Water level observation pipe capable of realizing layered report of frozen wall intersection conditions

A technology for water level observation and freezing of walls, which is applied to measurement devices, engine lubrication, liquid/fluid solid measurement, etc., can solve problems such as driving speed restriction, difficulty in selecting the construction position of water level observation holes, etc. The effect of reducing the risk of difficult to make circles and reducing the amount of drilling construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

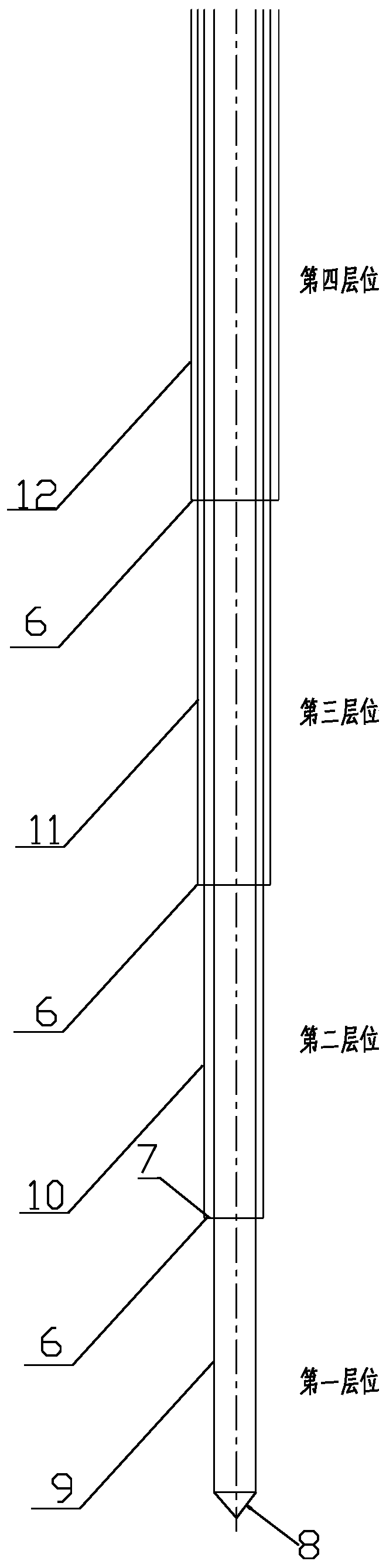

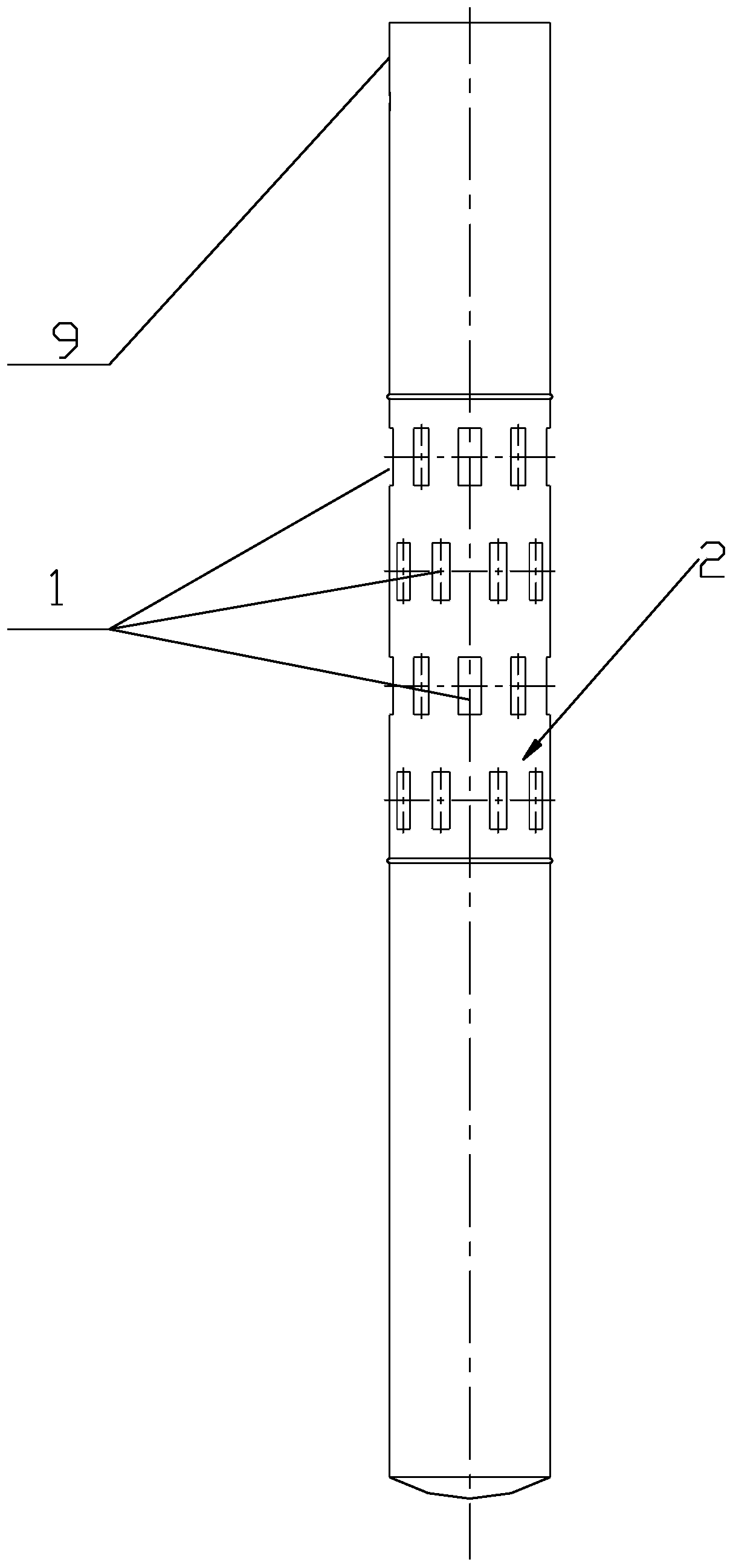

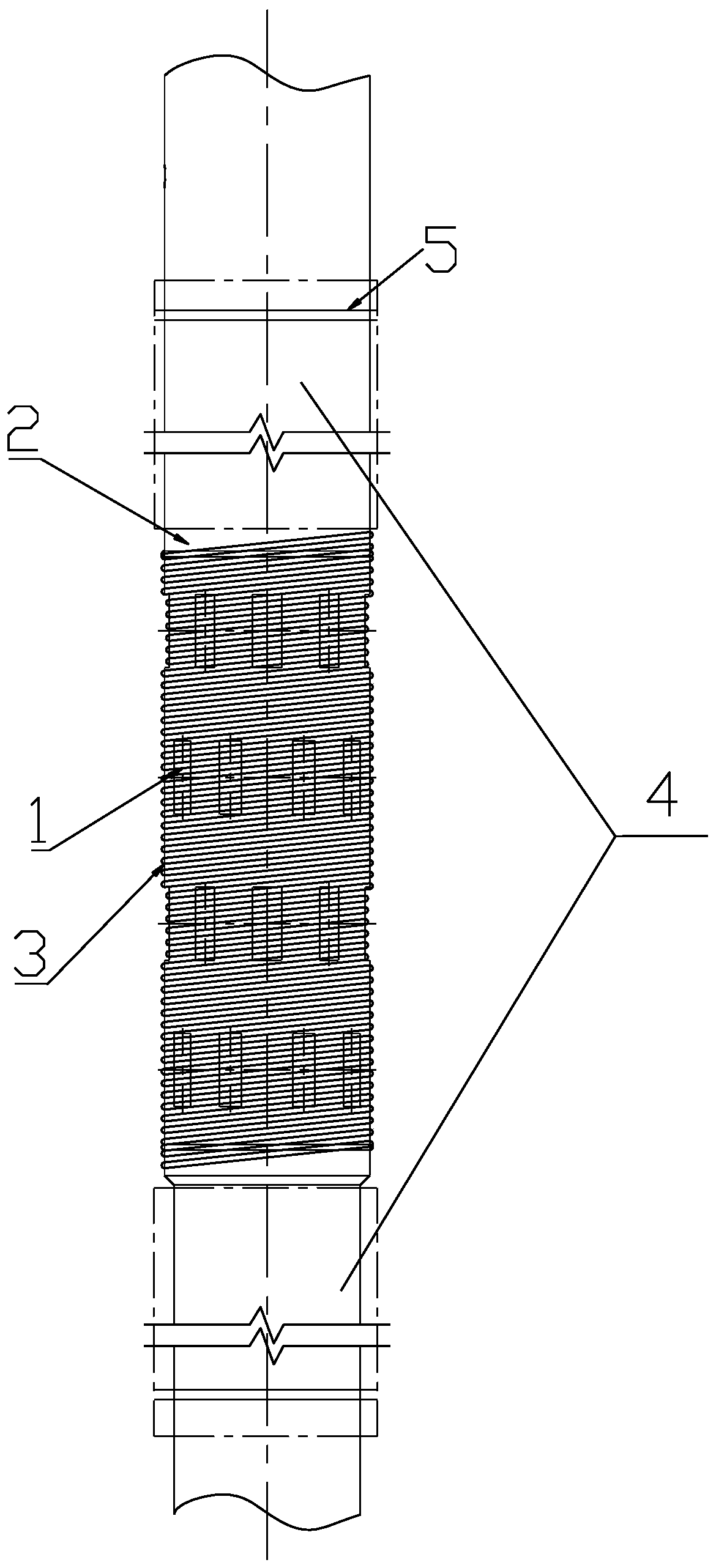

[0031] A water level observation tube that can realize layered reporting of the intersection of freezing walls, including N horizon observation tubes, where N is a positive integer and greater than or equal to 2; N said horizon observation tubes are coaxially fitted together, and The upper ends all extend out of the ground, and the lower ends are located at different observation levels.

[0032] In this embodiment, N is 4, that is, four observation horizons.

[0033] Such as figure 1 Shown: The horizon observation tube includes φ76 seamless steel pipe 9 used to report the intersection of the frozen wall at the first horizon, φ108 seamless steel tube 10 used to report the intersection of the frozen wall at the second horizon, and The φ133 seamless steel pipe 11 used to report the intersection of the frozen wall at the third level and the φ159 seamless steel pipe 12 used to report the intersection of the frozen wall at the fourth level, the first level, the second level, The third l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com