A kind of forging method of high-speed train axle box body

A technology of axle box and pre-forging, which is applied to railway car body parts, manufacturing tools, vehicle parts, etc. It can solve the problems that have not yet been involved in the distribution of the volume of the forging of the axle box, the distribution of the forging streamline of the shape of the pre-forging, and achieve the deformation of the forging Good uniformity, reduced extrusion load, and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

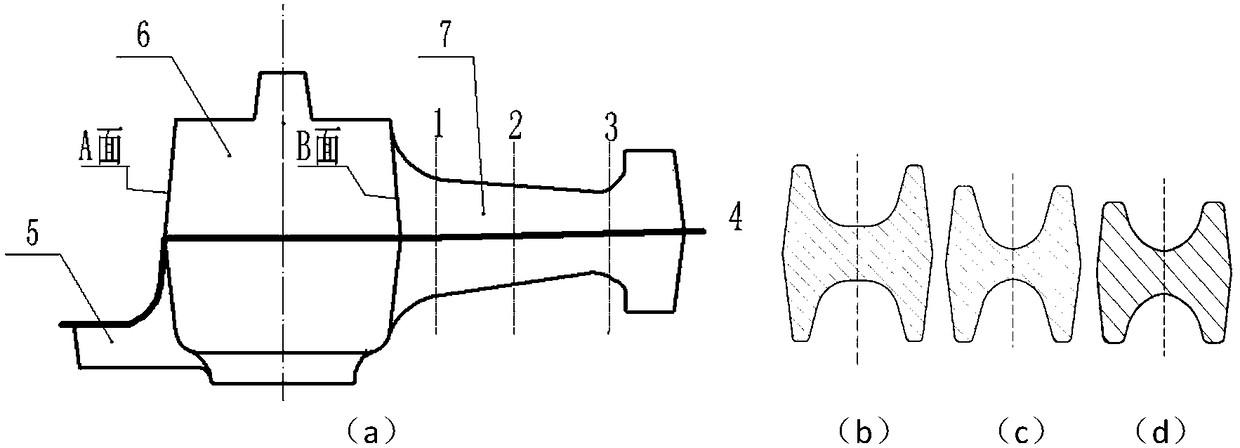

[0043] like figure 1 Shown is the outline diagram of the main geometric features of the high-speed train axle box forging. The axle box forging is composed of the end part 5 of the axle box forging, the middle part 6 of the axle box forging and the rod part 7 of the axle box forging (referred to as the end part 5 , middle part 6 and rod part 7), the material is 7050 high-strength aluminum alloy, and the total volume of the axle box hot forging (including flash) is about 3.404×10 7 mm 3 , the middle part 6 occupies the largest volume, about 2.5515×10 7 mm 3 , the volume of rod 7 is 6.749×10 6 mm 3 , while the volume of end 5 is only 1.736×10 6 mm 3 , it can be seen that the volume of each part is very different. In addition, the maximum contour lines of the end part 5, the middle part 6 and the rod part 7 are not on the same horizontal l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com