Conveying structure used for triangular magnesium pipe sintering equipment

A sintering equipment, triangular technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of inability to compact magnesium powder, low shrinkage rate, and inability to adapt to the cross-sectional shape of triangular magnesium tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

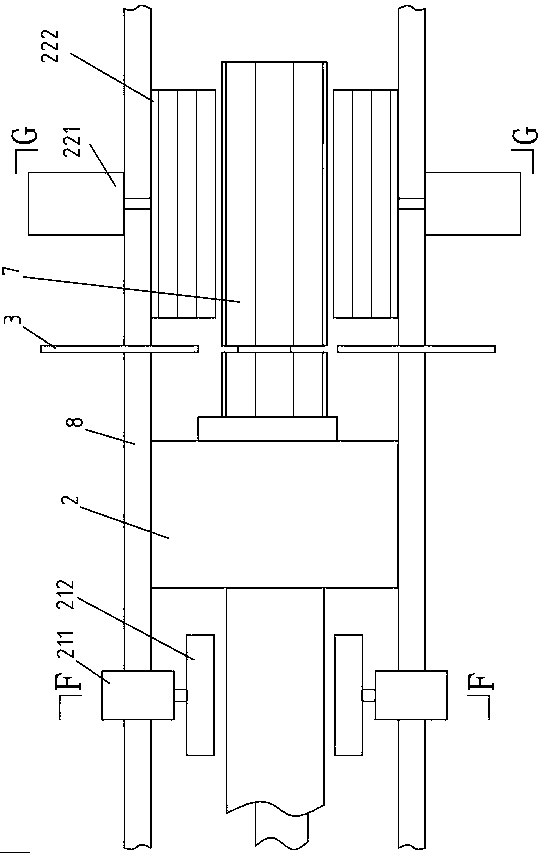

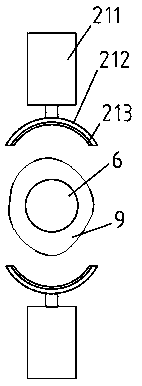

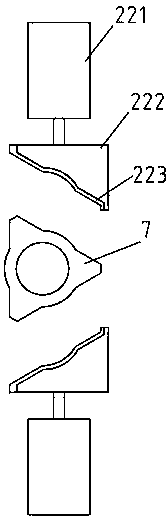

[0025] As shown in the figure, a conveying structure for triangular magnesium tube sintering equipment includes a stirring tank 1 capable of mixing high-purity magnesium oxide powder, adhesive, and tap water into a dough-like irregular mixture 9, and a stirring tank 1 The bottom outlet is connected with an extruder 2 capable of extruding the dough-like irregular mixture 9 into a triangular magnesium tube with an inverted triangular cross-section. The wet triangular magnesium tube is cut into a cutting machine 3 for segmental triangular magnesium tube 7, and the side of the cutting machine 3 is connected with a dryer 4 and a calciner 5 in sequence; The irregular mixture has a hollow inner cavity and can be transported to the subsequent extruder 2 and cutting machine 3 through the hollow inner cavity along the guide core; the two sides of the extruder 2 are symmetrically provided with guide rails 8, and the front of the entrance of the extruder 2 is provided with can The irregul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com