Backing roller core shaft

A backing and roll core technology, applied in the field of friction lubrication of rolling mills, can solve the problems of limited lubricating oil storage space, shutdown lubrication, unstable lubrication effect, etc., and achieve good lubrication effect and good lubrication effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

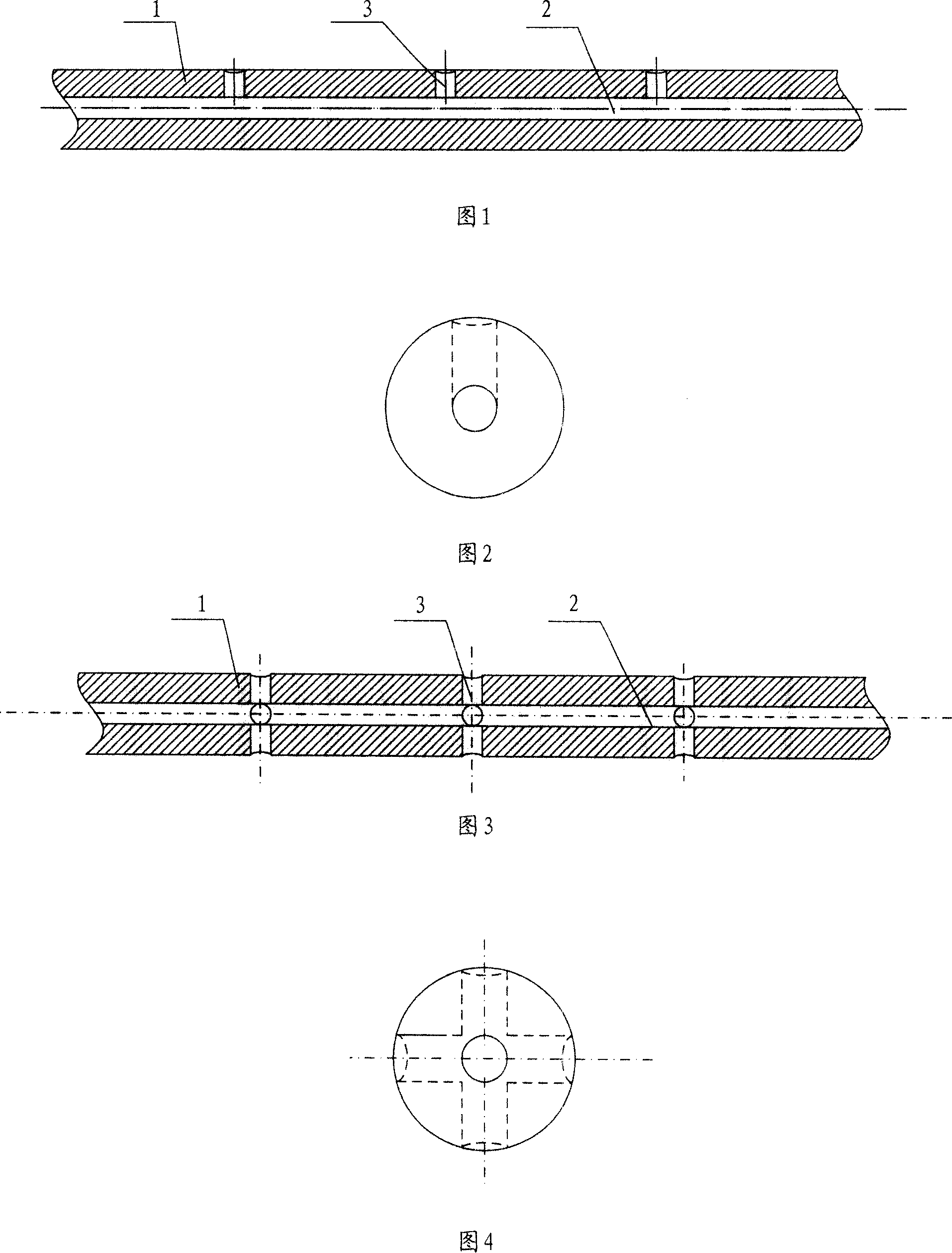

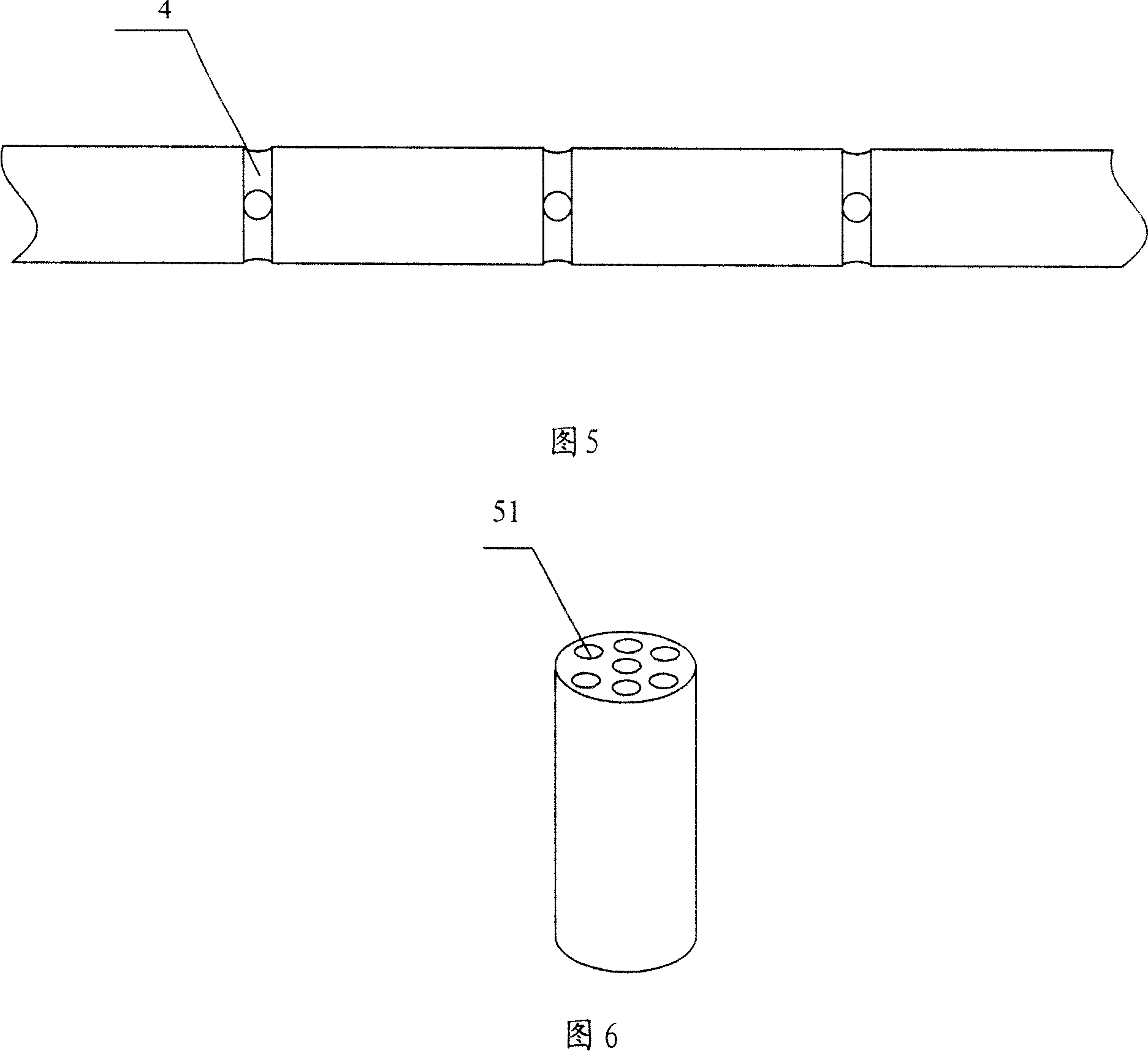

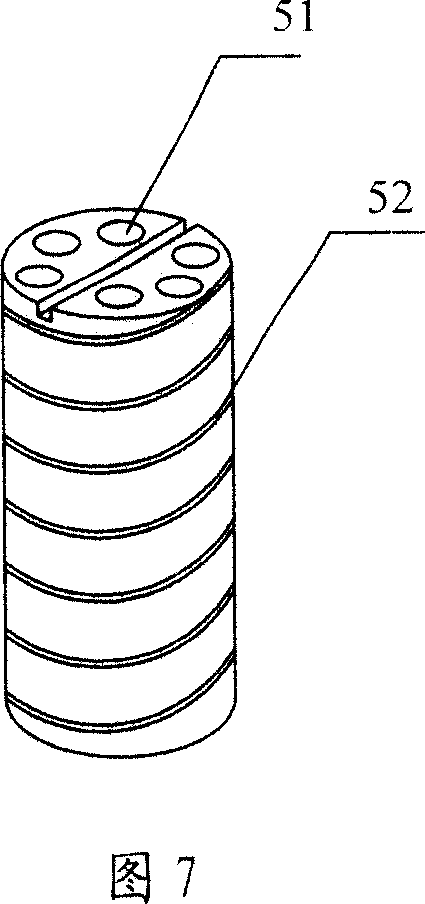

[0022] Please refer to Fig. 1 and Fig. 2. Fig. 1 is an axial sectional view of Embodiment 1 of the backing roller mandrel of the present invention, and Fig. 2 is a left view of Embodiment 1 of the backing roller mandrel of the present invention, combined with Fig. 1 and Fig. 2 The structure of the present invention can be understood more clearly. As shown in the figure, the mandrel of the backing roller includes a shaft body 1, and the shaft body 1 has a channel 2 in the axial direction for conveying lubricating oil. middle. The shaft body 1 is radially opened with an oil hole 3 , and the oil hole 3 penetrates through the channel 2 from the outer surface of the core shaft body 1 . The lubricating oil seeps out through the oil hole 3, and the backing roller bearing is installed at the position of the oil hole 3, the outer surface of the bearing is in contact with the middle support roller, and the inner surface of the bearing is in contact with the outer surface of the mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com