Electric motor

A rotor and space technology, applied in the field of motors driving inertial separators, can solve problems such as leakage and easy wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

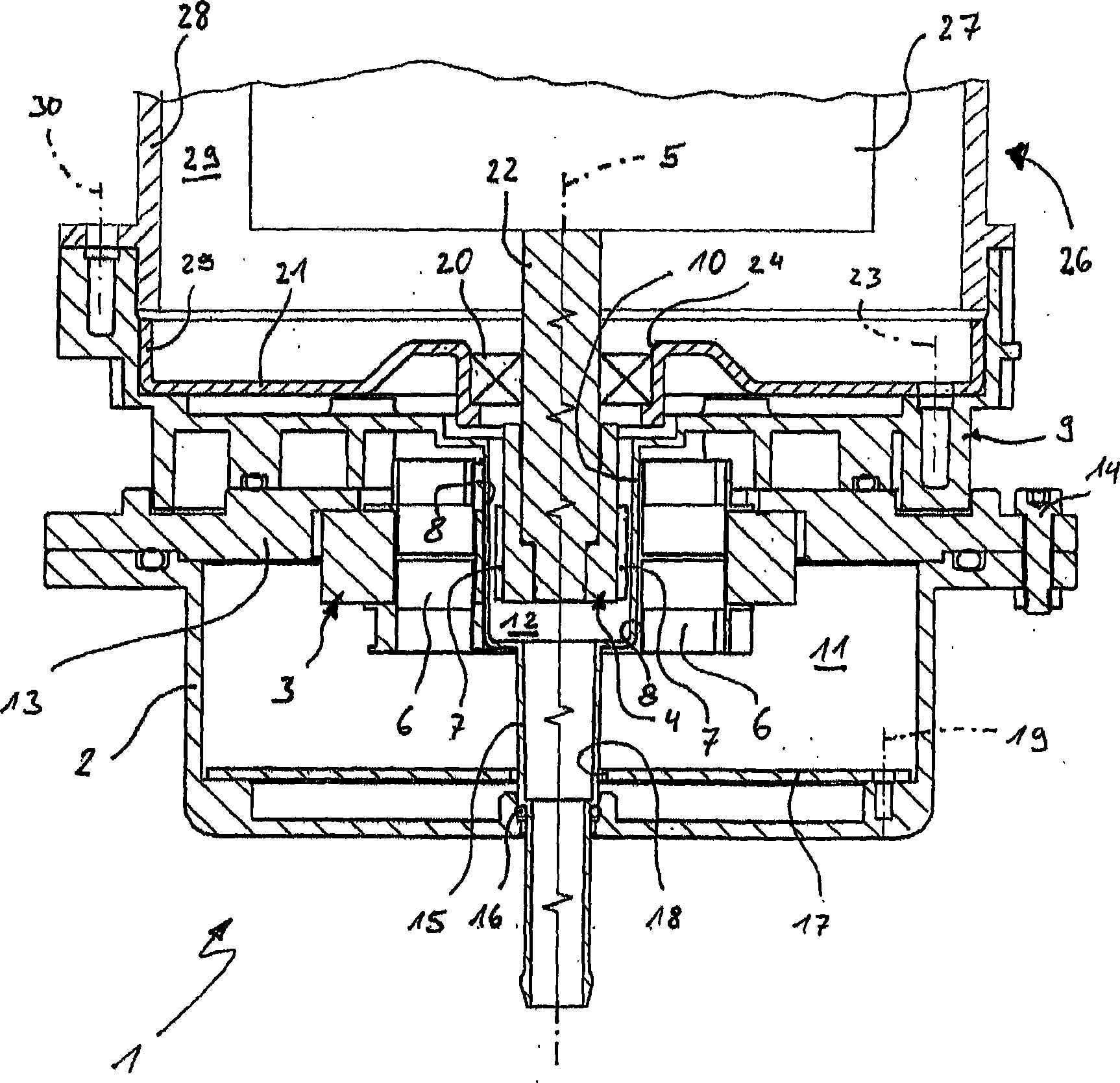

[0012] according to figure 1 , the inventive motor 1 comprises a stator housing 2 , a stator 3 disposed therein and a rotor 4 , wherein the rotor 4 is arranged coaxially with the stator 3 relative to the axis of rotation 5 . The motor 1 is designed as a brushless motor 1 . The stator 3 has at least one electromagnetic coil 6 for generating a magnetic field rotating about the axis of rotation 5 . The rotor 4 has at least one permanent magnet 7 which is able to transmit torque to the rotor 4 by means of electromagnetic force.

[0013] An annular gap 8 is formed radially between the rotor 4 and the stator 3 , which gap also extends coaxially with the axis of rotation 5 .

[0014] Furthermore, the electric machine 1 is equipped with a housing base 9 extending substantially through the axis of rotation 5 . The housing base 9 is designed and arranged relative to the other components of the electric machine 1 to extend through the annular gap 8 together with a non-magnetic part 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com