Steel forging and pressing equipment

A technology for forging equipment and steel, applied in the field of steel manufacturing, can solve the problems of safety incidents, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

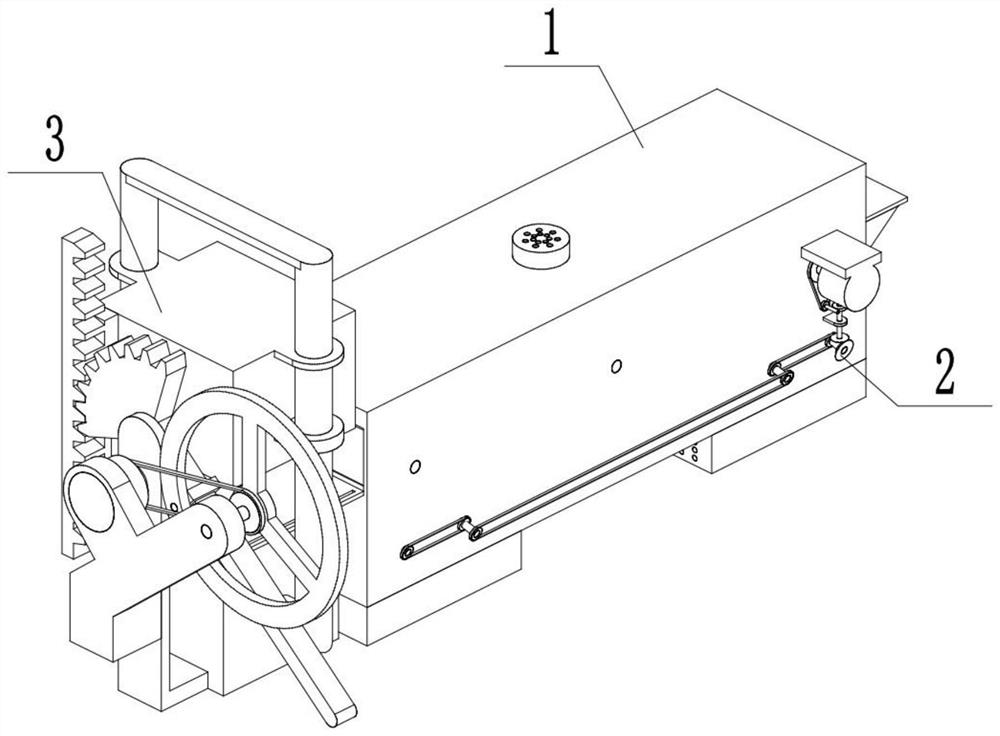

[0032] Combine below Figure 1-17 Describe this embodiment, a steel forging equipment, including a transportation assembly 1, a heating assembly 2 and a forging assembly 3, the transportation assembly 1 is connected to the heating assembly 2, and the transportation assembly 1 is connected to the forging assembly 3 .

specific Embodiment approach 2

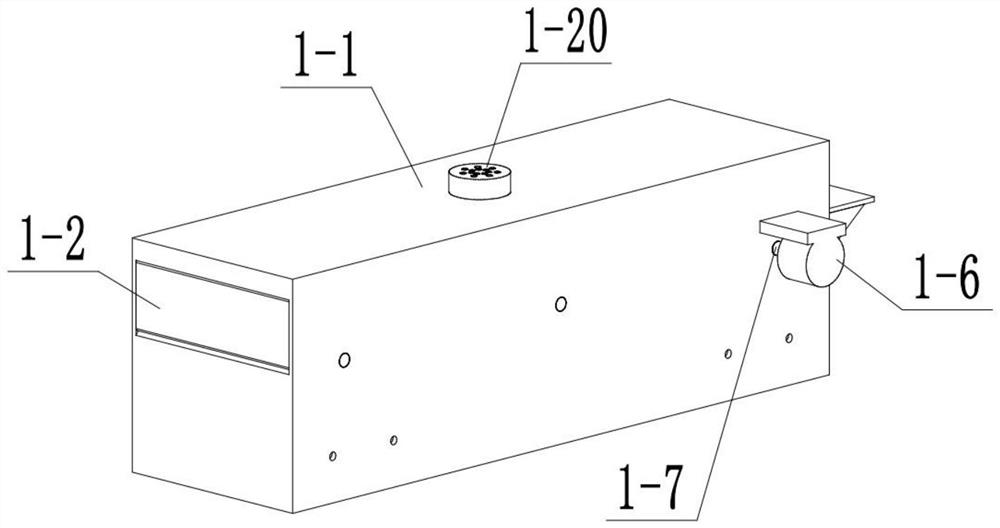

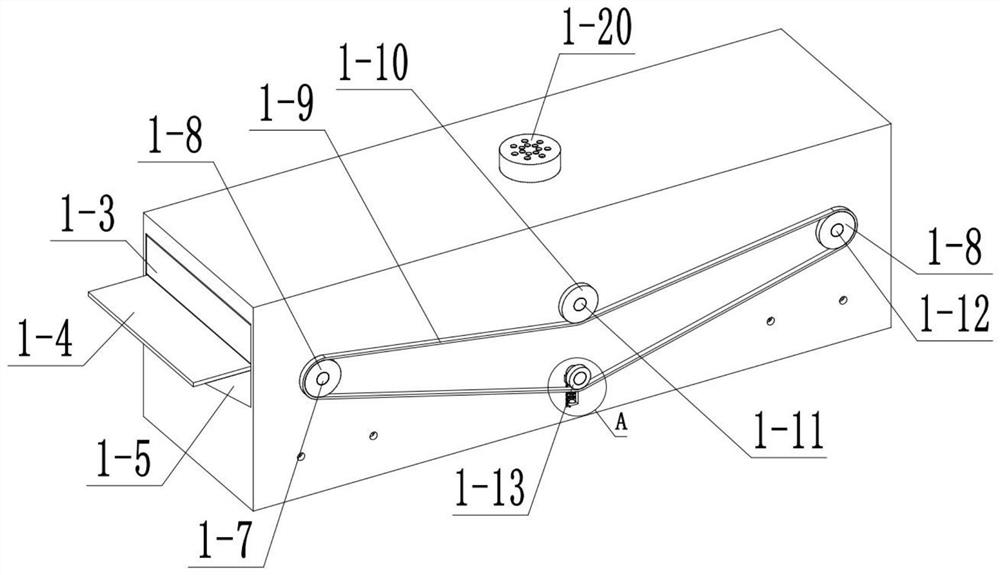

[0034] Combine below Figure 1-17Describe this embodiment, this embodiment will further explain the first embodiment, the transport assembly 1 includes a box body 1-1, a discharge door 1-2, a feed door 1-3, a feed platform 1-4, a platform Bracket 1-5, motor Ⅰ 1-6, motor Ⅰ shaft 1-7, sprocket Ⅰ 1-8, chain Ⅰ 1-9, sprocket Ⅱ 1-10, sprocket Ⅱ shaft 1-11, side shaft 1-12, Zhang Tightening sprocket 1-13, tensioning shaft 1-14, tension spring 1-15, tensioning shaft chute 1-16, toggle roller 1-17, connecting rod 1-18, hinged shaft 1-19, filter screen 1-20 and discharge inclined plate 1-21, discharge door 1-2, and feed door 1-3 are hinged with box body 1-1, and feed platform 1-4 is connected with box body 1-1, Feeding platform 1-4 is connected with platform support 1-5, platform support 1-5 is connected with box body 1-1, motor I1-6 is connected with motor I shaft 1-7, motor I1-6 is connected with box body 1-1 phase connection, the motor I axis 1-7 is rotationally connected with the ...

specific Embodiment approach 3

[0036] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain Embodiment 1, the heating assembly 2 includes a sprocket III 2-1, a chain II 2-2, a sprocket IV 2-3, a worm 2-4, a worm wheel 2-5, a worm wheel Shaft 2-6, worm gear shaft support 2-7, bevel gear Ⅰ 2-8, bevel gear Ⅱ 2-9, fan blade shaft 2-10, fan blade 2-11, baffle plate 2-12, air outlet 2-13, fan Blade shaft connecting sprocket Ⅰ 2-14, fan blade shaft connecting chain 2-15, fan blade shaft connecting sprocket Ⅱ 2-16, bottom plate with holes 2-17, combustion chamber 2-18, fuel adding door 2-19 and filter hole 2-20, motor I shaft 1-7 is connected with sprocket III 2-1, sprocket III 2-1 is connected with sprocket IV 2-3 through chain II 2-2, sprocket IV 2-3 is connected with worm 2-4 , the worm 2-4 is rotationally connected with the box 1-1, the worm 2-4 is meshed with the worm wheel 2-5, the worm wheel 2-5 is connected with the worm shaft 2-6, and the worm shaft 2-6 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com