Secondary hole sealing method for underground coal mine gas drainage drill hole

A technology for secondary sealing and gas drainage, which is applied in the direction of gas discharge, mining equipment, mining equipment, etc., can solve the problems of complex construction process, high grouting cost, poor drilling stability, etc., and achieve efficient gas prevention Improve the drainage effect, improve the concentration and efficiency of drainage, and reduce the effect of drilling engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

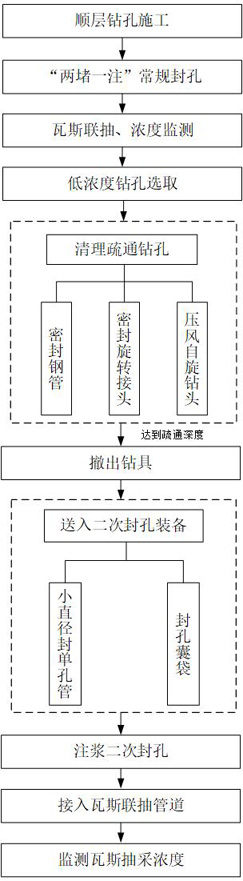

[0063] Such as figure 1 Shown, a kind of coal mine underground gas drainage borehole secondary sealing method of the present invention comprises the following steps:

[0064] (1) Adopt the bag-type grouting sealing device and the conventional sealing process of "two plugging and one injection" to implement the first sealing and continuous pumping. The outer diameter of the sealing tube used in the "two plugging and one injection" conventional hole sealing process is not less than 50mm.

[0065] (2) During gas drainage, select low-concentration gas drainage boreholes and disconnect the connected gas drainage pipelines.

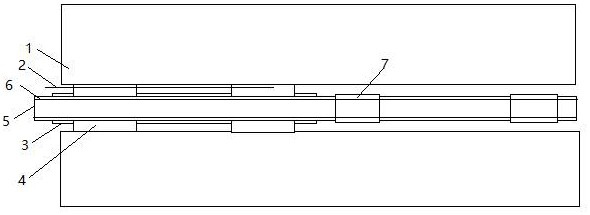

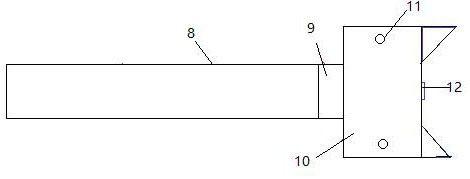

[0066] (3) After the sealed steel pipe is connected to the compressed air spin drill bit, a cleaning and dredging device is formed. The cleaning and dredging device is inserted into the gas drainage drilling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com