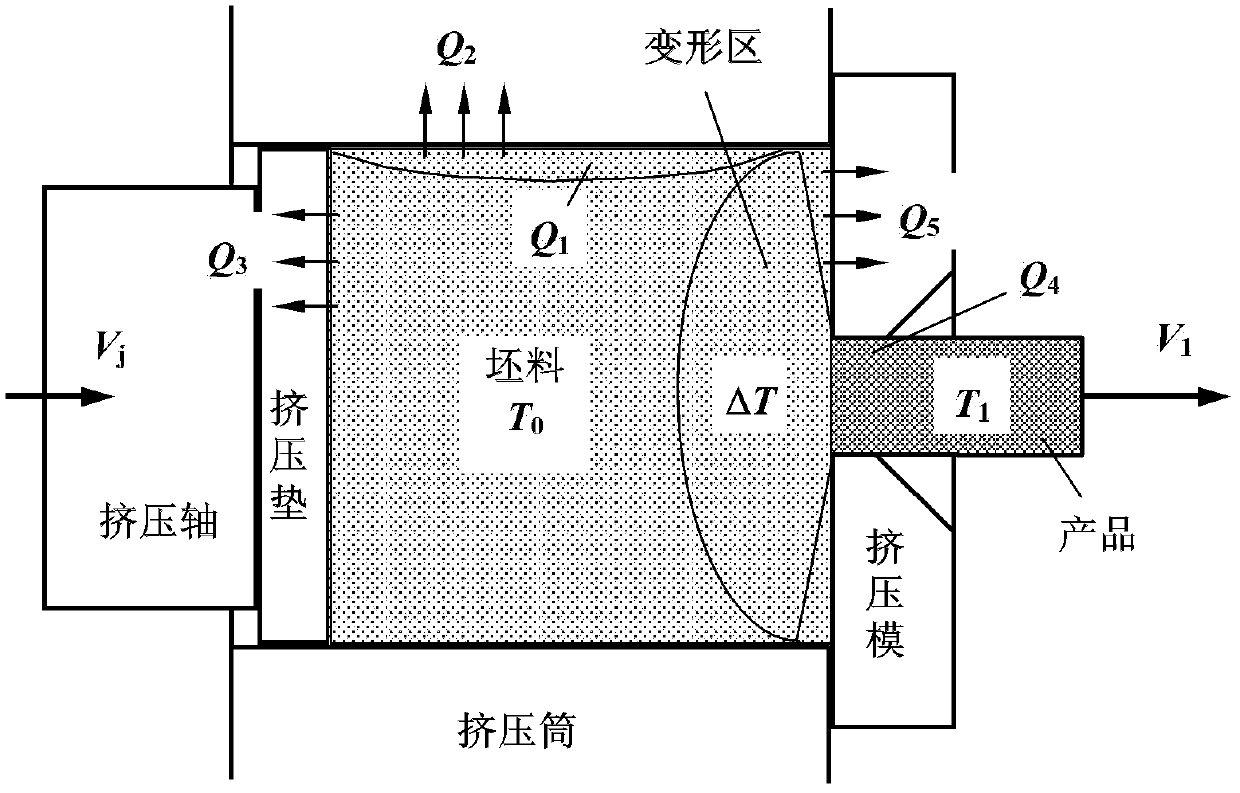

Method used

Image

Examples

Embodiment 1

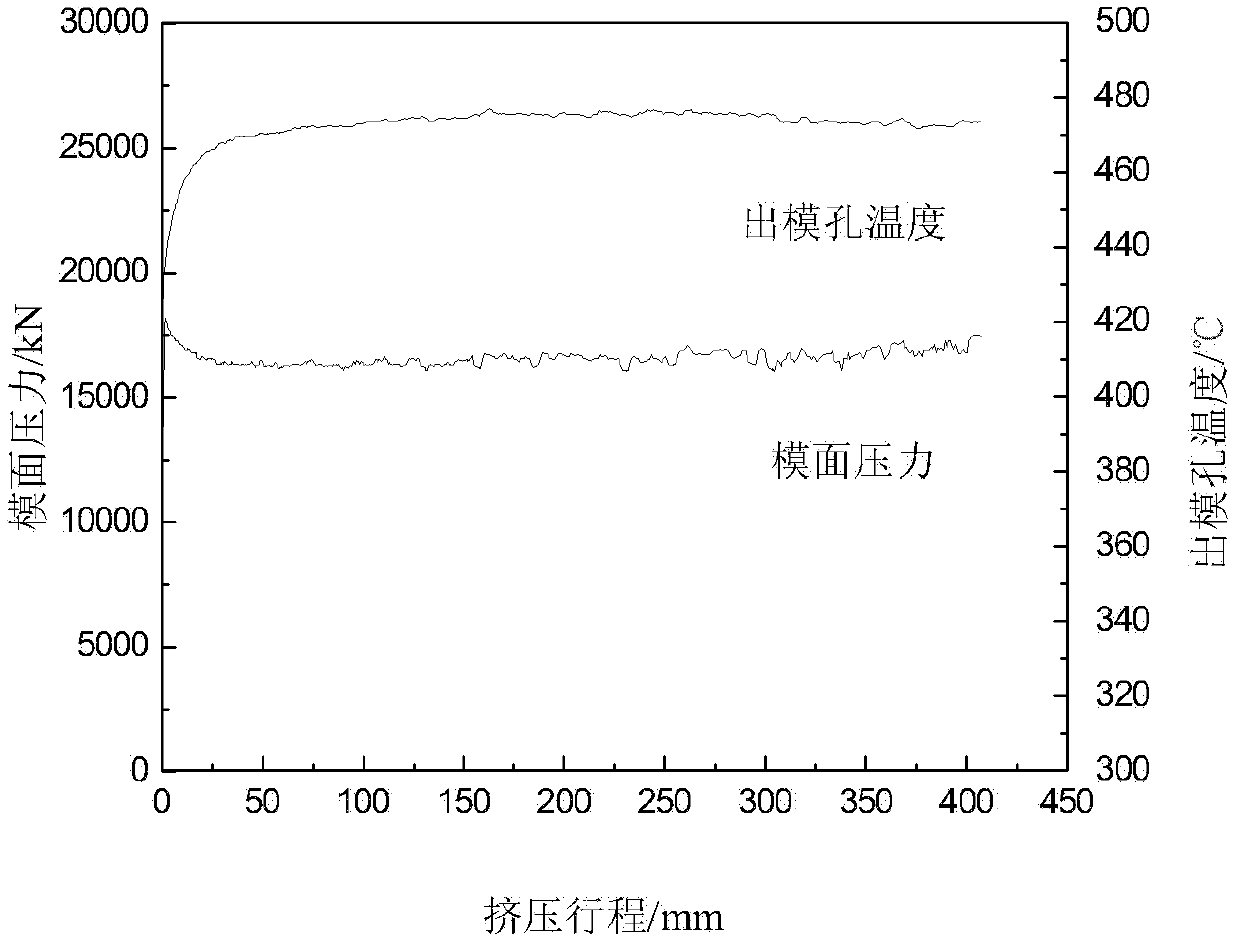

[0082] Example 1: Isothermal Extrusion of 7050 Aluminum Alloy Bar

[0083] (1) To extrude 7050 aluminum alloy rods with a diameter of Φ80mm, the diameter of the extrusion cylinder is Φ300mm, the length of the extrusion blank is 500mm, the diameter of the die hole is Φ80mm, the length of the working belt is 8mm, and the extrusion ratio is 14.

[0084] (2) According to production experience and data, determine the maximum allowable temperature T of 7050 aluminum alloy extrusion die hole 1 475°C, billet heating temperature T 0415°C, extruded gasket temperature T d It is 395°C (generally, the actual temperature of the extruded gasket is about 20°C lower than the billet temperature).

[0085] (3) Use formula (1) to calculate ΔT as 60°C, and then determine the extrusion speed V by formula (2) and formula (4) j It is 1.32mm / s.

[0086] (4) According to the extrusion speed V j , billet heating temperature T 0 and gasket temperature T d , calculate the heating temperature T c I...

Embodiment 2

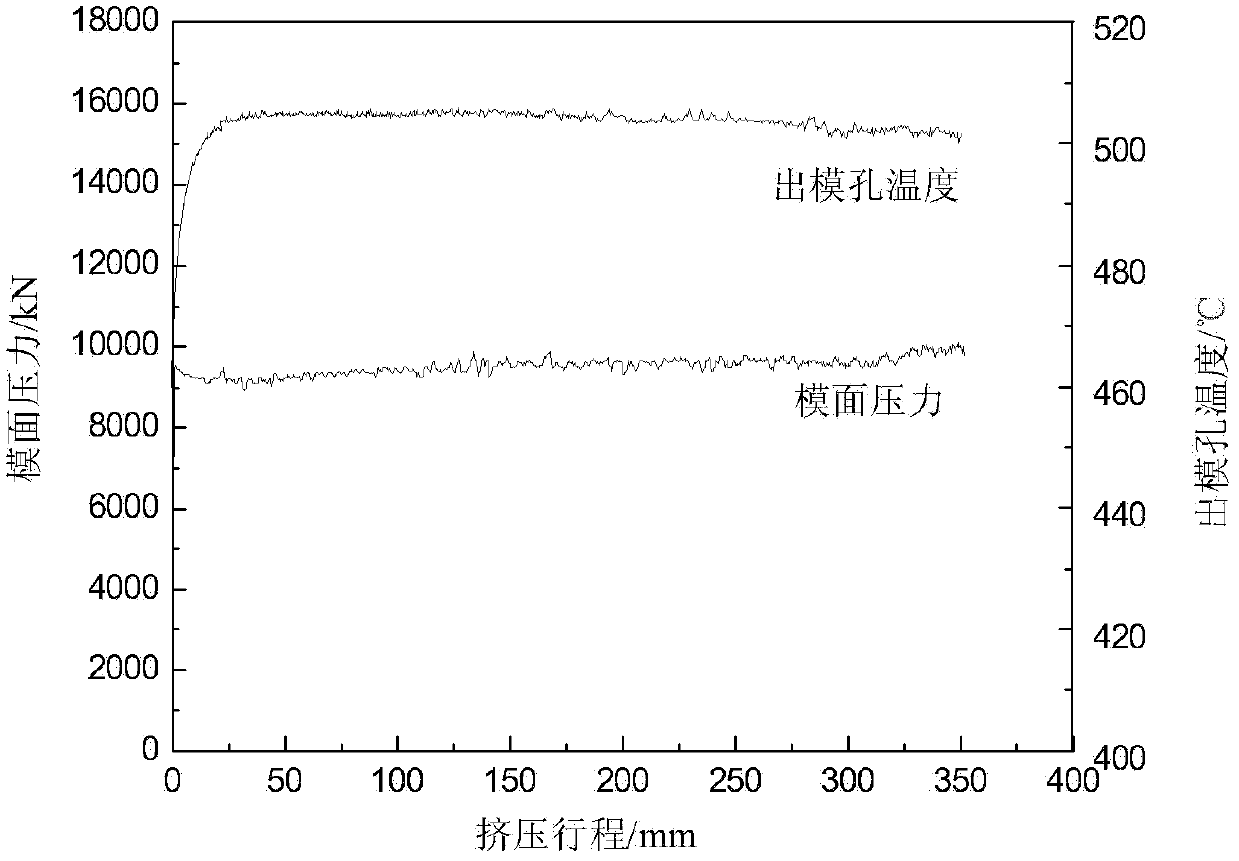

[0089] Embodiment 2: 2024 aluminum alloy rod isothermal extrusion

[0090] (1) To extrude 2024 aluminum alloy rods with a diameter of Φ60mm, the diameter of the extrusion cylinder is Φ240mm, the length of the extrusion blank is 400mm, the diameter of the die hole is Φ60mm, the length of the working belt is 6mm, and the extrusion ratio is 16.

[0091] (2) According to production experience and data, determine the maximum allowable temperature T of 2024 aluminum alloy extrusion die hole 1 500°C, billet heating temperature T 0 460°C, extruded gasket temperature T d It is 440°C.

[0092] (3) Use formula (1) to calculate ΔT as 40°C, and then determine the extrusion speed V by formula (2) and formula (4) j It is 1.18mm / s.

[0093] (4) According to the extrusion speed V j , billet heating temperature T 0 and gasket temperature T d , calculate the heating temperature T c It is 445°C.

[0094] (5) According to the extrusion process parameters determined above, the finite eleme...

Embodiment 3

[0095] Embodiment 3: 7050 aluminum alloy L-shaped profile isothermal extrusion

[0096] (1) extrusion attachment Figure 4 For the 7050 aluminum alloy L-shaped profile shown, the diameter of the extrusion cylinder is Φ190mm, the length of the extrusion billet is 250mm, and the extrusion ratio is 18.7.

[0097] (2) According to production experience and data, determine the maximum temperature T when 7050 aluminum alloy is extruded from the die hole 1 475°C, billet heating temperature T 0 420°C, extruded gasket temperature T d is 400°C.

[0098] (3) Use formula (1) to calculate ΔT as 55°C, and then determine the extrusion speed V by formula (2) and formula (4) j is 0.75mm / s.

[0099] (4) According to the extrusion speed V j , billet heating temperature T 0 and gasket temperature T d , the heating temperature T of the extrusion cylinder can be determined by formula (5) ~ formula (8) c It is 402°C.

[0100] (5) According to the extrusion process parameters determined abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com