Patents

Literature

39results about How to "Automatic lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

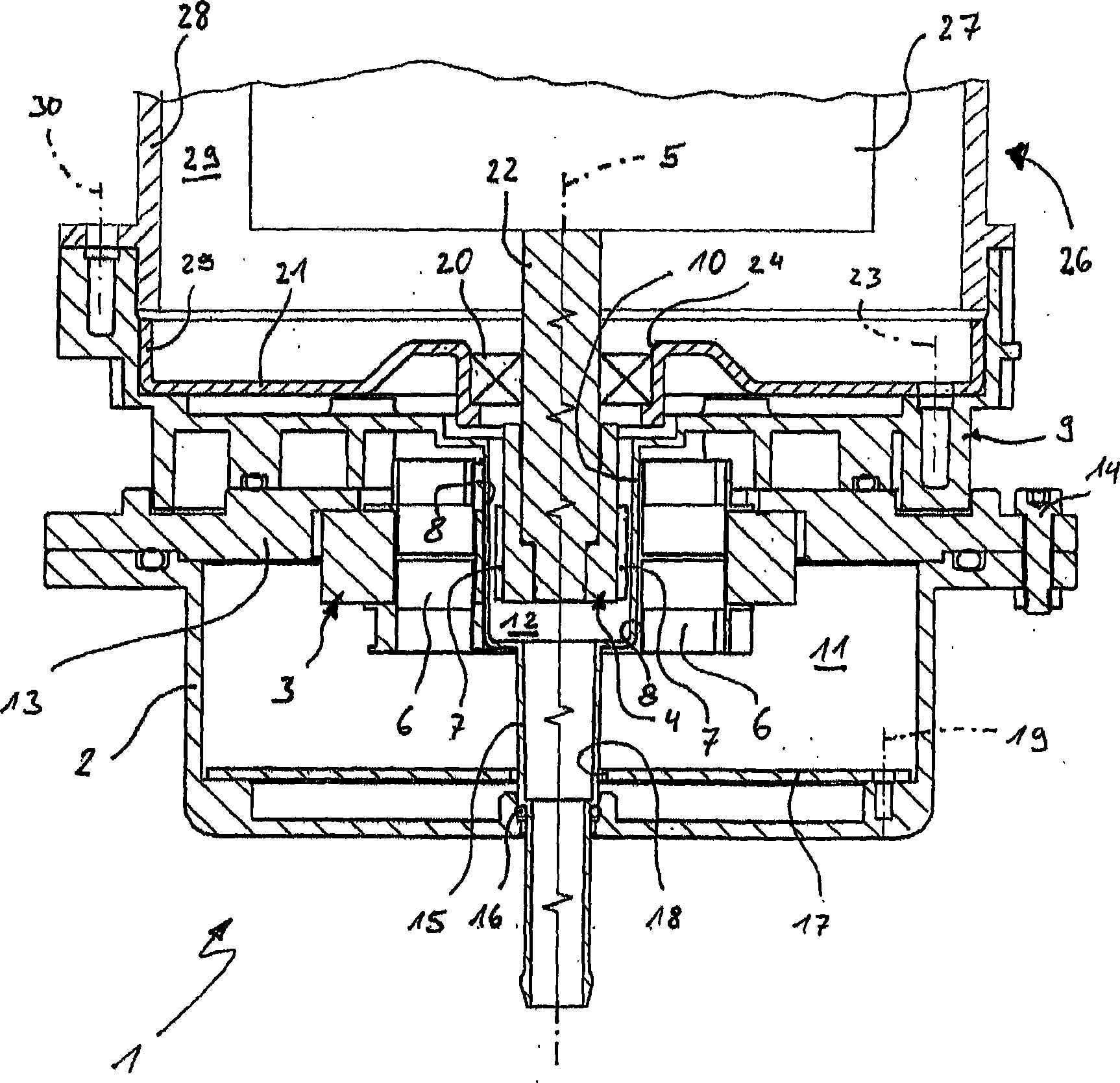

Electric motor

InactiveCN101390274AFree from impuritiesAutomatic lubricationCentrifugesMechanical energy handlingEngineeringNon magnetic

The present invention relates to an electric motor (1) for driving an inertia separator (26), comprising a stator (3), which is arranged in a stator housing (2), and a rotor (4), which is arranged concentrically with respect to the stator (3) and is drive-connected to a rotor (27) of the inertia separator (26). In order to be able to seal off the electric motor (1) more easily, a housing bottom (9) extends with a non-magnetic section (10) through an annular gap (8), which is formed radially between the rotor (4) and the stator (3), such that it separates a stator space (11), which accommodates the stator (3) and is in the interior of the stator housing (2), from a rotor space (12), which accommodates the rotor (4) and is open towards a rotor space (29) accommodating the rotor (27) of the inertia separator (26).

Owner:MAHLE INT GMBH

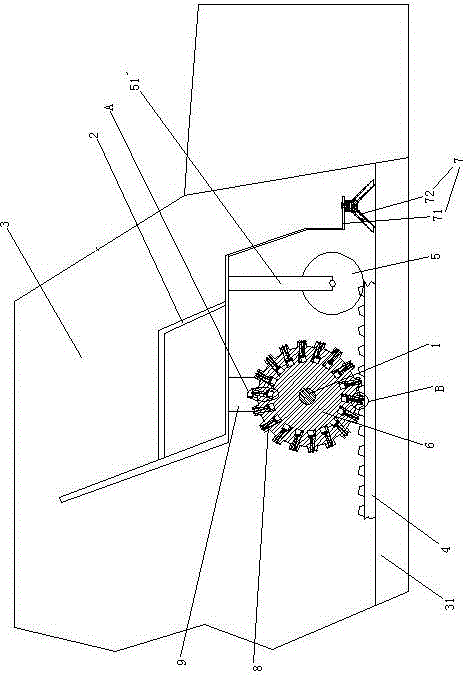

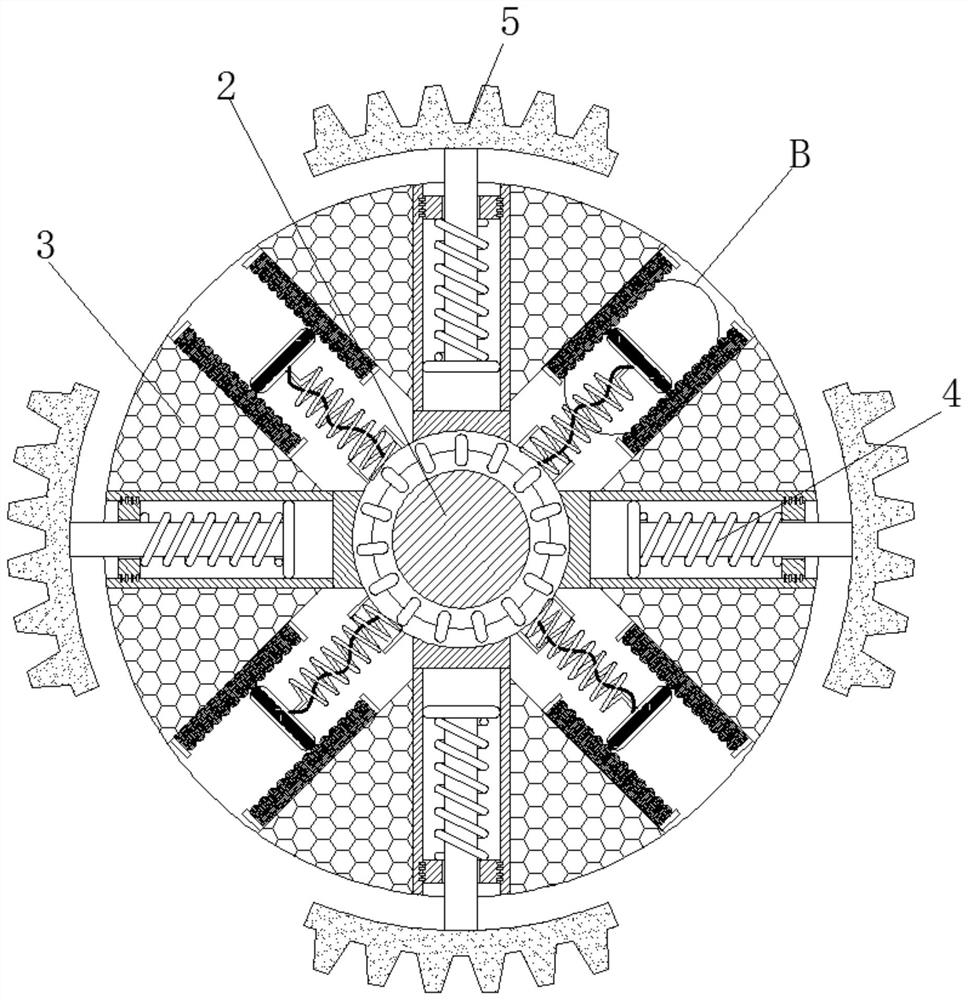

Automobile with movable automobile seat

The invention relates to automobiles, in particular to an automobile with a movable automobile seat. The automobile comprises an automobile body, racks and the seat, the seat is provided with traveling gears meshed with the racks, and a plurality of lubricating mechanisms are arranged in the traveling gears. Each lubricating mechanism comprises an oil outlet, an air supply port, a seal head, a first spring, a cylinder body and a piston, wherein the first spring drives the seal head to seal the oil outlet, the piston is slidably and hermetically connected onto the cylinder body and partitions the cylinder body into an air cavity and an oil cavity, the piston is provided with a check valve opened towards the air cavity, the piston is connected with the seal head through a connection rod, the oil outlet is communicated with the oil cavity through an oil passage, and the air supply port is communicated with the air cavity through an air passage. The oil outlets are formed at the tops of teeth of the traveling gears, and the extension distance of each seal head extending out of the corresponding tooth top of the traveling gears is larger than a tooth top gap between each traveling gear and the corresponding rack. The automobile with the movable automobile seat has the advantage that the seat is capable of moving and lubricating automatically, and the problem that an existing automobile seat is unmovable and requires manual lubrication is solved.

Owner:YANCHENG INST OF TECH

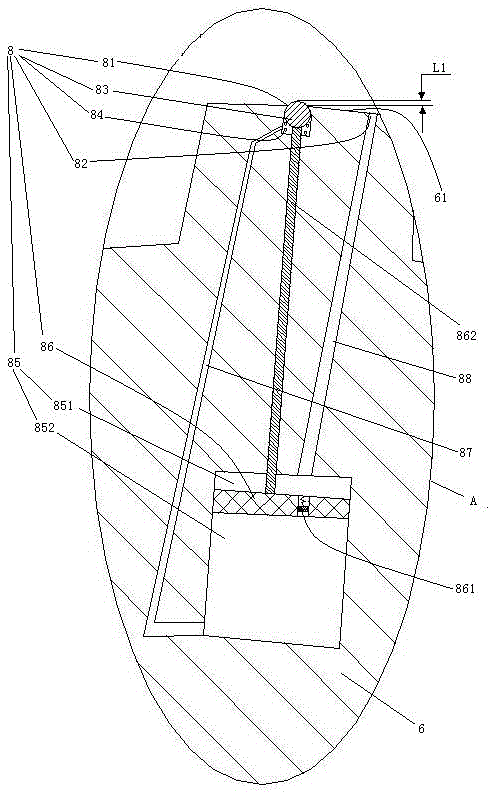

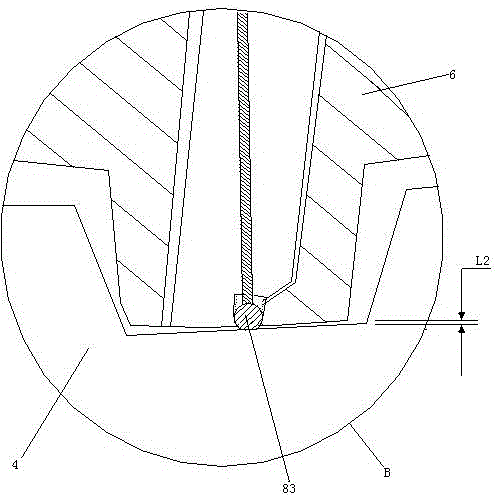

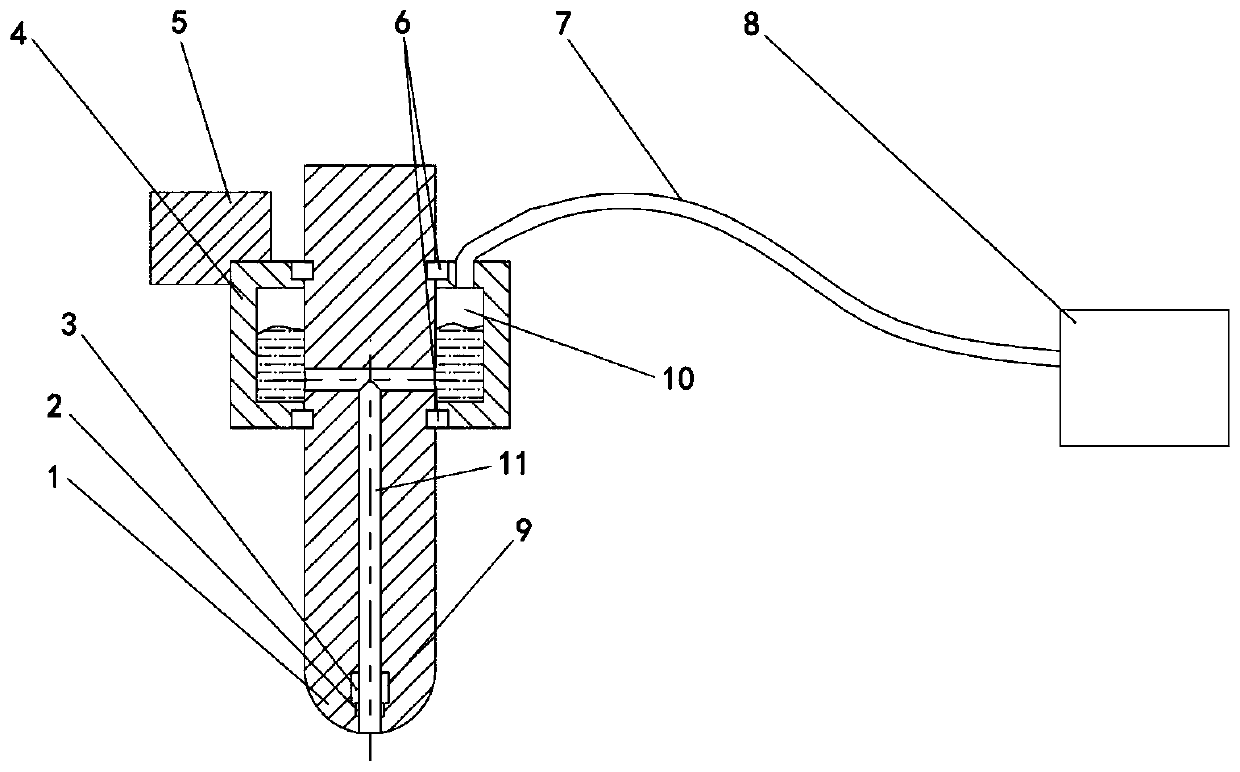

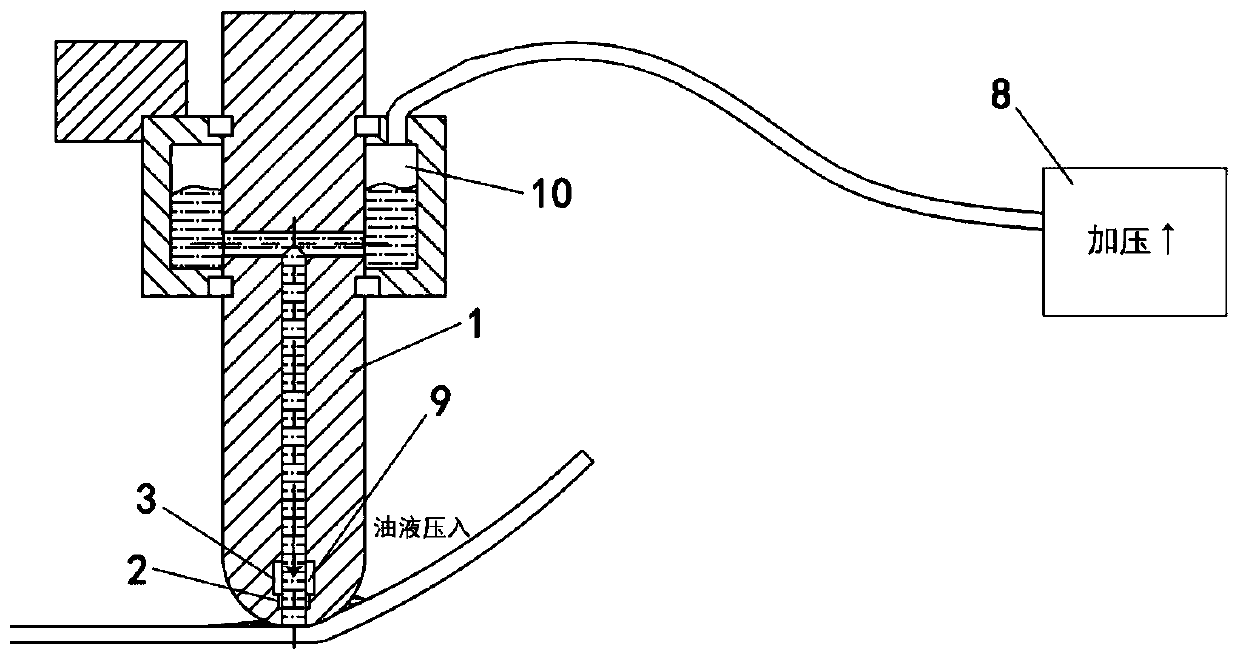

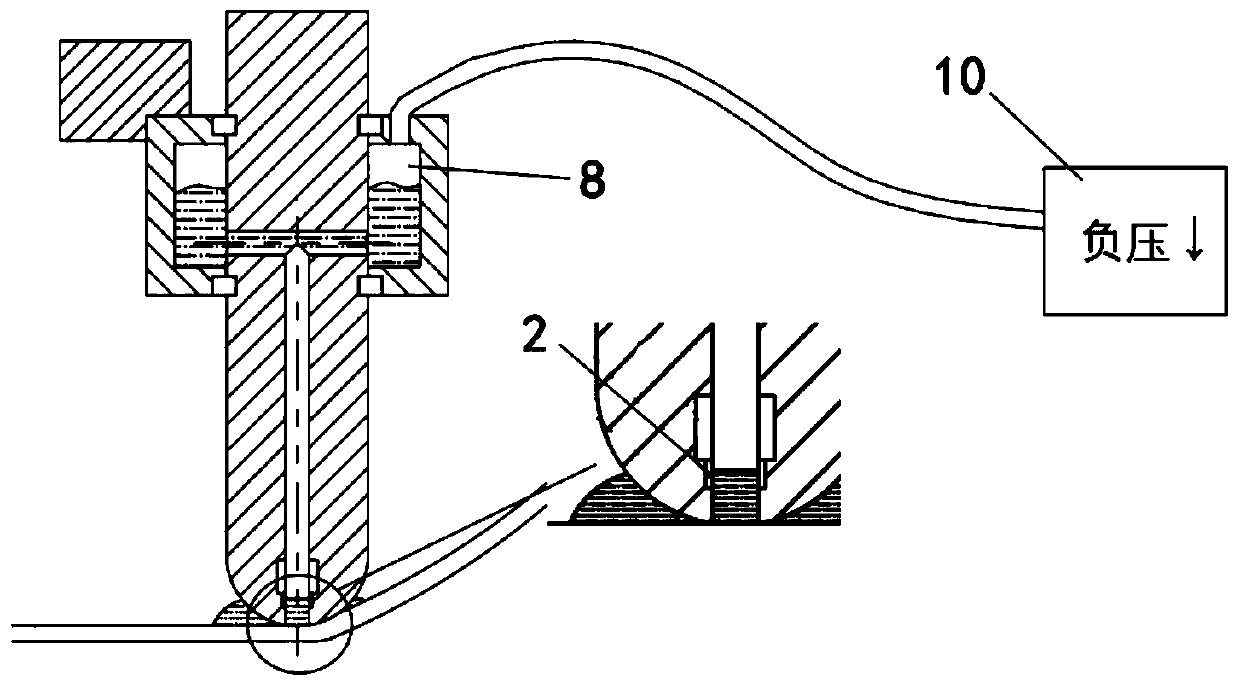

Incremental forming tool with automatic lubrication function

ActiveCN109622753ASave human effortImprove working environmentShaping toolsPressure controllerLubrication

The invention relates to an incremental forming tool with an automatic lubrication function. The progressing forming tool with the automatic lubrication function comprises a gripping handle, an oil tank, a sealed bearing, a forming tool head, a gas pipe and a pressure controller; the forming tool head is mountedon a main shaft of an incremental forming machine tool, the upper end of the forming tool head penetrates through the oil tank, and the oil tank is connected with a fixed part of the incremental forming machine tool by connecting with the gripping handle; the sealed bearing is installedat the joint of the oil tank and the forming tool head, an oil groove is formed inside the forming tool head, an outlet of the oil groove is formed in the lower end of the forming tool head, and an inlet of the oil groove is connected with the oil tank. Compared with the prior art, the incremental forming tool with the automatic lubrication function has the advantages that automatic lubrication of the tool head and the sheet processing position during incremental forming is achieved,special lubricating oil adding equipment is no longer required, precise control over lubricating oil quantity inthe forming process is realized only by adjusting an input air pressure value,thus surface quality and processing efficiency of an incrementally-formed machined workpiece are improved, the labor costislowered, and the working environment is improved.

Owner:SHANGHAI JIAO TONG UNIV

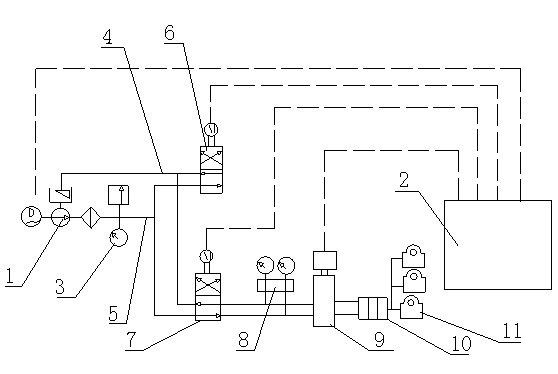

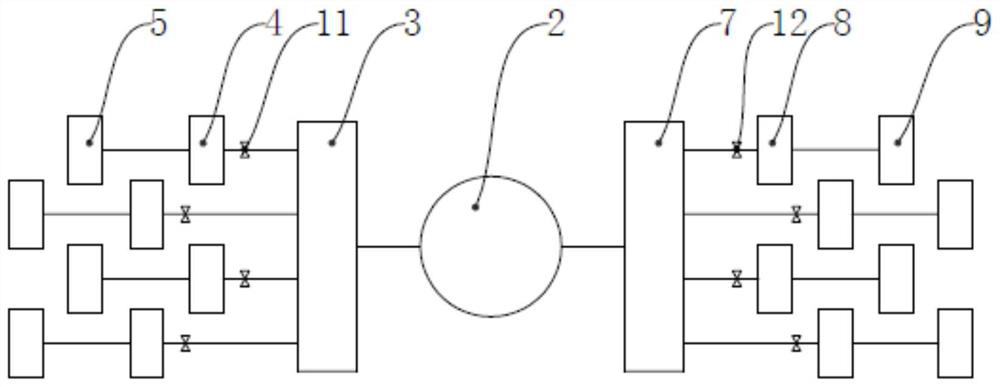

Portal crane intelligent centralized lubricating system

InactiveCN103133841AAutomatic lubricationLubricating pumpsConduits/junctionsDifferential pressureEngineering

The invention discloses a portal crane intelligent centralized lubricating system. The portal crane intelligent centralized lubricating system comprises a plunger fuel pump and an electric control cabinet, wherein a pumping set pressure gauge is installed on the plunger fuel pump, one end of the plunger fuel pump is connected with a main pipeline I, the other end of the plunger fuel pump is connected with a main pipeline II, a hydraulic reversing valve is installed on the main pipeline I, a reversing valve is installed on the main pipeline II, the reversing valve is connected with a tail end pressure gauge group through the main pipeline II, the tail end pressure gauge group is connected with a differential pressure switch through the main pipeline II, the differential pressure switch is connected with a distributor through the main pipeline II, and the distributor leads to each lubricating point. The portal crane intelligent centralized lubricating system has the advantages that the main pipeline I and the main pipeline II are led from the plunger fuel pump, the hydraulic reversing valve is installed on the main pipeline I, a two-position four-way reversing valve is installed on the main pipeline II, and two return circuits are formed by the two-position four-way reversing valve to carry out automatic lubrication at regular intervals to a fixed point of each lubricating point of a portal crane.

Owner:南通市华东润滑设备有限公司

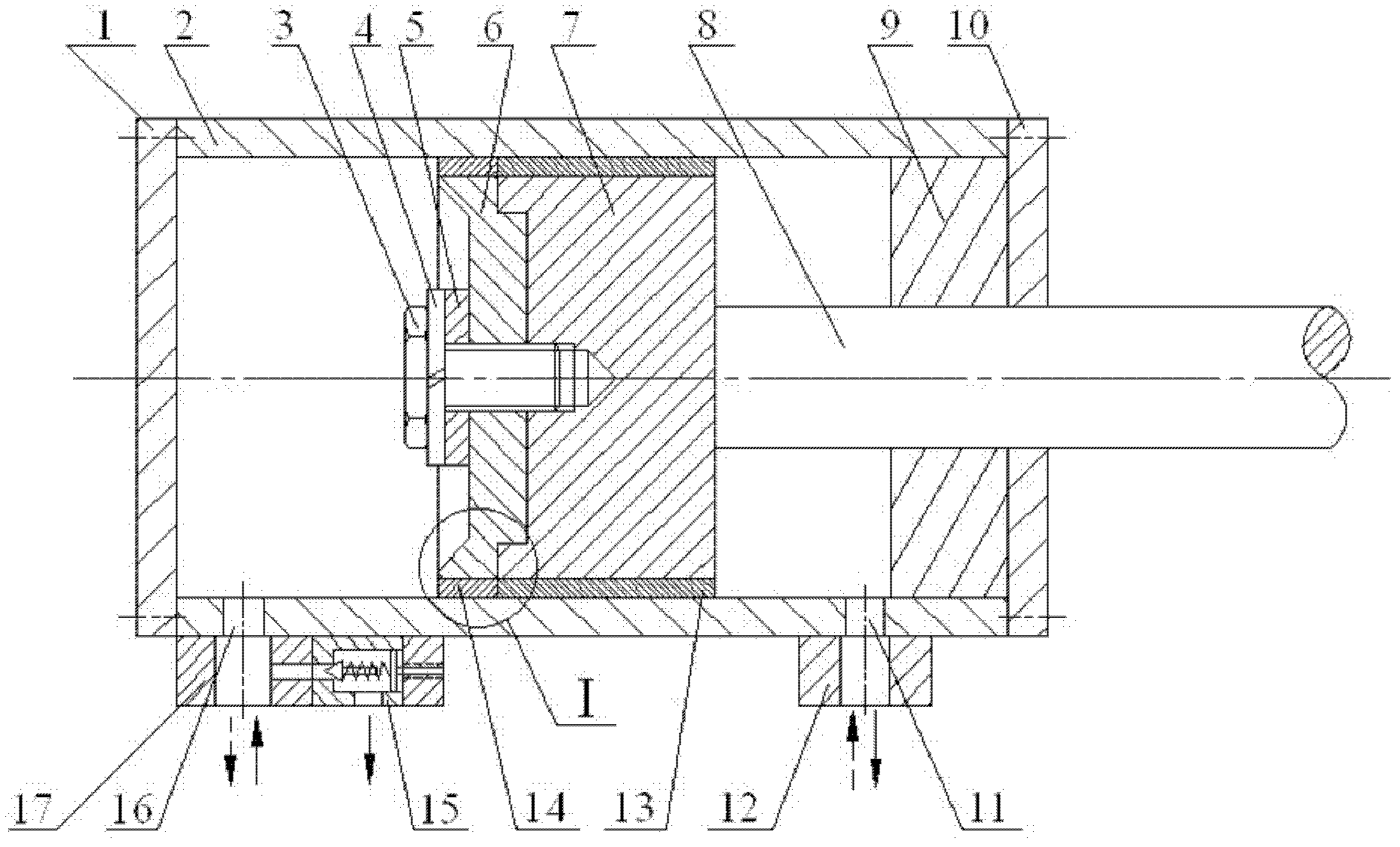

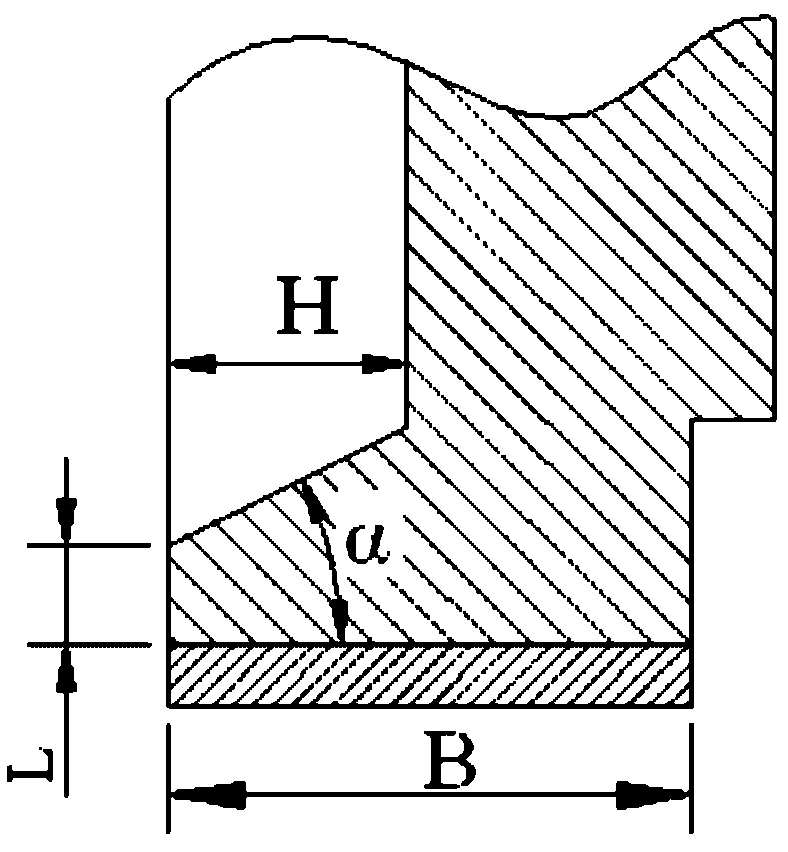

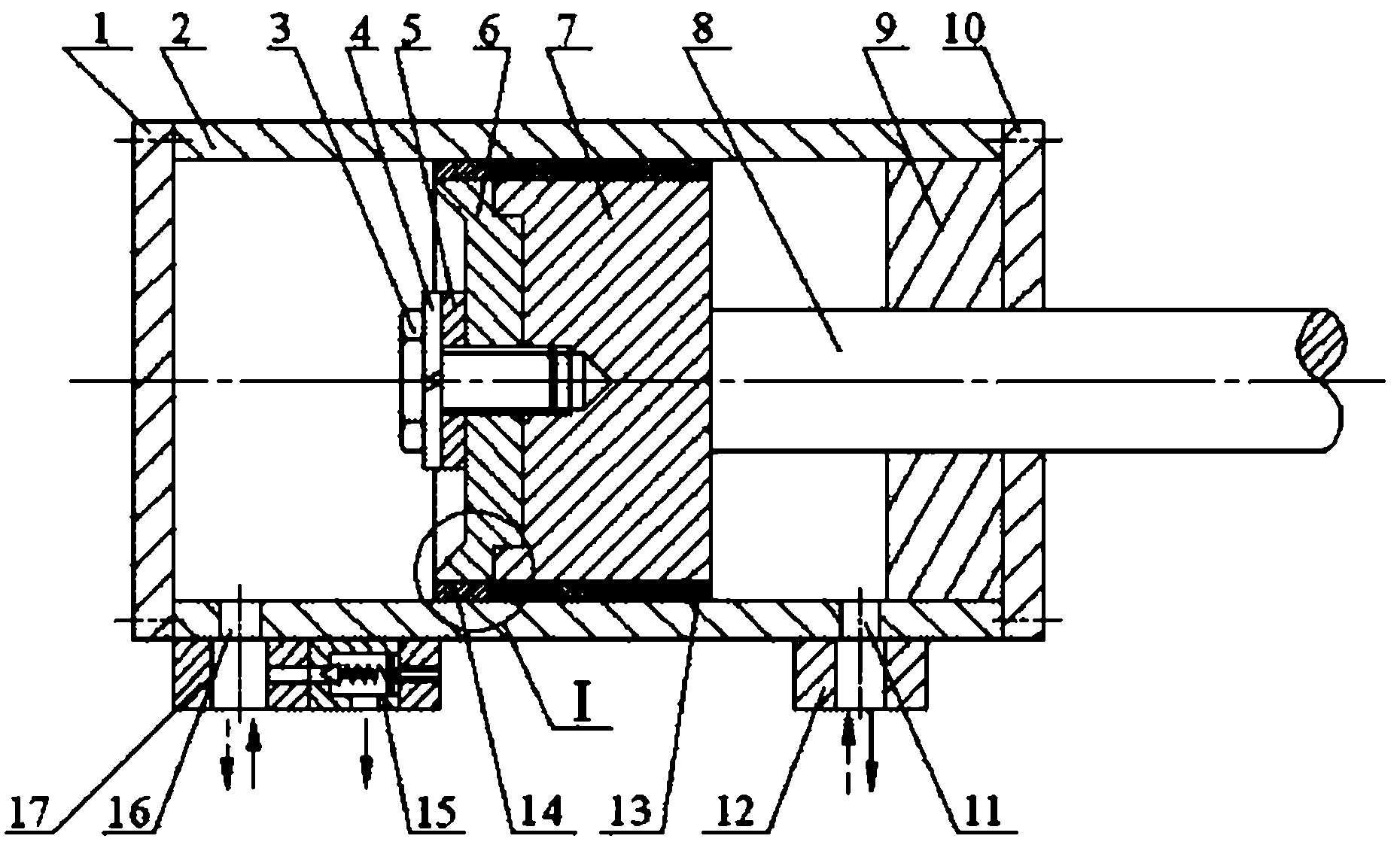

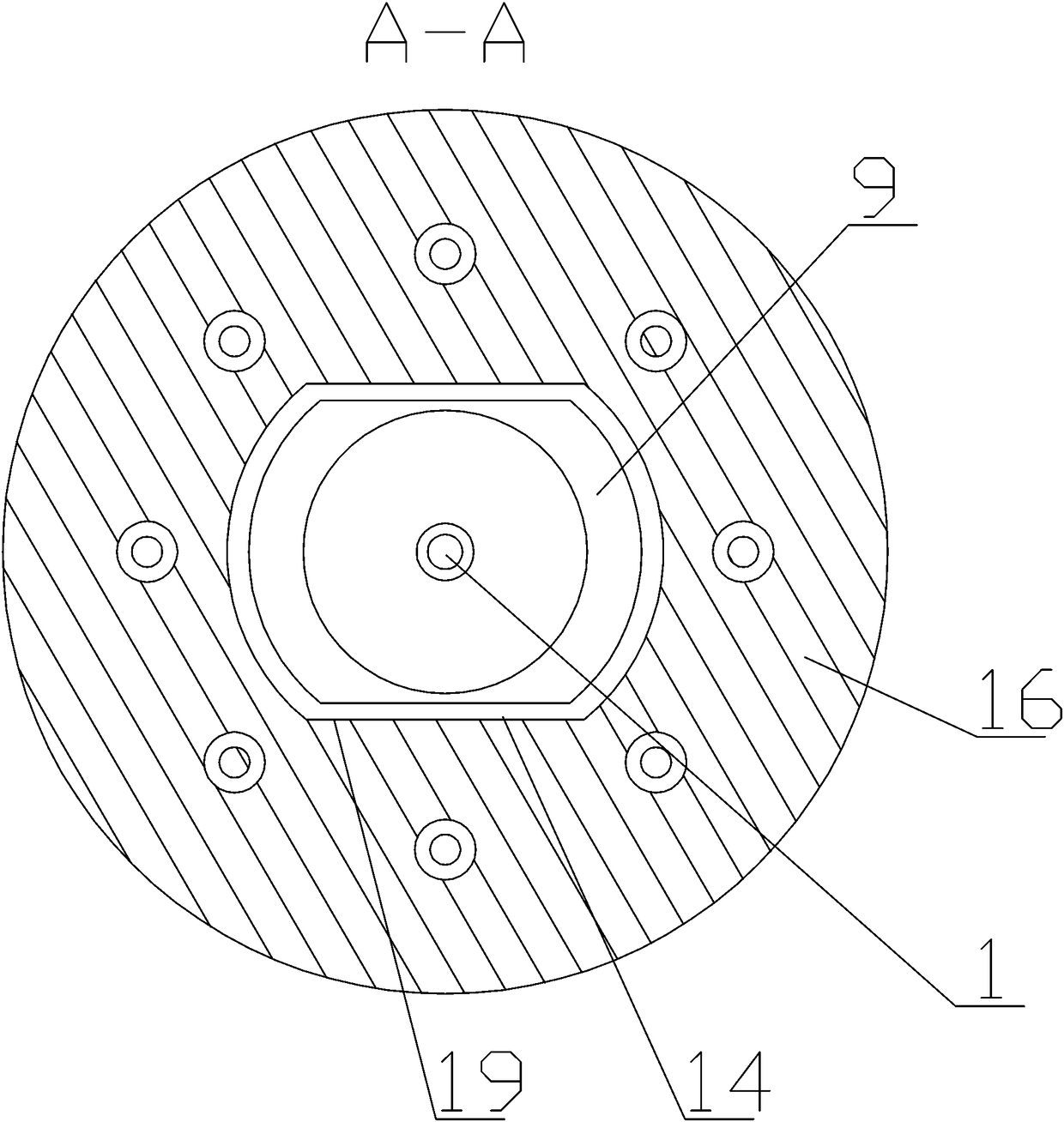

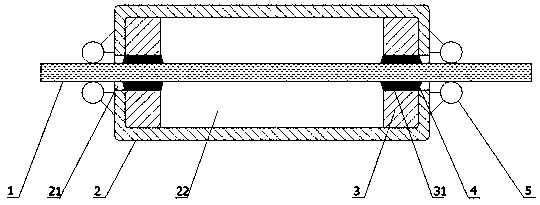

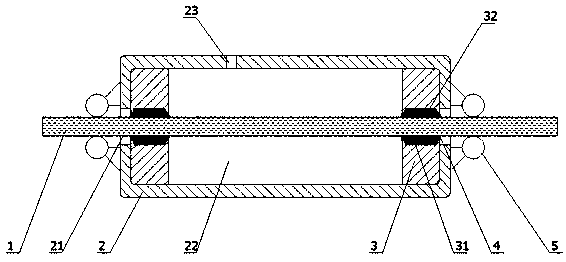

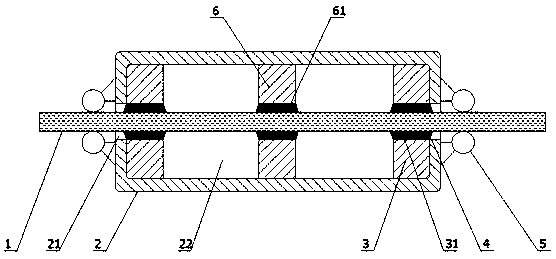

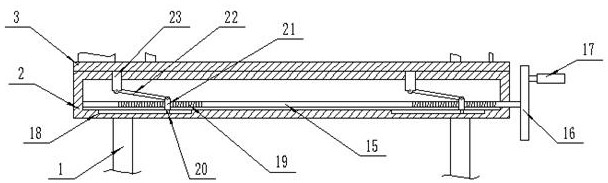

Gap seal hydraulic cylinder based on deformable piston ring

The invention relates to a gap seal hydraulic cylinder based on a deformable piston ring. The hydraulic cylinder provided by the invention is characterized in that the cylindrical boss end face and the annular bottom surface of the deformable piston ring (6) are concentrically and closely clung to the concave round bottom and the annular boss end face of a piston (7); the deformable piston ring (6) and the piston (7) have the same outer diameter; the deformable piston ring (6) is fixed with the piston (7) by a screw (3); the cylindrical surfaces of the deformable piston ring (6) and the piston (7) are correspondingly welded with a first aluminum bronze layer (14) and a second aluminum bronze layer (13); the left end face of the deformable piston ring (6) is composed of a concave round bottom in an obconical frustum shape and an annular boss which are arranged concentrically, and the annular boss with a right-trapezoidal section forms the lip of the deformable piston ring (6); a second valve block (17) is concentrically fixed at an oil port (16) of a rod-less cavity; and a pressure limiting valve (15) is closely clung to a cylinder barrel (2) and is fixed on the second valve block (17). The hydraulic cylinder provided by the invention has the characteristics of long service life, low friction performance, high frequency response, high efficiency, high reliability, low maintenance cost and overload protection performance.

Owner:WUHAN UNIV OF SCI & TECH

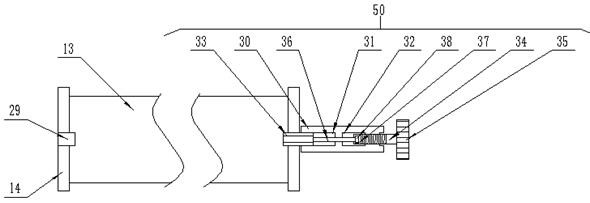

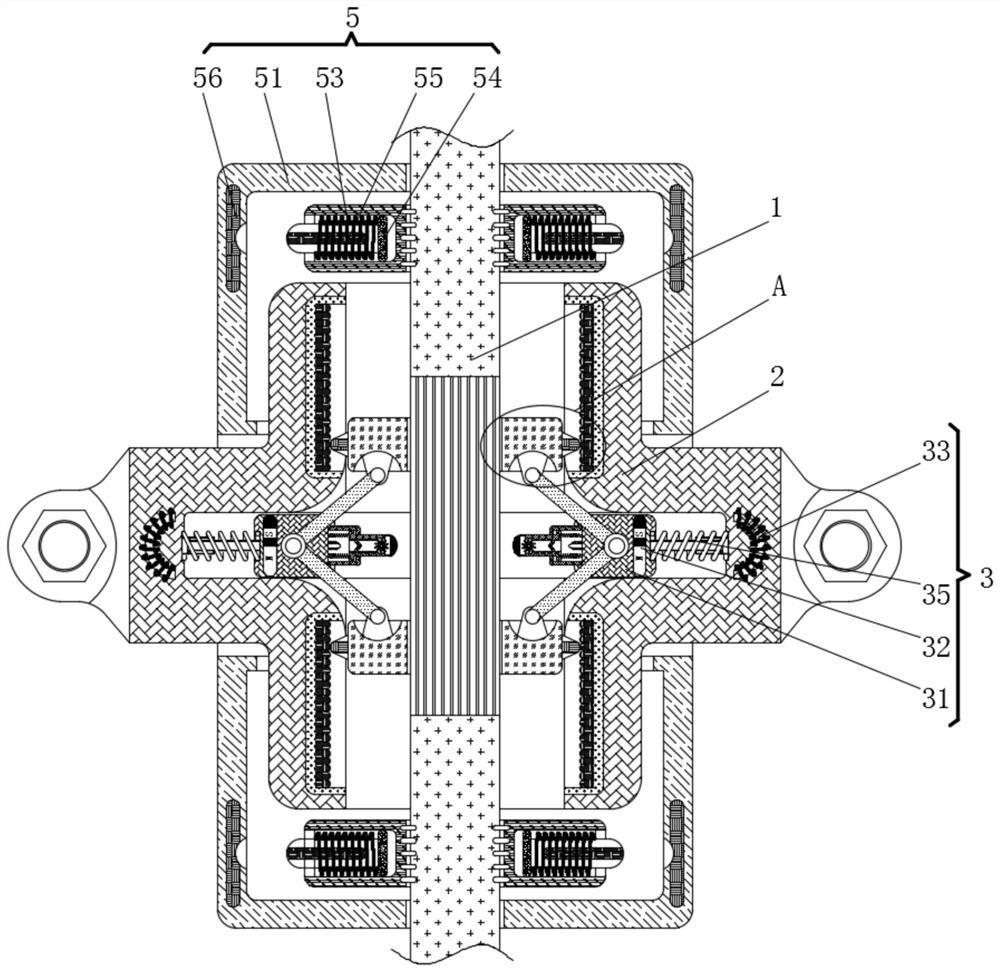

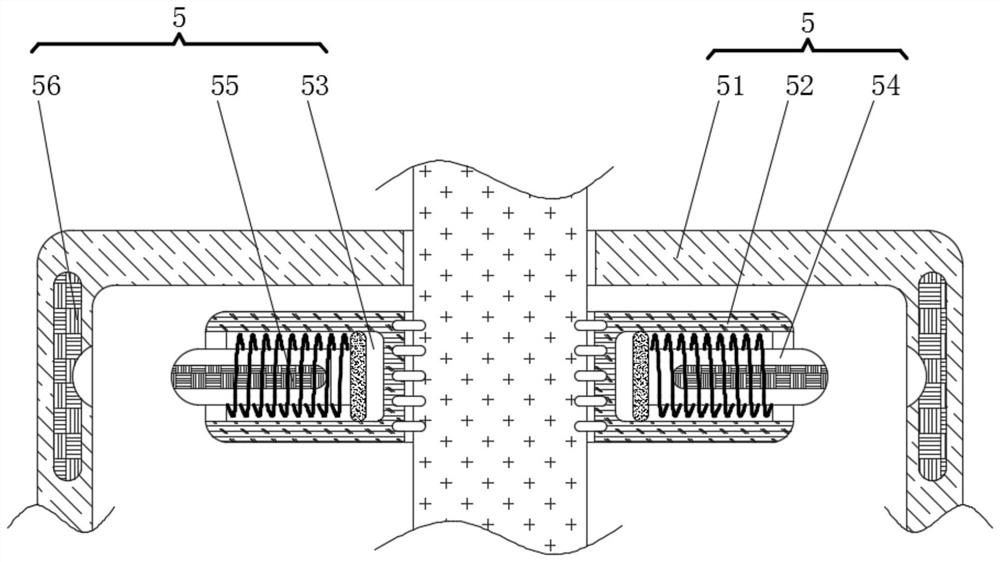

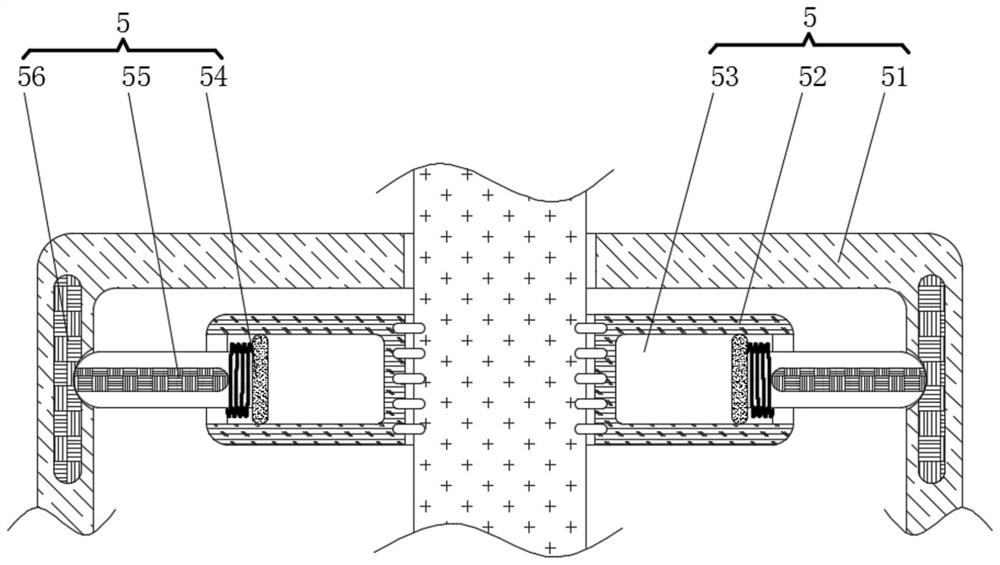

Automatic lubricating device for steel wire rope for swabbing truck

PendingCN108626558AStable lubricationGuaranteed adequate lubricationWinding mechanismsEngine lubricationTruckEngineering

The invention discloses an automatic lubricating device for a steel wire rope for a swabbing truck. The device comprises a shell, oil cavities, a trigger mechanism and a switching connecting rod, wherein the oil cavities, the trigger mechanism and the switching connecting rod are arranged in the shell; the shell is fixed on a running track of the steel wire rope of the swabbing truck, and a passing channel which allows the steel wire rope to penetrate through the shell is formed in the shell through sliding mechanisms; the oil cavities are distributed on the periphery of the steel wire rope ina surrounding mode, first oil outlet holes are formed in the bottom of the wall surface, facing the steel wire rope, of the oil cavities, and a spigot structure for limiting a switching joint is arranged on the outer sides of the first oil outlet holes; the trigger mechanism is clamped on the steel wire rope, and generates displacement / idling due to friction force in the operation of the steel wire rope; and the switching connecting rod is connected between the parts, at the trigger mechanism and the first oil outlet holes, of the spigot structure, and cooperates with the displacement / idlingstate of the trigger mechanism on the steel wire rope so as to enable the switching joint to be capable of achieving switching between two kinds of stations which allow the first oil outlet holes inthe oil cavities to be opened or plugged. According to the device, the steel wire rope of the swabbing truck can be conveniently, efficiently, timely, fully and stably lubricated.

Owner:SINOPEC SSC +1

Pin shaft and connecting structure and assembling method thereof

PendingCN108286554AReduce frictionAutomatic lubricationBoltsLubrication check valvesAxial forceHeavy equipment

The invention discloses a pin shaft and a connecting structure and an assembling method thereof. The pin shaft comprises a pin shaft body, and the pin shaft body penetrates through a first pin shaft connecting piece and a second pin shaft connecting piece; pin shaft pressing plates used for axially limiting the pin shaft body are symmetrically arranged at the two ends of the pin shaft body, the pin shaft pressing plates are arranged on fixing plates through first screw, and pin shaft fixing screw caps are arranged on the outer end faces of the pin shaft pressing plates; and pin shaft fixing nuts are arranged at the two tail ends of the pin shaft body. Oil groove notches are formed in the position of the pin shaft body and the second pin shaft connecting piece, the pin shaft body and the second pin shaft connecting piece do relative movement and are in contact with each other, and the oil groove notches are connected with a lubricating oil filling device. The pin shaft and the connecting structure thereof are used in heavy equipment and can bear large axial force, the abrasion of the pin shaft is effectively reduced by adopting the lubricating system, and the service life of the pinshaft is prolonged.

Owner:HUBEI LIDI MACHINE TOOL

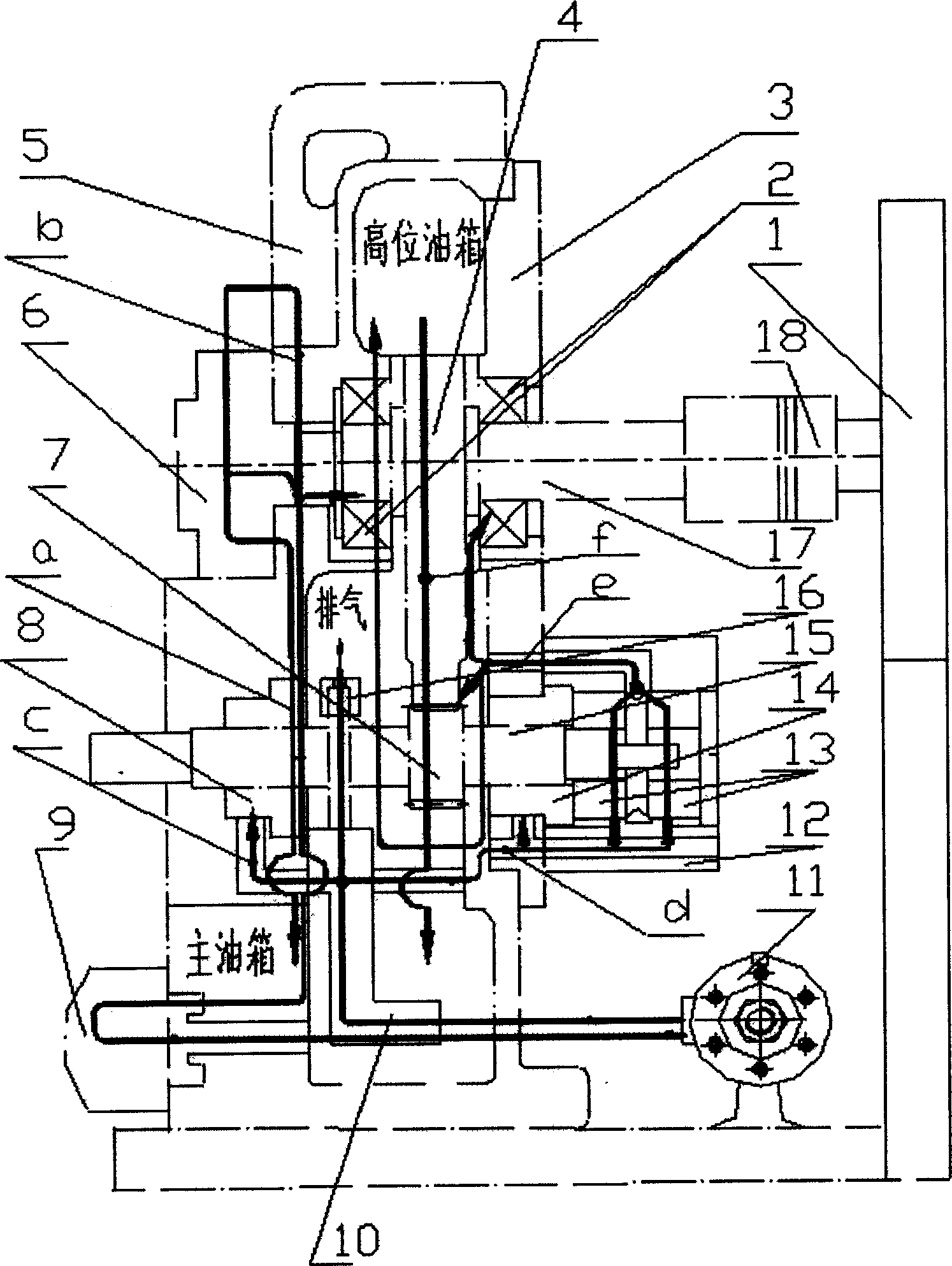

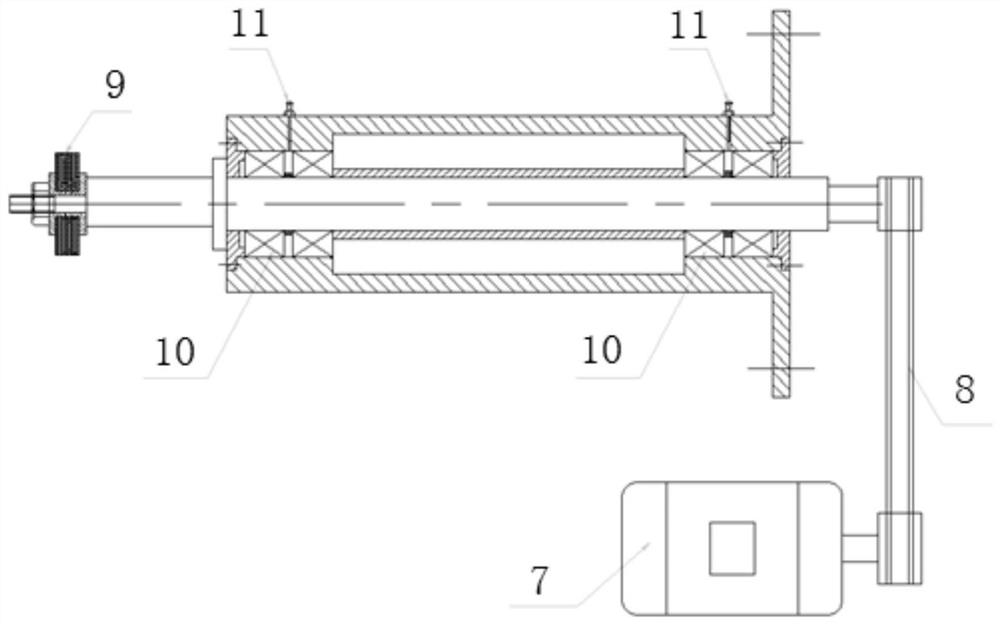

High speed gear spead increaser having automatic lubricating system

InactiveCN1793691ASimple structureAchieve cycleGear lubrication/coolingToothed gearingsLow speedBall bearing

The invention discloses a high speed gear speed increaser with auto-lubricating system, and its structure: an electric motor is connected with a low speed shaft, the low speed shaft engages with a high speed shaft by gear, an oil pump is installed on the low speed shaft, an oil circuit (a) is connected with a main oil tank, the oil pump, and a left-end ball bearing and an oil circuit (b); the oil circuit (b) is connected in turn with a filter, a cooler and an oil circuit block; the outlet of the oil circuit block is divided into three parts, one part is connected with an oil circuit (c) which is connected with a front radial bearing, one part is connected with an exhaust valve and another part is connected with an oil circuit (d); the oil circuit is connected in turn with a rear radial bearing, and two thrust bearings; one end of an oil circuit (e) is connected with the two thrust bearings and the other end is connected with a right-end ball bearing, the engaging place of the low speed gear and the high speed gear and a high level oil tank; an oil circuit (f) is connected with the high level oil tank and the main oil tank. The invention uses an electric machine to drive the speed increaser and the oil pump at the same time, having simple structure and good lubricating effect.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

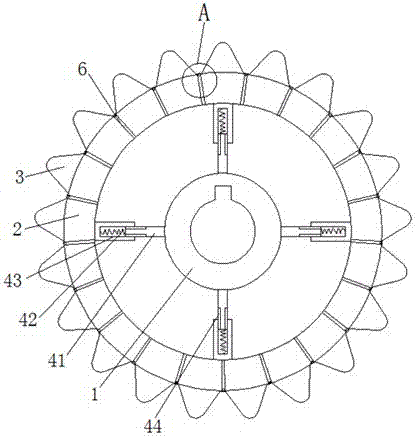

Agricultural machine transmission gear

InactiveCN107143639AAvoid burnsImprove the lubrication effectGear lubrication/coolingPortable liftingGear wheelAgricultural engineering

The invention discloses an agricultural machine transmission gear. The agricultural machine transmission gear comprises a first fixing ring, a second fixing ring and gear teeth. An annular groove is formed in the outer wall of the first fixing ring and internally connected with the second fixing ring in a sliding mode, and the second fixing ring extends to the outside the annular groove; the multiple gear teeth arranged in an array mode are arranged on the outer wall of the second fixing ring, four evenly-distributed retractable columns are arranged between the first fixing ring and the second fixing ring and located in the annular groove; and each retractable column comprises a first connecting column body, a first spring and a second connecting column body, one ends of the second connecting column bodies are welded to the inner wall of the second fixing ring, and the other ends of the second connecting column bodies are provided with sliding grooves; and the sliding grooves are slidably connected with the first connecting column bodies, and one ends of the first connecting column bodies are connected with the first springs. According to the agricultural machine transmission gear, the great economic loss which is caused by the fact that a motor is stuck and thus burned away can be prevented, and automatic lubrication can be conducted when the transmission gear is slightly clamped or collided.

Owner:ANHUI AOTAI POWDER METALLURGY

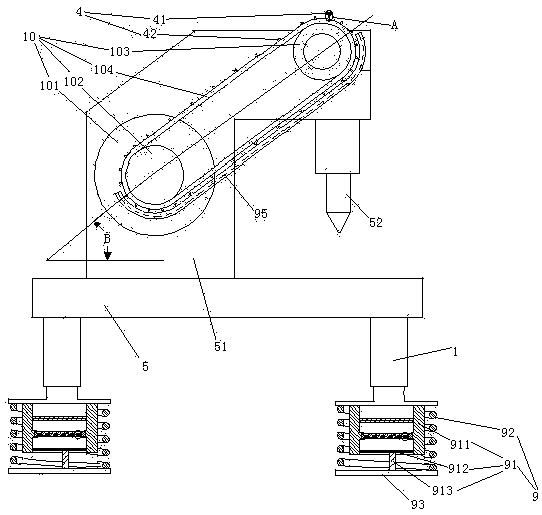

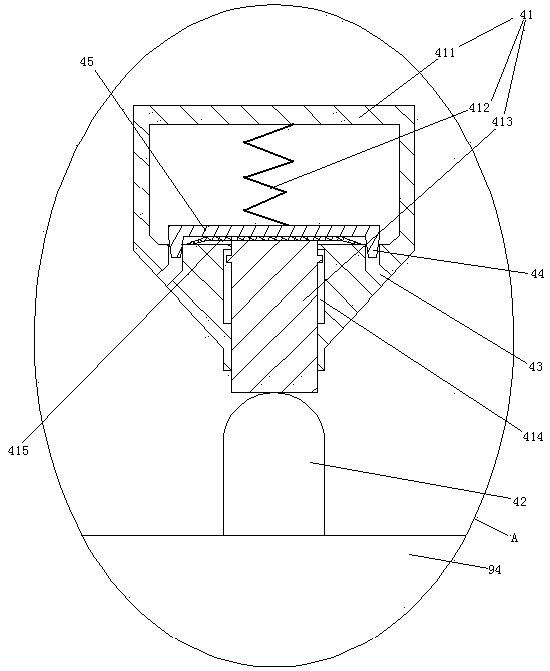

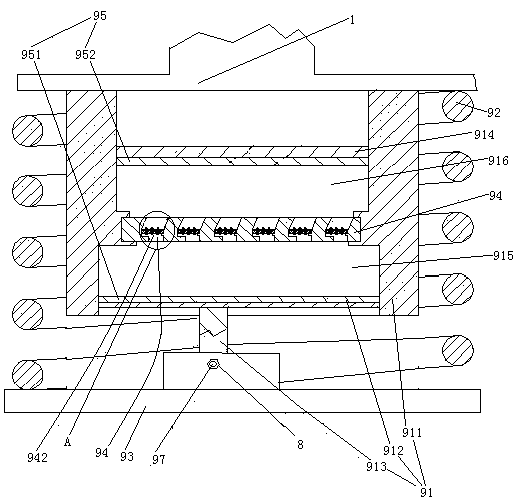

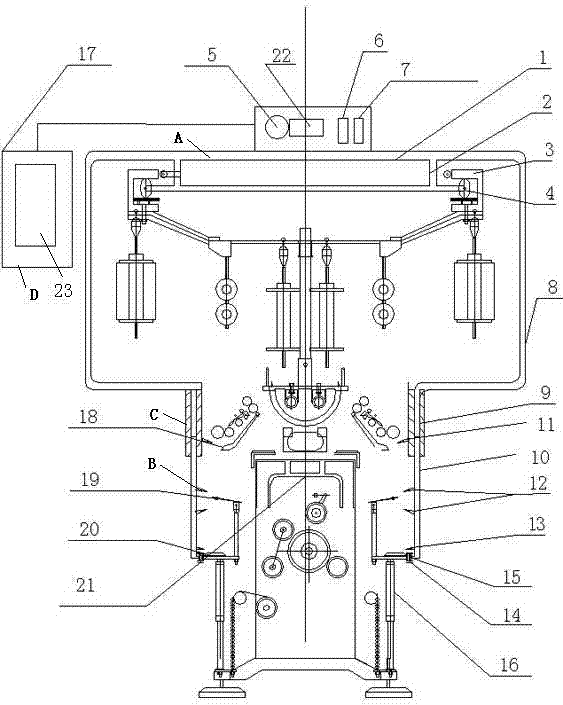

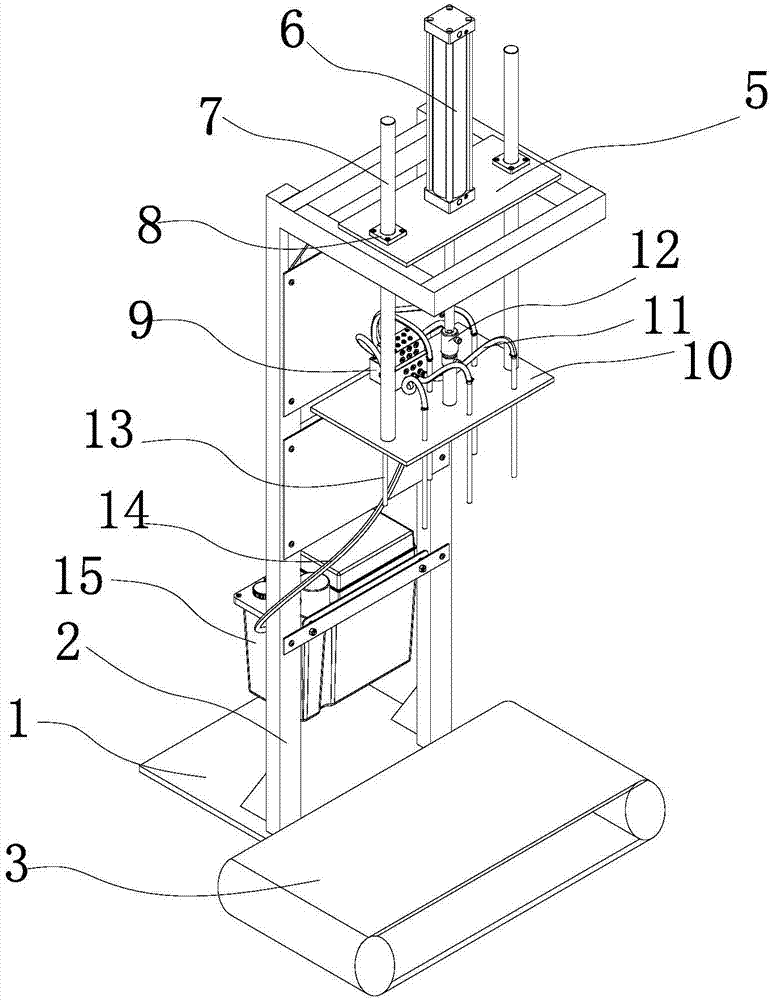

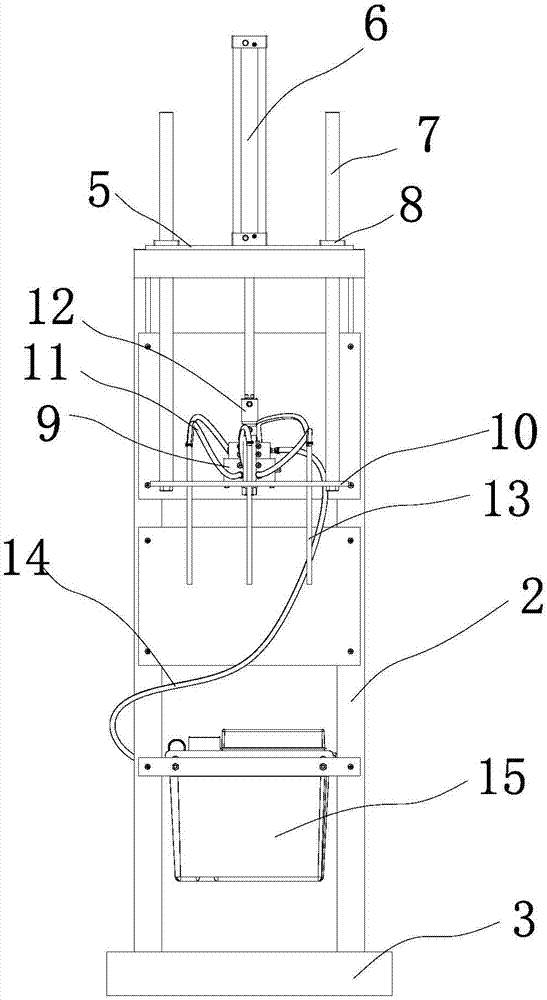

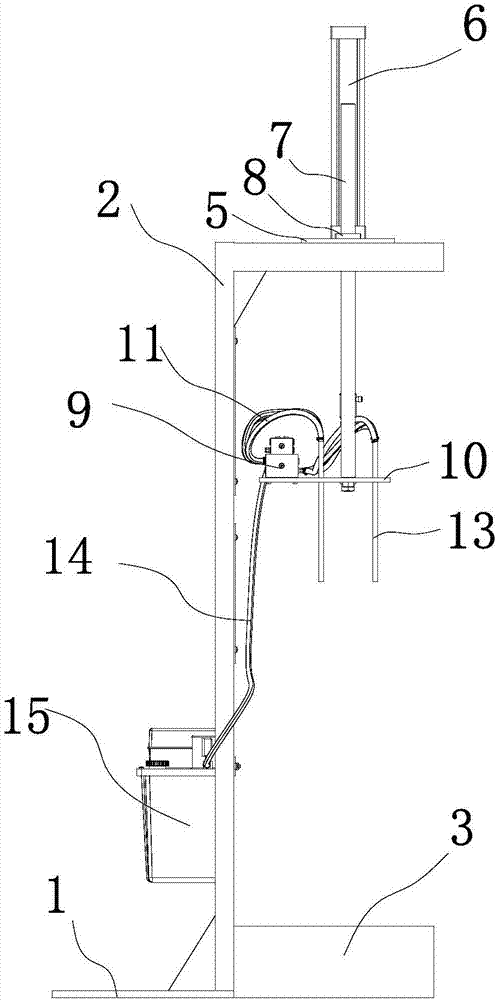

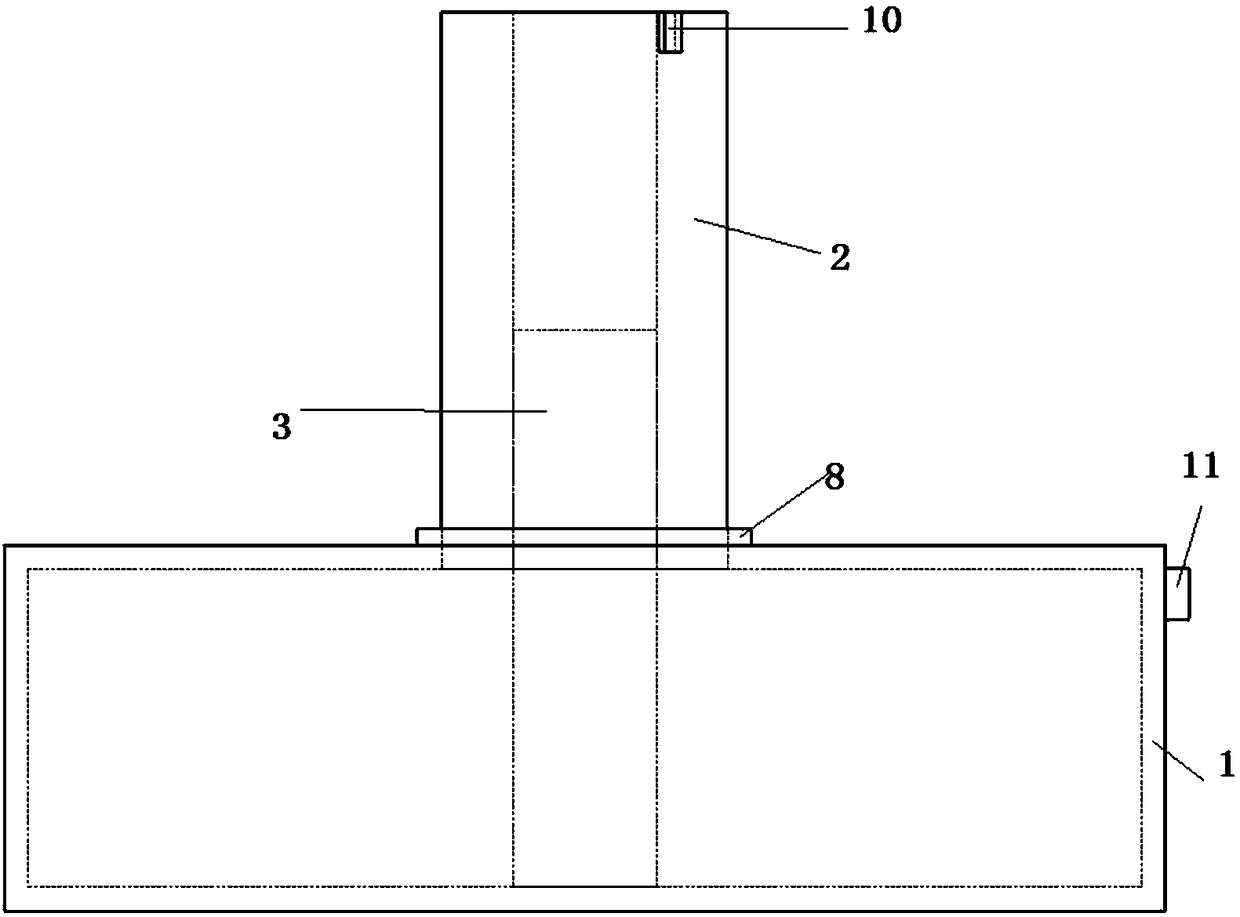

Self-lubricating vibration isolation type bench drill for vehicle remanufacturing

InactiveCN107775360AAutomatic lubricationGood shock isolationLarge fixed membersDriving apparatusIsolation effectLubrication Problem

The invention relates to tools for vehicle manufacturing, in particular to a self-lubricating vibration isolation type bench drill for vehicle remanufacturing. The self-lubricating vibration isolationtype bench drill for vehicle remanufacturing comprises a tabletop, supporting legs, a lubricating mechanism and an oil collecting groove, the tabletop is provided with a drill body and a driving mechanism, the driving mechanism comprises a chain and a motor driving the chain to rotate, the lubricating mechanism is used for automatically lubricating the chain, and the supporting legs are providedwith damping structures. The self-lubricating vibration isolation type bench drill which is for vehicle remanufacturing, can be automatically lubricated, make lubricating oil falling from the chain collected together and is good in vibration isolation effect is provided and solves the problem that an existing bench drill is poor in vibration isolation effect and needs to be manually lubricated.

Owner:杭州宏基输送机械有限公司

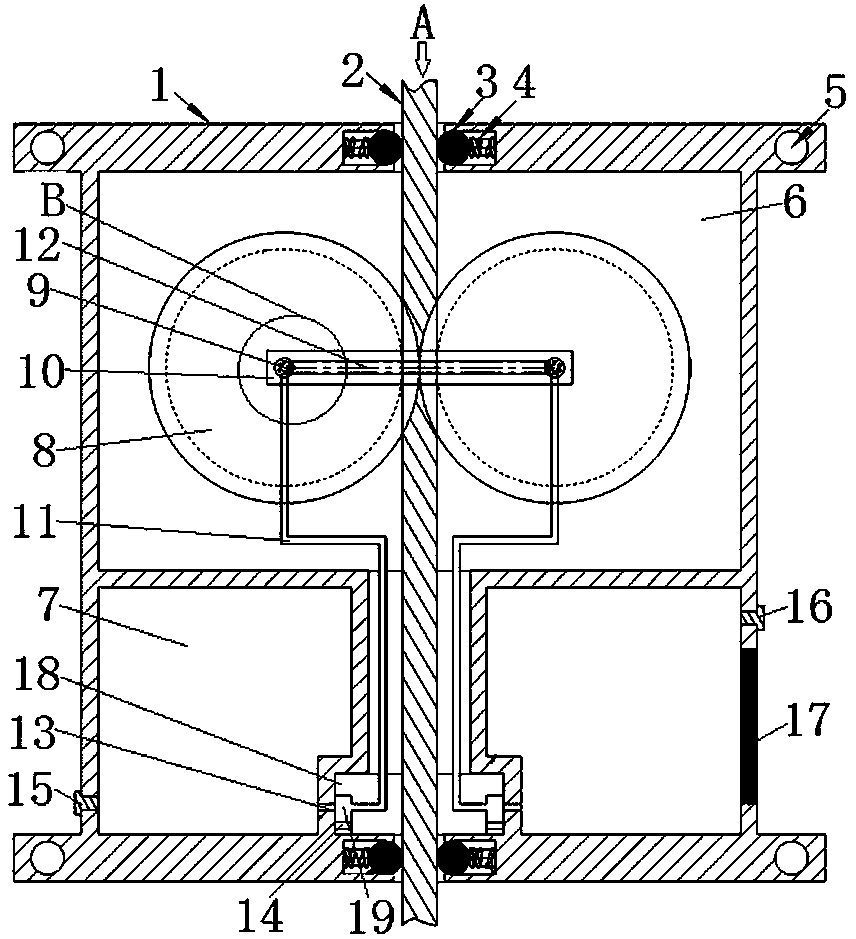

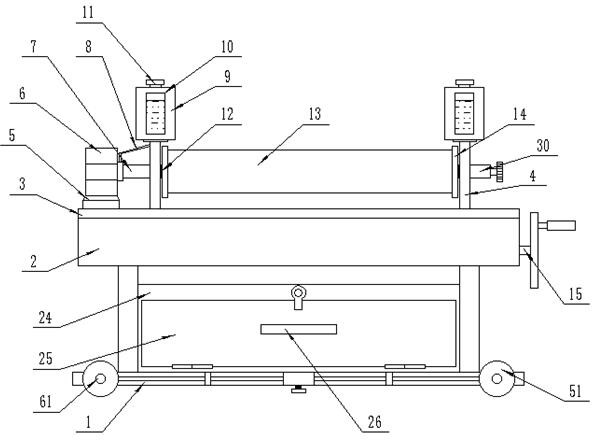

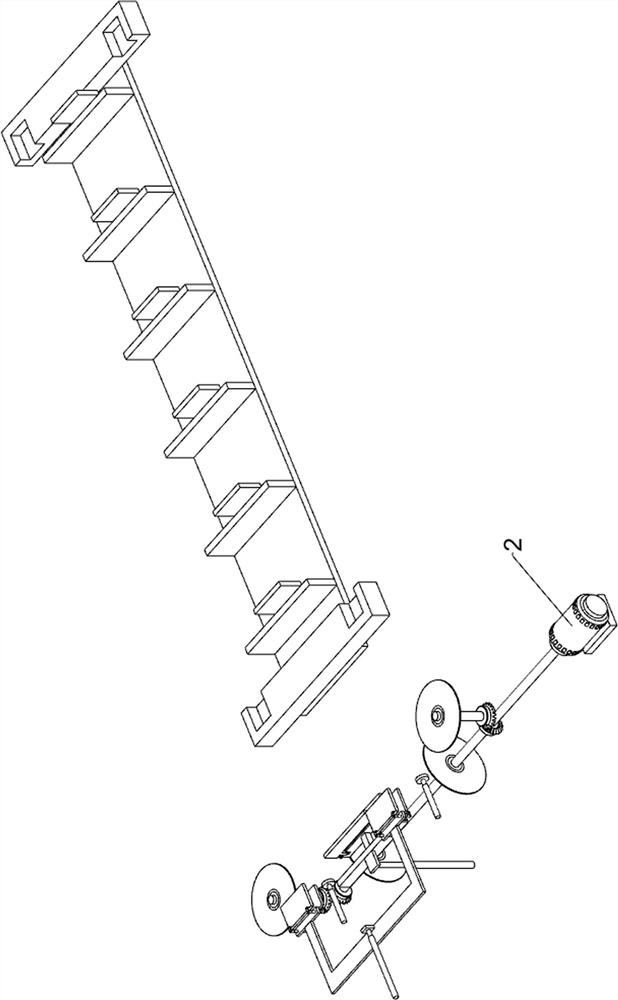

Water spraying and oil spraying device of flax wet-spinning spinning machine

ActiveCN103031627APrecision cleaningAccurate lubricityTextiles and paperEngine lubricationThermal sprayingReciprocating motion

The invention relates to a water spraying and oil spraying device of a flax wet-spinning spinning machine, which is arranged on the flax wet-spinning spinning machine. The water spraying and oil spraying device comprises a control component, a walking component, a water spraying and oil spraying component, and a steel ring plate hoisting follow-up component, wherein the water spraying and oil spraying component comprises two groups of water spraying nozzles and a group of oil spraying nozzles; the walking component is arranged above a rack of the flax wet-spinning spinning machine and does reciprocating motion; one part of the walking component, which corresponds to a probe rod of the flax wet-spinning spinning machine, is provided with the first group of the water spraying nozzles; the steel ring plate hoisting follow-up component is arranged on the flax wet-spinning spinning machine; the second group of the water spraying nozzles and the oil spraying nozzles are arranged on the steel ring plate hoisting follow-up component; and the control component is respectively connected with the walking component and the water spraying and oil spraying component. The water spraying and oil spraying device disclosed by the invention can be accurately controlled and can be additionally arranged on various types of equipment.

Owner:浙江金达亚麻有限公司

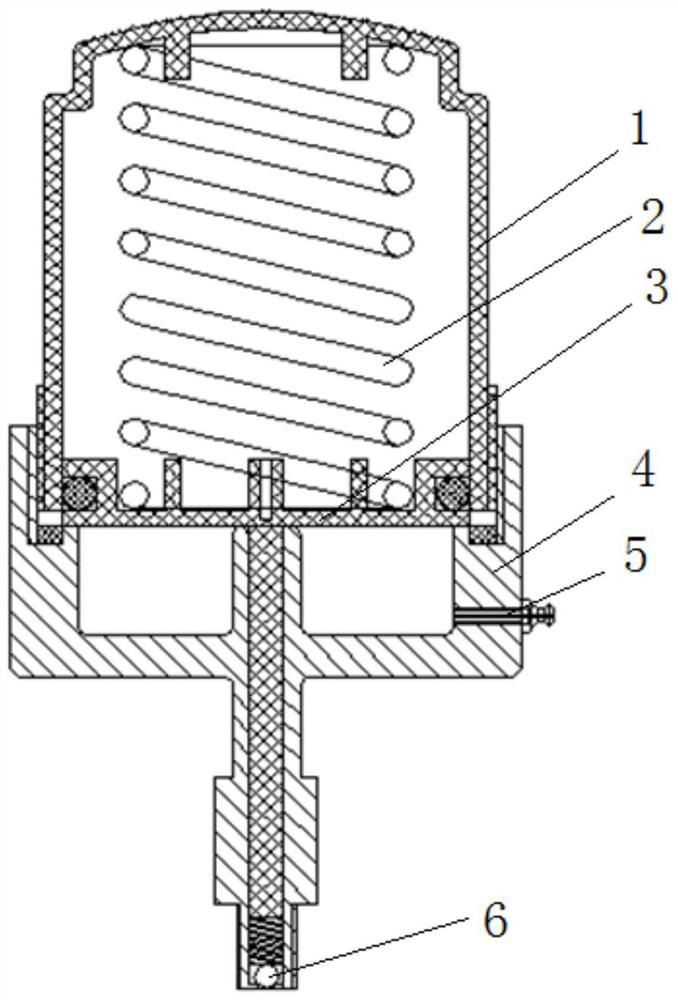

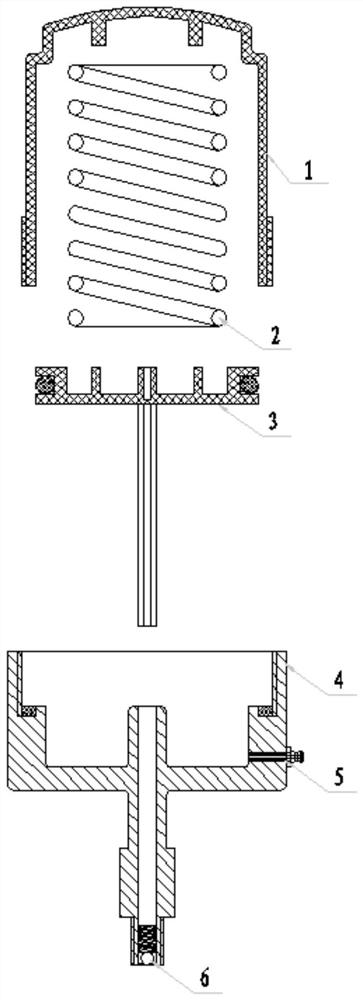

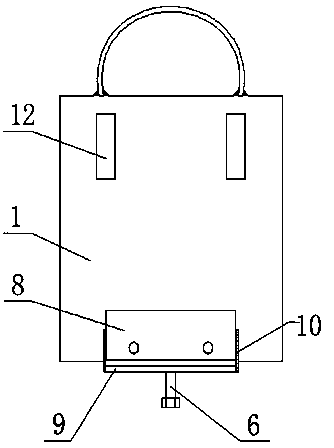

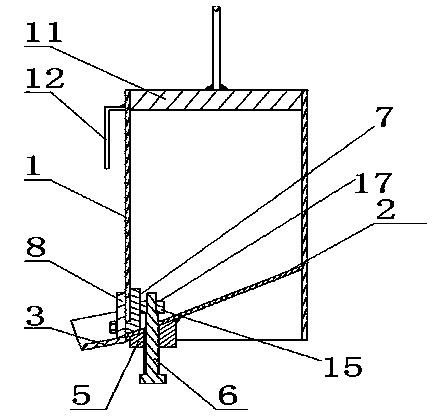

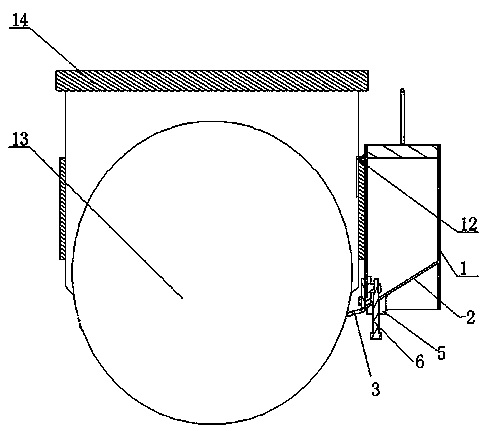

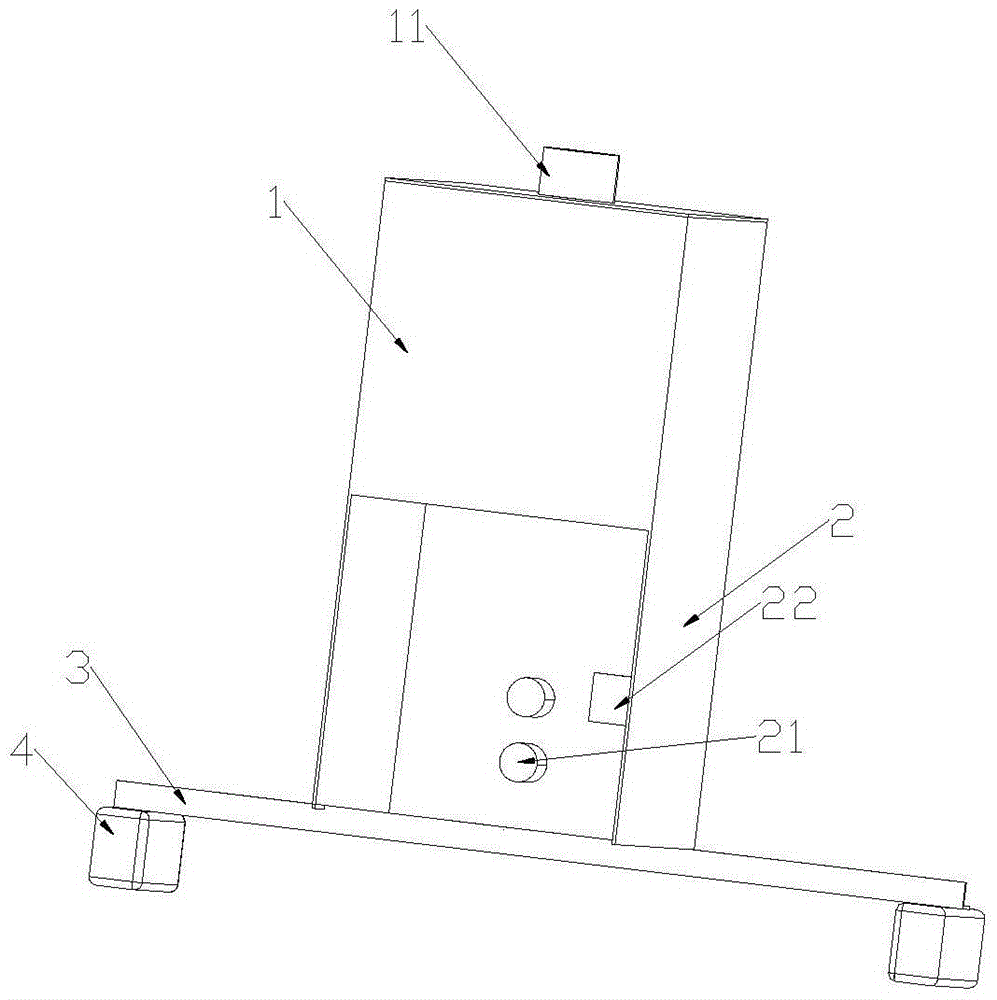

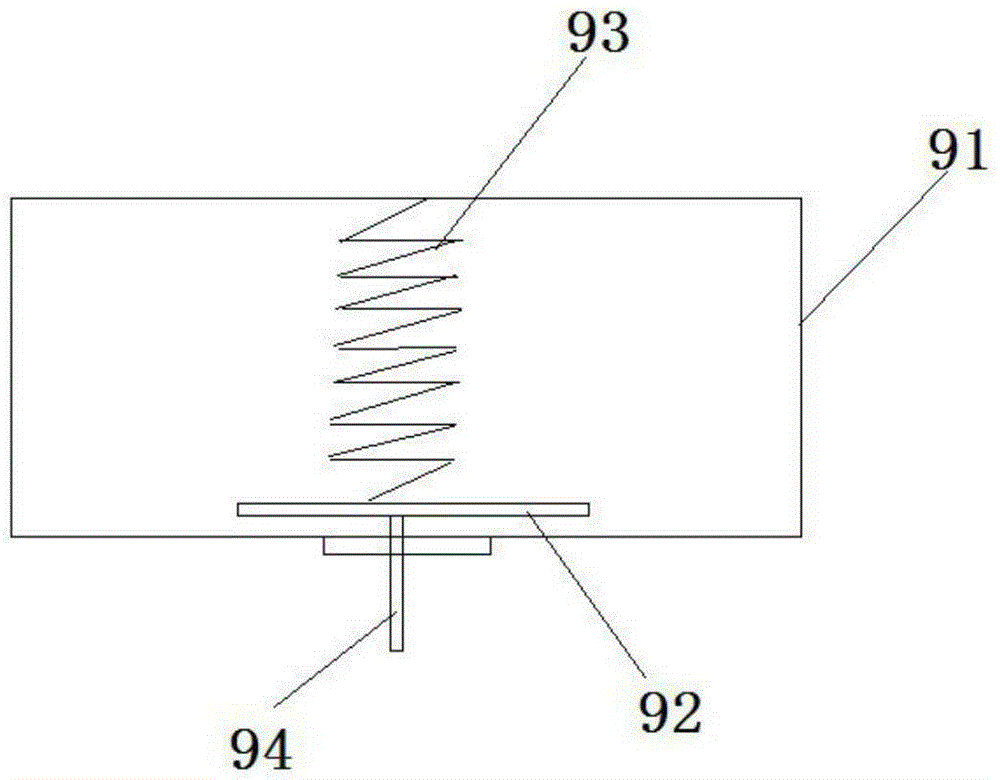

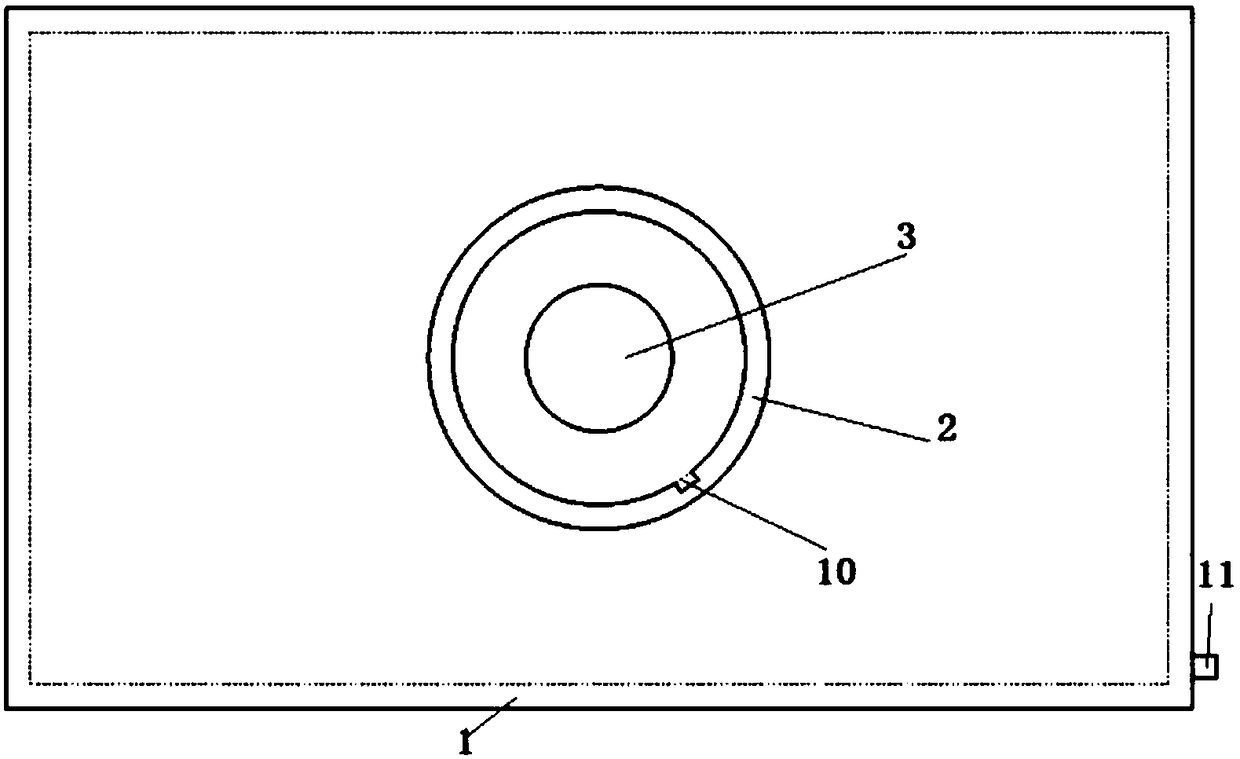

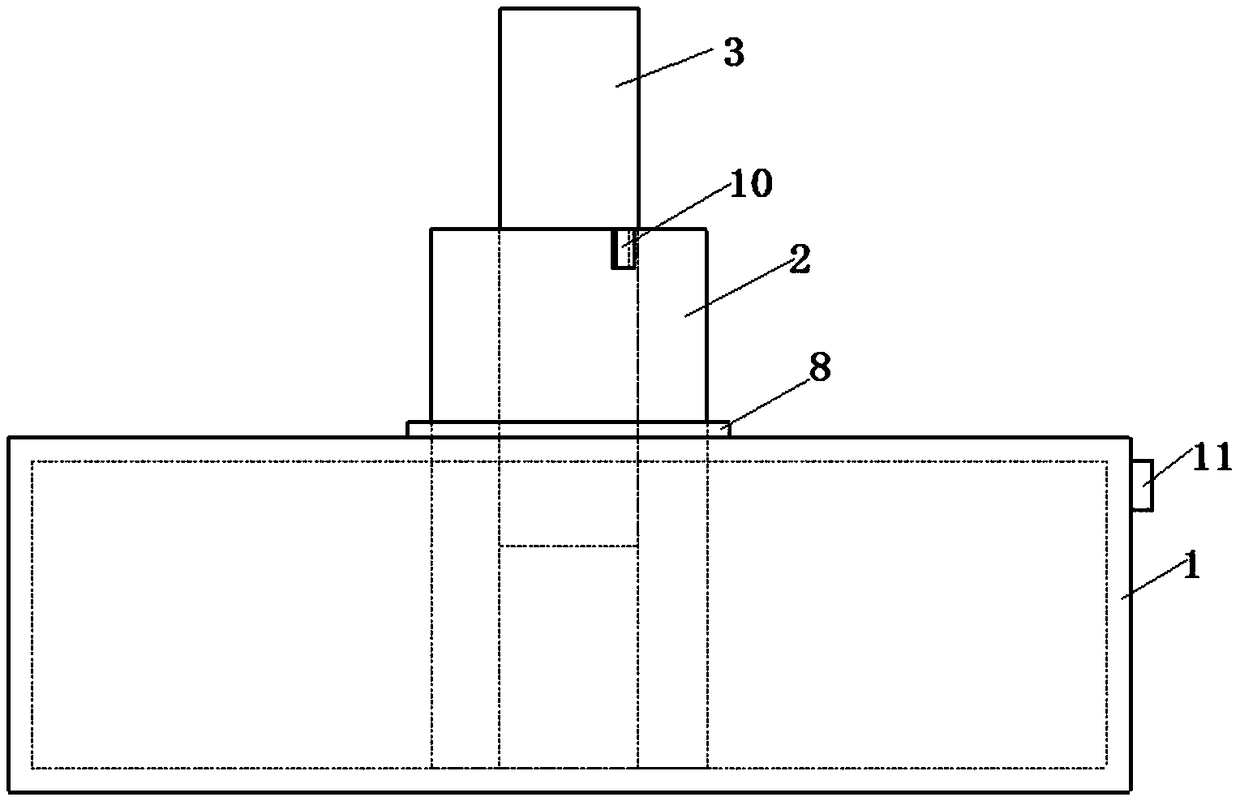

Automatic lubricating device of polisher shaft head bearing

The invention provides an automatic lubricating device of a polisher shaft head bearing. The automatic lubricating device of the polisher shaft head bearing comprises an oil storage box and a base; the bottom of the oil storage box is arranged in an opened manner; the lower end of the oil storage box is connected to the base to form a sealed cavity; a piston is arranged in the oil storage box; a spring is arranged between the piston and the top of the oil storage box; the spring is arranged perpendicular to the piston; a one-way oil filling port is arranged in the oil storage box or the base,and the position of the piston is always higher than the one-way oil filling port; an oil outlet guide pipe is arranged on the base; a piston rod at the bottom of the piston extends into the oil outlet guide pipe; a gap is formed between the oil outlet guide pipe and the piston rod at the bottom of the piston; and a one-way oil outlet is formed in the bottom of the oil outlet guide pipe. By meansof the automatic lubricating device of the polisher shaft head bearing, the damage of the bearing rotating at a high speed due to oil shortage and overheating caused by manual lubrication careless oromission is avoided, and the consequences that equipment is shut down and losses are caused are avoided.

Owner:AECC AVIATION POWER CO LTD

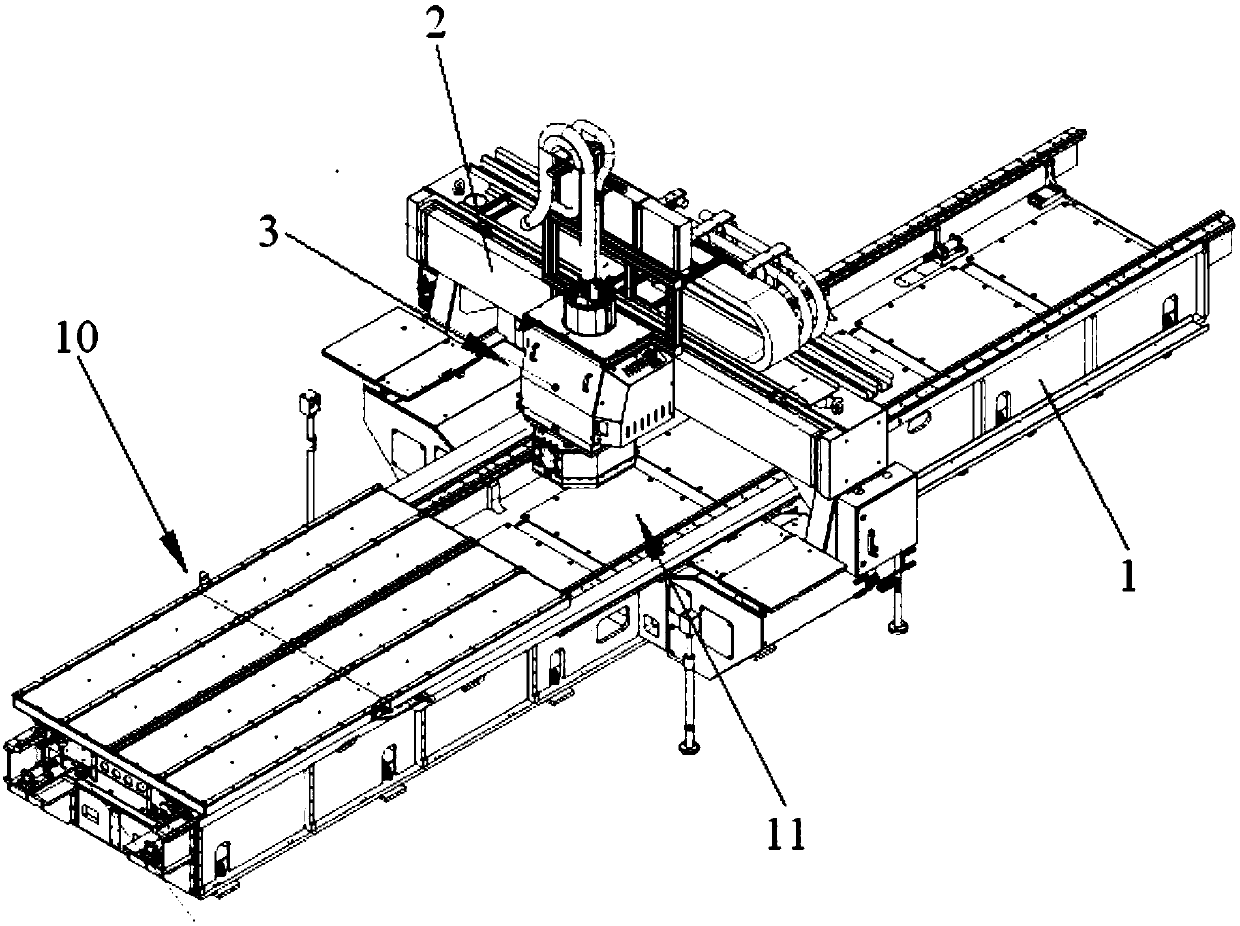

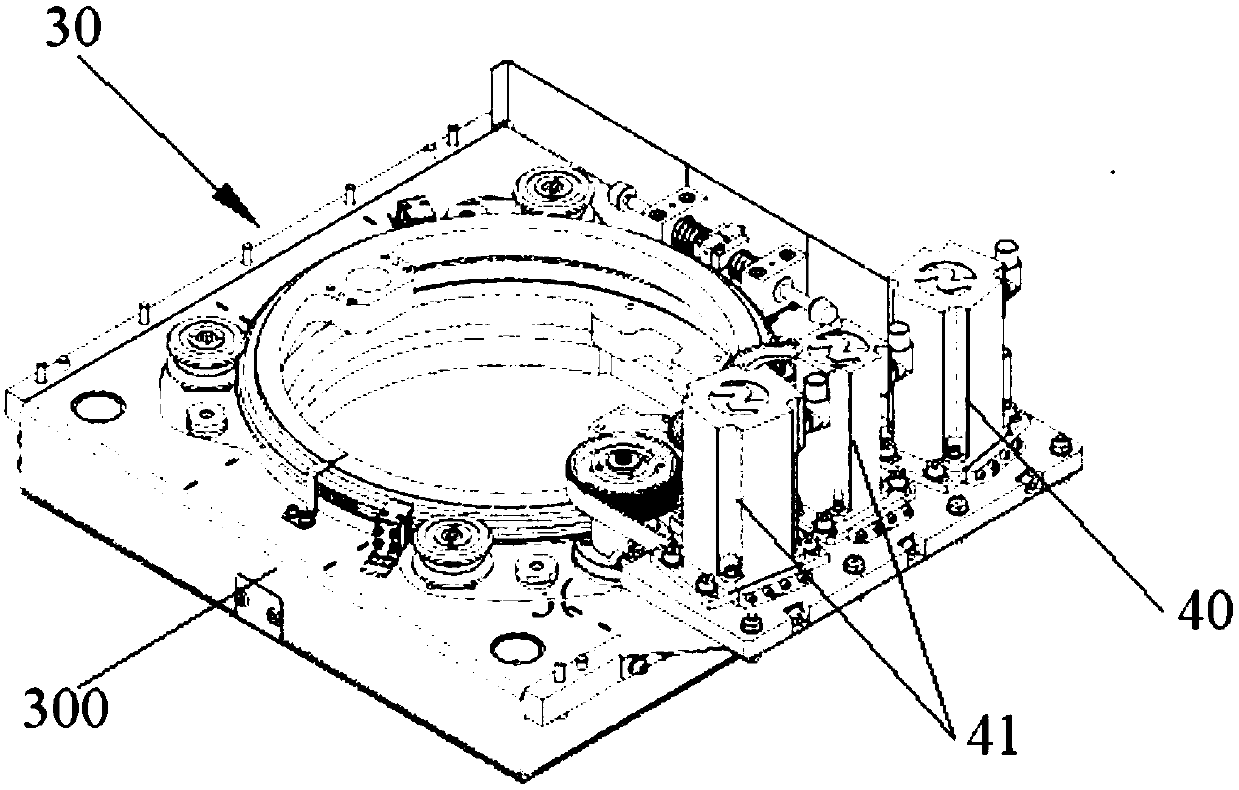

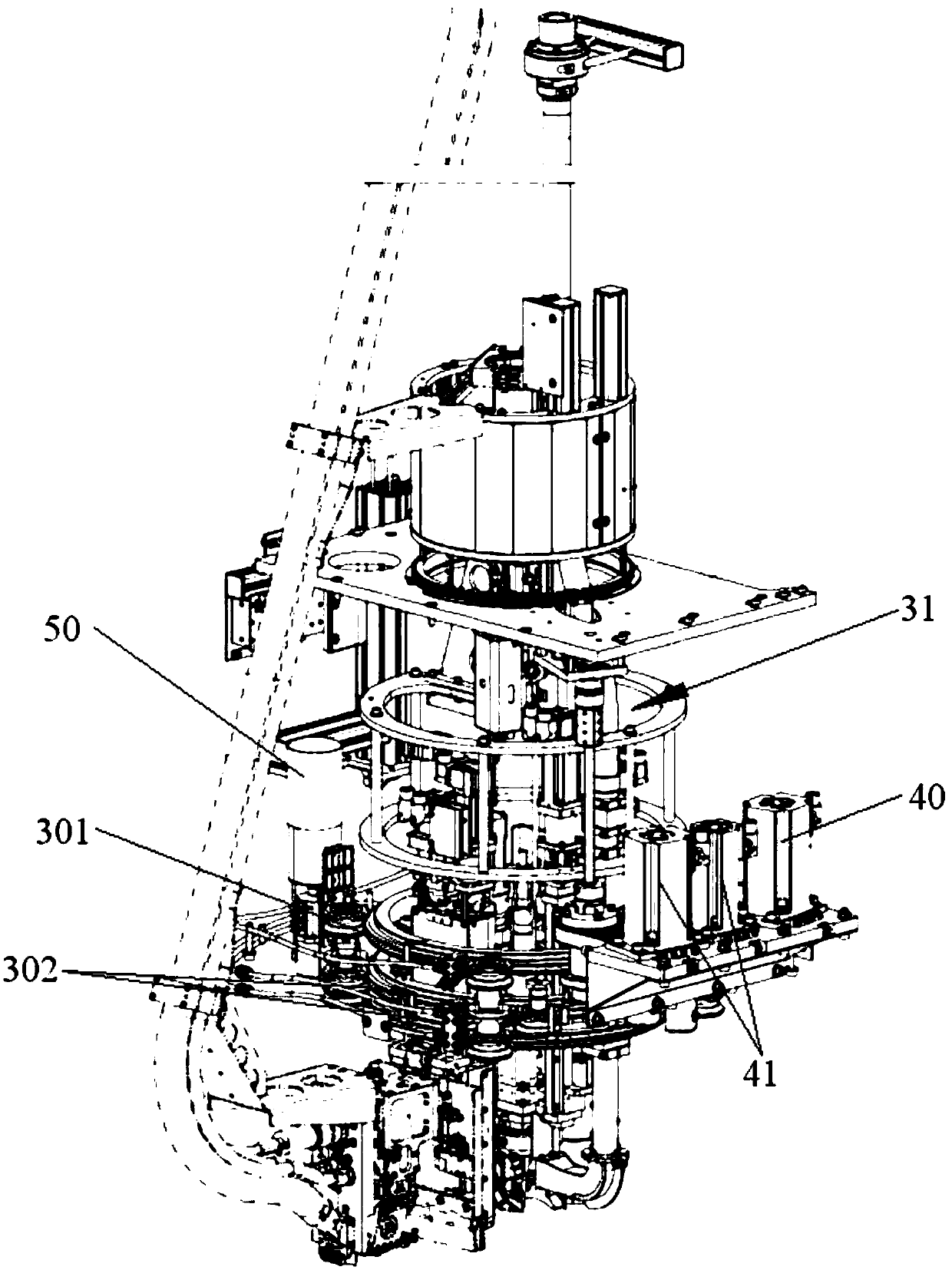

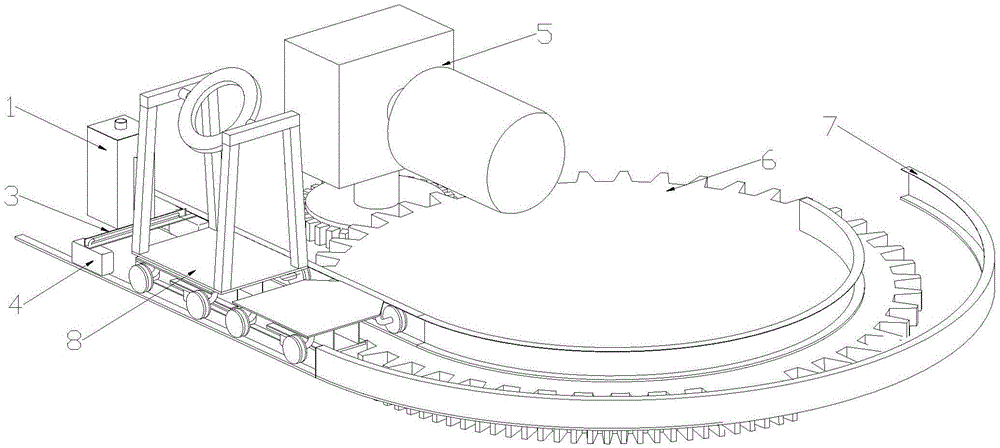

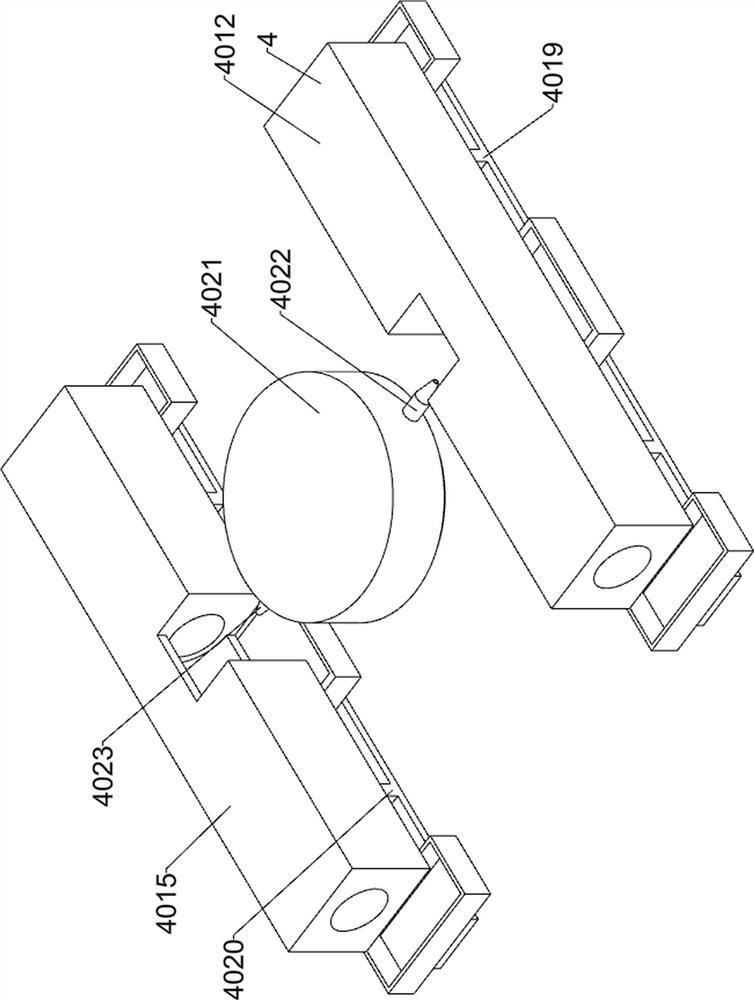

Door ring line automatic laser welding system

ActiveCN109570757AHigh degree of automationIncrease productivityLaser beam welding apparatusControl systemEngineering

The invention discloses a door ring line automatic laser welding system. The door ring line automatic laser welding system comprises a main frame. A positioning area and a welding area are arranged onthe main frame in the extending direction of the main frame, wherein the positioning area is used for positioning a workpiece, and the welding area is used for welding the workpiece. The welding areais provided with a welding main machine. The welding main machine comprises a laser frame, a welding laser, a detection camera shooting part, a frame driving part and a detection driving part, wherein the welding laser is arranged in the laser frame, the frame driving part is used for driving the laser frame to rotate relative to the welding laser, and the detection driving part is used for driving the detection camera shooting part to rotate relative to the welding laser. The door ring line automatic laser welding system is high in automation degree, higher in production efficiency and convenient to operate. Parameter-based workpiece positioning is adopted, wherein different parameters of a workpiece positioning device are set under the help of corresponding parameter menu pages of an equipment control system. The welding quality and percent of pass of products are improved. With the function of automatic lubricating, the door ring line automatic laser welding system is convenient tomaintain.

Owner:华安钢宝利高新汽车板加工(常熟)有限公司

Automatic oil spraying device for bolt holes of engine bodies

InactiveCN107461595AImprove the lubrication effectEvenly lubricatedConduits/junctionsSlide plateEngineering

The invention relates to an automatic fuel injection device for bolt holes of an engine body, belonging to the technical field of engine supporting equipment. It includes a frame with a fixed plate on the frame, a drive device on the fixed plate, the working end of the drive device runs through the fixed plate and connects to the slide plate, an oil-air mixer is installed on the slide plate, and the output end of the oil-air mixer is connected to the nozzle through the first hose , the spray head is set through the slide plate, and the input end of the oil-air mixer is connected to the lubricating pump through the second hose. The invention can accurately penetrate into the bolt holes for atomized oil injection lubrication, has good lubricating effect, less oil consumption, automatic lubrication and high efficiency.

Owner:WEIFANG VOCATIONAL COLLEGE

Mechanical arm bearing protection device capable of avoiding corrosion and reducing friction

InactiveCN113007578APrevent rustReduce frictionBearing componentsCleaning using toolsEngineeringStructural engineering

The invention relates to the technical field of mechanical arms, and discloses a mechanical arm bearing protection device capable of avoiding corrosion and reducing friction. The mechanical arm bearing protection device comprises a rack, a rotating shaft is rotatably connected in the rack, a rotating disc is fixedly connected to the end, away from the rack, of the rotating shaft, sliding rods are slidably connected in the rotating disc, and balancing weights are fixedly connected to the ends of the sliding rods. Cleaning tanks are slidably connected in the rack, spray heads are fixedly connected to the circle centers of the cleaning tanks, spring buttons are fixedly connected to the side wall, close to the rotating disc, of the rack, and movable rods are fixedly connected in the spring buttons. Baffles are opened through movable connecting rods, at the moment, lubricating liquid is input into liquid bins and sprayed to the surface of a bearing through the spray heads, and therefore the effects that the bearing can be automatically lubricated, friction at the position of the bearing of a mechanical arm is reduced, the contact area is increased through the atomized lubricating liquid, material waste is reduced, and energy is saved are achieved.

Owner:永康市双智工贸有限公司

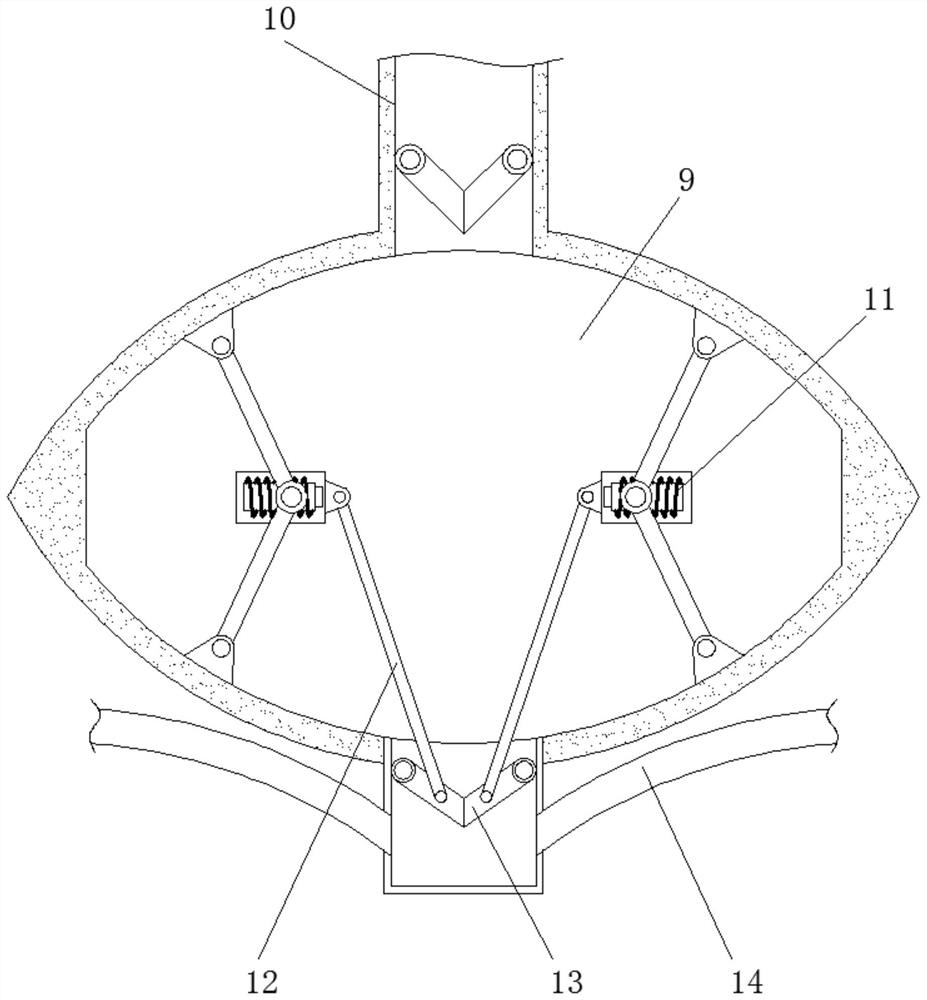

Lubricating device for steel wire rope

PendingCN107940212AGood dynamic and static sealing effectLong-term efficient sealing functionEngine sealsTextile cablesWire ropeMaterials science

The invention discloses a lubricating device for a steel wire rope, which comprises a shell and a magnetic sealing device. A containing space is arranged in the shell and both ends are provided with openings; and the magnetic sealing device comprises sealing magnetic parts arranged in the openings, the magnetic parts are provided with sealing inner holes, and magnetic lubricating grease is arranged in the sealing inner holes. The lubricating device for a steel wire rope can automatically lubricate the steel wire rope, the magnetic sealing design is used between the moving steep wire rope and the shell, and better dynamic and static sealing effects are realized. The sealing of the magnetic lubricating grease has no problem of operation wearing, and the lubricating device for a steel wire rope has the long-term and efficient sealing function, avoids the leakage of the lubricating grease and environment pollution and improves the use efficiency of the lubricating grease.

Owner:湖南星沙机床设备有限公司

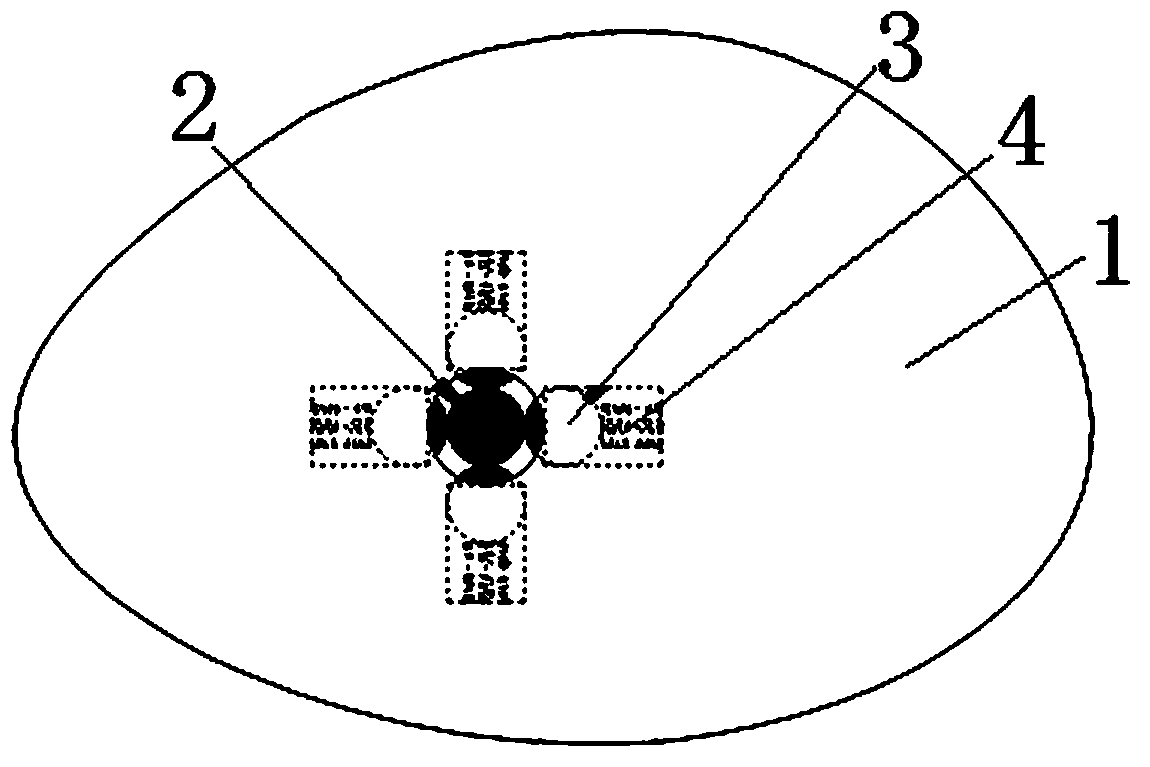

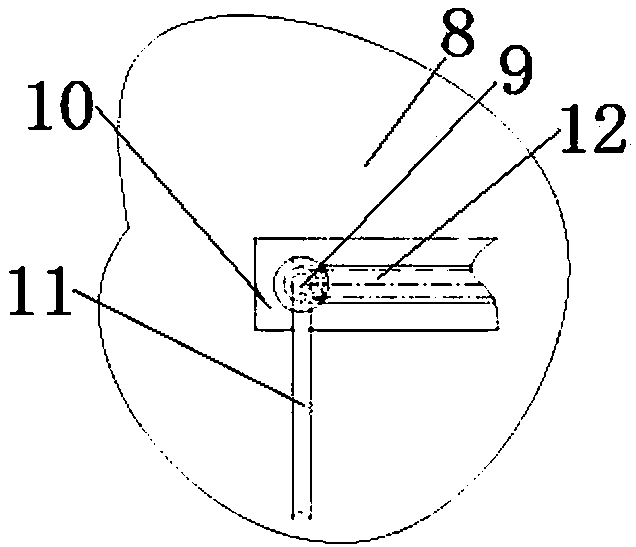

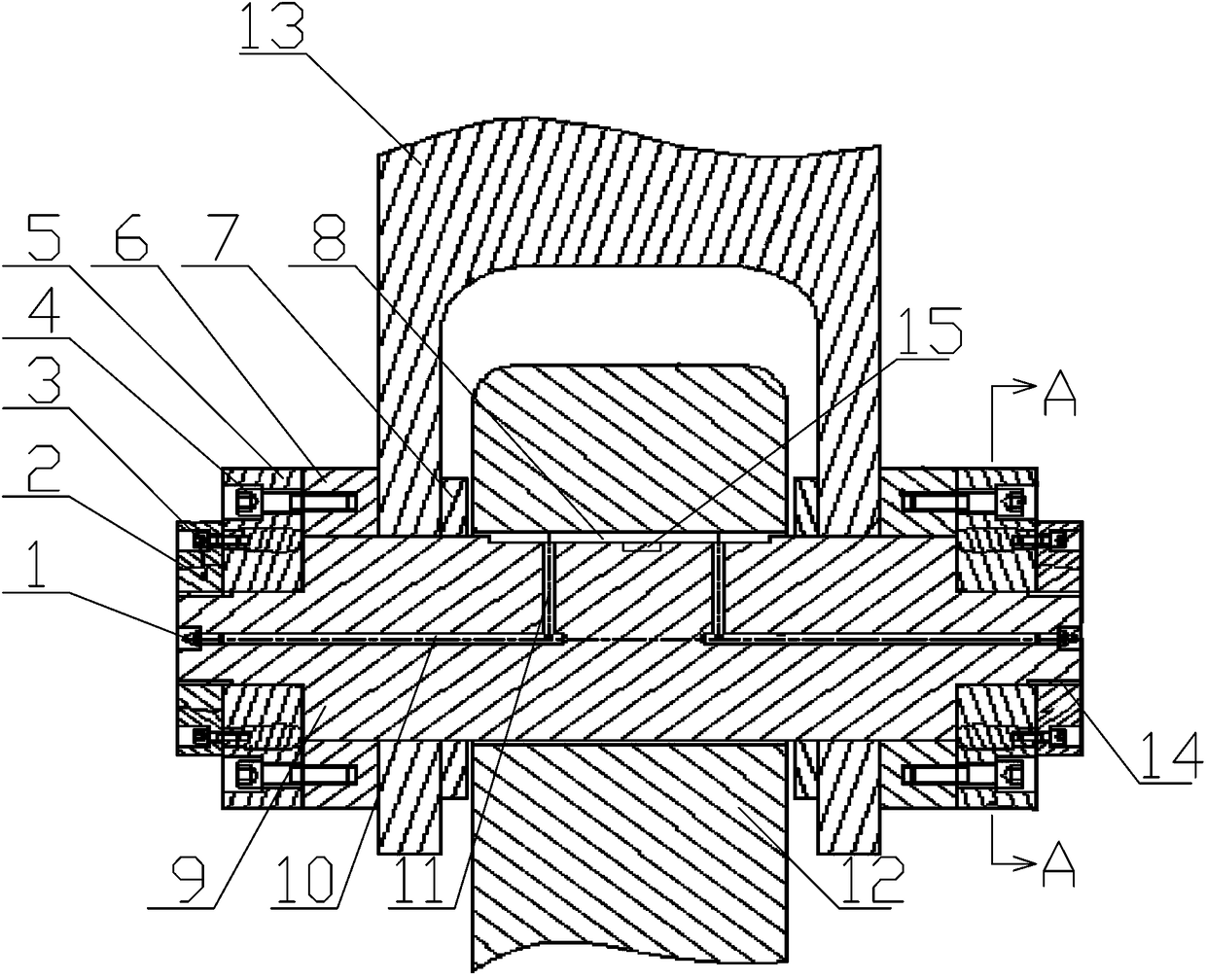

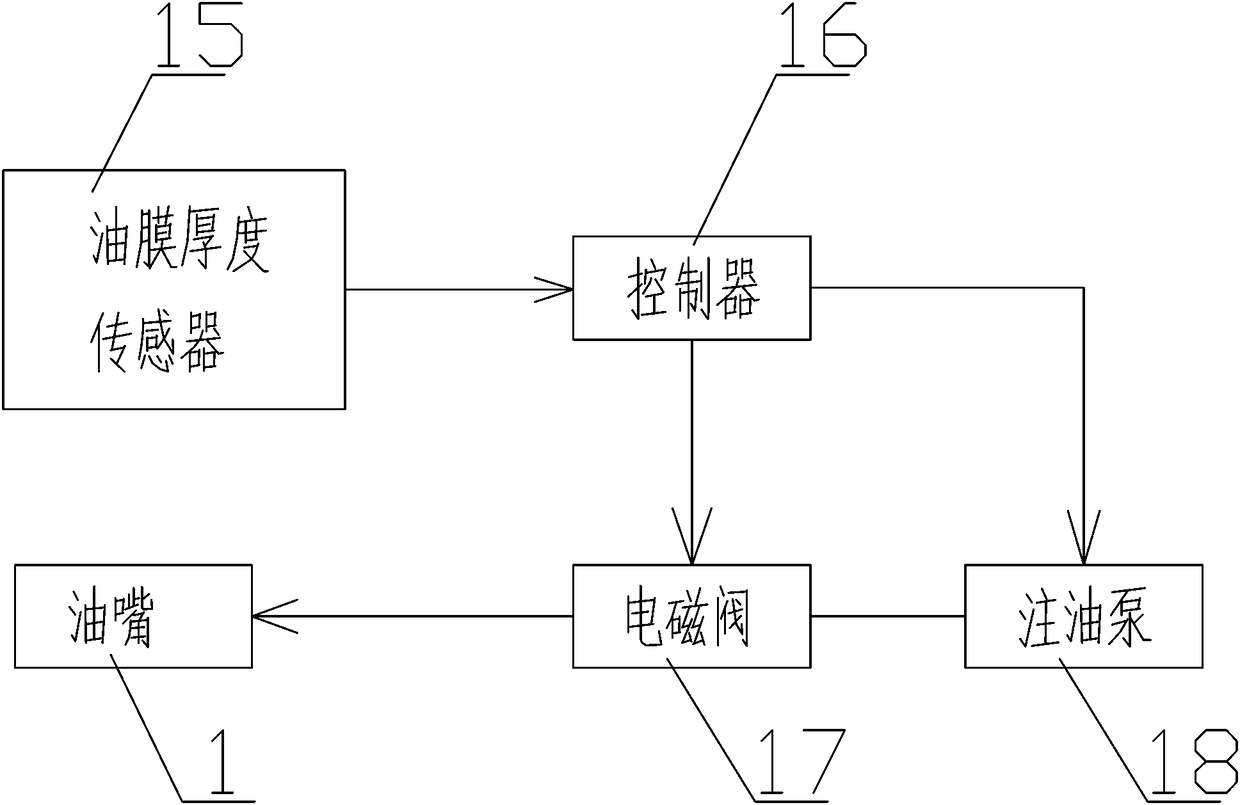

Automatic lubricating device for surface of CSP swing segment wheel

The invention relates to an automatic lubricating device for the surface of a CSP swing segment wheel, and belongs to the technical field of steel rolling equipment. The automatic lubricating device is used for solving the technical problem that due to the fact that a wheel and a guide rail in the prior art cannot be lubricated automatically in good time, the wheel and the guide rail are abraded and damaged. According to the technical scheme, the automatic lubricating device comprises a grease box, an inner flow guide plate and an outer flow guide plate, the inner flow guide plate is fixed to the inner side wall of the grease box, an acute included angle is formed by the inner flow guide plate and a bottom plate of the grease box, an oil hole is formed in the side wall of the grease box, the bottom of the oil hole is located at the connecting position of the lower side of the inner flow guide plate and the side wall of the grease box, the outer flow guide plate is fixed to the position, at the bottom of the oil hole, of the outer side wall of the grease box, and an acute included angle is formed by the plane of the outer flow guide plate and the horizontal plane. The automatic lubricating device can effectively solve the problem that due to the fact that the wheel and the guide rail are abraded due to poor lubrication, the service life of the wheel and the guide rail is prolonged, and the action rate of a heating furnace is improved. The automatic lubricating device is suitable for automatic and timely lubrication of wheels and guide rails in relevant fields, and is wide in popularization prospect.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

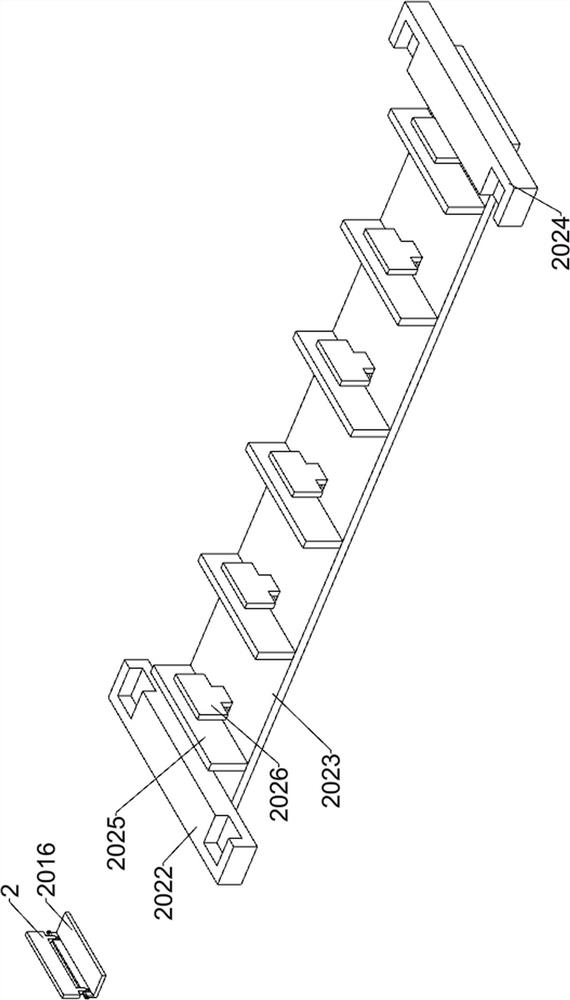

Automatic oil feeder for assembly line and hook head assembly line containing same

The invention relates to an automatic oil feeder for an assembly line and the hook head assembly line containing the same. The automatic oil feeder for the assembly line comprises a support and an oil tank, wherein the oil tank is fixed to the support, an oil injection opening is formed in the top of the oil tank, an oil outlet pipeline is arranged on the bottom of the oil tank, and the support is provided with a control switch used for opening or closing the oil outlet pipeline in time. The hook head assembly line comprises a power device, a main drive sprocket, a guide rail and a bearing table, wherein the tail end of the bearing table is connected with the automatic oil feeder for the assembly line or the automatic oil feeder for the assembly line is fixedly arranged on the outer side edge of the rail. The automatic oil feeder for the assembly line and the hook head assembly line containing the same have the beneficial effects that lubrication and maintenance can be carried out on the assembly line automatically, artificial control is not needed, the labor cost is lowered, and the service life of equipment on the assembly line is prolonged; according to the operation condition of the assembly line, lubrication and maintenance are carried out selectively, lubricating grease is prevented from being used for a long time and at large amount, and the production cost is saved.

Owner:周德

Textile roller capable of automatically detecting and adjusting lubricity and using method thereof

ActiveCN112320419AEasy to disassemble and replaceSave FixturesBearing componentsConduits/junctionsRaw materialSupport plane

The invention discloses a textile roller capable of automatically detecting and adjusting the lubricity and a using method thereof. The textile roller comprises a supporting frame, a horizontal plateand a textile roller body, wheel shafts are movably arranged on the two sides of the front end of the supporting frame in a penetrating and inserting mode, moving wheels are fixedly installed at the front ends of the wheel shafts, and a limiting mechanism is arranged at the front end of the supporting frame; and a storage mechanism is arranged in the center of the upper end of the supporting frame. According to the textile roller, raw materials are wound around the outer side end of the textile roller body, then a user rotates a rotary disc through a rocker to enable the rotary disc to drive amovable shaft to rotate, a movable ring moves leftwards through threads, a first connecting rod is extruded leftwards accordingly, a movable block moves upwards to jack up a supporting plate, and therefore the height of the supporting plate is increased conveniently; and when the height of the supporting plate needs to be lowered again, the user only needs to reversely rotate the rotary disc, thetensioning degree of the wound raw materials is adjusted through vertical movement of the supporting plate, and therefore the raw materials are in the proper tensioning degree in the winding process.

Owner:苏州市卓群纺织科技有限公司

Unmanned aerial vehicle rotating shaft protection device capable of avoiding fan blade shaking and achieving automatic lubrication

InactiveCN113753232AIncrease contact areaImprove stabilityRotocraftEngine lubricationFlight vehicleLubrication

The invention relates to the technical field of intelligent unmanned aerial vehicles and discloses an unmanned aerial vehicle rotating shaft protection device capable of preventing fan blades from shaking and achieving automatic lubrication. The unmanned aerial vehicle rotating shaft protection device comprises a lubricating mechanism, wherein the lubricating mechanism comprises a sliding block, a magnetic block is fixedly connected to the interior of the sliding block, and an electromagnetic rod is placed on the side face of the sliding block; a reset spring is fixedly connected to the side wall of the side, close to the electromagnetic rod, of the sliding block, an infusion tube is fixedly connected to the side wall of the sliding block, and a guide block is fixedly connected to an end, away from the infusion tube, of the sliding block. The magnetic block is pushed to move through the electromagnetic rod, the magnetic block is fixedly connected into a sliding block, a surface of the sliding block is rotationally connected with a movable connecting rod, and the other end of the movable connecting rod is rotationally connected with a movable block, so the contact area of the movable block and the rotating shaft is increased, and stability of the rotating shaft is improved by increasing the contact area of a stabilizing mechanism and the rotating shaft; vibration generated by rotation of the rotating shaft is prevented from being transmitted to the fan blades, and stability of the fan blades is improved.

Owner:杭州肃清科技有限公司

Crawling ladder welding device based on ground rail robot

InactiveCN113385860ALow efficiencyEliminate skewWelding/cutting auxillary devicesAuxillary welding devicesLubricationPhysics

The invention relates to the field of ground rail robots, in particular to a crawling ladder welding device based on a ground rail robot. The technical problem to be solved is to provide the crawling ladder welding device based on the ground rail robot. According to the technical scheme, the crawling ladder welding device based on the ground rail robot comprises a material placing assembly, a welding assembly and the like, and the material placing assembly is connected with the welding assembly. When the crawling ladder welding device is used, cutting is carried out on an L-shaped cross rod in advance, the two ends of a horizontal part of the L-shaped cross rod exceed the two ends of a vertical part respectively, then the two ends of the horizontal part are lapped on two vertical rods respectively, the the welding operation is carried out, and therefore the problem of poor stability caused by a small welding area is eradicated, the L-shaped transverse rod is perpendicular to the two vertical rods at the same time and then the welding operation is carried out, the phenomenon that the transverse rods are inclined after welding is eradicated, welding is sequentially carried out on the six transverse rods through a ground rail, meanwhile, automatic lubrication can be achieved, and lubricating oil is prevented from dripping into the device.

Owner:孙瑞琴

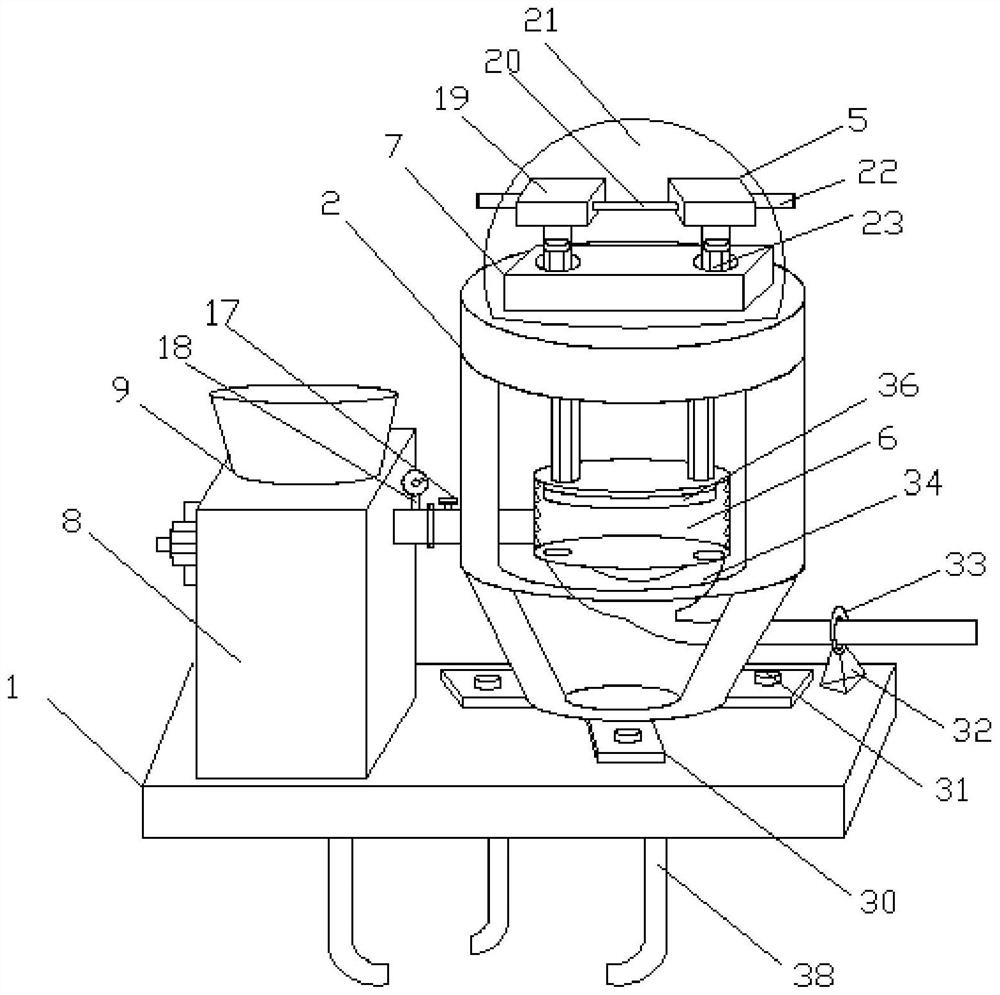

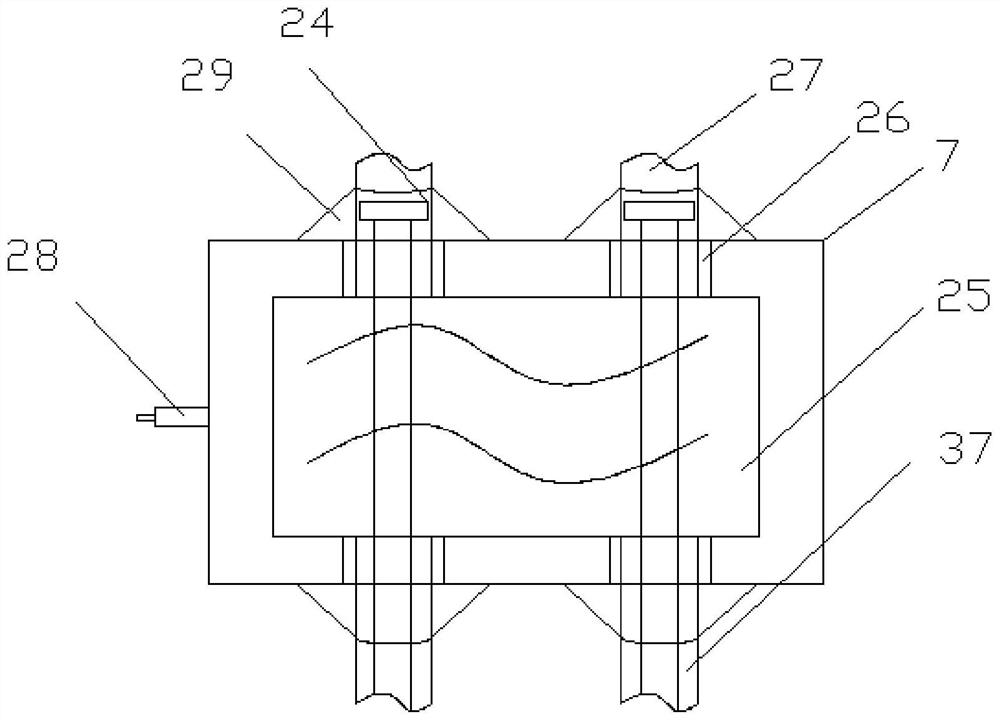

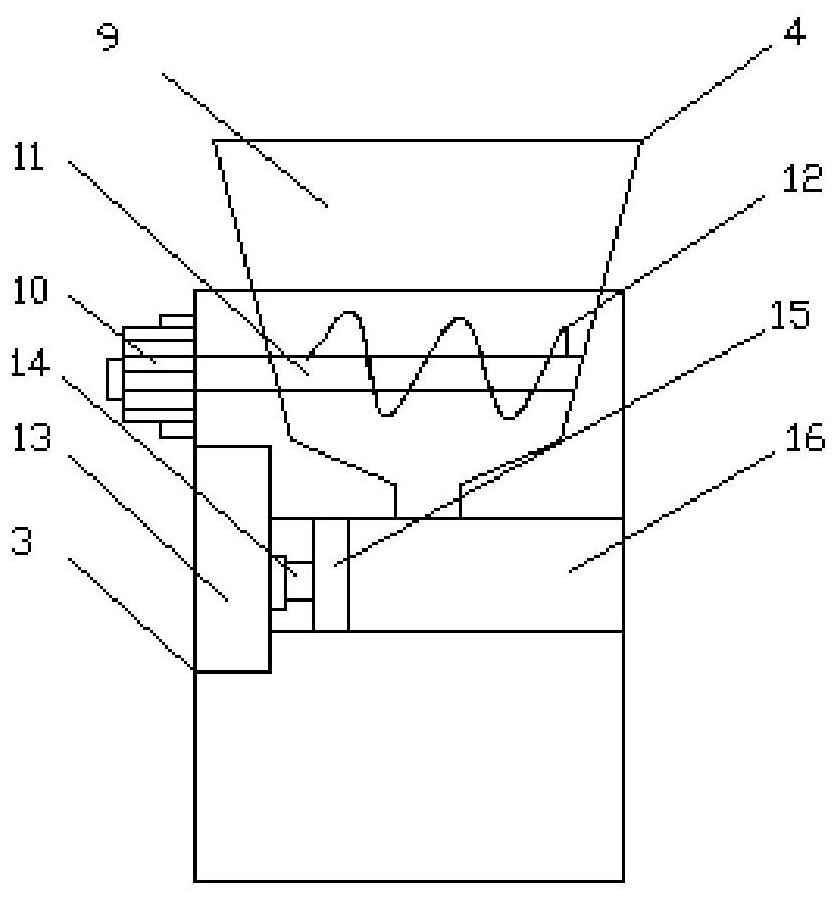

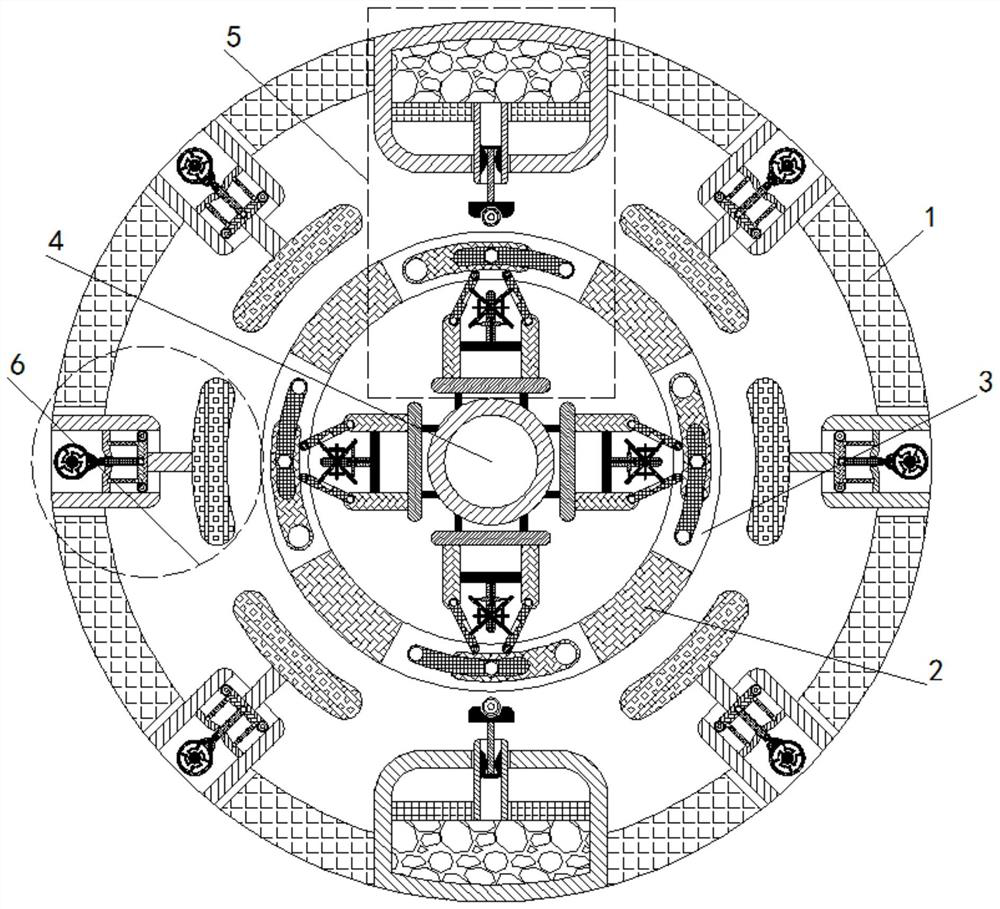

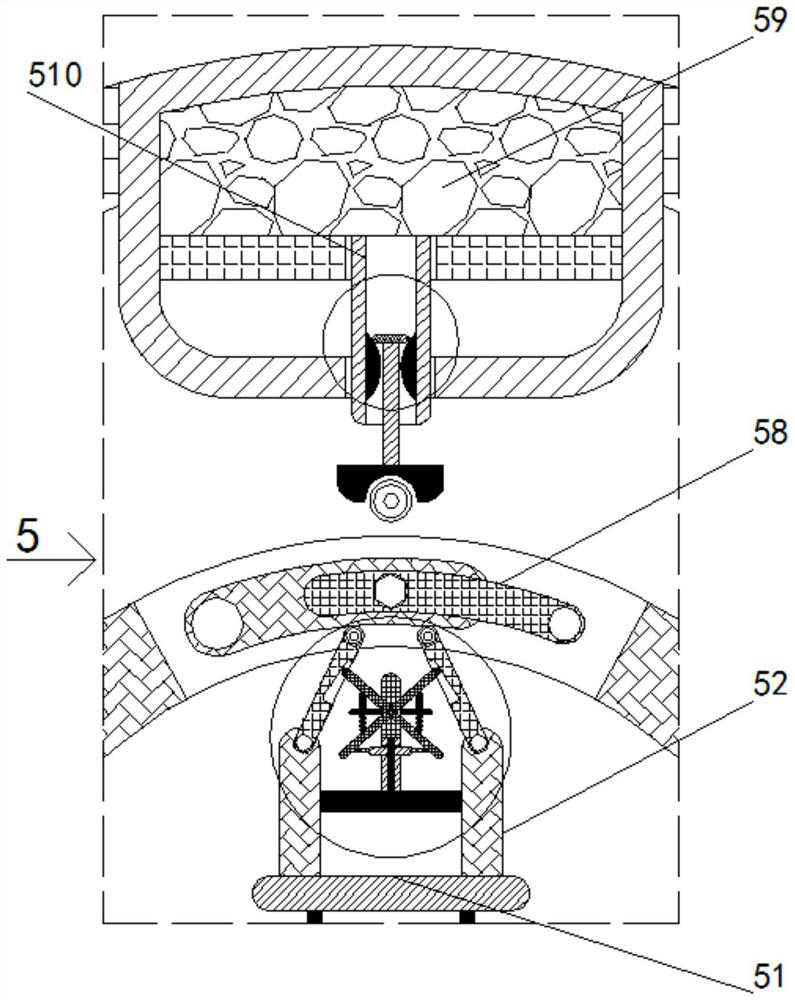

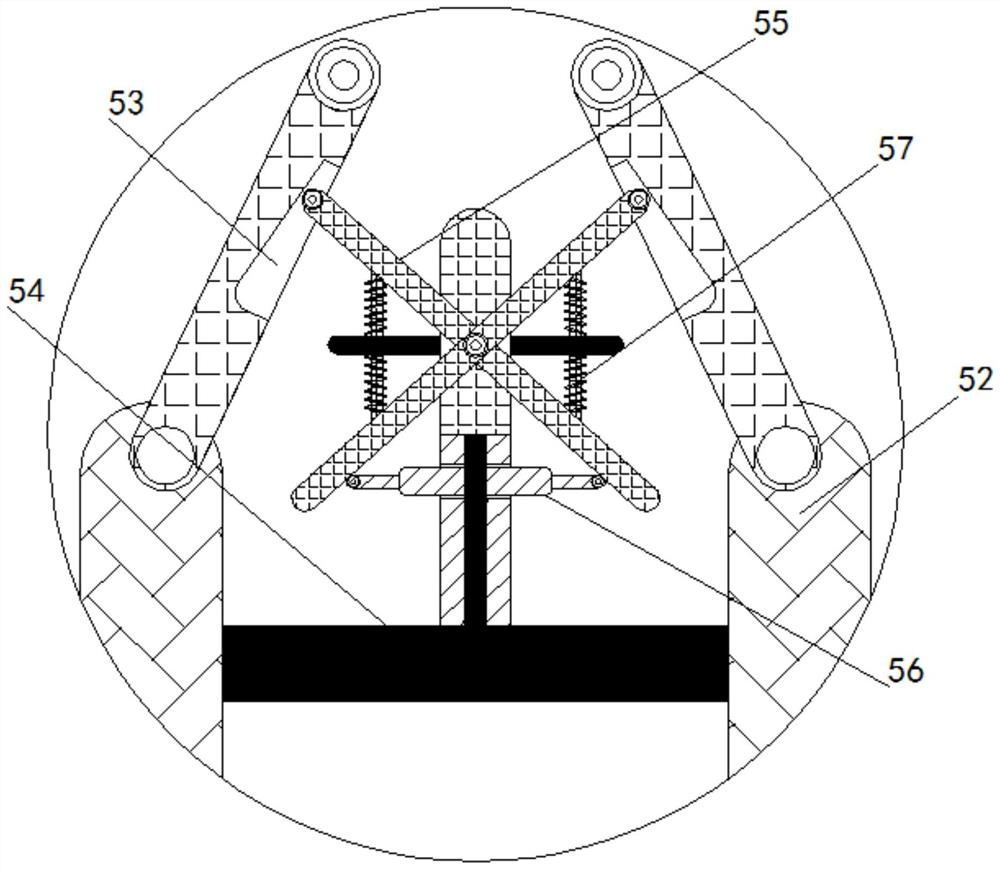

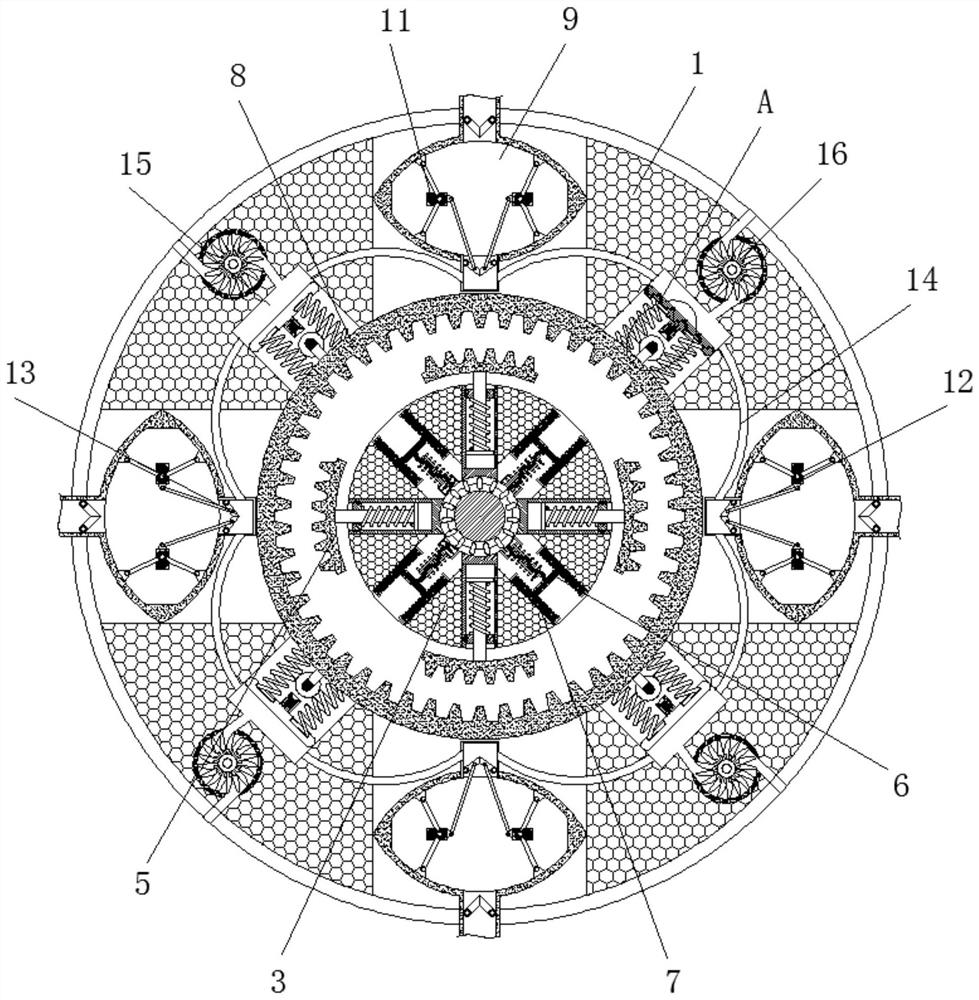

A high-pressure concrete stamping feeding device

ActiveCN110181672BImprove reinforcementPrevent collapseFeeding arrangmentsPunchingElectric machinery

The invention discloses a high-pressure concrete punching and feeding device, which includes a machine base, a punching device, a feeding device, a feeding box and a pre-stirring device. The punching device includes a punching box, a mixing tank, a lubricating box, an oil pressure box, a first A punching tube, a second punching tube, a punching rod, a punching piston and a punching disc, the pre-mixing device includes a hopper, a stirring motor, a stirring shaft and a rotary knife, and the feeding device includes a reciprocating motor, a telescopic push rod, and a feeding pipeline and plugging, the stamping rod is provided with a stamping piston at one end close to the oil pressure tank, the other end of the stamping rod is connected to the stamping plate located inside the mixing tank, and the feeding pipe is connected to the bottom of the supply hopper The end of the feeding pipeline away from the reciprocating motor communicates with the middle of the mixing tank, and the inner wall of the mixing tank is provided with pointed thorns. The invention improves the bearing capacity of loose soil by stamping the concrete and effectively mixing the concrete while eliminating air bubbles in the concrete.

Owner:贾国平

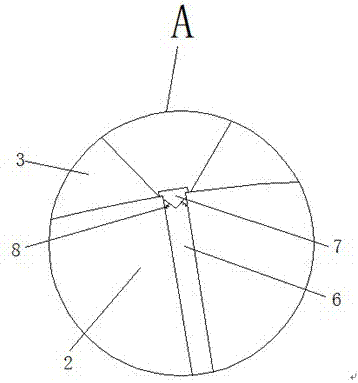

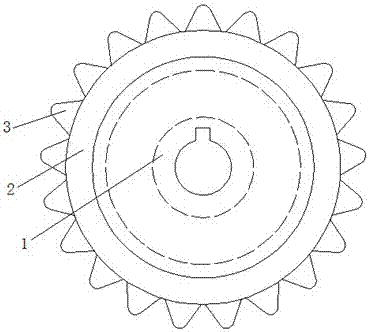

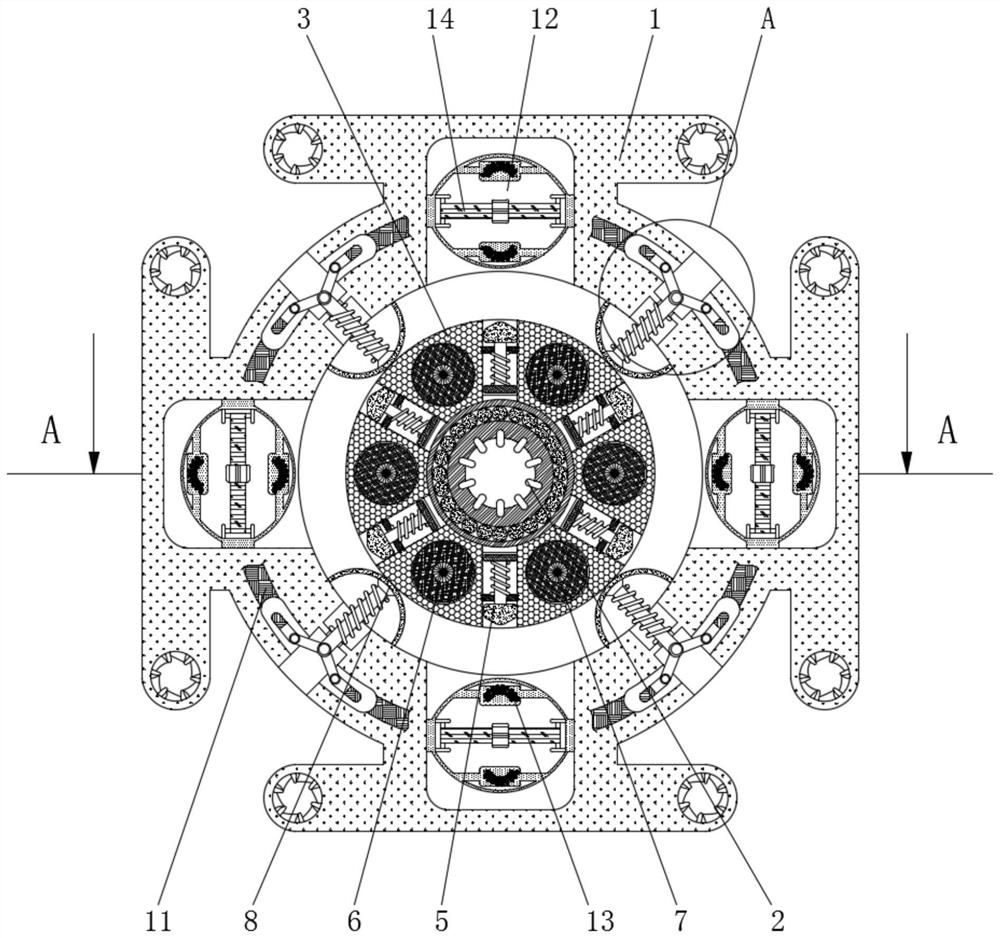

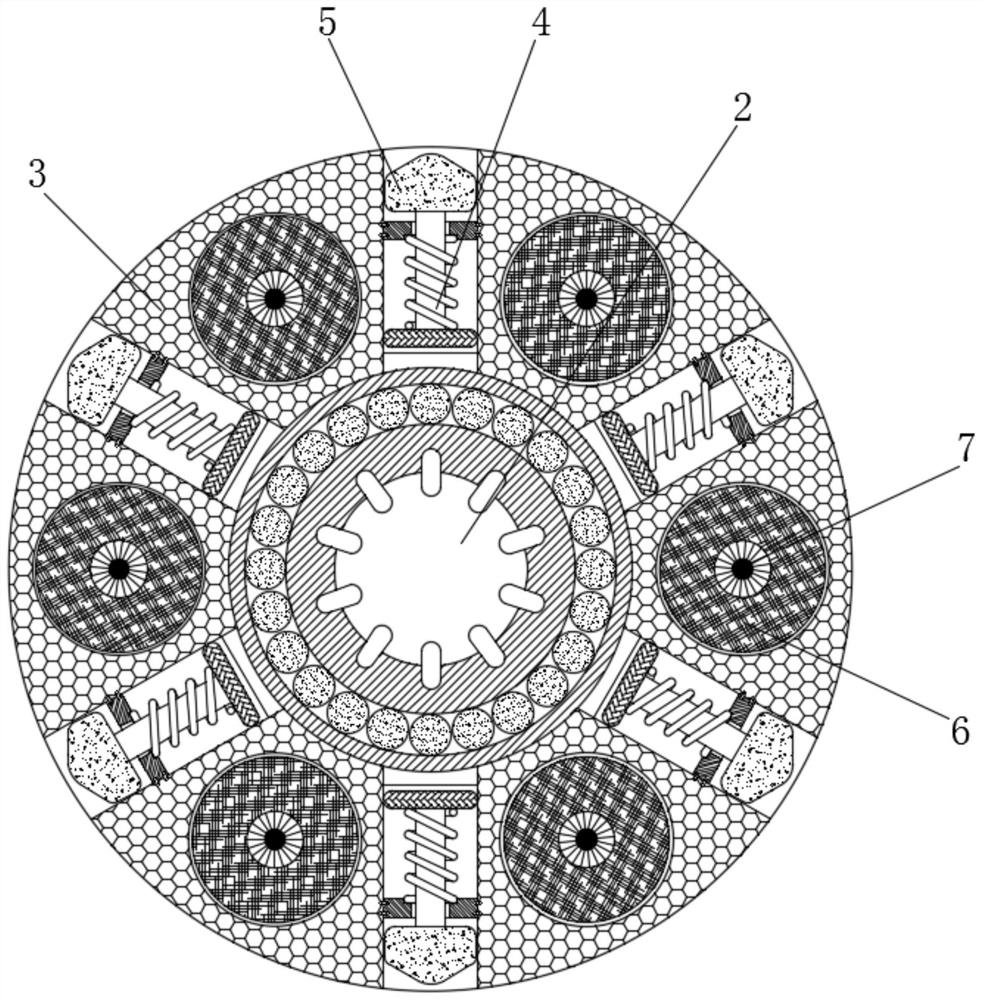

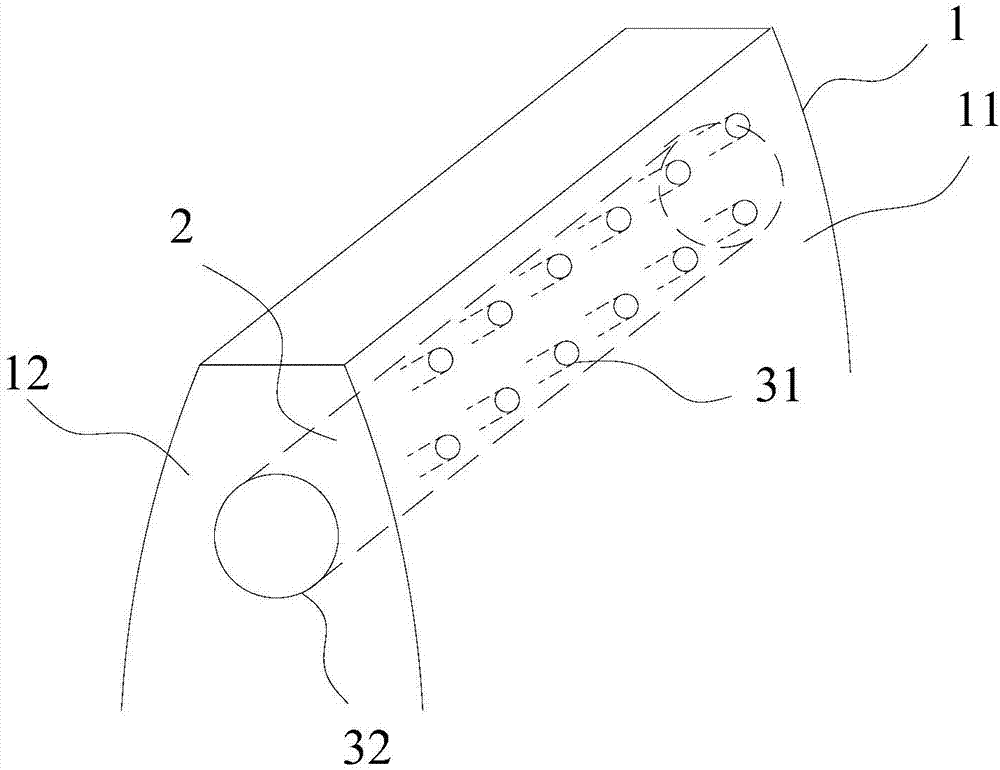

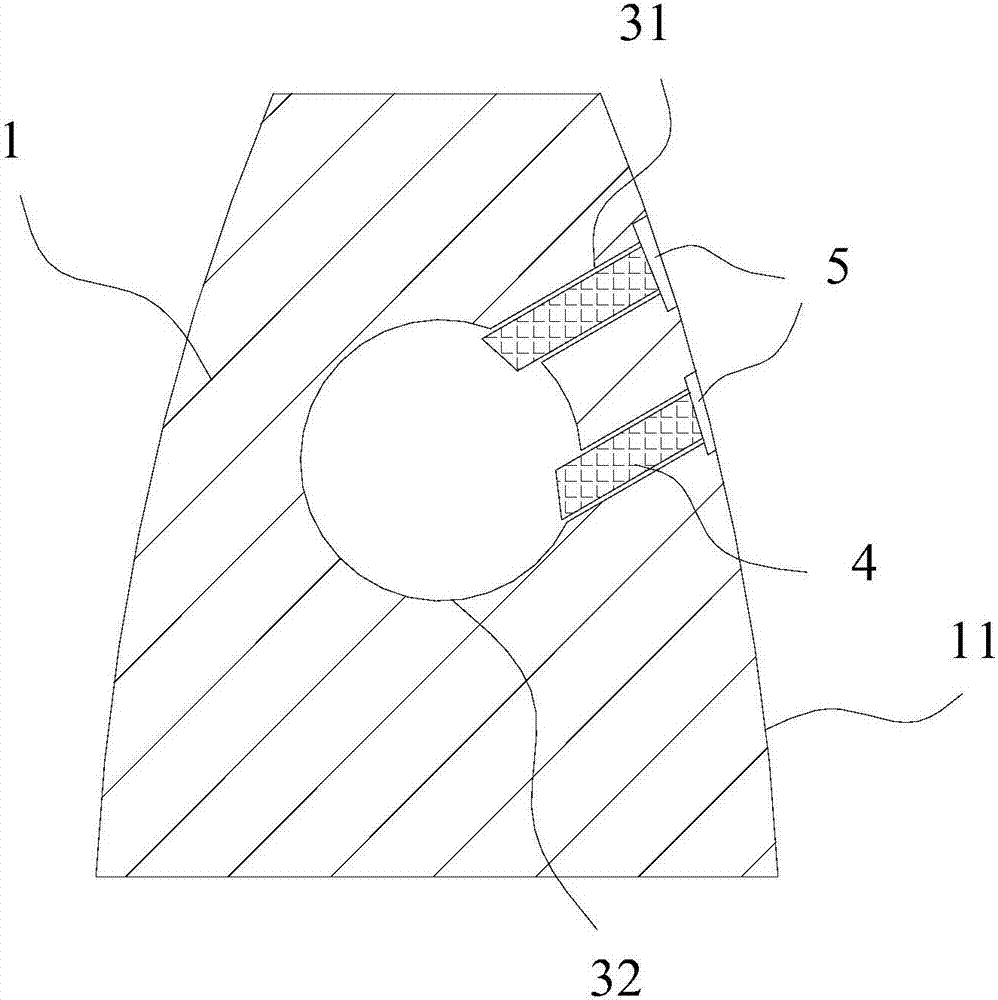

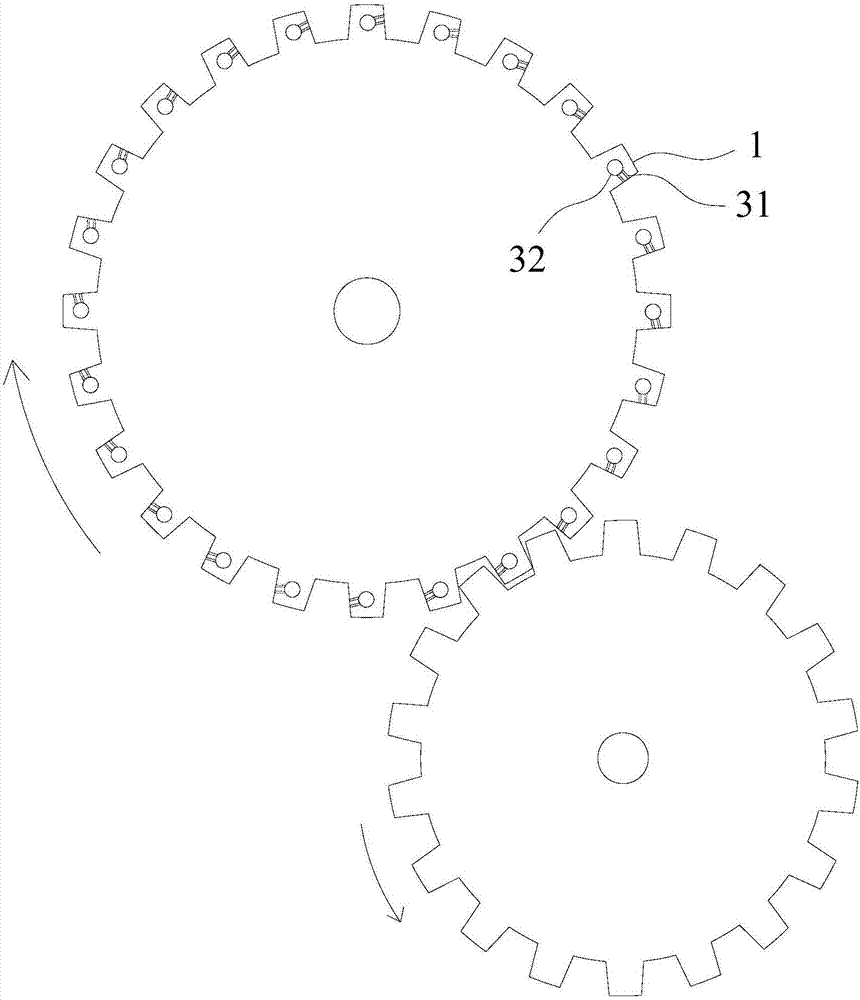

Novel internal self-lubricating gear

PendingCN107061693AReduce wearExtended service lifeGear lubrication/coolingPortable liftingReduction driveGear wheel

The invention relates to a novel internal self-lubricating gear which comprises a plurality of gear teeth. Each gear tooth is internally provided with a cavity. The engagement area of each gear tooth is provided with a plurality of first holes. A body is provided with one or more second holes. The first holes and the second holes all communicate with the cavities. The second holes are provided with one-way valves. By adoption of the novel internal self-lubricating gear, the engagement areas of the gear tooth can be automatically and continuously lubricated, the lubricating effect is improved, the lubrication area is wide, abrasion to the gear teeth is reduced, the service life of the gear is prolonged, reliability and safety of gear working are improved, the safety problem that lubricating oil is inconvenient to add during work of the gear is solved, lubricating oil waste is reduced, lubricating oil leakage caused by an oil bath mode is avoided, cost is saved, the structure is simple, machining is convenient, and the gear is particularly suitable for a low-speed heavy-load large reducer.

Owner:CHENGDU TECHCAL UNIV

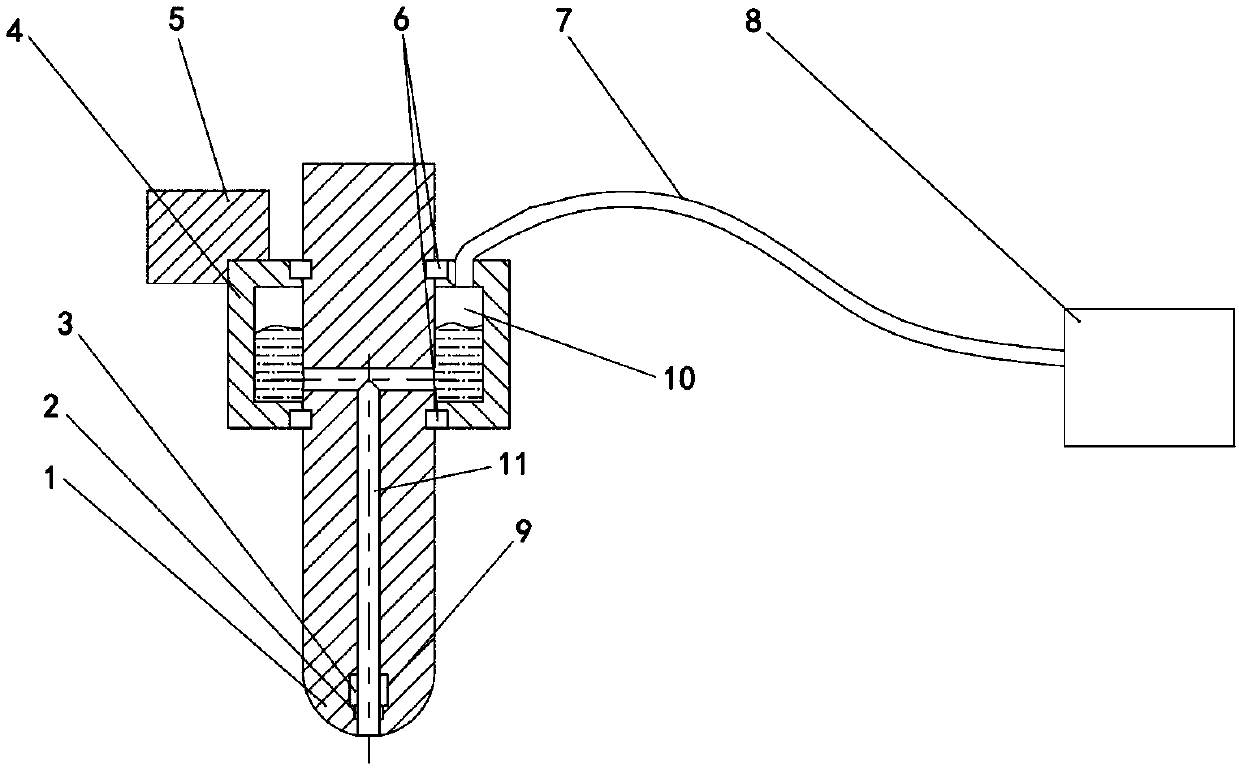

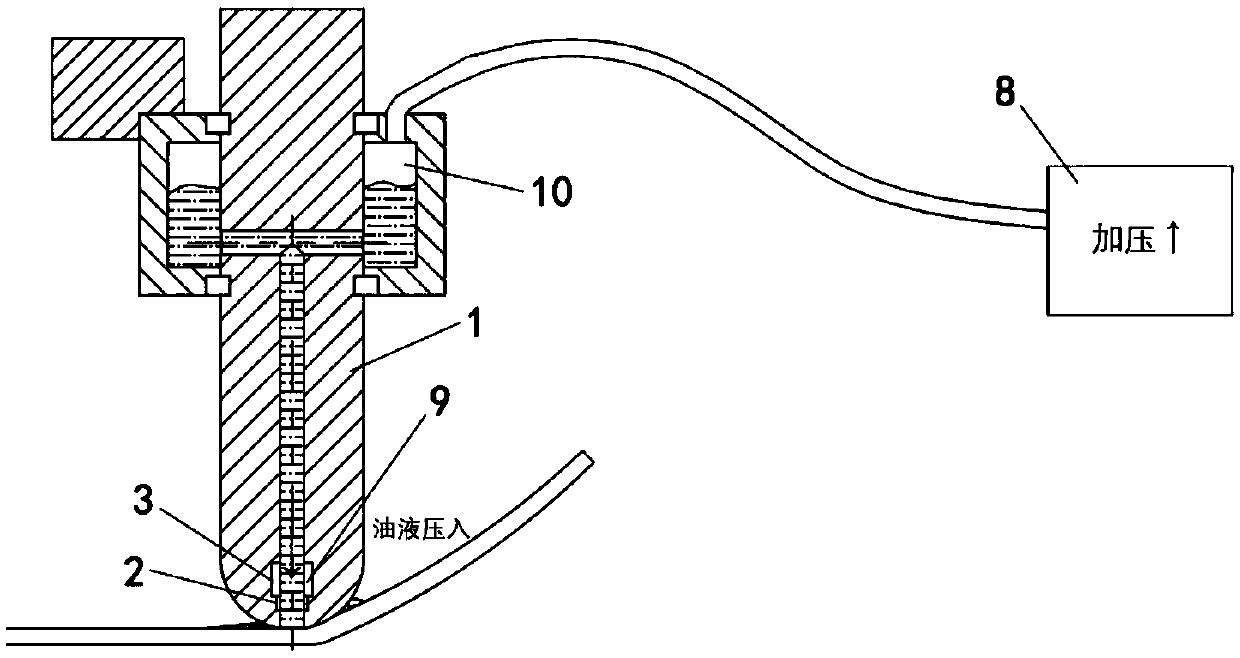

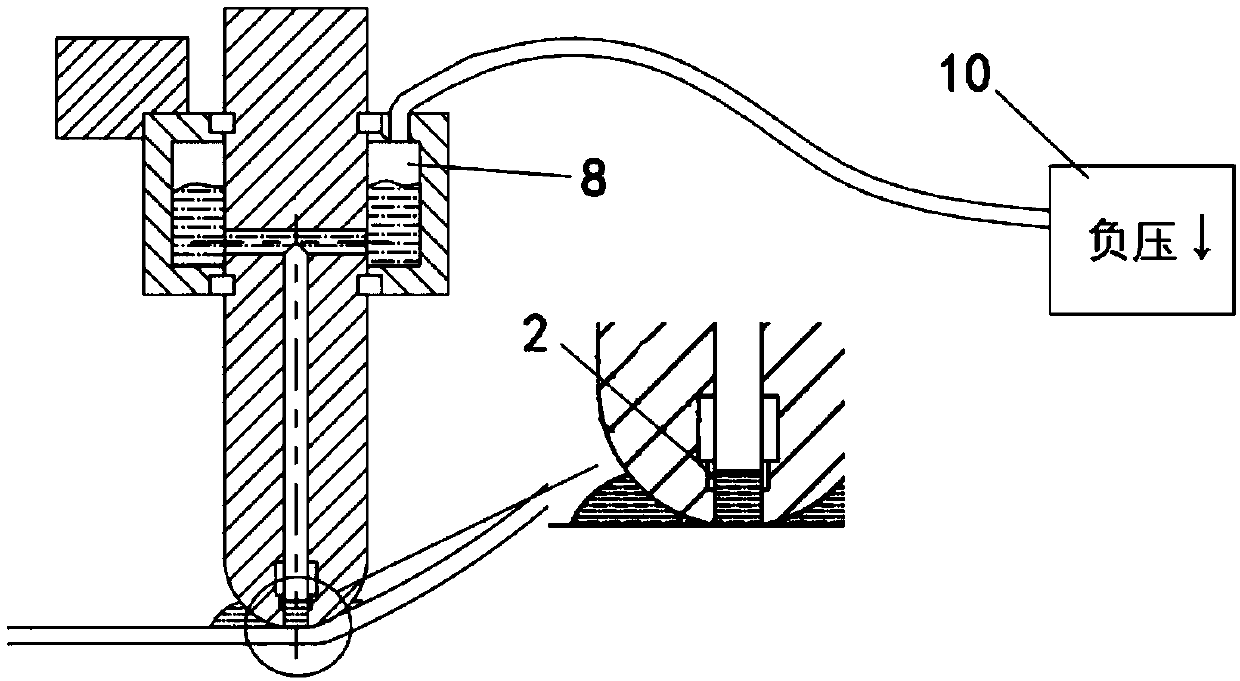

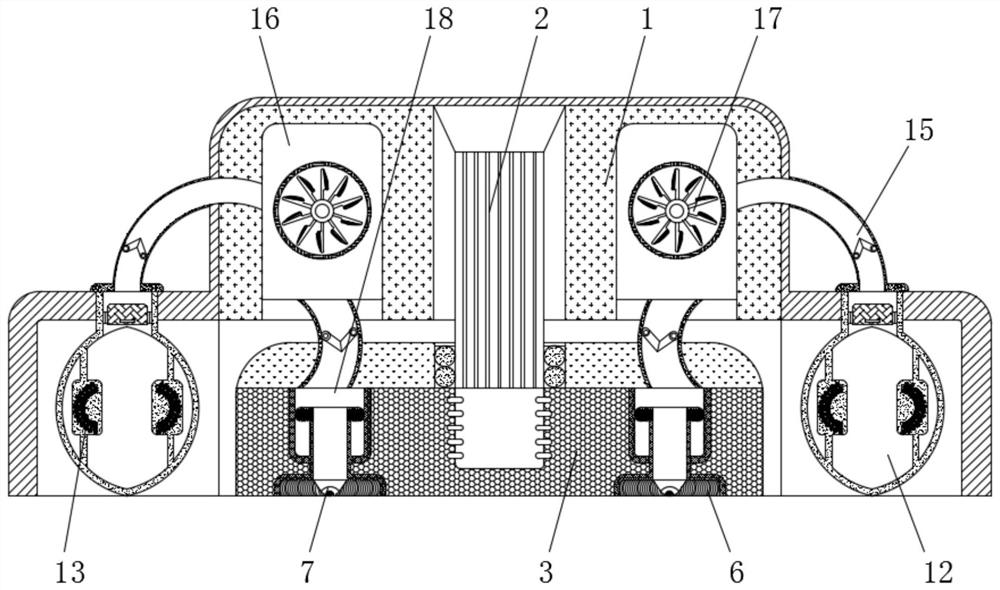

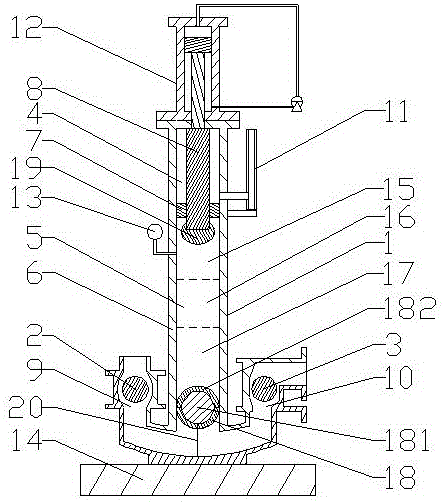

A vertical hydraulic plunger mud pump

ActiveCN104819117BAutomatic lubricationExtended service lifePump testingPositive displacement pump componentsWear resistantTransportation capacity

The invention relates to a water conservation facility, and in particular, discloses a vertical hydraulic plunger slurry pump. The vertical hydraulic plunger slurry pump comprises a vertical plunger type mortar cylinder, wherein a hydraulic oil cylinder is connected to the inner upper side of the mortar cylinder; the output end of the hydraulic oil cylinder is connected with a piston column of the mortar cylinder; a wear resistant cap is arranged at the lower end of the piston column; a radiating position indicator is mounted on an upper cavity divided by an annular support sealing ring; a pressure sensor is arranged at the upper part of a lower cavity; and a side inlet and a side outlet are formed in the lower part, and are respectively provided with a one-way floating ball valve and a one-way gravity ball valve. The vertical hydraulic plunger slurry pump uses the hydraulic oil cylinder for pushing the piston column of the mortar cylinder to reciprocate so as to extrude clear water in the lower cavity to achieve the mortar extruding purpose, and has such characteristics as simple structure, convenience for operation, strong sand transportation capacity, high efficiency, low energy consumption, environmental protection and operation safety and reliability.

Owner:山东国地水利土地勘察设计有限公司

A progressive forming tool with automatic lubrication function

ActiveCN109622753BImplement automatic additionSave human effortShaping toolsThermodynamicsWorking environment

The invention relates to an incremental forming tool with an automatic lubrication function. The progressing forming tool with the automatic lubrication function comprises a gripping handle, an oil tank, a sealed bearing, a forming tool head, a gas pipe and a pressure controller; the forming tool head is mountedon a main shaft of an incremental forming machine tool, the upper end of the forming tool head penetrates through the oil tank, and the oil tank is connected with a fixed part of the incremental forming machine tool by connecting with the gripping handle; the sealed bearing is installedat the joint of the oil tank and the forming tool head, an oil groove is formed inside the forming tool head, an outlet of the oil groove is formed in the lower end of the forming tool head, and an inlet of the oil groove is connected with the oil tank. Compared with the prior art, the incremental forming tool with the automatic lubrication function has the advantages that automatic lubrication of the tool head and the sheet processing position during incremental forming is achieved,special lubricating oil adding equipment is no longer required, precise control over lubricating oil quantity inthe forming process is realized only by adjusting an input air pressure value,thus surface quality and processing efficiency of an incrementally-formed machined workpiece are improved, the labor costislowered, and the working environment is improved.

Owner:SHANGHAI JIAOTONG UNIV

Device for automatically lubricating and reducing noise in small and special electric machine

InactiveCN114352919AReduce noiseAutomatic lubrication reachesSupports/enclosures/casingsEngine lubricationAcoustic noise reductionWater vapor

The invention relates to the technical field of small and special electric machine lubrication, and discloses a small and special electric machine internal automatic lubrication and noise reduction device, which comprises a lubrication device main body, a rotating disc is rotatably mounted in the lubrication device main body, a through hole is formed in the outer wall of the rotating disc, and a water tank is welded in the rotating disc. And a noise reduction mechanism is welded in the lubricating equipment main body. A water solution in a water tank is evaporated into water vapor which enters an air cylinder in a rotating wheel, the air cylinder stretches out, two stop rods drive the rotating wheel to deflect, and due to the fact that a protruding arc block on the outer wall of the rotating wheel is located on one side of a push rod at the beginning, after the rotating wheel deflects, the push rod is pulled away from the circle center of a rotating disc under the action of an internal magnet; the push rod moves to drive the sliding rod to move towards the outer side of the circle center, the sound absorption plate can be far away from the rotating disc, and the effects that after the temperature rises, friction between the rotating disc and the sound absorption plate is avoided, the sound absorption plate is damaged, and the service life of the sound absorption plate is prolonged are achieved.

Owner:徐州力达电机技术有限公司

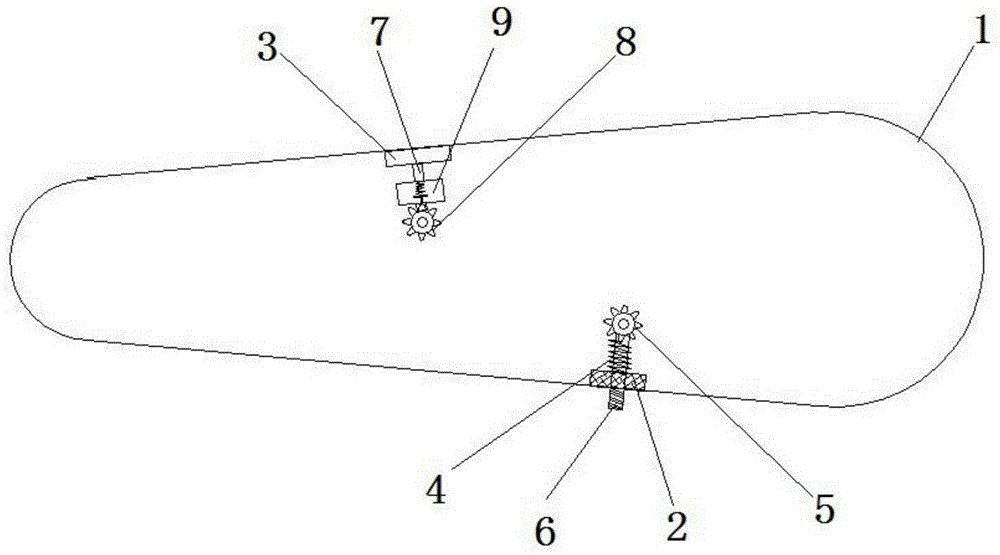

Lubricating shell for bicycle chain

The invention discloses a lubricating shell for a bicycle chain. The lubricating shell comprises a shell body, a first fixing base, a second fixing base, a spring, a first gear, a screw, a connecting rod, a second gear and an oil box device. The first fixing base is arranged on the inner side of the lower end of the shell body and provided with the screw. The spring is arranged on the outer side of the screw. The first gear is arranged at the top end of the screw and engaged with the chain. The second fixing base is arranged on the inner side of the top end of the shell body. The connecting rod is arranged at the lower end of the second fixing base. The second gear is arranged at the lower end of the connecting rod. The connecting rod is provided with the oil box device, and the second gear makes contact with the oil box device. The lubricating shell for the bicycle chain is simple in structure and convenient to use, disengagement of the chain is avoided, self lubrication is achieved, and time, effort and materials are saved.

Owner:TIANJIN DACHENG IND & TRADE

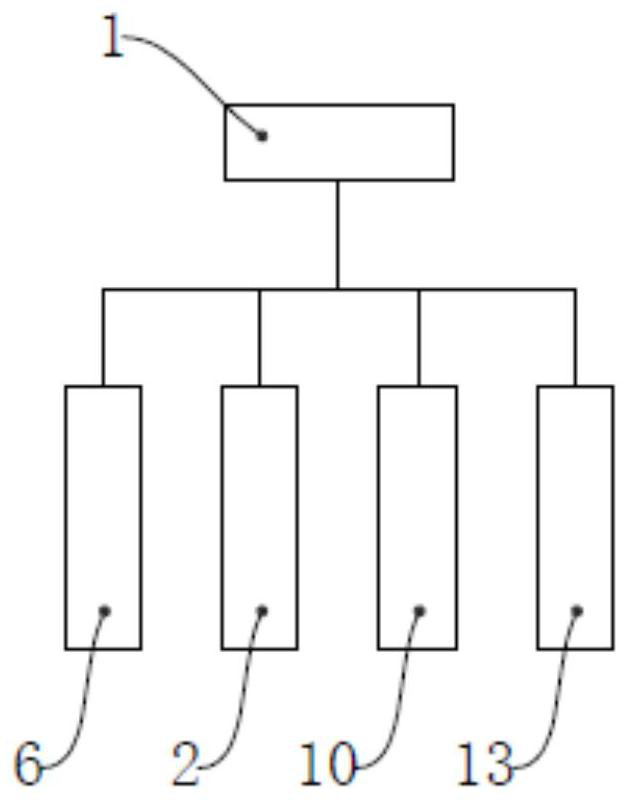

Automatic lubricating system of high-speed enamelling machine

InactiveCN112325139AEasy to operateExtended service lifeEngine pressureSignal processingControl engineeringProcess engineering

The invention discloses an automatic lubricating system of a high-speed enamelling machine. The automatic lubricating system comprises a control terminal, a delivery pump, a primary oil distributor, secondary oil distributors, first fans and a first pressure detection unit, wherein the control terminal is electrically connected to the delivery pump and the first pressure detection unit, and the control terminal is used for driving the delivery pump to perform quantitative delivery; the delivery pump communicates with the primary oil distributor, the plurality of the secondary oil distributorsare arranged, and the primary oil distributor communicates with each secondary oil distributor; the plurality of the first fans are arranged, and all the secondary oil distributors communicate with bearing parts of the corresponding first fans; and the first pressure detection unit is arranged at the oil outlet end of the primary oil distributor and used for detecting a pressure of a conveying pipeline. The invention aims to provide the automatic lubricating system of the high-speed enamelling machine which can automatically add oil to bearings of the fans.

Owner:GUANGDONG JINGXUN LIYA SPECIAL WIRE

A rotating shaft lubrication device with automatic lubrication and more uniform application of lubricating fluid

The invention relates to the technical field of picks, and discloses a rotating shaft lubricating device with automatic lubrication and more even application of lubricating fluid, including a mounting frame, a rotating shaft is connected to the center of the mounting frame, and a mounting bracket is fixedly connected to the surface of the rotating shaft. The inside of the installation plate is slidably connected with a slide bar, the end of the slide bar is fixedly connected with a fixed block, the inside of the installation plate is slidably connected with a metal contact, and the side of the metal contact is slidably connected with a The resistance bar is fixedly connected with a transmission gear at the center of the circle inside the installation frame. Through the change of the mutual attraction between the electromagnetic rods, the attractive force between the electromagnetic rods increases when the speed is slow, the baffle can be opened and the internal lubricating fluid can be discharged, and the baffle can be closed when the speed is fast to stop lubrication, thus achieving In order to be able to automatically lubricate when the surface of the shaft is rusted and dry, and to prevent the effect of shaft wear due to insufficient lubrication during work.

Owner:临沂边锋自动化设备有限公司

An experimental device for controlling the basic accuracy of machine tools

ActiveCN106759533BExtended service lifeAutomatic lubricationFoundation testingReciprocating motionHydraulic pump

The invention discloses an experimental device for adjusting machine tool foundation precision. A container is fixed on a foundation, and is fully filled with hydraulic coil; a large-diameter cylinder is a hollow solid, and is positioned in an upper surface opening of the container fully filled with the hydraulic coil; a small-diameter cylinder is positioned in the hollow of the large-diameter cylinder, is smoothly contacted with the large-diameter cylinder, and can slide up and down under pressure of the hydraulic oil; a pressure sensor A is bonded on the outer side of the large-diameter cylinder by glue; according to the data of the pressure sensor, a hydraulic pump controls the ascending height of the small-diameter cylinder through adjusting the pressure of the hydraulic oil container by a control valve; an anti-leaking ring can prevent leakage of the hydraulic oil to guarantee tightness of the container; a fixed ring is used for fixing the large cylinder to guarantee a up-down reciprocating motion of the large cylinder; and a pressure sensor B is used for detecting the pressure change of the hydraulic oil container, and can adjust the oil pressure of the container according to the pressure change, so that the ascending height of the small-diameter cylinder is adjusted, the stability of the machine tool foundation precision is guaranteed, and the experimental accuracy is improved.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com