Hole drilling and sealing device and method with continuous belt pressure

A hole sealing device and technology in boreholes, applied in safety devices, earthwork drilling, sealing/isolation, etc., can solve the problem that it is difficult to seal borehole fissures, affect the gas drainage effect, and cannot provide re-grouting channels and other problems, to achieve the effect of good sealing effect, wide practicability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

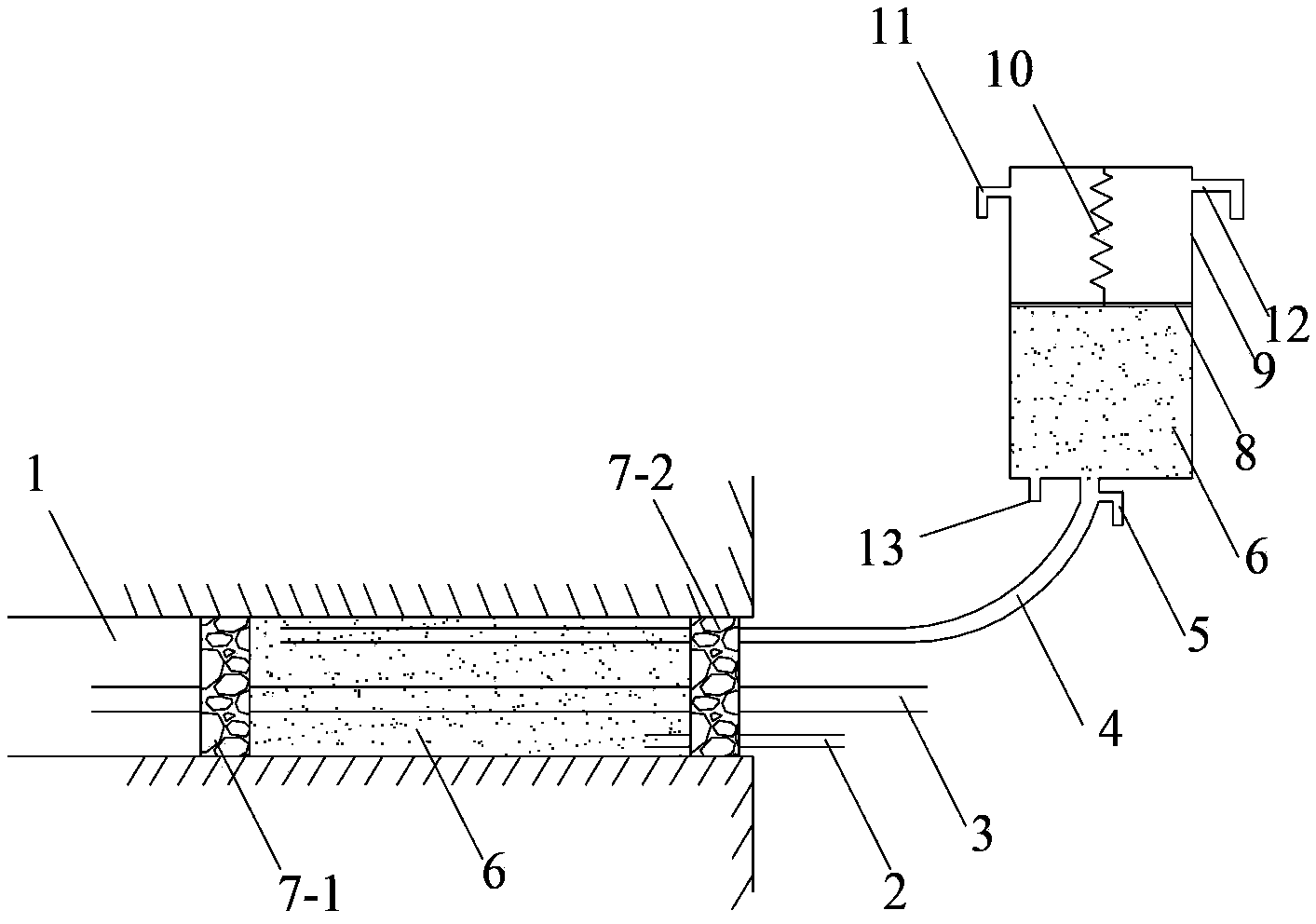

[0016] exist figure 1 Among them, the continuous pressurized drilling and sealing device of the present invention is mainly composed of a gas extraction pipe 3, a grouting pipe 2, a grout return pipe 4, a slurry storage tank 9, an inner plugging disc 7-1, and an outer plugging disc 7 -2 composition, gas drainage pipe 3, grouting pipe 2, grout return pipe 4, inner plugging slurry disc 7-1, outer plugging slurry disc 7-2 are arranged in the borehole 1, in the grout return tube 4 A slurry storage tank 9 is connected to the top, and the slurry storage tank 9 is provided with a slurry filling valve 5, a grouting valve 13, a pressure relief valve 11 and an air receiving valve 12. A grouting plate 8 is arranged in the slurry storage tank 9, and a sealing gasket is provided between the grouting plate 8 and the inner wall of the slurry storage tank 9, and a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com