Full-area rapid dredging and descending method after underground curtain closure

An all-area, curtain technology, applied in underground chambers, earthwork drilling, safety devices, etc., can solve the problem of low dredging efficiency, difficult dredging of aquifers in water storage media, and inability to meet rapid and safe dredging in the whole area And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

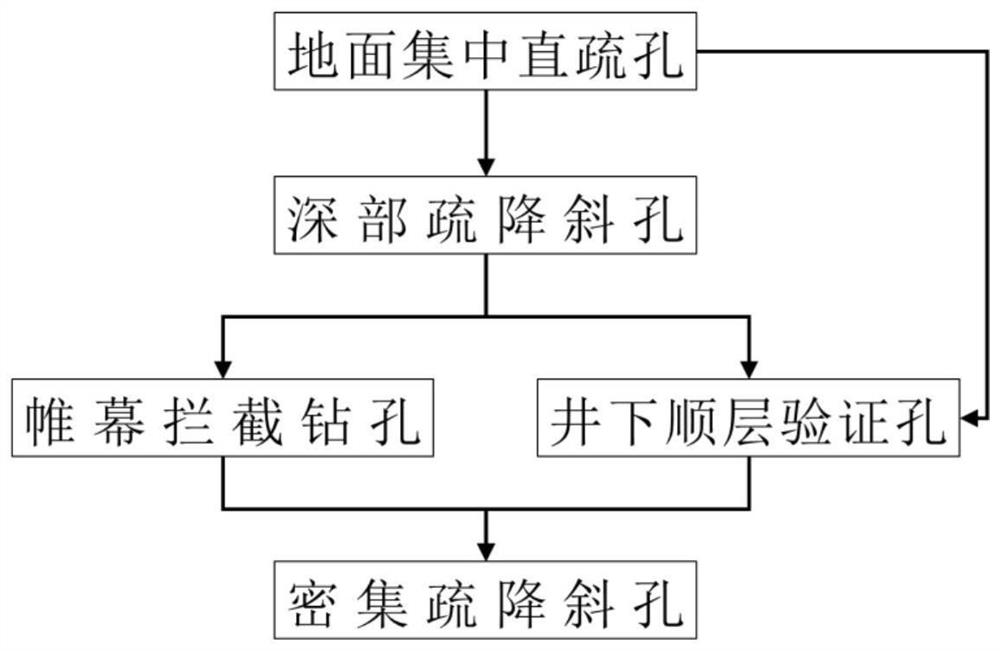

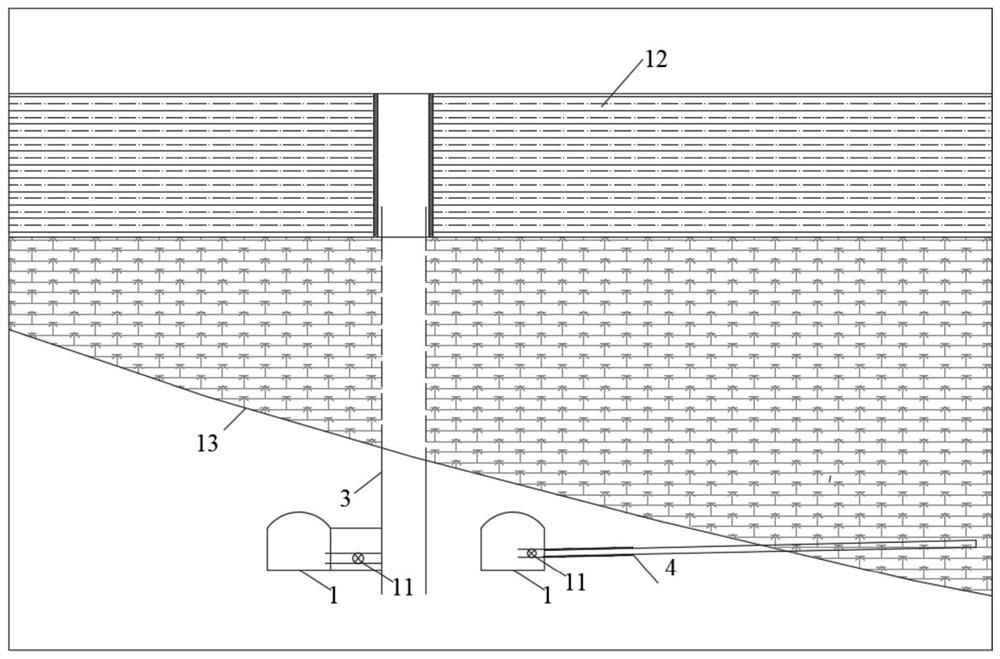

[0053] Step 1: See figure 2 and image 3, according to the aquifer 13 and the actual conditions up and down the well, arrange the ground drainage holes 3, connect the aquifer 13 and the downhole drainage system, and perform centralized drainage of the aquifer 13, specifically, the following sub-steps may be included:

[0054] Step 1.1: According to the location of the underground roadway 1, select the position of the ground straight dredging hole 3, and the distance from the target roadway plane is 5-10m;

[0055] Step 1.2: Construction starts from the ground surface to above the aquifer 13, runs the casing and cements the well, completes the water stop and conducts the pressure test until it is qualified;

[0056] Step 1.3: Construct the second casing to 15m below the floor level of the target roadway 1, and lower the second casing, which is a flying tube, which overlaps with the first casing by 20m; the second casing includes the flowers of the 13th section of the aquifer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com