180-m large-span steel pipe arch pouring method

A steel pipe arch and large-span technology, applied in the field of steel pipe arch pouring, can solve problems such as unreasonable concrete configuration, interrupted cavity site, improper cooling measures, etc., achieve continuous and uninterrupted concrete supply, slow down the solidification speed, and reduce the effect of steel pipe temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

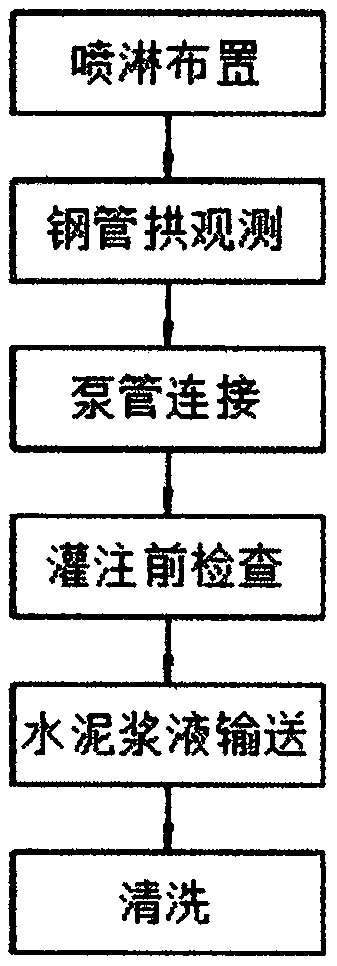

[0024] A method for pouring a 180m long-span steel pipe arch, comprising the following steps:

[0025] Step 1: Sprinkler layout: the pump pipe joints are arranged on the vault, and the automatic sprinkler devices are arranged at an interval of two meters to effectively reduce the temperature of the steel pipes and ensure that the concrete solidification speed is slowed down;

[0026] Step 2: Steel pipe arch observation: Concrete is pressed to each control point, and the arch axis and elevation are measured once, and the measurement results are drawn as a curve with time or working conditions. According to this curve, the steel pipe can be understood more intuitively The changes of the arch during the various stages of pumping concrete;

[0027] Step 3: Pump pipe connection: connect the pump pipe to multiple tank trucks, and use multiple tank trucks to continuously pump concrete to ensure continuous and uninterrupted concrete supply. There are high-power concrete pumps fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com