Patents

Literature

32results about How to "Guaranteed full filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

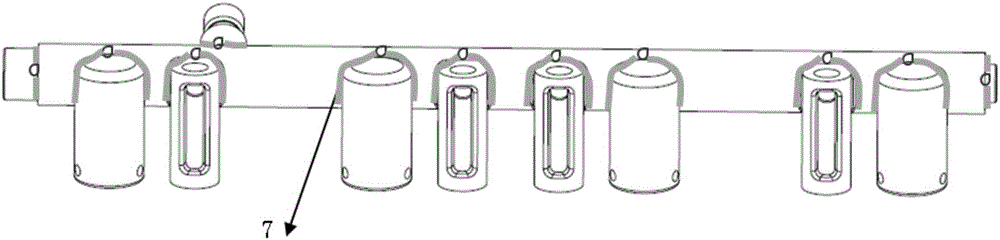

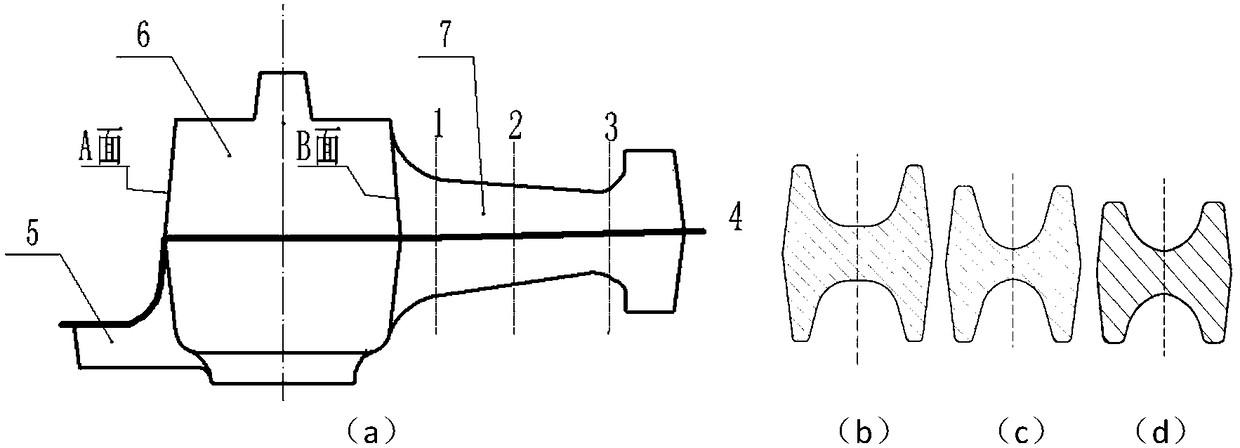

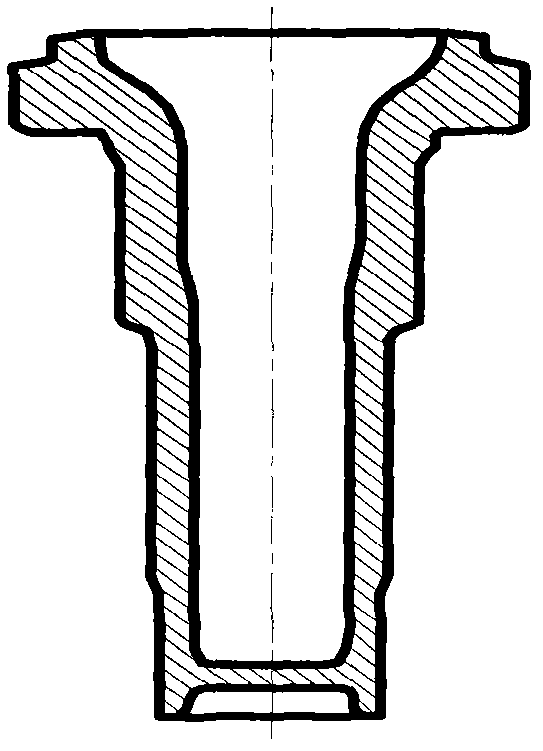

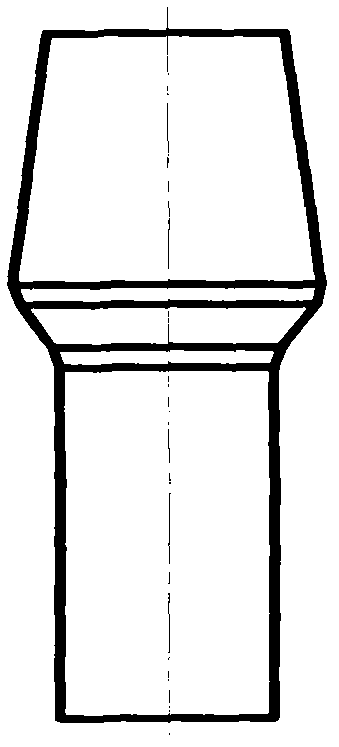

Technical method for forming semi-axle housing tube for large-diameter flange

ActiveCN102513791AReduce equipment investment costsReduce process difficultyForming forceEngineering

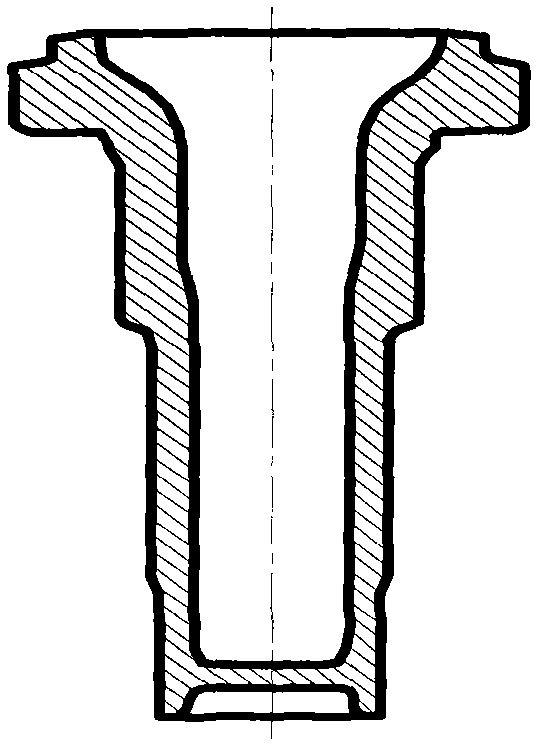

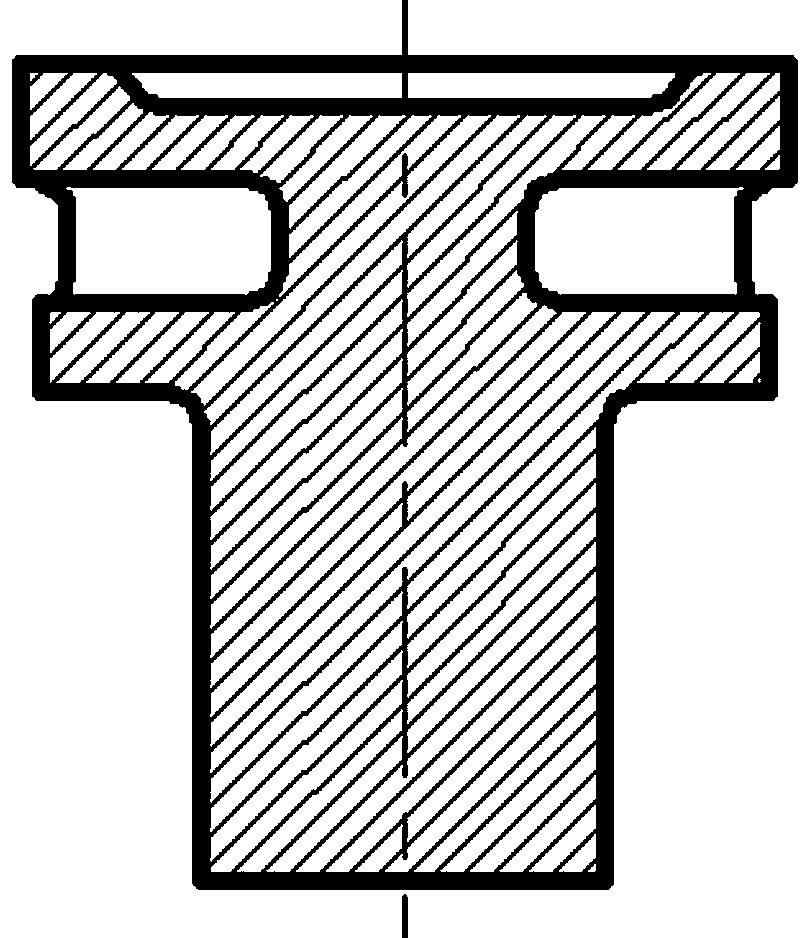

The invention discloses a technical method for forming a semi-axle housing tube for a large-diameter flange. The technical method comprises the following steps of: sawing hot-rolled round steel serving as a blank, heating, and upsetting by using an extruding machine; performing rotary forging for forming by using a rotary forging press; and performing forward extrusion once and backward extrusion to form a forged piece of the semi-axle housing tube. According to technical method, in the maximum process step of forming force required by the semi-axle housing tube, the flange is formed by the rotary forging press; and only an outer step axle and an inner step hole are formed when the head flange is formed by the rotary forging and is extruded. The technical method has the advantages that: the full filling of flange corners is ensured effectively, the investment cost of equipment is reduced effectively, the process difficulty of the subsequent extrusion process step is reduced, the coaxiality of finished products is easy to ensure, and the production cost of the forged piece is reduced while the yield of the products is improved.

Owner:SHIYAN YUANJUN IND & TRADE

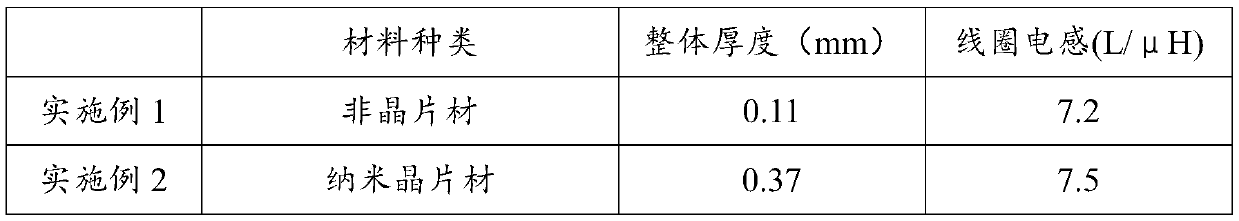

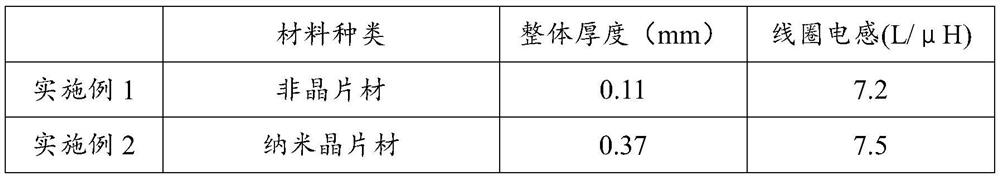

Heat-dissipating magnetic conductive sheet for wireless char and preparation method thereof

ActiveCN110415952AReduce lossesGuaranteed full fillingTransformers/inductances coolingTransformersAdhesiveCopper foil

The invention belongs to the technical field of wireless charging components, in particular to a heat-dissipating magnetic conductive sheet for wireless charging. The heat-dissipating magnetic conductive sheet comprises a magnetic conductive substrate, an insulating heat conductive adhesive layer, a graphite layer and a copper foil. The magnetic conductive substrate is composed of a plurality of amorphous or nanocrystalline fragment units. A gap is formed between two adjacent amorphous or nanocrystalline fragment units. The insulating heat conductive adhesive layer is arranged in the gap and on the surface of the amorphous or nanocrystalline fragment units. The graphite layer is arranged between the insulating heat conductive adhesive layer and the copper foil. Compared with the sheets inthe prior art, the heat-dissipating magnetic conductive sheet has good shielding performance and heat dissipation performance. In addition, the invention also provides a preparation method of the heat-dissipating magnetic conductive sheet for wireless charging.

Owner:DONGGUAN HONGYI THERMAL CONDUCTMTY MATERIAL CO LTD

Novel 4Al3 aluminum alloy used for vacuum soldering

ActiveCN102357744AIncrease contentLow melting pointWelding/cutting media/materialsSoldering mediaTrace elementSoldering

The invention provides a novel 4Al3 aluminum alloy used for vacuum soldering, which can solve the problems of high soldering temperature and undesirable soldering quality of the traditional 4Al3 aluminum alloy used for vacuum soldering, and can solve the problem that a surface oxide film of a workpiece can be removed only by Mg-contained soldering flux by the 4Al3 aluminum alloy to carry out vacuum soldering, and the vacuum soldering technology can be simplified. The novel 4Al3 aluminum alloy is characterized by comprising the following raw materials according to 100 parts by weight: more than 8.2-9 parts of Si, 0-6 parts of Fe, 0-0.2 part of Cu, 0-0.2 part of Mn, 0.08-0.2 part of Mg, 0-0.2 part of Zn, 0-0.15 part of Ti, 0-0.15 part of other impurity trace elements and the balance of Al.

Owner:YINBANG CLAD MATERIAL

Plant cushion for filling plant growing mediums and application thereof

ActiveCN102972125AGuaranteed full fillingReduce usageCultivating equipmentsSeed arrangmentsSurface layerSlurry

The invention provides a plant cushion for filling plant growing mediums. The plant cushion comprises a plurality of filling bags which are integrally sewed; each filling bag is formed by a bottom layer and a surface layer, which are sewed together; the surface layer of each filling bag is provided with a feeding opening; and each filling bag is filled with the plant growing mediums. The invention further provides a method for applying the plant cushion to treat a slope surface. The plant cushion disclosed by the invention is used for filling slurry-shaped plant growing mediums into filler bags; the construction is simple and the efficiency is high; water in slurry-shaped materials can be extruded to flow out in a filling process so as to guarantee that the filling bags are fully filled; and compared with a plant growing medium spraying greening technology, the efficiency is improved by 2-3 times and the cost is comprehensively reduced by 30-40%. After the construction is finished, the gap between the bags can be used for storing materials including dry branches and fallen leaves, humus, soil and the like and the water and soil loss prevention effect is obvious. Plant seedlings can grow from surface-layer materials; and meanwhile, technologies of transplant, cottage and the like are combined so that plant varieties are enriched.

Owner:江苏绿之源生态建设有限公司

Surface cleaning method before brazing repairing of single crystal turbine guide vane crack

InactiveCN109434233AWill not recrystallizeEfficient removalSoldering apparatusGas phaseSurface cleaning

The invention relates to a surface cleaning method before brazing repairing of a single crystal turbine guide vane crack. The surface cleaning method before brazing repairing of the single crystal turbine guide vane crack is characterized in that a method combining physics and chemistry is adopted to remove a carbon deposition layer and an aluminizing layer on the surface of a vane, to remove an oxidation film on the surface of the crack and to provide a clean surface for final brazing repairing. The surface cleaning method comprises the steps of (1) sand blasting treatment, (2) chemical cleaning, (3) aluminized coating stripping, (4) gas phase fluorinion cleaning, and (5) vacuum purification treatment. The surface cleaning method before brazing repairing of the single crystal turbine guide vane crack is suitable for an alitizing single crystal high temperature alloy turbine guide vane, the vane after being cleaned through the surface cleaning method has a good brazing repairing effect, and a repaired vane body has no recrystallization; the surface cleaning technical problem of single crystal high temperature alloy turbine guide vane non-recrystallization repairing is solved, and conspicuous innovativeness is achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Copper brazing manufacturing method of fuel distribution pipe and radial connecting part of main pipe

InactiveCN106424999AImprove uniformityGuaranteed full fillingSoldering apparatusFuel injection apparatusFuel distributionAdhesive

The invention discloses a copper brazing manufacturing method of a fuel distribution pipe. The method is characterized in that press fitting and projection welding, instead of argon-arc welding or laser welding, are carried out to position, so that the uniformity of welding gaps among parts can be effectively improved, and the consistency of the quality of the welding gaps formed after the copper brazing can be ensured; a built-in copper ring or copper sheet is used and replaces externally-paved copper adhesive, so that copper can permeate from inside to outside during the copper brazing process, and as a result, the welding gaps can be fully filled with the copper adhesive; in addition, the flowing conidtio of the copper adhesive in the welding gaps can be inspected through the appearance rather than a destructive way, so that he production cost can be reduced. The invention discloses a radial connecting part of the main pipe.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

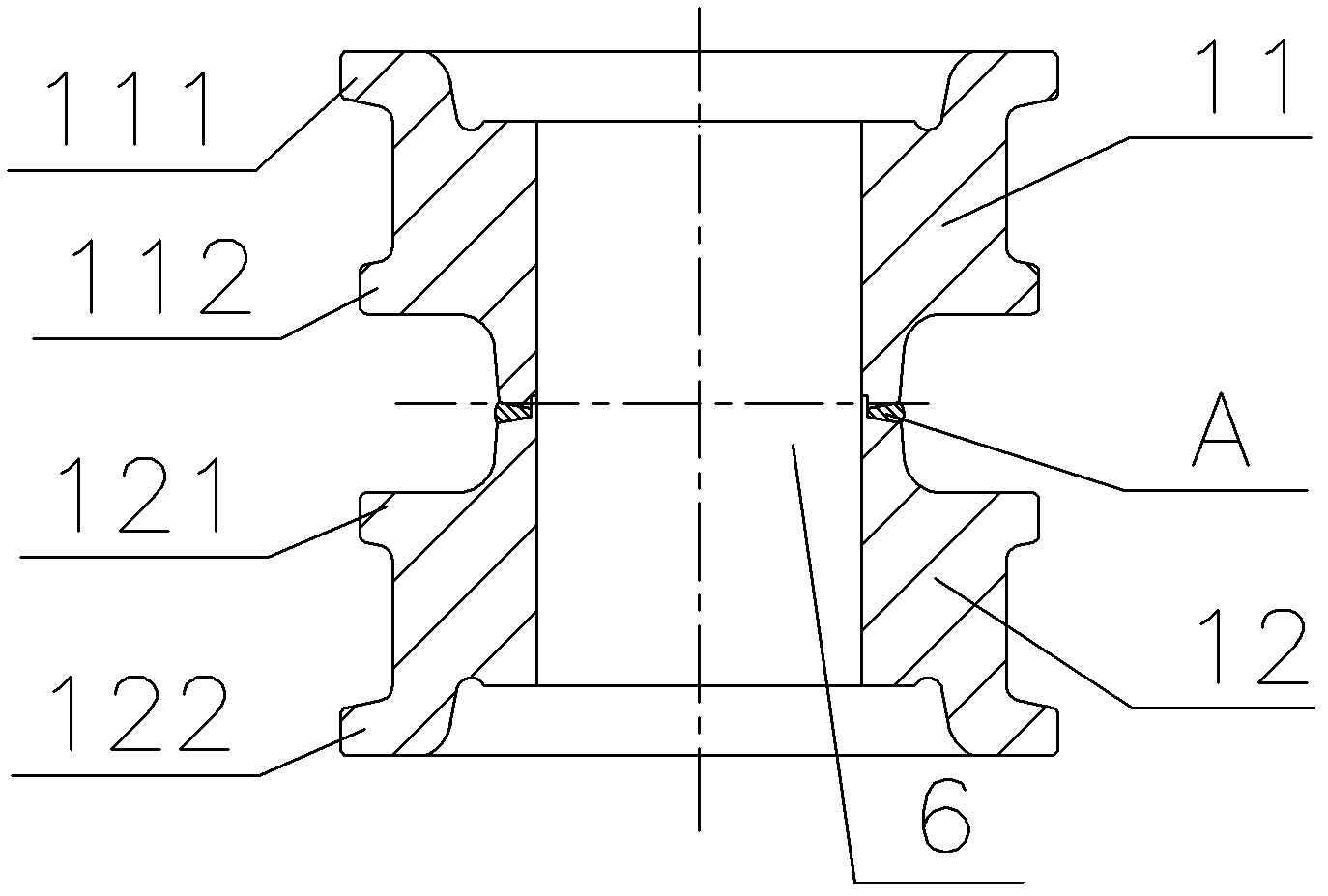

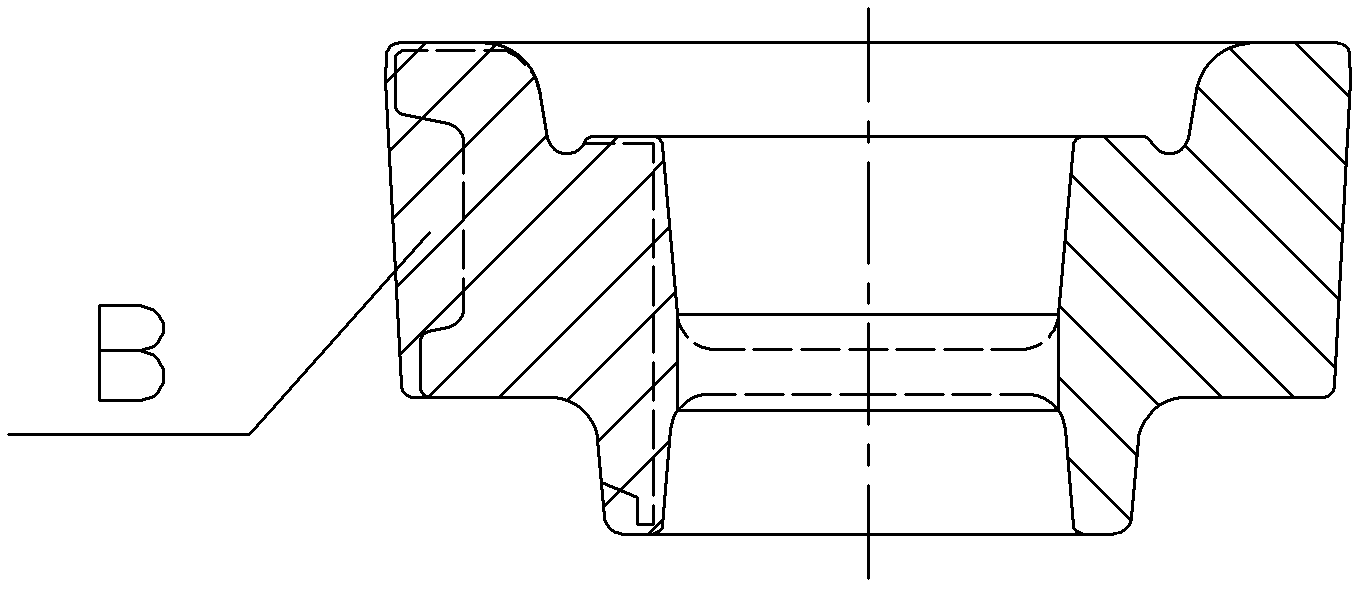

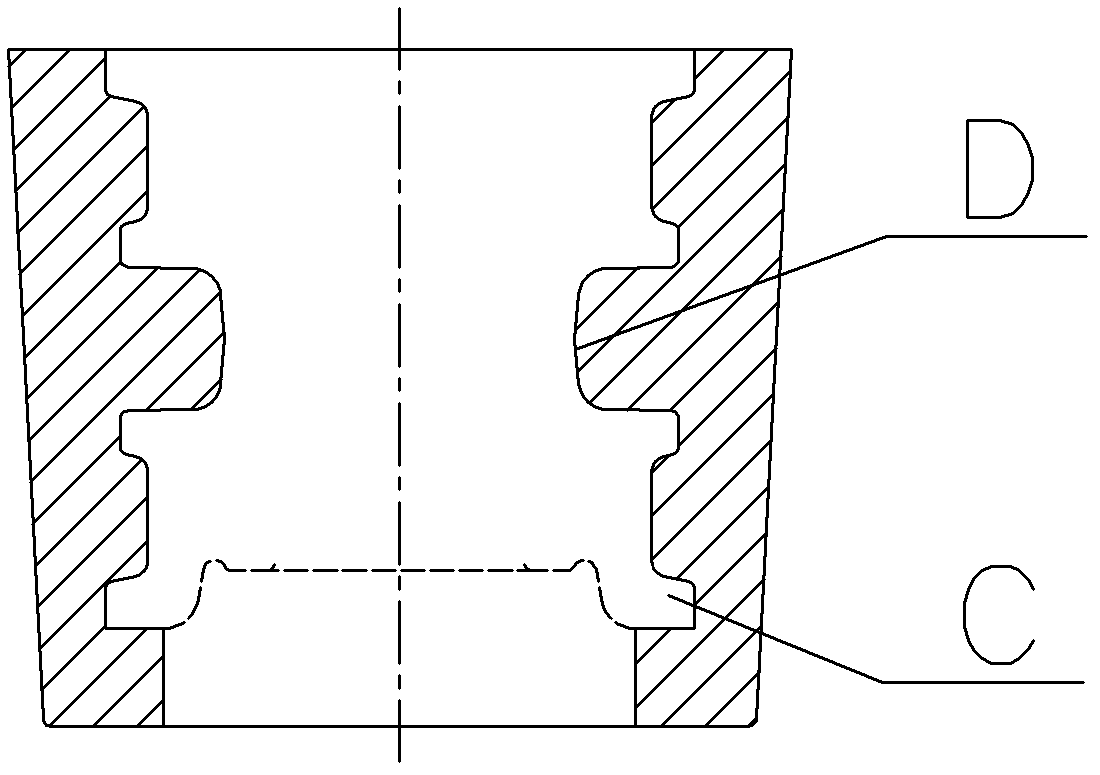

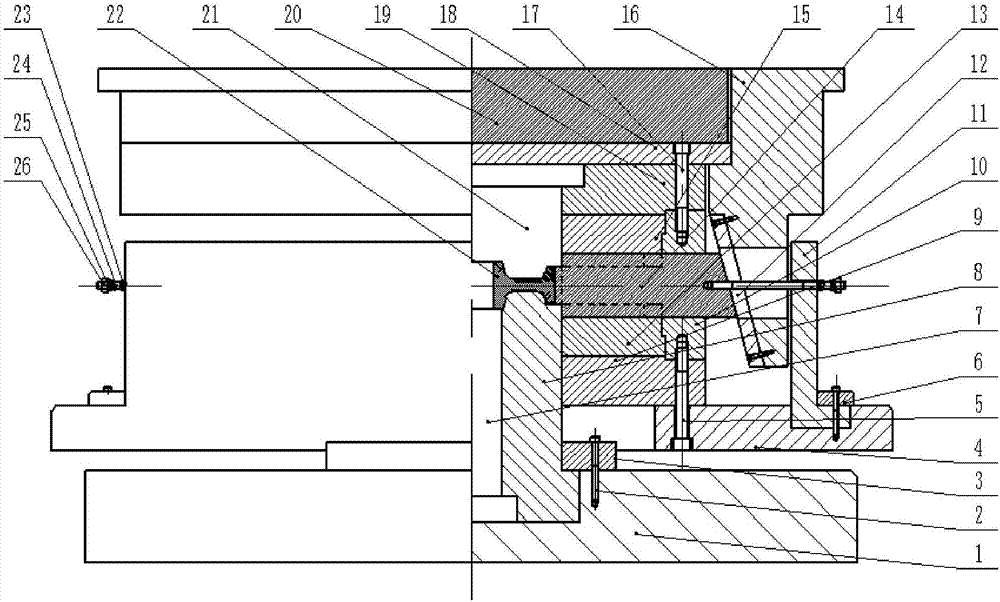

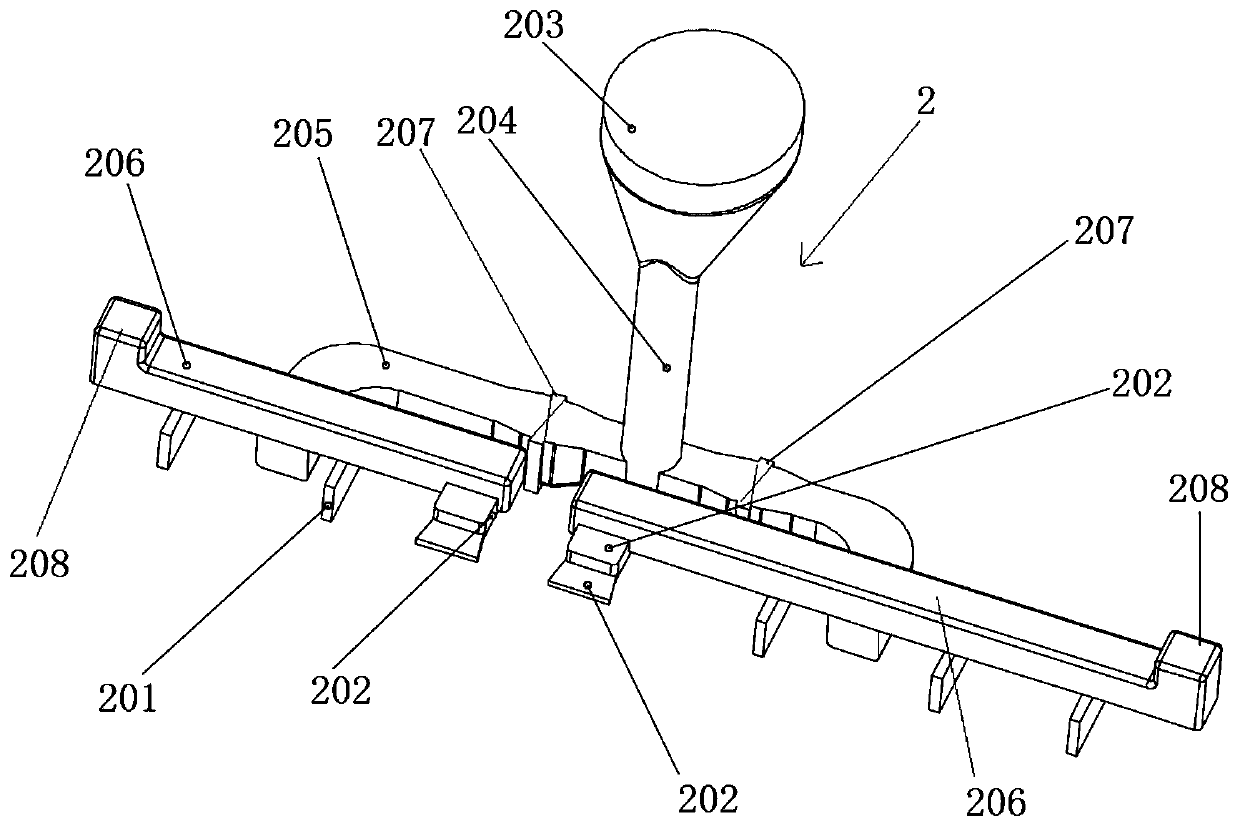

Multi-directional numerical control linkage precision forming process of transmission planetary carrier

ActiveCN109433985ALow costGuaranteed positioning accuracyForging/hammering/pressing machinesNumerical controlHigh volume manufacturing

The invention discloses a multi-directional numerical control linkage precision forming process of a transmission planetary carrier. The process is characterized in that a heated metal bar is formed through numerical control linkage of an upper punch, a front punch, a rear punch, a left punch and a right punch in five directions, and a precise forging of the transmission planetary carrier with thecomplicated shape is prepared in a single station and through one-time heating and multi-directional forming; and the front punch, the rear punch, the left punch and the right punch in a die are arranged in four side square holes in a female die, and are not separated all the time in the forming process. The forging forming planet carrier forge piece is small in machining allowance, the production efficiency is greatly improved, the cost can be reduced to a great extent, and a certain foundation can be laid for mass production of the current part.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

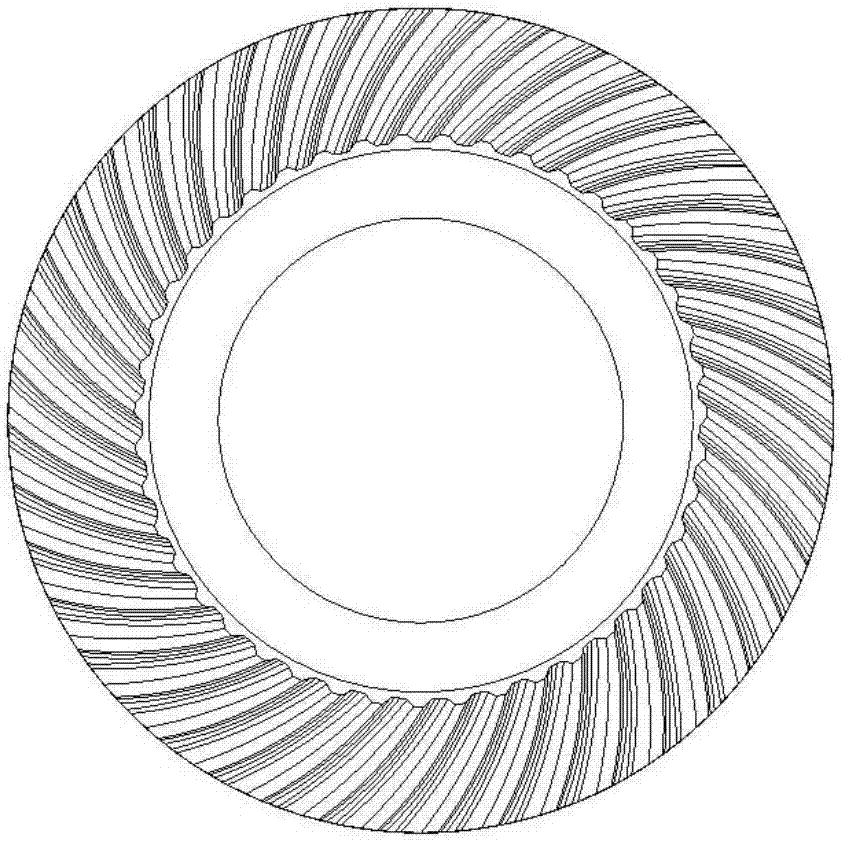

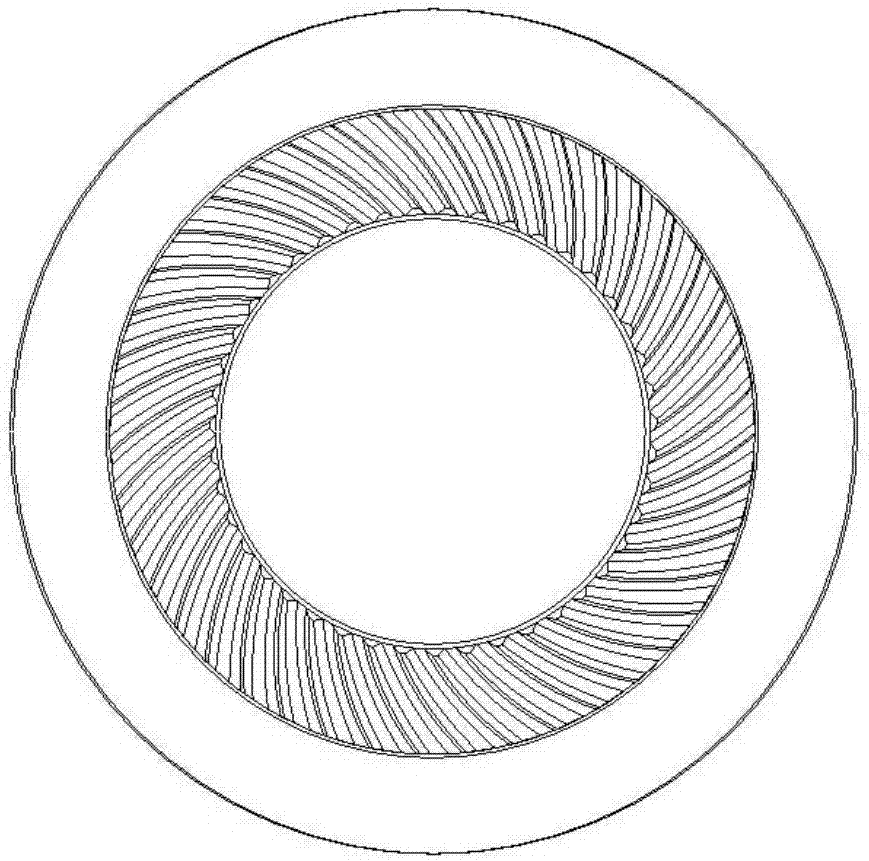

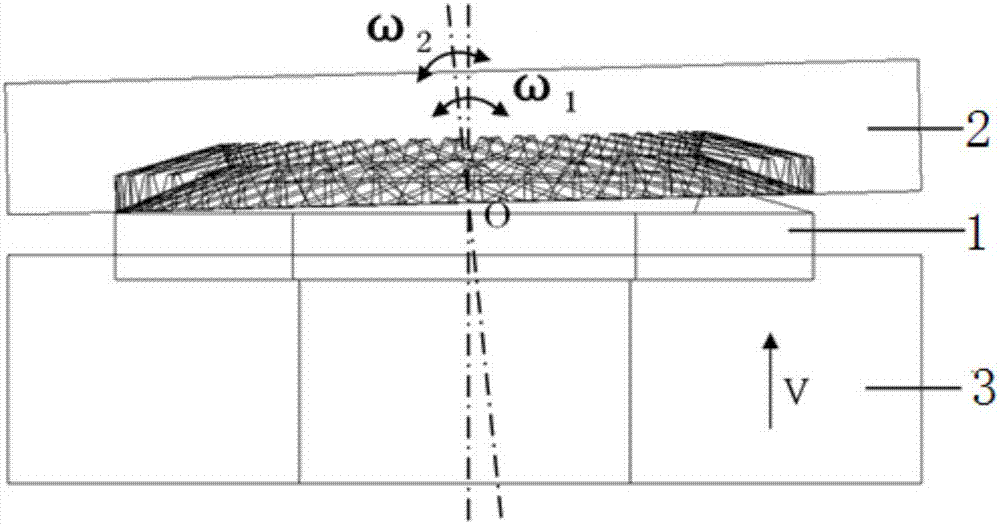

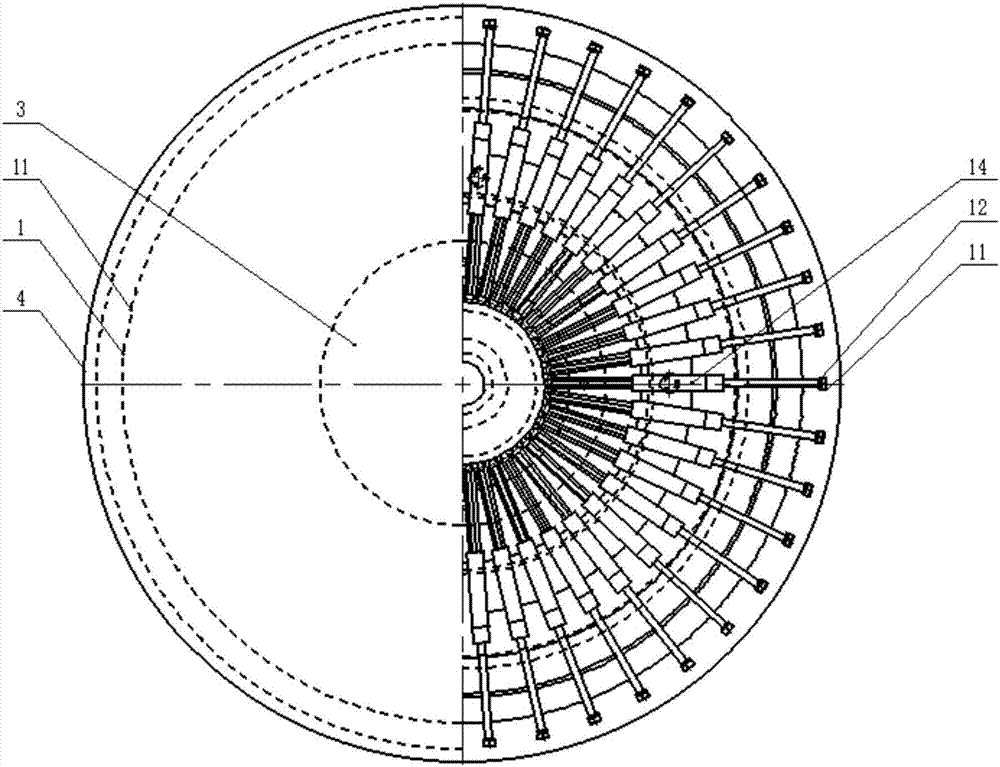

Spiral bevel gear swing rolling formation method

ActiveCN107008836AImprove mechanical propertiesSpeed up the flowForging/hammering/pressing machinesWheelsMechanical engineeringForming force

The invention discloses a spiral bevel gear swing rolling formation method. A spiral bevel gear is formed in a swing rolling manner by a swing rolling mold; the swing rolling mold includes a swing head and a swing rolling lower mold oppositely arranged up and down; the swing head performs a circular trajectory motion; the swing rolling lower mold performs an upward linear feeding motion; and the swing rolling formation method comprises the following steps: a spiral bevel gear blank is placed between the swing head and the swing rolling lower mold; a tooth shape of the spiral bevel gear is formed through swinging of the swing head; and the spiral bevel gear and a back part opposite to the tooth shape are formed by the swing rolling lower mold. The spiral bevel gear swing rolling formation method can refine grains and densify streamlines to greatly improve the gear mechanical performances, is low in forming force, high in tooth shape precision, long in mold life and liable to demold, and has the advantages of high production efficiency, high material utilization rate and low cost.

Owner:WUHAN UNIV OF TECH

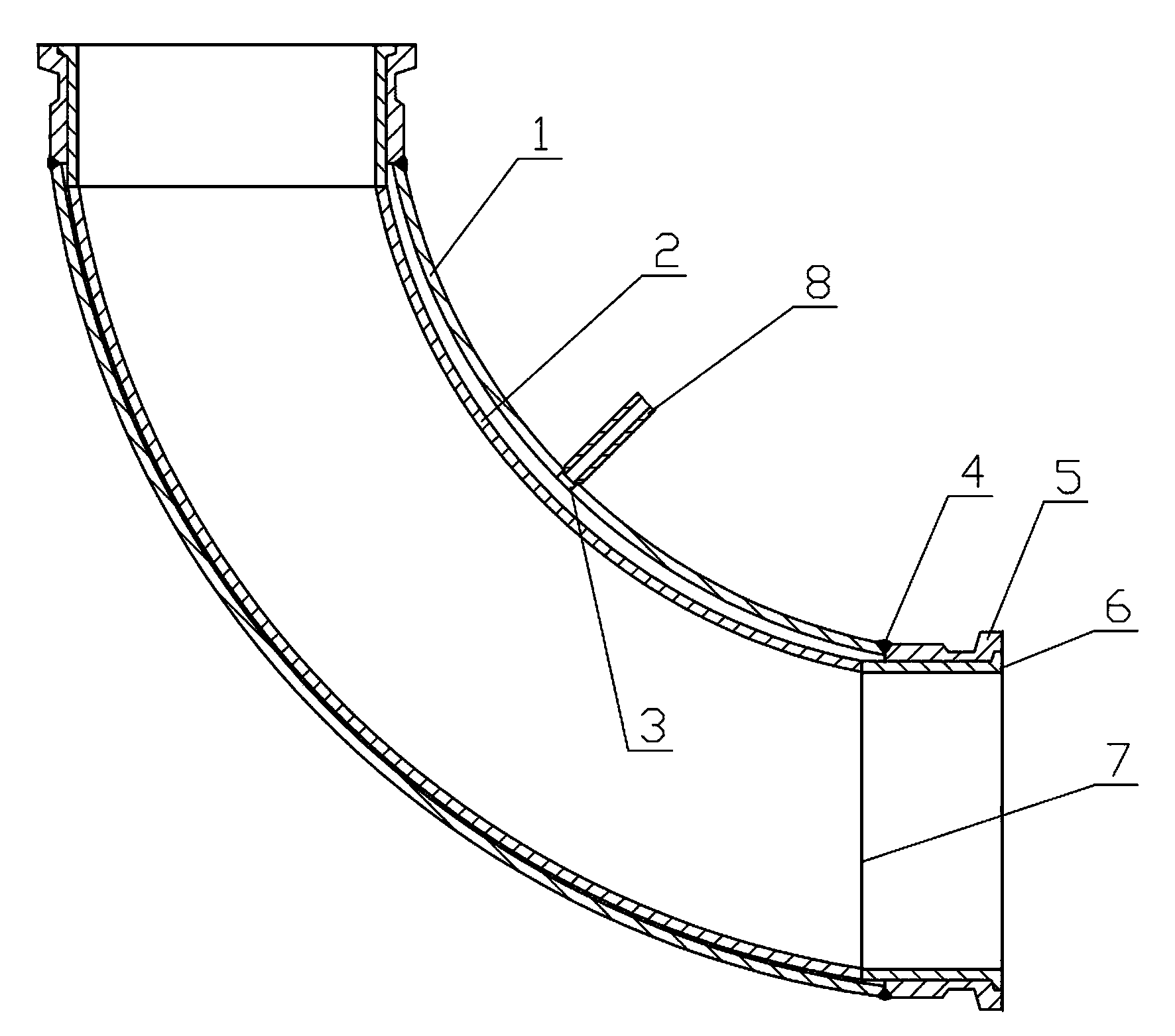

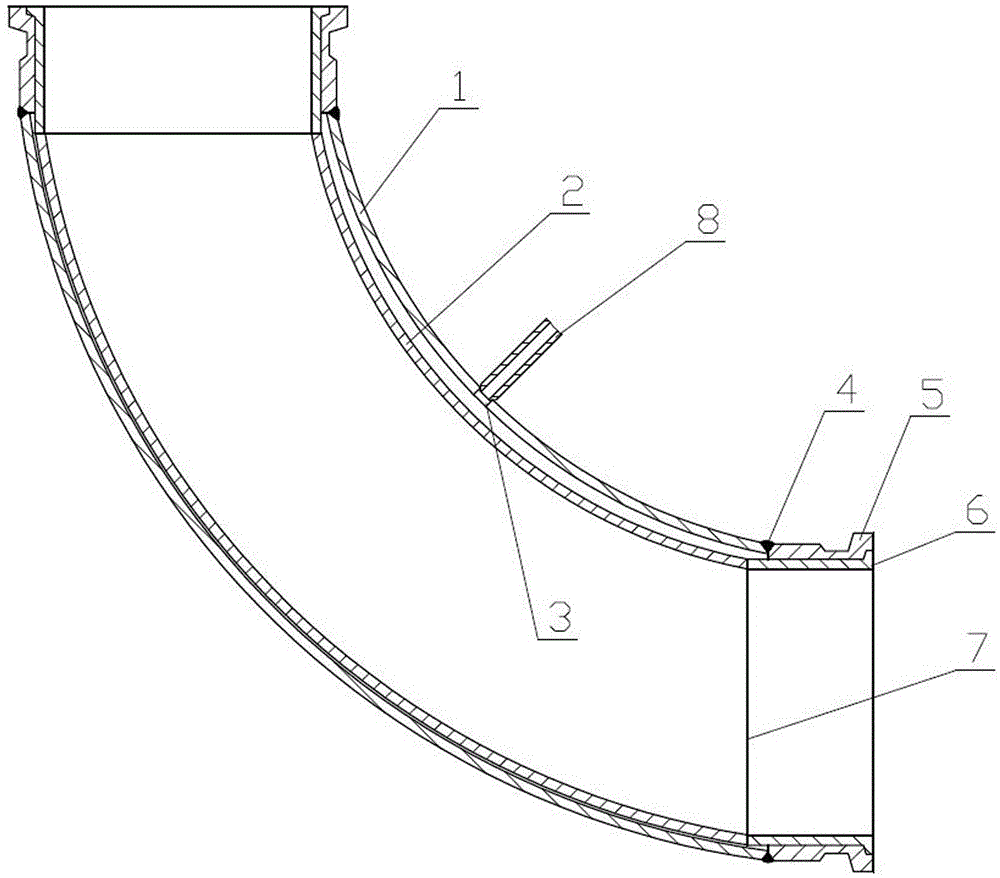

Crack filling method of compound bent pipe and abrasion-resistant compound bent pipe

The invention relates to a crack filling method of a compound bent pipe and the abrasion-resistant compound bent pipe, and belongs to the technical field of machining. The crack filling method of the compound bent pipe and the abrasion-resistant compound bent pipe resolve the problems that an interval exists between a lining and an outer shell in an existing abrasion-resistant compound bent pipe, so that in the use process, more than 90 percent of compound bent pipes will crack and can not be used any longer. The crack filling method is characterized in that (1) the lining and the outer shell are combined in a sleeved mode, and an injection hole is drilled in the outer shell; (2) two flanges are adopted and respectively comprise a flange inner ring and a flange outer ring, and after each flange inner ring and the corresponding flange outer ring are combined in a sleeved mode, the outer ends are welded into a whole; (3) the outer shell is welded to the flange outer rings, the lining and the flange inner rings are in clearance fit to form an assembly interval crack; (4) paste is injected from the injection hole through an injection gun to fill the interval between the lining and the outer shell; (5) after the paste is cured, plug welding is carried out on the injection hole. The crack filling method of the compound bent pipe has the advantage that the high chromium cast iron compound bent pipe is not prone to cracking when subjected to an impact load, and is mainly used for manufacturing the abrasion-resistant compound bent pipe.

Owner:XIANGYANG TO WIN MACHINERY

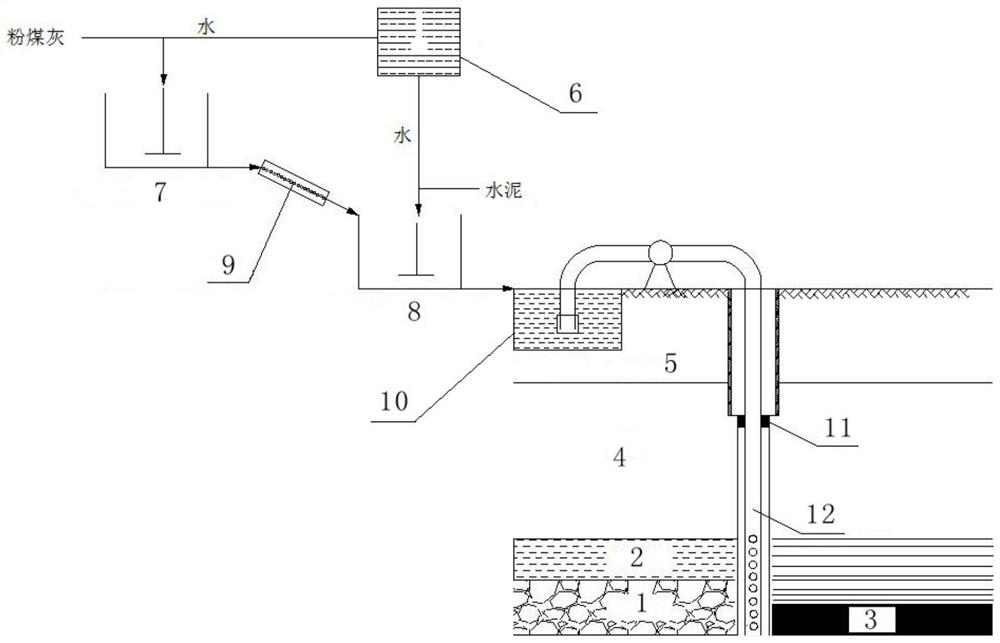

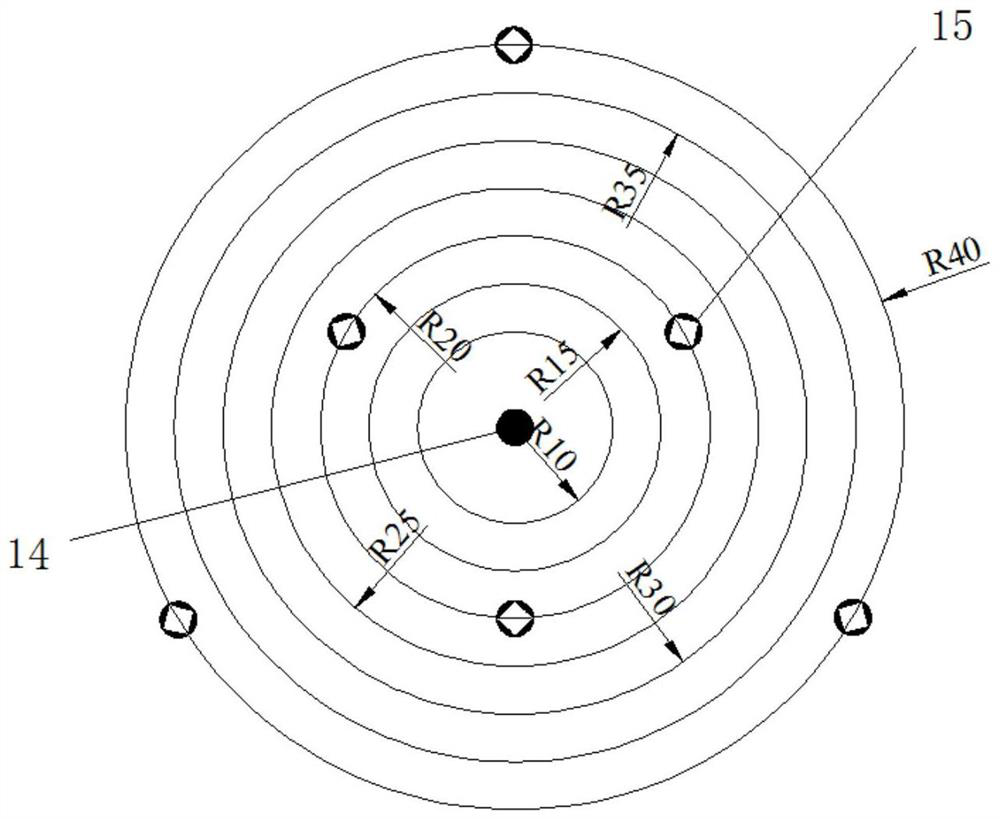

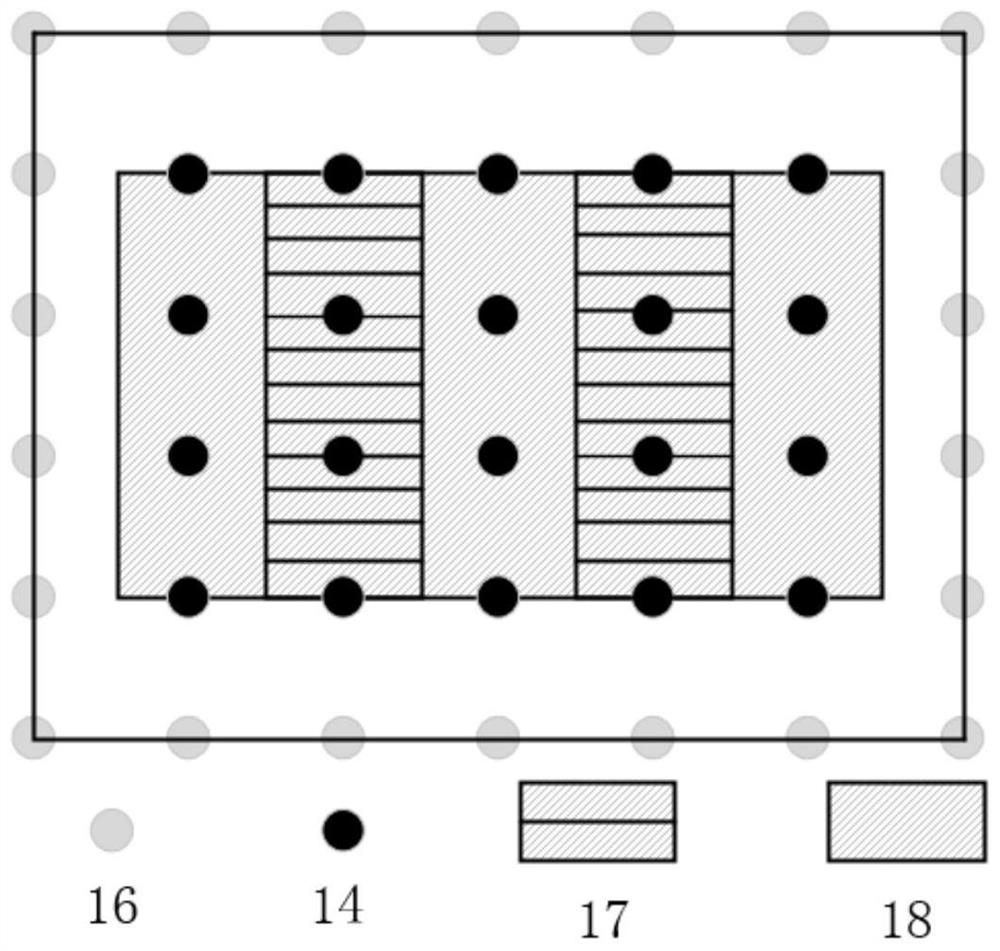

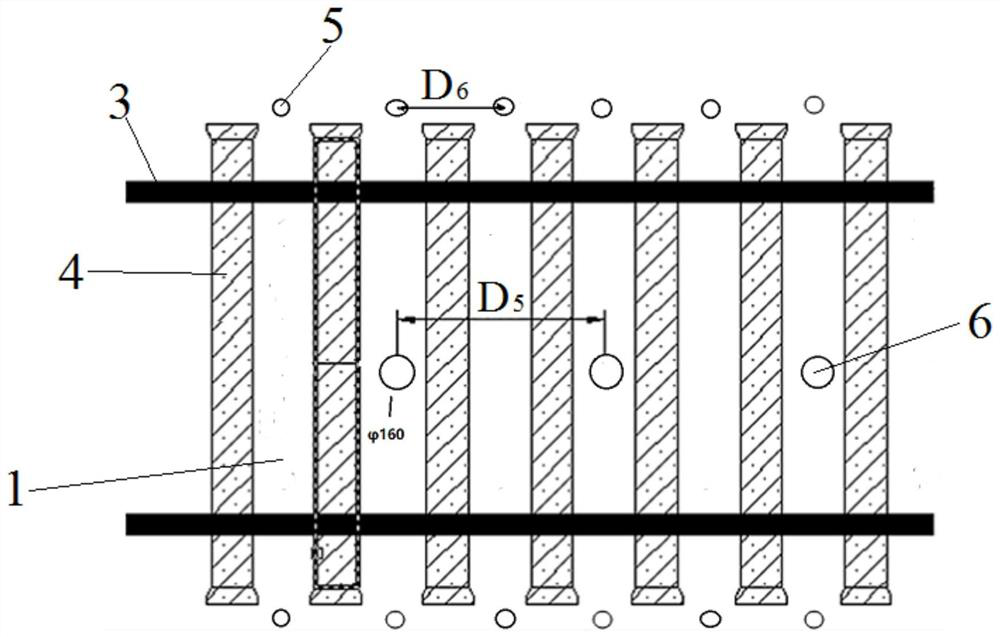

CO2 mineralization grouting method for old goaf

PendingCN114673551AReduce the amount of drilling workLow cost of grouting fillingMining devicesMaterial fill-upExhaust fumesSlurry

The invention discloses a CO2 mineralization grouting method for an old goaf, and belongs to the technical field of goaf treatment. Comprising the following steps that firstly, the goaf grouting range is divided into a straddling zone and a fissure zone, the grout diffusion radius of a caving zone and the grout diffusion radius of the fissure zone under the isobaric grouting condition are determined through experimental area grouting, the caving zone and the fissure zone share the same drill hole for grouting, the grout diffusion radius of the caving zone serves as an index to design the drill hole distance for grouting filling work, and the grouting filling work is completed; filling a caving zone and a fissure zone; then, a mineralizing material and industrial waste gas are injected into the goaf, injected mineralizing material slurry can react with the industrial waste gas, and the goaf is supported while the industrial waste gas is fixed. The industrial waste gas is injected into the goaf to react with the slurry to be sealed underground, the environmental pollution is effectively reduced, a product generated after the reaction with the slurry plays a role in supporting and protecting the goaf, and a positive role is played in environmental protection and treatment.

Owner:ANHUI UNIV OF SCI & TECH

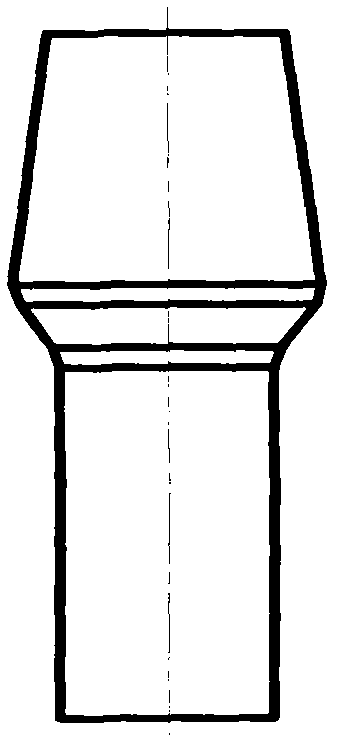

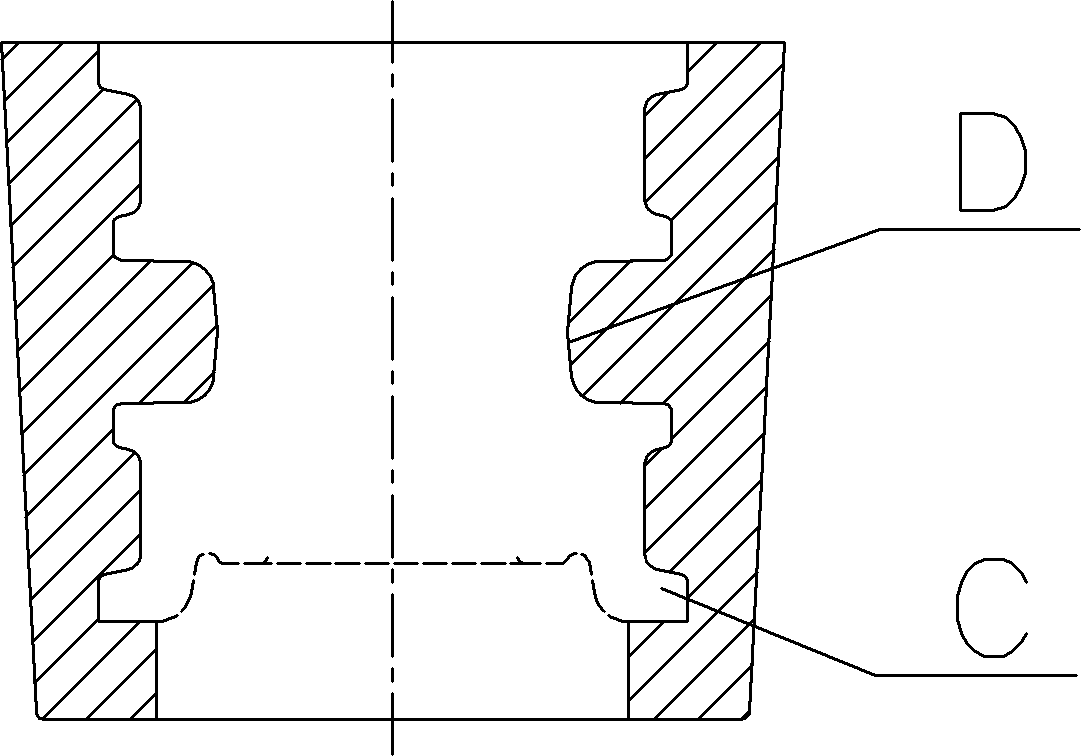

Method for forging roller for crawler excavator

The invention provides a method for forging a roller for a crawler excavator. The method comprises the following steps of: firstly heating a blank bar; secondly forging the upper half part of the roller through an initial forging die; thirdly, forming the lower half part of the roller through a final forging die, namely forging the two parts of the roller respectively by means of two sleeved dies, wherein the forged rollers have the same central axis and do not need to be welded. Besides, the method is capable of ensuring full filling of a forge piece and also capable of effectively avoiding the deformation failure of the die.

Owner:SHANGHAI YUNLIANG ENTERPRISE DEV

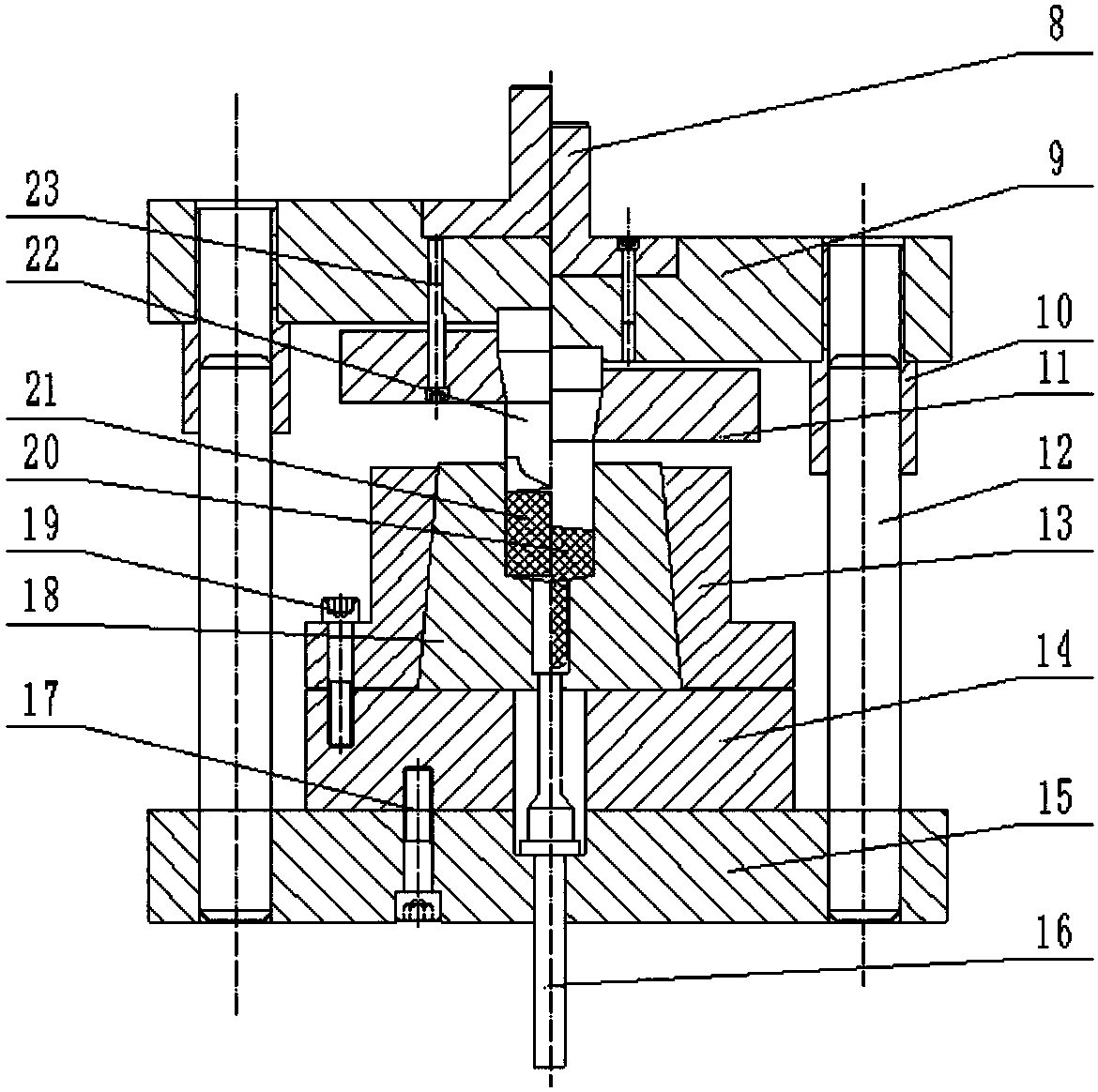

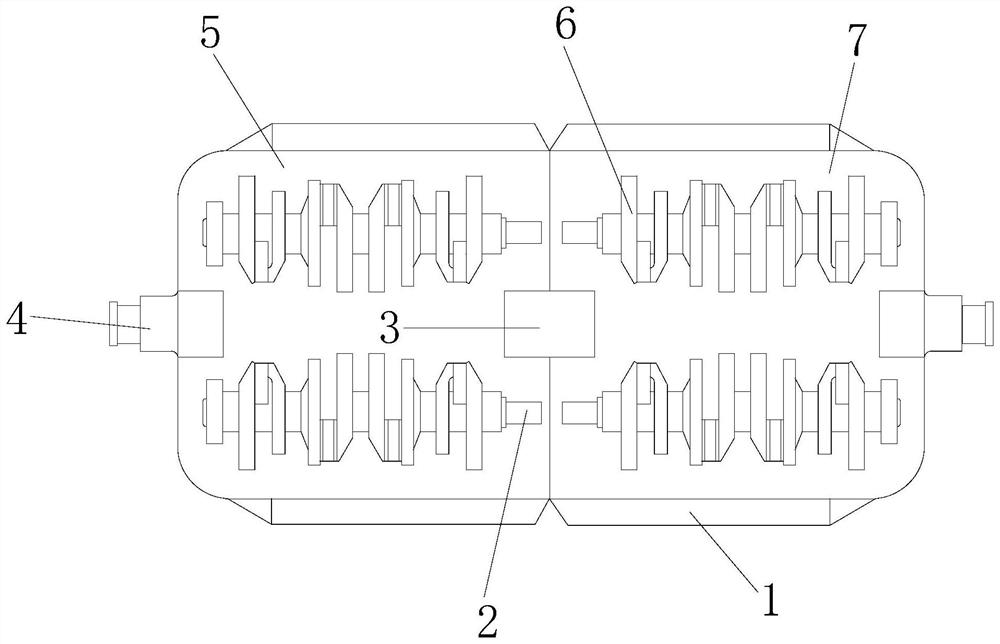

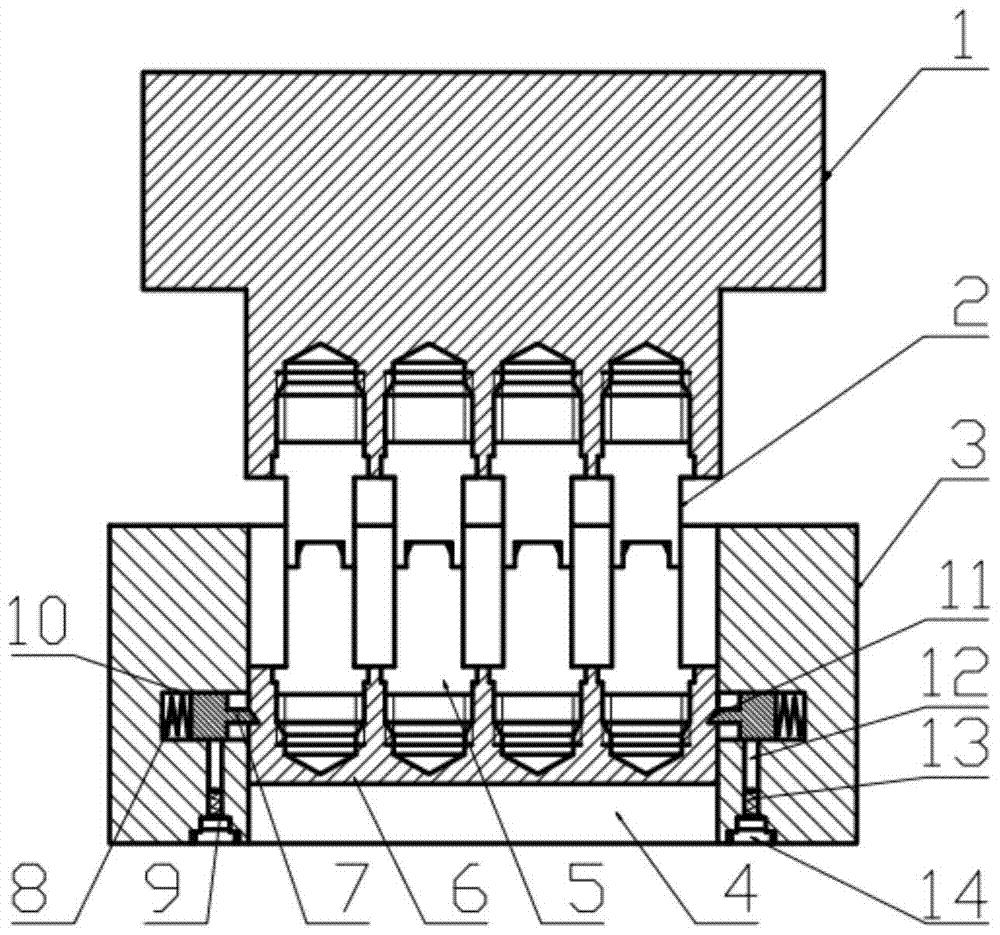

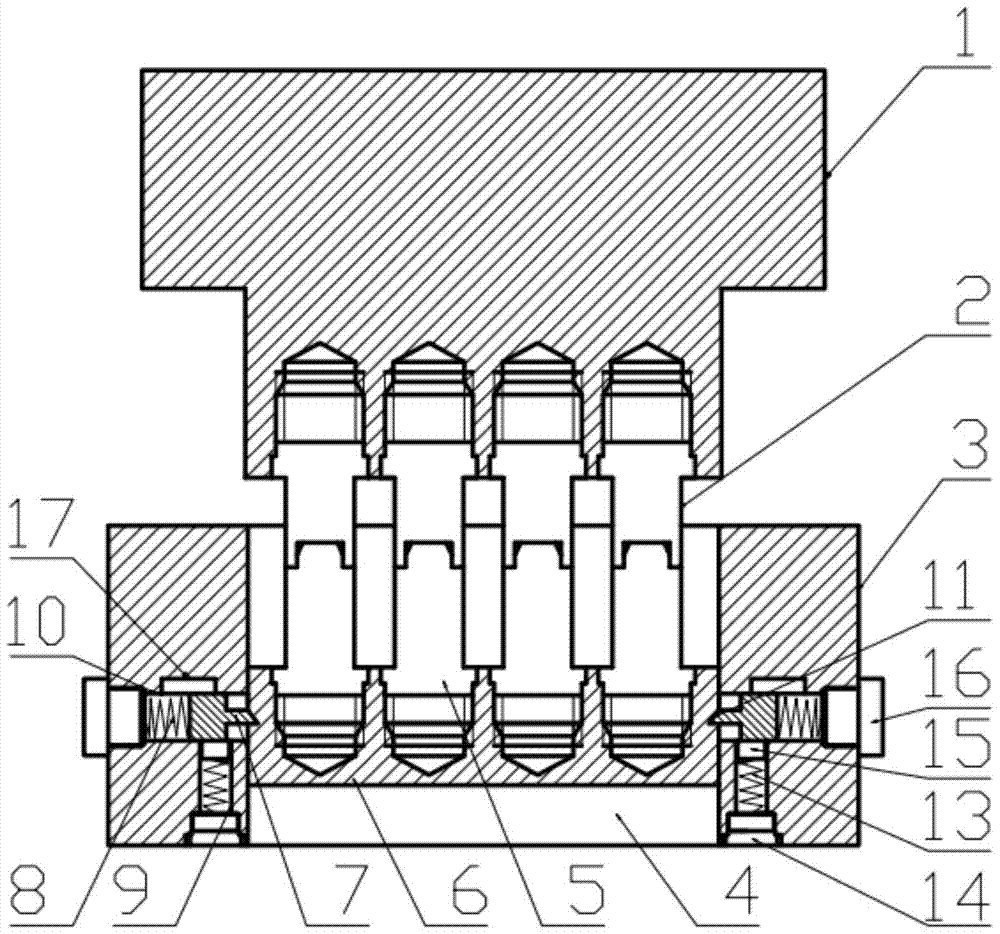

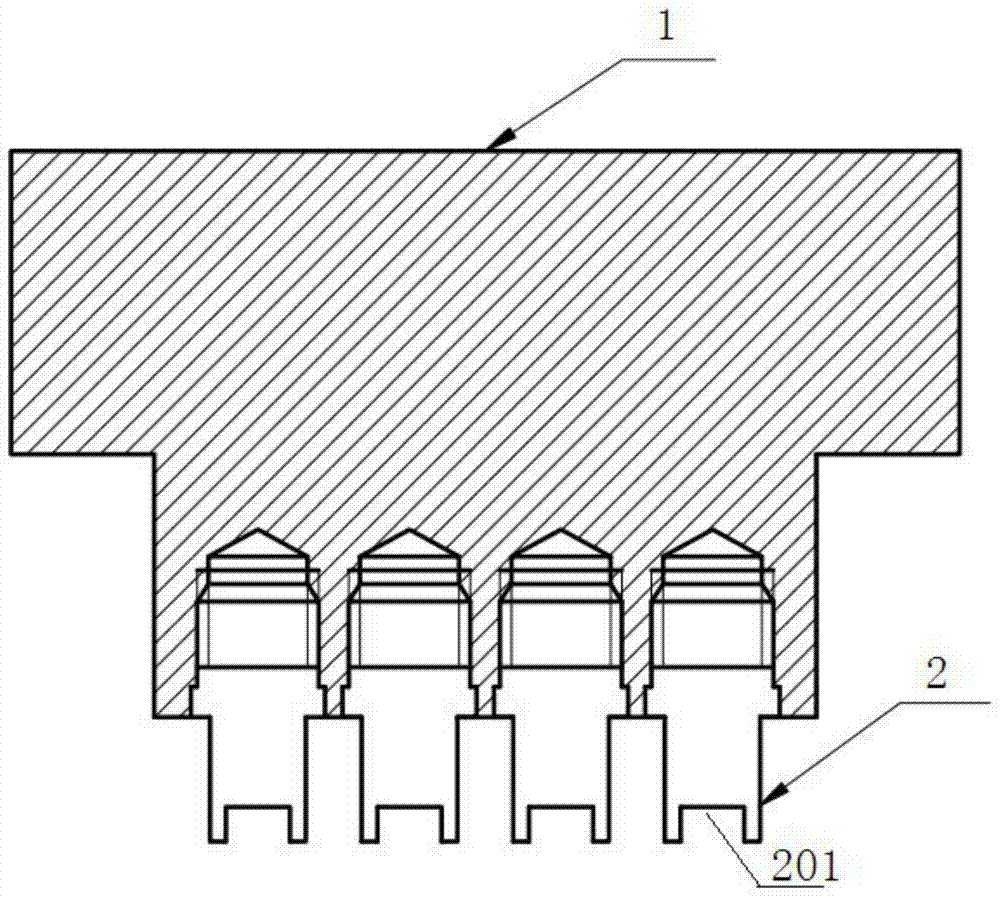

Straight-tooth cylindrical gear radial extrusion die and method

The invention discloses a spur gear radial extrusion molding die and method, comprising an upper die, a lower die and a radial extrusion die fixed between the upper and lower dies, the elastic body of the upper die and the cylindrical wedge The pressure motor beam is connected, in which the elastic body is embedded in the upper end of the cylindrical wedge, and the lower mold is fixed on the press table. When extrusion is formed, the upper mold and the lower mold are firstly fixed to fix the gear blank, and then the press compresses it. At the same time, the cylindrical wedge continues to move downward under pressure, and transmits the force to the side punch, so that the side punch moves radially in the upper and lower chute plates and the side mold fixing plate, and completes the radial extrusion of the gear. Forming, the press is picked up, the cylindrical wedge moves upward, and the side punch moves in reverse under the restoring force of the spring bolt, the mold is fully opened, and the gear part is taken out. The invention reduces the load on the mold, improves the life of the mold, fills the tooth cavity more fully, and improves the production efficiency and qualified rate of the gear.

Owner:YANSHAN UNIV

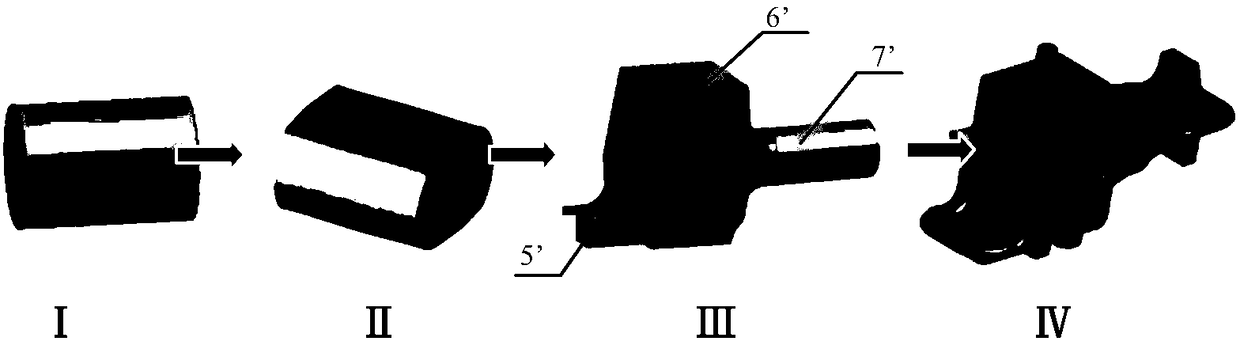

A kind of forging method of high-speed train axle box body

ActiveCN106734799BGood volume distributionEasy to shapeRailway componentsForging/hammering/pressing machinesBar stockManufacturing engineering

The invention discloses a forging method of a high-speed train axle box body. The forging method comprises the following steps that 1, blank blanking is conducted, wherein a blank is a cylindrical extrusion bar, and the blank with the set length is obtained through sawing blanking; 2, transverse flattening upsetting is conducted, wherein transverse flattening upsetting is conducted on the blank to obtain a prefabricated blank; 3 the prefabricated blank is extruded to obtain a pre-forging piece, wherein the pre-forging piece sequentially comprises an end corresponding to the shape of the axle box body, a middle and a rod portion in the length direction, and volume distribution of the pre-forging piece is matched with that of the axle box body; 4, final forging piece molding is conducted, wherein the pre-forging piece is placed in a final forging mold to be subjected to final forging, and a final forging piece is obtained. Volume distribution of the pre-forging piece is well matched with that of the final forging piece, an extrusion process is adopted in pre-forging piece molding, no flash is generated, the pre-forging piece is stably positioned in a final forging mold cavity, and therefore it can be guaranteed that the final forging piece is well molded.

Owner:SHANDONG UNIV +1

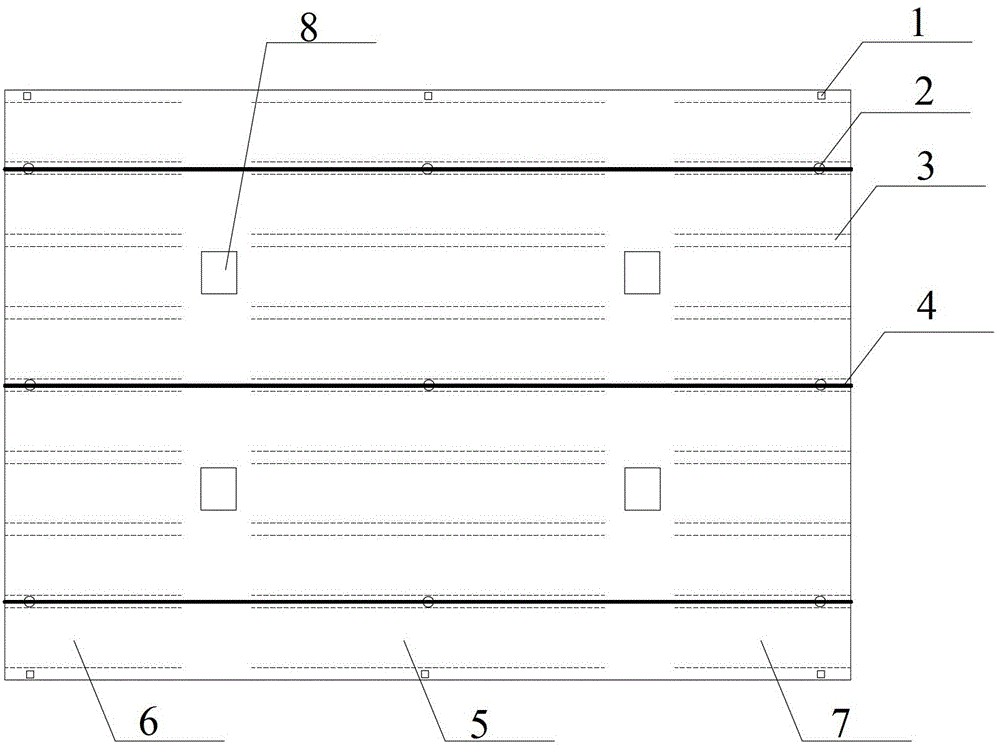

Method and sand core assembly for rapid casting of distributor of engine for large ships

PendingCN110976778AQuality assuranceGuaranteed full fillingFoundry mouldsFoundry coresOil waterRapid casting

The invention discloses a method for rapid casting of a distributor of an engine for large ships. The casting method comprises the following steps: a casting runner is formed in one side of a sand core group, a vertical inner gate aligned to a vertical interlayer die cavity in a cavity of the sand core group and a transverse inner gate aligned to a transverse interlayer die cavity in the cavity ofthe sand core group are formed in the casting runner, and molten iron flows into the casting runner and fill the cavity of the sand core group via the vertical inner gate and the transverse inner gate. The invention further discloses a sand core assembly for rapid casting of the distributor of the engine for the large ships. According to the method and sand core assembly for rapid casting of thedistributor of the engine for large ships, the vertical inner gate is aligned to a vertical oil-water channel interlayer of the distributor in the die cavity and the transverse inner gate is aligned to a transverse oil-water channel interlayer of the distributor in the die cavity, smooth and rapid molten iron filling can be guaranteed effectively, the oil-water channel interlayer of the inner cavity is fully filled, and the sealing performance of the oil-water channel interlayer is guaranteed, so that the casting quality of the distributor is guaranteed.

Owner:GUANGXI YUCHAI MASCH CO LTD

Compound mold for forging automobile crankshaft

The invention discloses a compound mold for forging an automobile crankshaft. The compound mold structurally comprises an adjustment device, a fixing shaft, a connecting buckle, a clamping rod, an upper mold, an injection molding cavity and a lower mold. When the compound mold is improved for use, the upper mold and the lower mold are fixedly clamped through mounting clamping blocks; friction force generated between the upper mold and the lower mold is increased through a blocking friction plate, so that the upper mold and the lower mold cannot move on the injection mold; and a worker adjustsa rolling rotating wheel, two clamping sleeves are pulled inwards, and it is guaranteed that the upper mold and the lower mold can be steadily superposed together. The worker presses the upper mold and the lower mold, bouncing rods can be stressed to bounce back, so that the upper mold and the lower mold can vibrate; the vibration amplitude of a vibrating guide plate is controlled through bracingrods and a cushion plate, and the phenomenon that a forging compound overflows is prevented; a swing wheel drives a vibrating cavity to swing through traction of a pull rope, and the forging compoundcan be uniformly distributed inside the injection molding cavity; and quality of workpieces obtained after forging production is improved.

Owner:艾凤英

Forging method of roller for crawler excavator

The invention provides a method for forging a roller for a crawler excavator. The method comprises the following steps of: firstly heating a blank bar; secondly forging the upper half part of the roller through an initial forging die; thirdly, forming the lower half part of the roller through a final forging die, namely forging the two parts of the roller respectively by means of two sleeved dies, wherein the forged rollers have the same central axis and do not need to be welded. Besides, the method is capable of ensuring full filling of a forge piece and also capable of effectively avoiding the deformation failure of the die.

Owner:SHANGHAI YUNLIANG ENTERPRISE DEV

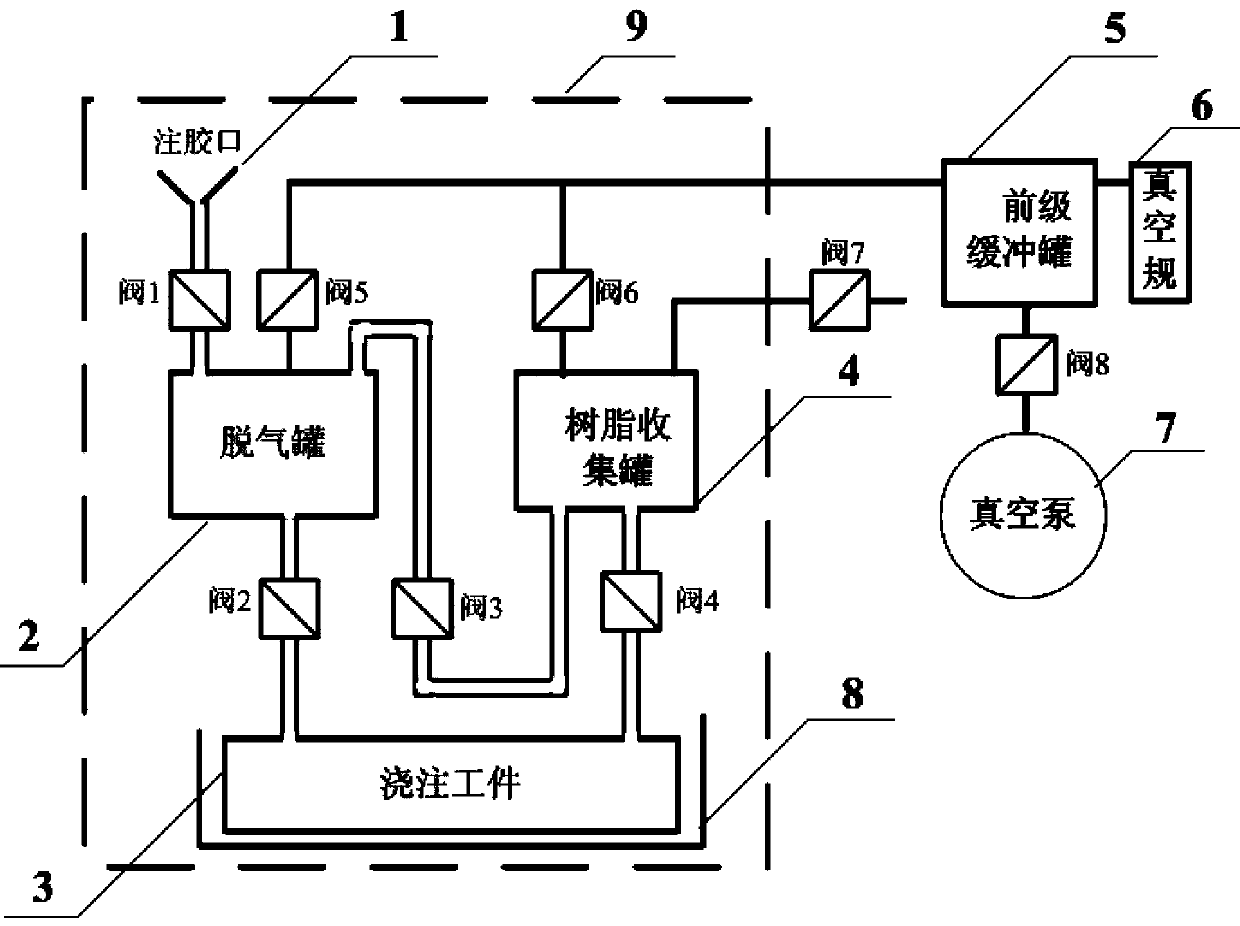

A vacuum casting device and casting method for room temperature curing epoxy resin

The invention discloses a room-temperature curing epoxy resin vacuum pouring device which comprises an environment temperature adjusting component, a sealant assembly, and a vacuum pressure adjustingcomponent; the environment temperature adjusting component is composed of a semi-closed operation box and an air conditioner; the sealant component consists of a resin defoaming tank, a pouring workpiece, and a resin collection tank disposed in the semi-closed operation box, a shell of the pouring workpiece is provided with a resin in-and-out port, and a mold groove is arranged outside the pouringworkpiece; the vacuum pressure adjusting component comprises a pump preceding stage buffer tank, a vacuum gauge, and a vacuum pump, wherein the pump preceding stage buffer tank is separately connected with an air extraction port and the resin collection tank; and the invention also discloses a debubbling method, the pouring device and the debubbling method can meet the demand for high-amount room-temperature curing epoxy resin vacuum pouring, the pouring rate is high, the resin temperature can be effectively controlled, the curing time can be prolonged, the debubbling efficiency can be increased within a limited time, and full mold filling of resin can be guaranteed.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

A kind of subway tunnel track bed and drainage ditch structure reinforcement method

The invention relates to a method for reinforcing the structure of a track bed and a drainage ditch of a subway tunnel, which specifically includes: judging the disease degree of the track bed and the drainage ditch, the disease degree includes serious disease and general disease, and if the disease degree is a general disease, chisel out loose structures, Arrange grouting holes in the track bed and drainage ditch according to the plum-blossom pile shape, and grouting into the grouting holes on the track bed and drainage ditch. If the disease degree is serious, the loose structure shall be chiseled, and the space cleared on the track bed shall be filled with dilute and quick filling. Hard castable, the space cleared on the drainage ditch is shaped with PVC half-pipe and double-speed cement, several pouring holes are opened at the center of the track bed, grouting holes are arranged in the drainage interval, and the pouring holes are poured into the pouring holes successively. Hard castable and thick fast hard castable, and then pour epoxy resin slurry into the grouting hole. Compared with the prior art, the present invention has the advantages of saving manpower and material resources, high construction efficiency, and no influence on operation.

Owner:SHANGHAI RAIL TRANSIT MAINTENANCE SUPPORT

Gap filling method for composite elbow and wear-resistant composite elbow

ActiveCN104121443BUnbreakableQuality improvementConstructions elementsSiphonsWear resistantEngineering

The invention relates to a crack filling method of a compound bent pipe and the abrasion-resistant compound bent pipe, and belongs to the technical field of machining. The crack filling method of the compound bent pipe and the abrasion-resistant compound bent pipe resolve the problems that an interval exists between a lining and an outer shell in an existing abrasion-resistant compound bent pipe, so that in the use process, more than 90 percent of compound bent pipes will crack and can not be used any longer. The crack filling method is characterized in that (1) the lining and the outer shell are combined in a sleeved mode, and an injection hole is drilled in the outer shell; (2) two flanges are adopted and respectively comprise a flange inner ring and a flange outer ring, and after each flange inner ring and the corresponding flange outer ring are combined in a sleeved mode, the outer ends are welded into a whole; (3) the outer shell is welded to the flange outer rings, the lining and the flange inner rings are in clearance fit to form an assembly interval crack; (4) paste is injected from the injection hole through an injection gun to fill the interval between the lining and the outer shell; (5) after the paste is cured, plug welding is carried out on the injection hole. The crack filling method of the compound bent pipe has the advantage that the high chromium cast iron compound bent pipe is not prone to cracking when subjected to an impact load, and is mainly used for manufacturing the abrasion-resistant compound bent pipe.

Owner:XIANGYANG TO WIN MACHINERY

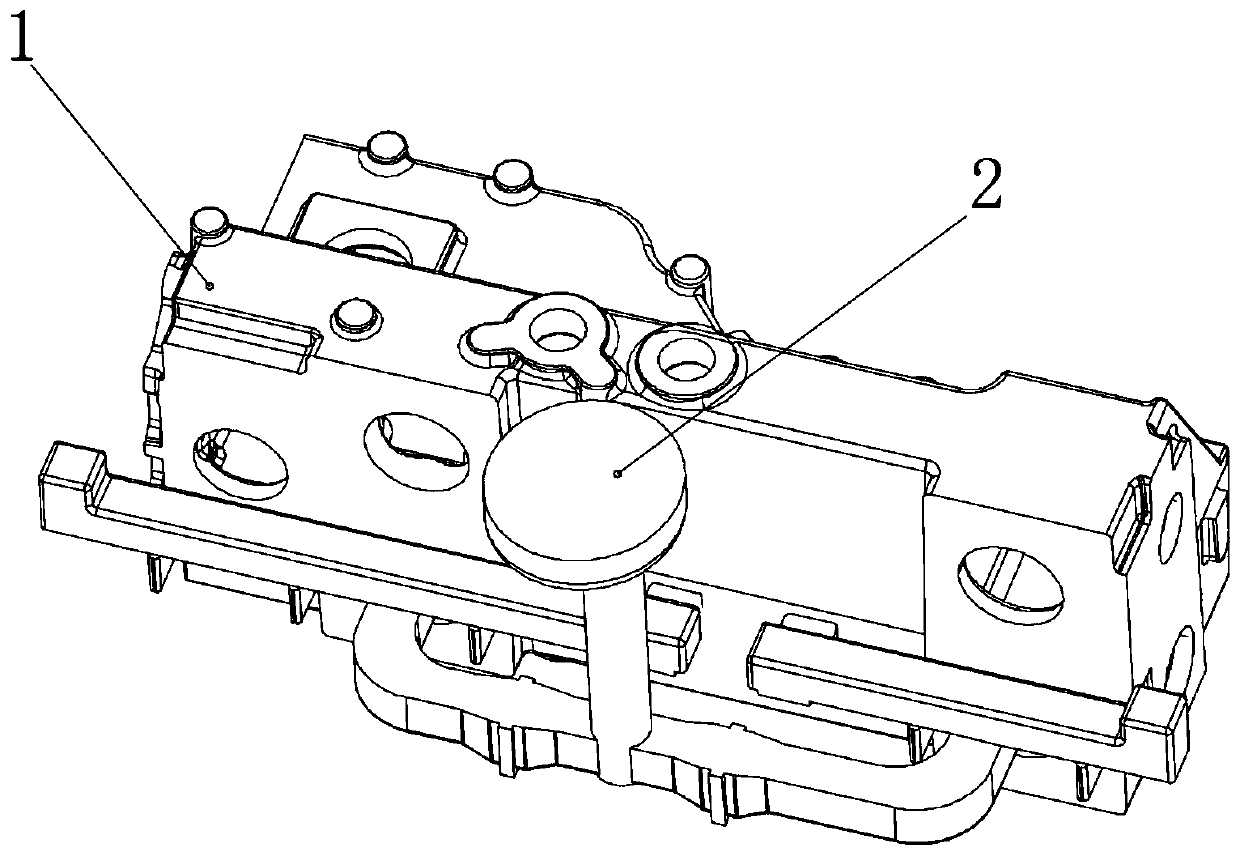

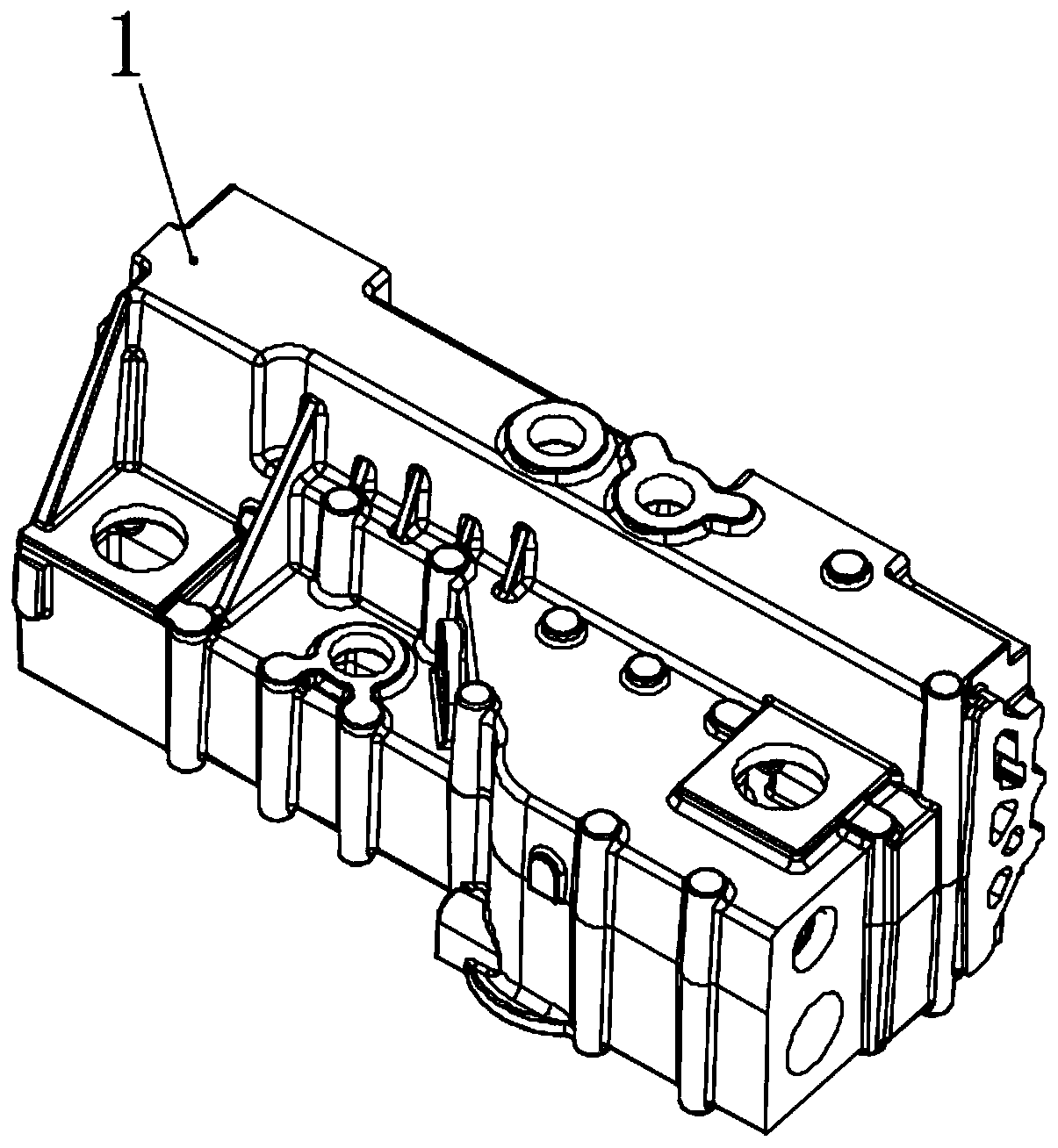

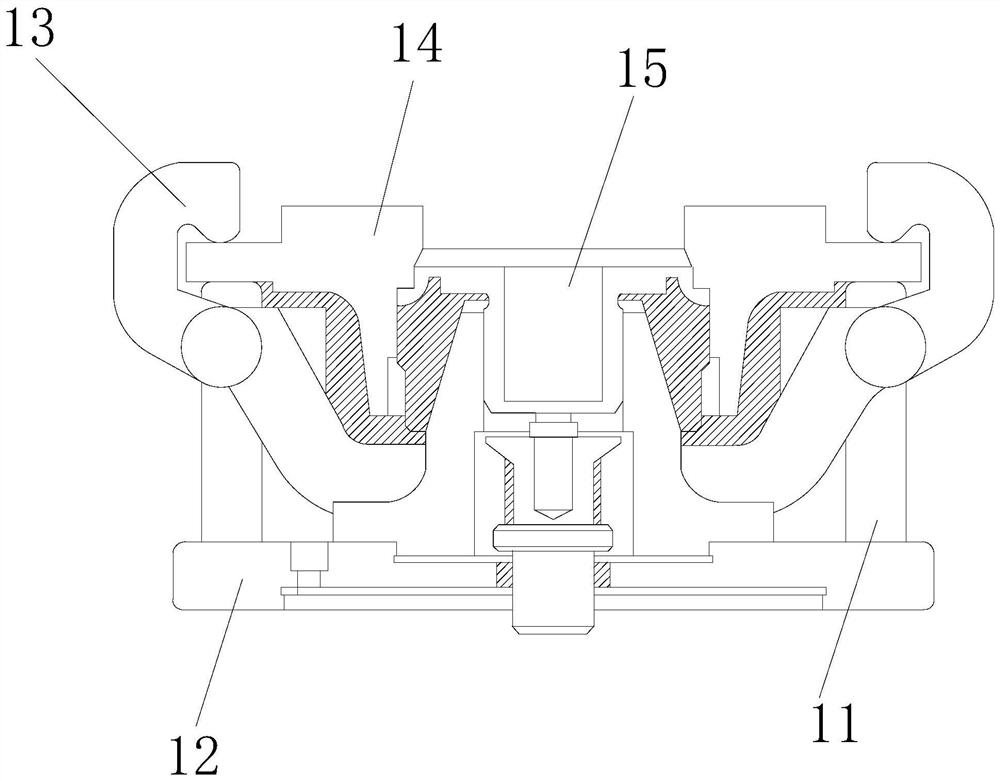

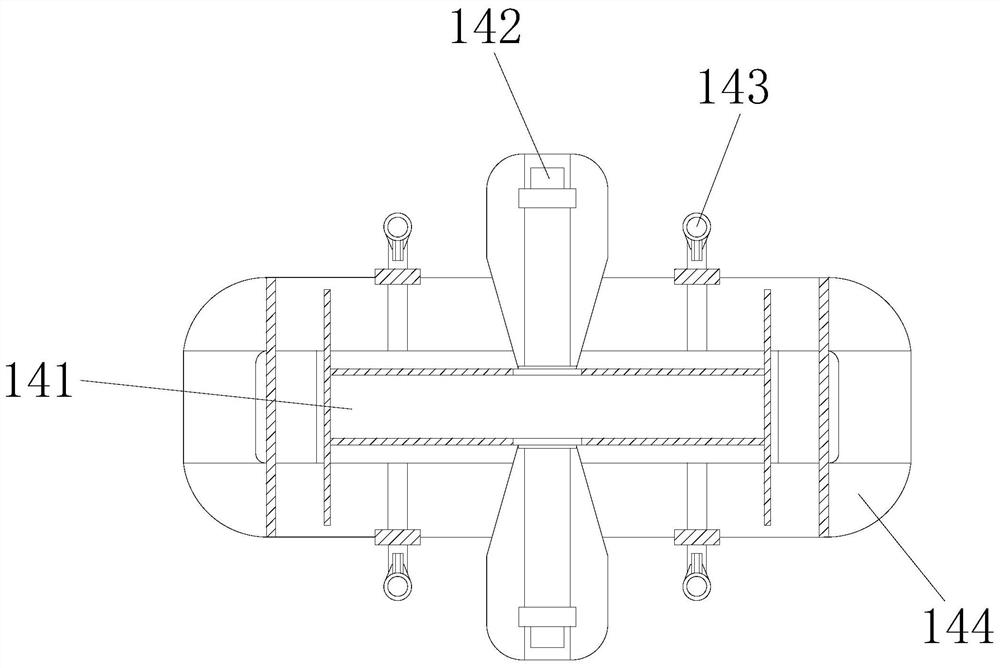

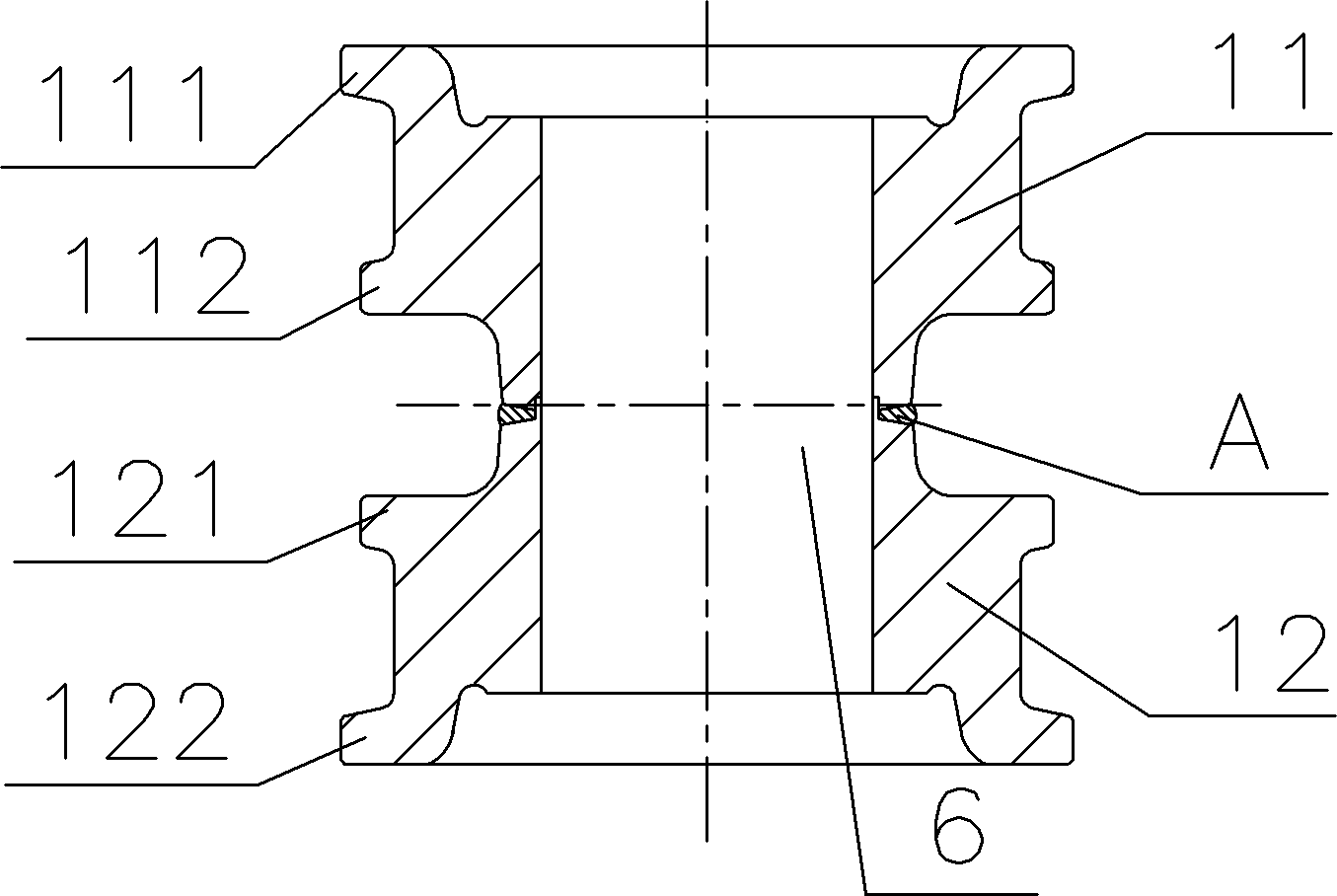

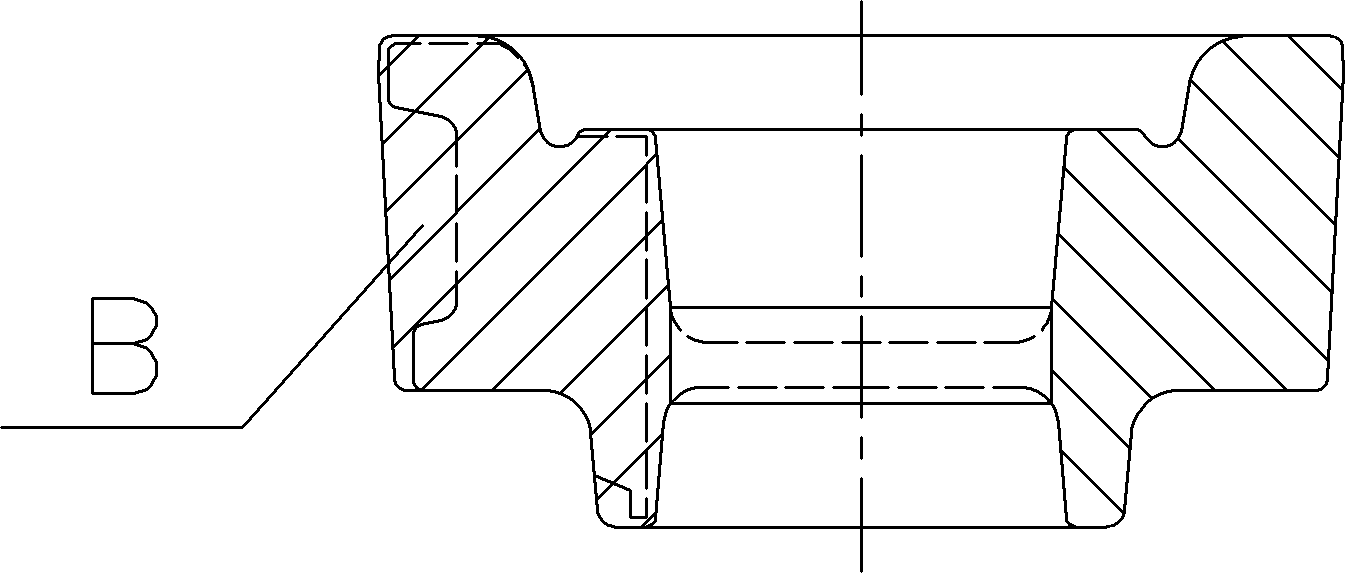

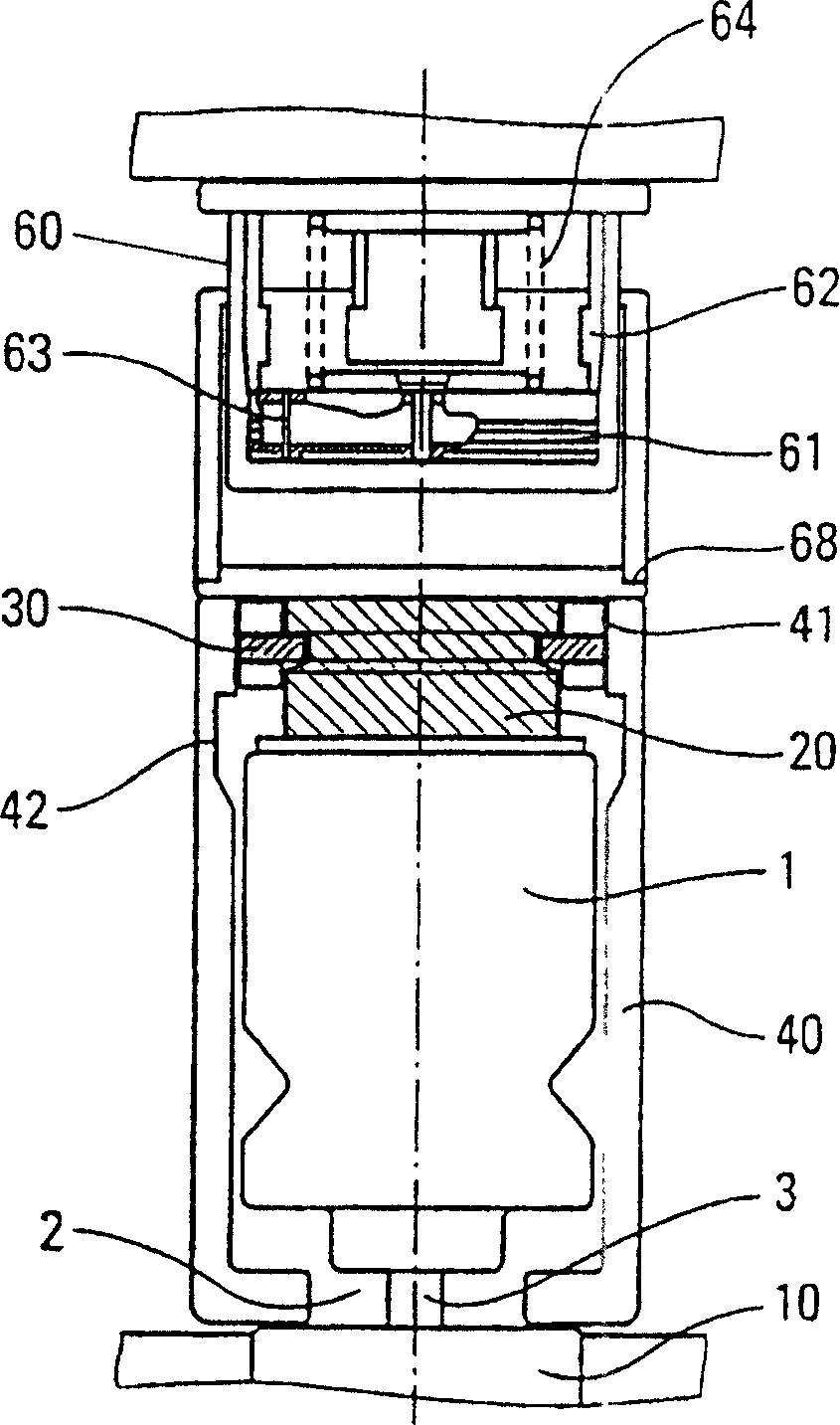

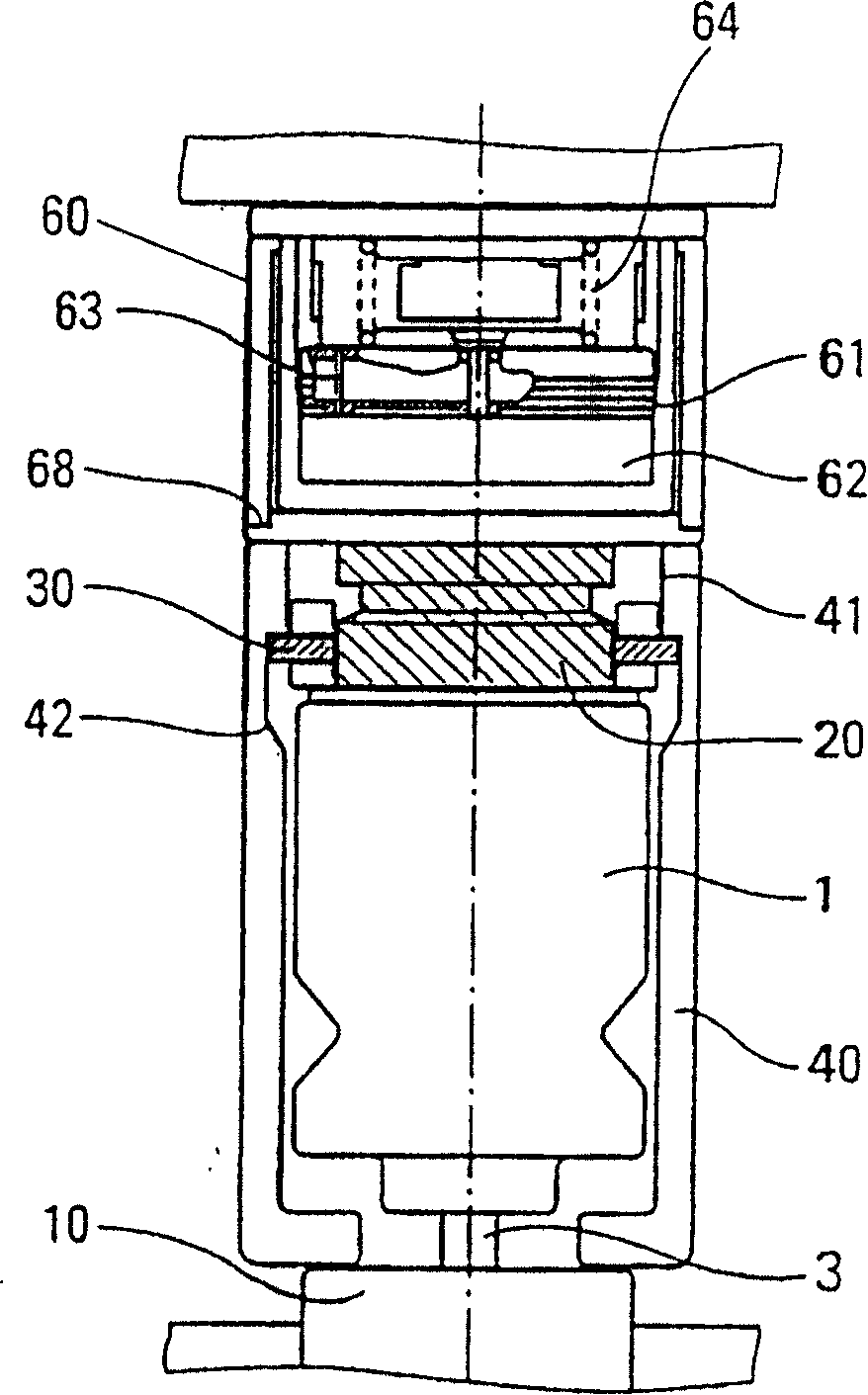

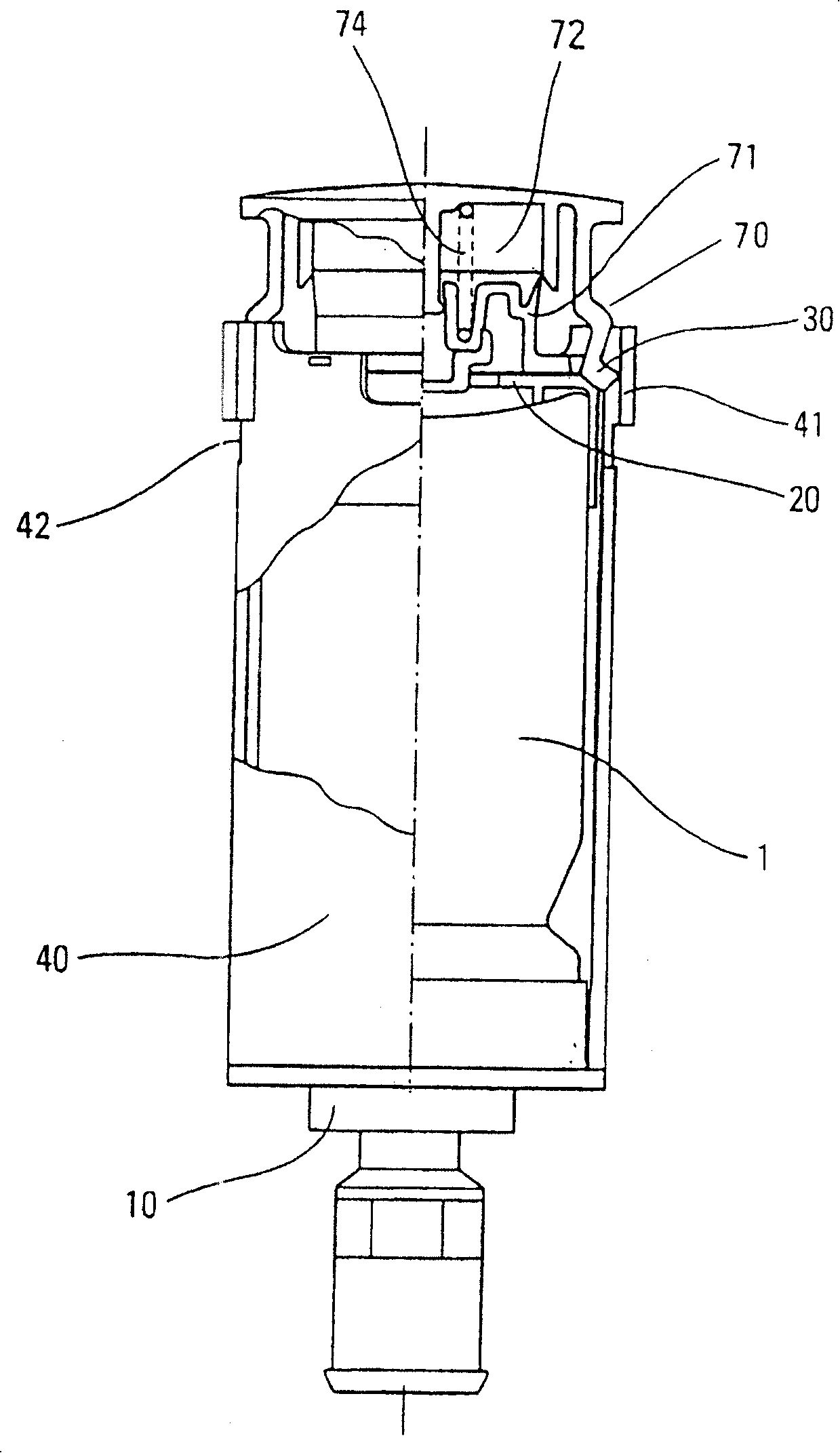

Fluid product dispensing device

InactiveCN100393375CGuaranteed dose roomGuaranteed full fillingMedical atomisersInhalatorsRest positionActuator

A fluid dispenser device comprising: a reservoir ( 1 ) containing the fluid and a propellant; a metering valve ( 2 ) mounted on said reservoir and comprising a metering chamber, and a valve member ( 3 ) that is movable between a rest position and a dispensing position; and an automatic trigger system, preferably actuated by the user inhaling in order to actuate said valve, said trigger system including an actuator element ( 10 ) adapted to displace one of the valve member ( 3 ) and the reservoir ( 1 ) relative to the other so as to bring the valve member ( 3 ) of the valve ( 2 ) into its dispensing position, the device being characterized in that it includes, in combination, a brake system ( 60, 70 ) which co-operates with the reservoir ( 1 ) or with the valve member ( 3 ) in order to slow down displacement of the valve member ( 3 ) towards its dispensing position while the device is being actuated, and a valve-member release system that is actuated automatically when the valve member ( 3 ) reaches its dispensing position, and which returns said valve member ( 3 ) to its rest position independently of the position of said actuator element ( 10 ).

Owner:VALOIS SA

Novel 4Al3 aluminum alloy used for vacuum soldering

ActiveCN102357744BIncrease contentLow melting pointWelding/cutting media/materialsSoldering mediaTrace elementSoldering

The invention provides a novel 4Al3 aluminum alloy used for vacuum soldering, which can solve the problems of high soldering temperature and undesirable soldering quality of the traditional 4Al3 aluminum alloy used for vacuum soldering, and can solve the problem that a surface oxide film of a workpiece can be removed only by Mg-contained soldering flux by the 4Al3 aluminum alloy to carry out vacuum soldering, and the vacuum soldering technology can be simplified. The novel 4Al3 aluminum alloy is characterized by comprising the following raw materials according to 100 parts by weight: more than 8.2-9 parts of Si, 0-6 parts of Fe, 0-0.2 part of Cu, 0-0.2 part of Mn, 0.08-0.2 part of Mg, 0-0.2 part of Zn, 0-0.15 part of Ti, 0-0.15 part of other impurity trace elements and the balance of Al.

Owner:YINBANG CLAD MATERIAL

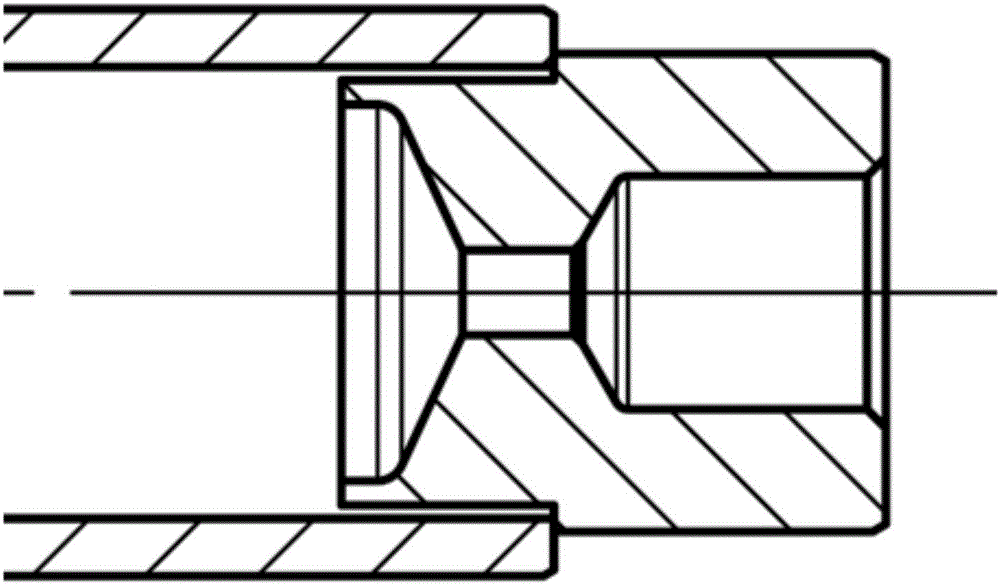

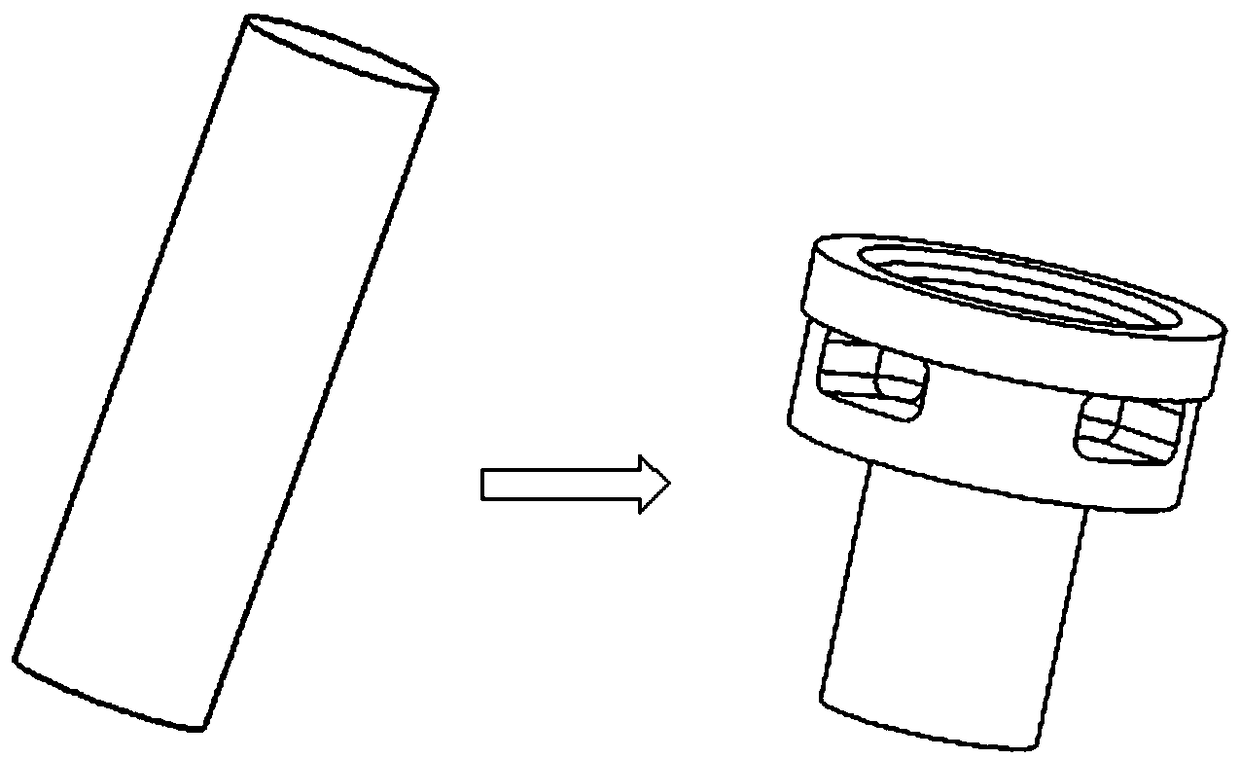

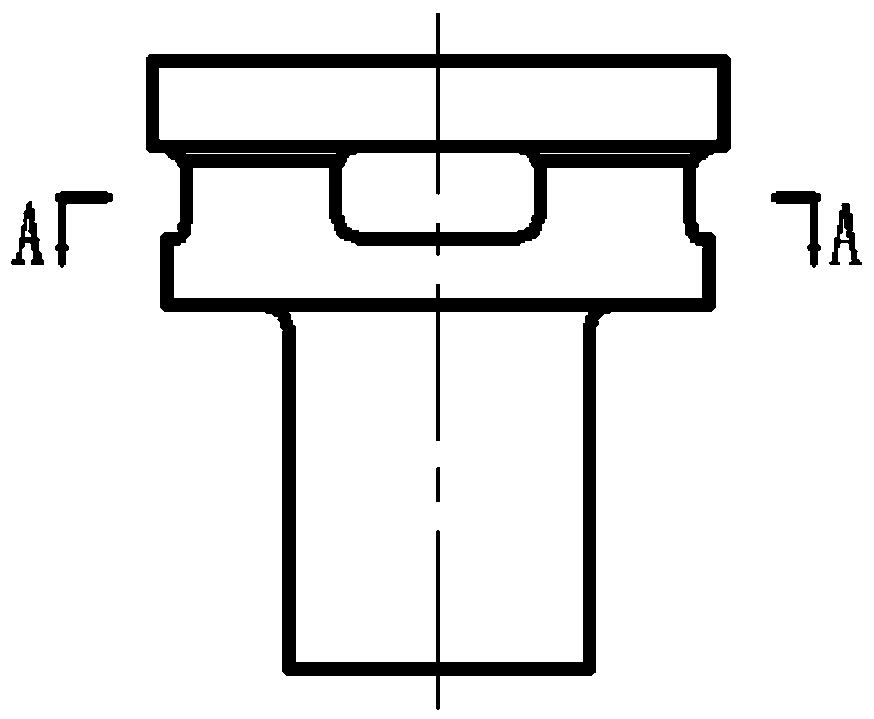

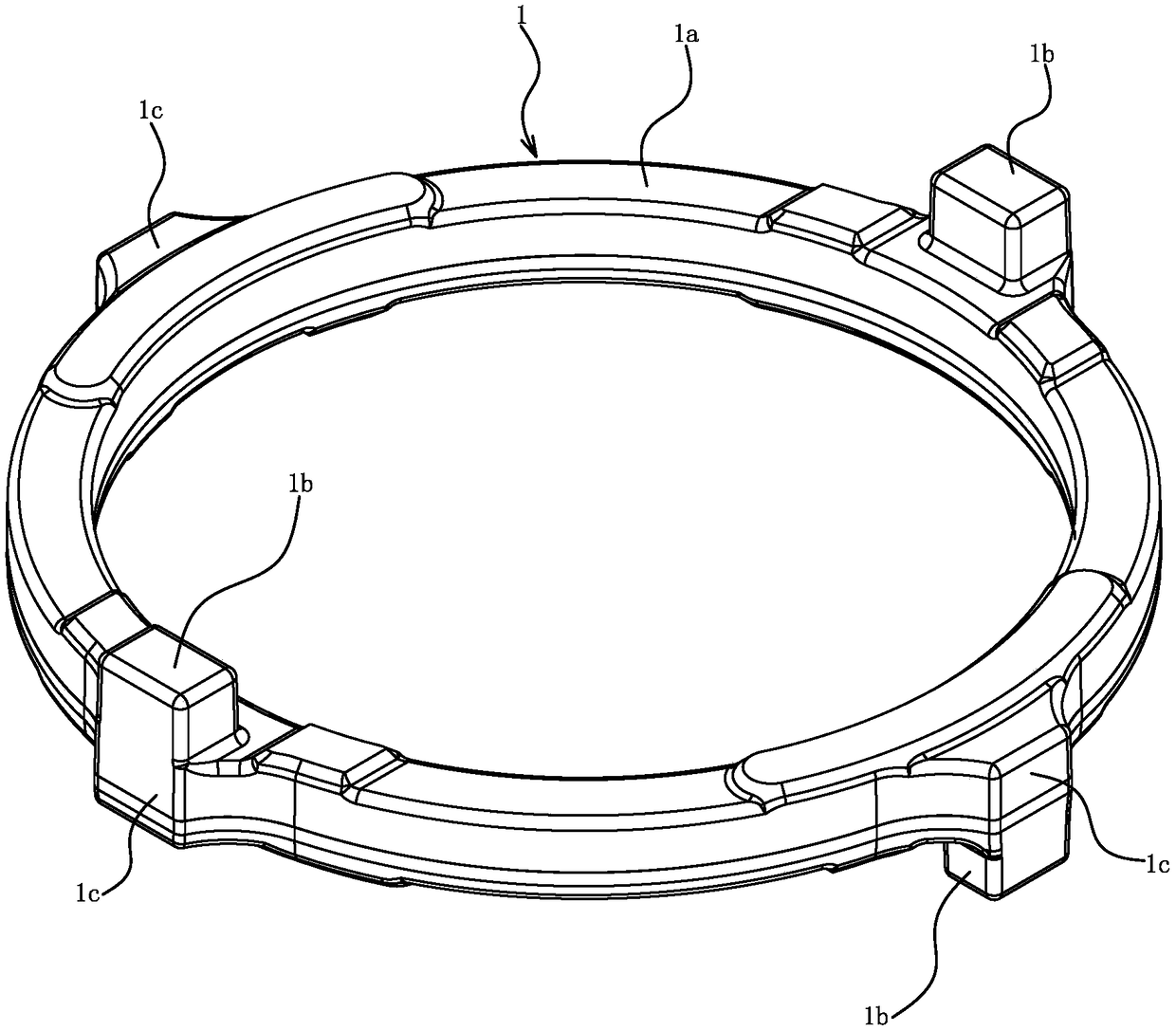

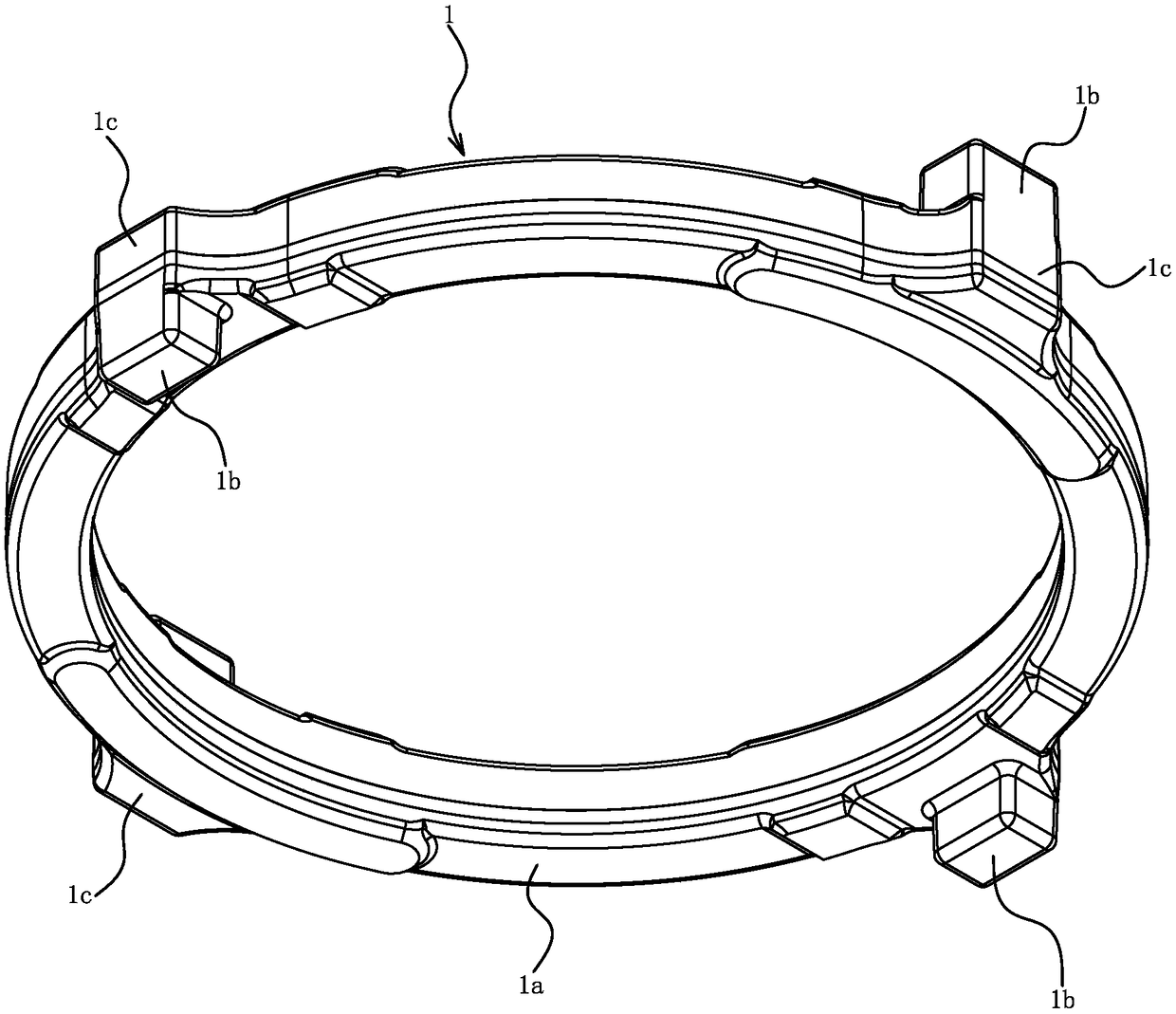

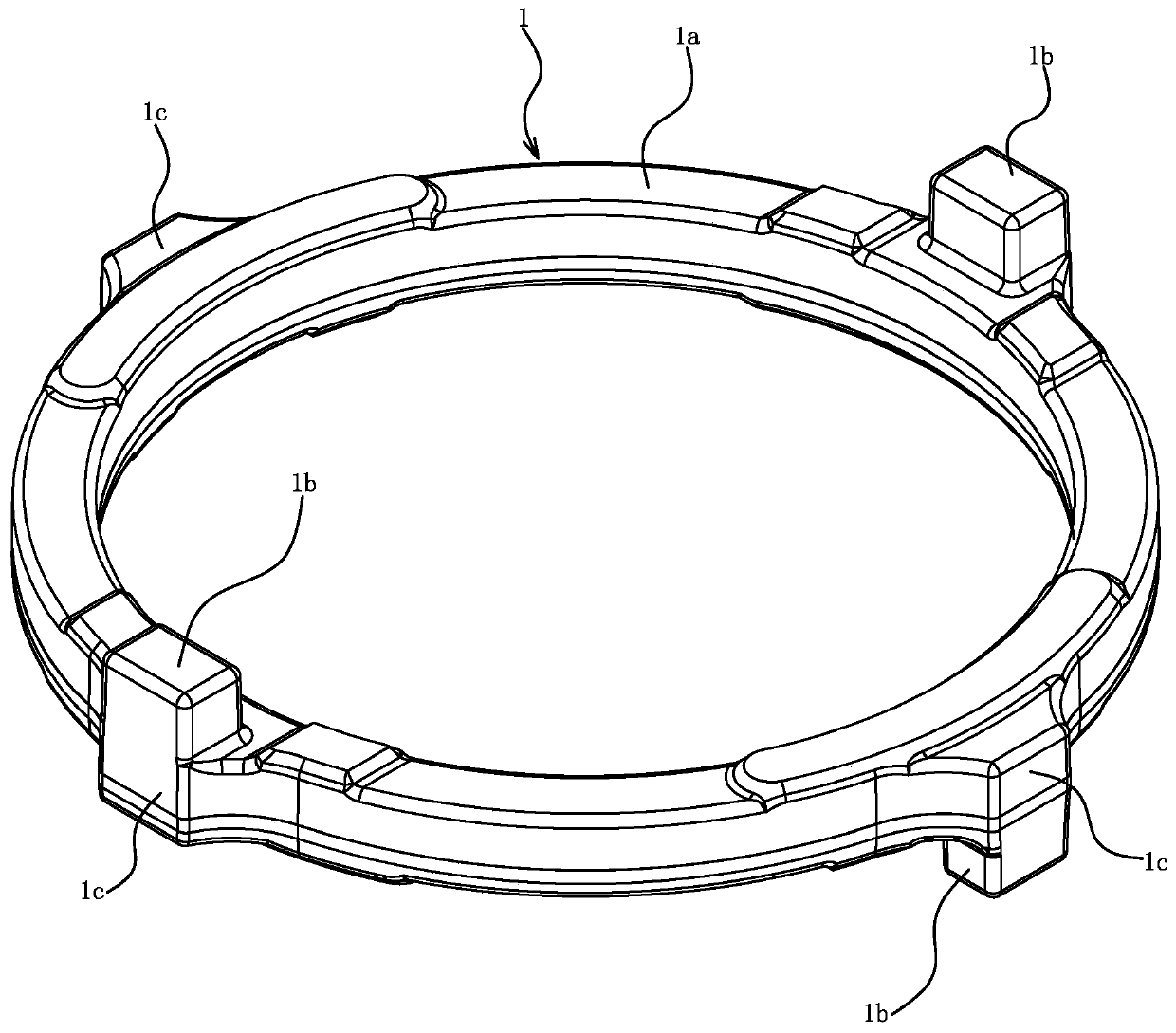

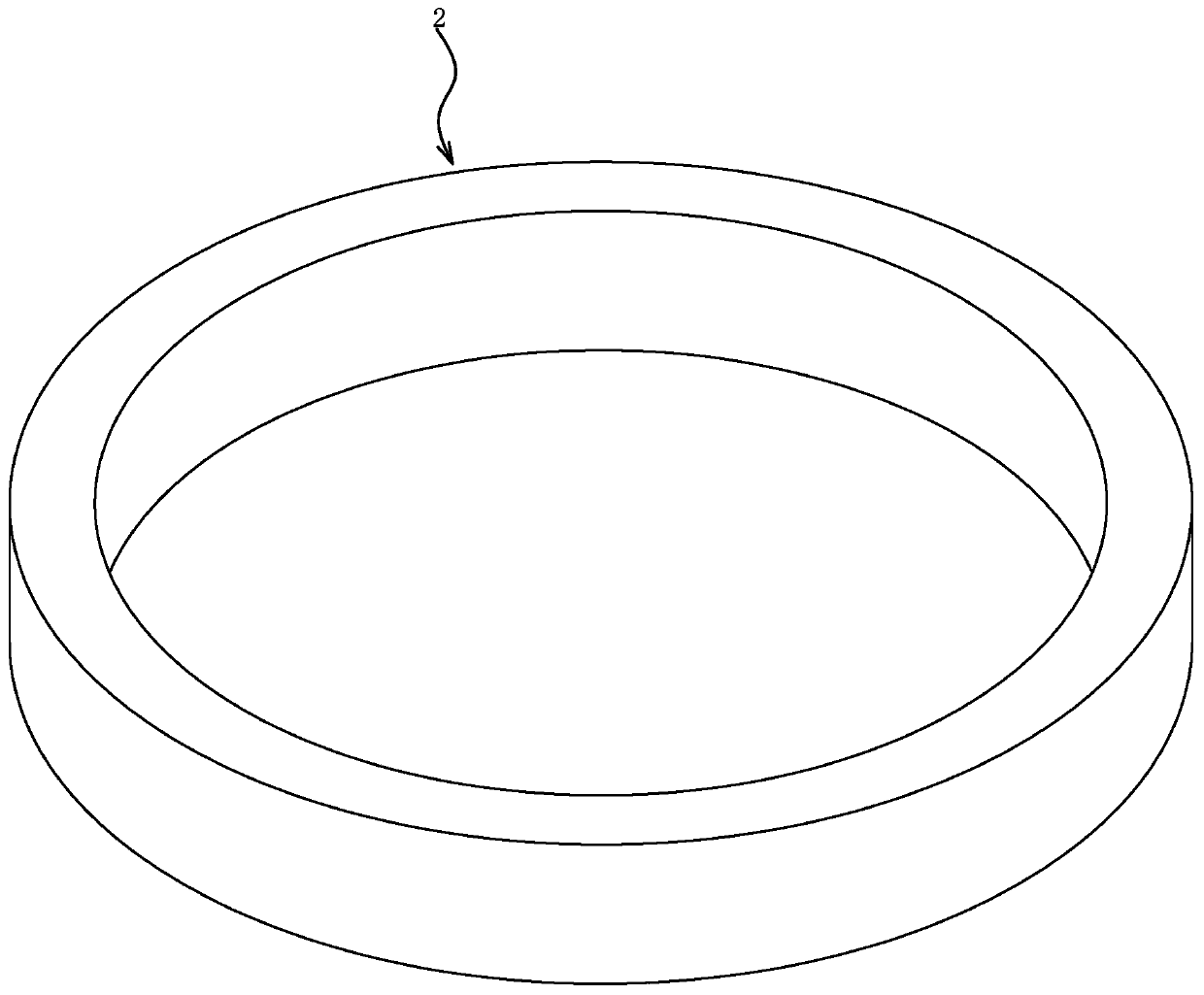

Method for manufacturing cross ring of scroll compressor

ActiveCN109201928AReduce procurement costsGuaranteed full fillingShaping toolsRotary piston pumpsEngineeringWear resistance

The invention provides a method for manufacturing a cross ring of a scroll compressor, and belongs to the technical field of compressors. The method solves the problems that in the case of an existingcross ring manufacturing method, the yield is low, the production efficiency is low and the manufacturing cost is high. The method for manufacturing the cross ring of the scroll compressor is performed according to the following sequential steps of firstly, cutting a round tube into a circular ring-shaped blank according to the required height; secondly, heating the blank, moreover, putting the blank into a pre-forming die for extrusion molding, then obtaining a rough blank, and forming four pre-forming portions corresponding to protruding keys in the cross ring in position on the outer sidesurface of the rough blank; and thirdly, heating the rough blank, moreover, putting the rough blank into a fine forming die for extrusion forming, and then obtaining a fine blank. According to the method for manufacturing the cross ring of the scroll compressor, the cross ring blank is formed by adopting hot extrusion, so that the wear resistance and strength of the cross ring are improved, the cross ring blank formed by hot extrusion does not generate air holes, and then the percent of pass of the cross ring blank is improved.

Owner:浙江百达精工股份有限公司

A combination core of pressurized multi-channel pipe splitting mold

InactiveCN105149375BReduce manufacturing costImprove pressure bearing capacityExtrusion diesCore needleMold filling

The invention belongs to the field of micro-aperture multi-channel pipe material preparation, and provides a pressurized multi-channel pipe material splitting mold combined mold core, including a mold core, a lower mold and a lower mold support plate; the center of the lower mold is provided with a lower mold through hole The outer contour of the lower mold support plate is the same as the shape and size of the lower mold through hole, the thickness is smaller than the thickness of the lower mold, and it is located inside the lower mold through hole; the bottom of the mold core is equipped with a plurality of upper mold core needles, and the lower mold support plate The top is equipped with a plurality of lower mold core needles that cooperate with the upper mold core needle; the inner wall of the lower mold is symmetrically opened with two horizontal sliding grooves; the spring and the boss slider connected with the spring are fixed horizontally in the sliding groove; the boss The slider includes a boss and a base; a supporting groove matching the front end of the boss is opened on the supporting plate of the lower mold, and the supporting plate of the lower mold is supported inside the through hole of the lower mold through the boss; the front end of the boss shrinks into the sliding groove Can be fixed in the sliding groove. The invention improves extrusion force, mold filling efficiency and mold filling ability during extrusion molding, and further improves product molding quality.

Owner:JIANGSU UNIV

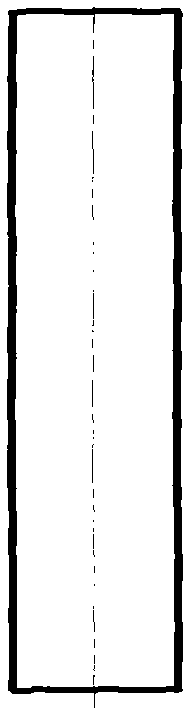

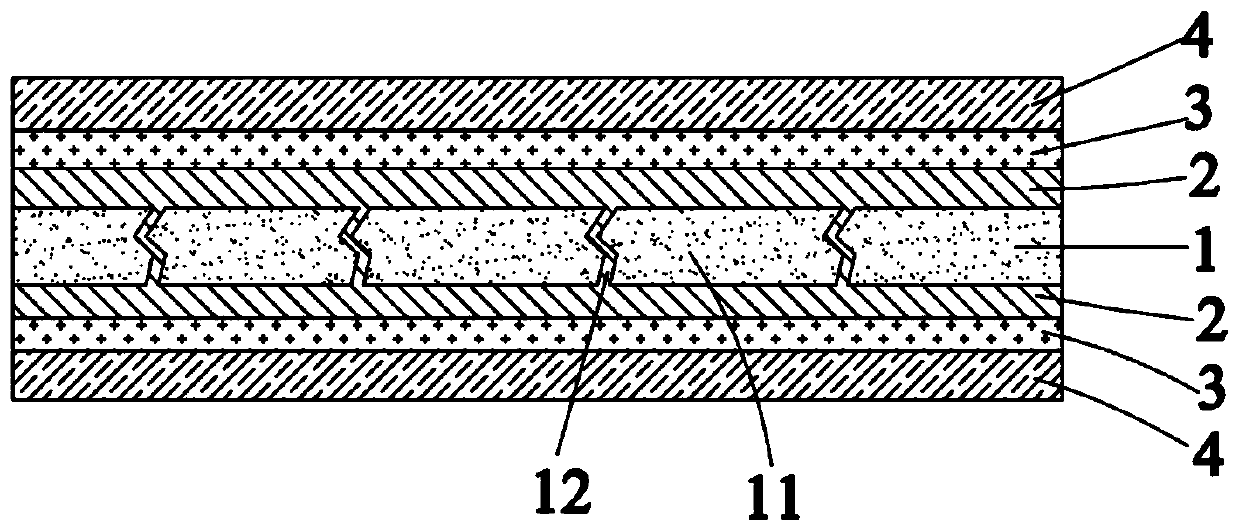

A wireless charging heat dissipation magnetic conductive film and its preparation method

ActiveCN110415952BReduce lossesGuaranteed full fillingTransformers/inductances coolingTransformersPhysical chemistryCopper foil

The invention belongs to the technical field of wireless charging components, and in particular relates to a heat-dissipating magnetic conductive sheet for wireless charging, which includes a magnetic conductive base material, an insulating and thermally conductive adhesive layer, a graphite layer and a copper foil. The magnetic conductive base material is composed of a plurality of amorphous or nanocrystalline fragmentation units, a gap is formed between two adjacent amorphous or nanocrystalline fragmentation units, and the insulating and thermally conductive adhesive layer is arranged on the gap and the surface of the amorphous or nanocrystalline fragmentation unit, The graphite layer is disposed between the insulating and thermally conductive adhesive layer and the copper foil. Compared with the prior art, the invention has good shielding performance and heat dissipation performance. In addition, the present invention also provides a method for preparing a heat-dissipating magnetic conductive sheet for wireless charging.

Owner:DONGGUAN HONGYI THERMAL CONDUCTMTY MATERIAL CO LTD

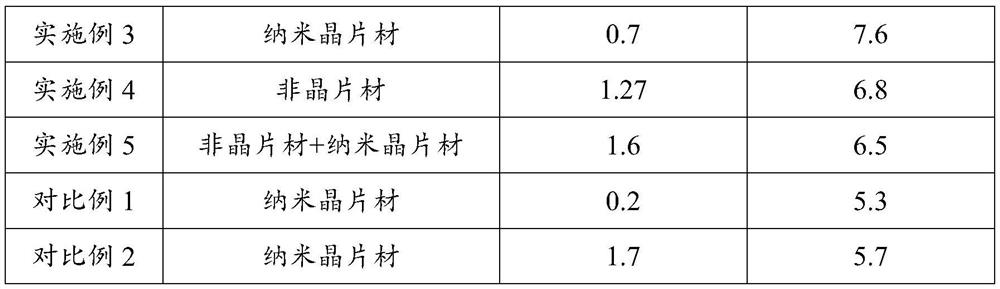

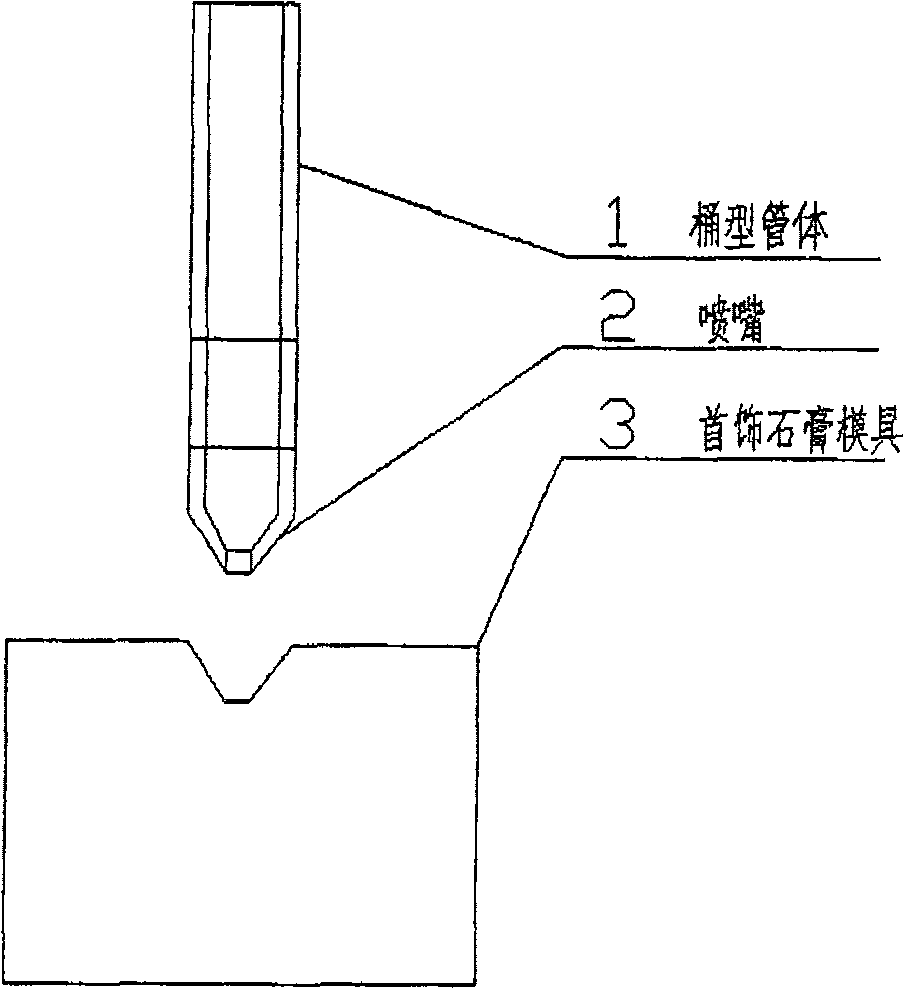

Method for producing amorphous alloy jewelry and its pipe sprayer

The invention relates to jewelry preparation technology, in particular to a method for preparing amorphous alloy jewelry and nozzle equipment specially used for the method for preparing amorphous alloy jewelry. First put the master alloy into the nozzle, heat until the alloy is melted and keep warm, fit the nozzle and the injection port of the jewelry plaster mold tightly, blow inert gas into the nozzle, and inject the molten alloy into the jewelry plaster mold; The nozzle used, the barrel-shaped body of the nozzle body is a barrel type, the nozzle at the end of the nozzle is a conical cone, the nozzle taper is 5-75°, and the difference between the taper of the injection port of the jewelry plaster mold is not more than 2°. The outer surface of the nozzle is frosted. The invention adopts cheap gypsum molds to prepare amorphous jewelry, has low price, simple process, high yield and high product surface quality, and is suitable for batch industrial production.

Owner:BEIHANG UNIV

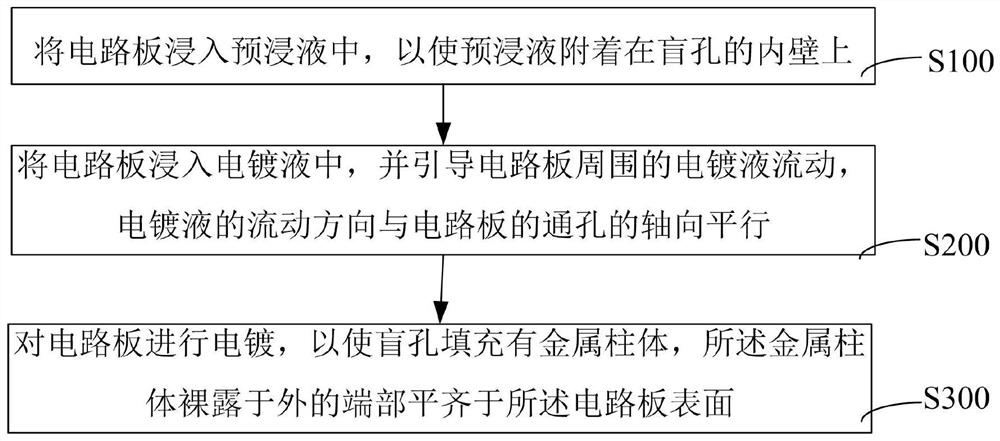

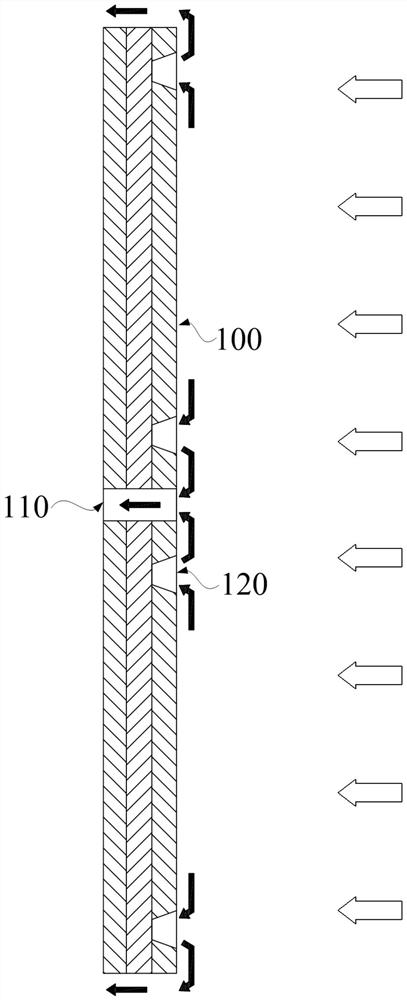

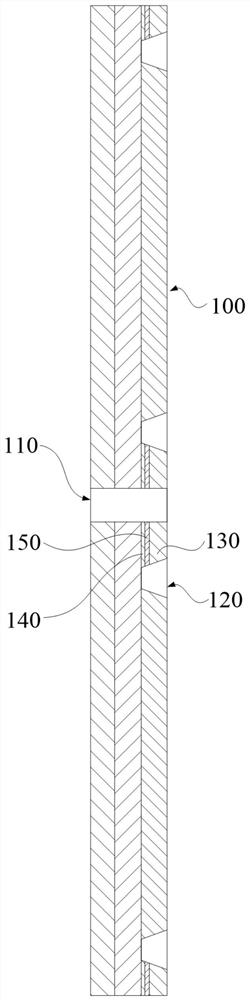

Blind hole electroplating filling method and circuit board

ActiveCN112437558BGuaranteed processing efficiencyIncrease concentrationPrinted circuit aspectsElectrical connection printed elementsEngineeringMechanical engineering

The present application provides a blind hole electroplating filling method and a circuit board. The above-mentioned blind hole electroplating and filling method is used to fill blind holes on a circuit board, and the blind hole electroplating and filling method includes the following steps: immersing the circuit board in a pre-dipping liquid, so that the pre-dipping liquid adheres to On the inner wall of the blind hole; the circuit board is immersed in the electroplating solution, and the electroplating solution around the circuit board is guided to flow, and the flow direction of the electroplating solution is in line with the axis of the through hole of the circuit board to be parallel; the circuit board is electroplated, so that the blind hole is filled with a metal column, and the exposed end of the metal column is flush with the surface of the circuit board. The electroplating hole filling method adopted in the present invention has the advantages of uniform plating growth rate on the surface of the circuit board and inside the blind hole, high electroplating and hole filling efficiency, and good blind hole filling effect.

Owner:HUAIAN TECHUANG TECH CO LTD

Scroll compressor cross ring manufacturing method

ActiveCN109201928BReduce procurement costsGuaranteed full fillingShaping toolsRotary piston pumpsWear resistanceUltimate tensile strength

Owner:浙江百达精工股份有限公司

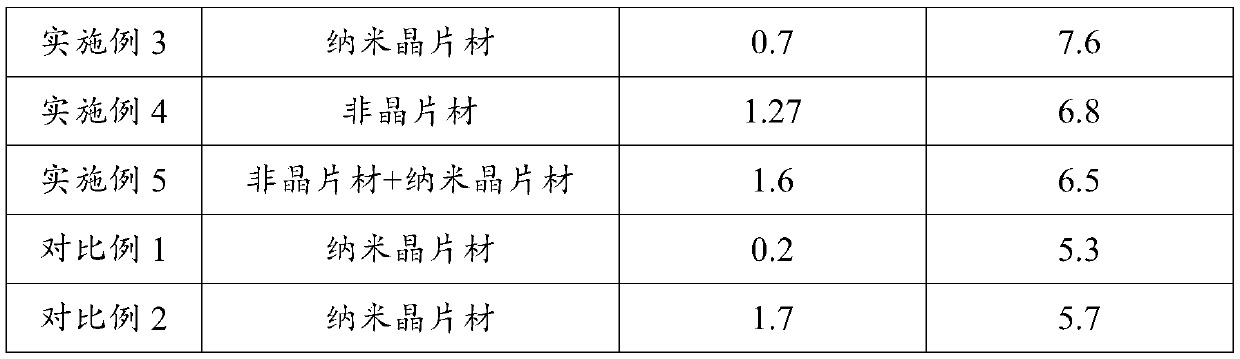

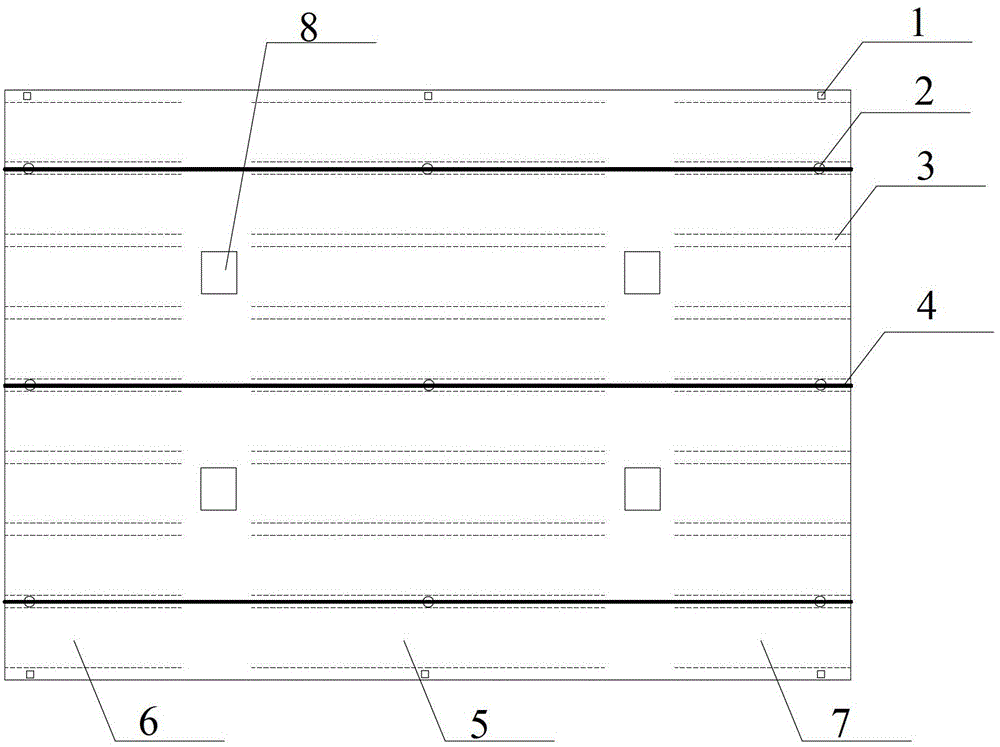

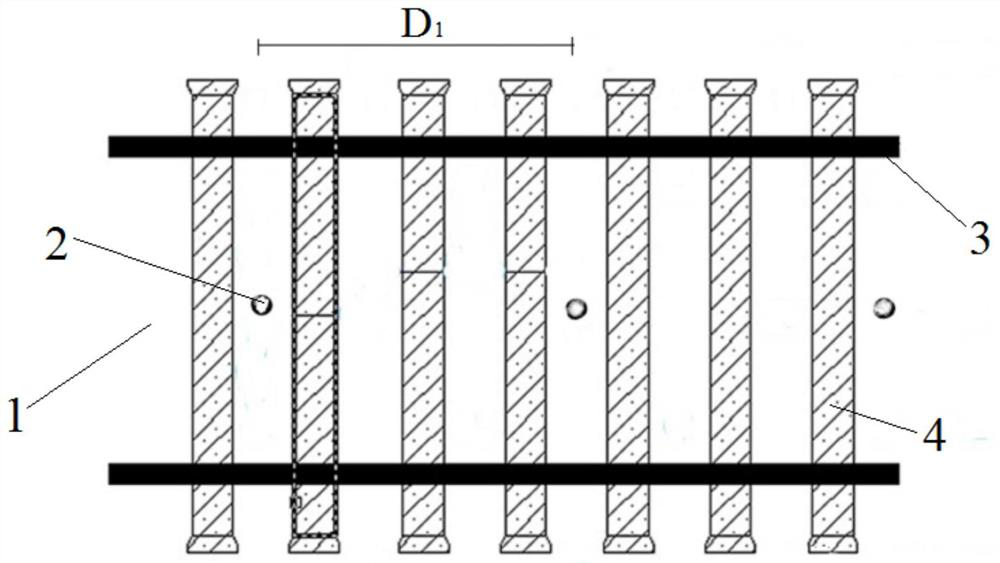

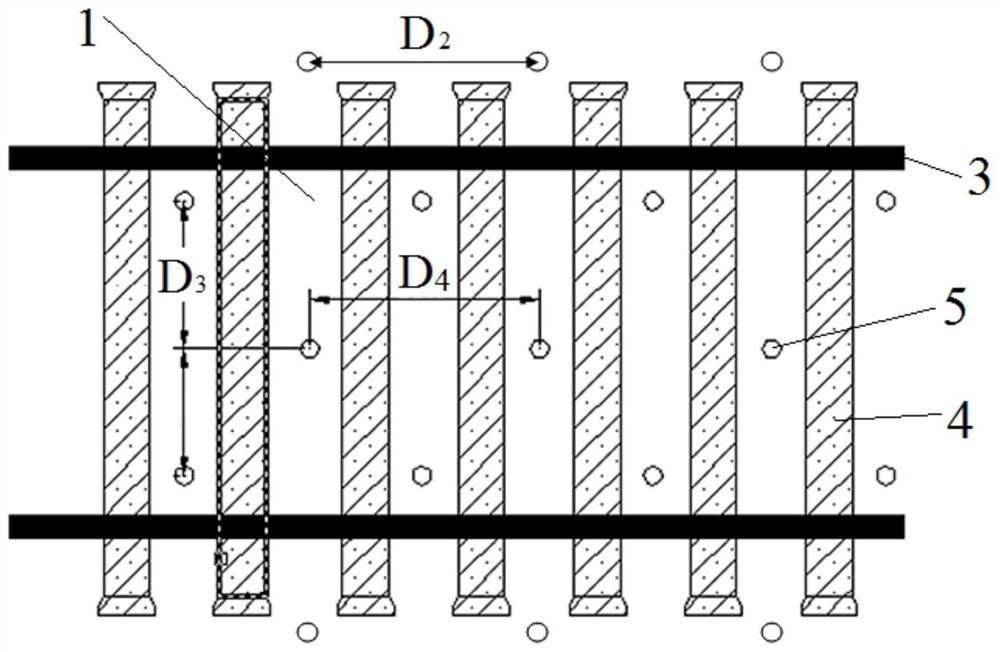

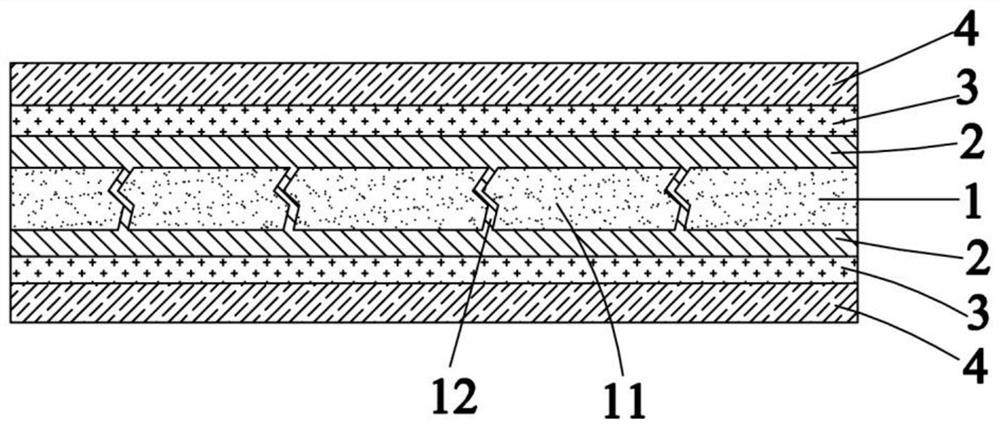

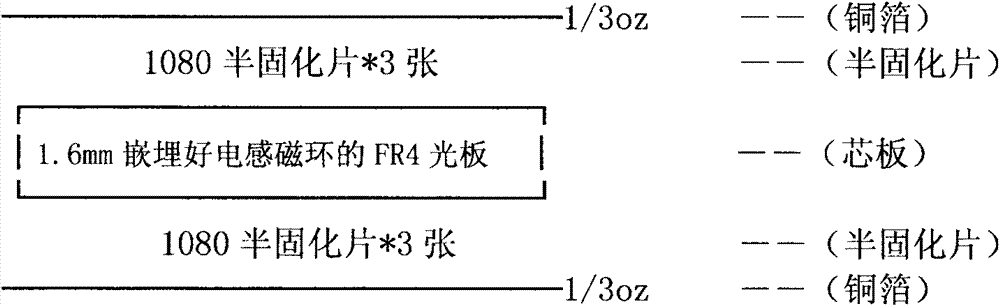

Lamination manufacturing method for imbedded inductance magnet ring

ActiveCN102045965BGuaranteed full fillingGuaranteed bonding strengthPrinted electric component incorporationMultilayer circuit manufactureEngineeringInductance

The invention relates to a lamination manufacturing method for an imbedded inductance magnet ring and aims to solve the problems of frequent holes and uncompleted glue filling because the conventional circuit board manufacturing process is complicated and inaccurate. The method comprises the following steps of: finishing hole position, hole number, hole diameter, hole shape and layout designs by using circuit auxiliary software CAM350; referring according to the size and the thickness of the inductance magnet ring; designing and determining the thickness sorting standard and the hole diametersize of a substrate; estimating the theoretical glue filling amount of a filling hole during lamination through the accounting of the size and the number of holes according to different substrate thickness requirements; determining the number of used half-fixed sheets 1080 during lamination; and imbedding the inductance magnet ring with the outer diameter of 3.55mm manually and laminating according to process requirements. By the manufacturing method, the inductance magnet ring is imbedded at a fixed position on a printed circuit board (PCB), the aim of manufacturing an inductance magnet ringplate can be fulfilled only by the design of wiring on the PCB and the like subsequently and the problems of holes and uncompleted glue filling are solved. The manufactured inductance magnet ring hashigh quality, low cost and high accuracy and is beneficial to popularization.

Owner:广州市合成电子制品有限公司

Technical method for forming semi-axle housing tube for large-diameter flange

The invention discloses a technical method for forming a semi-axle housing tube for a large-diameter flange. The technical method comprises the following steps of: sawing hot-rolled round steel serving as a blank, heating, and upsetting by using an extruding machine; performing rotary forging for forming by using a rotary forging press; and performing forward extrusion once and backward extrusion to form a forged piece of the semi-axle housing tube. According to technical method, in the maximum process step of forming force required by the semi-axle housing tube, the flange is formed by the rotary forging press; and only an outer step axle and an inner step hole are formed when the head flange is formed by the rotary forging and is extruded. The technical method has the advantages that: the full filling of flange corners is ensured effectively, the investment cost of equipment is reduced effectively, the process difficulty of the subsequent extrusion process step is reduced, the coaxiality of finished products is easy to ensure, and the production cost of the forged piece is reduced while the yield of the products is improved.

Owner:SHIYAN YUANJUN IND & TRADE

Plant cushion for filling plant growing mediums and application thereof

ActiveCN102972125BImprove water and moisture retention capacityVarious combinationsCultivating equipmentsSeed arrangmentsSurface layerEngineering

The invention provides a plant cushion for filling plant growing mediums. The plant cushion comprises a plurality of filling bags which are integrally sewed; each filling bag is formed by a bottom layer and a surface layer, which are sewed together; the surface layer of each filling bag is provided with a feeding opening; and each filling bag is filled with the plant growing mediums. The invention further provides a method for applying the plant cushion to treat a slope surface. The plant cushion disclosed by the invention is used for filling slurry-shaped plant growing mediums into filler bags; the construction is simple and the efficiency is high; water in slurry-shaped materials can be extruded to flow out in a filling process so as to guarantee that the filling bags are fully filled; and compared with a plant growing medium spraying greening technology, the efficiency is improved by 2-3 times and the cost is comprehensively reduced by 30-40%. After the construction is finished, the gap between the bags can be used for storing materials including dry branches and fallen leaves, humus, soil and the like and the water and soil loss prevention effect is obvious. Plant seedlings can grow from surface-layer materials; and meanwhile, technologies of transplant, cottage and the like are combined so that plant varieties are enriched.

Owner:江苏绿之源生态建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com