Device for automatically lubricating and reducing noise in small and special electric machine

An automatic lubrication, micro-motor technology, applied in the direction of mechanical equipment, engine lubrication, electric components, etc., can solve the problems of micro-motor noise, unfavorable long-term operation of micro-motor, damage to sound-absorbing panels, etc., to improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

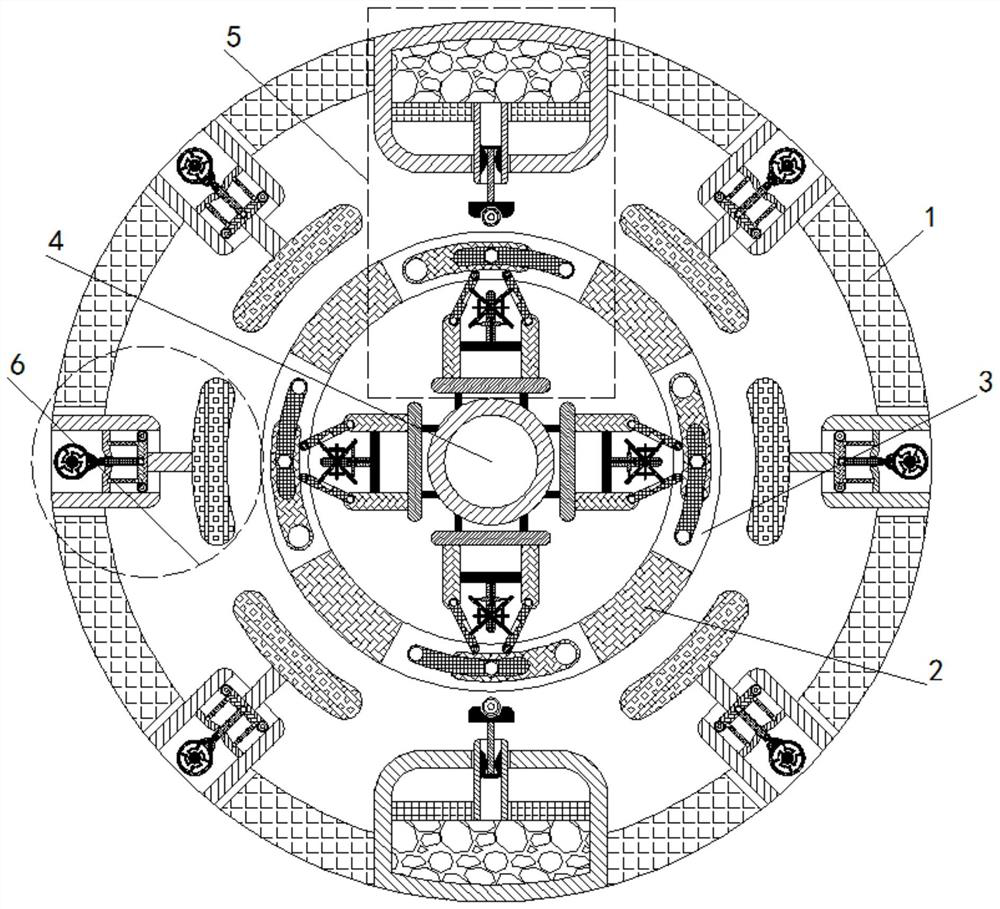

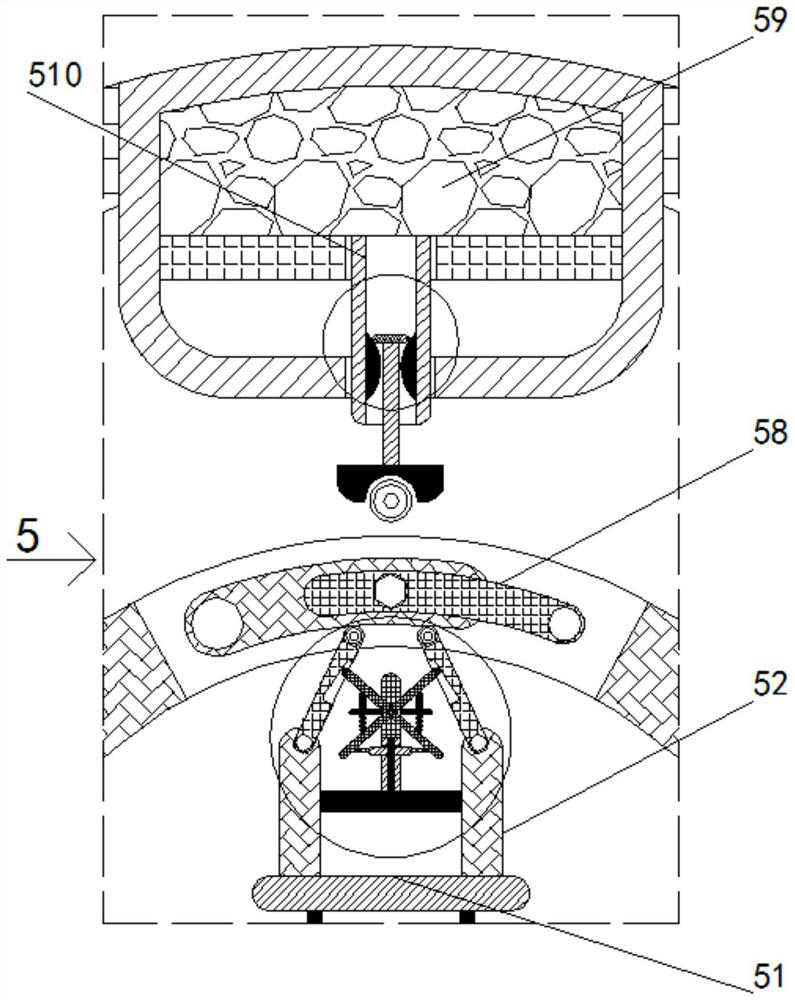

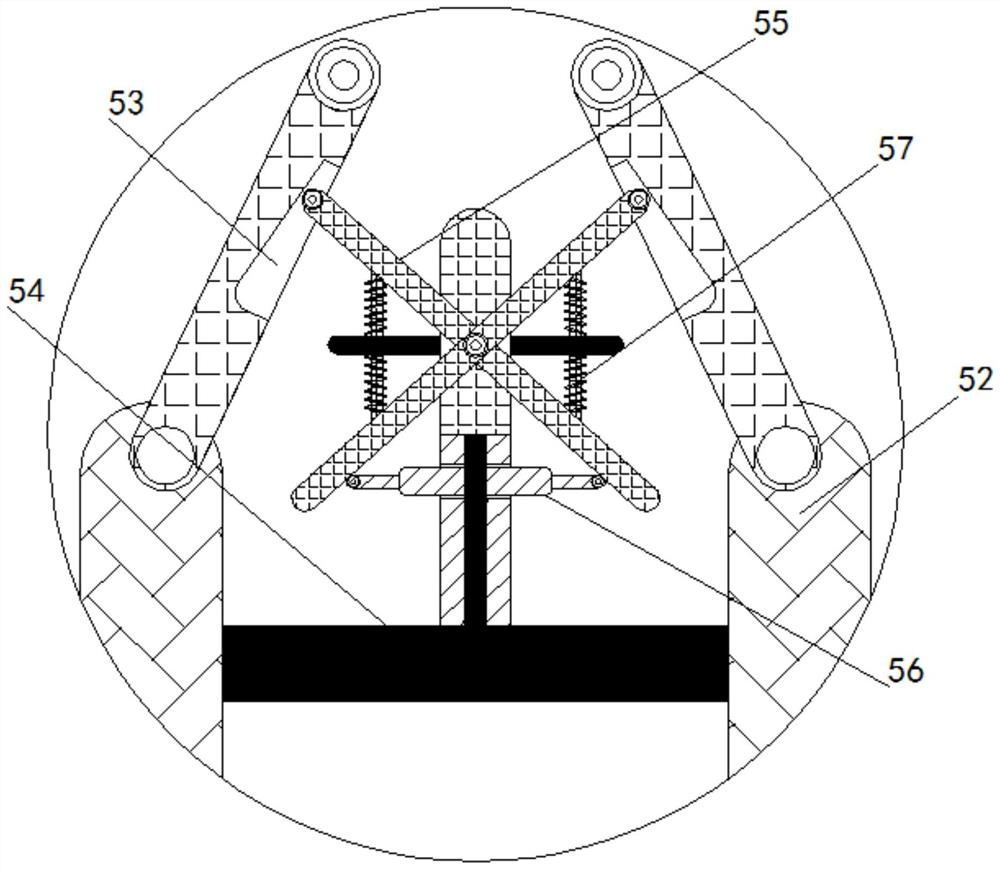

[0029] see Figure 1-4 , a device for automatically lubricating and reducing noise inside a micro-motor, including a main body 1 of lubricating equipment, a rotating disk 2 is installed inside the main body 1 of the lubricating equipment, and the outer wall of the rotating disk 2 is provided with a through hole 3, and the interior of the rotating disk 2 A water tank 4 is welded, a lubricating mechanism 5 is welded inside the main body 1 of the lubricating device, a fixing frame 51 is welded inside the lubricating mechanism 5, a rotating rod 52 is welded on the top of the fixing frame 51, and a chute 53 is opened inside the rotating rod 52, The top of the fixed frame 51 is welded with a bracket 54, the front of the bracket 54 is rotatably installed with a sliding rod 55, the left and right sides of the bracket 54 are welded with a cylinder 56, the bottom of the sliding rod 55 is welded with an elastic rod 57, and the interior of the through hole 3 is rotated and installed There...

Embodiment 2

[0032] see figure 1 and 5 -6, a device for automatically lubricating and reducing noise inside a micro-motor, comprising a main body 1 of a lubricating device, a rotating disk 2 is rotatably installed inside the main body 1 of the lubricating device, the outer wall of the rotating disk 2 is provided with a through hole 3, and the rotating disk 2 A water tank 4 is welded inside the lubricating device body 1, a noise reduction mechanism 6 is welded inside the main body 1 of the lubricating equipment, a telescopic cylinder 61 is welded inside the noise reduction mechanism 6, a runner 62 is rotatably installed inside the telescopic cylinder 61, and the inside of the telescopic cylinder 61 is welded. There is a stator 63, a blocking rod 64 is welded on the inner wall of the runner 62, a magnet 65 is welded inside the stator 63, a push rod 66 is slidably connected to the interior of the through hole 3, and a sliding rod 67 is slidably connected to the interior of the telescopic cyli...

Embodiment 3

[0035] see Figure 1-6 , a device for automatically lubricating and reducing noise inside a micro-motor, including a main body 1 of lubricating equipment, a rotating disk 2 is installed inside the main body 1 of the lubricating equipment, and the outer wall of the rotating disk 2 is provided with a through hole 3, and the interior of the rotating disk 2 A water tank 4 is welded, and the water tank 4 is made of a heat-accumulating metal material. The lubricating device main body 1 is welded with a lubricating mechanism 5 , and the lubricating device main body 1 is welded with a noise reduction mechanism 6 .

[0036]Preferably, a fixed frame 51 is welded inside the lubricating mechanism 5 , a rotating rod 52 is welded on the top of the fixed frame 51 , and a chute 53 is opened inside the rotating rod 52 . Constantly extending into the interior of the rotating rod 52, the top of the fixed frame 51 is welded with a bracket 54, the front of the bracket 54 is rotatably installed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com