Patents

Literature

85results about How to "Guaranteed continuous lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

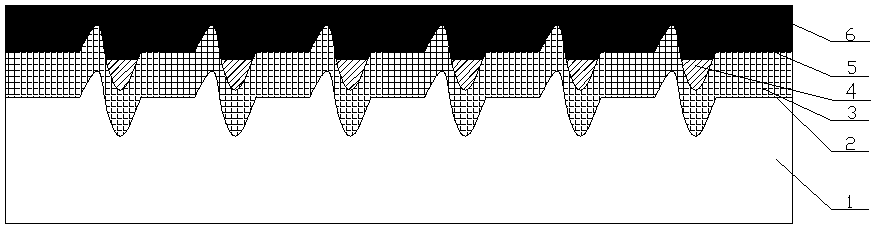

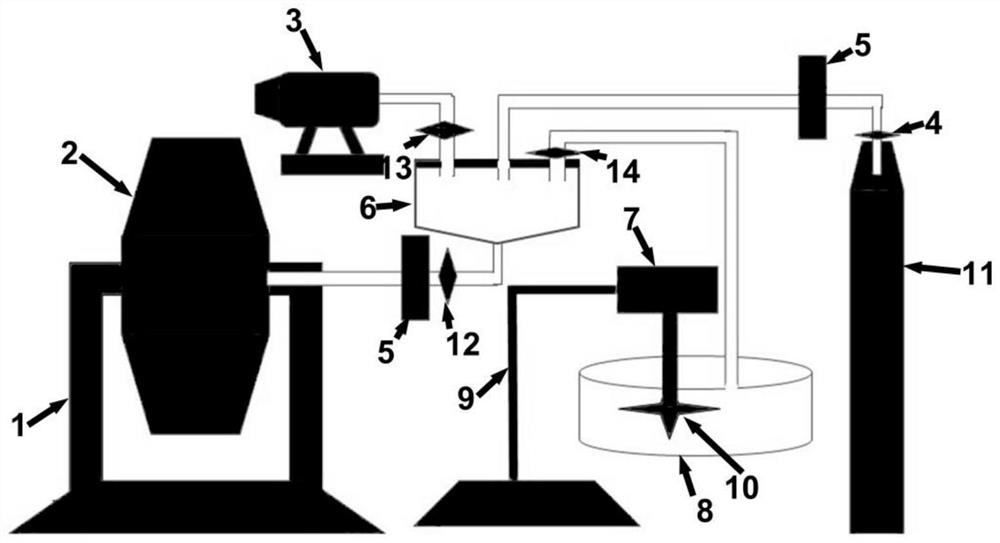

Magnetic-fluid-coated textured surface lubricating substrate and processing method thereof

PendingCN107557784AImprove wear resistanceEasy to useSuperimposed coating processLaser beam welding apparatusLaser processingThin membrane

The invention provides a magnetic-fluid-coated textured surface lubricating substrate and a processing method of the magnetic-fluid-coated textured surface lubricating substrate and belongs to the field of machine manufacturing. For the problems that a hard coating is low in bonding strength and easily peeled off, active processing of the micro-texture composite morphology, coating and magnetic fluid lubricating is conducted on the surface mainly bearing the friction and wear of the substrate material. The processing method comprises the steps that texturing processing is conducted on the surface of the substrate through a laser processing technology, the hard coating serves as a hard support layer, texturing processing is conducted on the surface of the magnetic hard surface through the laser processing technology, a magnetic film is deposited in the microstructure through an electro-deposition technology, magnetizing is conducted, and finally the texturing surface is coated with themagnetic fluid as a lubricating phase. By the adoption of the magnetic-fluid-coated textured surface lubricating substrate and the processing method, the service life of the substrate is prolonged, the wear to the material is reduced, and the bonding strength of the coating is enhanced.

Owner:JIANGSU UNIV +2

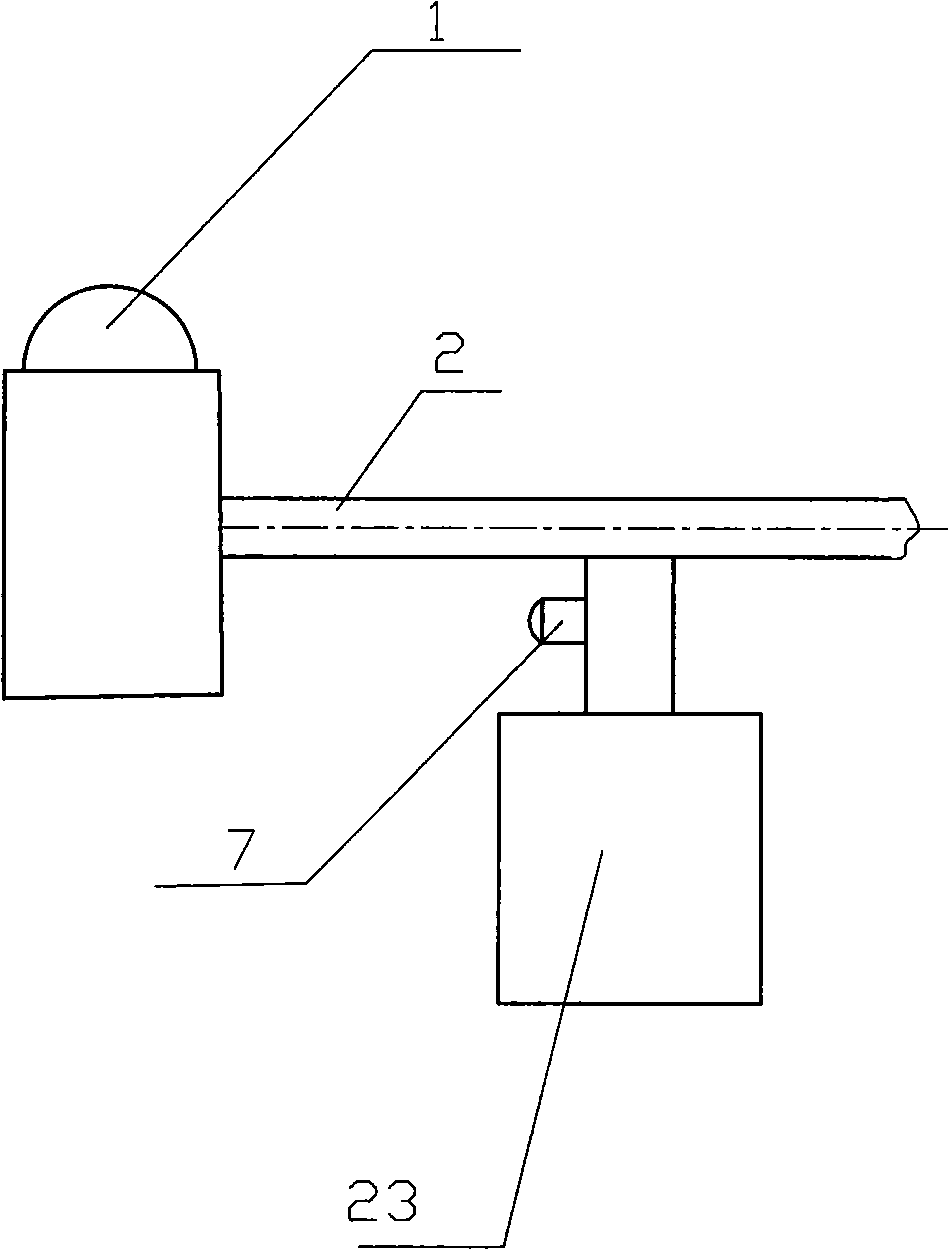

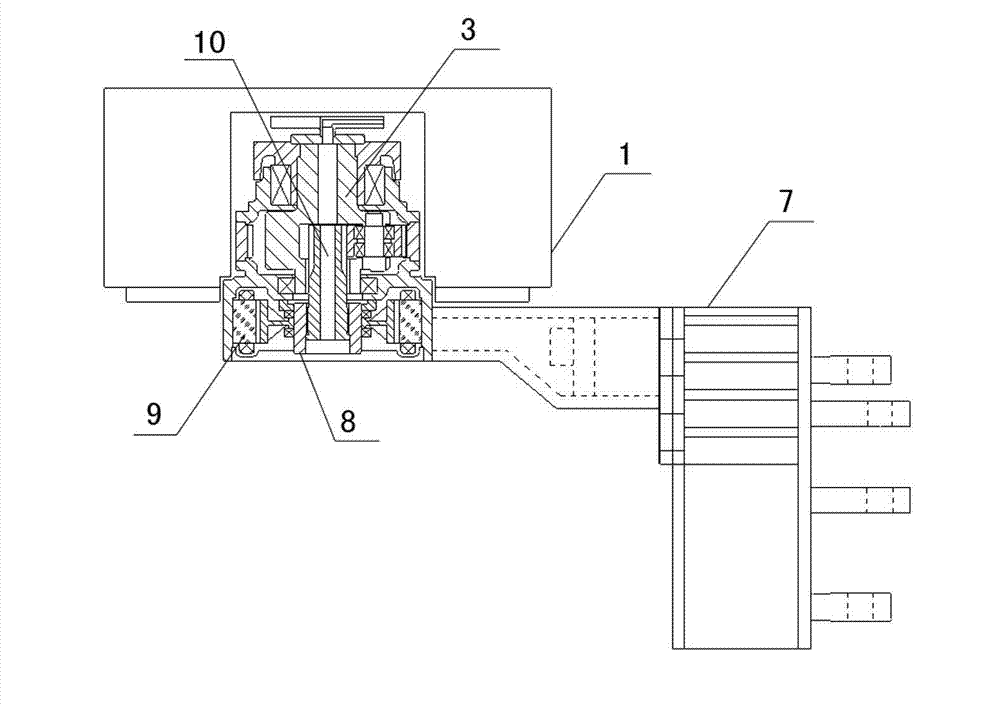

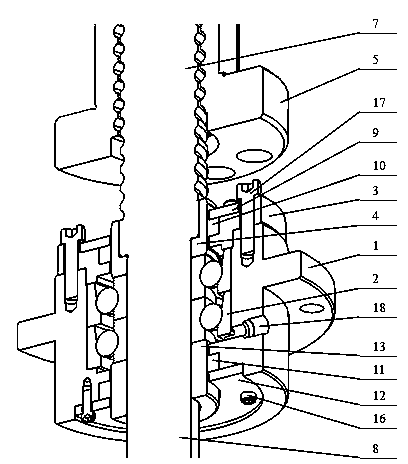

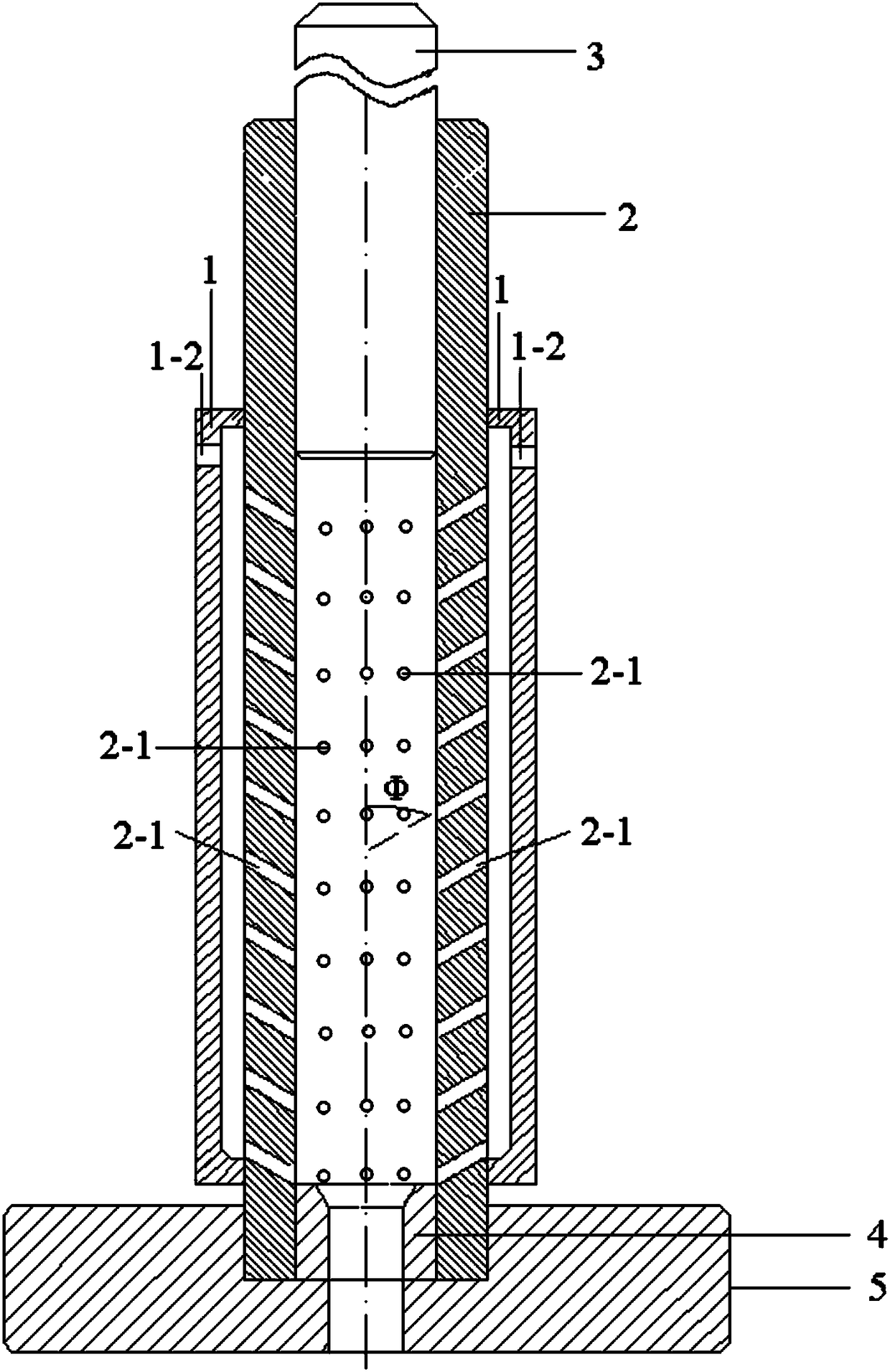

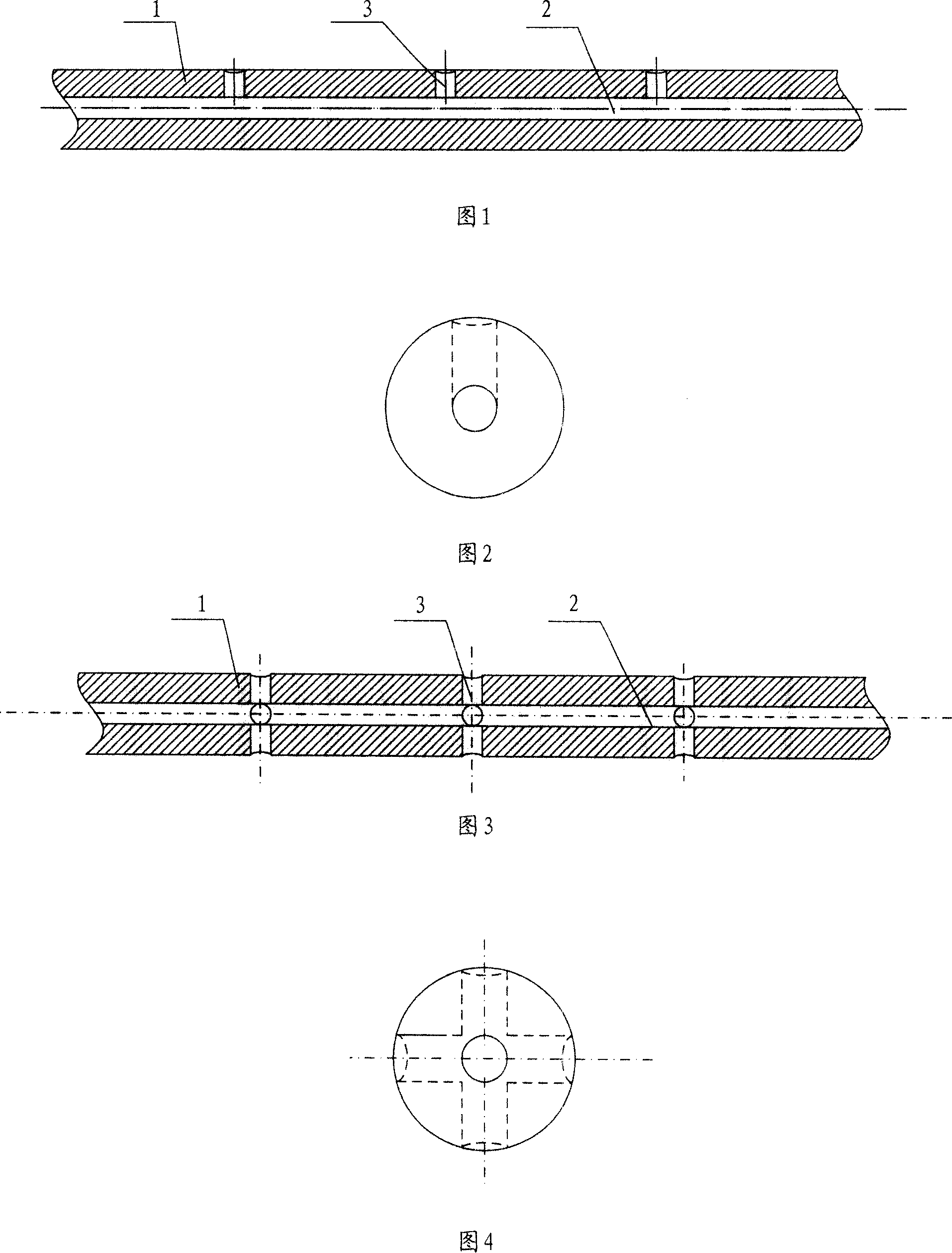

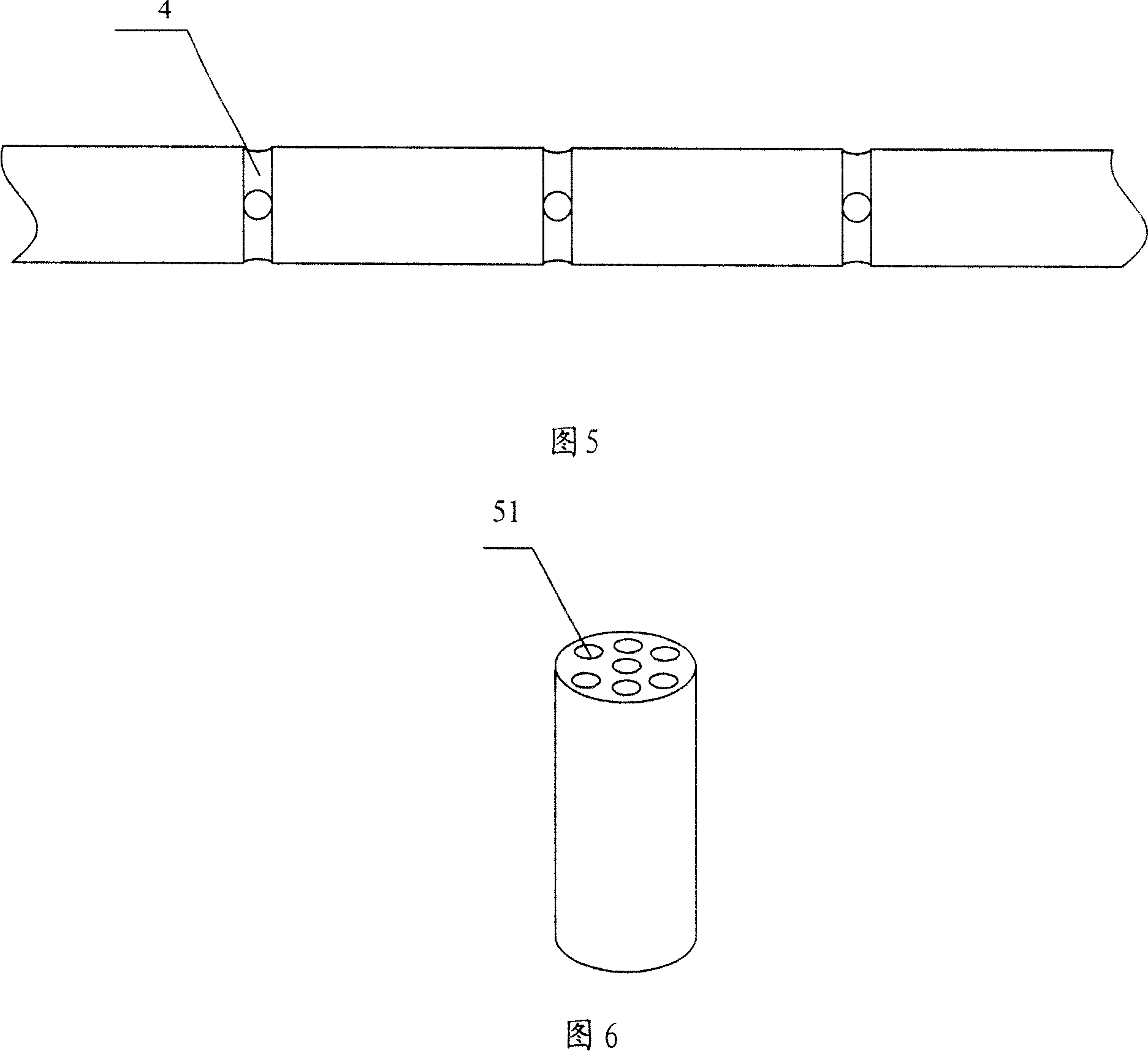

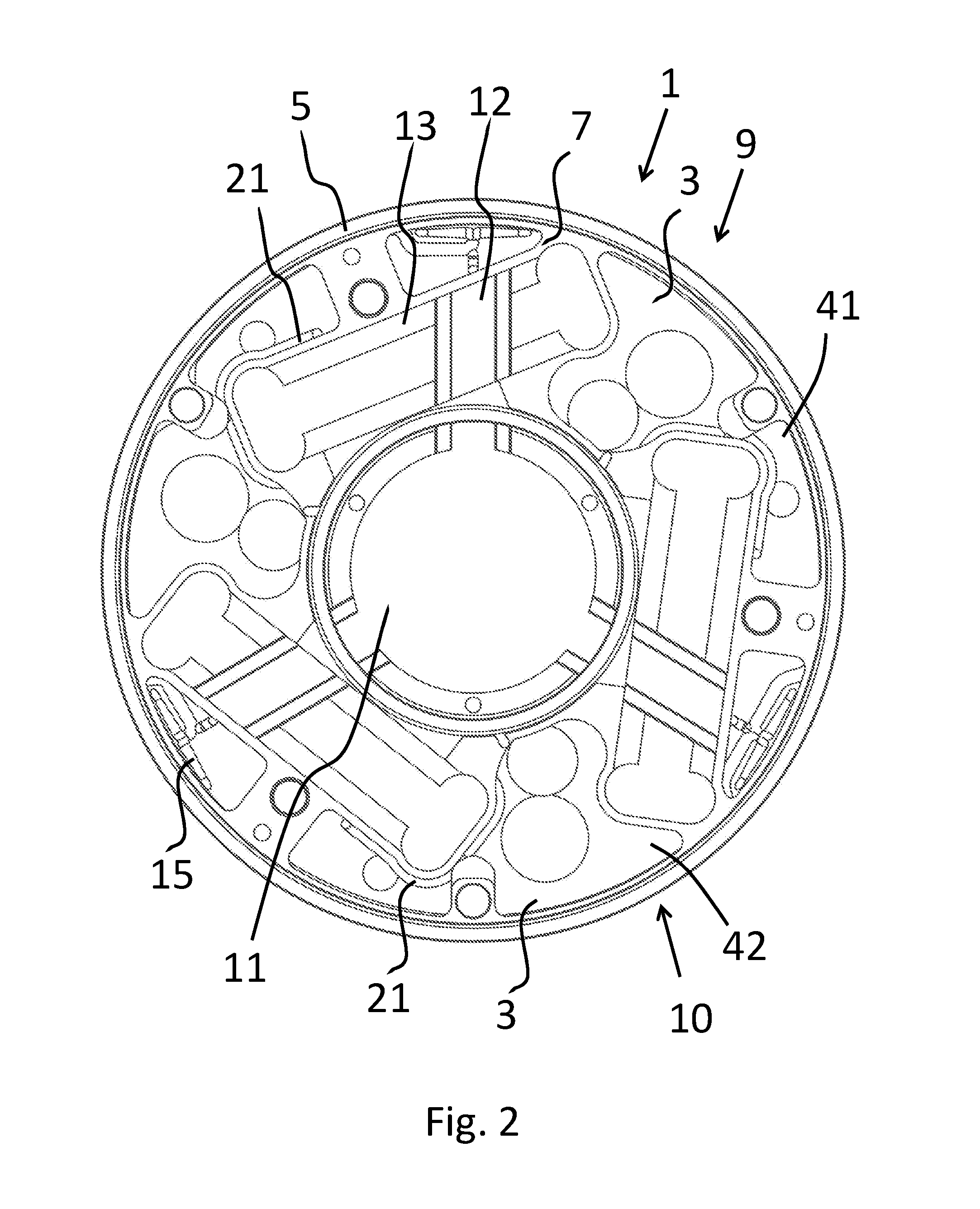

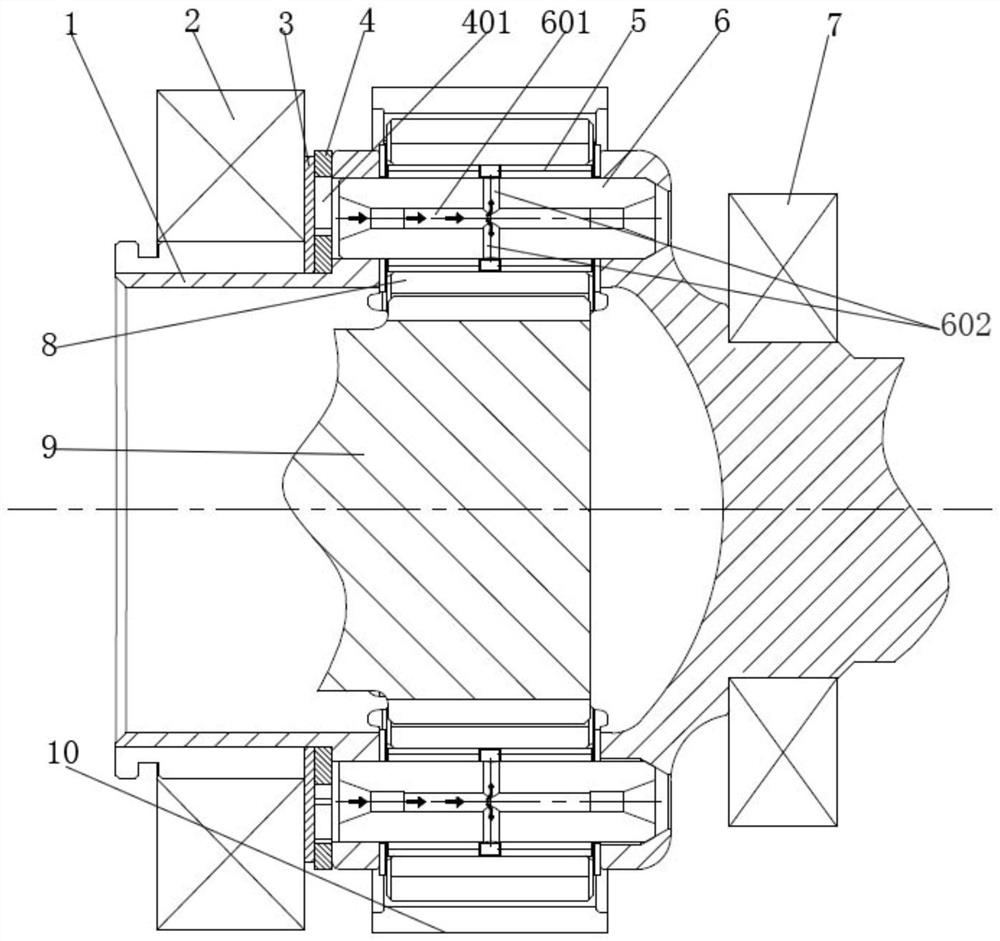

Lubrication system for rotating shuttle components of embroidery machines

ActiveCN101545184AExtend your lifeIncrease rotation speedLubrication/cooling devicesAuxillary devicesEngineeringGuide tube

The invention relates to a lubrication system for rotating shuttle components of embroidery machines, in particular to a rotating-shuttle-component lubrication system consisting of a rotating shuttle, a rotating-shuttle shaft and a rotating-shuttle shaft sleeve, wherein the inside of the rotating-shuttle shaft is provided with a through hole coaxial with the rotating-shuttle shaft; one end of the through hole is a lubricating oil inlet communicated with a rotating-shuttle oil supply device through a duct, and the other end of the through hole is a lubricating oil outlet communicated with an inner cavity of the rotating shuttle; and the surface of the rotating-shuttle shaft is provided with an oil spray hole communicated with the through hole. The lubrication system not only can continue oiling the rotating shuttle, the rotating-shuttle shaft and the rotating-shuttle shaft sleeve, but also can cool and clean the components.

Owner:杭州大云自动化科技有限公司

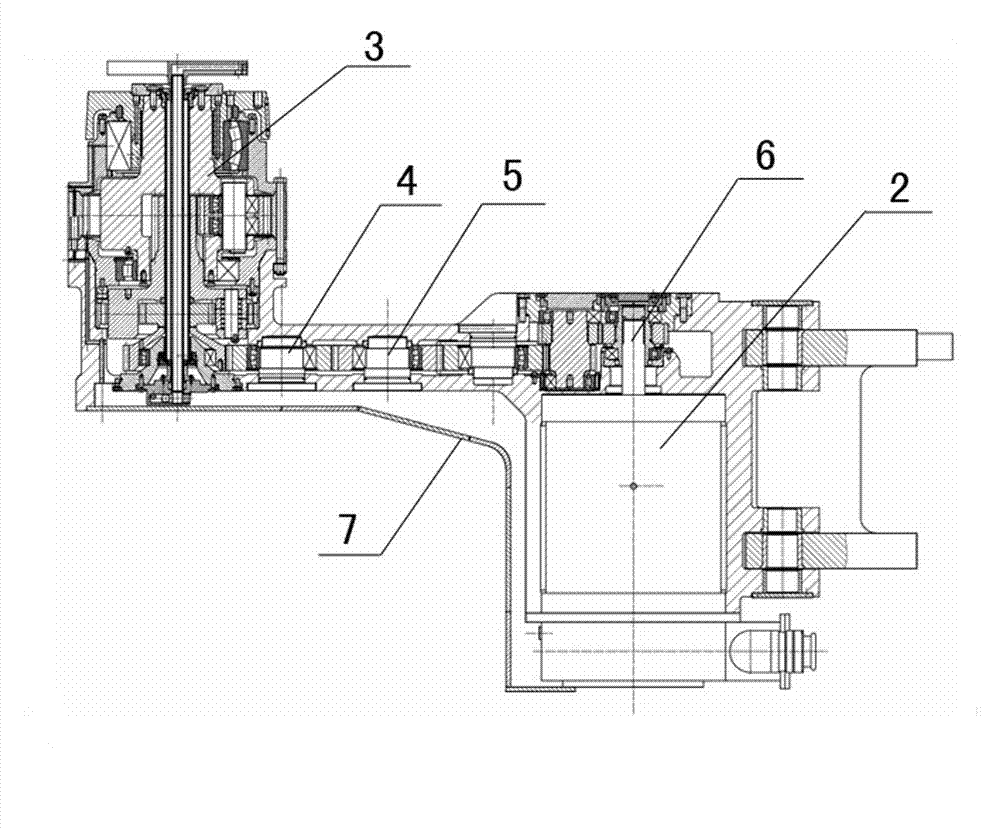

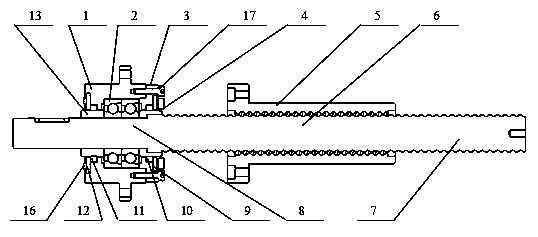

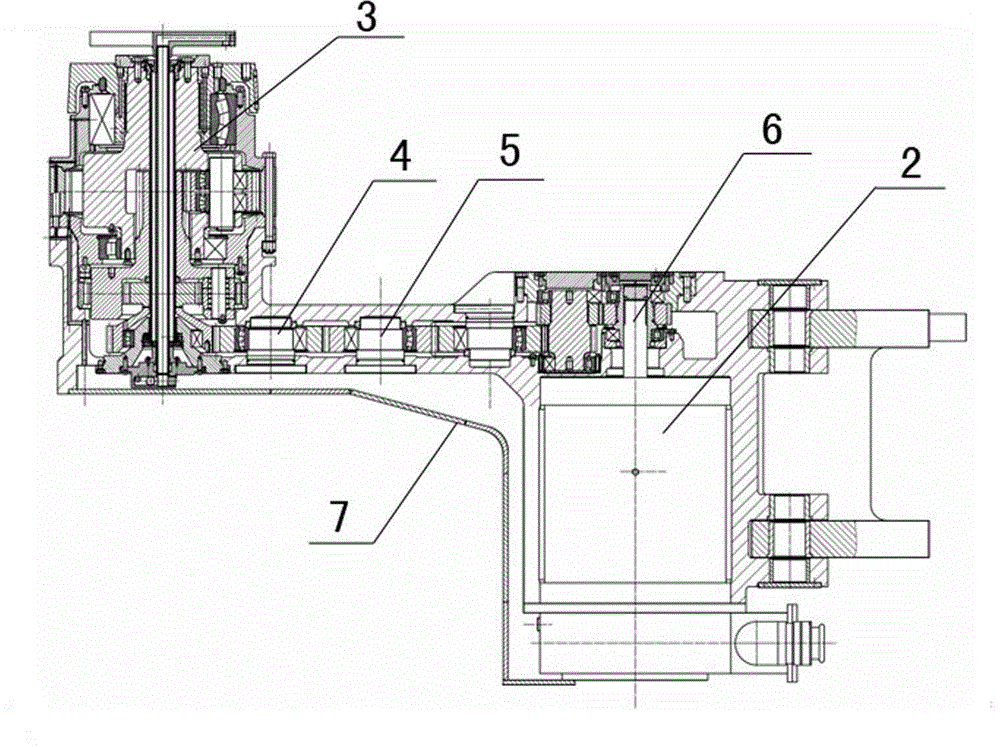

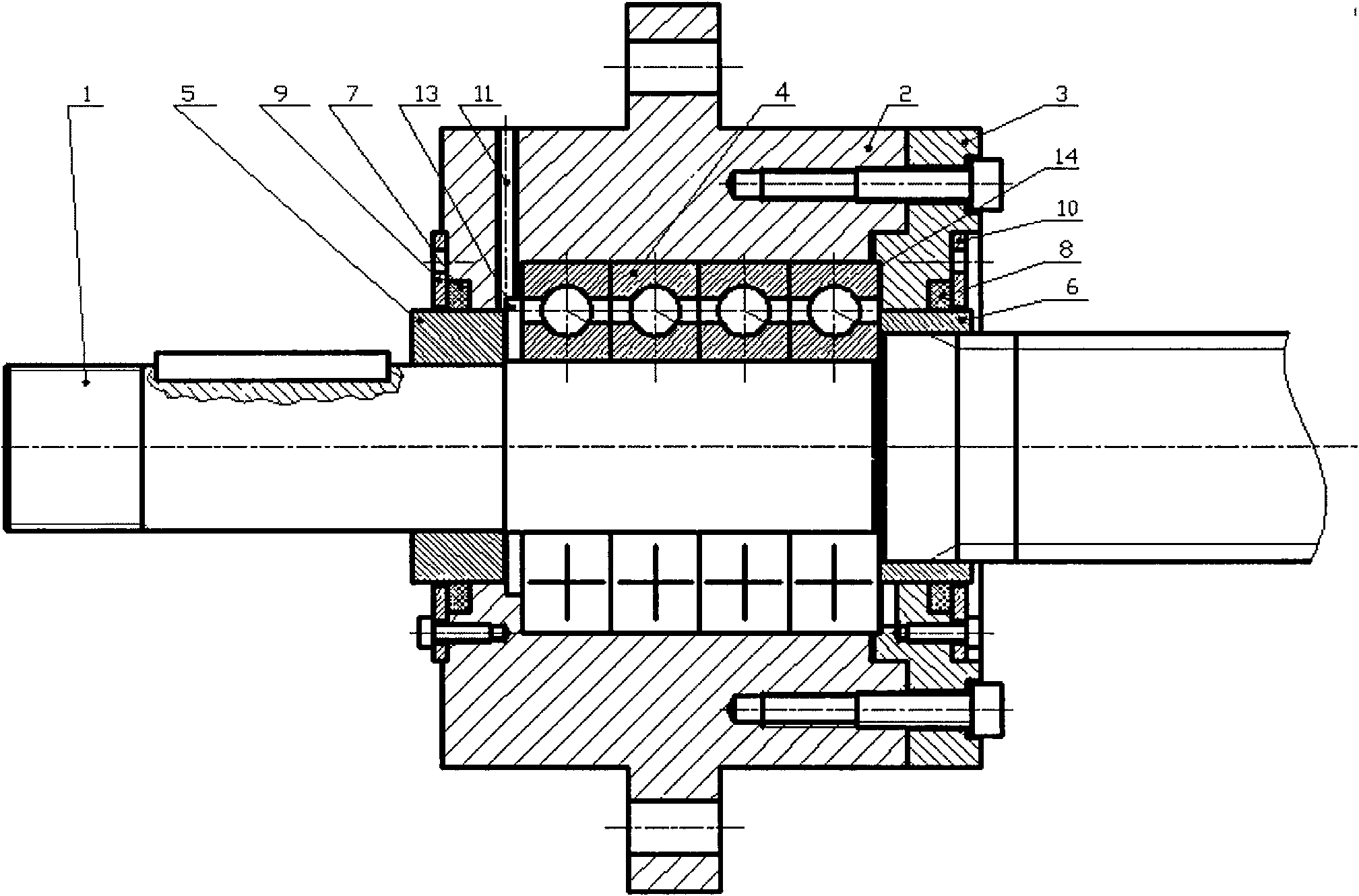

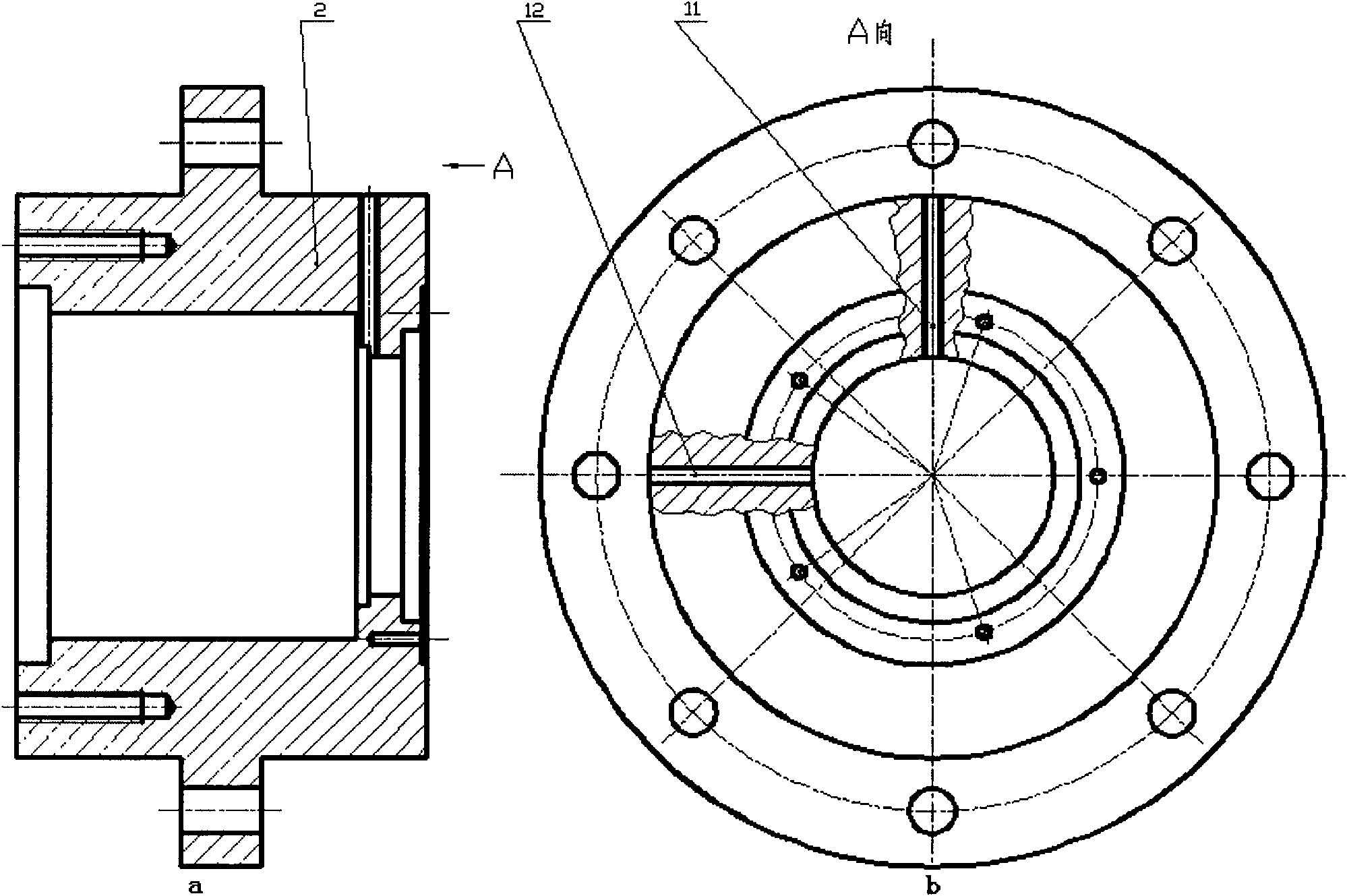

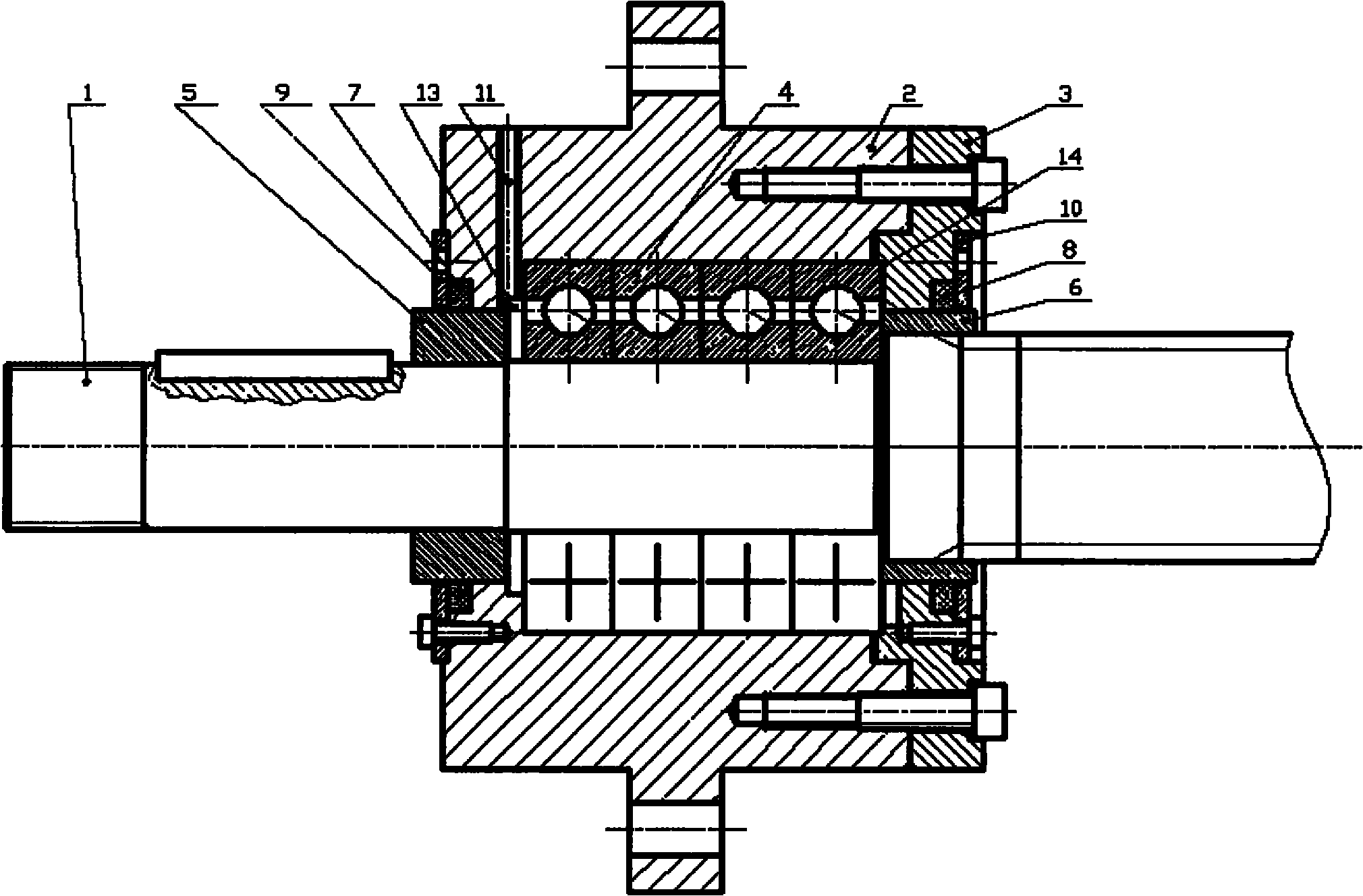

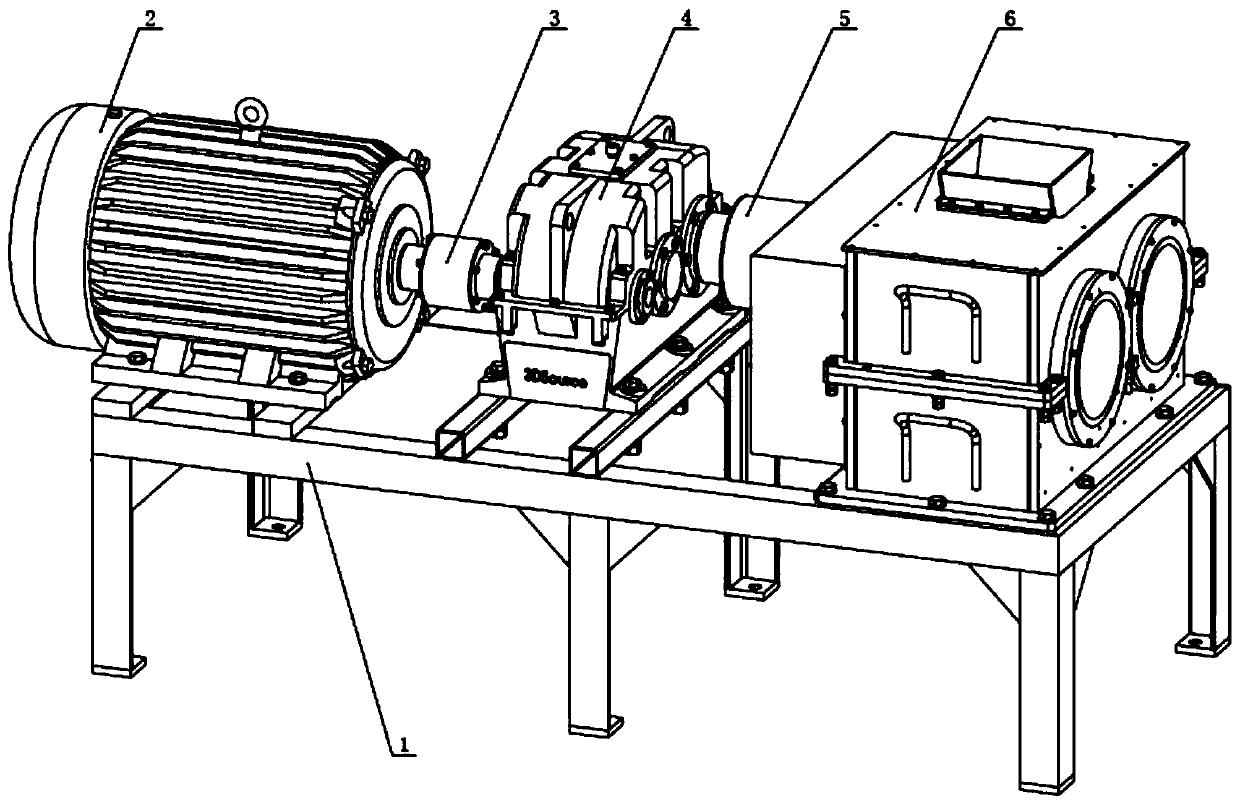

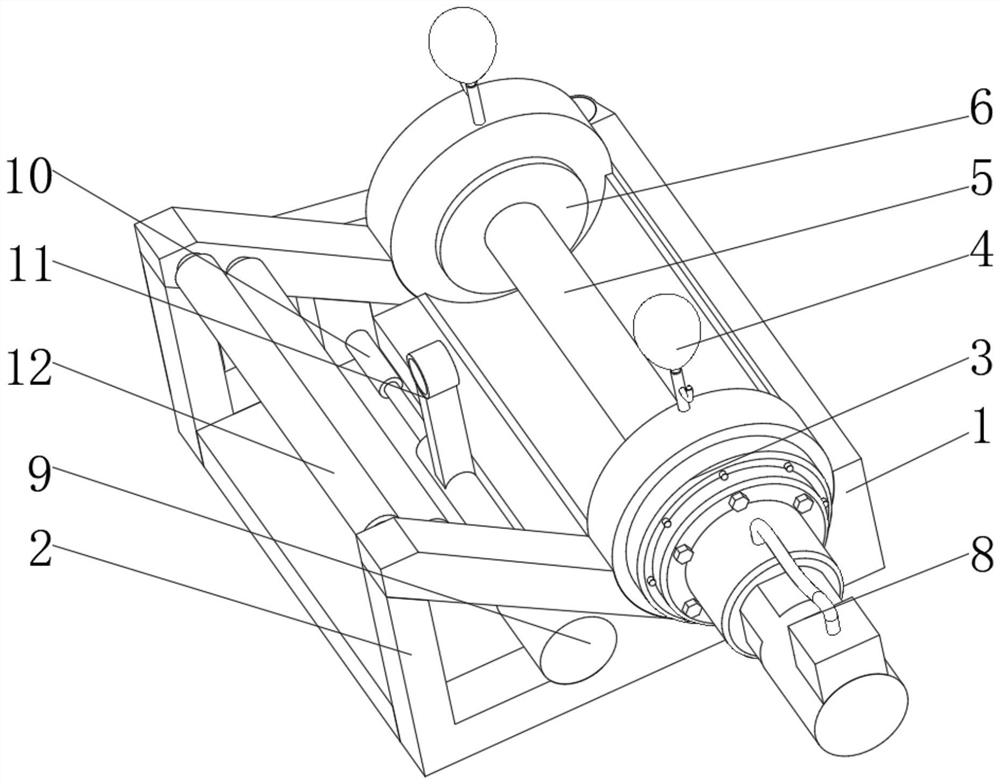

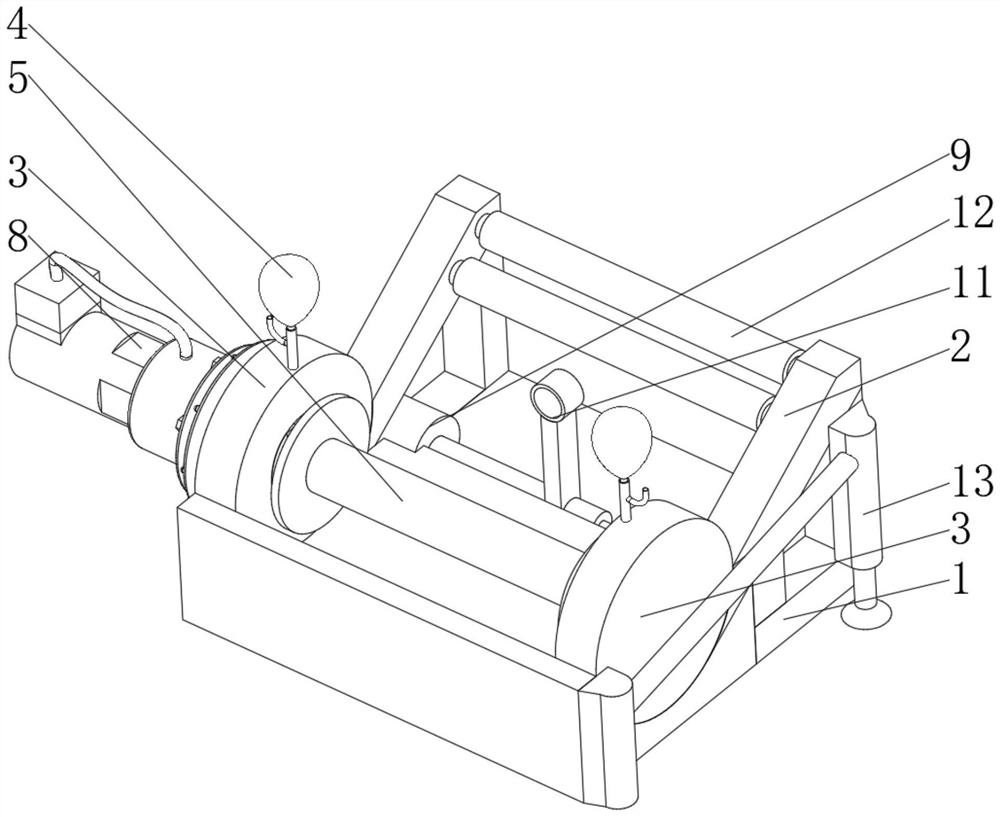

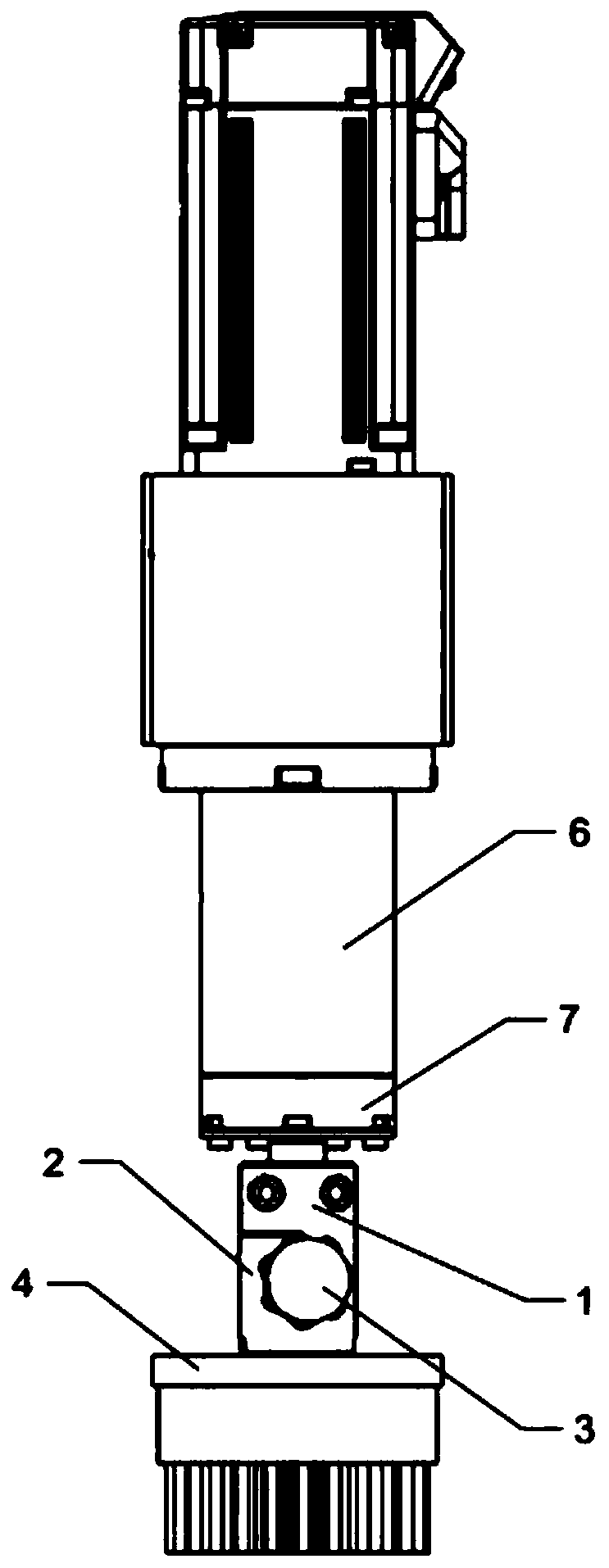

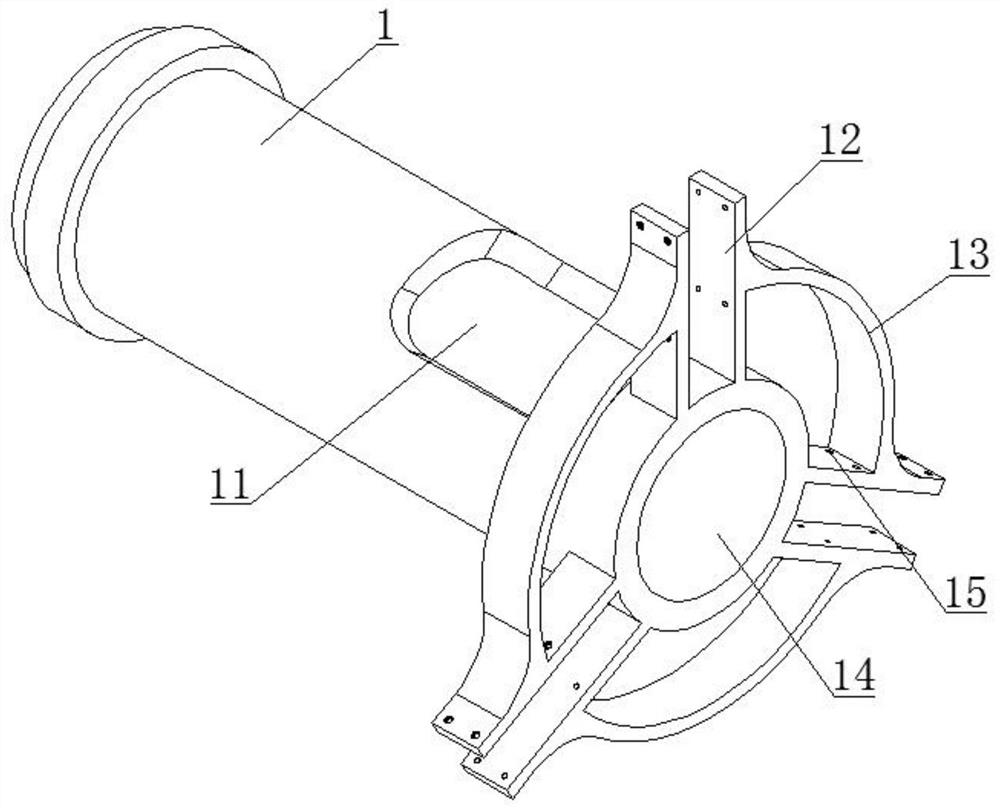

Drum-type coal cutter rocker arm

ActiveCN102877841ANovel structureCompact structureMechanical energy handlingDriving meansInduction motorReducer

The invention relates to the field of drum-type coal cutter components, and particularly relates to a drum-type coal cutter rocker arm. The rocker arm comprises a rocker arm shell and a speed reduction transmission system, wherein the speed reduction transmission system is composed of planetary reducers arranged at the head part inside the rocker arm shell; the coal cutter rocker arm further comprises a low-speed large torque permanent magnet motor which is vertically arranged below the planetary reducers in the rocker arm shell; the permanent magnet motor comprises an inner rotor and an outer stator; the permanent magnet motor is in driving connection with the planetary reducers through a spline shaft which is fixedly arranged in an inner rotor shaft core. The drum-type coal cutter rocker arm provided by the invention is novel in structure and smart in design; the permanent magnet motor having the characteristic of large torque is adopted to take the place of an asynchronous motor with high speed and small torque; and meanwhile mechanical transmission chains of the speed reduction transmission system between a cutting drum and the permanent magnet motor are eliminated; components in the rocker arm can be lubricated constantly no matter how severely the coal cutter rocker arm is tilted, so that the service life of the coal cutter rocker arm is prolonged.

Owner:晋能控股装备制造集团金鼎山西煤机有限责任公司

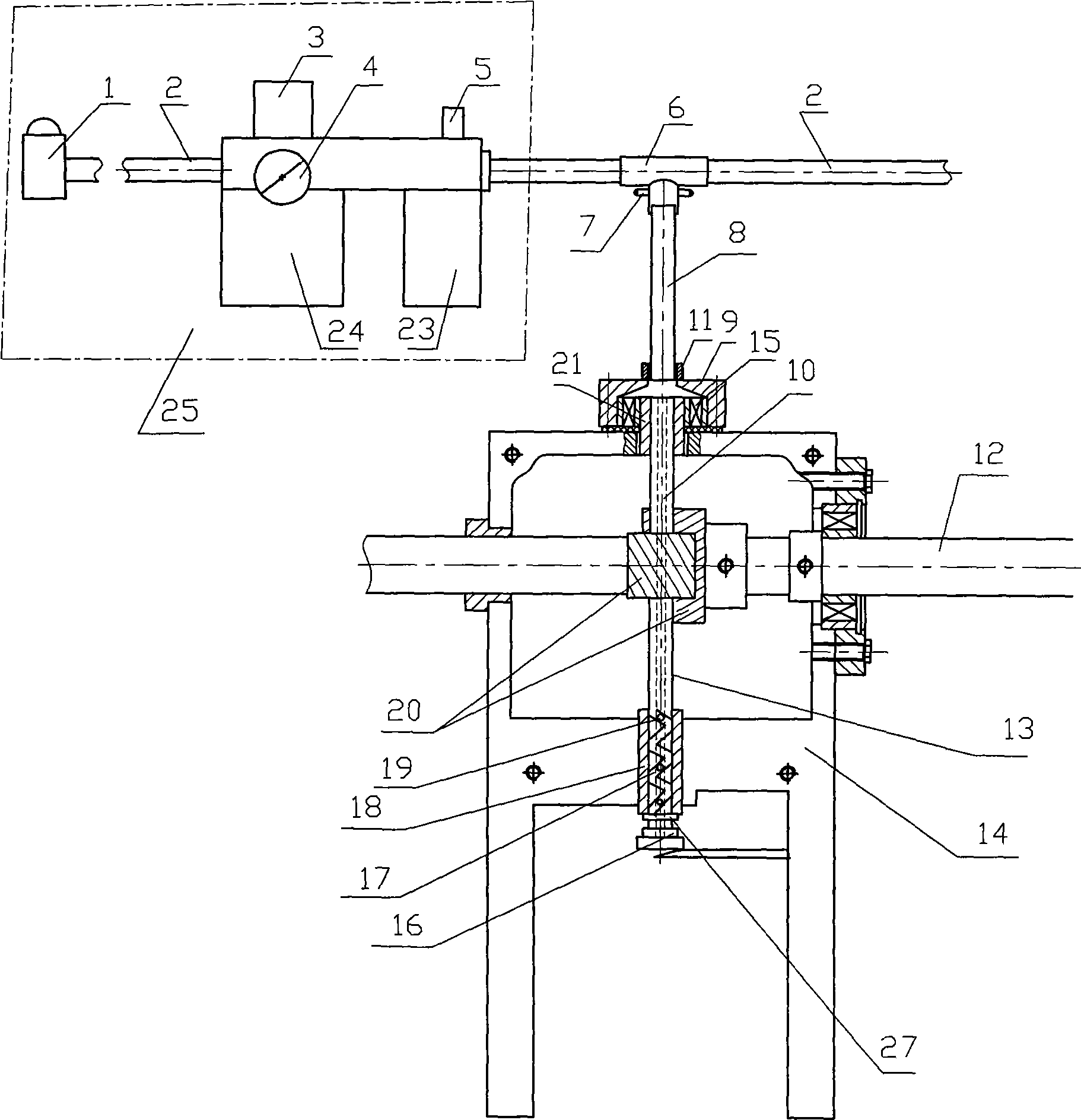

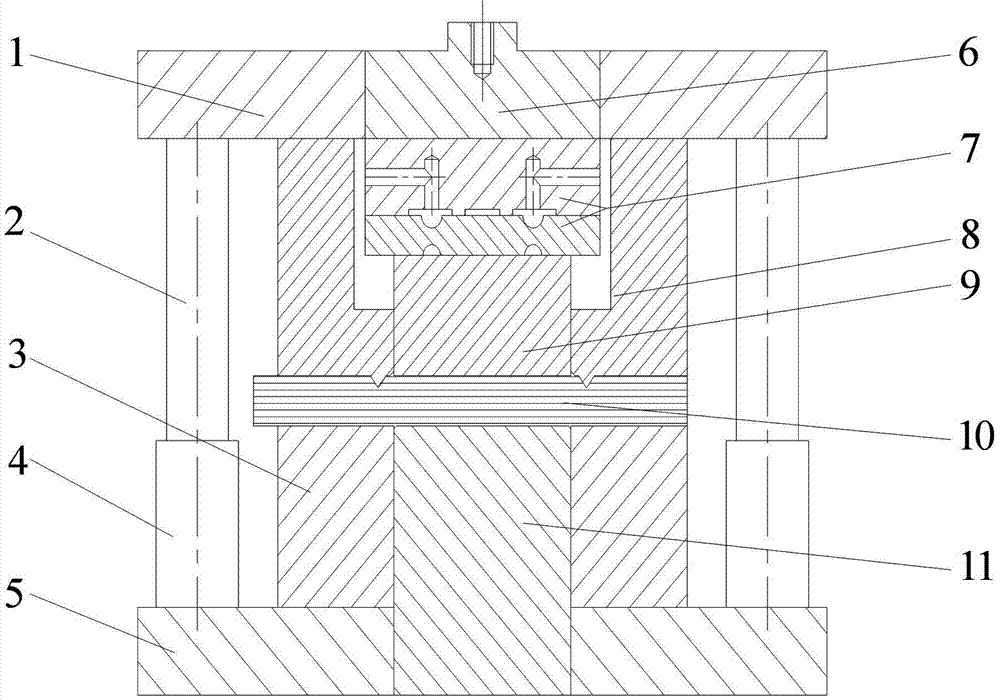

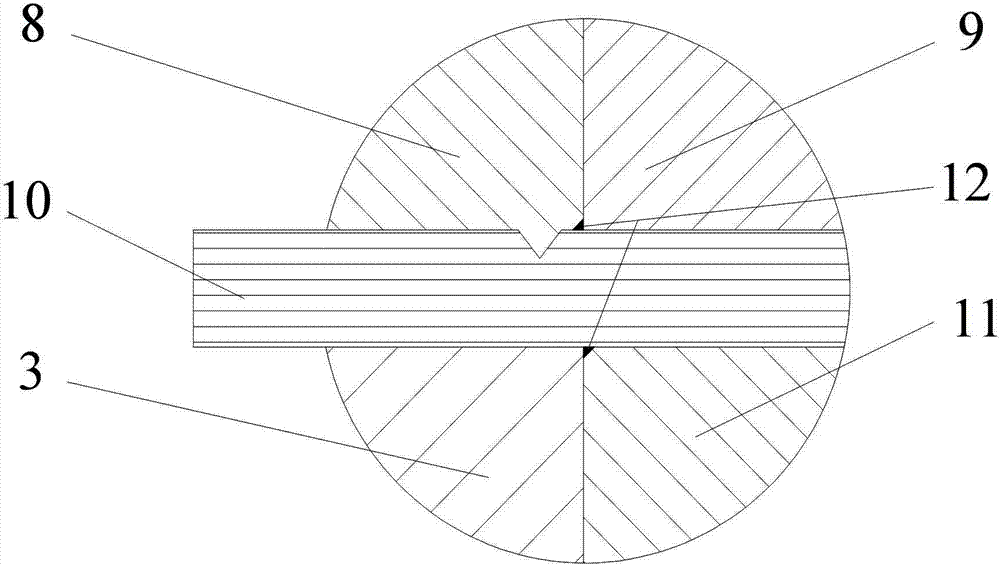

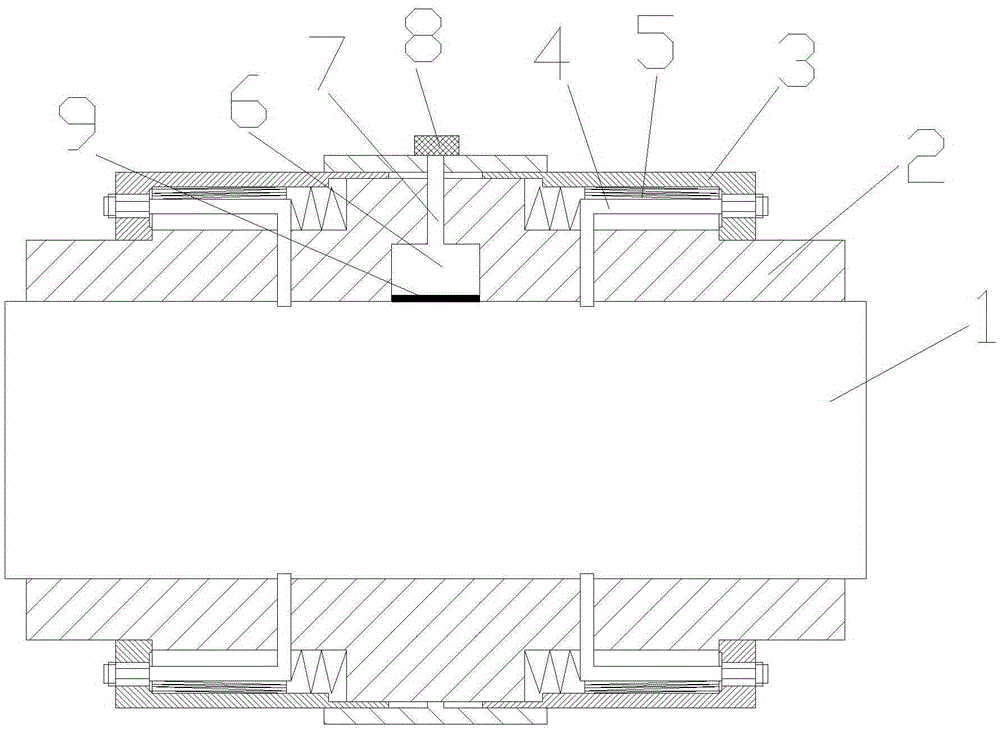

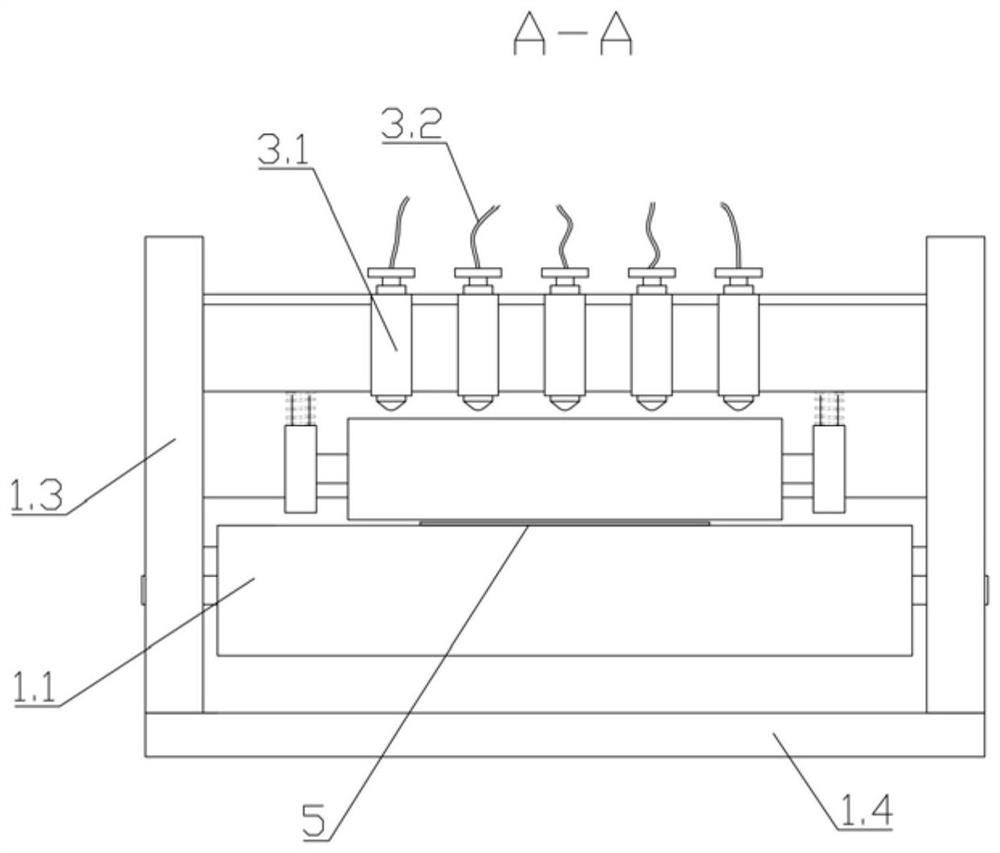

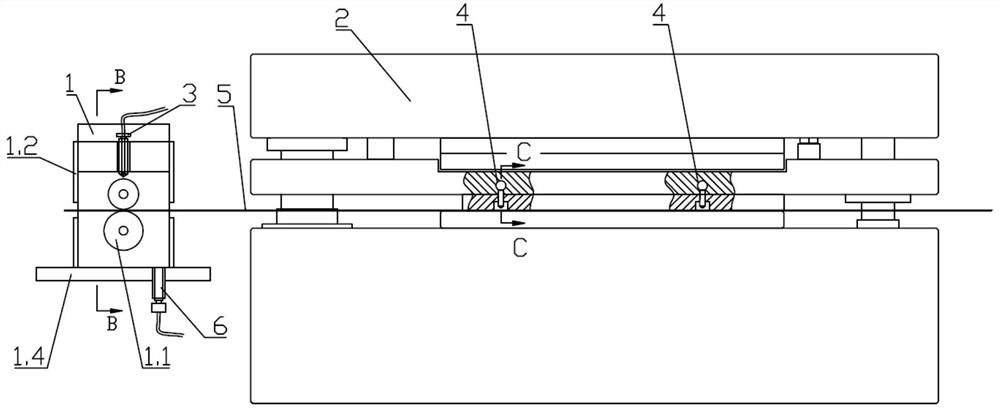

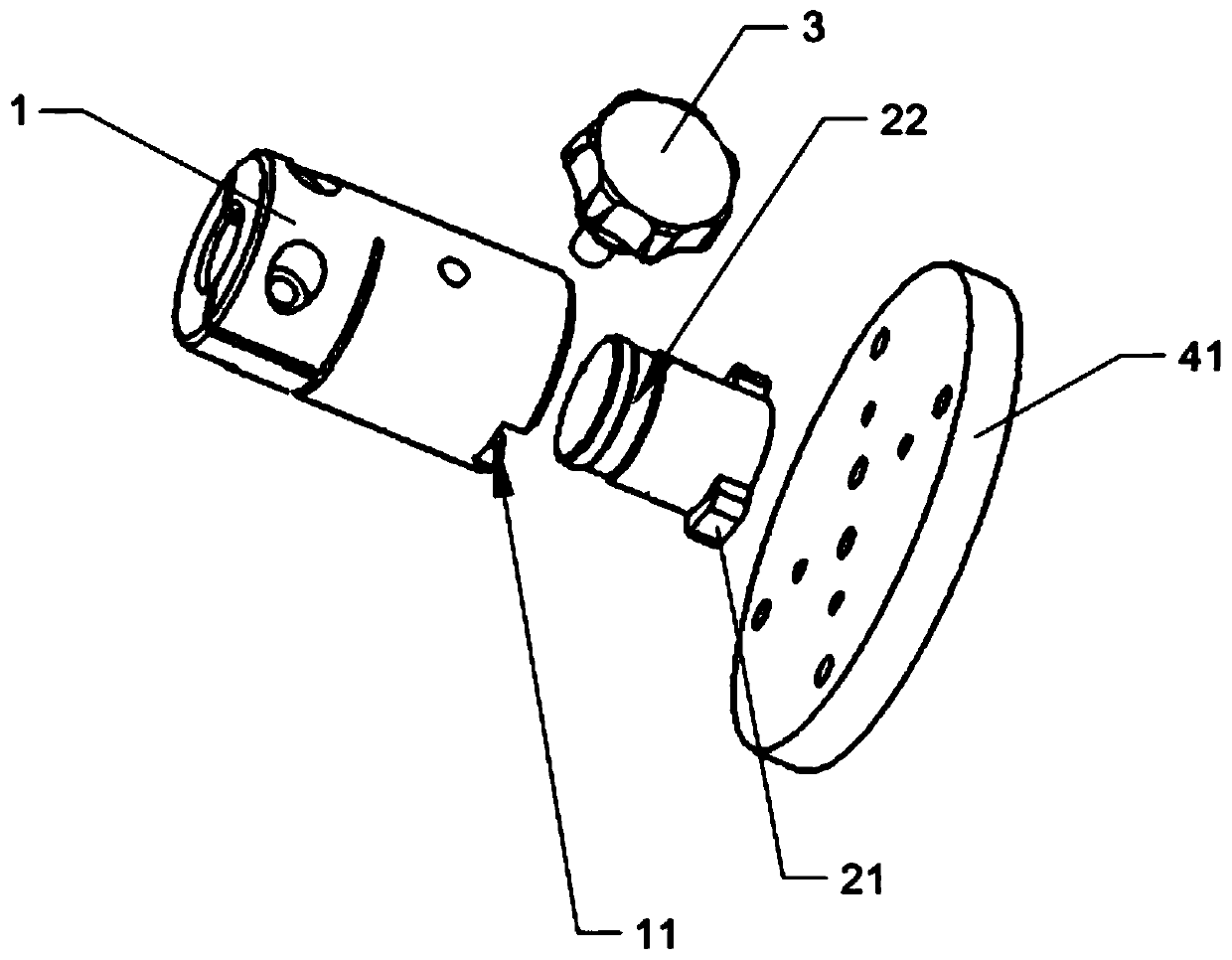

Lubricating device of precisely-stamped die

ActiveCN103567305AExtend your lifeGuaranteed continuous lubricationShaping toolsPressesHydraulic ramEngineering

The invention relates to a device capable of effectively improving die lubrication in the fine-stamping process, in particular to a lubricating device of precisely-stamped dies. The lubricating device of the precisely-stamped dies comprises a pressure base plate of the precisely-stamped dies, a male die, a V-shaped blank holder and a reverse ejection rod. The pressure base plate is located above the male die. The reverse ejection rod is connected with a hydraulic plunger. The V-shaped blank holder is fixed to an upper die plate. A chamfer is arranged at the inner side, close to a cutting edge of the male die, of the V-shaped blank holder. An oil storage groove is formed between the V-shaped blank holder and the male die. A chamfer is arranged at the outer side, close to the cutting edge of a female die, of the reverse ejection rod and an oil storage groove is formed between the reverse ejection rod and the female die. The lubricating device of the precisely-stamped dies is characterized in that a vibration generating device is fixed to the portion between the pressure base plate and the male die. Lubricating oil in the oil storage grooves is continuously led to a friction face through vibration. The lubricating device of the precisely-stamped dies can effectively improving the lubricating effect in the composite fin-stamping forming process and prolong the service of the dies.

Owner:WUHAN UNIV OF TECH

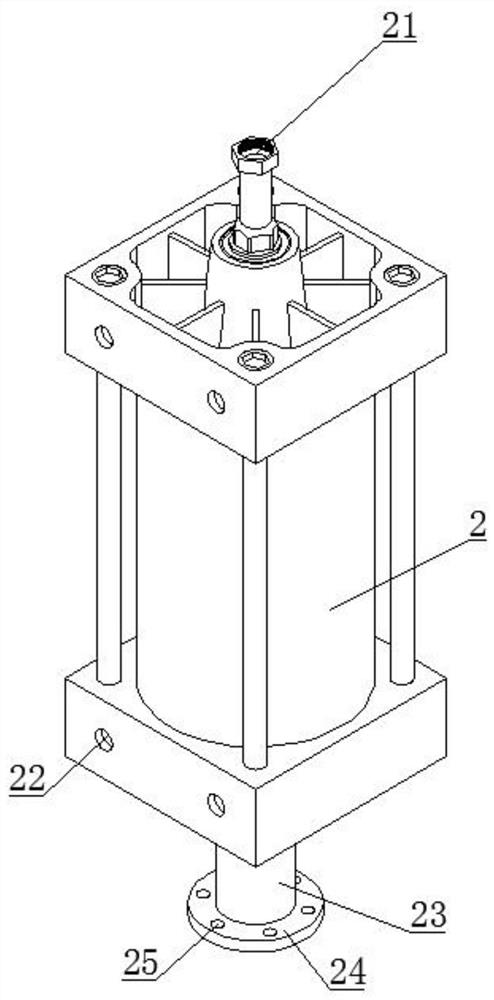

Method for assembling screw rod and rolling bearing assembly

InactiveCN104029001AGuaranteed levelGuaranteed coaxialityRolling contact bearingsMetal working apparatusBall screwEngineering

The invention discloses a method for assembling a screw rod and rolling bearing assembly. The method comprises the steps of mounting a screw rod flange, mounting a rolling bearing, mounting a screw rod fixing sleeve, fixing a screw rod flange and the screw rod fixing sleeve and finally obtaining the assembled screw rod and rolling bearing assembly. The method is simple, convenient and easy to achieve, and the assembled screw rod and rolling bearing assembly is tight, firm and clean. The parallelism between the screw rod and a working table linear guide rail in the horizontal and vertical directions, the coaxiality between a bearing seat and a ball nut and the rotating precision of a ball screw are guaranteed, namely, radial runout precision and axial float precision are guaranteed, continuous lubrication can be achieved, leakage of lubricating oil inside is avoided, external dust is prevented from entering the assembly, and long-term stable work of parts is facilitated.

Owner:ZHEJIANG UNIV

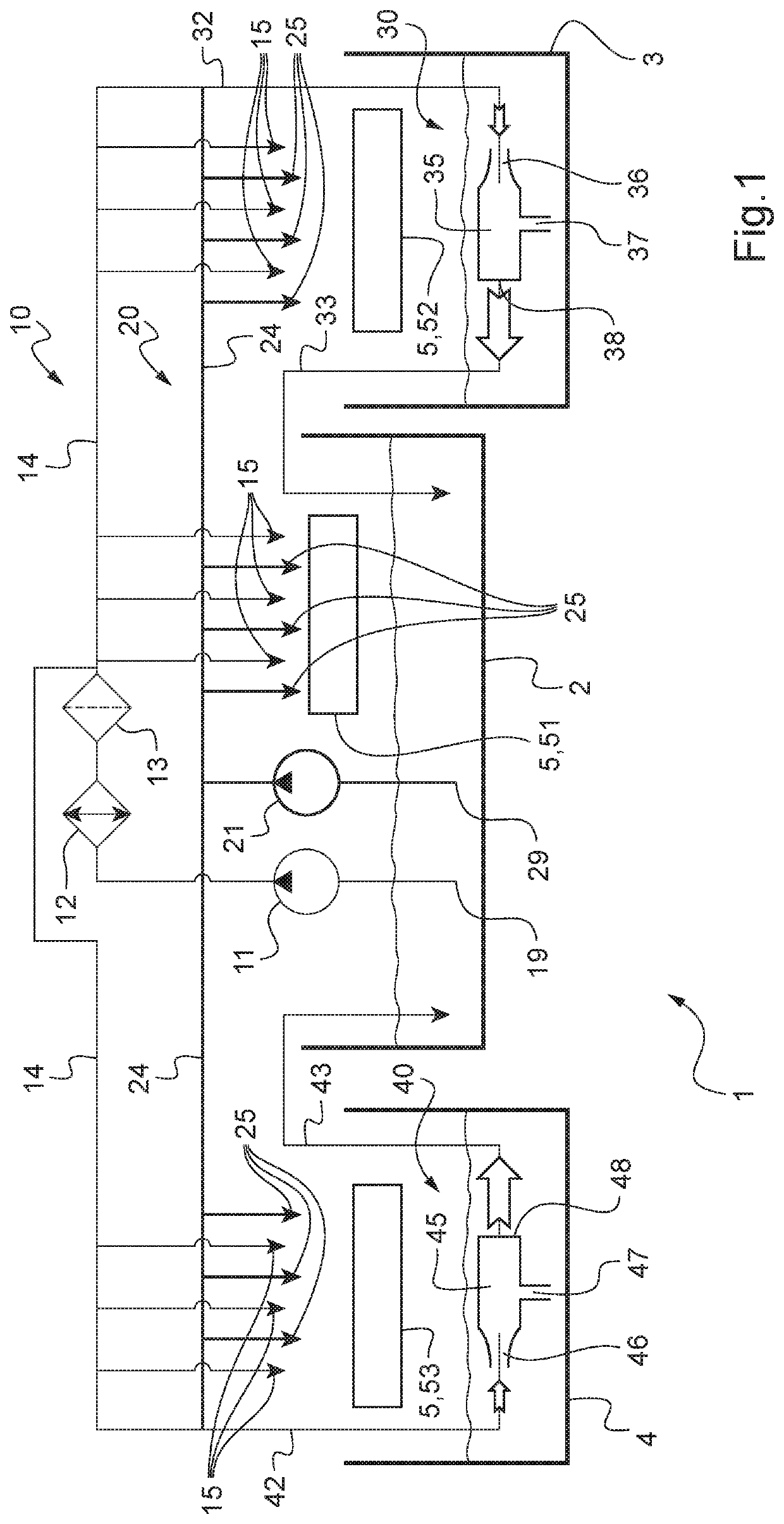

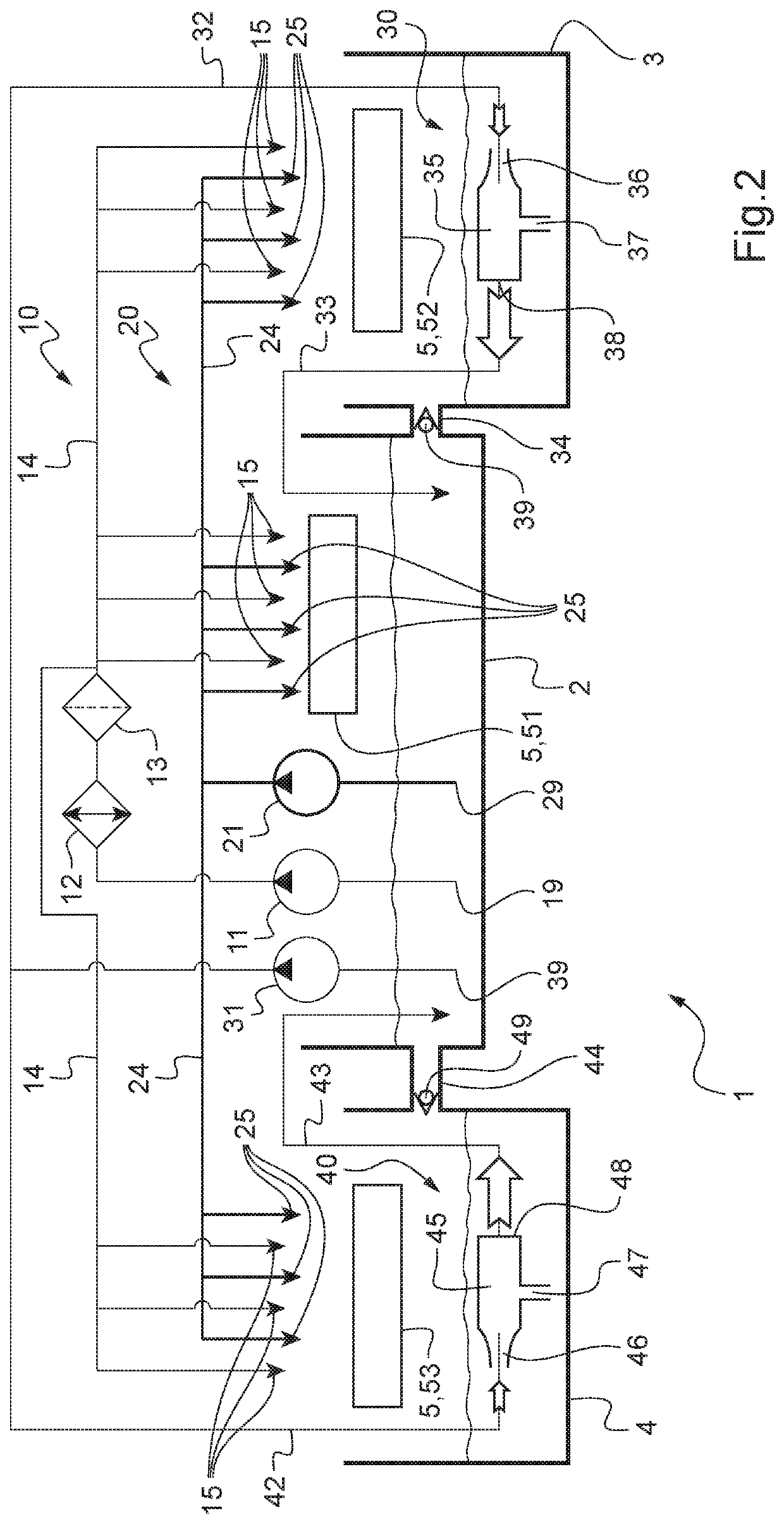

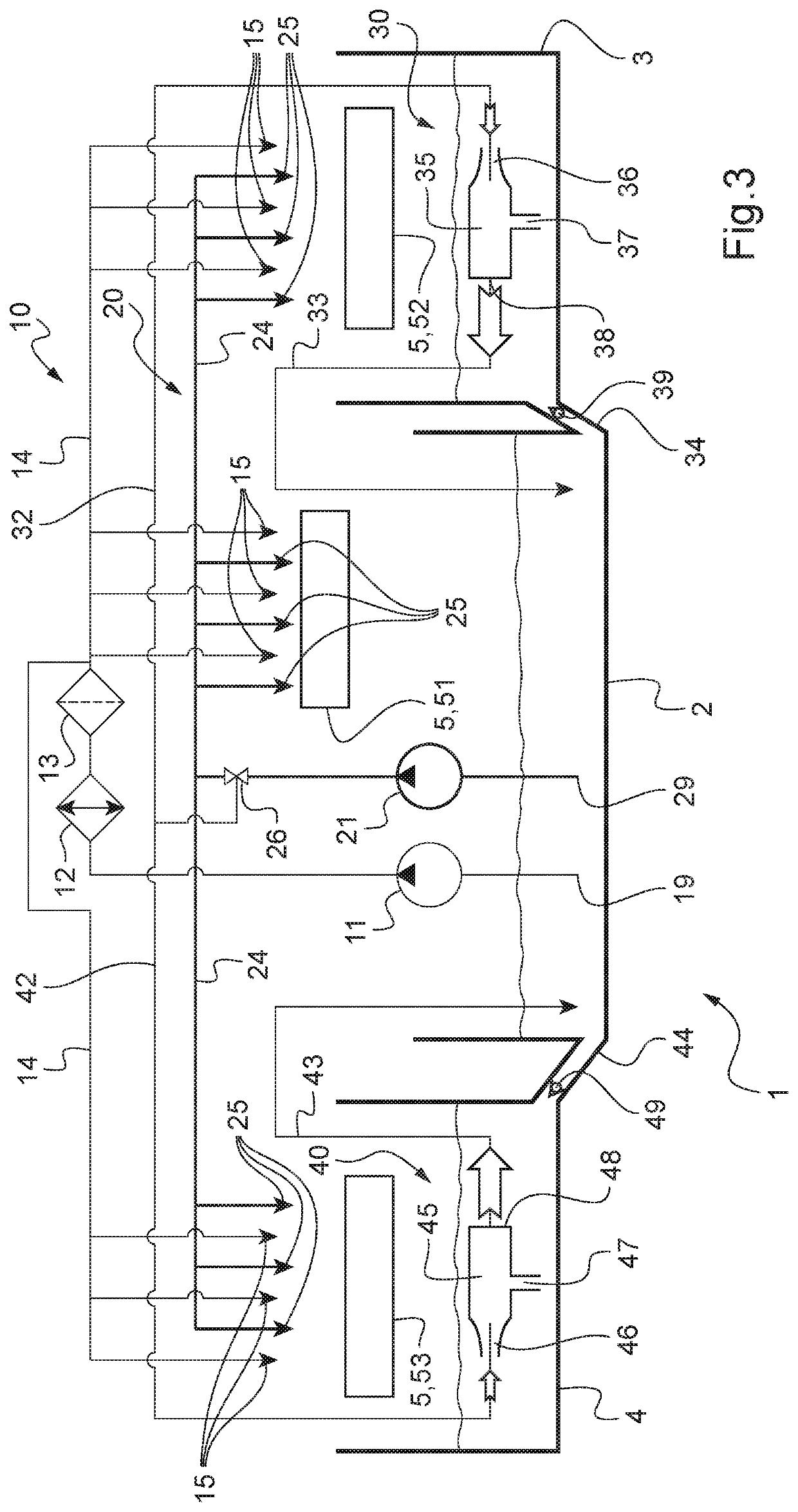

Lubrication device having a plurality of lubrication liquid recovery tanks, and optimized and reliable delivery means to a main tank

ActiveUS10844948B2Simplify delivery systemControlling the riskGearboxesGear lubrication/coolingLubricationDelivery system

A lubrication device of a mechanical system, the lubrication device having a main tank, at least one recovery tank, a lubrication circuit, a flow generator supplying the lubrication circuit with a lubrication liquid located in the main tank and a delivery system for each recovery tank. Each delivery system has an ejector arranged in a recovery tank and first and second conduits linking the ejector firstly to the lubrication circuit and secondly to the main tank in order to deliver the lubrication liquid located in the recovery tank to the main tank using the ejector.

Owner:EUROCOPTER

Continuous-lubrication extrusion mold

InactiveCN108213104AContinuous and stable lubricationImprove deformation uniformityExtrusion diesMachining processMaterials science

The invention discloses a continuous-lubrication extrusion mold, relates to an extrusion mold, aims to solve the technical problems of undesirable lubrication effect since the surfaces of the mold andblank materials are coated with a lubrication agent, increase of the mold manufacturing cost and difficulty caused by adopting a method of surface coating treatment, and gradual abrasion and separation of the coating on the surface of the mold in a forming process. The continuous-lubrication extrusion mold consists of a lubrication agent storage tank and an extrusion mold, an upper part of the side wall of the lubrication agent storage tank is provided with at least one lubrication agent injection hole; at least on lubrication agent hole is formed on the side wall of the extrusion mold; and the lubrication agent storage tank is sleeved outside the extrusion mold. The continuous-lubrication extrusion mold has the advantages that: the blank and the extrusion mold can keep a good and continuous stable lubrication state in a machining process, the abrasion on the mold is lowered, and the service life of the mold is prolonged. The continuous-lubrication extrusion rod can be applied to themachining field of materials.

Owner:HARBIN INST OF TECH

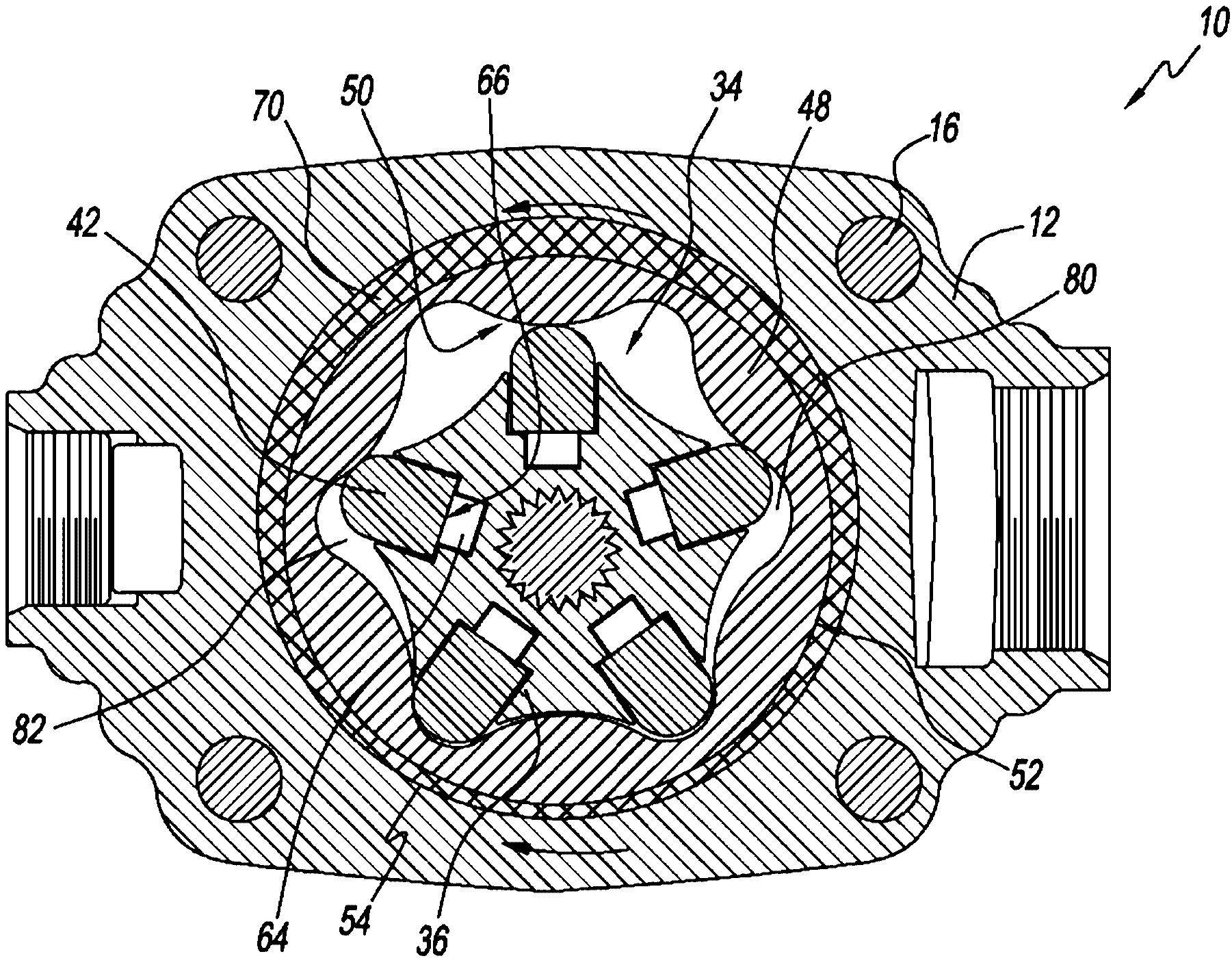

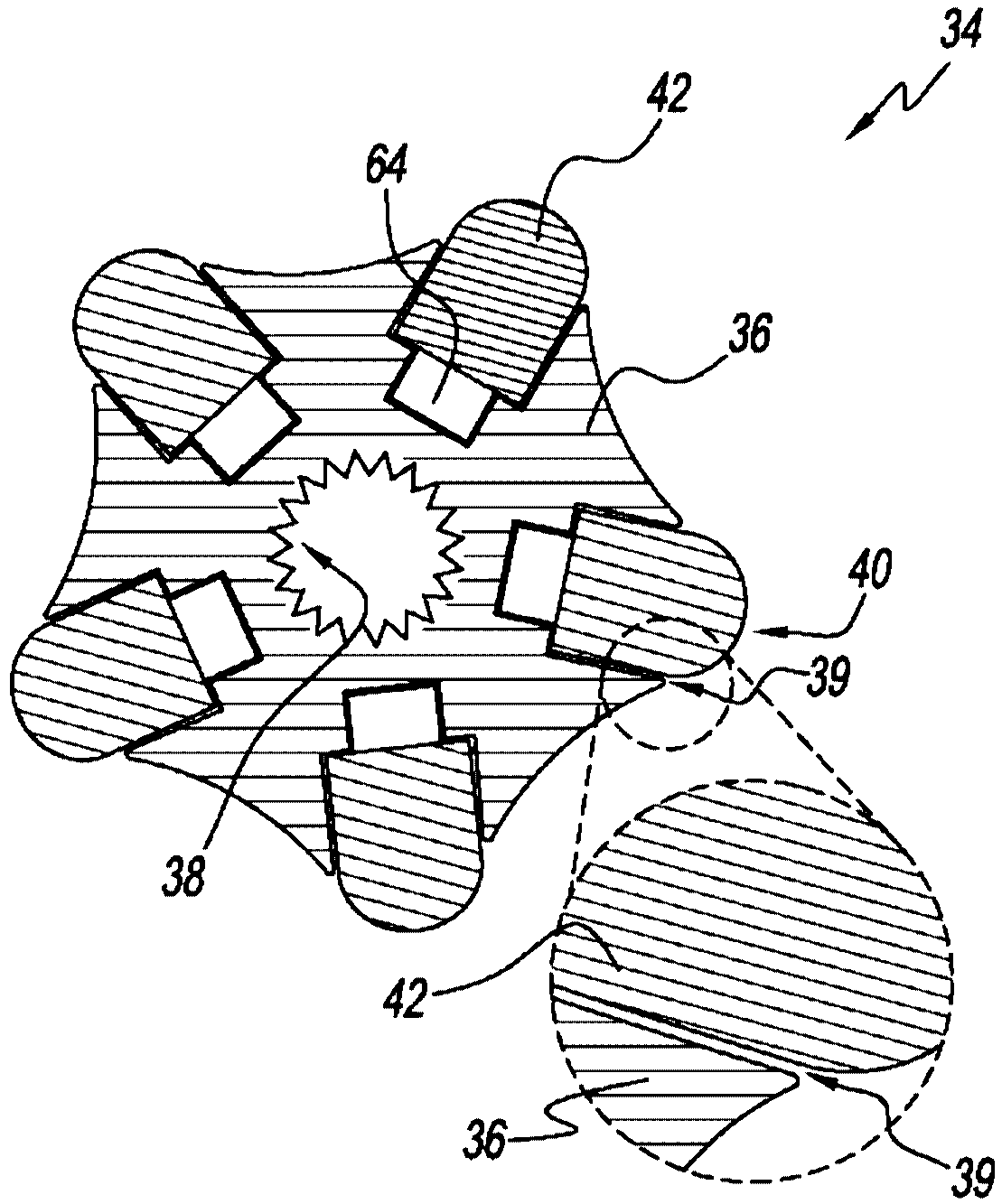

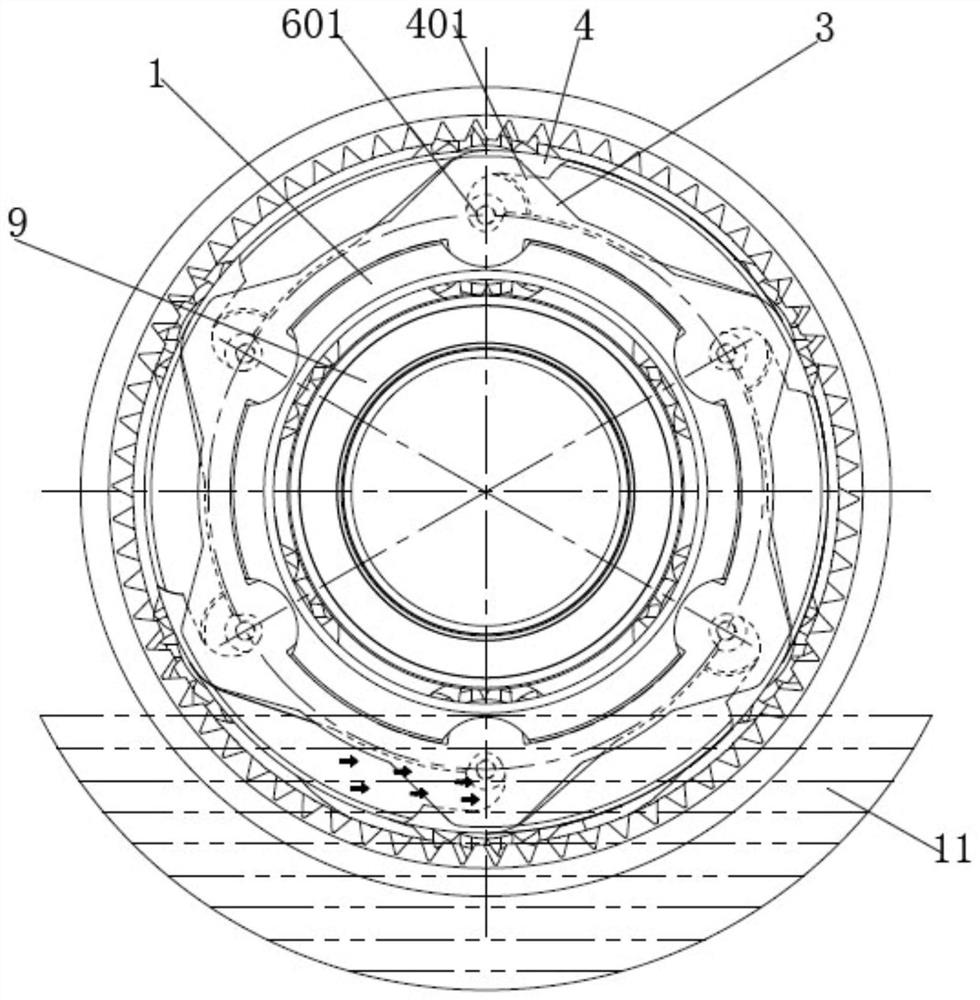

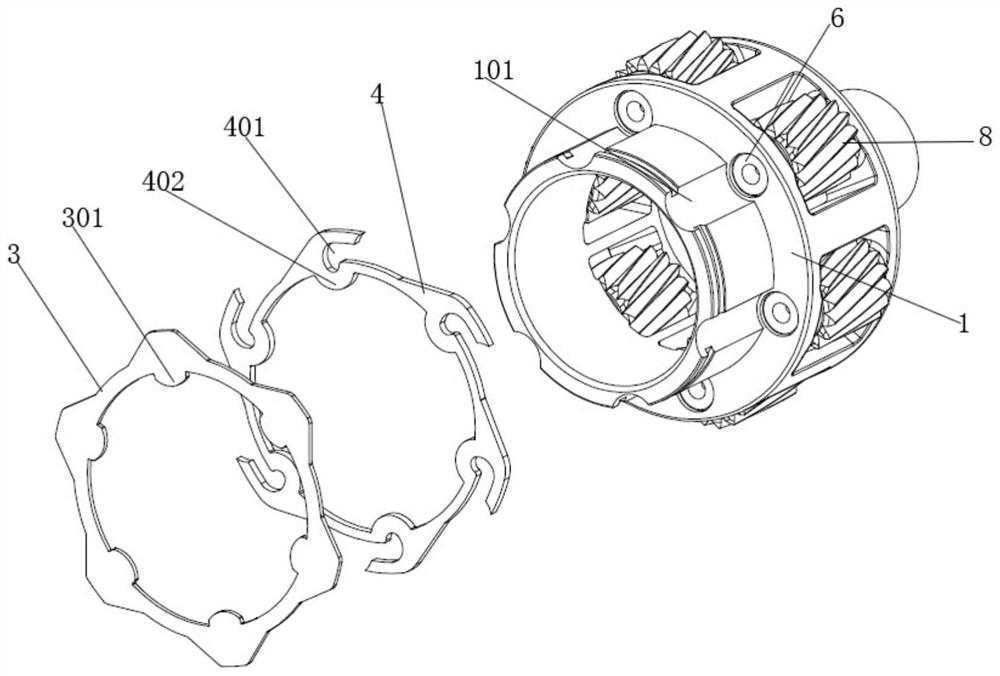

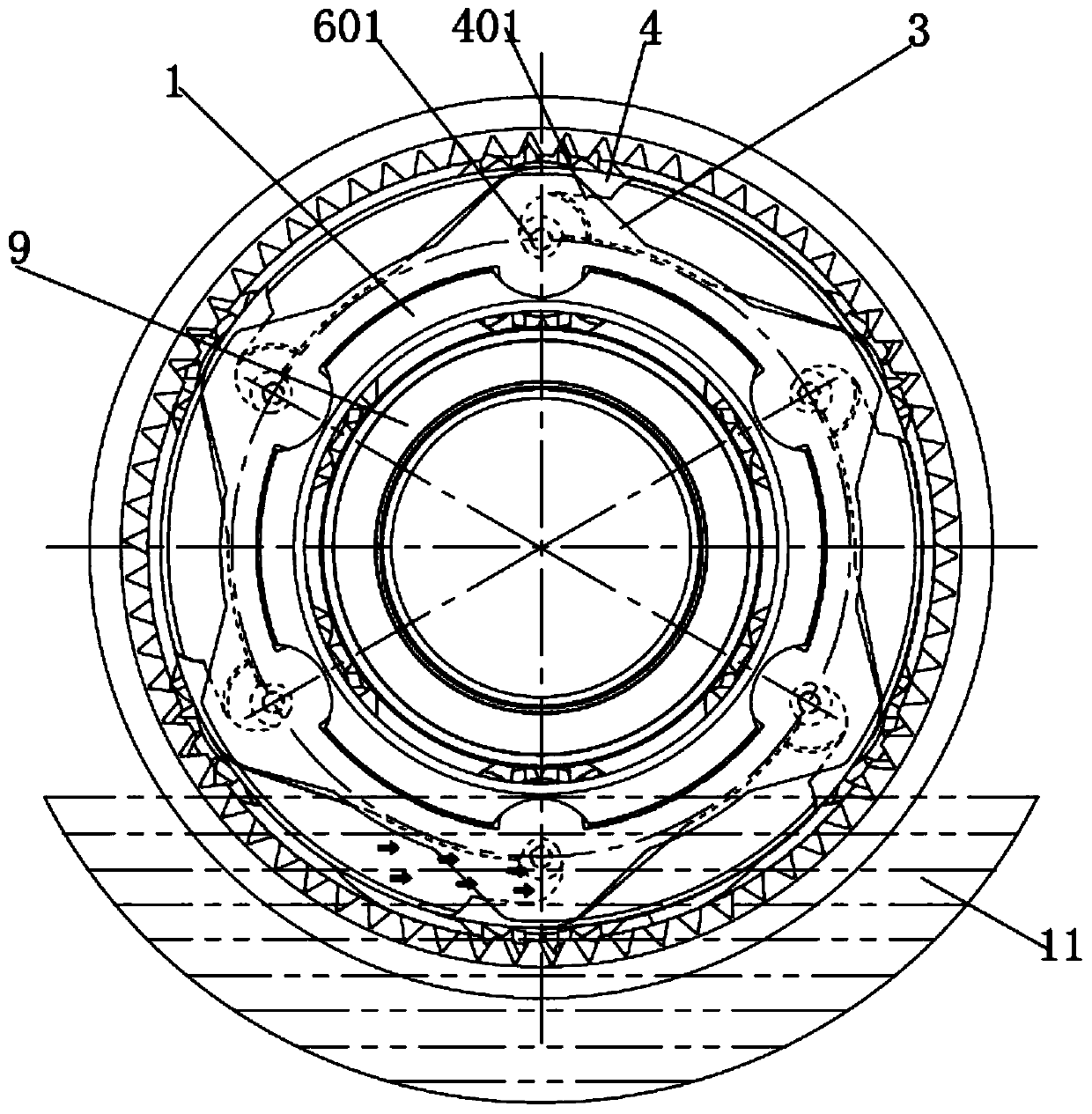

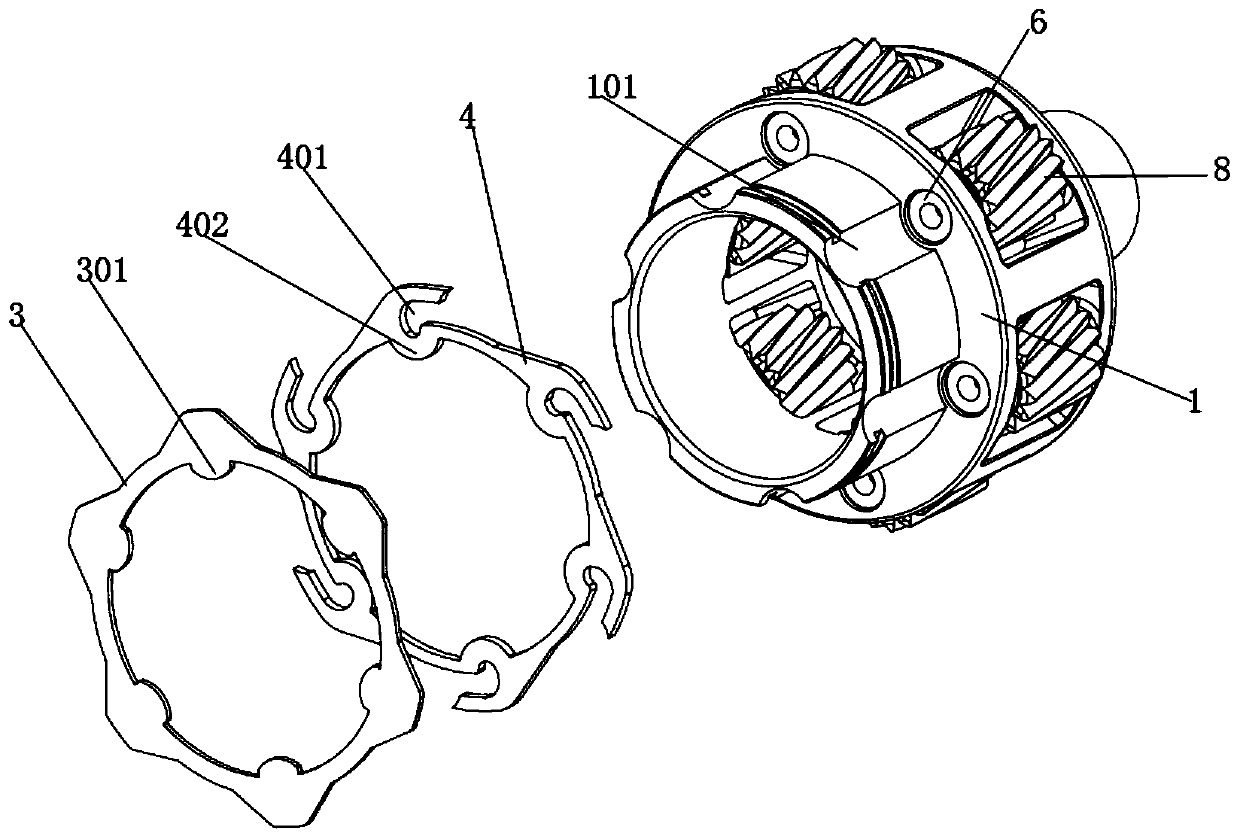

Gerotor hydraulic pump

InactiveCN102162444AImprove volumetric efficiencyHigh production pressure capabilityPump componentsRotary piston pumpsFluid intakeHydraulic pump

A gerotor pump having an outer rotor defining an inner surface of the outer rotor, a thrust plate, a pressure plate, an inlet chamber for fluid intake through the thrust plate to be pressurized, and an outlet chamber for outputting pressurized fluid from the pressure plate. The gerotor pump includes an inner rotor assembly in rotating engagement with the outer rotor. The inner rotor assembly rotating about an axis, the inner rotor assembly comprises a rotor body, wherein the rotor body includes N (an integer greater than one) vane slots defining a first sealing surface, and the rotor body includes N inner openings around the axis, each of the inner opening adjoining a vane slot; and a plurality of vanes defining a second sealing surface, wherein the vane is disposed in the vane slot and in sealing engagement with the rotor body via the first and second sealing surfaces. The inner rotor assembly is in sealing engagement with the outer rotor by the vane engaging on the inner surface of the outer rotor.

Owner:蔡希逾

Drum-type coal cutter rocker arm

ActiveCN102877841BNovel structureCompact structureMechanical energy handlingDriving meansInduction motorReducer

The invention relates to the field of drum-type coal cutter components, and particularly relates to a drum-type coal cutter rocker arm. The rocker arm comprises a rocker arm shell and a speed reduction transmission system, wherein the speed reduction transmission system is composed of planetary reducers arranged at the head part inside the rocker arm shell; the coal cutter rocker arm further comprises a low-speed large torque permanent magnet motor which is vertically arranged below the planetary reducers in the rocker arm shell; the permanent magnet motor comprises an inner rotor and an outer stator; the permanent magnet motor is in driving connection with the planetary reducers through a spline shaft which is fixedly arranged in an inner rotor shaft core. The drum-type coal cutter rocker arm provided by the invention is novel in structure and smart in design; the permanent magnet motor having the characteristic of large torque is adopted to take the place of an asynchronous motor with high speed and small torque; and meanwhile mechanical transmission chains of the speed reduction transmission system between a cutting drum and the permanent magnet motor are eliminated; components in the rocker arm can be lubricated constantly no matter how severely the coal cutter rocker arm is tilted, so that the service life of the coal cutter rocker arm is prolonged.

Owner:晋能控股装备制造集团金鼎山西煤机有限责任公司

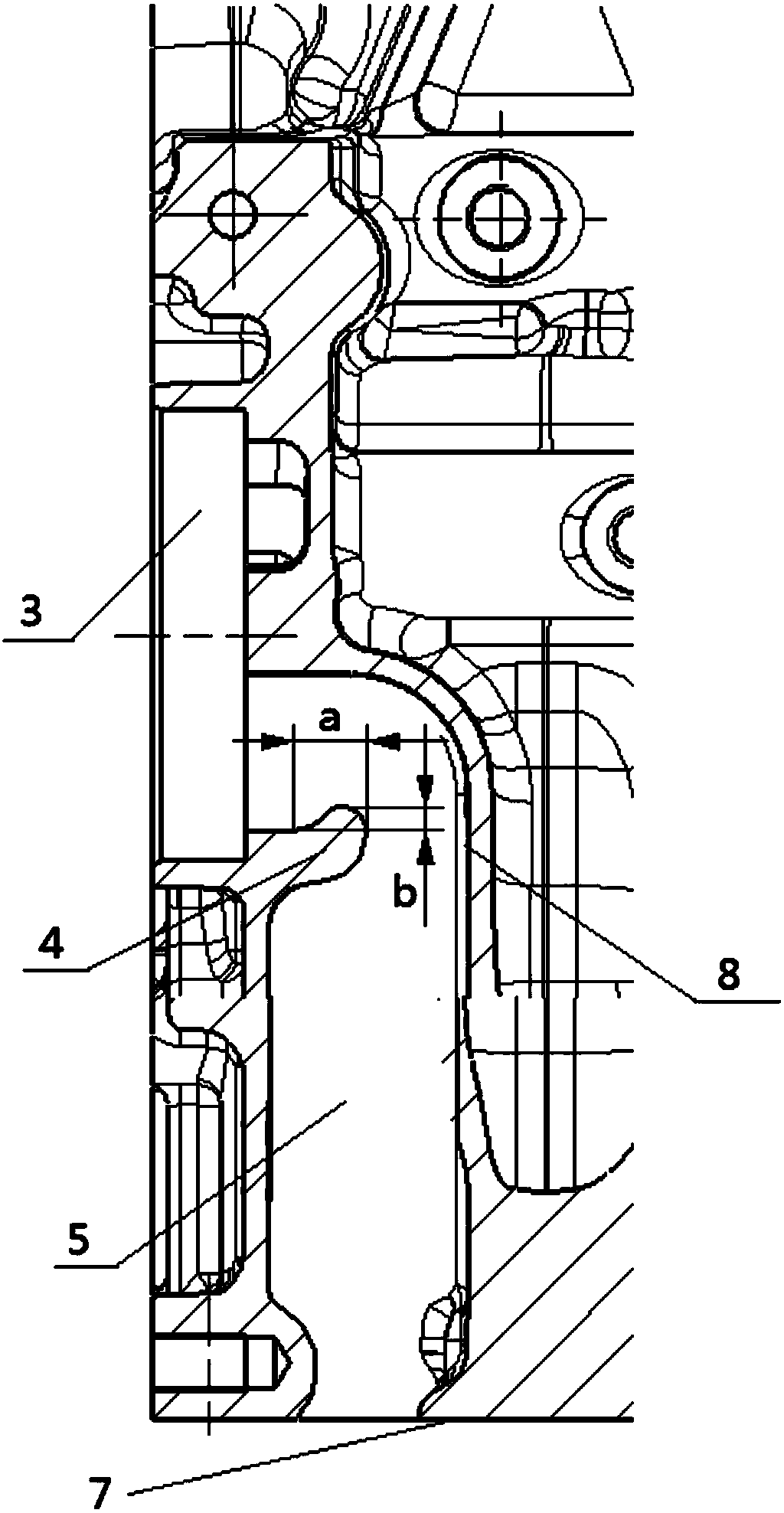

Oil return structure of engine oil pump of engine

InactiveCN107780992AGuaranteed continuous lubricationReduce wearLubricant conduit arrangementsOilsumpsOil canCylinder block

The invention discloses an oil return structure of an engine oil pump of an engine. The oil return structure comprises a cylinder block, an engine oil pump, a main oil duct, an engine oil incoming duct and an oil bottom shell, the oil bottom shell is communicated with the engine oil incoming duct, the engine oil pump and the main oil duct, and an oil-return-preventive convex rib structure is arranged at the upper end of the engine oil incoming duct and used for blocking part of engine oil to fall back into the oil bottom shell when an engine stops running. The oil return structure is reasonable in structural design; when the engine stops running, part of the engine oil can be stored around an engine oil pump mounting hole so as to continuously lubricate the engine oil pump, and wear of theengine oil pump when the engine is restarted is reduced, so that service life of the engine oil pump is prolonged.

Owner:GUANGXI YUCHAI MASCH CO LTD

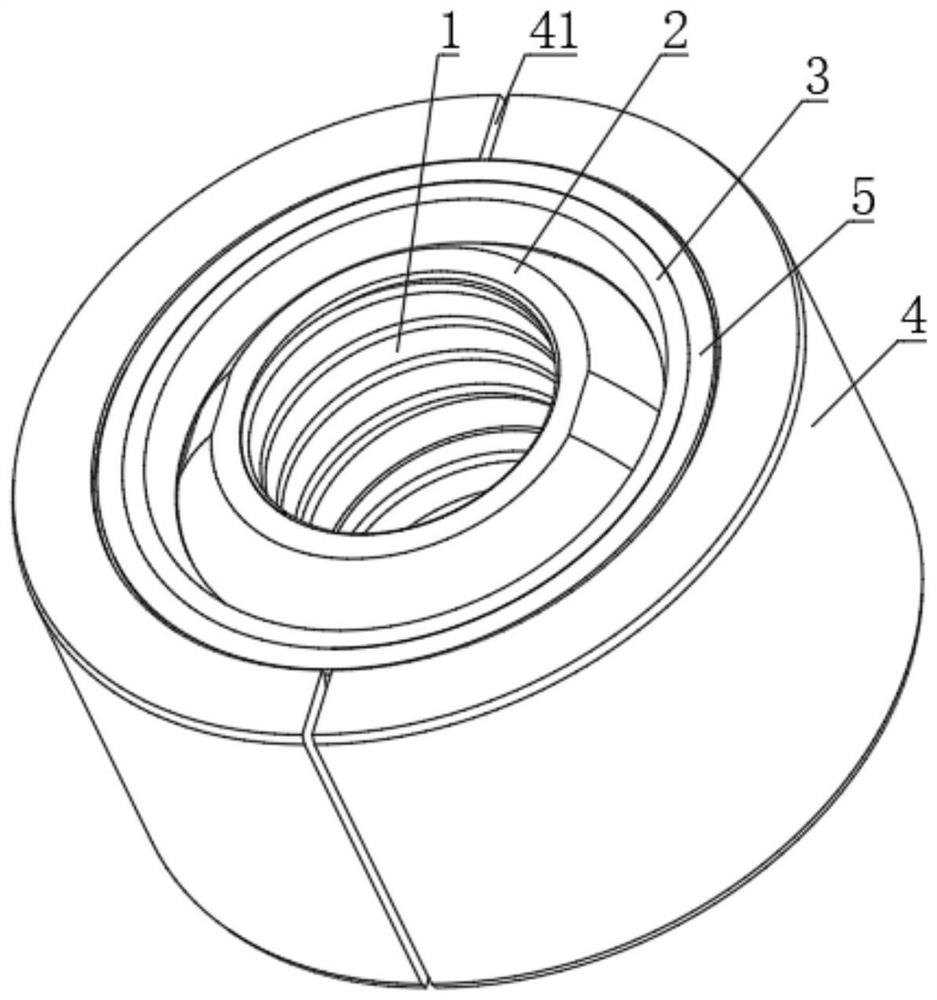

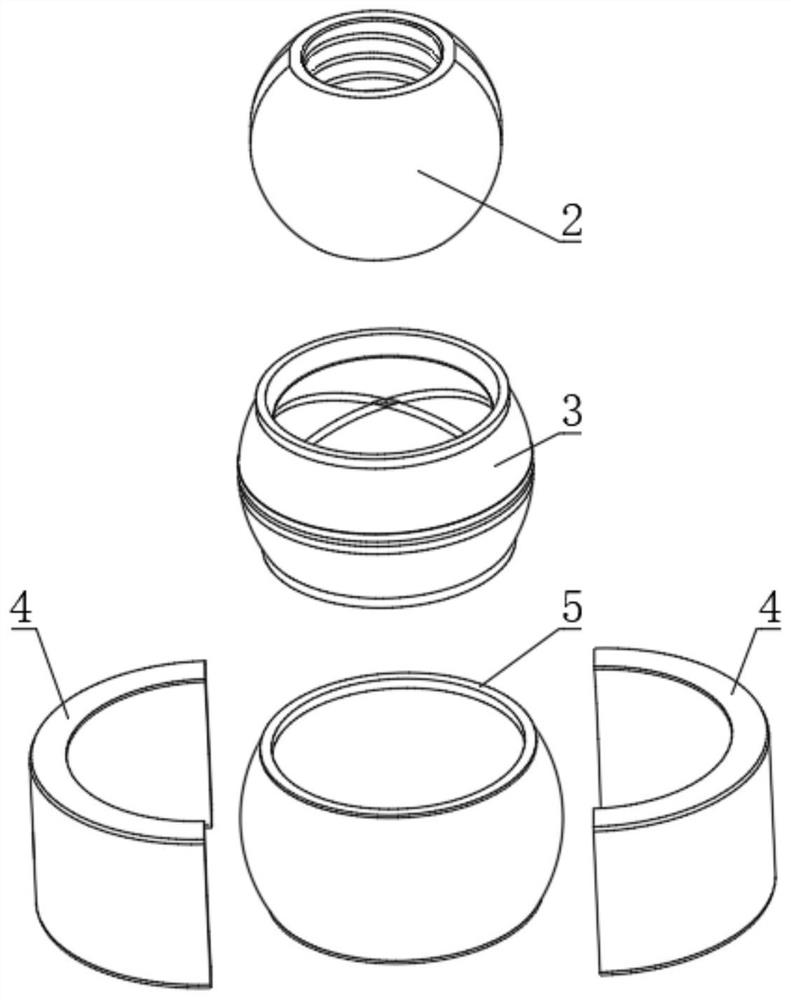

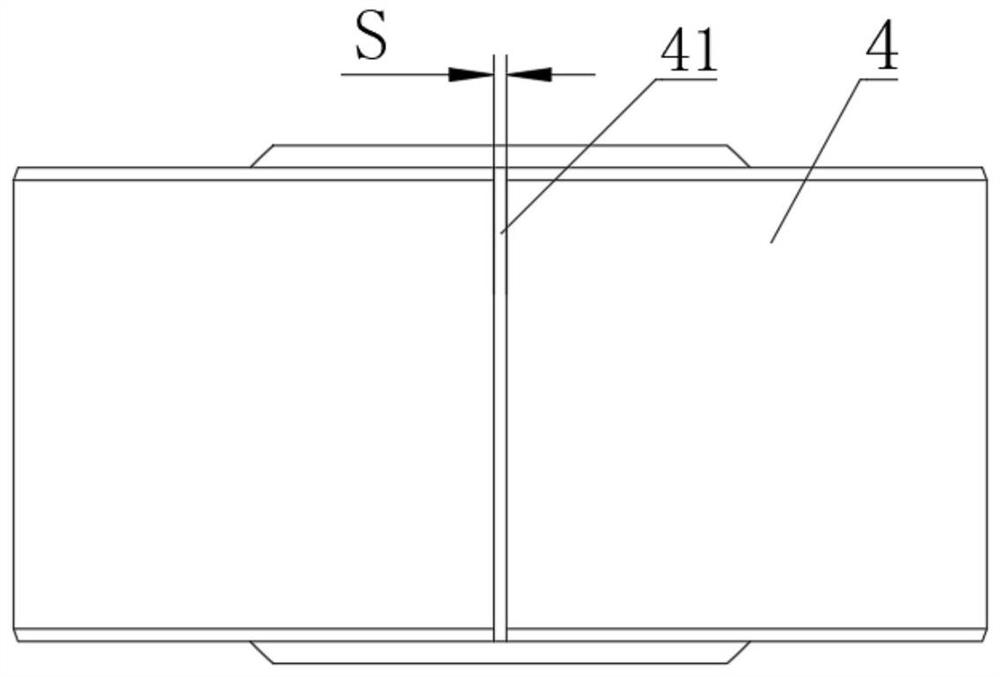

Rigidity-adjustable ball joint and thrust rod assembly

PendingCN112879417AExtended service lifePrevent extrusionPivotal connectionsPivoted suspension armsSuspension (vehicle)Ball joint

The invention discloses a rigidity-adjustable ball joint and thrust rod assembly, and belongs to the technical field of automobile suspension systems. The assembly comprises a thrust rod bracket, a pin shaft, a thrust rod, a ball body, a bearing outer ring and rigidity adjusting sleeves, wherein the ball body is in sliding universal connection with the bearing outer ring; the bearing outer ring is connected with the rigidity adjusting sleeves through an elastic layer; adjusting gaps are formed by the corresponding end faces of the rigidity adjusting sleeves on the two sides; the thrust rod and the rigidity adjusting sleeves are fixedly mounted; and the pin shaft is inserted into a mounting shaft hole and is connected with the thrust rod bracket. Free universal rotation of the thrust rod assembly is achieved through a ball joint, torsion stress of the elastic layer is released, and the elastic layer is only subjected to pressure load; the elastic layer achieves the buffering function of the thrust rod assembly, and the impact load in the force transmission process of the thrust rod is reduced; and the rigidity adjusting sleeves are provided with the adjusting gap, so that rigidity adjustment of the thrust rod assembly is achieved, the reliability of the thrust rod assembly is improved, the service life is prolonged, meanwhile, flexible connection of a suspension system and an axle assembly is achieved, and the comfort of a whole vehicle is improved.

Owner:SINO TRUK JINAN POWER

Backing roller core shaft

InactiveCN101003057AContinuous supplyGuaranteed continuous lubricationRolling equipment maintainenceCounter-pressure devicesLubricationMechanical engineering

A mandrel of baking roller for improving the lubrication effect has an axial lubricating oil channel with one or more radial oil releasing holes whose surficial ends are on the bottom of a ring slot.

Owner:郑红专 +1

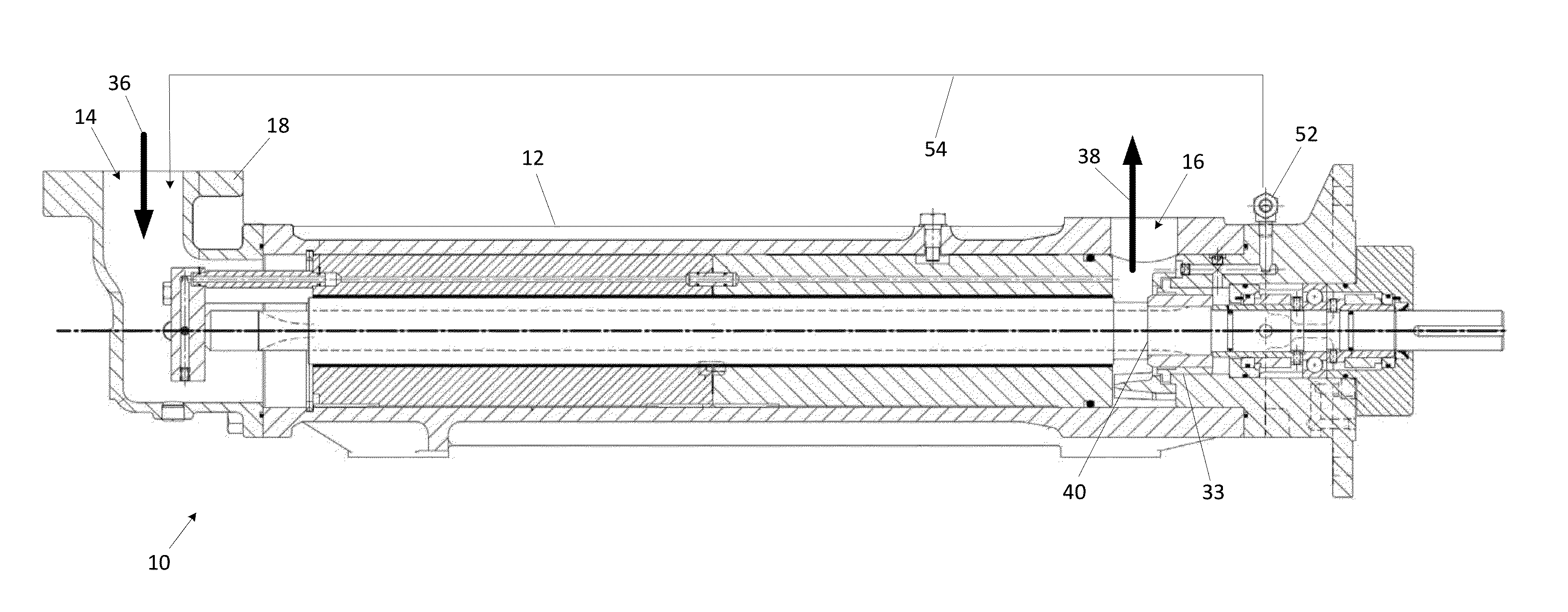

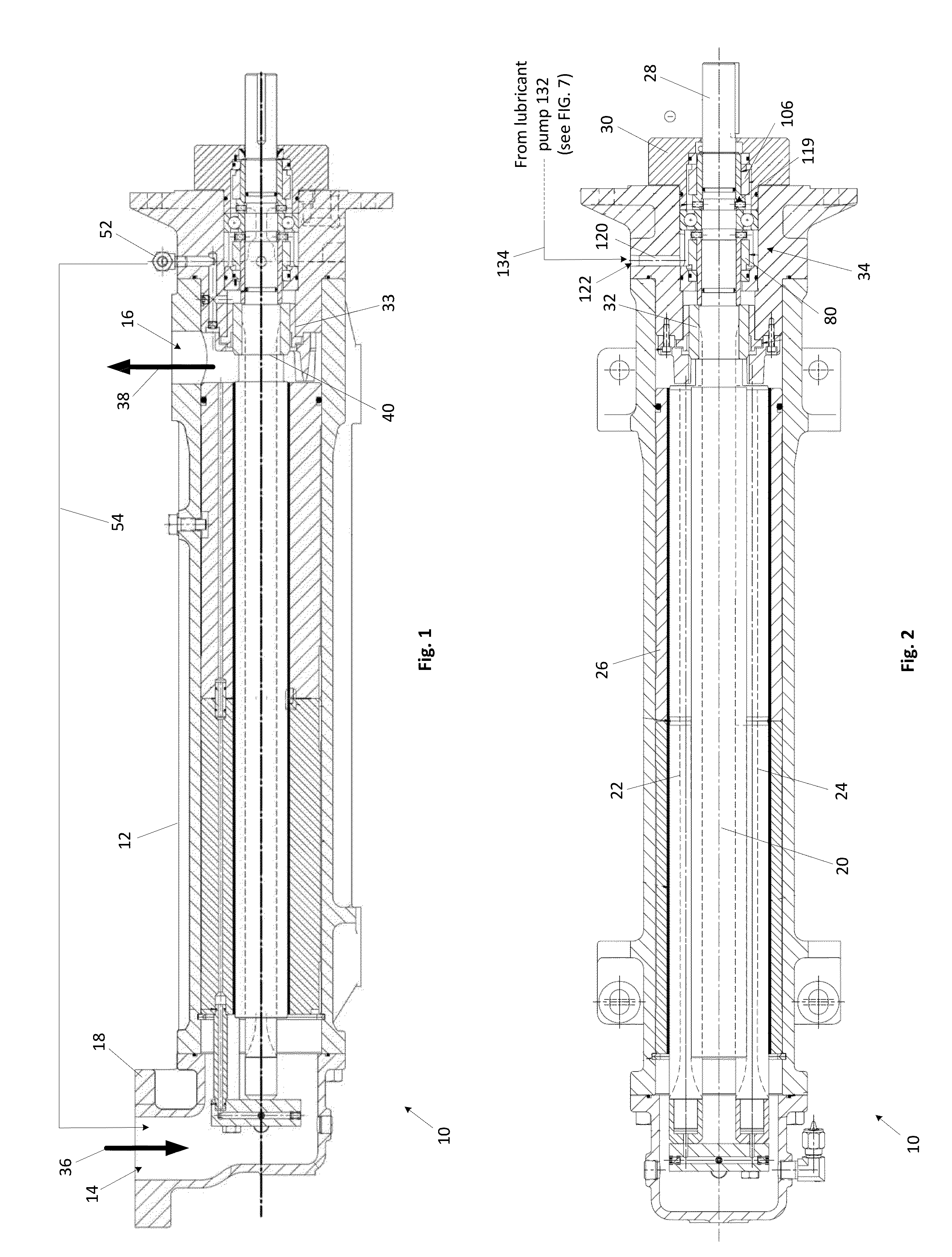

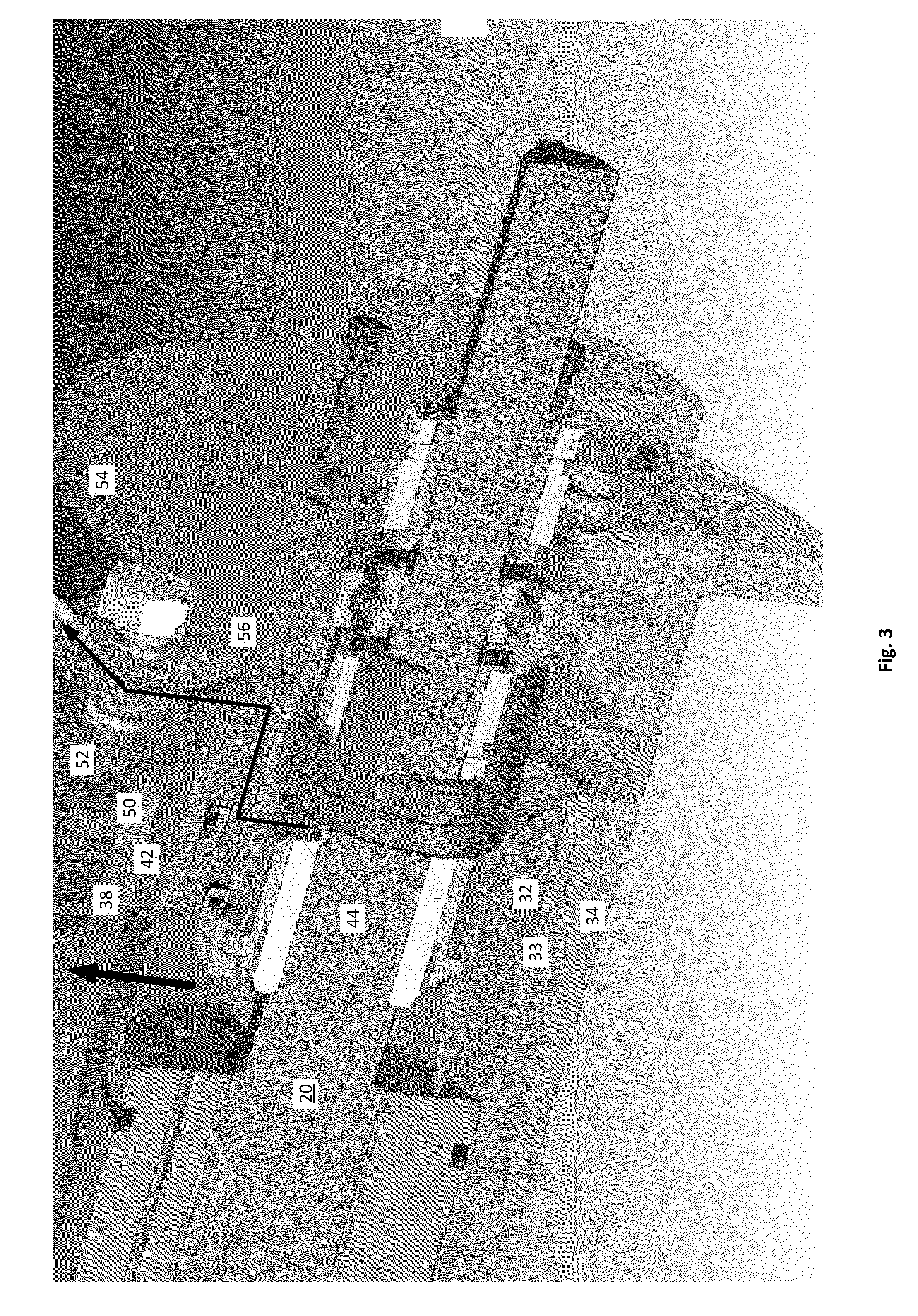

Ultra-lightweight clamping device

InactiveUS20160256934A1Reduce weightReduce vibrationAdditive manufacturing apparatusWorkpiecesBiomedical engineering

Owner:ROHM GMBH

Cantilever shaft supporting device

InactiveCN101968081AImprove carrying capacityGuaranteed lubrication effectBearing unit rigid supportRolling-element bearingFriction loss

The invention relates to a cantilever shaft supporting device which comprises a shaft, a bearing seat, a bearing cap, at least four rolling bearings, two sleeve barrels, two sealing rings and two compression rings, wherein the rolling bearings are positioned in the bearing seat; the inner ring of each rolling bearing is tightly fixed with the shaft, and the outer ring of each rolling bearing is tightly fixed with the bearing seat; two orthogonal radial through holes which are positioned in the same plane are formed on the bearing seat; the two radial through holes are positioned at the end part of each rolling bearing and are communicated with the inner cavity of each rolling bearing; a gap is formed between the first sleeve barrel and the end surface of each rolling bearing; and a gap is formed between the bearing cap and the end surface of each rolling bearing. In the cantilever shaft supporting device, lubricating oil enters the rolling bearings through the two through holes on the bearing seat; and the cantilever shaft supporting device not only has the advantages of the traditional supporting device but also has strong bearing capacity, small friction loss and convenient and quick lubrication, and can realize continuous lubrication.

Owner:ZHEJIANG UNIV

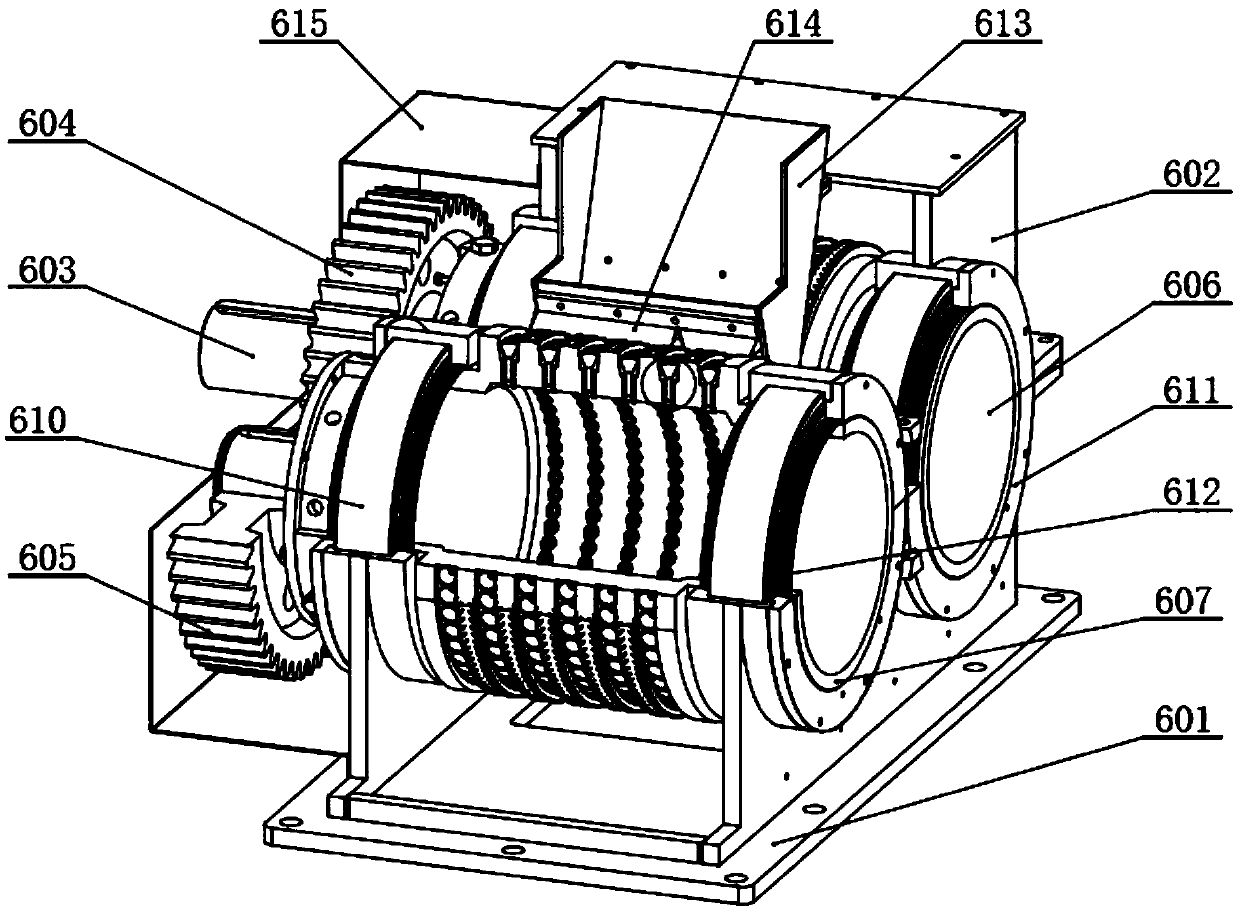

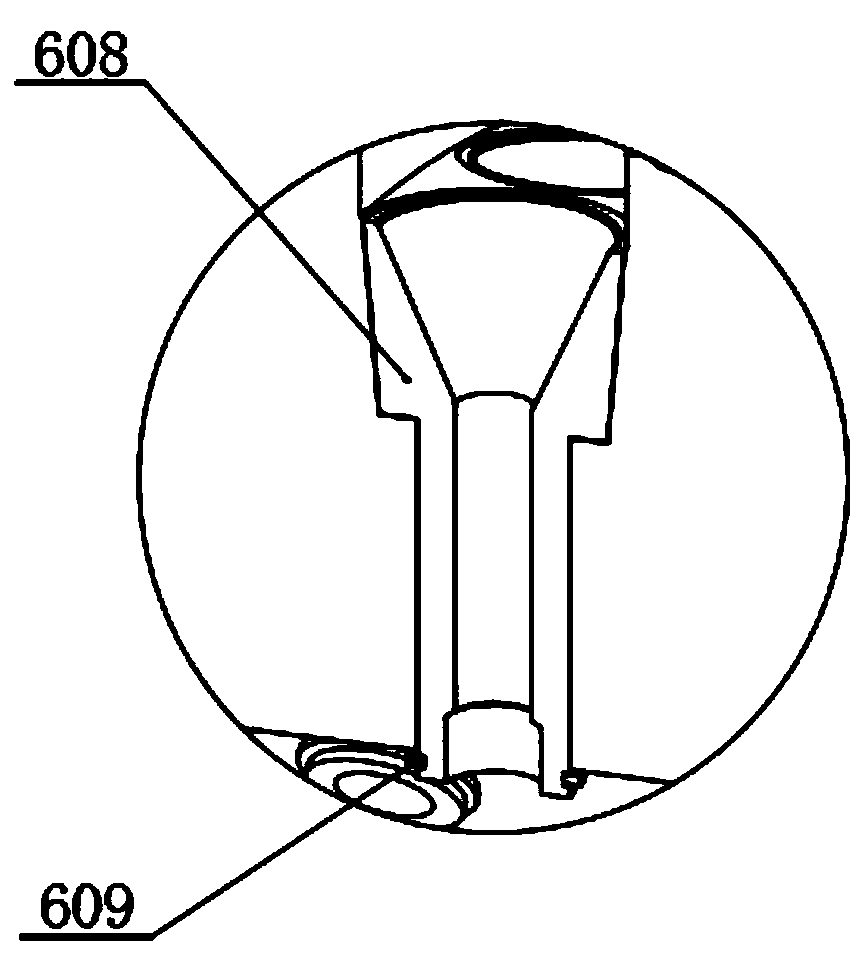

Double-roll biological coal granulator

PendingCN109647286AExtended service lifeContinuous cycle coolingBiofuelsSolid fuelsEngineeringRoll forming

The invention discloses a double-roll biological coal granulator, and relates to the field of biological coal forming. The double-roll biological coal granulator comprises a rack, a double-roll forming mechanism located on the rack, and a driving mechanism for providing power for work of the double-roll forming mechanism. According to the biological coal granulator, a double-roll relative rotatingextrusion forming mechanism is adopted, flanges and grooves on two rollers are staggered, the two rollers extrude each other, forming of biomass fuel is achieved, a cantilever shaft is not adopted any more, and structural stress is reasonable. Due to the fact that the rollers are of rotation structures, a bearing and a box are fixed and are in a relatively static work state, the bearing can be subjected to continuous cyclic cooling through cooling oil, and it is avoided that the service life of the bearing is rapidly shortened in a high-temperature environment. According to the rollers, the flanges, the grooves and herringbone grooves in the surfaces of the flanges are arranged, the rollers are used for increasing flowing of biomass raw materials in the rolling process and reducing bonding of the biomass raw materials and the flanges of the rollers, the materials enter a forming mold at a flowing state, and the effective utilization rate of energy is increased.

Owner:河北省机电一体化中试基地有限公司 +2

Hydraulic winch for hoisting building materials and using method thereof

ActiveCN112174002AImprove stabilityWind evenlyWinding mechanismsEngine lubricationHydraulic motorArchitectural engineering

The invention relates to the technical field of winches, and discloses a hydraulic winch for hoisting building material and a using method thereof. The hydraulic winch comprises a base table, a supporting frame is fixedly installed on the front face of the top of the base table, fixed discs are fixedly installed at the two ends of the top of the base table, and bearings are fixedly installed in the middles of the interiors of the two fixed discs. A winding pipe is fixedly installed on the inner sides of the two bearings, limiting discs are fixedly installed at the two ends of the winding pipe,and oil injectors are fixedly installed at the tops of the two fixed discs. According to the hydraulic winch for hoisting the building materials, the base table, the supporting frame, a guide ring and the like are arranged to achieve the purpose of being good in winding effect, the two ends of a rope are fixedly installed at the winding pipe and the building material end correspondingly, then a hydraulic motor starts to control the winding pipe to rotate, at the moment, the rope can stably complete the hoisting work without shaking under cooperative work of the supporting frame, a guide roller and the guide ring, so that the stable effect of the work is guaranteed, and the rope can be wound when the starting work is completed.

Owner:杭州拓胜建筑工程有限公司

Lubrication and adjustment valve body

InactiveCN105333192AImprove the lubrication effectGuaranteed continuous lubricationPlug valvesValve housingsEngineeringLubrication

The invention discloses a lubrication and adjustment valve body. The lubrication and adjustment valve body comprises a valve main body and a valve seat. The valve main body is arranged in the valve seat. Adjustment bases are arranged on the outer portion of the valve seat. Adjustment bent rods are arranged in the adjustment bases. One end of each adjustment bent rod extends out of the corresponding adjustment base, and the other end of each adjustment bent extends into the valve main body. Compression springs are arranged between the adjustment bent rods and the inner walls of the adjustment bases. An oil storage tank is arranged at the upper end of the valve main body, communicated to the outer portion of the valve main body through an oil guide way and sealed through a sealing cover. An oil leakage film is arranged at the bottom of the oil storage tank. According to the scheme, the adjustment bases are arranged on the outer portion of the valve main body and can adjust the overall pre-tightening force, the oil storage tank is arranged at the upper end of the valve main body, and therefore the valve main body can be conveniently lubricated, lubricating oil can be stored in the oil storage tank through the oil guide way, the valve main body is slowly lubricated by the lubricating oil through the oil leakage film, and the adjustment bases are arranged outside the valve main body and are easy to assemble while the lubricating property in the valve main body is kept.

Owner:SUZHOU SONGSHUN HARDWARE

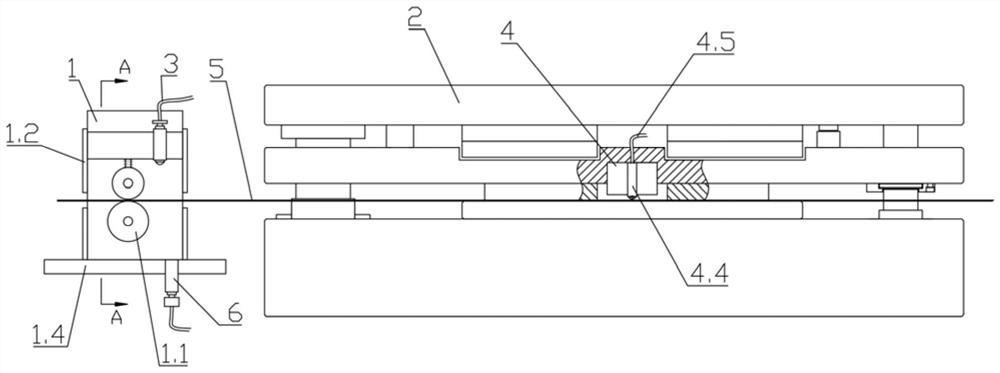

Lubricating device for stamping equipment

PendingCN112007996AReduce precisionQuality assuranceShaping toolsMetal-working feeding devicesLubricationIndustrial engineering

The invention discloses a lubricating device for stamping equipment. The lubricating device comprises a feeding mechanism, a mold, an oil tank, a first lubricating mechanism, a second lubricating mechanism and a material belt, the feeding mechanism is arranged on the side of the mold, the material belt passes through the feeding mechanism and penetrates through the mold, the first lubricating mechanism and the second lubricating mechanism are arranged above the material belt, the first lubricating mechanism is arranged on the feeding mechanism, the second lubricating mechanism is arranged on the mold, and the oil tank is connected with the first lubricating mechanism and the second lubricating mechanism. The first lubricating mechanism lubricates the material belt at the feeding mechanism;when the material belt lubricated by stamping oil is stamped, the mold can be lubricated together; when the material belt moves to the middle rear section of the mold, the stamping oil is consumed, the second lubricating mechanism lubricates the material belt again, it is guaranteed that the middle rear section of the mold can also be lubricated by the stamping oil, the quality of finished workpieces is guaranteed through sufficient lubrication, and meanwhile the consequence that the service life of the mold is shortened or the precision is reduced can be avoided.

Owner:宁波康迪普瑞模具技术有限公司

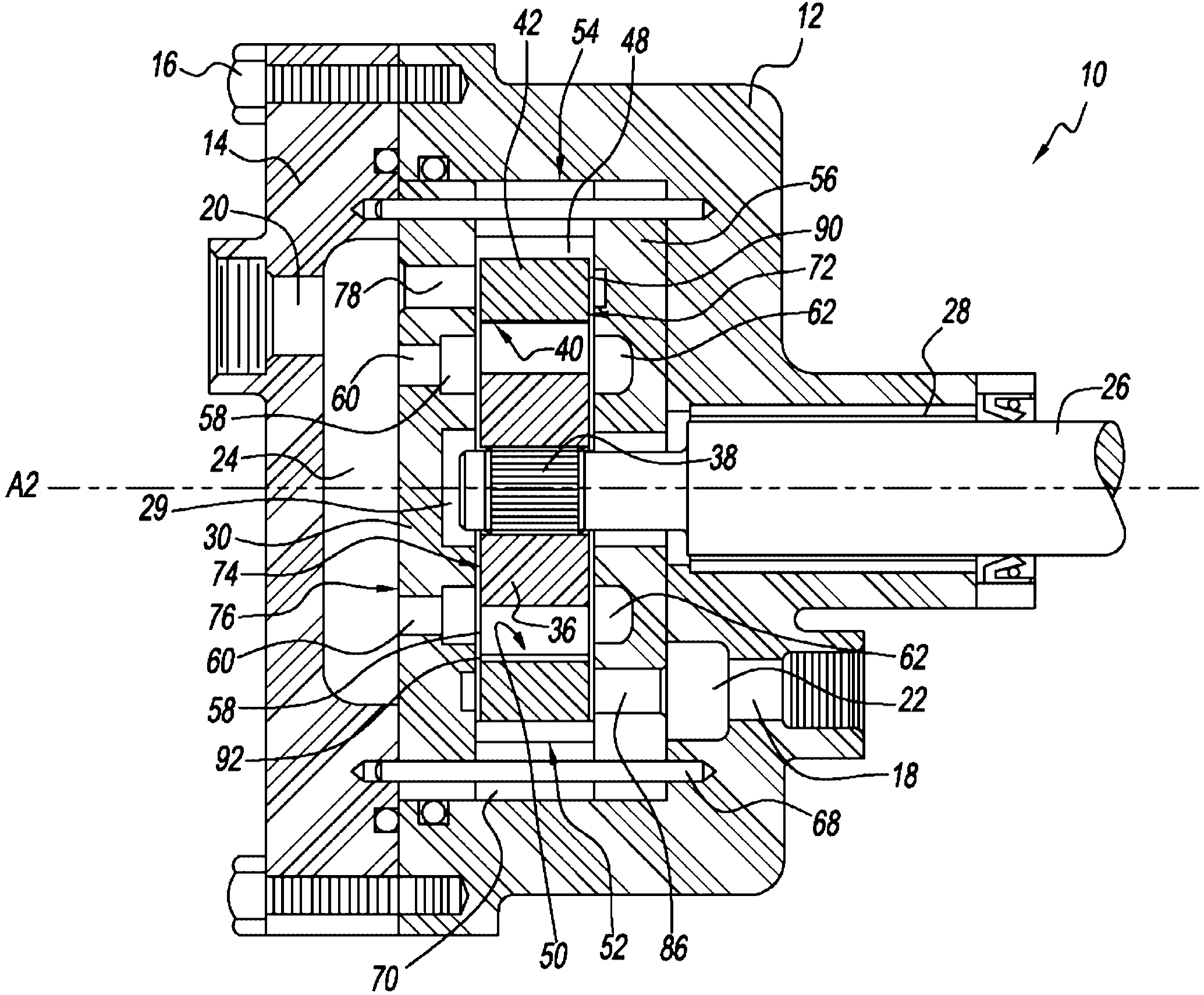

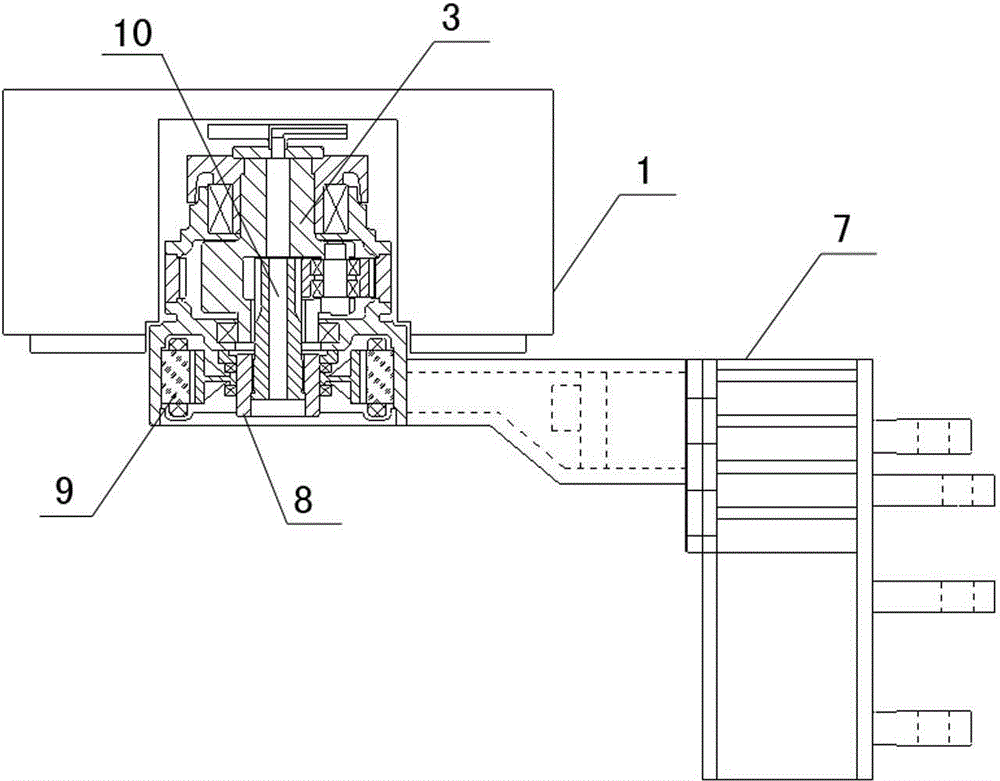

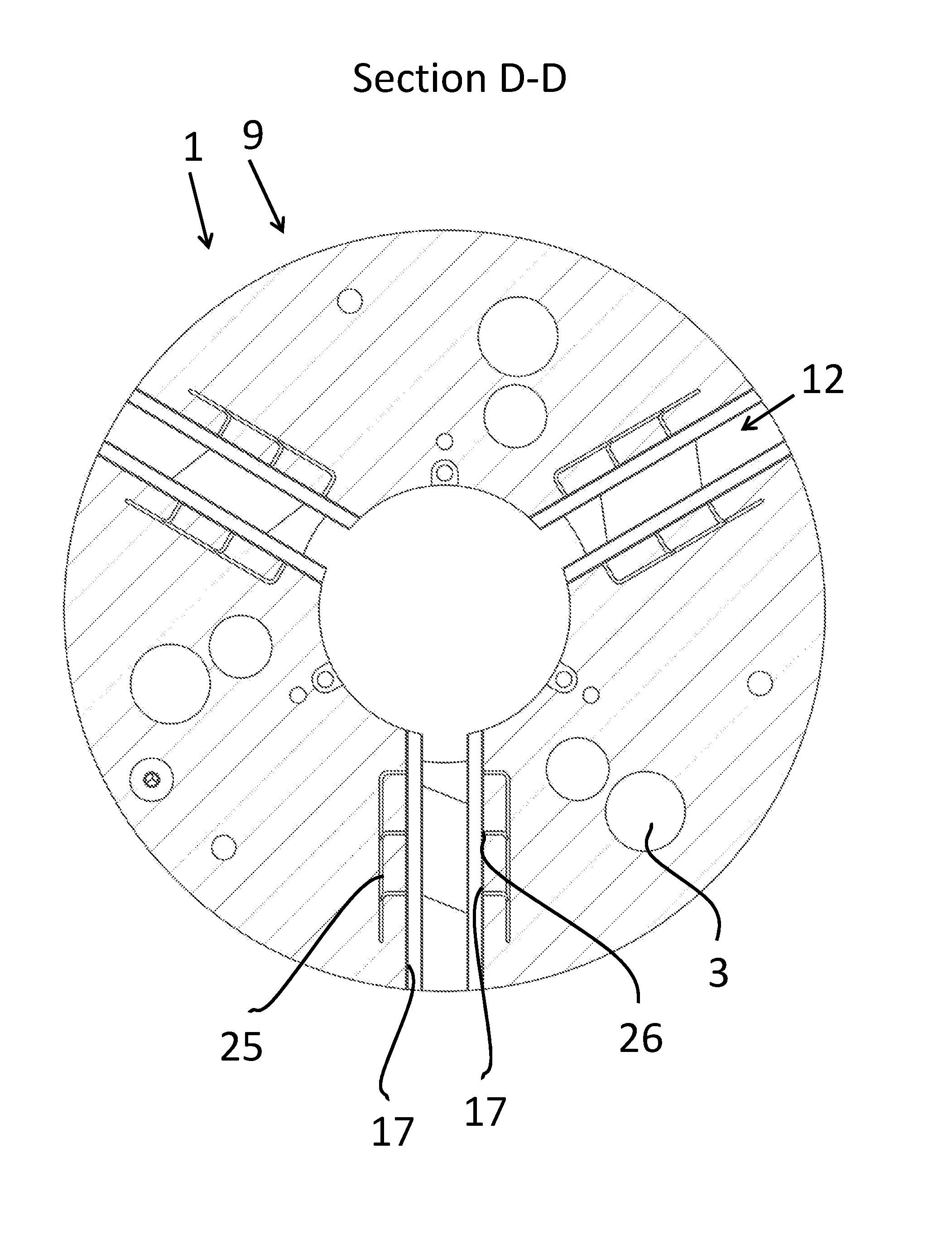

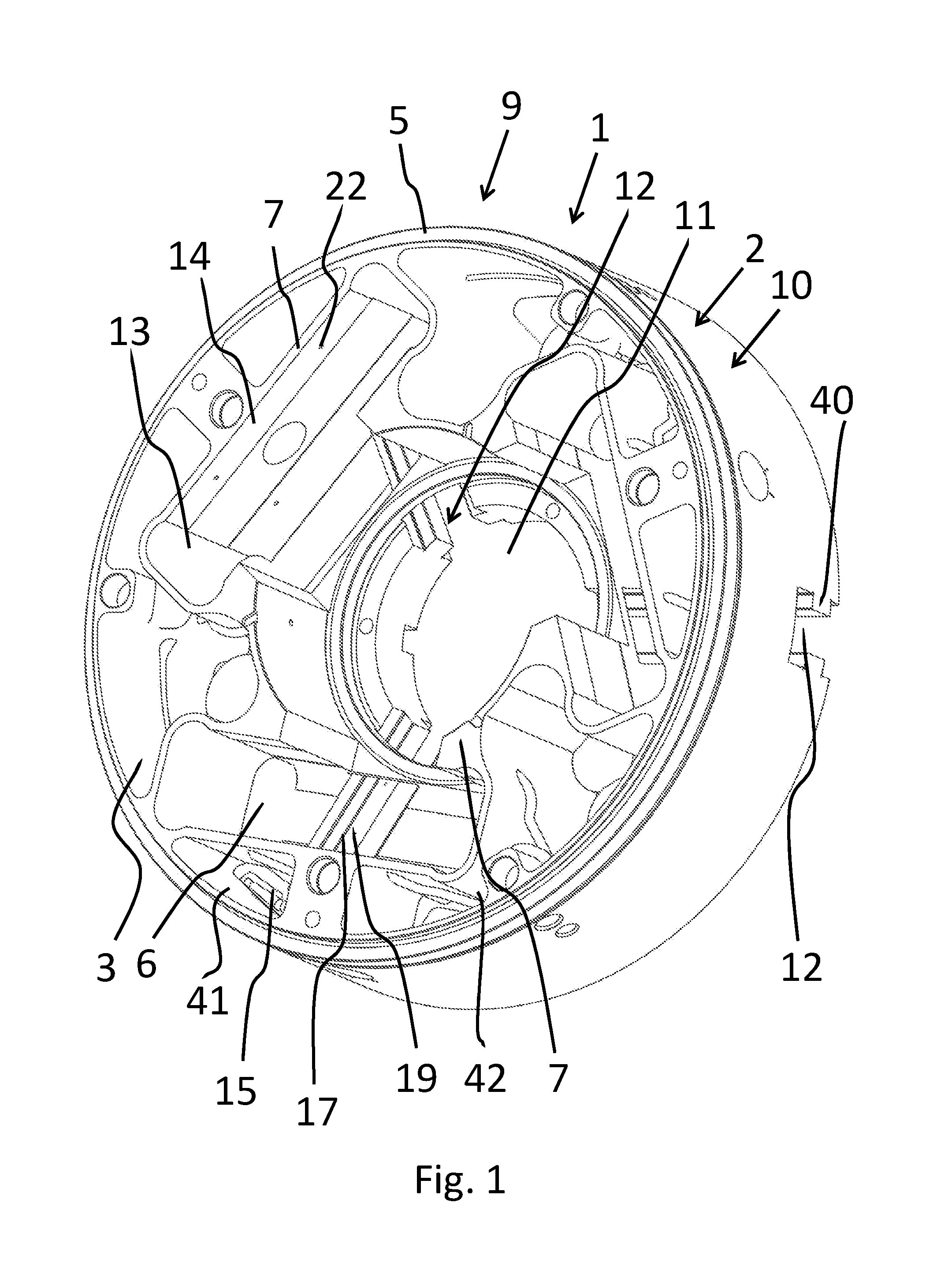

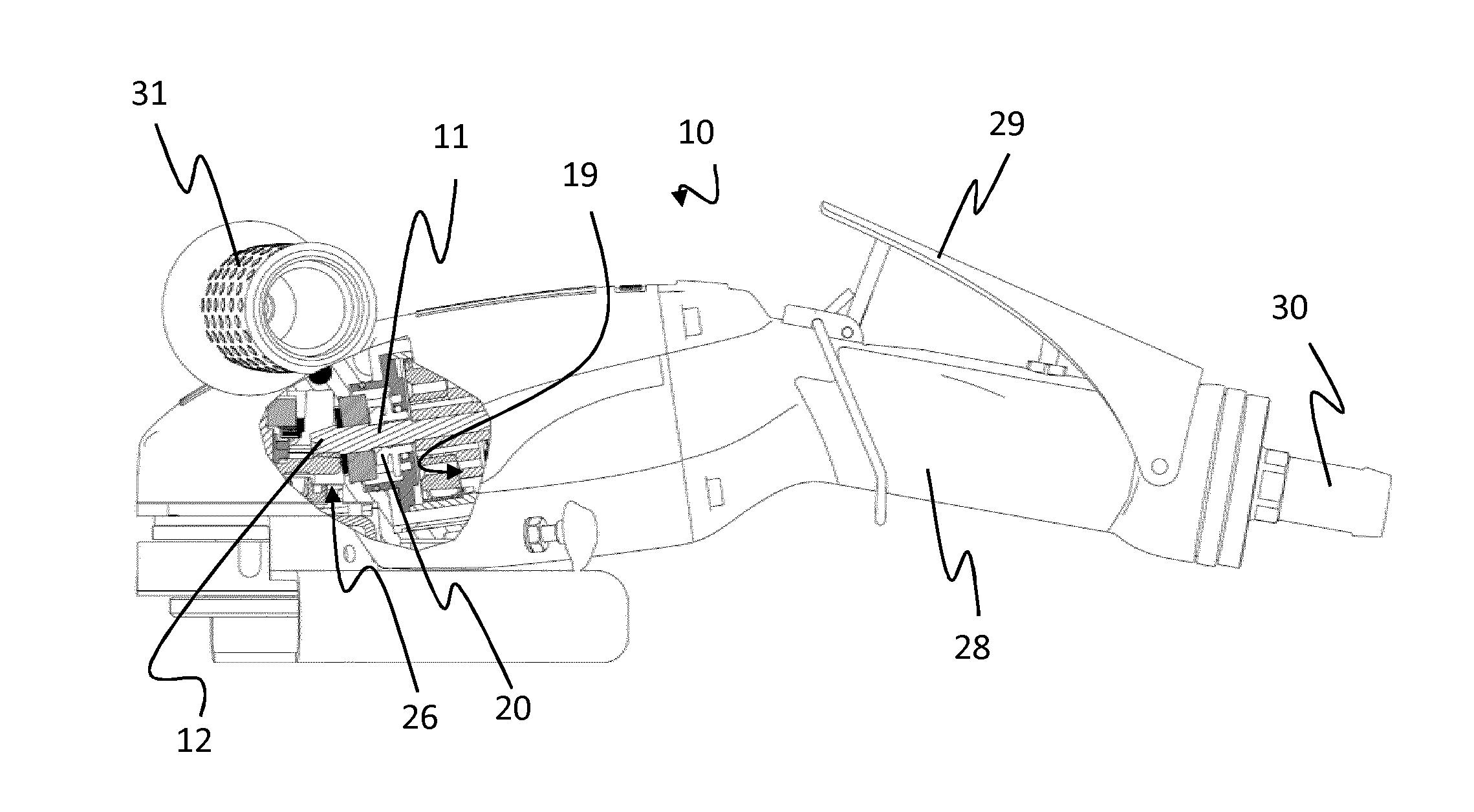

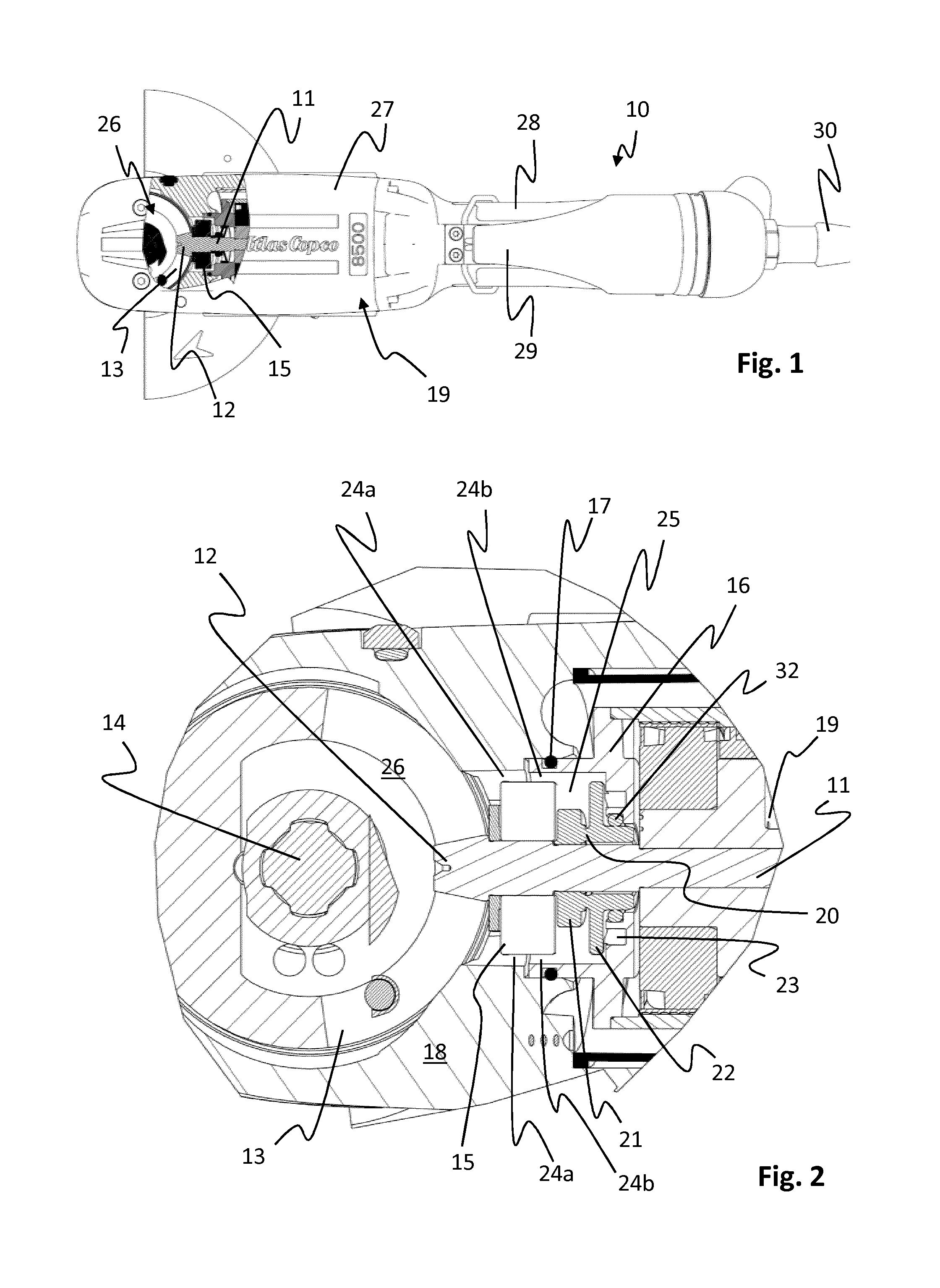

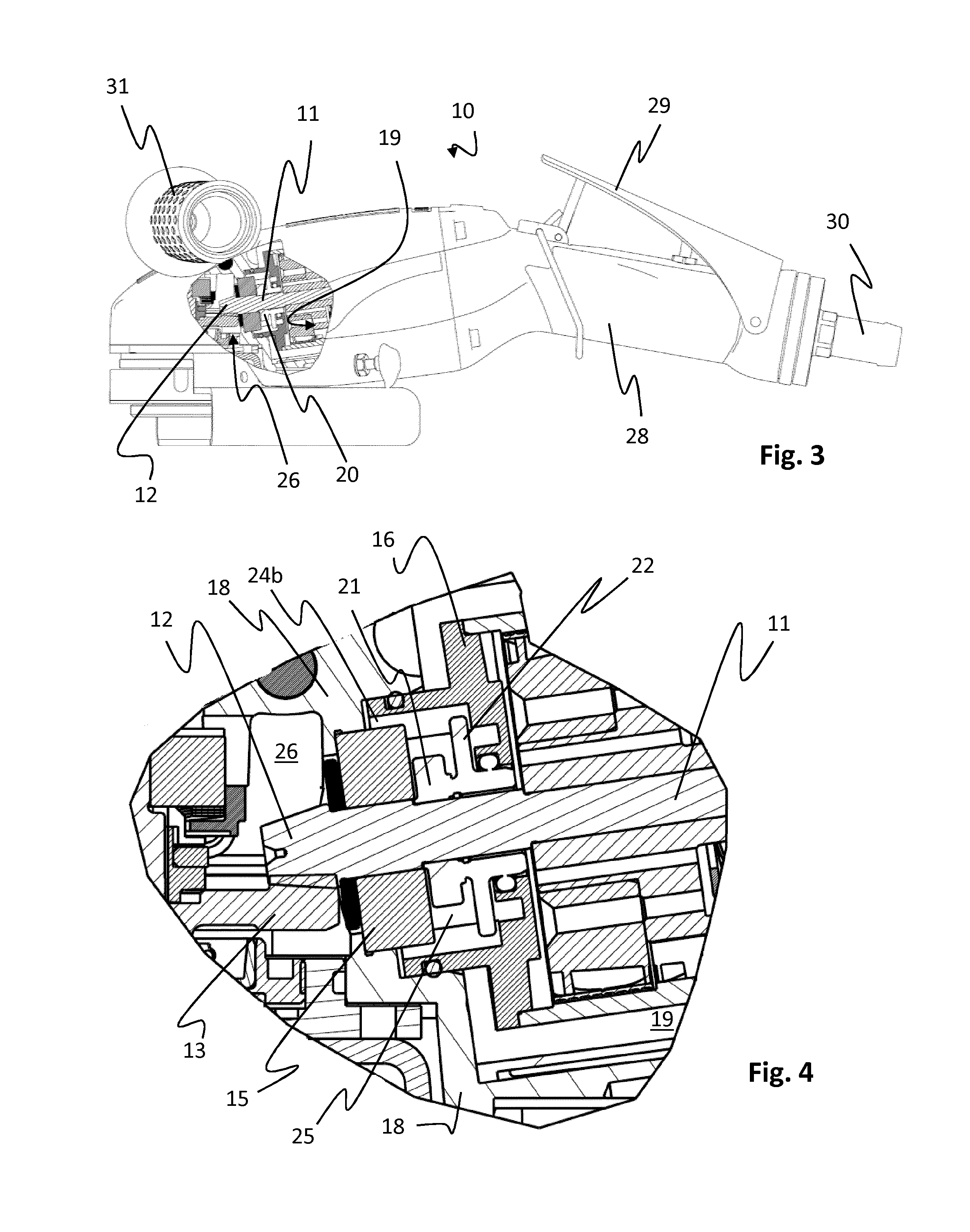

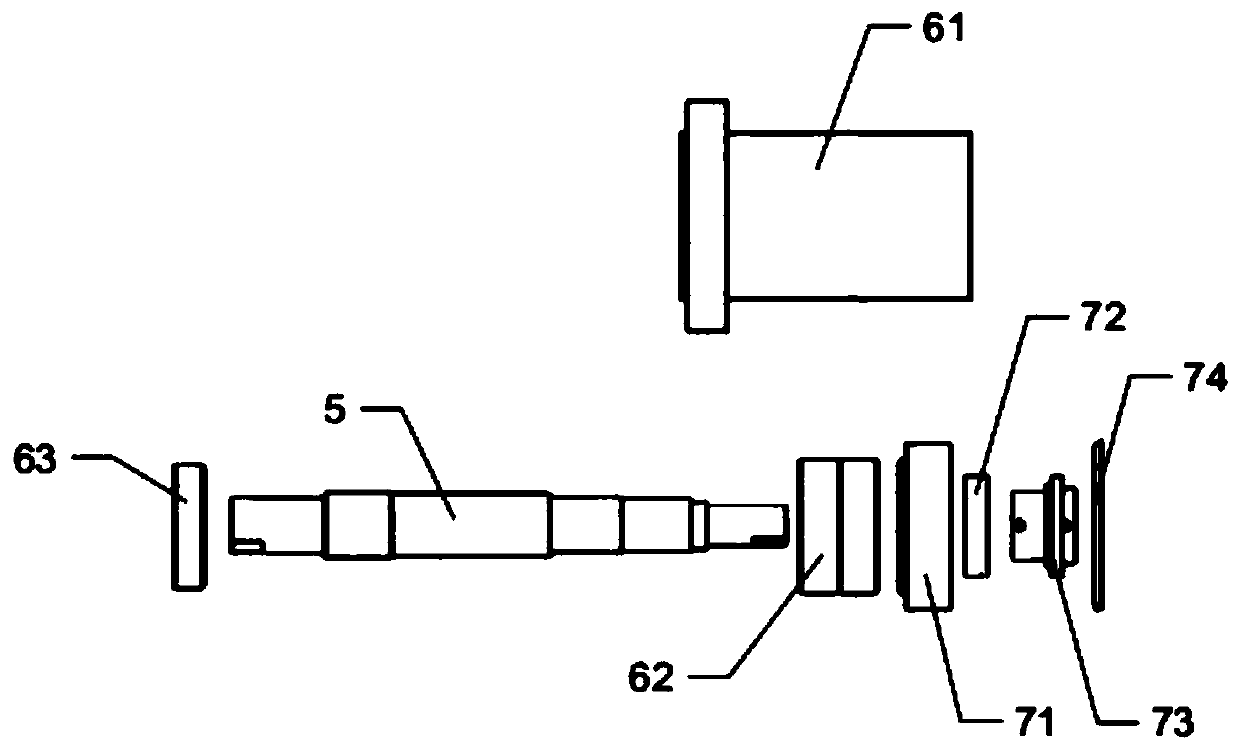

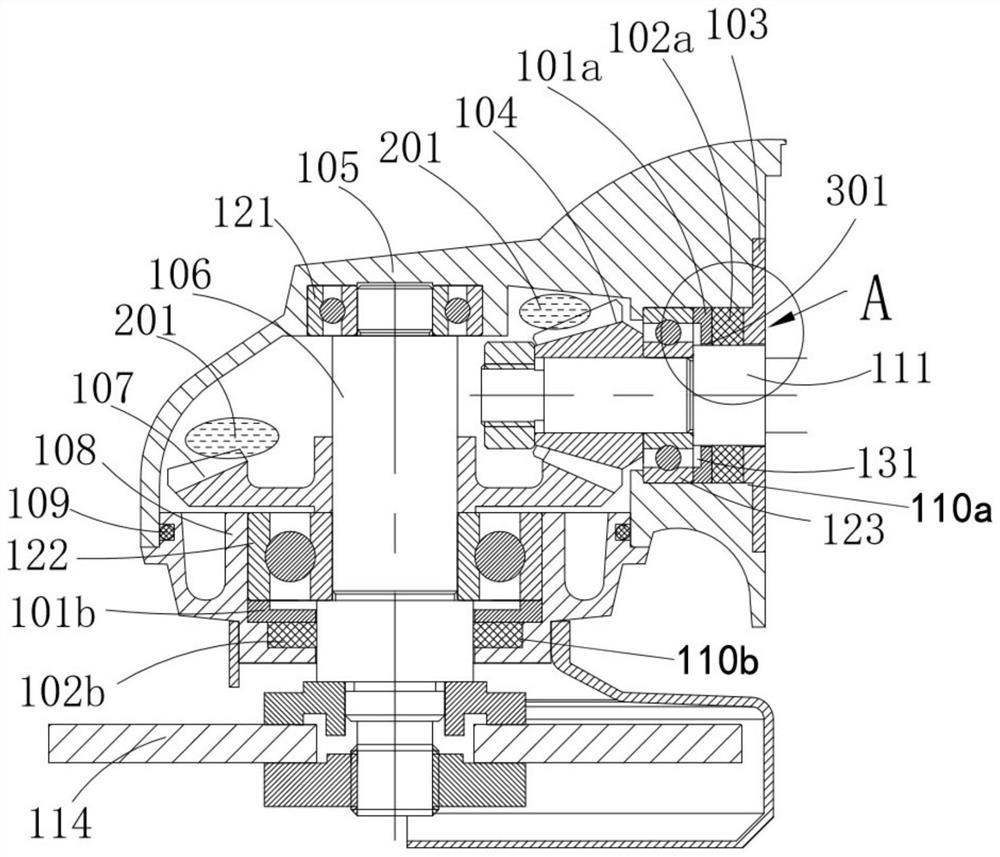

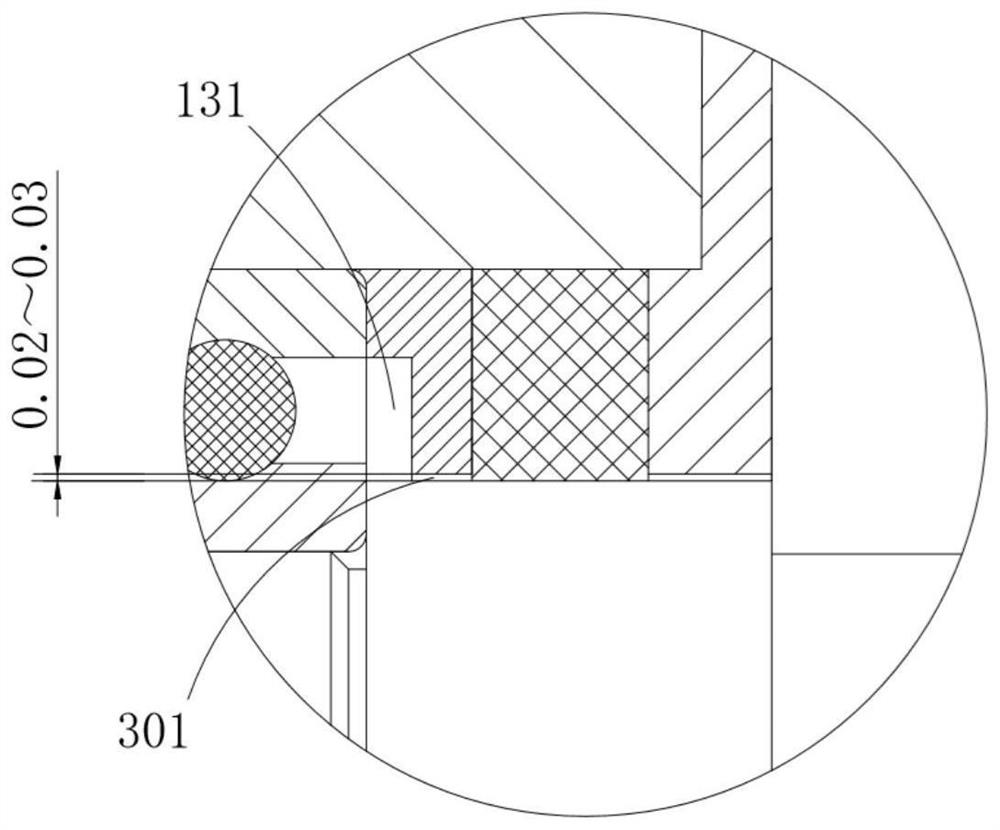

Power tool

ActiveUS20150158138A1Maintain functionGuaranteed continuous lubricationDrilling rodsConstructionsPower toolCrown gear

A hand held power tool includes: a motor room housing a motor that drives an output shaft; a bevel gear including interconnected pinion and crown gears, wherein the pinion gear is connected to a pinion shaft drivingly connected to the output shaft and the crown gear is drivingly connected to a tool holding shaft; a gear housing that delimits a fluid tight gear space around the bevel gear; a bearing, around the pinion shaft and close to the pinion gear, which delimits a confined space around the pinion shaft and within the gear space; and a fluid tight axial sealing, around the pinion shaft inside the confined space of the gear space, which seals off the gear space from the motor room. At least one fluid conveying opening is arranged to put the confined space of the gear space in fluid contact with the rest of the gear space.

Owner:ATLAS COPCO INDAL TECHN

Aluminum alloy automobile hub structure

The invention relates to an aluminum alloy automobile hub structure. The aluminum alloy automobile hub structure comprises a hub main body, a hub bearing and an anti-slip chain fixing mechanism, wherein the hub bearing is connected into the hub main body; the anti-slip chain fixing mechanism is installed outside the hub main body; the hub main body comprises an inner ring, a spoke, a rim and a hubflange; the hub bearing comprises an oil storage cup, an inner ring, a steel rolling ball and a lubricating ball; and the anti-slip chain fixing mechanism comprises a first fixing ring, a second fixing ring, a connection bolt, a first placement sheet, a second placement sheet, a fixing plate and a clamping plate. The aluminum alloy automobile hub structure is capable of continuously lubricating the bearing in a running process, and adaptive adjustment is carried out on an applying amount of lubricating oil along with the change of a running speed; and in addition, through the arrangement forthe anti-slip chain fixing mechanism which is installed in a detachable manner, installation for an anti-slip chain is facilitated, and the occurrence of the case that the anti-slip chain causes damages to the hub can be effectively avoided.

Owner:INNER MONGOLIA HUATANGWEIYE RENEWABLE RESOURCES CO LTD

Multifunctional grinding head mechanism and main shaft

PendingCN111496672AAvoid accumulationAvoid affecting useGrinding wheel securing apparatusGear lubrication/coolingRotational axisEngineering

The invention discloses a multifunctional grinding head mechanism and a main shaft. The multifunctional grinding head mechanism comprises a chuck receiving handle, a grinding head handle and a handgrip, wherein the grinding head handle is arranged on the chuck receiving handle in an insertion manner, a rotary shaft is arranged on the chuck receiving handle; a sealing mechanism and a transmission mechanism are arranged on the rotary shaft in a sleeved manner; and a lug is arranged on the outer wall of the grinding head handle, a first limit groove adaptive to the lug is formed in the chuck receiving handle, a second limit groove adaptive to the handgrip is formed in the outer circumferential wall of the grinding head handle, the handgrip is in threaded connection with the chuck receiving handle, and a first grinding assembly or a second grinding assembly is arranged at one end away from the chuck receiving handle, of the grinding head handle. Compared with the prior, according to the multifunctional grinding head mechanism and the main shaft, through the arrangement for the lug and the handle, the grinding head handle can be rapidly fixed to the chuck receiving handle, and the structure is capable of avoiding the accumulation of grinding powder, so that the service life of the structure is prolonged; and due to separate design for the grinding head handle, the first grinding assembly and the second grinding assembly, cost reduction is benefited. The grinding head or a brush disc can be rapidly replaced as needed by rotating the handgrip, so that the working efficiency can beeffectively increased.

Owner:宇晶机器(长沙)有限公司

Die-casting machine charging barrel and injection rod

InactiveCN113319263AAvoid safety hazardsGuaranteed continuous lubricationHydraulic cylinderEngineering

The invention discloses a die-casting machine charging barrel and an injection rod. The structure of the die-casting machine charging barrel and the injection rod comprises a charging barrel, wherein a plurality of hydraulic cylinders are evenly arranged at the front end of the arc face of the charging barrel, the hydraulic cylinders and the charging barrel are connected together through bolts, pressing heads are arranged at the output ends of the hydraulic cylinders, the pressing heads and the output ends of the hydraulic cylinders are connected together through bolts, an injection rod is arranged at the front end of the charging barrel, and an injection plunger is arranged at the end, aligned with the front end of the charging barrel, of the injection rod. By the adoption of the charging barrel and injection rod assembly of the die-casting machine, the problems that in the existing die-casting industry, due to the fact that continuous lubrication cannot be achieved between a die-casting machine charging barrel and the injection plunger, the replacement frequency of the injection plunger is high, the standby time of the machine is long, the consumable cost of die-casting is high, and the production efficiency is high are solved. By improving and optimizing the structure of the die-casting machine charging barrel and the injection rod, the concentricity of the injection plunger and the charging barrel in the injection process is automatically corrected, and meanwhile it is guaranteed that continuous lubrication can be achieved between the injection plunger and the die-casting machine charging barrel when the injection plunger and the die-casting machine charging barrel are used in cooperation.

Owner:常州业能压铸材料有限公司

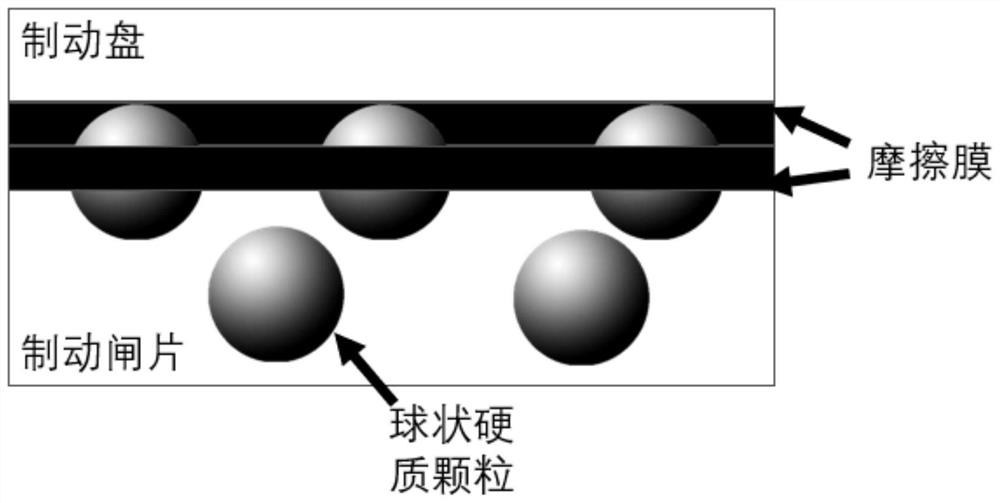

Powder metallurgy brake pad matched with carbon-ceramic brake disc and preparation method

ActiveCN112059171AHigh strengthWide variety of sourcesTransportation and packagingMetal-working apparatusPearlitePowder metallurgy

The invention discloses a powder metallurgy brake pad matched with a carbon-ceramic disc and a preparation method of the powder metallurgy brake pad. The components comprise iron powder, copper powder, flake graphite, graphene, ferrous sulfide powder, spherical chromium powder, molybdenum powder, ferrochrome powder, ferromolybdenum alloy powder, silicon carbide and titanium dioxide. The prepared iron-based brake pad is formed through the steps of powder mixing, pressing and sintering under oscillation pressure, and has the outstanding advantages that (1) the iron powder is high in strength, wide in source and low in price; (2) the graphene is uniformly distributed in the matrix and reacts with iron to generate pearlite, so that the strength of the matrix is further improved, and the friction coefficient stability and wear resistance at high temperature are improved; and (3) spherical hard particles are well combined with the interface of the iron matrix, and the damage to the carbon ceramic disc is small. The copper-based brake pad prepared through the method can be matched with the carbon ceramic disc to provide a stable and high friction coefficient and lower abrasion loss at a high speed, the service life of the brake disc is prolonged, and the copper-based brake pad is easy to prepare, low in cost and applicable to a high-speed railway train brake system with the speed of 350km / h or above.

Owner:UNIV OF SCI & TECH BEIJING

Dual mechanical seal with embedded bearing for volatile fluids

ActiveUS20150167671A1Avoid contactGuaranteed continuous lubricationOscillating piston enginesSealing arrangement for pumpsBall bearingDrive shaft

A fluid pump configured to prevent contact between volatile fluids and a ball bearing of the pump while providing the ball bearing with adequate lubrication. The fluid pump includes a pump casing having a fluid inlet and a fluid outlet, and a rotor set disposed within the pump casing for conveying fluid from the fluid inlet to the fluid outlet. The fluid pump further includes a recirculation chamber located adjacent the fluid outlet for collecting leaked fluid. The leaked fluid may be conveyed from the recirculation chamber back to the fluid inlet due to a pressure differential therebetween. The fluid pump may further include first and second seals that surround a drive shaft of the rotor, the first and second fluid seals defining a lubricant compartment therebetween that houses a ball bearing of the pump and that is filled with a continuously circulated, nonvolatile lubricant.

Owner:CIRCOR PUMPS NORTH AMERICA LLC

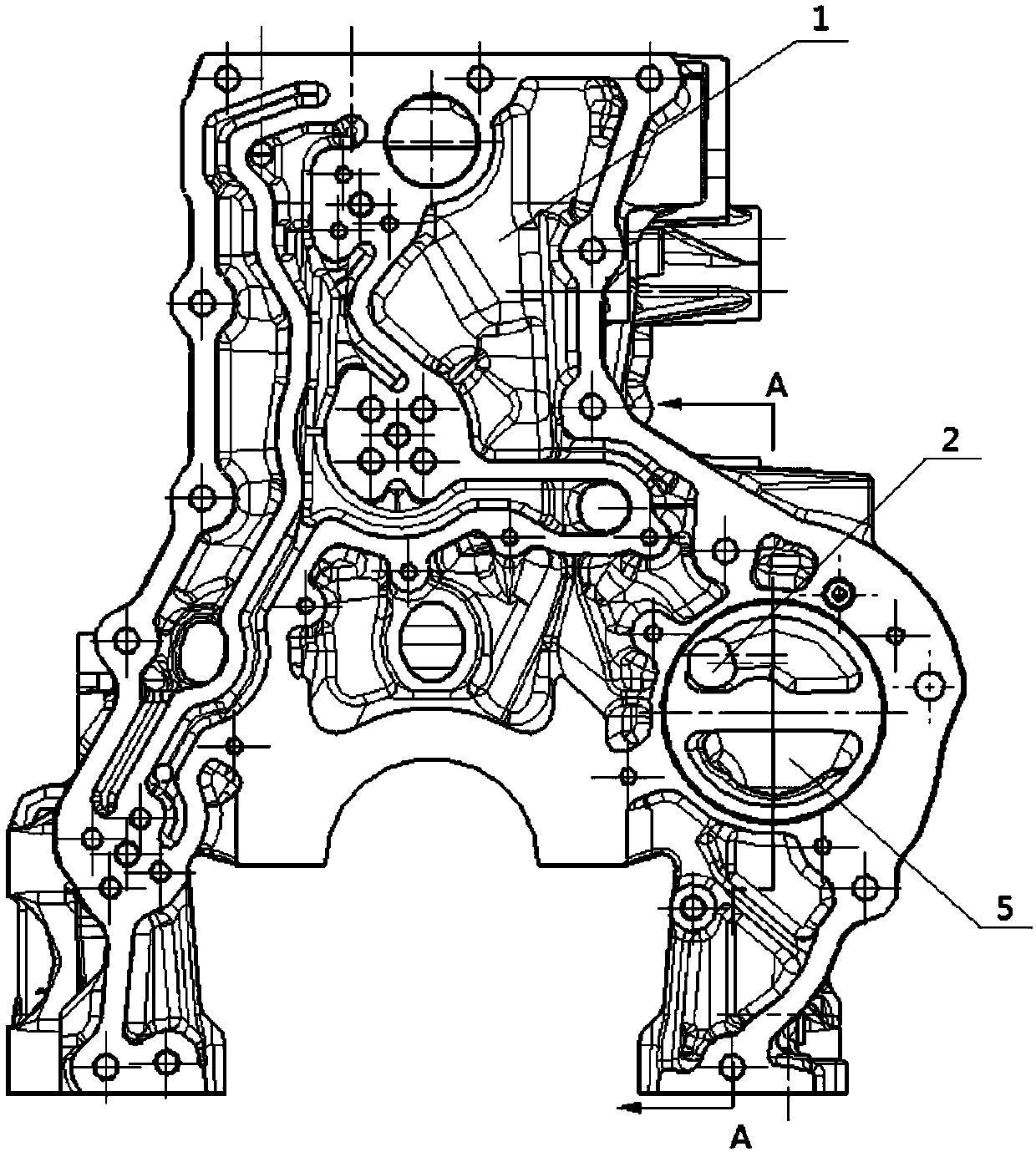

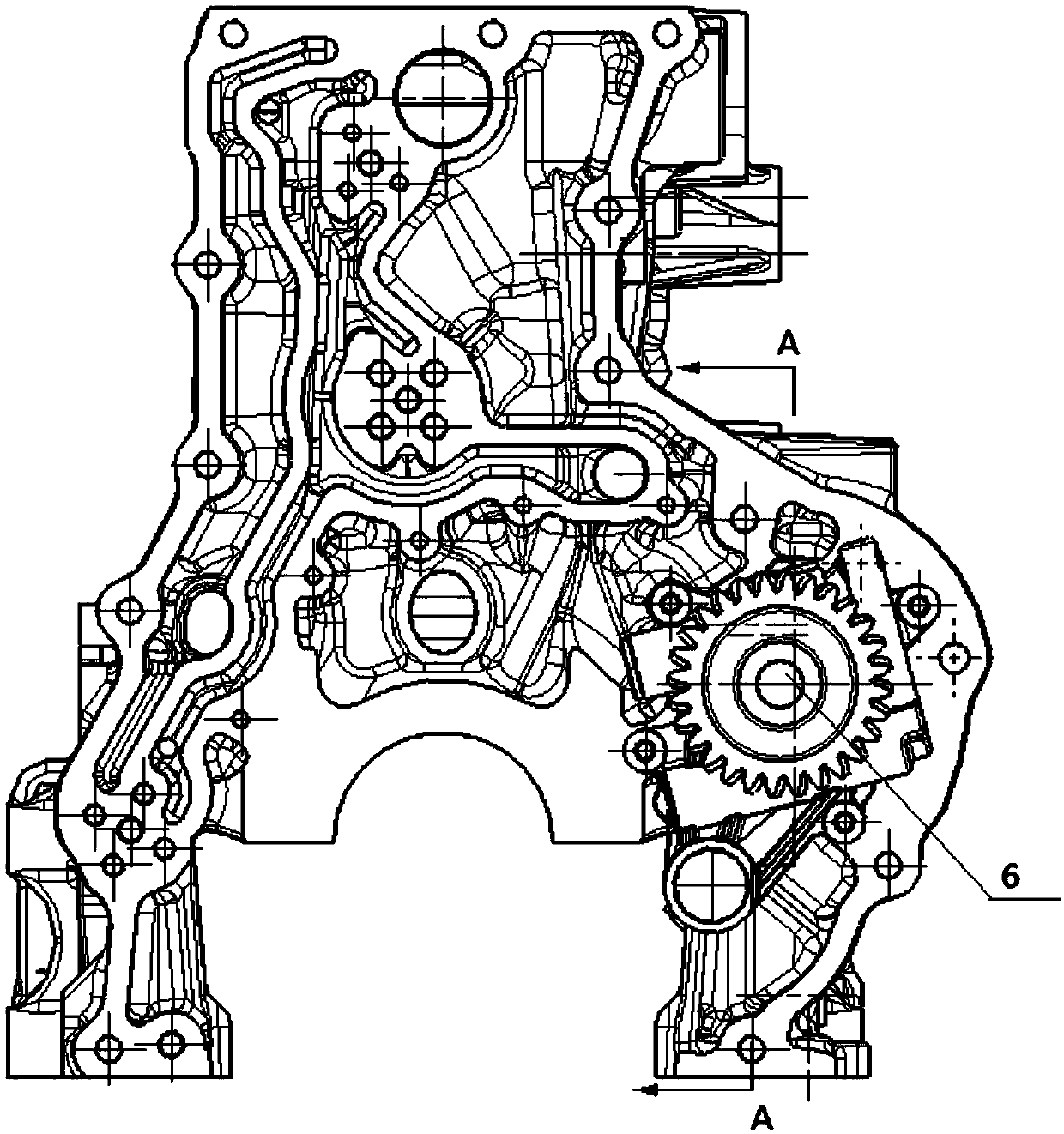

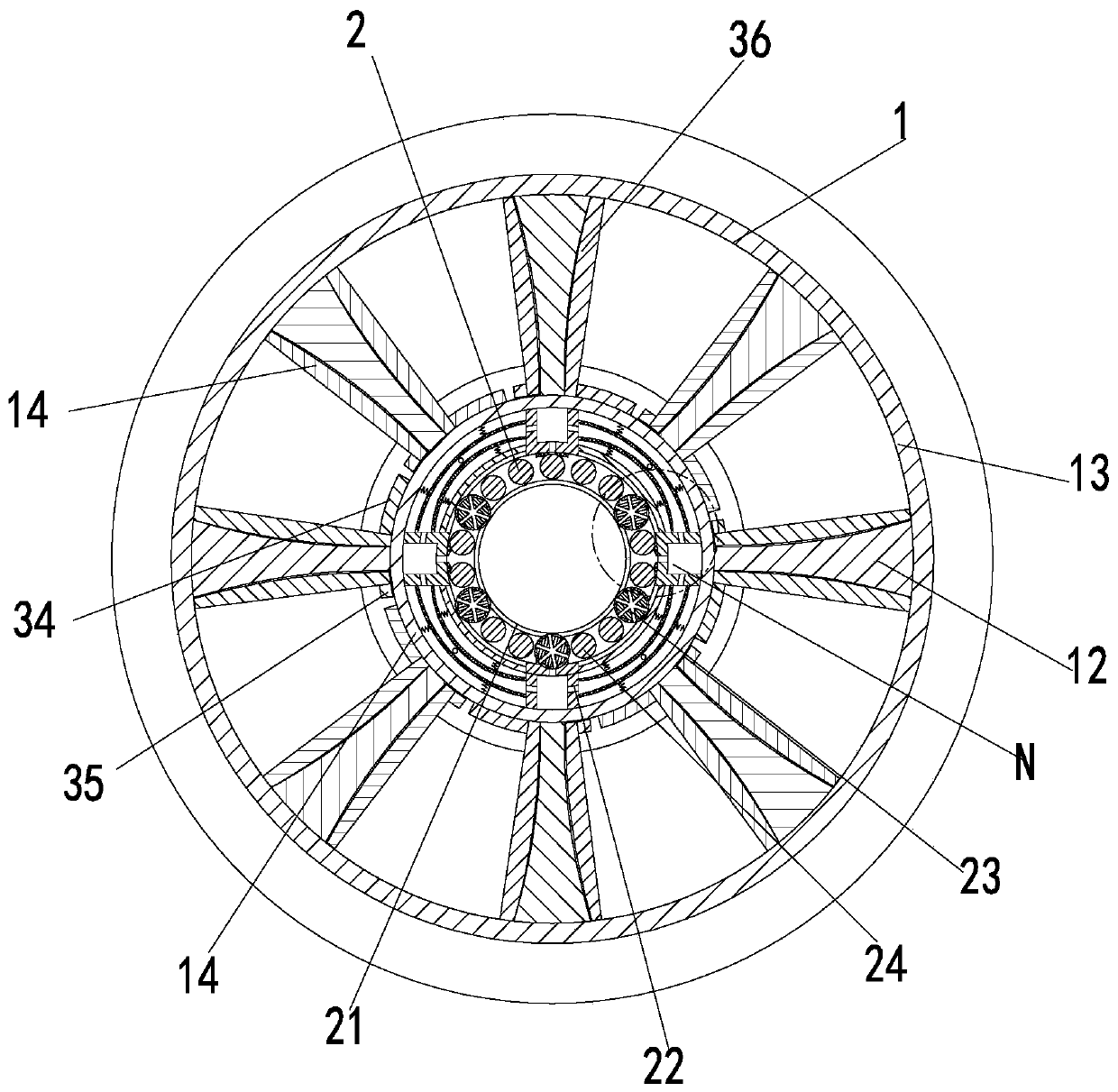

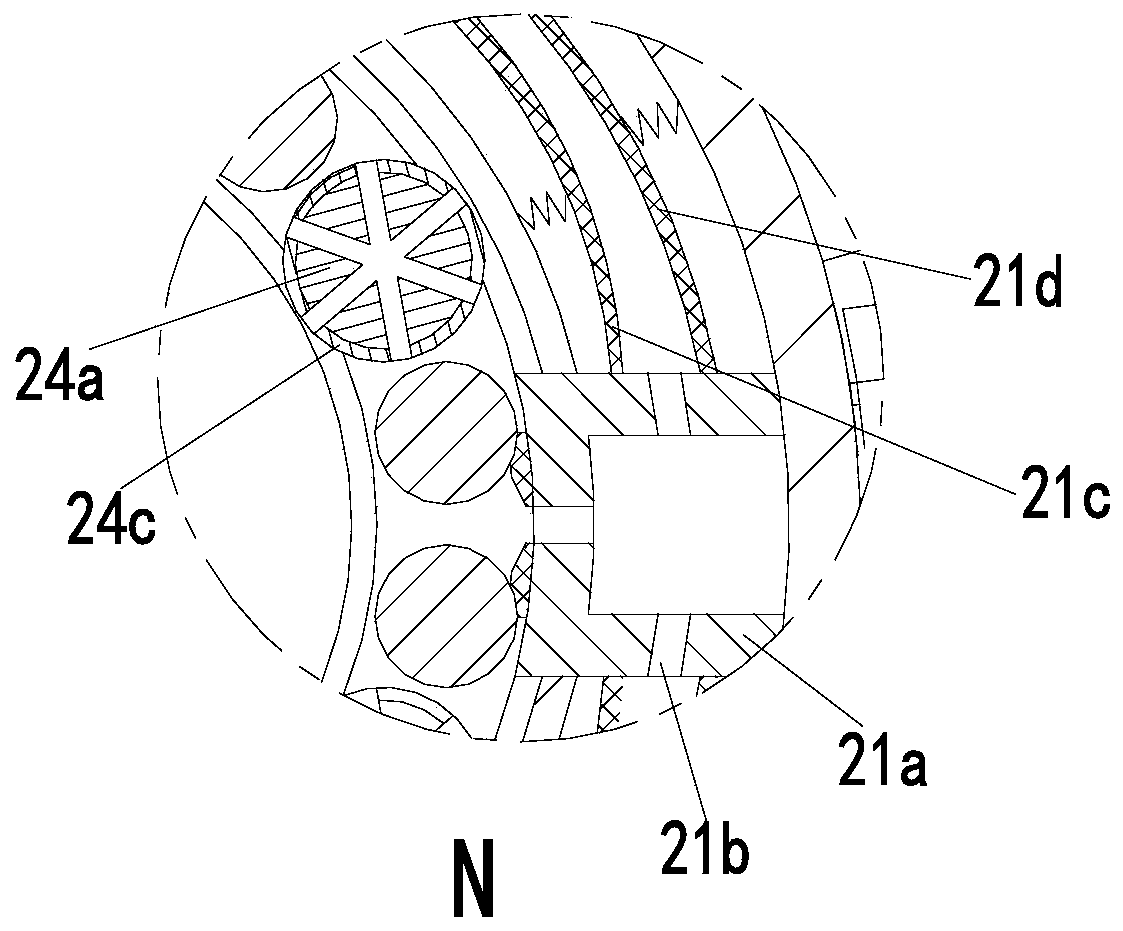

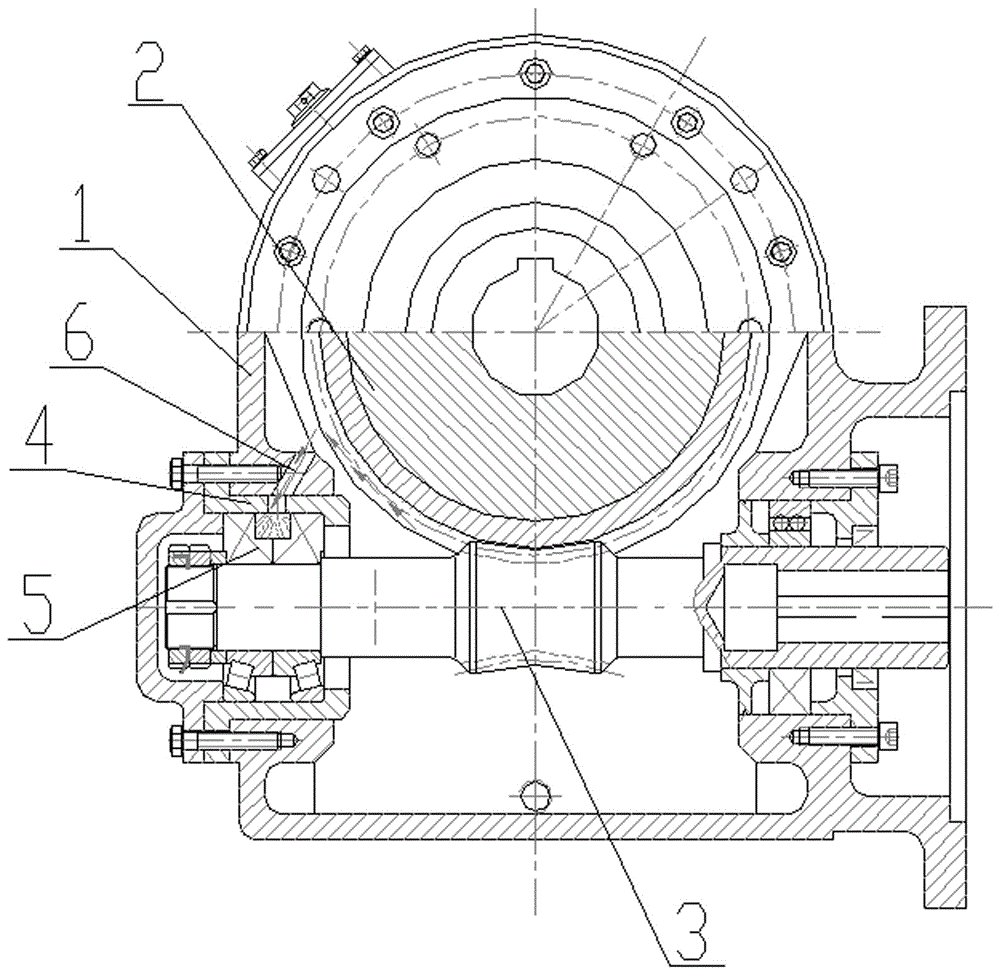

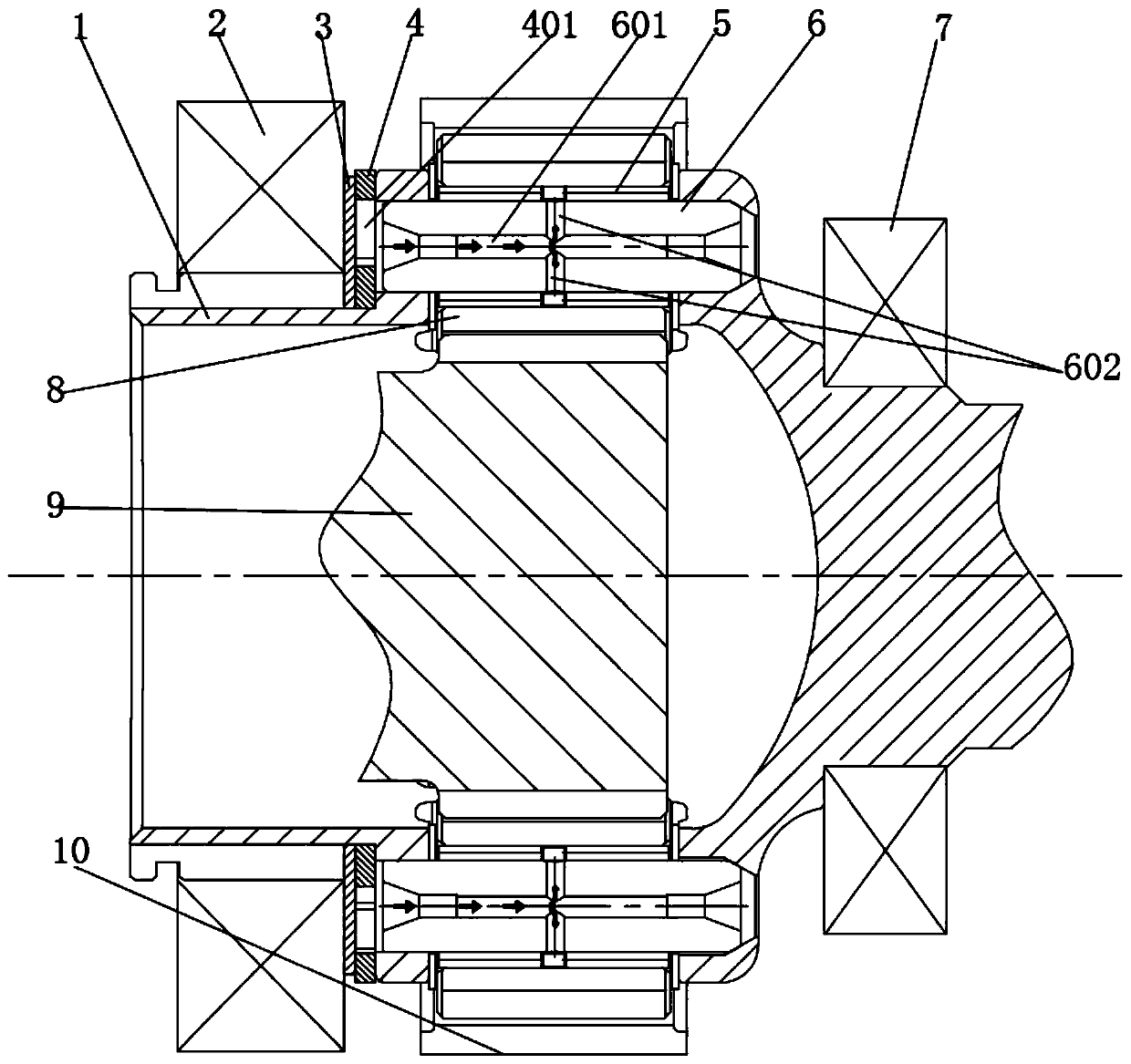

A planetary gear train bearing lubrication structure

ActiveCN109826942BGuaranteed continuous lubricationImprove the lubrication effectGear lubrication/coolingGear trainMechanical engineering

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

Speed reducer for worm wheel to throw oil so as to lubricate bearing

InactiveCN106224519AGuaranteed continuous lubricationLubrication is maintained continuouslyGear lubrication/coolingLubricationReducer

The invention relates to a speed reducer for a worm wheel to throw oil so as to lubricate a bearing. The speed reducer comprises a shell, the worm wheel and a worm. The worm is supported in the shell through a bearing block. An oil groove is formed in the inner wall of the part, below the worm wheel rotation tangent line position corresponding to the position above the bearing block, of the shell. The oil groove communicates with the bearing supporting the worm in the bearing block through oil ways on the shell and the bearing block, wherein the oil ways communicate with one another. The oil groove is formed in the inner wall of the part, below the worm wheel rotation tangent line position corresponding to the position above the bearing block, of the shell to collect oil, oil passes through the oil ways to lubricate the bearing, the shell communicates with the bearing block through the oil ways, the worm wheel throws lubricating oil in the shell out in the tangent line direction during rotation, the lubricating oil enters the oil groove or the oil ways below the worm wheel, and no power device needs to be additionally arranged; and lubrication can be continuously kept when the worm wheel works, it is ensured that the worm supports the continuous lubrication of the bearing, and the service life is better prolonged.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Planetary gear train bearing lubricating structure

ActiveCN109826942AGuaranteed continuous lubricationImprove the lubrication effectGear lubrication/coolingEngineeringGear train

The invention provides a planetary gear train bearing lubricating structure. A planetary gear train comprises a planet carrier, a plurality of planetary gears installed on the planet carrier through planetary gear shafts, and a bearing arranged between the planetary gears and the planetary gear shafts. The planetary gear train bearing lubricating structure comprises axial holes, at least one through hole, oil collecting plates and an oil pool, wherein the axial holes are distributed in the axial direction of the planetary gear shafts; the through holes extend from the axial holes to the diametric planes of the planetary gear shafts; at least one ends of the planetary gear shafts are provided with the oil collecting plates, the oil collecting plates are installed on the planet carrier, thepositions, opposite to the axial holes of the ends of the planetary gear shafts, of the oil collecting plates are provided with oil collecting grooves correspondingly, the opening direction of the oilcollecting tanks is consistent with the rotating direction of the planet carrier, and the oil collecting tank, the axial holes and the through holes form oil way channels for allowing lubricating oilto circulate; and the oil pool is located in a shell of the planetary gear train. The oil collecting plates rotate, when the oil collecting grooves rotate and pass through the oil pool, the lubricating oil is collected and conveyed to the outside of the planetary gear shafts through the oil way channels.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

Sealing structure of angle grinder gear box lubricated by lubricating oil and angle grinder

The invention discloses a sealing structure of an angle grinder gear box lubricated by lubricating oil and an angle grinder. The sealing structure of the angle grinder gear box lubricated by the lubricating oil comprises a shell, a transmission mechanism, a sealing assembly and liquid lubricating oil for lubrication. The transmission mechanism comprises a motor shaft, a driving gear, a driven gearand a driving output shaft, and the motor shaft and the driving output shaft are rotatably supported in the shell. The driving gear is assembled at the end of the motor shaft, the driven gear is assembled on the driving output shaft, and the driving gear and the driven gear are meshed and connected to form a rotary gear pair. The sealing assembly comprises an oil separation pressure reduction ring and a sealing ring, gap sealing is formed between the oil separation pressure reduction ring and the shaft, and contact sealing is achieved between the sealing ring and the shaft. The liquid lubricating oil is used in the gear box for the first time, the liquid lubricating oil can completely infiltrate and fully lubricate the meshed rotary gear pair, effective sealing can be achieved in the working state and the static state of the angle grinder, the sealing effect of the sealing assembly is matched, and therefore the service life of the angle grinder can be remarkably prolonged.

Owner:WUYI HENGYOU ELECTROCHEM ZHEJIANG PROV

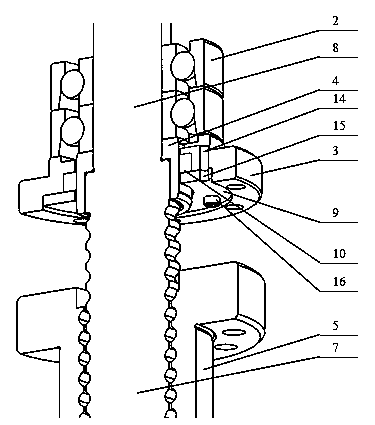

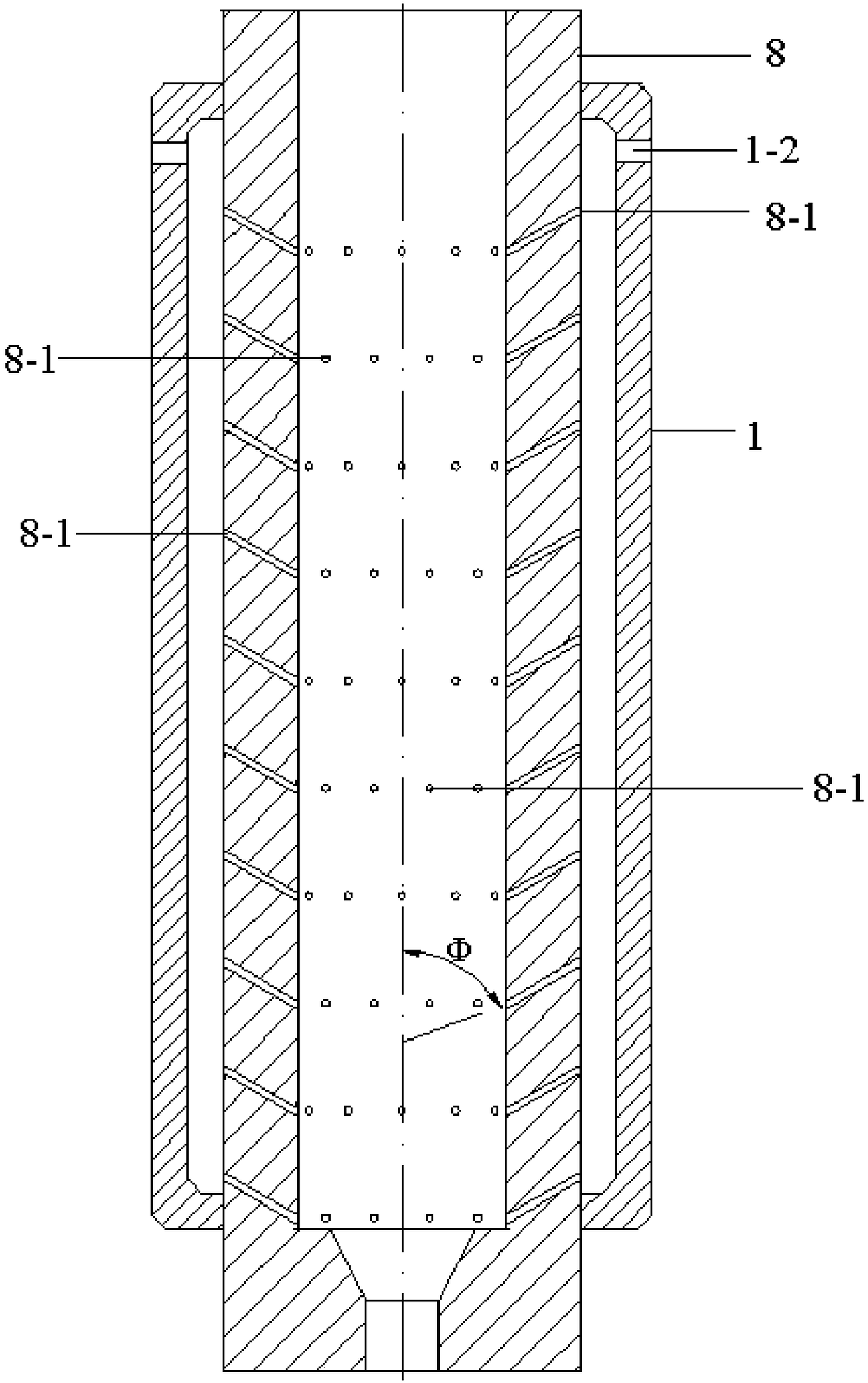

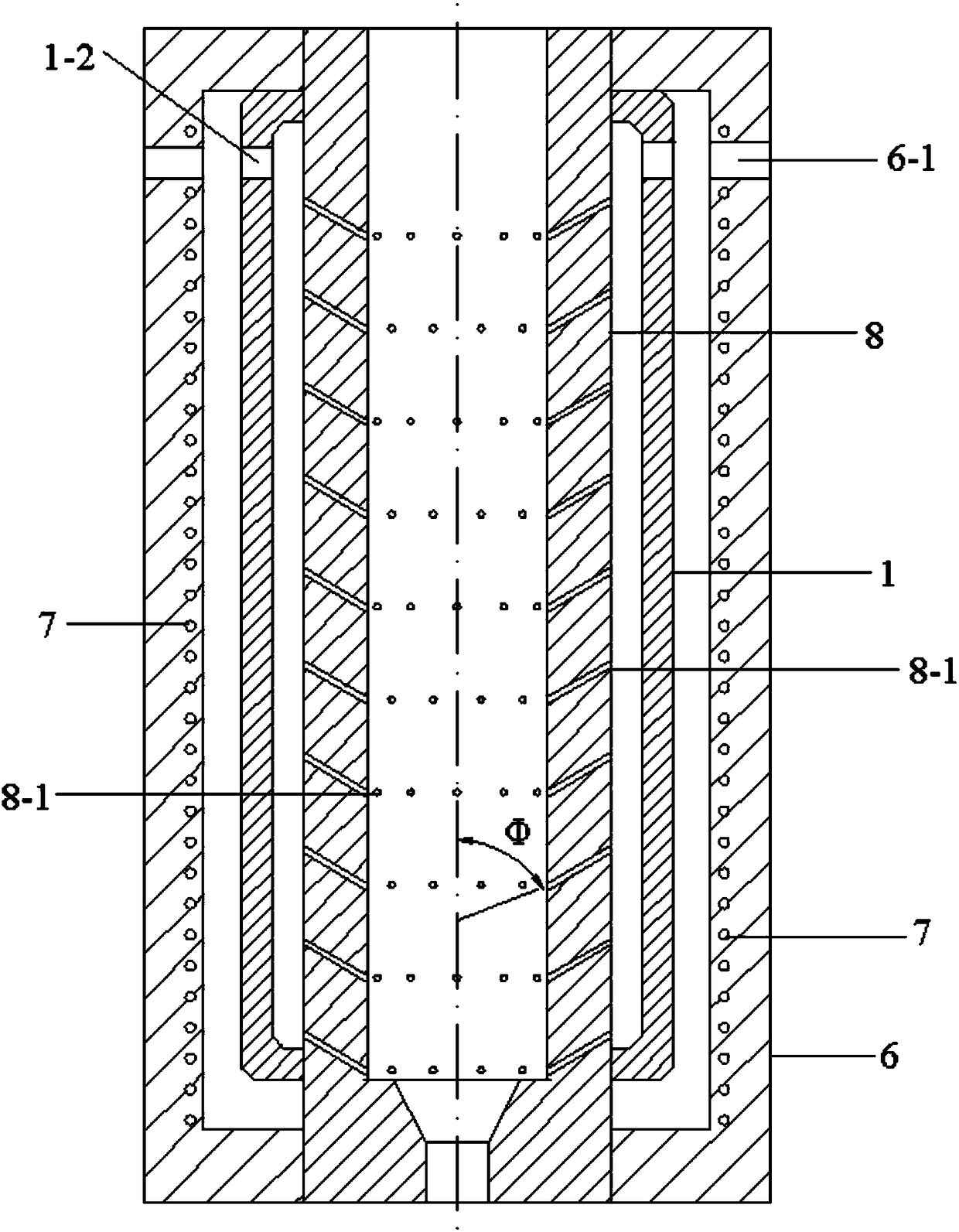

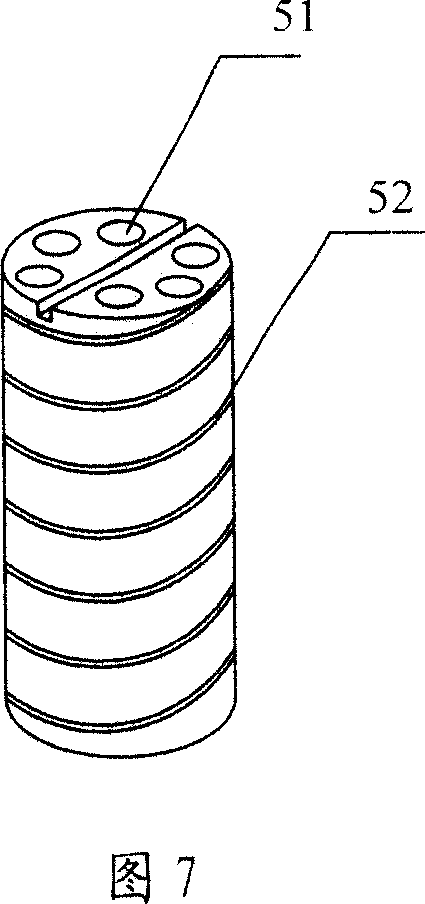

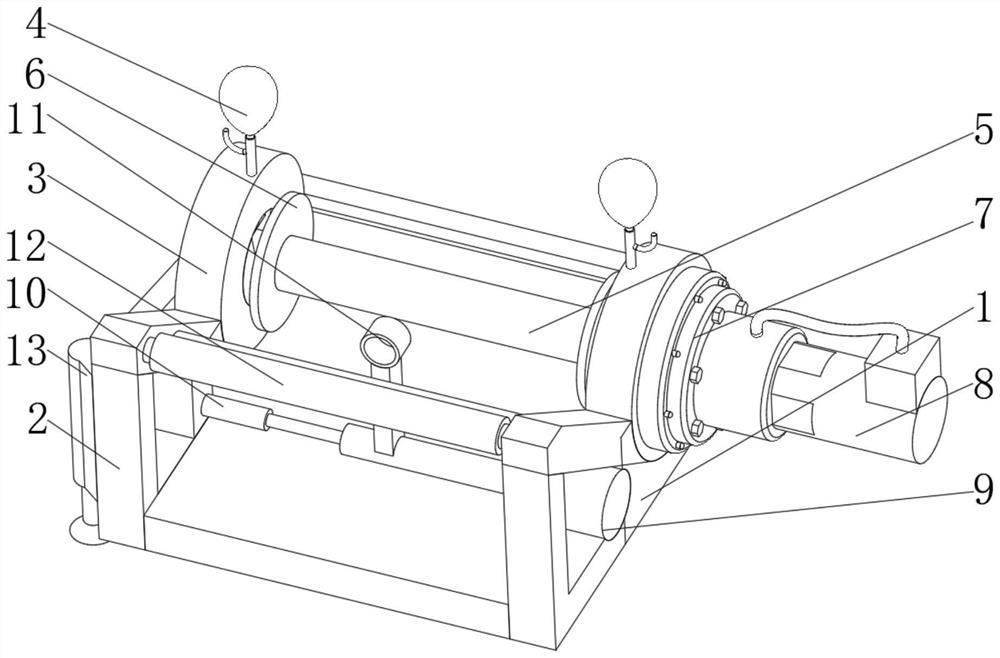

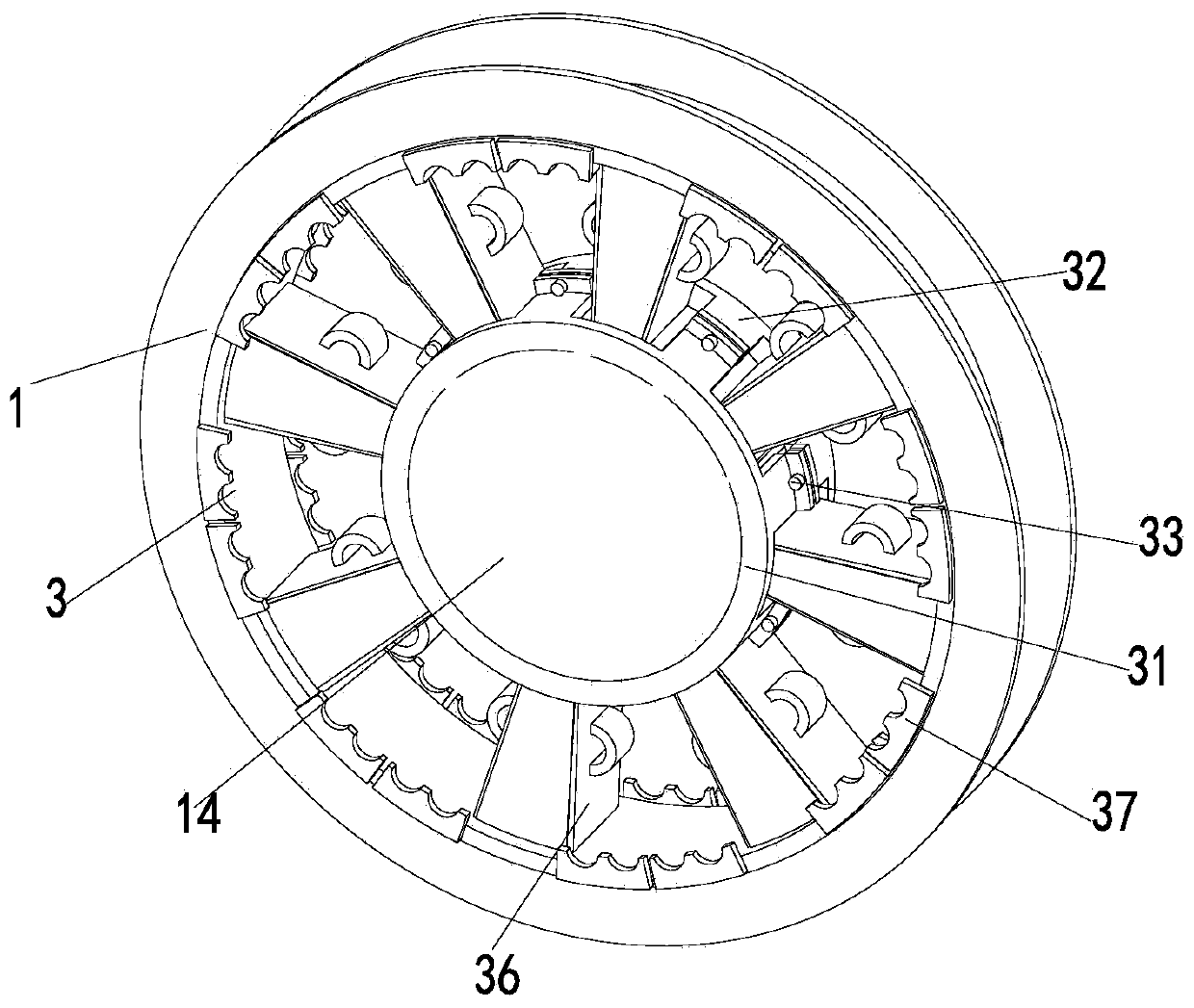

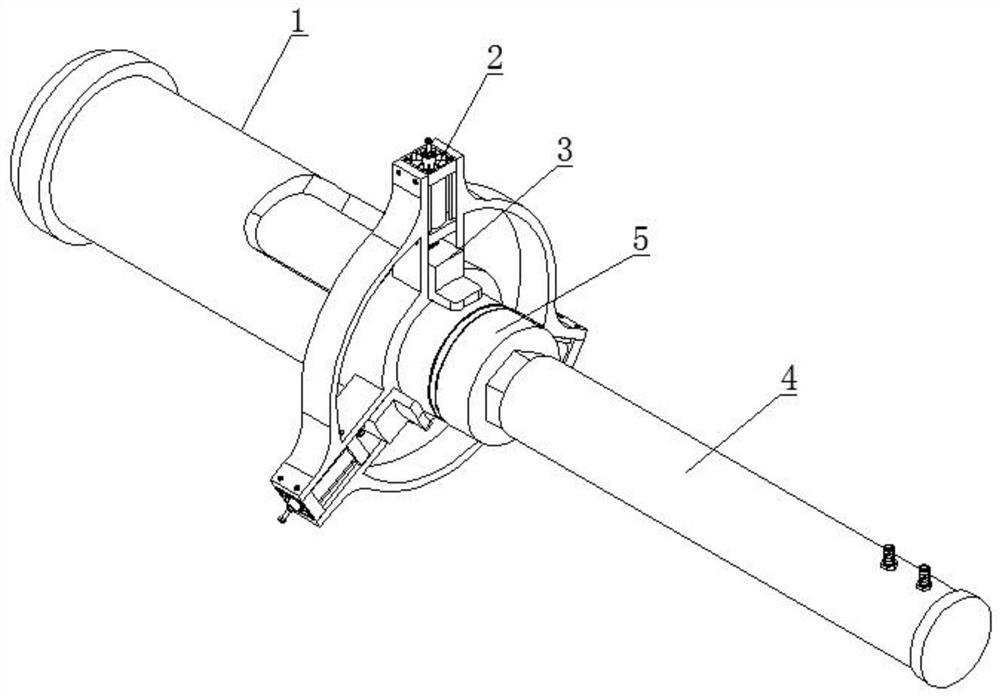

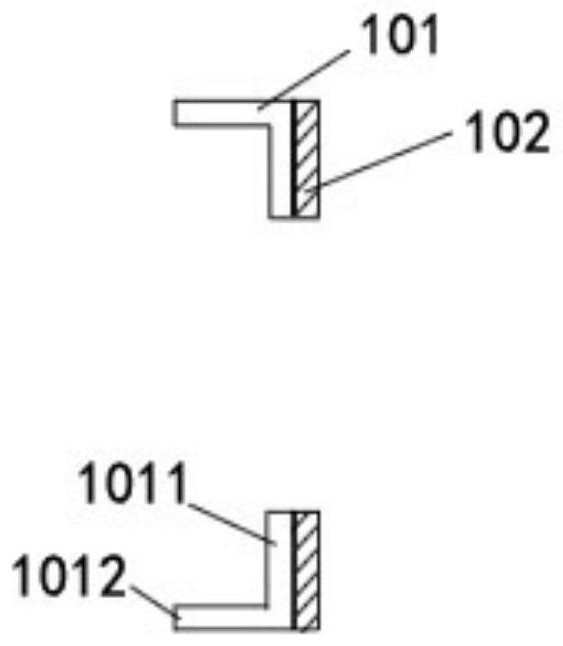

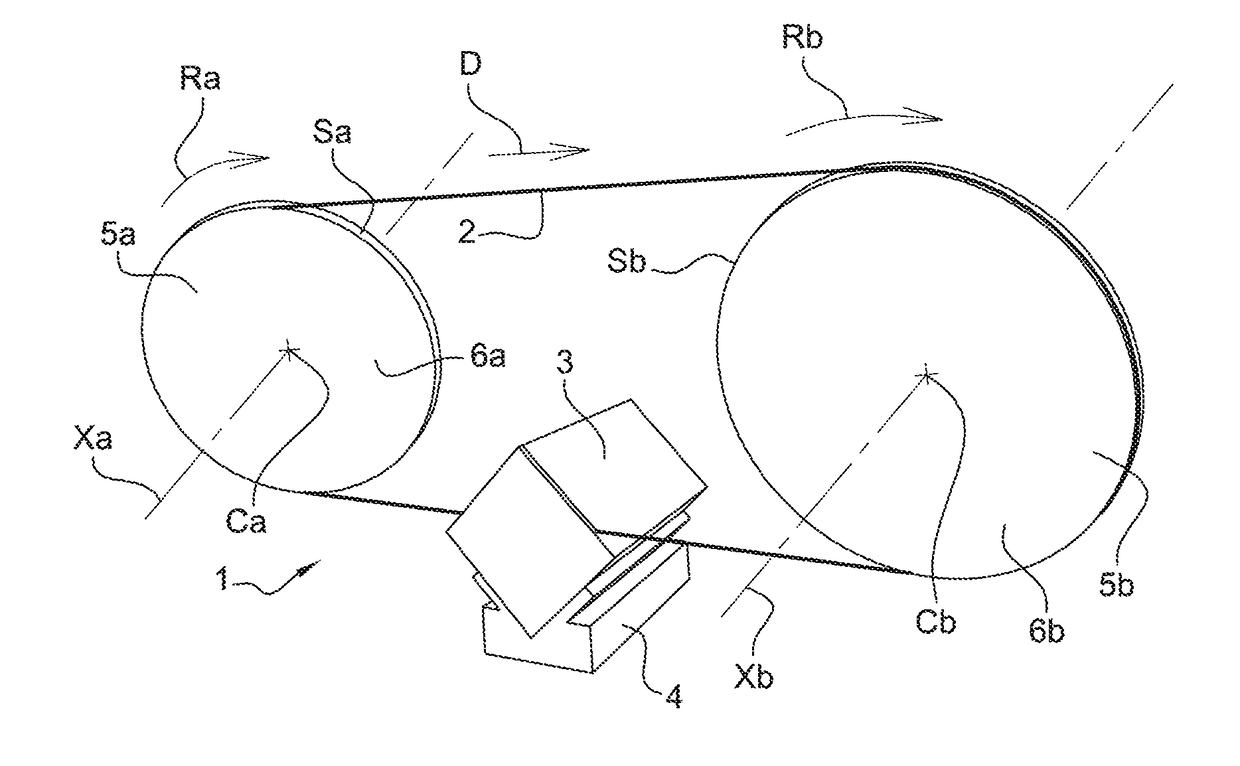

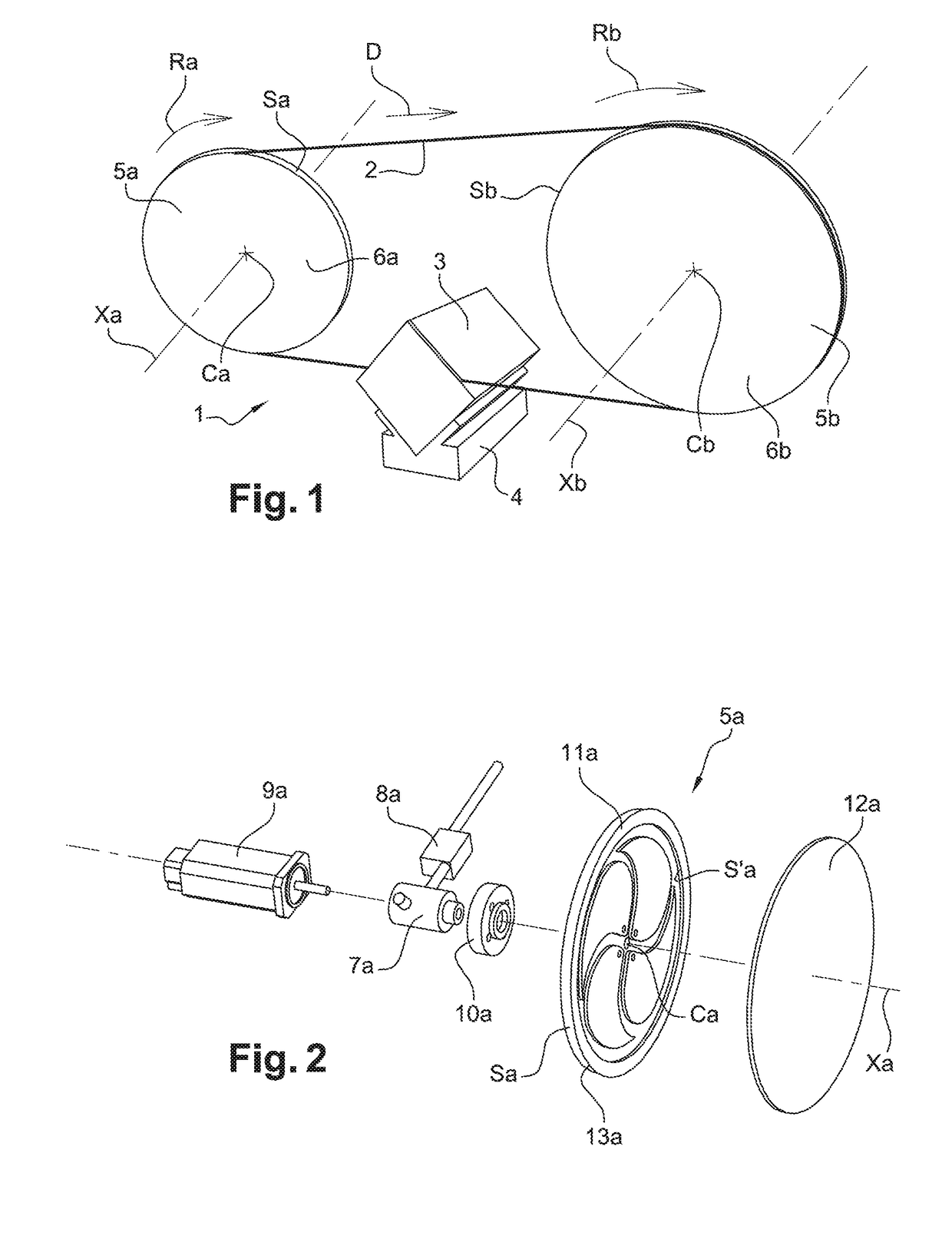

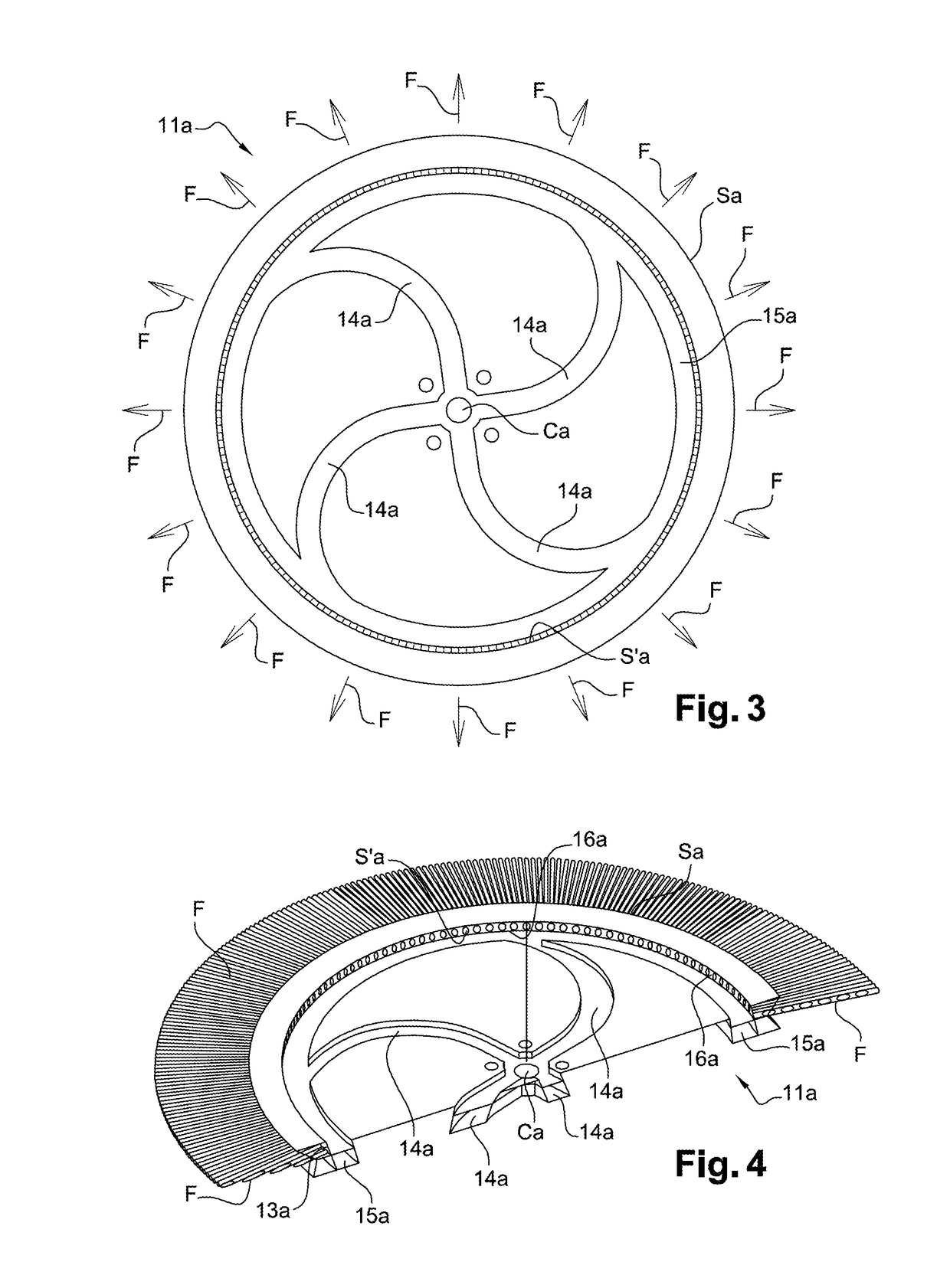

Wire cutting device comprising a rotary member provided with means for lubrication of the wire

InactiveUS20170136655A1Improve reliabilityGuaranteed continuous lubricationMetal sawing devicesFine working devicesWire cuttingEngineering

A device for cutting a wire piece, configured to move with respect to the wire piece, including: at least first and second rotary members rotating around respective first and second substantially parallel axes of rotation, the at least one first and second rotary members driving the wire substantially perpendicular to the first and second axes, the wire resting against external surfaces of each of the at least one first and second rotary members. At least one of the at least one first and second rotary members includes a lubrication mechanism of the wire to allow circulation of a lubricating liquid from the center thereof to an external surface thereof in contact with the wire, the lubrication mechanism including a lubrication liquid feed device, mounted on the axis of rotation of the at least one of the first and second rotary members, to supply the center thereof with lubrication liquid.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

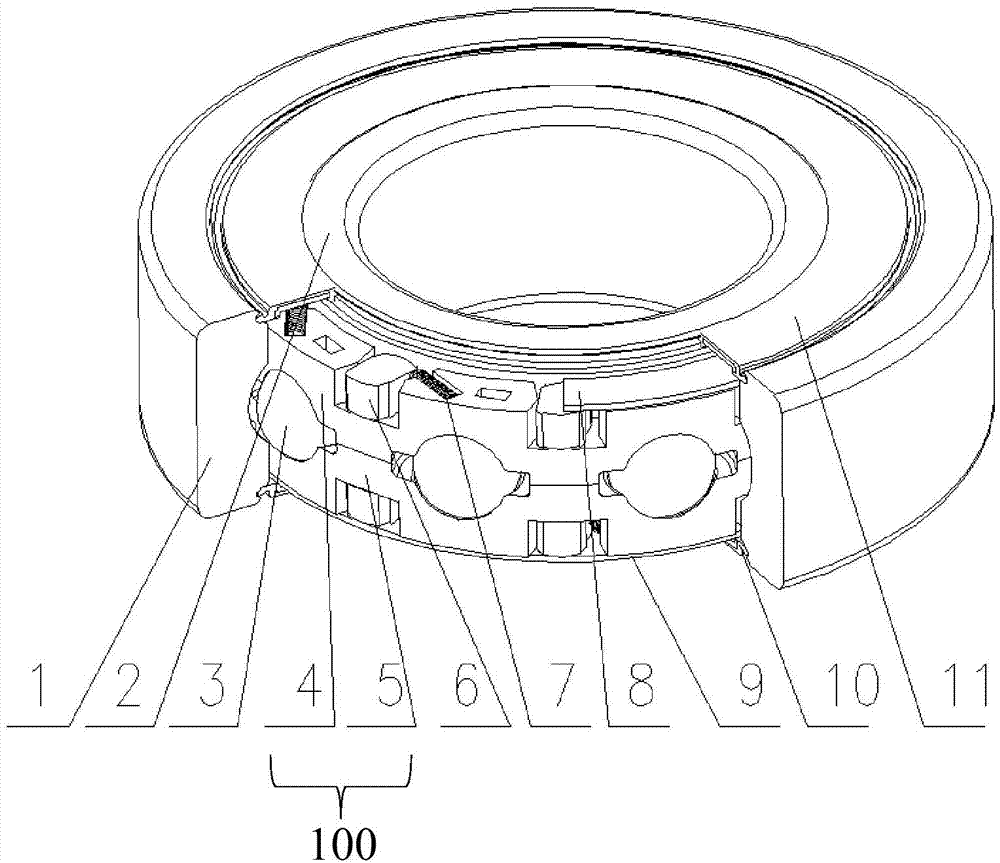

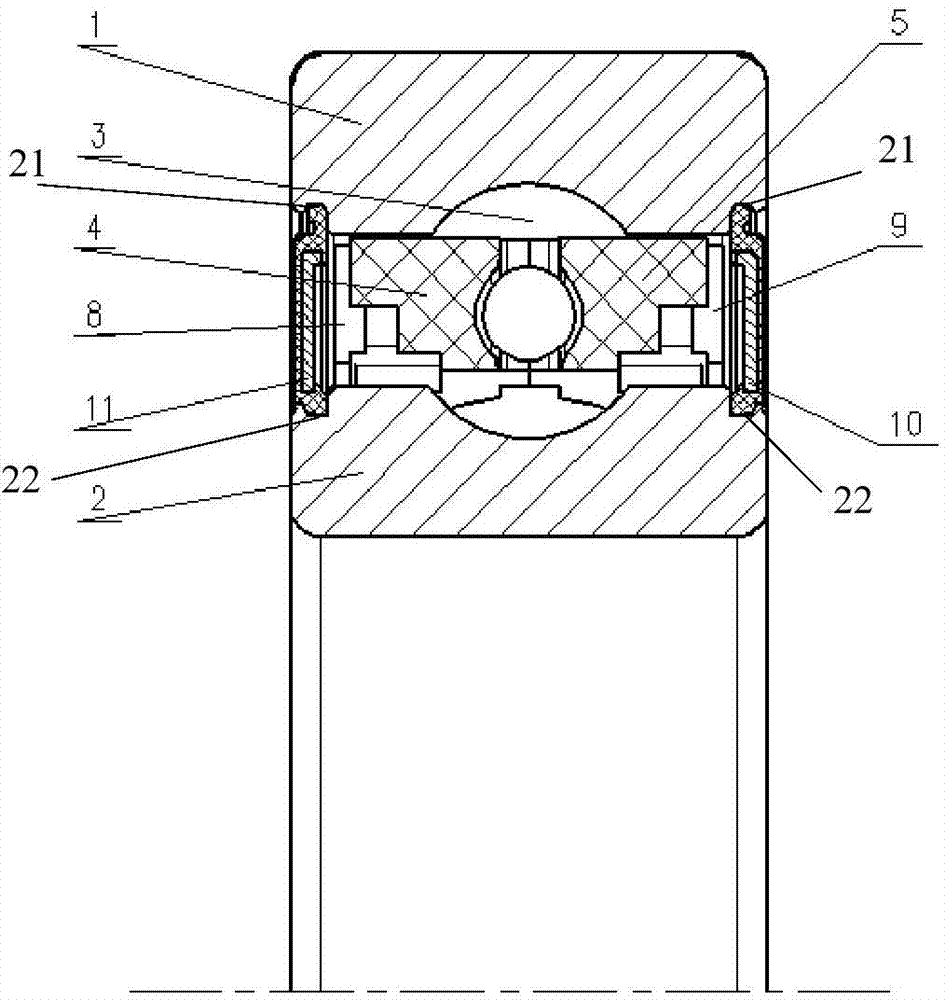

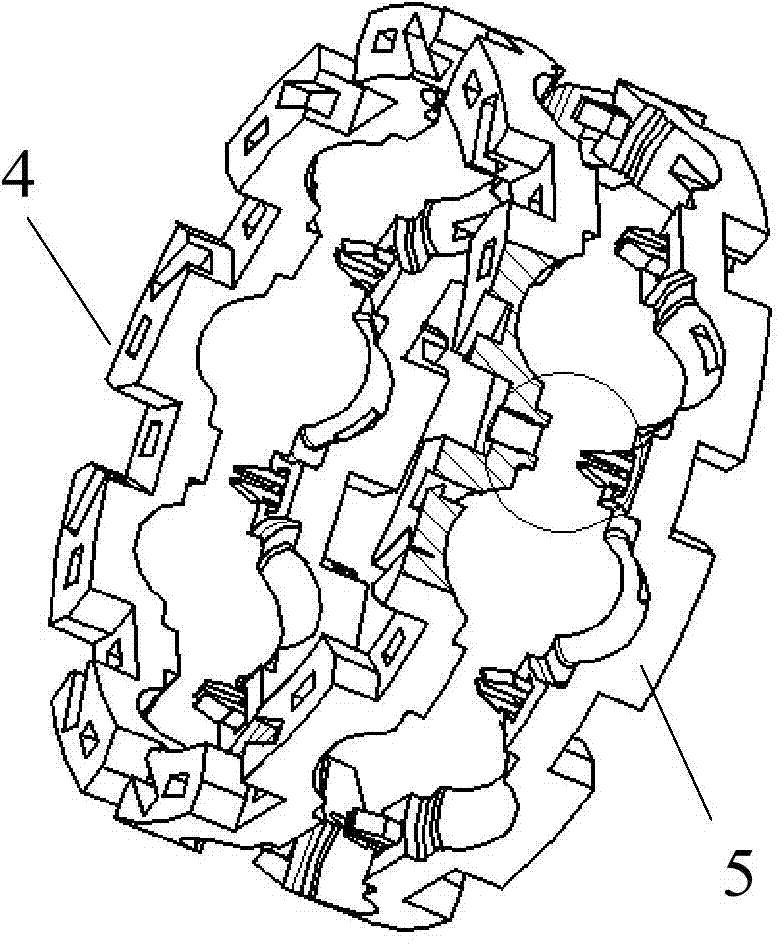

Double-wedge sealed buckled type reverse stop bearing

InactiveCN104728305ASave spaceComplete functional structureBearing assemblyBall bearingsSteel ballEngineering

The invention provides a double-wedge sealed buckled type reverse stop bearing which comprises a bearing outer ring, a bearing inner ring and steel balls. A double-wedge buckled type nylon retainer is arranged among the bearing outer ring, the bearing inner ring and the steel balls. The two sides of the retainer are both provided with multiple wedge block slots and spring slots. Wedge blocks and springs are arranged in the wedge block slots and the spring slots. The springs abut against the retainer and the wedge blocks, so that the wedge blocks are in contact with the outer ring and the inner ring, and the wedges are combined inversely and unbound forwards. An upper fixing cover and a lower fixing cover are assembled to the upper side face and the lower side face of the retainer respectively, and it is guaranteed that the wedge blocks and the springs are both at working positions. The steel balls are arranged in the middle of the bearing, the two sides of the bearing are both evenly provided with the wedge blocks, the springs enable the wedge blocks to be stressed evenly and stably, the buckling joints of the steel balls and the retainer are specially designed, continuous oil supply for the steel balls is guaranteed, a double-faced sealing structure is adopted, and therefore moisture in a washing machine can be effectively prevented from intruding into the bearing. Accordingly, a higher load requirement is met, the reliability is improved, noise is lowered, and the service life is prolonged.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com