Novel internal self-lubricating gear

A gear, a new type of technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve problems such as wear, reduced service life, poor lubrication effect, etc., to achieve a wide range of lubrication areas, reduce Effects of wear, improved reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

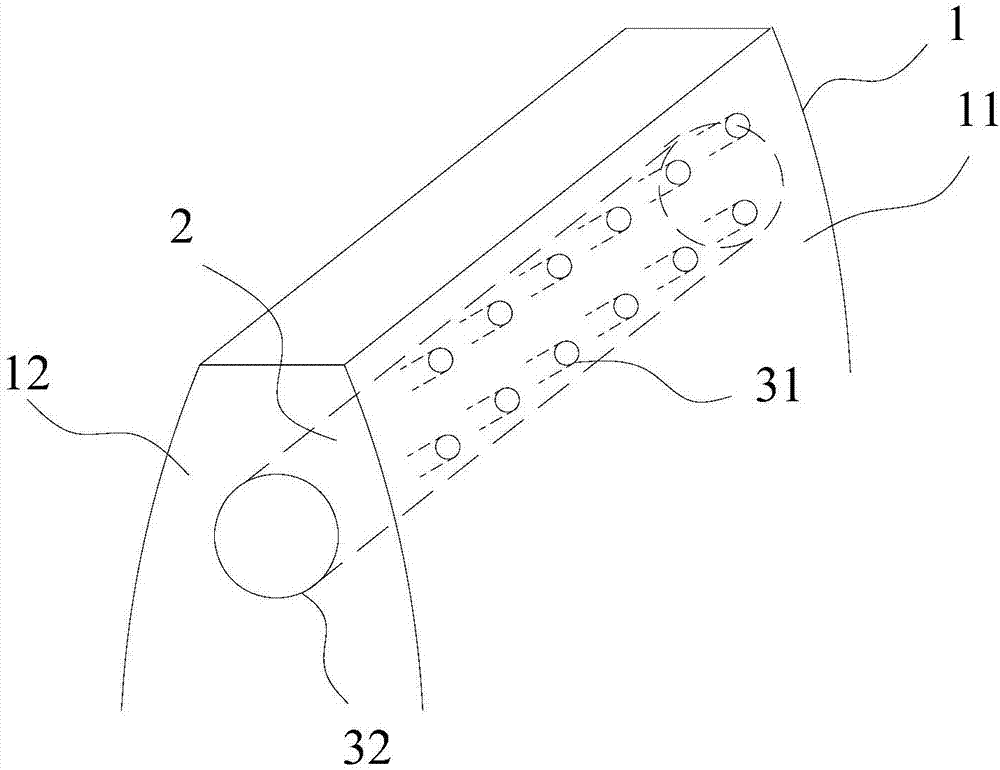

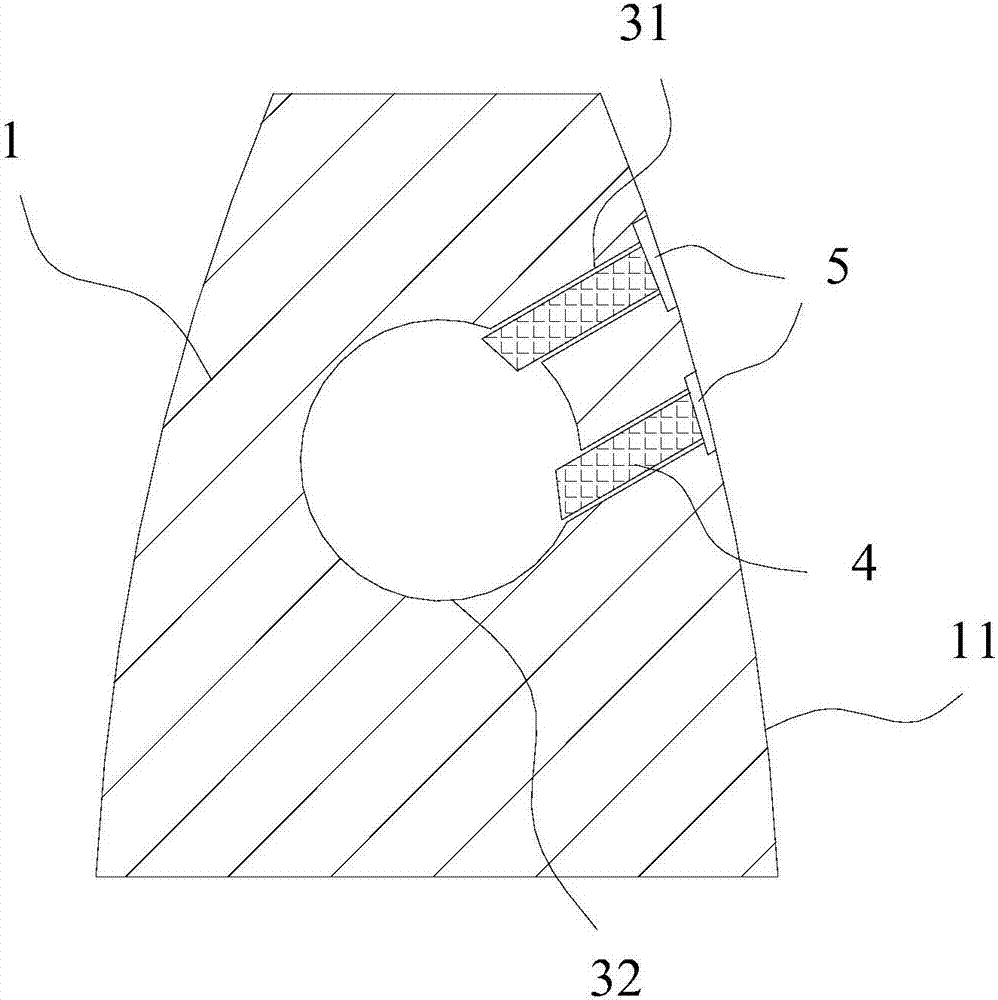

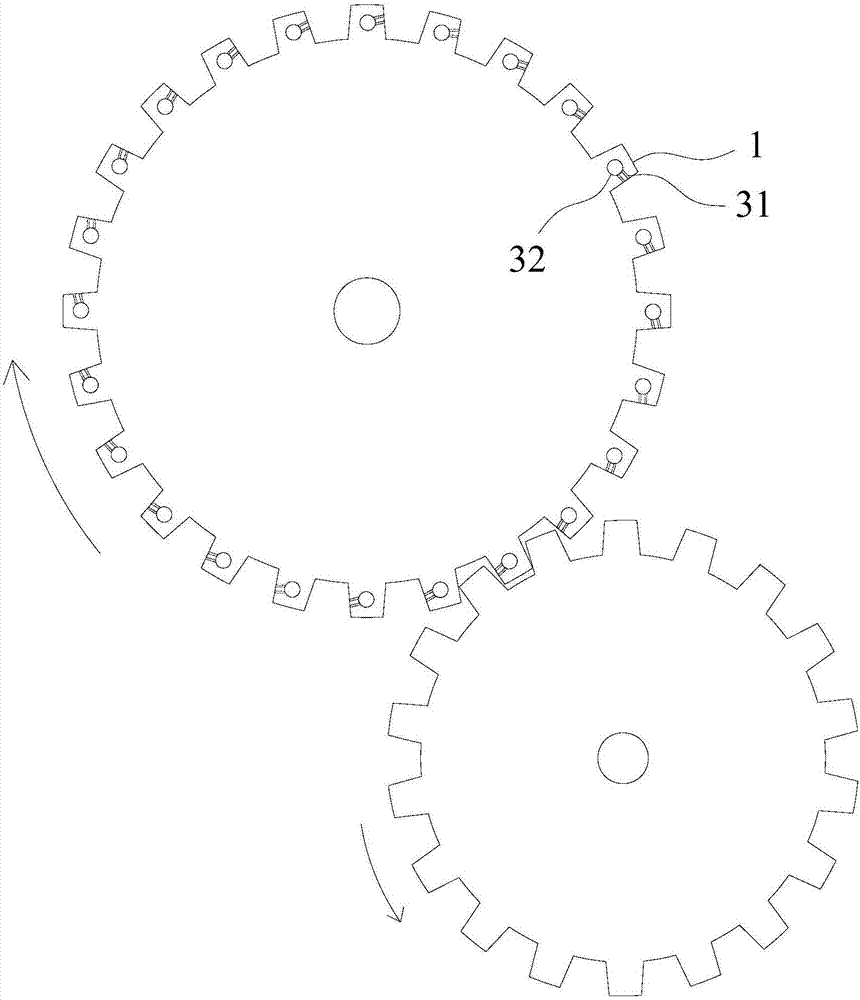

[0035] Such as Figure 1-3 , a new type of internal self-lubricating gear, the body meshes with another ordinary gear, the body always rotates clockwise, the line between the center of the body and the center of the ordinary gear is 60° to the horizontal direction, so The body includes a plurality of gear teeth, each of the gear teeth 1 is provided with a cavity 2, and the meshing area 11 of each of the gear teeth 1 is provided with a plurality of holes 31, and all the holes 1 31 are in the The meshing area 11 is evenly distributed on one side of the rotation direction, and the non-engaging area 12 on each side of the gear tooth 1 is provided with a hole 2 32, and the hole 31 and the hole 32 are both connected to the The cavities are connected, the second hole 32 is provided with a one-way valve, all the second holes 32 are arranged on the same side of each of the gear teeth 1, the first hole 31 and the second hole 32 are circular, The diameter of the first hole 31 is 1 / 25 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com