CO2 mineralization grouting method for old goaf

A goaf and grouting technology, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve the problem that the reaction place between mineralized material slurry and industrial waste gas is not fully utilized, the design deviation of grouting hole spacing, drilling There are many problems such as the number of holes, so as to achieve the effect of low cost of grouting and filling, reducing the amount of use, and reducing the number of drilling holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present application clearer, the present application will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

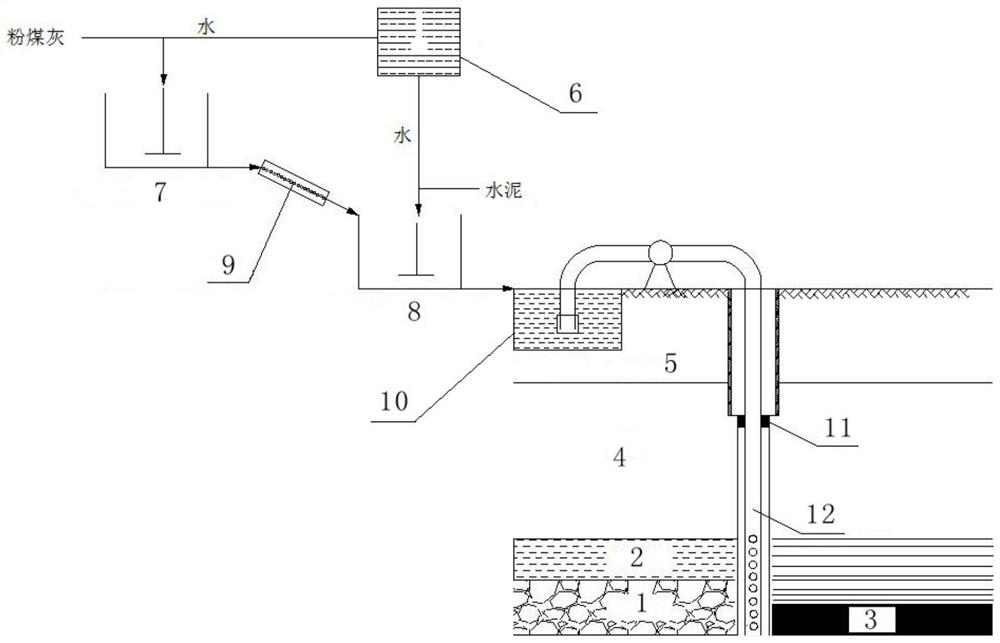

[0050] see figure 1 , the present invention provides an old goaf CO 2 The mineralization grouting method includes the following steps:

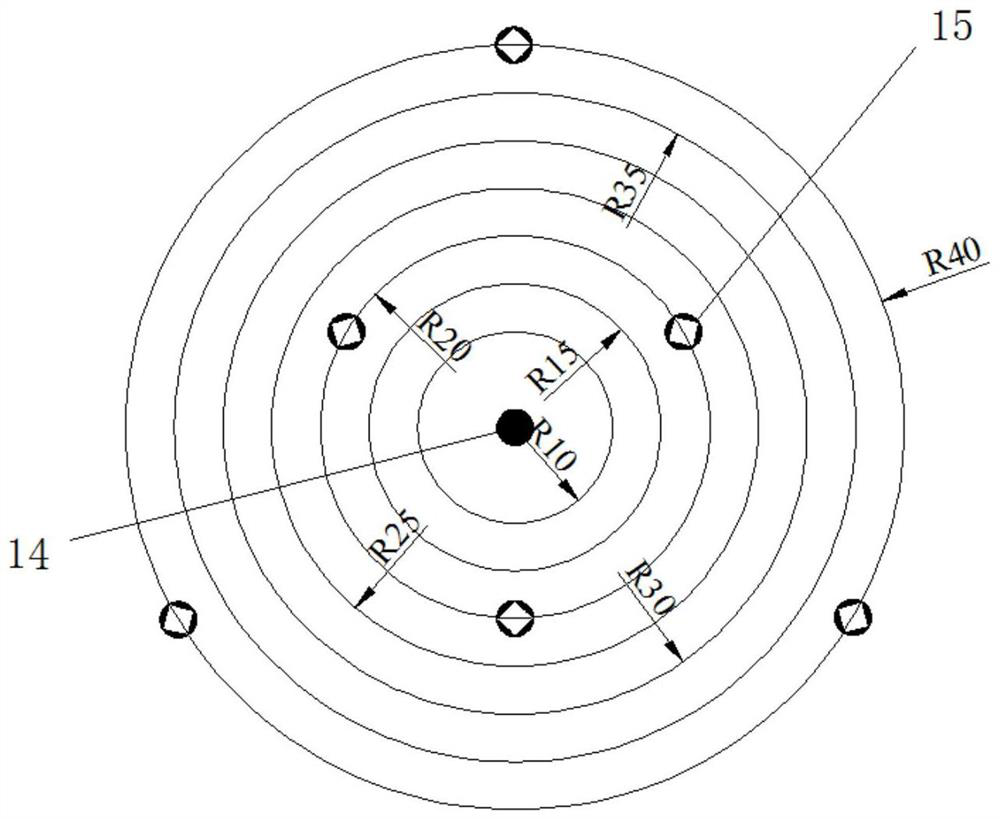

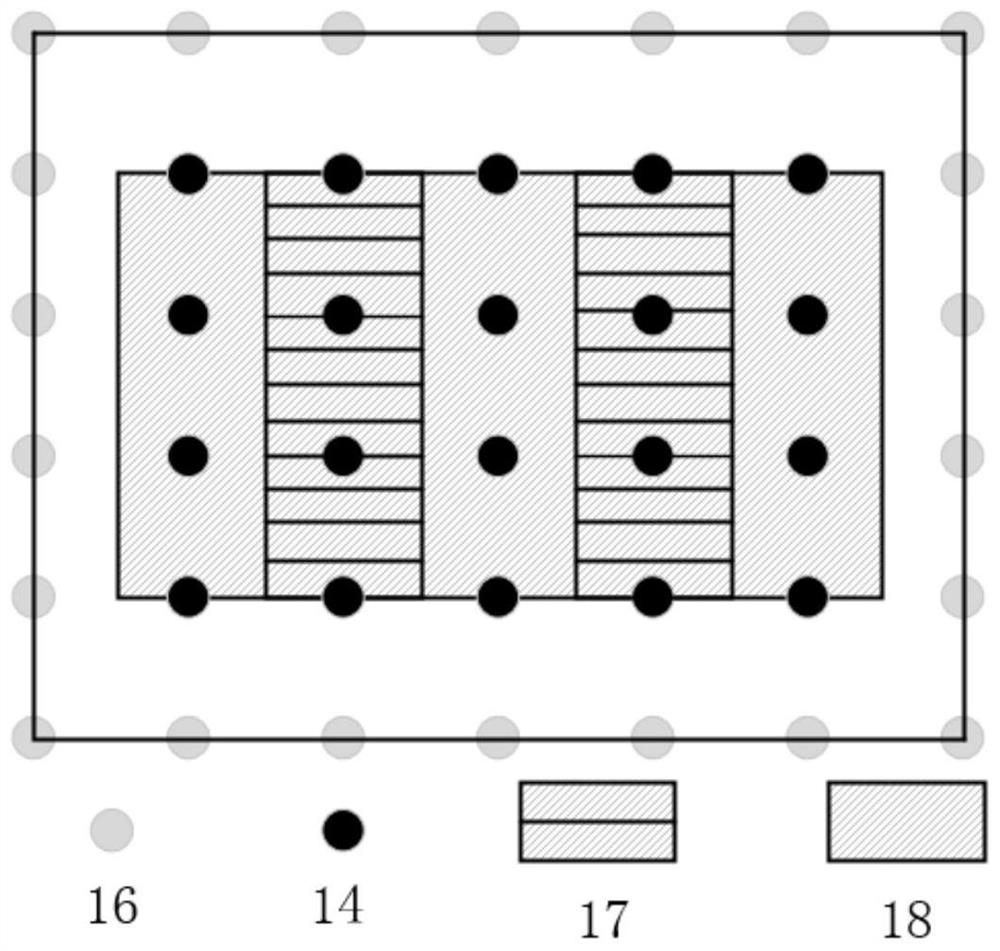

[0051] The grouting range of the goaf is divided into caving zone 1 and fissure zone 2, and the slurry diffusion radius of caving zone 1 and fissure zone 2 under the condition of isobaric grouting is determined by grouting in the experimental area, cavitation zone 1 and fissure zone 2 Share the same drilling hole for grouting, take the slurry diffusion radius of the caving zone 1 as the index to design the drilling h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com