Gas extraction downward hole sealing device and hole sealing method adopting same

A technology of gas drainage and hole sealing device, which is applied in the direction of gas discharge, safety device, sealing/isolation, etc. It can solve the problems of poor sealing, reduce the occupied space, save the cost of a single hole, and improve the quality of sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

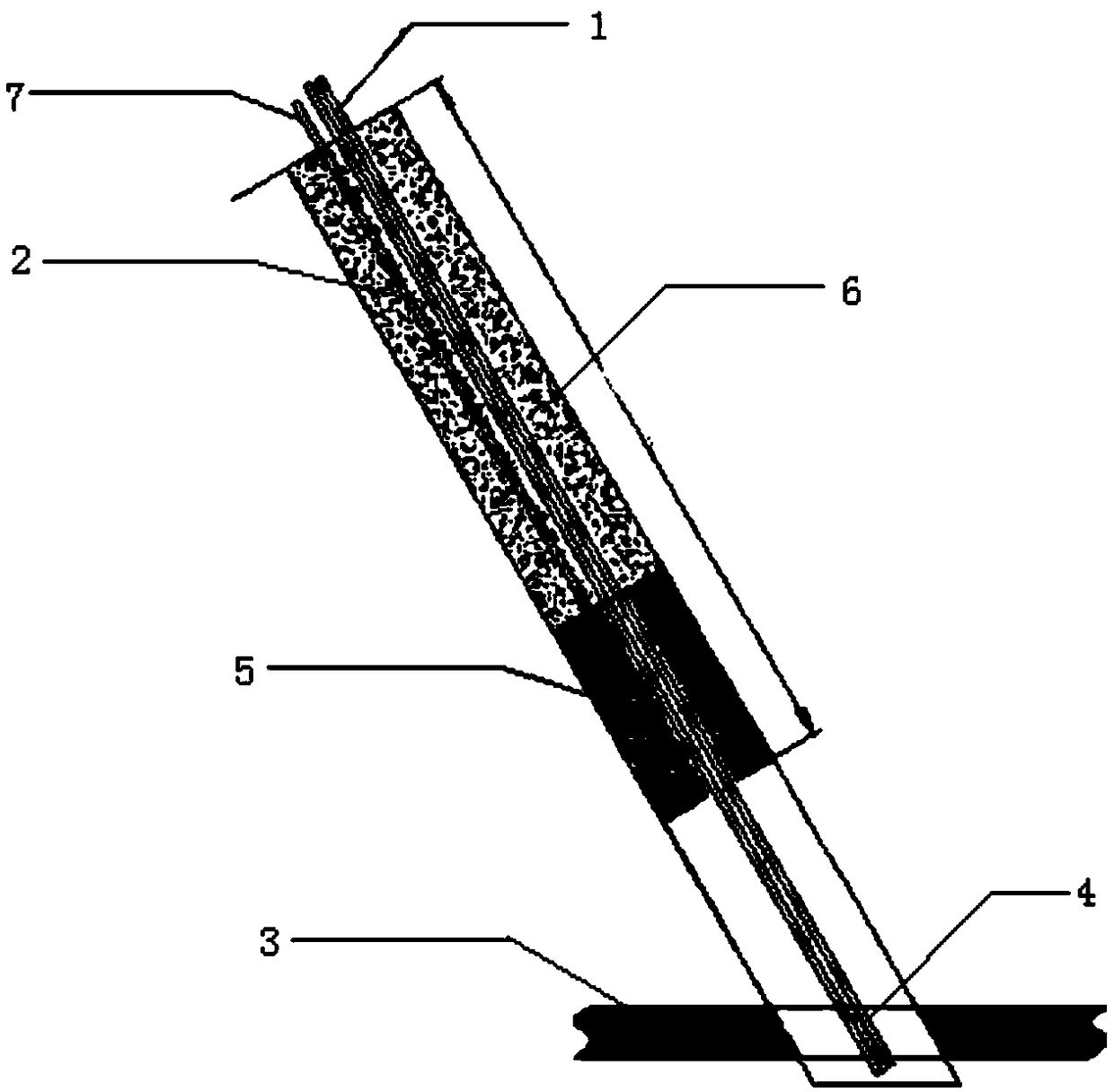

[0025] like figure 1 As shown in the figure, a downward hole sealing device for gas drainage includes two bundled pipes, which are respectively used as a extraction pipe 1 and a drainage pipe 2. The two bundled pipes go down to the bottom of the coal seam 3 at the bottom of the hole. There is a flower eye 4 in the area between the road bundle pipe down to the coal seam bottom plate and the hole bottom section; a sealing bag 5 is sleeved on the two road bundle pipes, and the sealing bag 5 is arranged at the bottom of the seat in the hole is used to seal the hole 6; the sealing bag 5 is also provided with a grouting pipe 7, and the grouting pipe 7 is inserted into the sealing bag 5 along the hole 6 for feeding The grouting is carried out in the sealing pouch 5 and in the drilled hole 6 .

[0026] In order to reduce the problem of air leakage at the splicing point, the two bundles of tubes are all made of a whole-disk type of polyvinyl chloride bundled tubes.

[0027] The lower...

Embodiment 2

[0030] A method for sealing down holes in gas drainage, using the above-mentioned device for sealing down holes in gas drainage, comprising the following steps:

[0031] 1) Downpipe: use a metal probe to go into two-way bundles from the orifice to the bottom of the hole, and the two-way bundles are respectively used as the extraction pipe 1 and the drain pipe 2; One way of casing is used to abut the drill bit, and the bundled tube is provided with a flower hole 4 in the area between the bottom of the coal seam 3 and the bottom of the hole.

[0032] 2) Capsule fixation: After the two-way bundle tubes are in place, the sealing capsular bag 5 is put on the two-way capsular tube, and the sealing capsular bag 5 is sent into the hole with a metal probe for seating. sealing;

[0033] 3) Install the grouting pipe: set the grouting pipe 7 at the orifice, and the grouting pipe 7 is inserted into the sealing bag 5 along the drilled hole 6;

[0034] 4) Grouting with grouting pipe: mix t...

Embodiment 3

[0036] Contrast construction situation of on-site mining and sealing of a track along the roof roadway:

[0037] (1) Site geological conditions and design specifications

[0038] The maximum gas pressure of the 1151(1) track along the roof roadway is 0.78MPa, and the maximum gas content is 4.83m3 / t. The design length is 2141m, the section specification: width × height (net) = 5200 × 3800mm (net), anchor net cable + set of 29U shed support. A drilling field is arranged every 50 meters in the roadway. Drilling holes are drilled down to the layers in the drilling field and the roadway. A group of drilling holes is designed every 10 meters along the direction of the roadway, with 10 drilling holes in each group. It is required to seal the hole with casing during the whole drilling process, and the length of the sealing hole shall not be less than 12 meters.

[0039] (2) Comparison of drilling and sealing construction

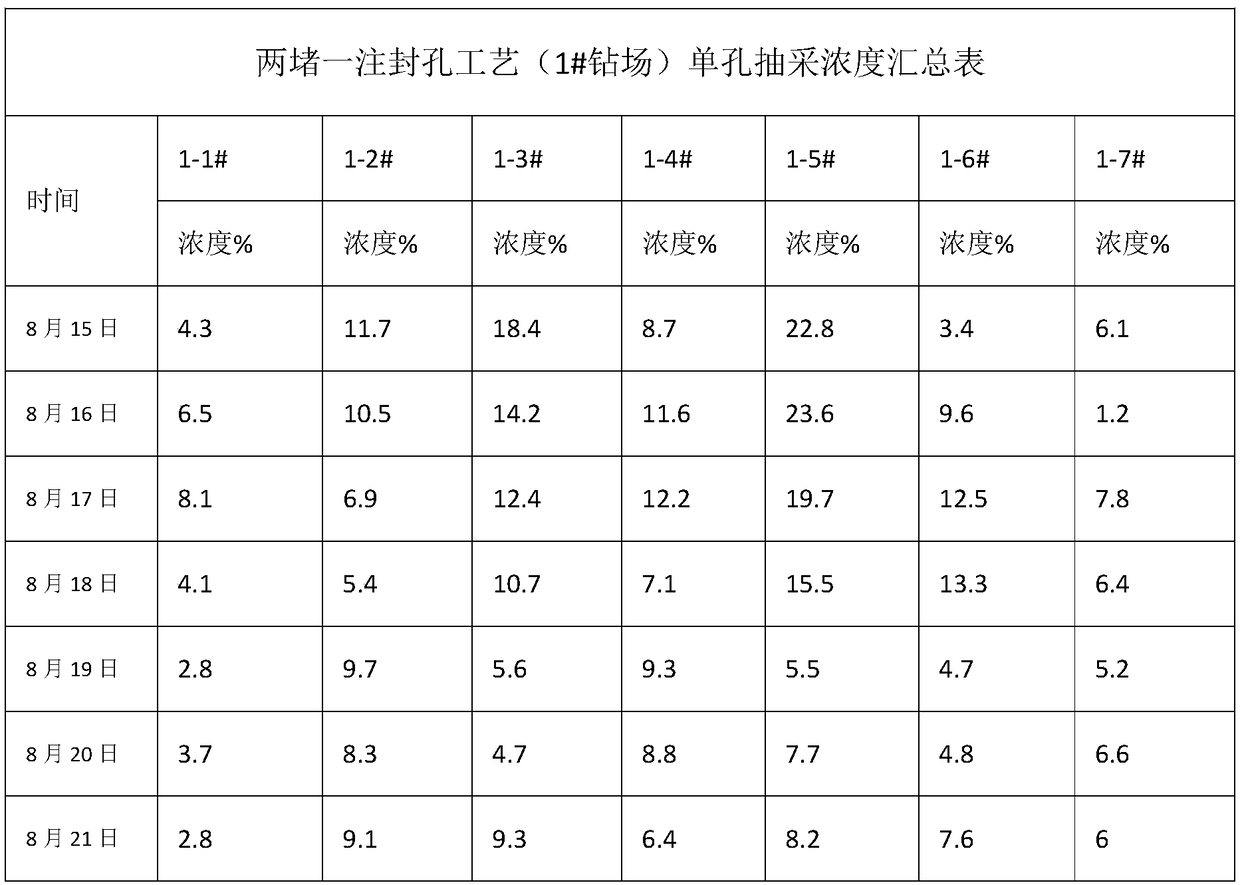

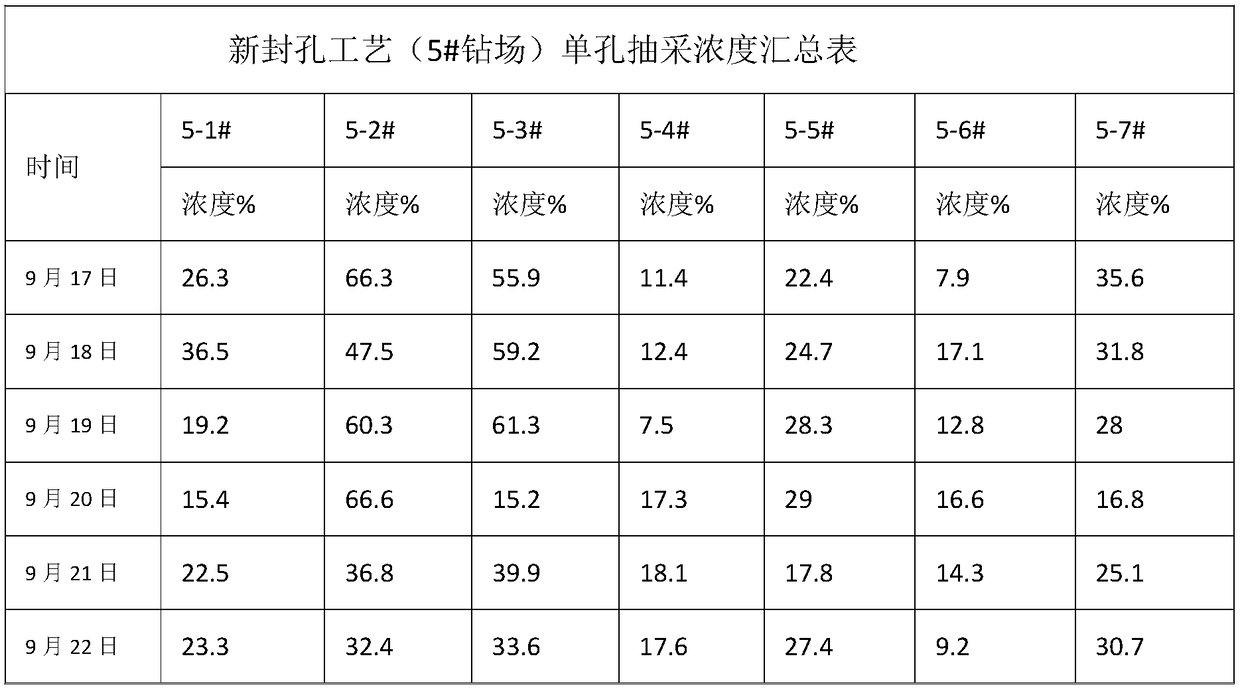

[0040] The first group adopts the traditional two-plug and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com