Patents

Literature

45results about How to "Reduce overpressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipeline protection systems

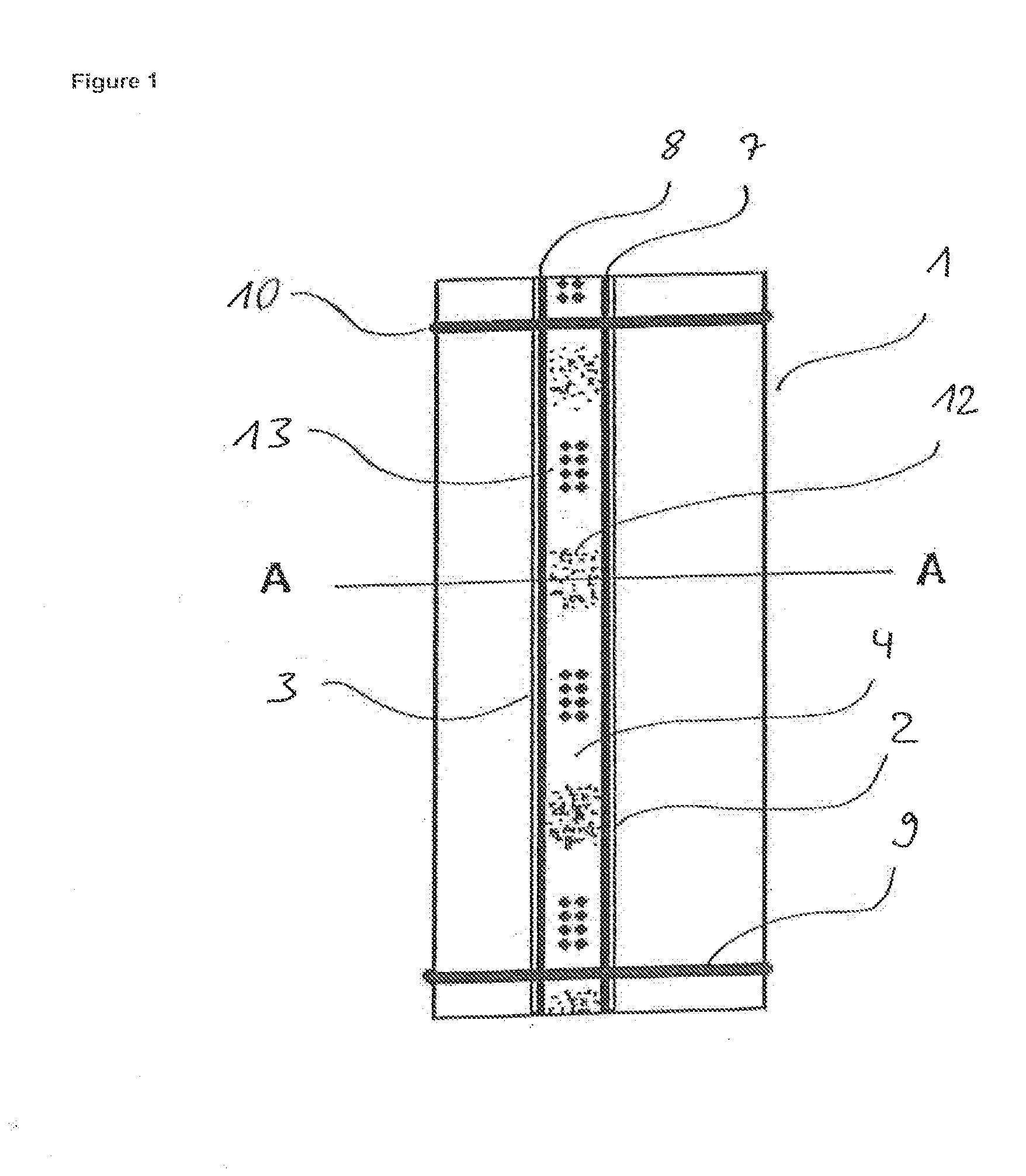

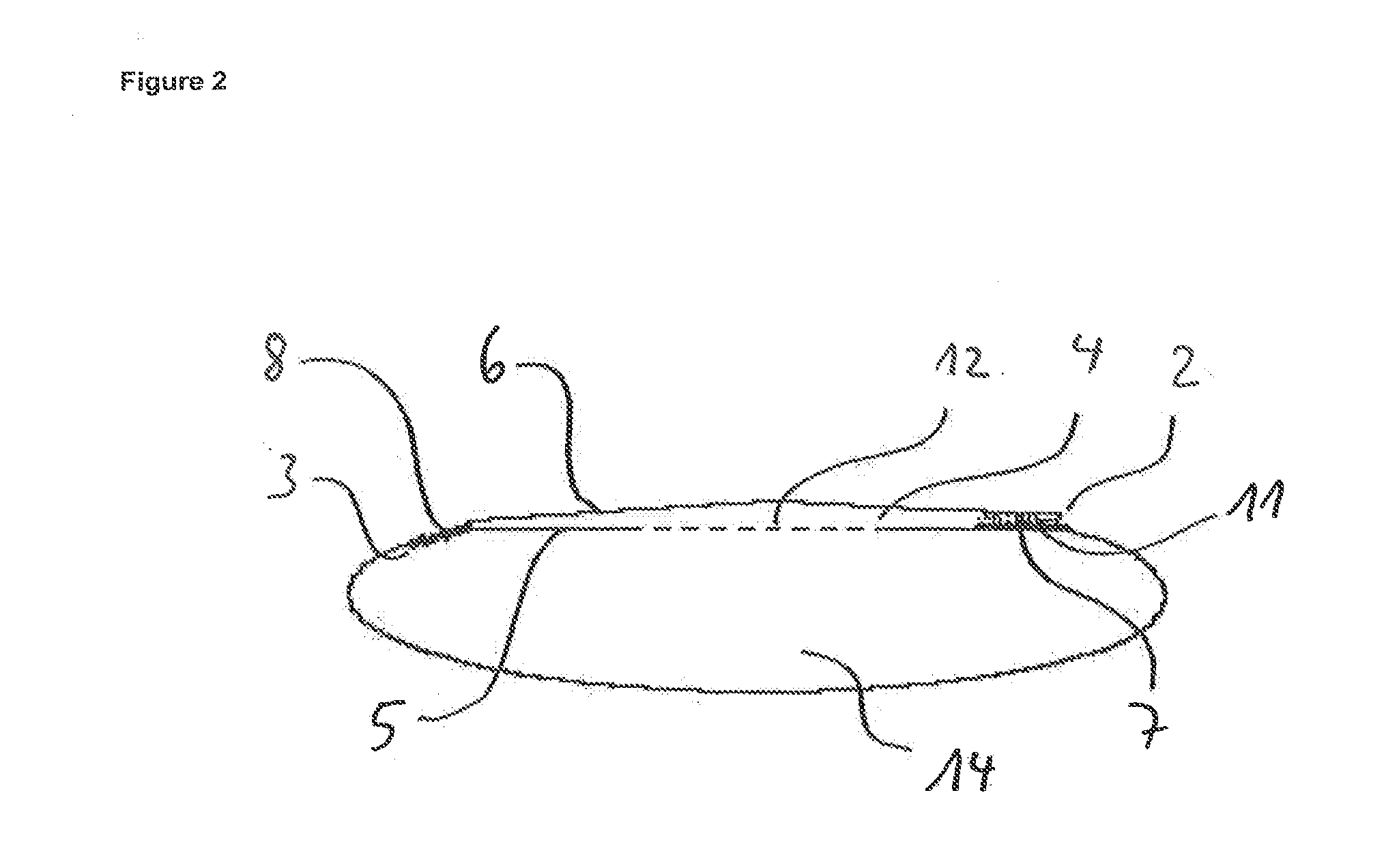

InactiveUS20110240157A1Risk minimizationOverpressure is reducedEqualizing valvesSafety valvesEngineeringProtection system

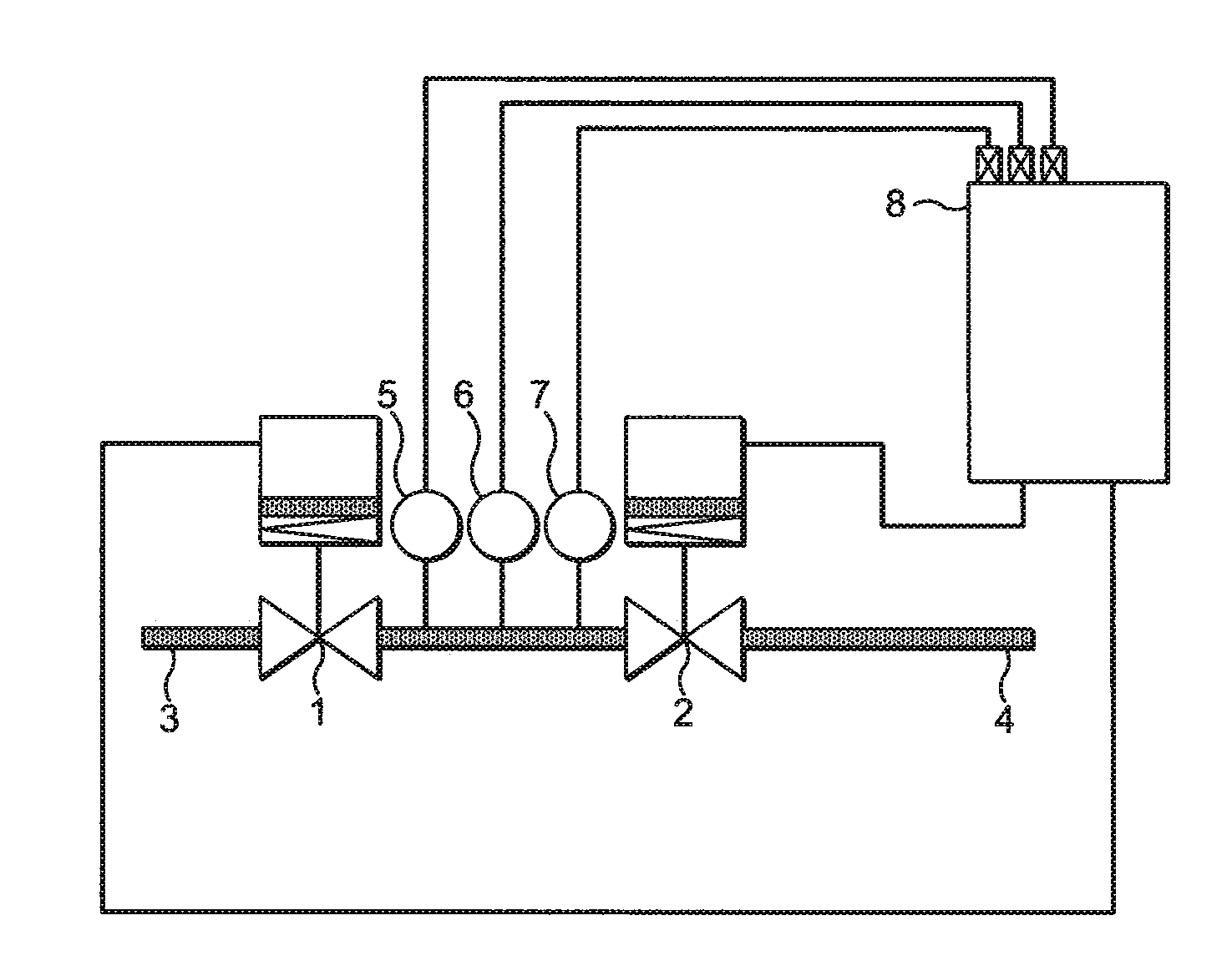

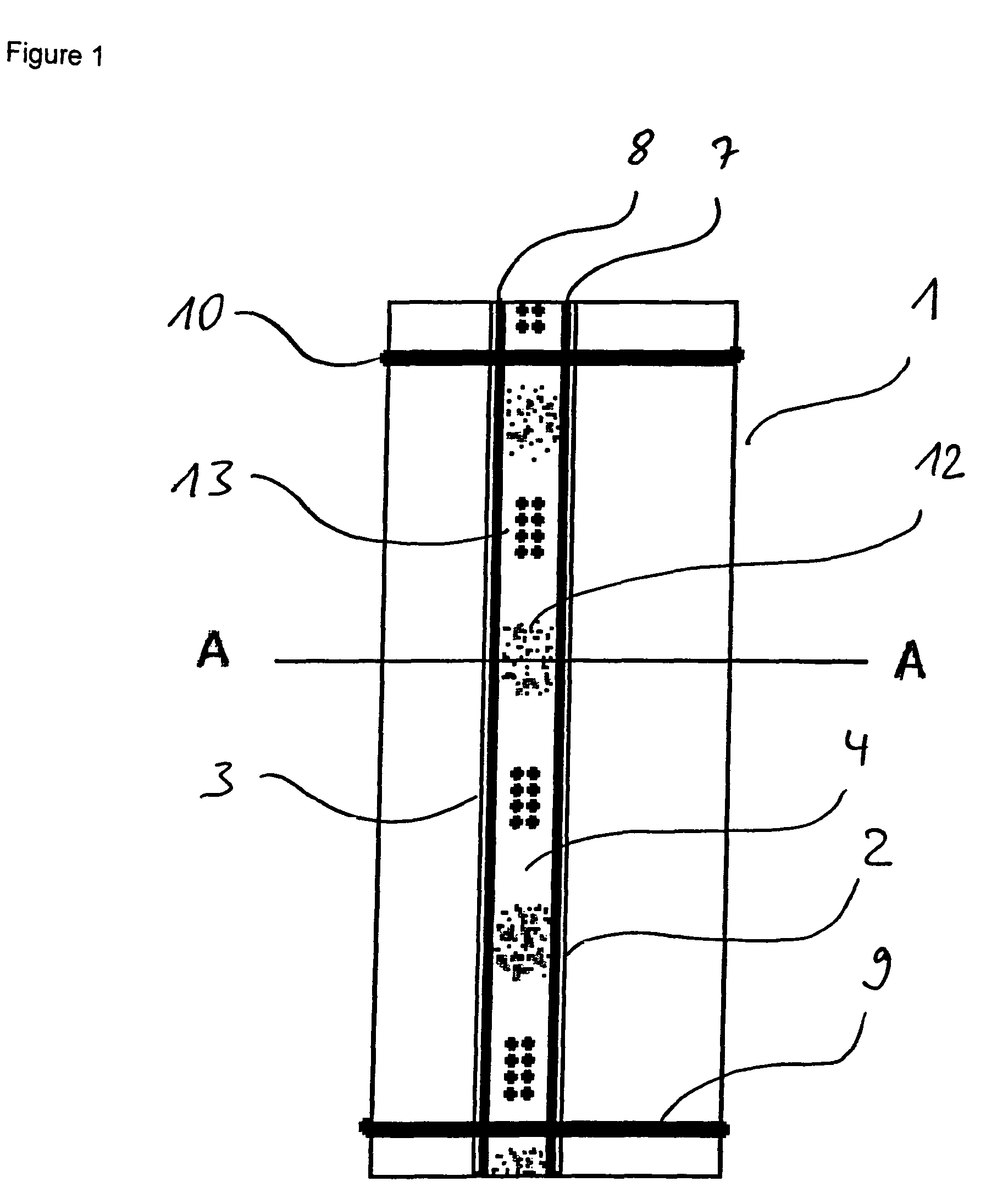

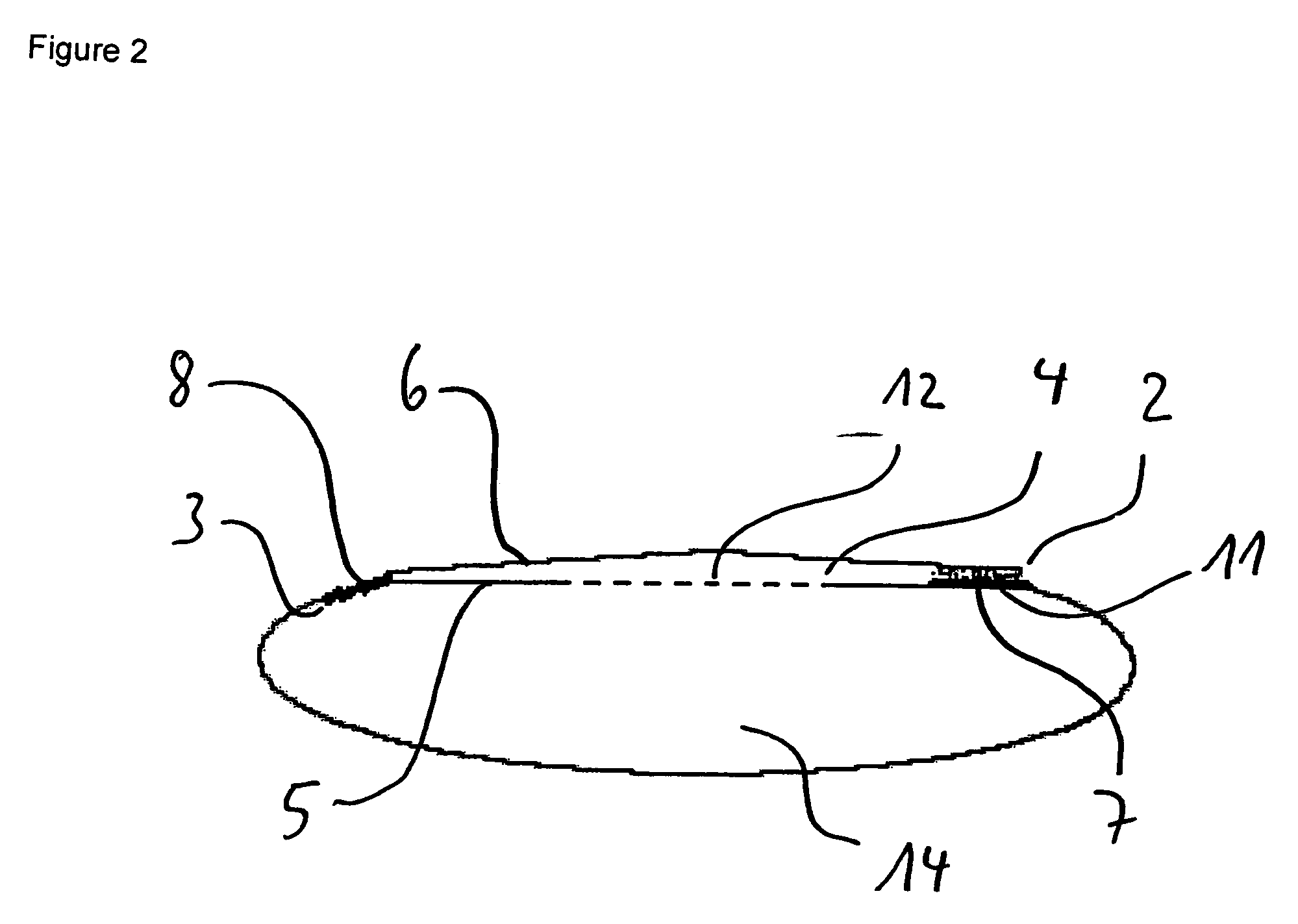

A valve arrangement for a pipeline protection system comprises a plurality of barrier valves in series with each other for coupling in a pipeline, wherein the valves are received in a metallic block.

Owner:GE OIL & GAS UK LTD

Plastic bag with overpressure relief

ActiveUS20050281493A1ImproveReduced strengthBox making operationsPaper-makingPlastic bagInternal zone

Owner:HEINEMEIER SABINE +2

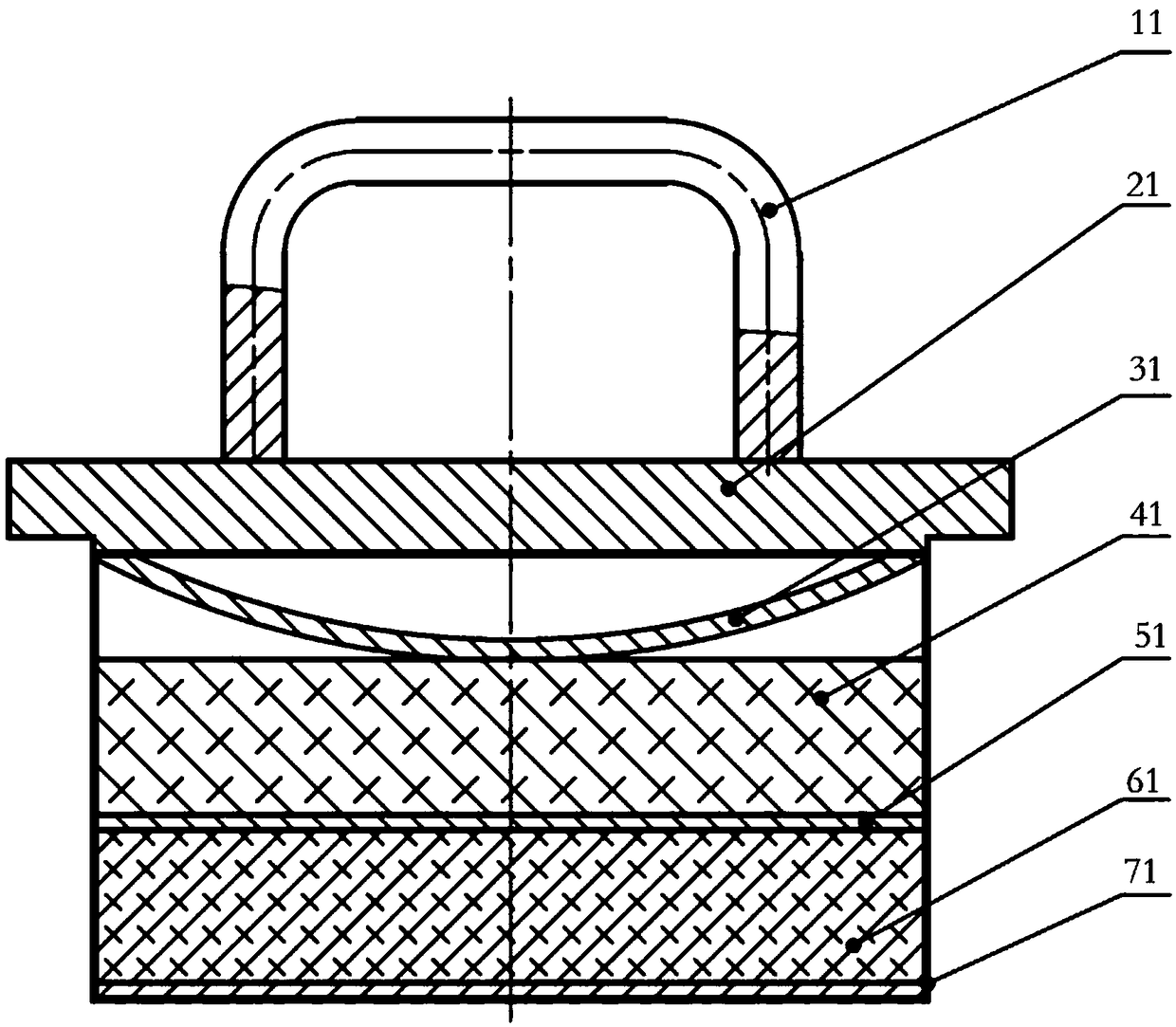

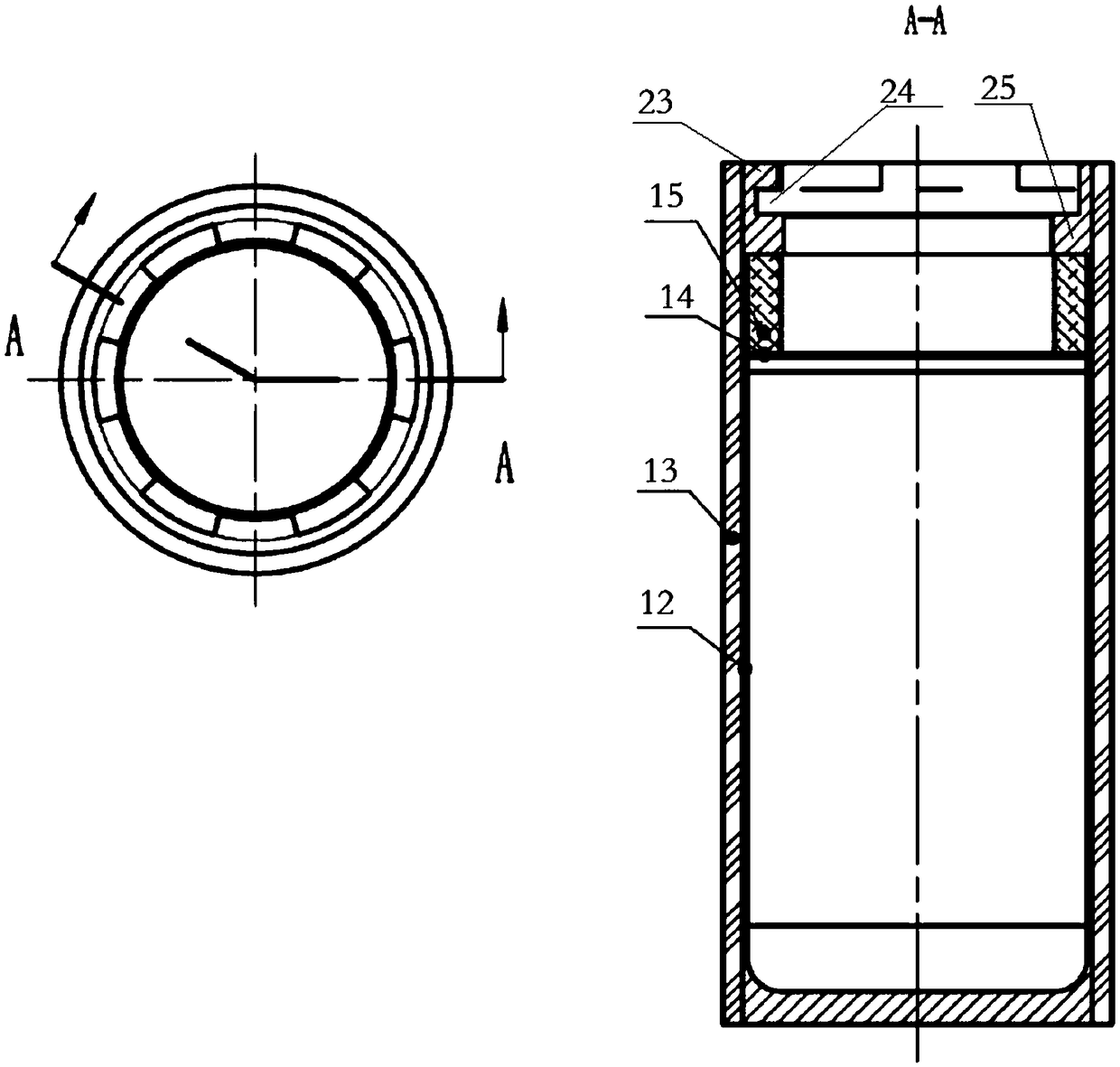

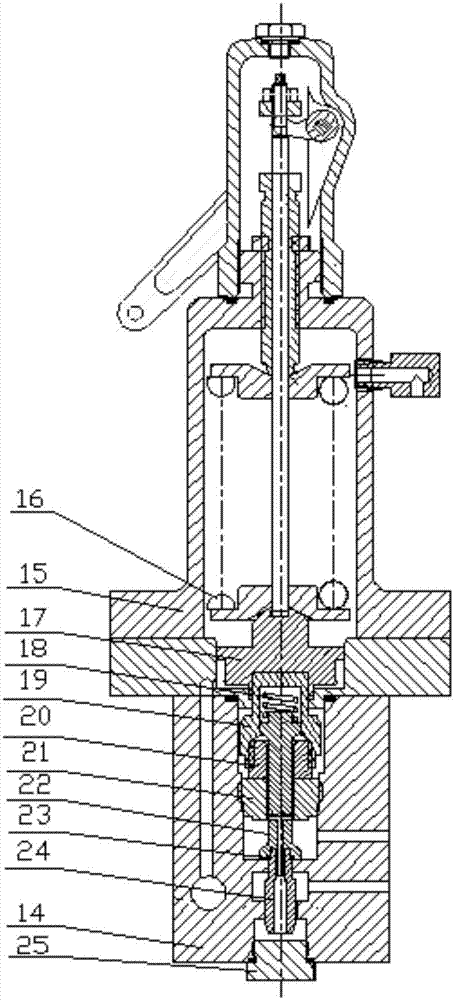

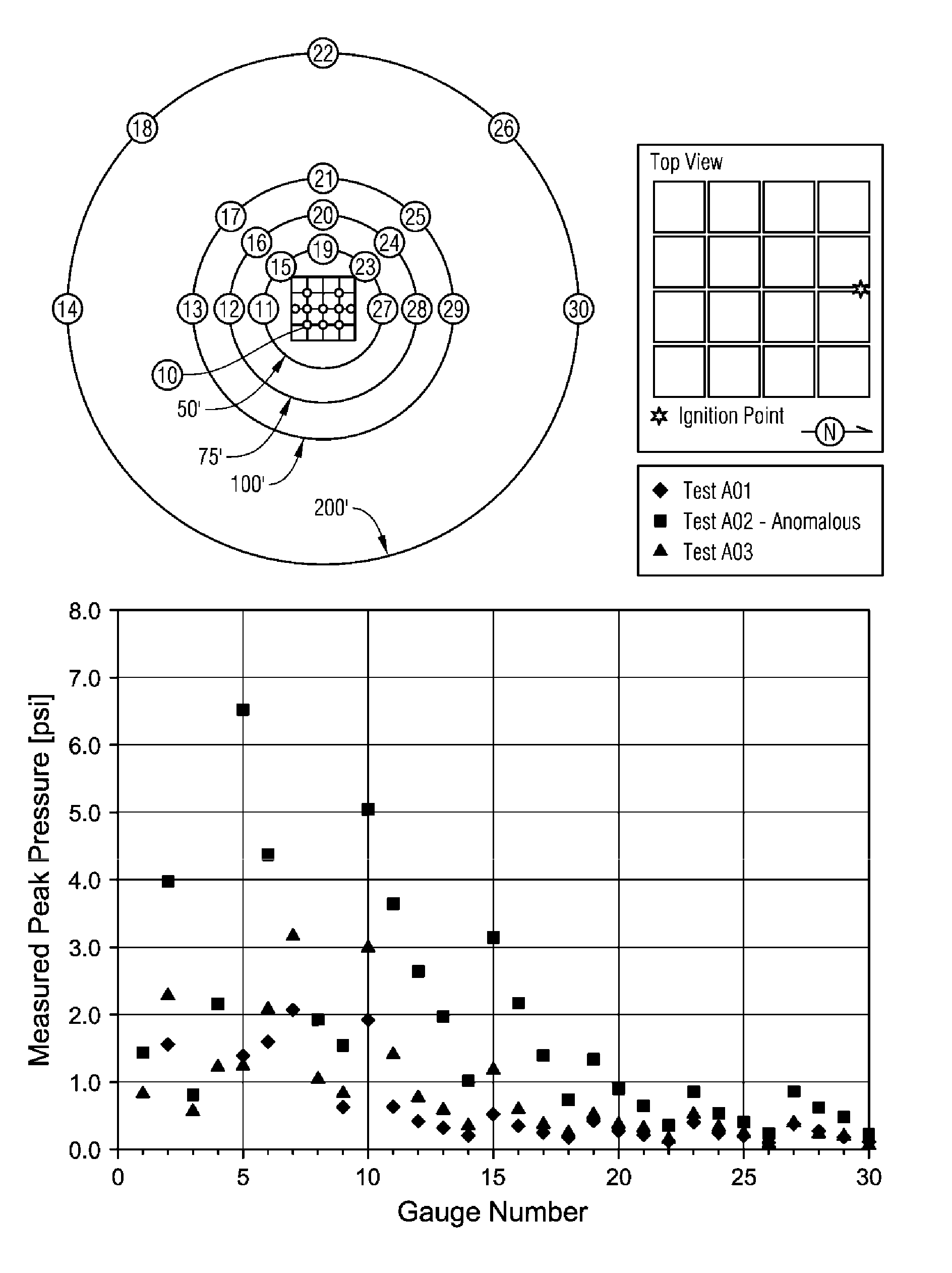

Implantable shunt system and associated pressure sensors

ActiveUS20140243703A1Reduce overpressureElectrotherapyCircuit arrangementsDual stageThermal coefficient

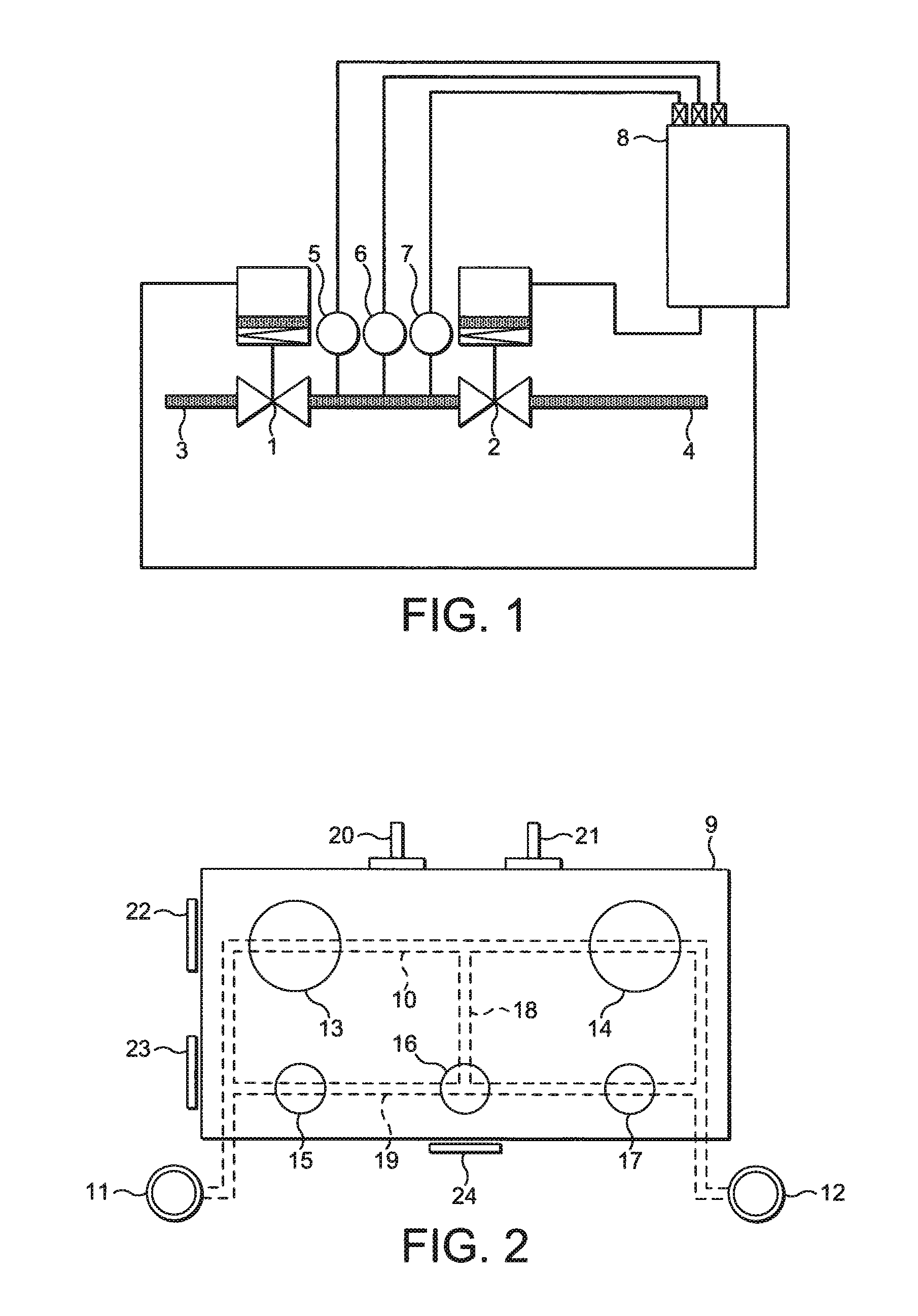

A hermetically sealed biocompatible pressure sensor module configured for implant at a desired site at which a pressure is to be measured. Anodic bonding of the pressure module package components which have similar thermal coefficients of expansion provides low stress bonding and maintains long term reliability, dependability and accuracy. The pressure sensor module includes a pressure sensitive membrane which is in direct contact with the environment at which a pressure is to be measured. The pressure sensor module forms a part of a pressure measuring system which uses a telemetry link between the pressure sensor module and an external controller for data transmission and transfer. Operating power for the pressure sensor module is provided by the external controller and an internal rechargeable energy storage component. Accordingly, the pressure measuring system provides a dual stage power and data transfer capability for use with an implantable system. An exemplary use of the pressure sensor module is in a three pressure sensor system including a flow control valve in a shunt to treat hydrocephalus. The use of integrated circuit chips and an internal coil with an optional ferrite core in the pressure sensor module provides for low power consumption and reliable signal processing. An embodiment of the invention includes a pressure sensor and associated electromagnetic coils embedded in the tip portion of the shunt for measuring the pressure of fluid externally of the shunt at the tip portion.

Owner:ALFRED E MANN FOUND FOR SCI RES

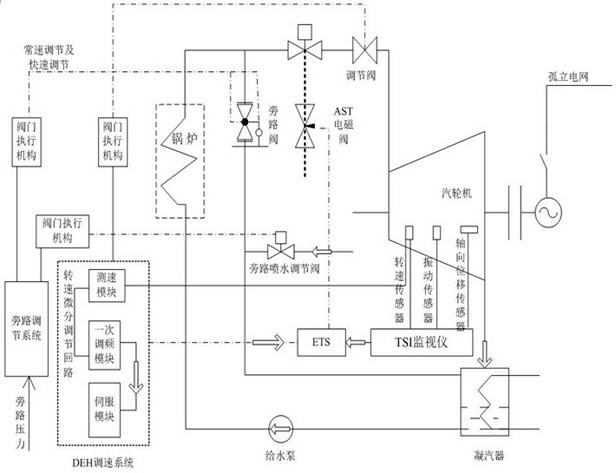

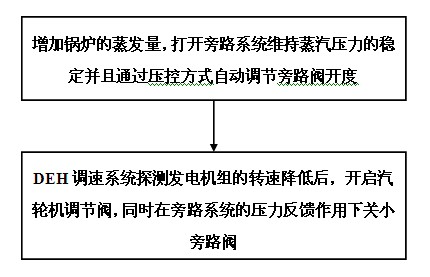

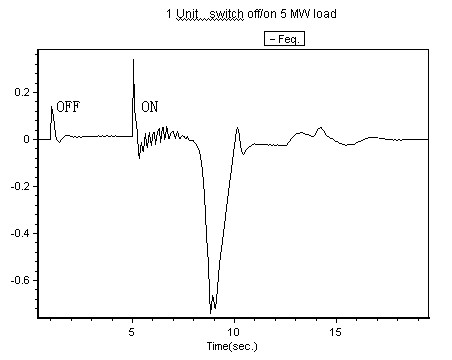

System and method for stabilizing frequency and voltage of system during large load phase step of isolated power grid system

ActiveCN102536343AQuick responseImprove overshoot problemMachines/enginesEngine componentsPressure feedbackPower grid

The invention discloses a system and a method for stabilizing frequency and voltage of the system during large load phase step of the isolated power grid system. The method includes: S1, increasing evaporation capacity of a boiler, starting a bypass system to maintain stability of steam pressure and automatically regulating opening of a bypass valve via a pressure control mode; and S2, opening a regulating valve of a steam turbine after a DEH (digital electric hydraulic) speed regulating system detects that the rotation speed of a generator set is reduced, and simultaneously reducing the opening of the bypass valve under a pressure feedback effect of the bypass system. By the aid of a large-capacity energy storage effect of the bypass system, the bypass valve is opened quickly, load of the boiler is reduced, and the system is protected against being in an over-voltage state; the bypass valve is closed quickly, output power of the generator set is quickly adjusted, large motor load is carried, balance of total power supply quantity is realized, and accordingly an isolated power grid outputs current with stable frequency and voltage under the condition of large load phase step; and required high power electric energy does not need to be outputted in advance, heat dissipation of the generator set of the isolated power grid can be realized effectively, debugging of the set is carried out conveniently, and cost is saved.

Owner:CHINA HUADIAN ENG

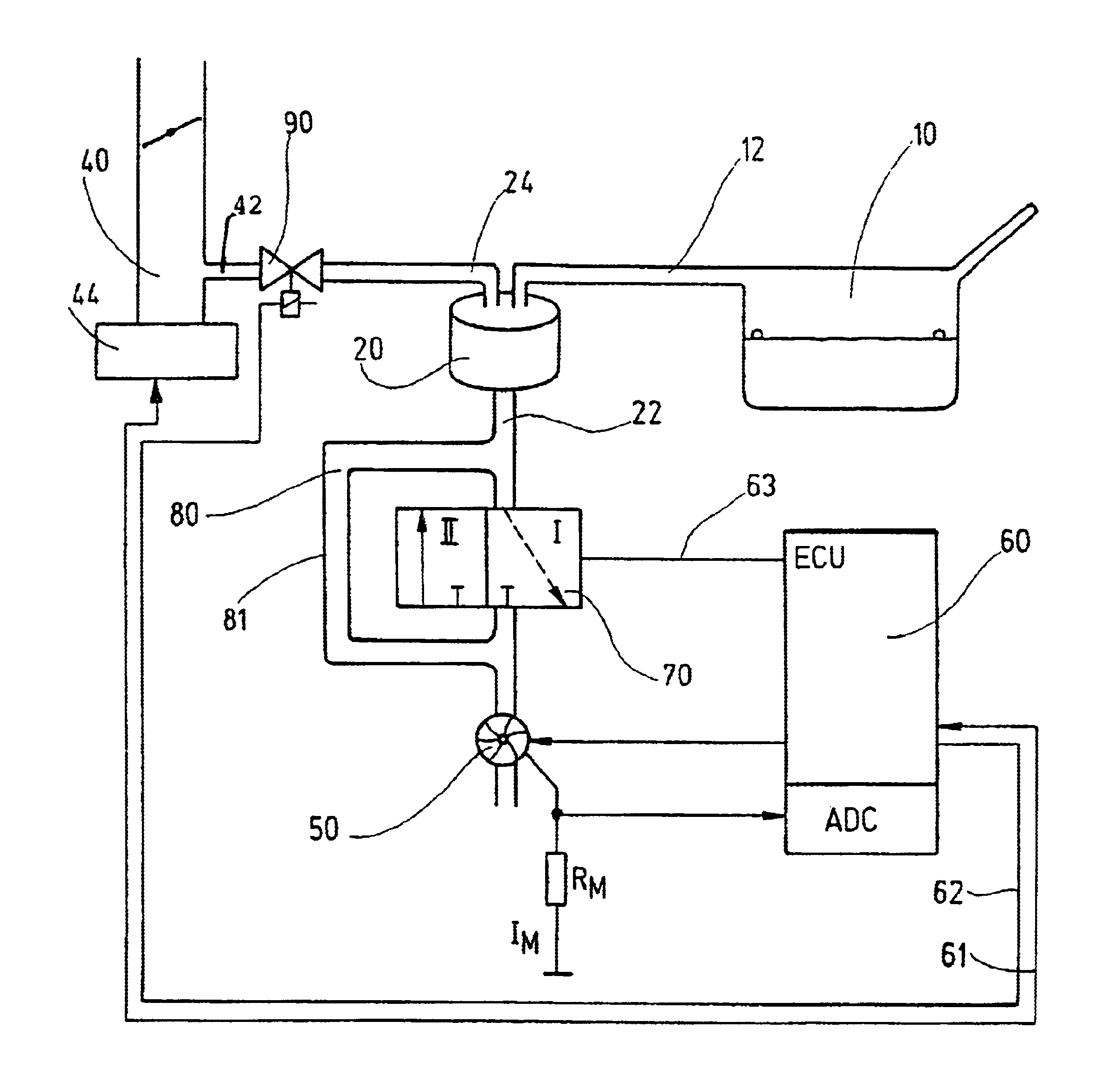

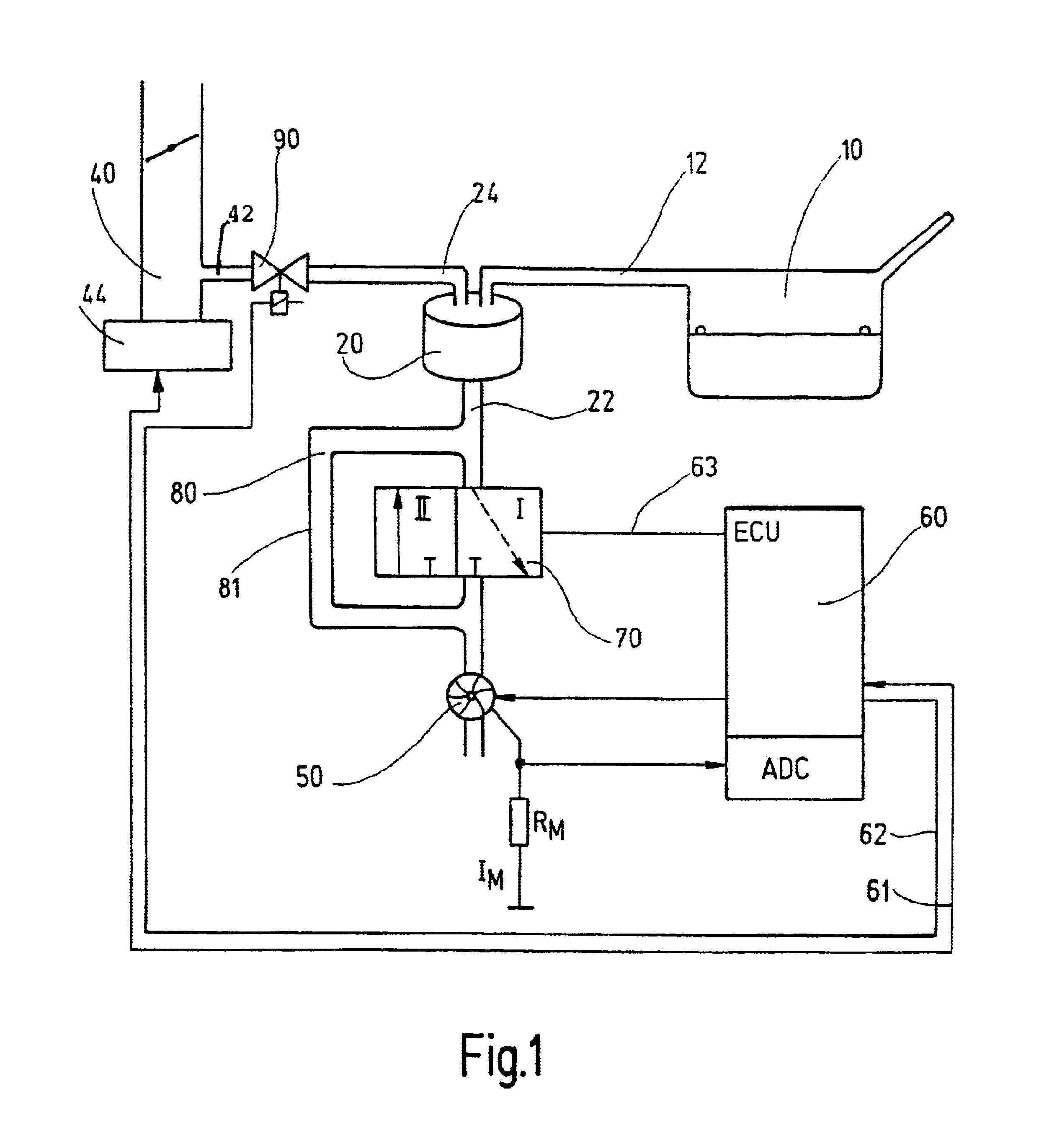

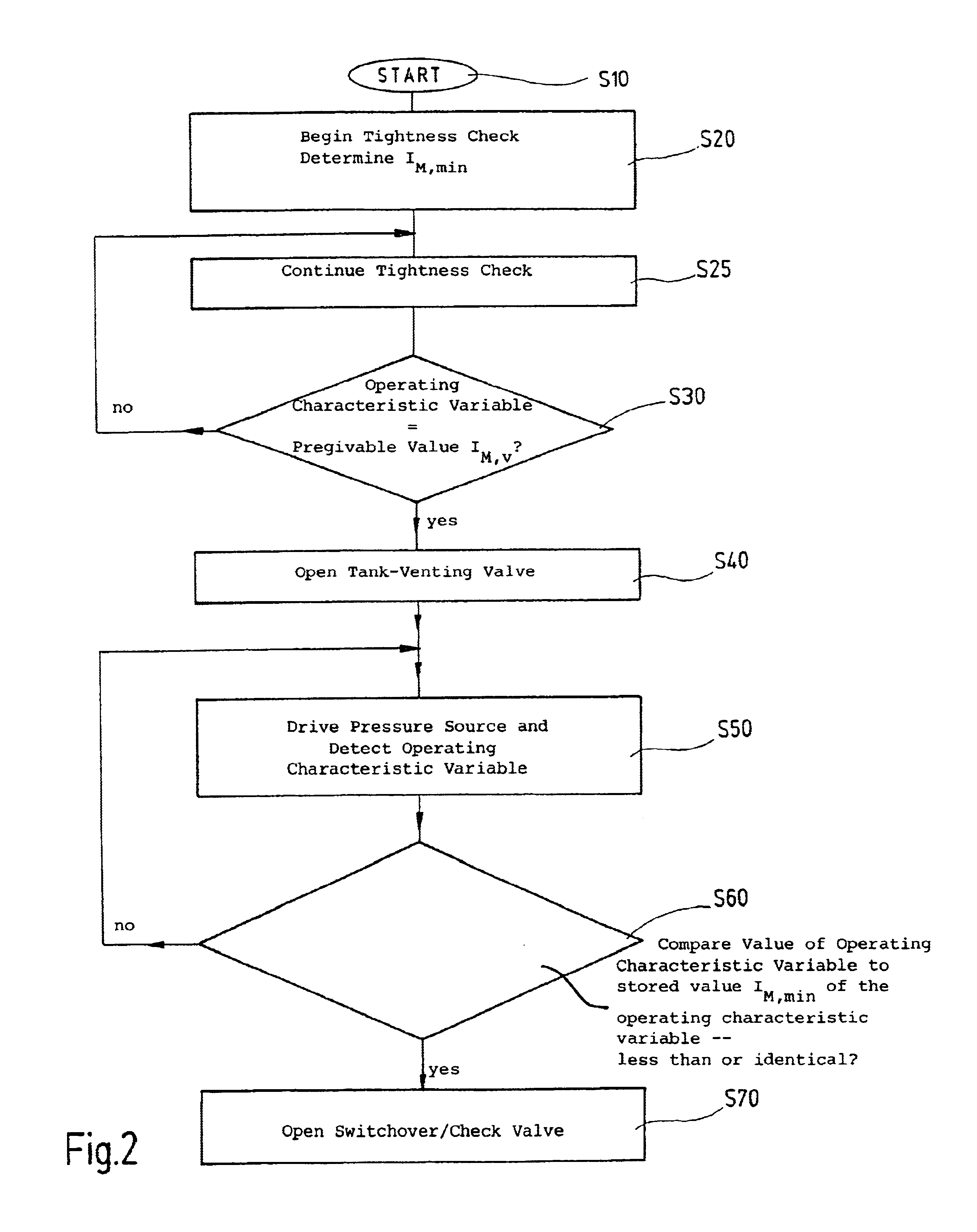

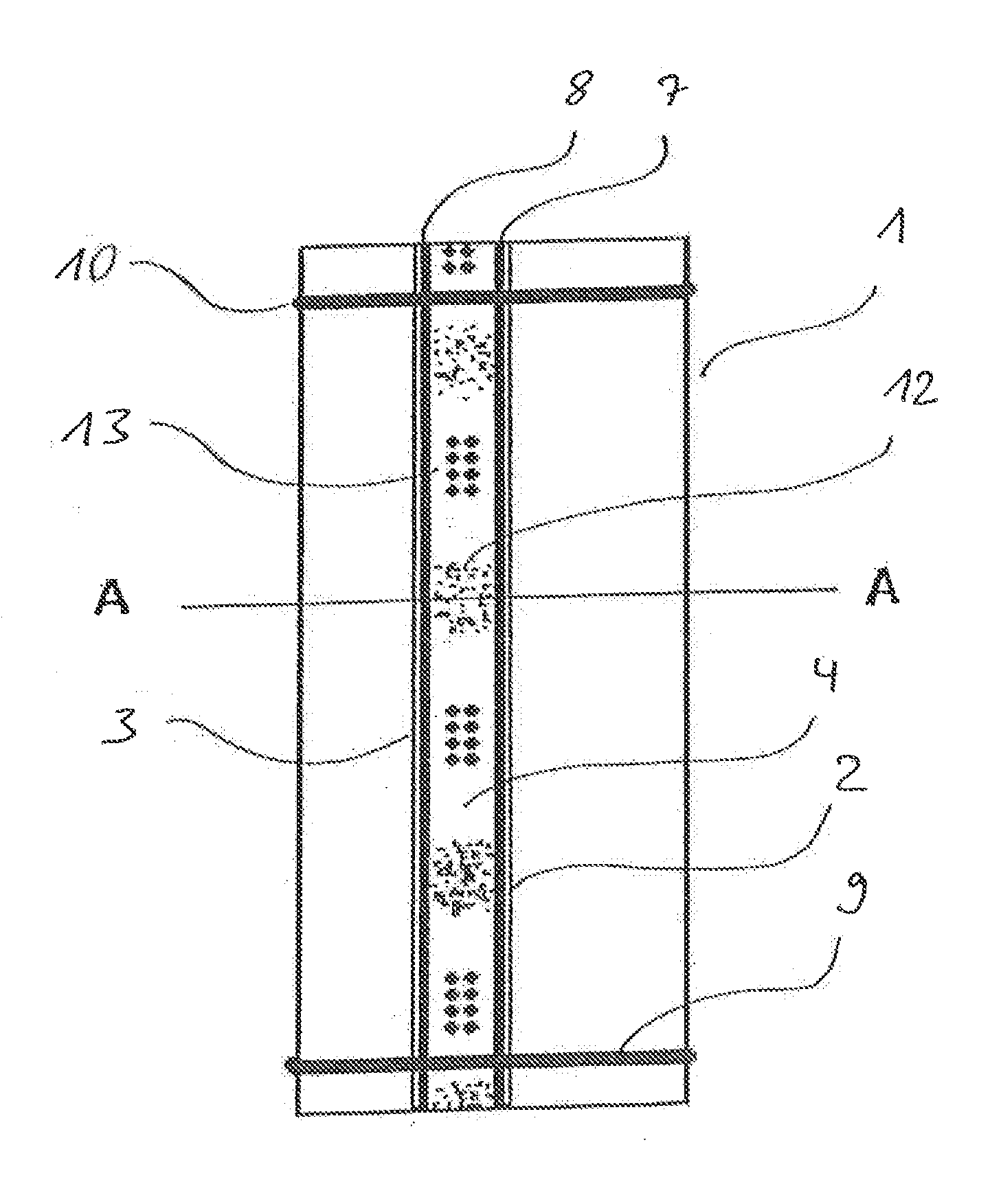

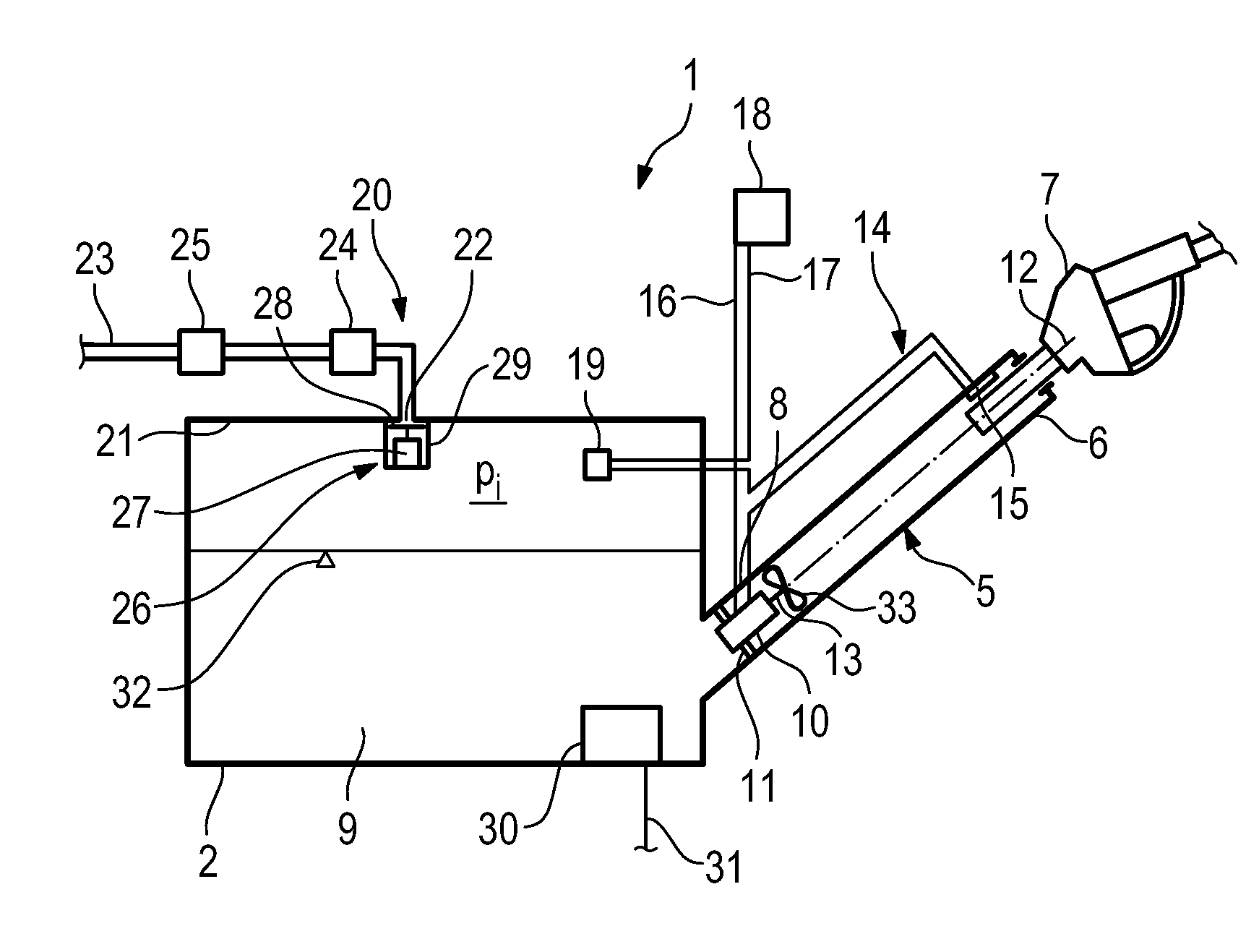

Tank-venting system in a motor vehicle and method for checking the operability of the tank-venting system

InactiveUS6889667B2Reduce overpressureEasy to chargeMeasurement of fluid loss/gain rateNon-fuel substance addition to fuelFuel tankOperability

A method checks the operability of a tank-venting system for a motor vehicle having an internal combustion engine. The tank-venting system includes a fuel tank (10), an adsorption filter (20) and a filter line (12) connecting the adsorption filter to the fuel tank. The adsorption filter (20) has a venting line (22) and a switchover / check valve (70) is provided for closing off the venting line (22). The system includes a tank-venting valve (90) and a valve line (24) connecting the tank-venting valve to the adsorption filter. In the method, an overpressure relative to atmospheric pressure is introduced into the tank-venting system utilizing a drivable pressure source (50). An operating characteristic variable of the pressure source is detected while introducing the overpressure to determine the pressure course. A conclusion is drawn as to the presence of a leak from the pressure course. The overpressure is reduced by opening the tank-venting valve (90) and simultaneously closing said switchover / check valve (70).

Owner:ROBERT BOSCH GMBH

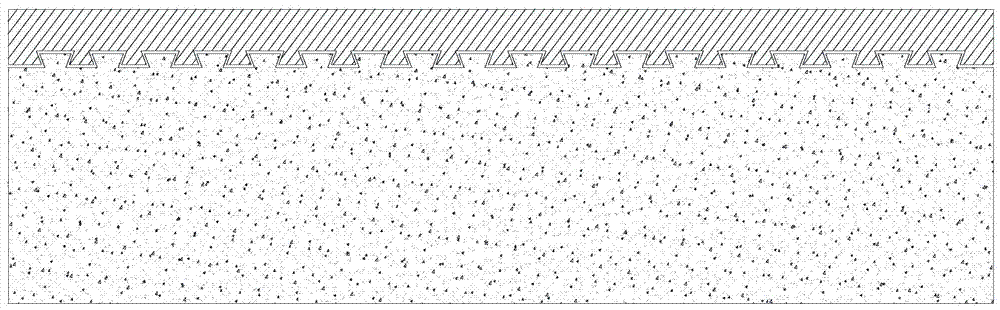

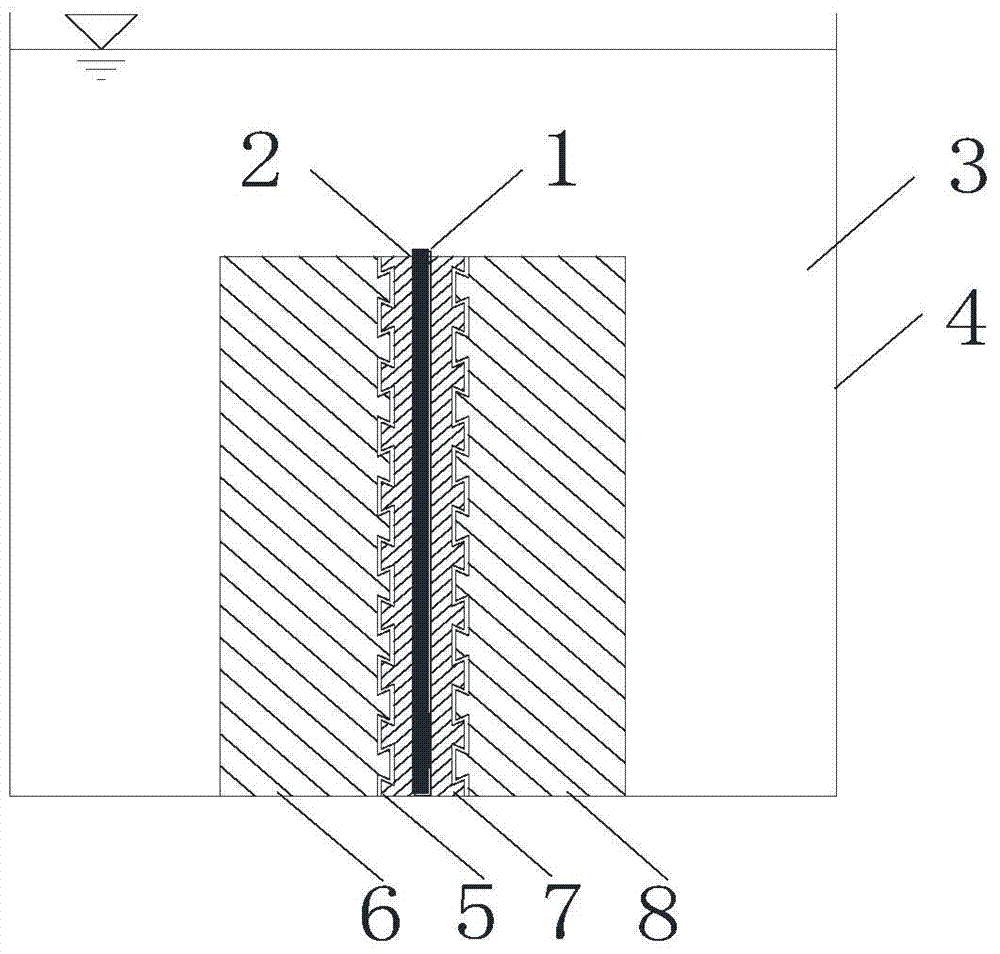

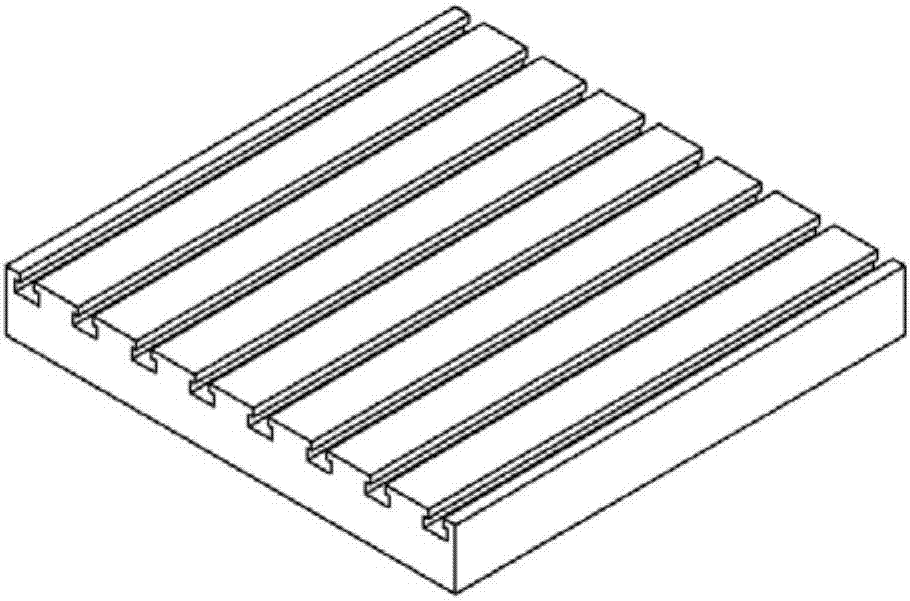

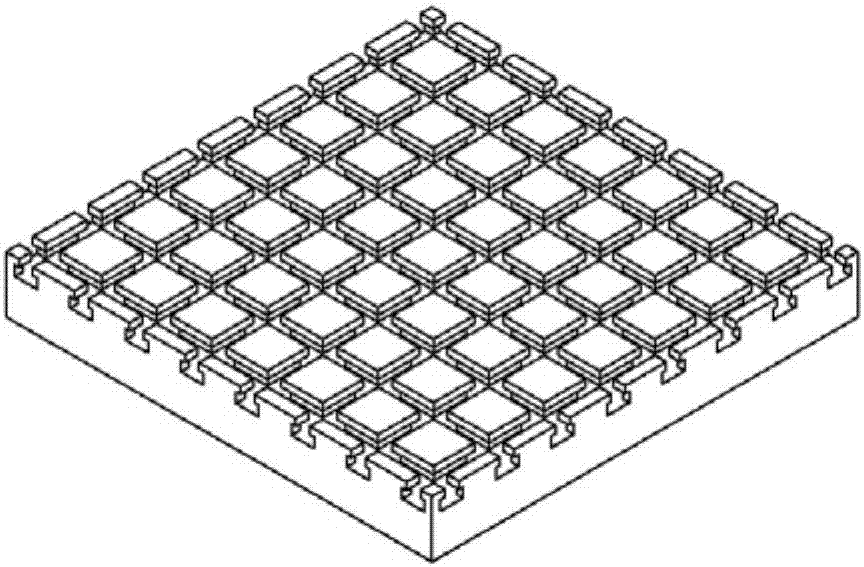

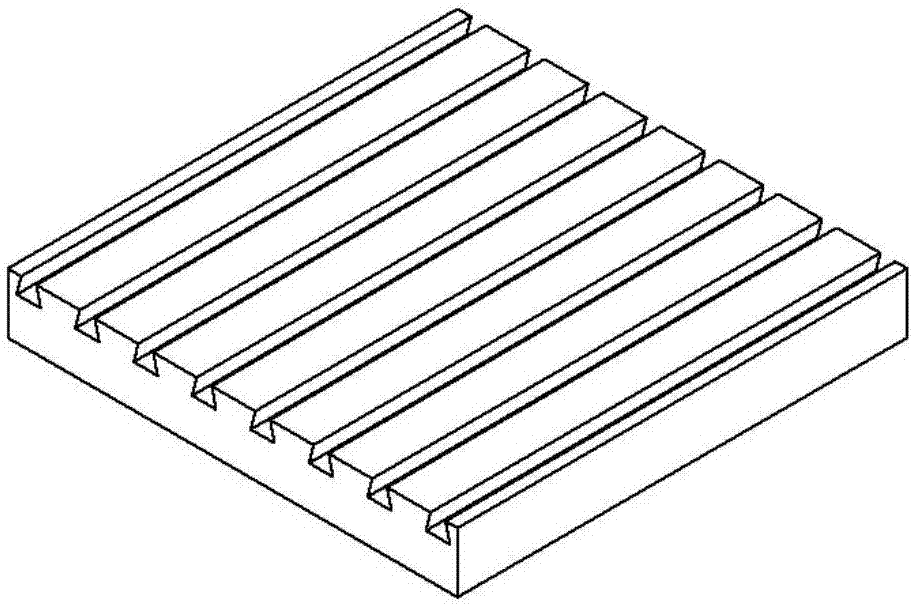

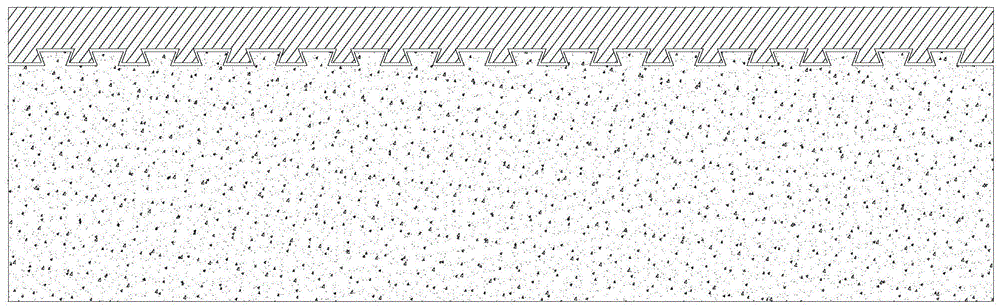

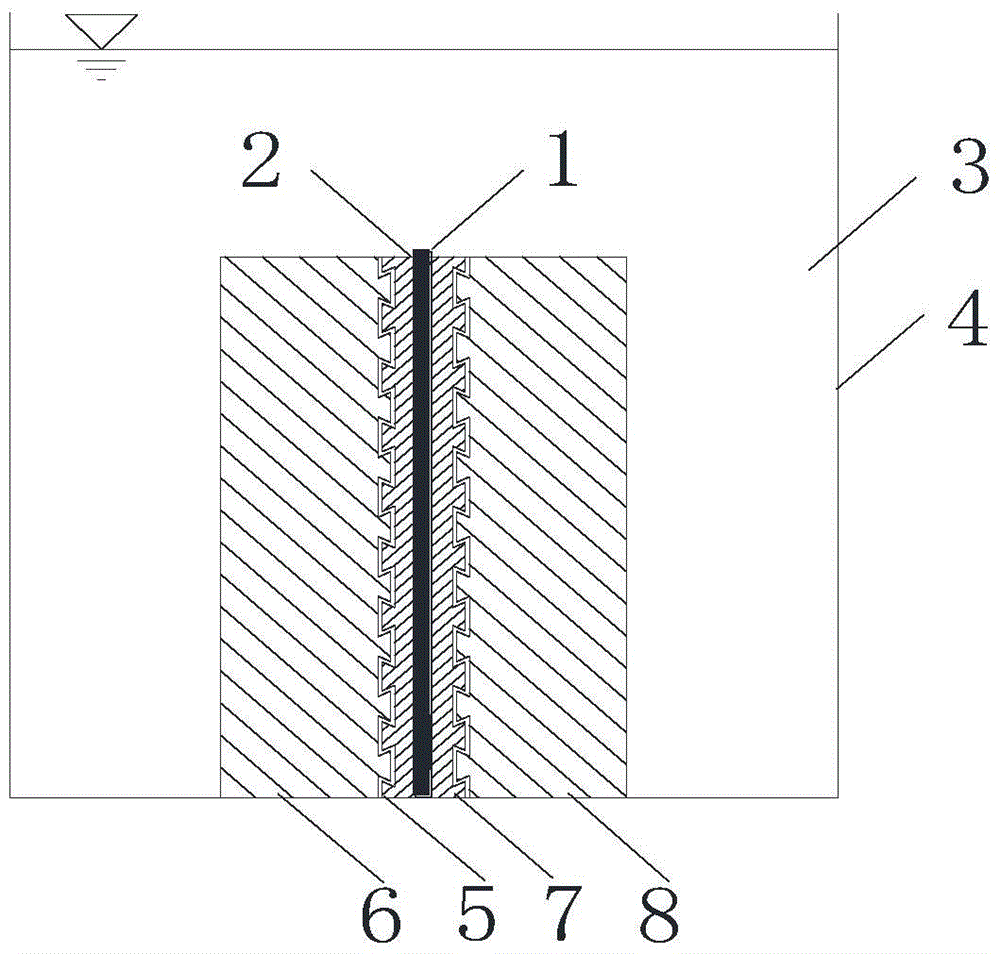

Compositing method of dovetail groove metal plate clearance fit interface

ActiveCN104289810AIncrease profitReduce pollutionMetal working apparatusNon-electric welding apparatusComposite effectInterference fit

The invention discloses a composting method of a dovetail groove metal plate clearance fit interface. The compositing method is realized through the explosive cladding method, the rolling method and the like. According to the method, after a base plate with dovetail grooves and a surface plate with dovetail grooves are in interference fit, the base plate and the surface plate are composited together through combination of a metallurgical bonding mode and a squeezing meshing mode of the dovetail grooves under the actions of energy of explosives or a rolling mechanism. Physical and chemical properties of metal sheets on the two sides of a dovetail groove combination interface are not changed, and large-area metal sheet composition can be conducted; the explosive charge for a unit of compositing area is small, and atmospheric pollution, noise pollution, explosion vibration and overpressure are reduced; during explosive welding of the metal sheets with the dovetail grooves, no boundary effect exists, the compositing effect on the periphery is good, and the lower limit and the upper limit of an explosive welding window are both increased. The compositing technology of the dovetail groove metal plate clearance fit interface can be applied to the fields such as chemical reaction containers and ships so as to meet the requirement for large-area metal composite plates.

Owner:UNIV OF SCI & TECH OF CHINA

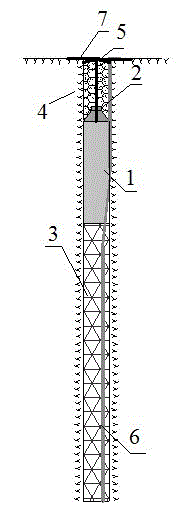

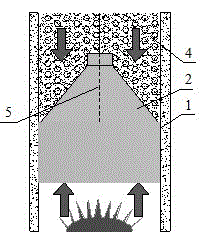

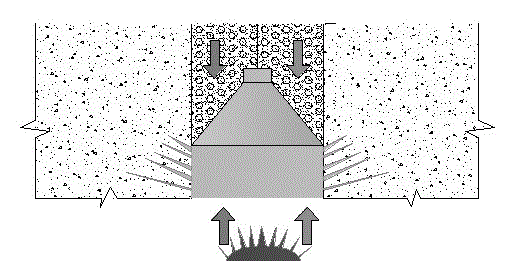

De-noising and dust removal blast hole stemming method for drilling blasting of earth and stone in urban and rural areas

The invention discloses a de-noising and dust removal blast hole stemming method for drilling blasting of earth and stone in urban and rural areas. According to the method, a stemming section comprises a bottom water bag, a middle inverted funnel and a conventional stemming material, the water bag is tied down by a traction rope and is lifted into a hole, the other end of the traction rope is tied to a bearing bar of an orifice of a blast hole, and the edge of the inverted funnel is clamped on the wall of the blast hole to be fixed. Most of shock wave energy generated by explosion can be converted into internal energy required by water vaporization and atomization and kinetic energy of water jet so as to weaken noise; meanwhile, the blasting dust can be wrapped by dispersed water mist to reduce pollution; and in addition, after the water bag is broken, the lower part of the funnel is filled with water, so that the strength of shock waves is indirectly reduced, the stemming time is prolonged, and the stemming effect is enhanced. The method provided by the invention can also be used in rock blasting construction of mines, water and electricity, traffic and other fields.

Owner:WUHAN UNIV

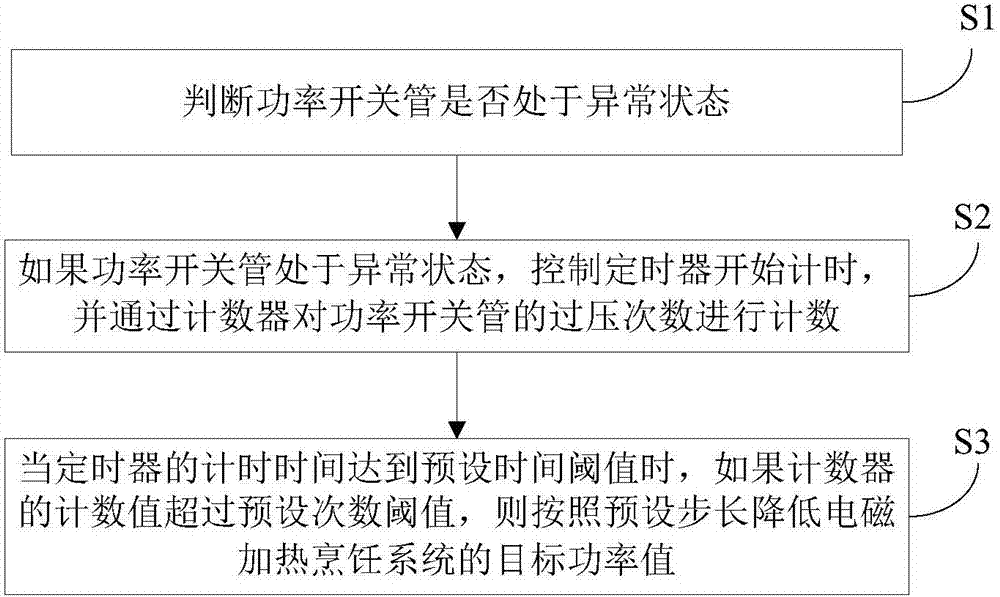

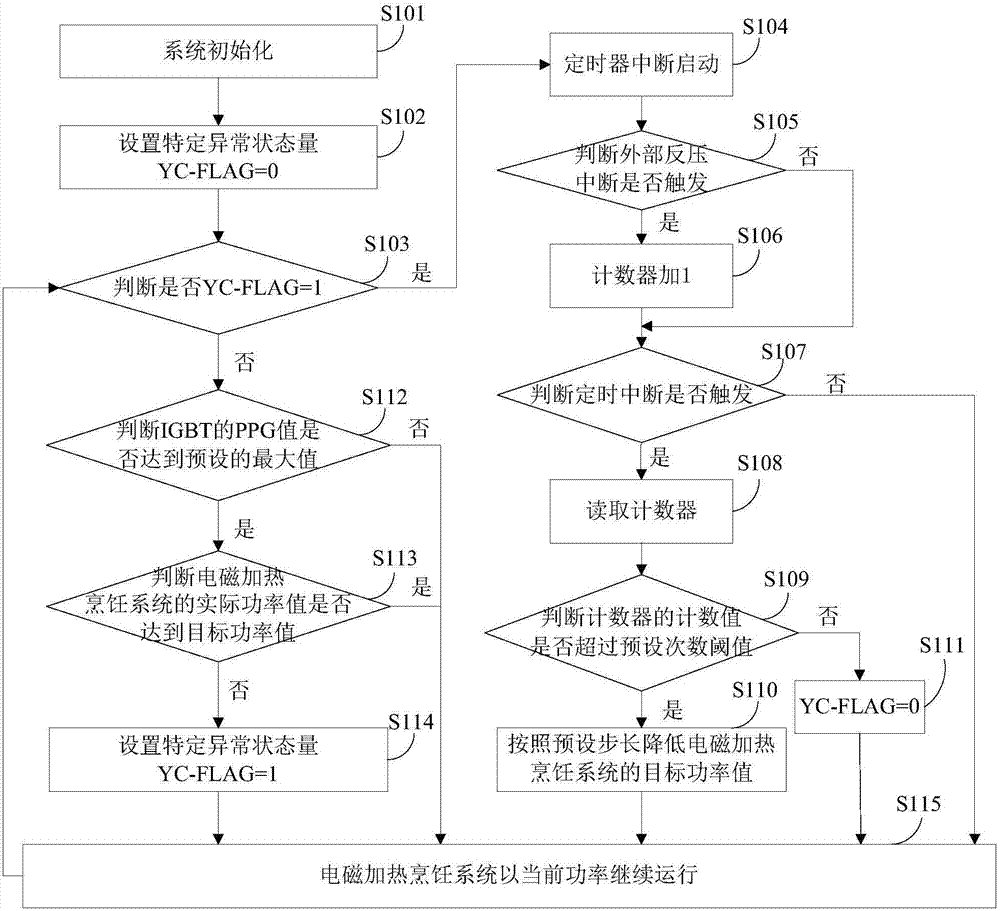

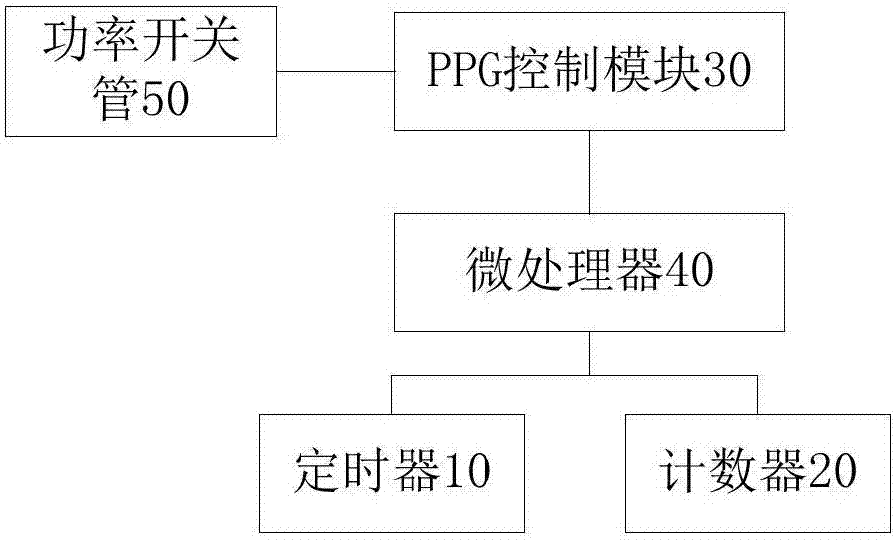

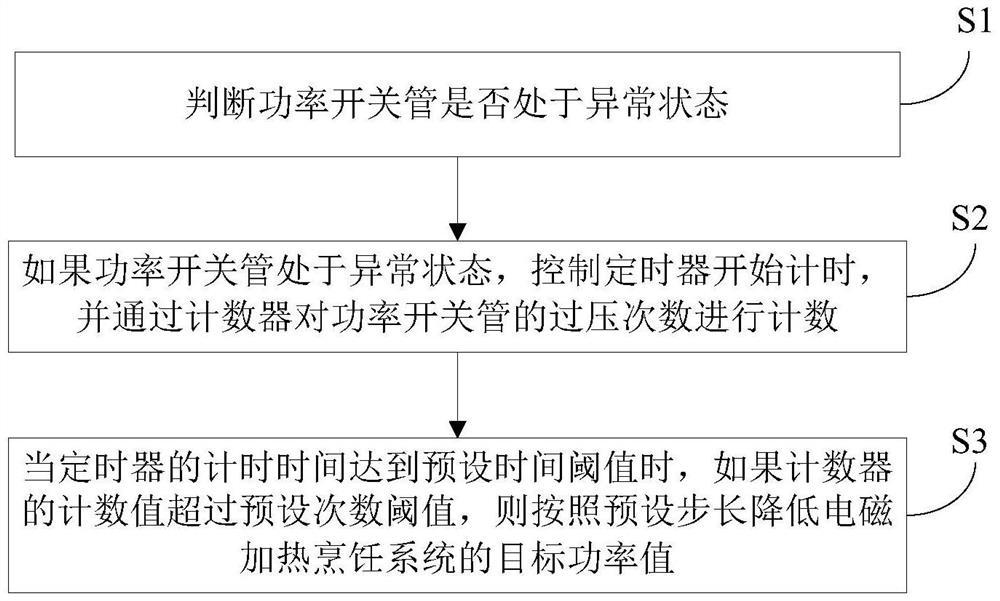

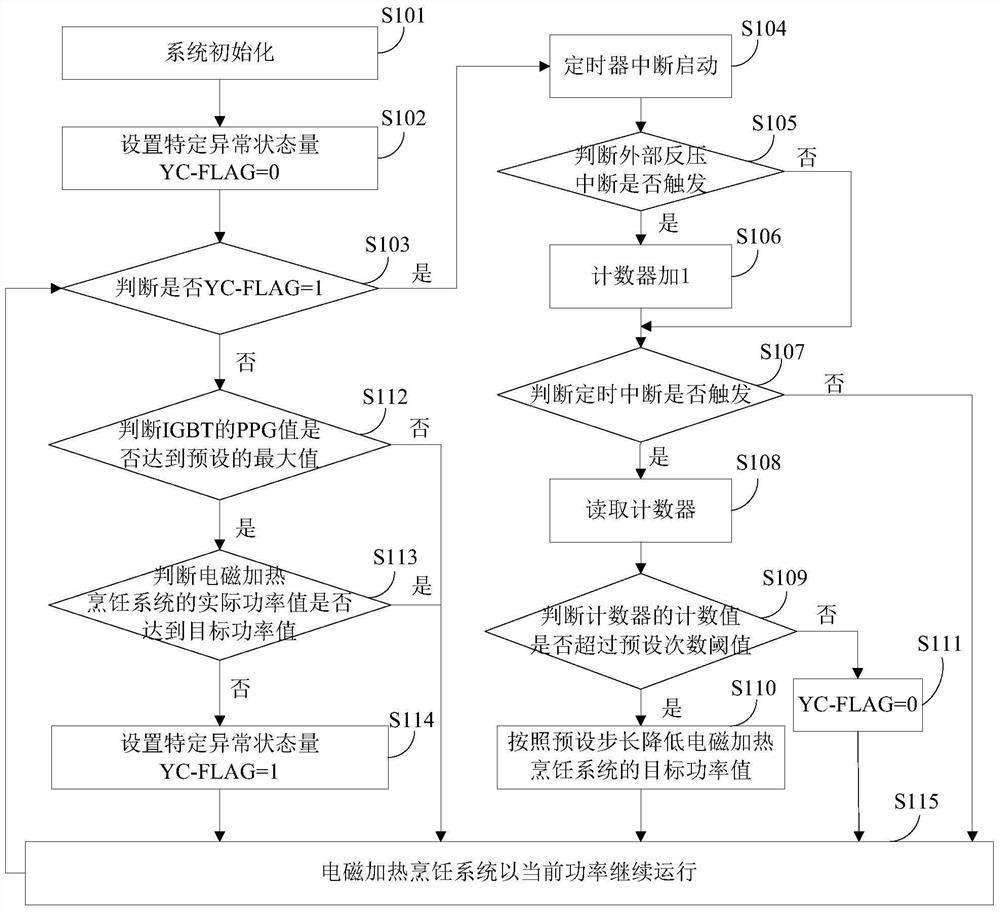

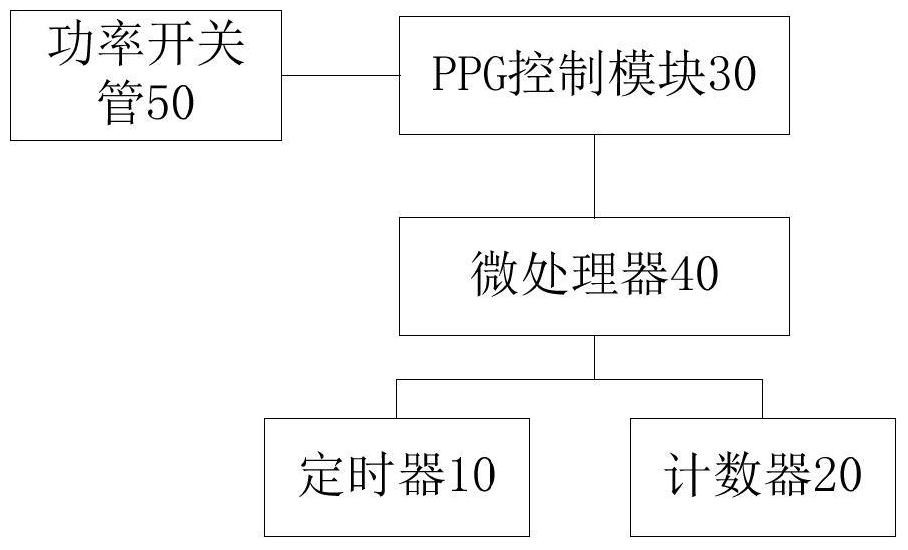

Overvoltage abnormal protection method and device for power switch tube in electromagnetic heating cooking system

ActiveCN107548177AReduce target power valueReduce overpressureInduction heating controlOvervoltageEngineering

The invention discloses an electromagnetic heating cooking system, and an overvoltage abnormal protection method and device for a power switch tube in the electromagnetic heating cooking system. The overvoltage abnormal protection method comprises the following steps: judging whether the power switch tube is in an abnormal state; if the power switch tube is in an abnormal state, a timer is controlled to count and the number of overvoltage times of the power switch tube is counted through a counter; and when the count time of the timer reaches a preset time threshold, if the count value of thecounter exceeds a preset number of times threshold, the target power value of the electromagnetic heating cooking system is reduced according to a preset step length. The method can protect the powerswitch tube to some extent by reducing the target power value of the electromagnetic heating cooking system and reducing the overvoltage degree of the power switch tube when the power switch tube is in an abnormal state.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Plastic bag with overpressure relief

ActiveUS7927015B2Reduced strengthReduce overpressureBox making operationsPaper-makingEngineeringPlastic bag

Owner:HEINEMEIER SABINE +2

Explosive cladding method for groove type hot melt interface of metal plate and explosive device

PendingCN106956073AReduce pollutionSmall amount of explosiveNon-electric welding apparatusExplosive claddingExplosive Agents

The invention provides an explosive cladding method for a groove type hot melt interface of a metal plate and an explosive device. According to the method, grooves are formed in the surface of a metal base plate at first, the grooved interface is cleaned up, raw materials of a covering plate are melted in a high-temperature furnace, a part of melted liquid flows into groove cavities, under the thermal action of the high-temperature liquid and the mechanical action of the grooves, primary combining of the covering plate and the base plate is achieved, then the covering plate is further squeezed into the grooves through an explosive method, the base plate and the covering plate squeeze each other and are combined closely, and tight combining force is achieved on the interface of the two metal plates. According to the explosive cladding method and the explosive device, the amount of explosives in unit area is small, a honeycomb aluminum explosive loading structure is adopted, the explosive amount and the cladding time can be saved, and meanwhile, atmospheric pollution, noise pollution, vibration and overpressure are reduced.

Owner:UNIV OF SCI & TECH OF CHINA

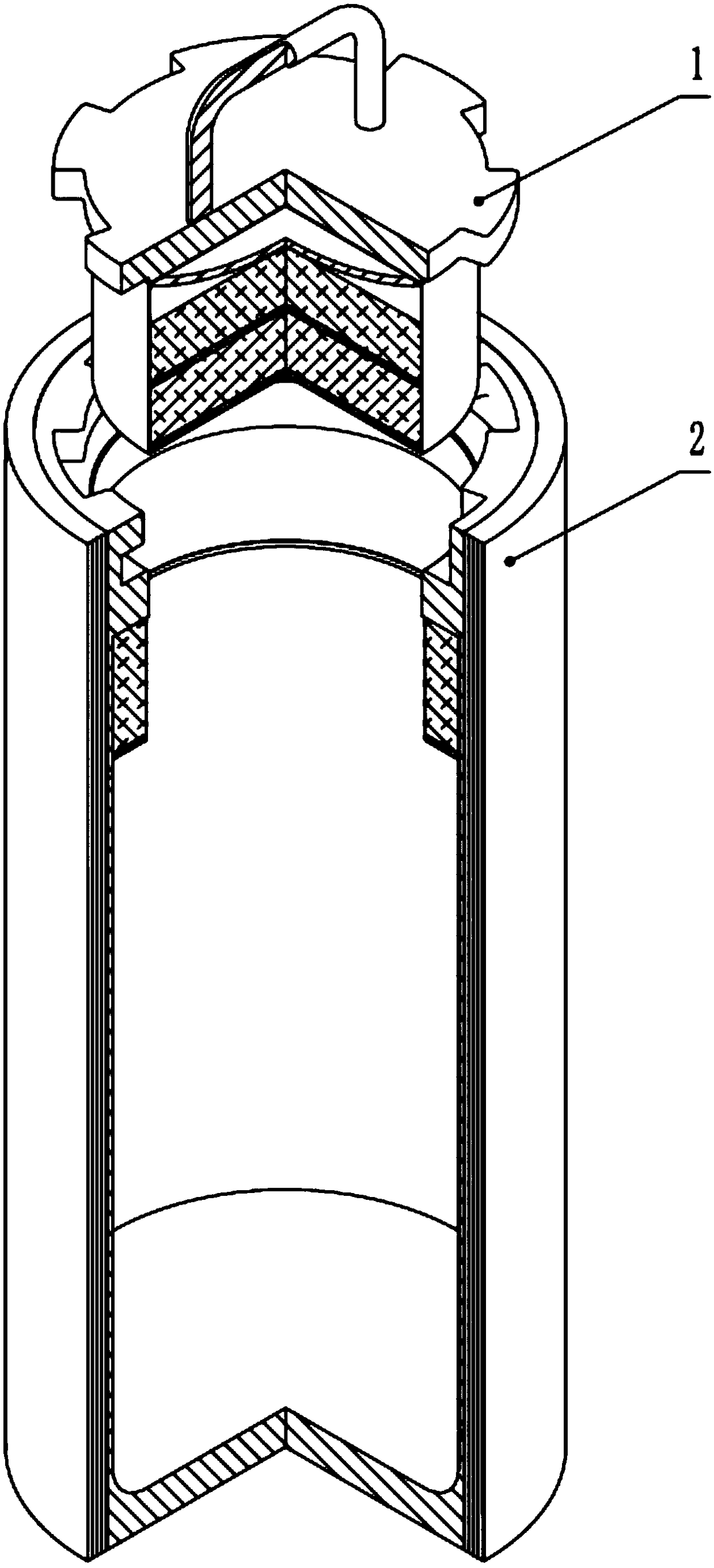

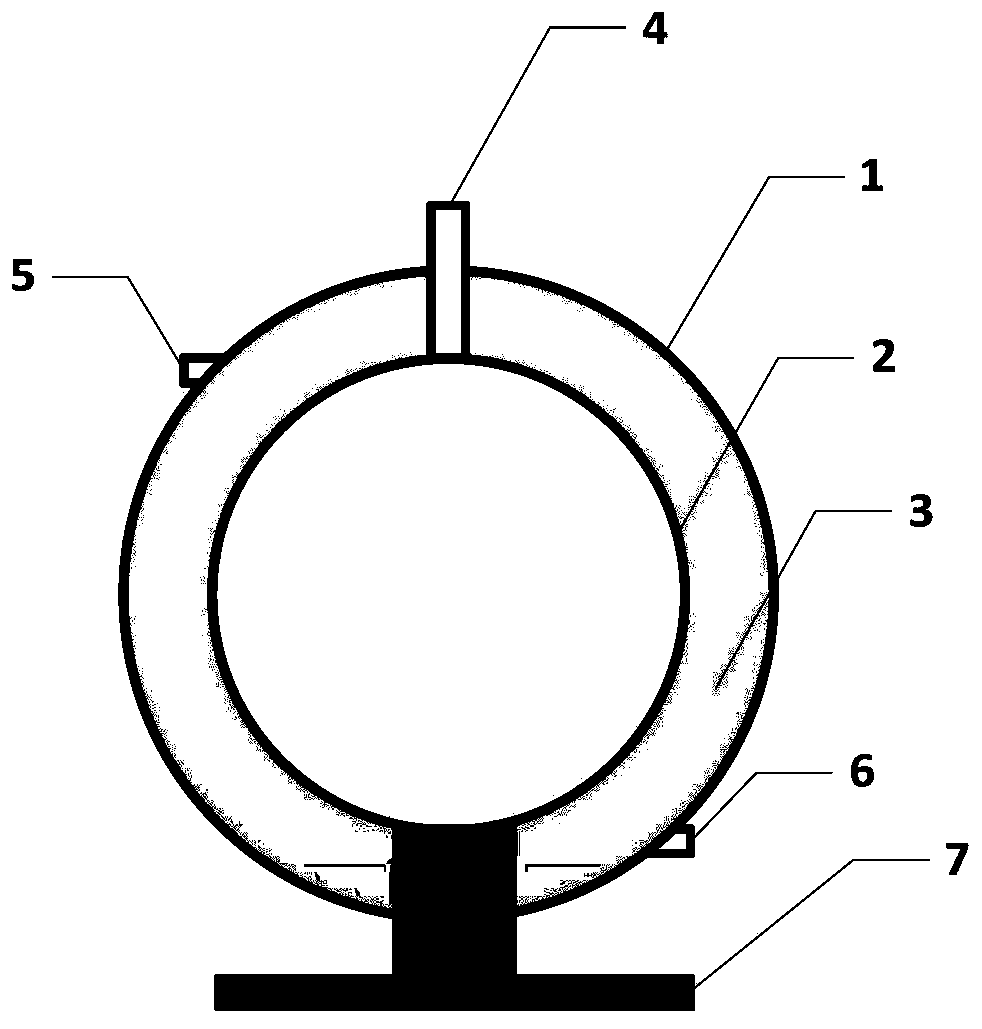

Fully sealed composite explosion-proof container

The invention discloses a fully sealed composite explosion-proof container comprising an end cover component and a container body. The end cover component is engaged and connected with the container body through a multi-tooth structure, and the end cover component comprises a cover plate of which the lower part is provided with a stainless steel jacket; the stainless steel jacket is internally provided with a high density aluminum foam layer, a separating plate, a low density aluminum foam layer and a spherical film from bottom to top in sequence; and the container body comprises a composite outer layer of which the interior is a metal inner barrel, and the upper part of the metal inner barrel is provided with an annular aluminum foam layer of which the bottom is provided with a separatingplate layer. According to the fully sealed composite explosion-proof container provided by the invention, the barrel is wound by carbon fiber reinforced epoxy resin matrix composites; and the structural strength is high, and the weight is light. The explosion-proof container has the advantages of the simple structure, quick opening and closure, reliable sealing and no fire phenomenon during explosion; the overpressure within the 30cm radius of the opening part is low, and less 20 kPa than the threshold that a human body can bear; and the explosion-proof container is light in weight, and can be handled by one person easily.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

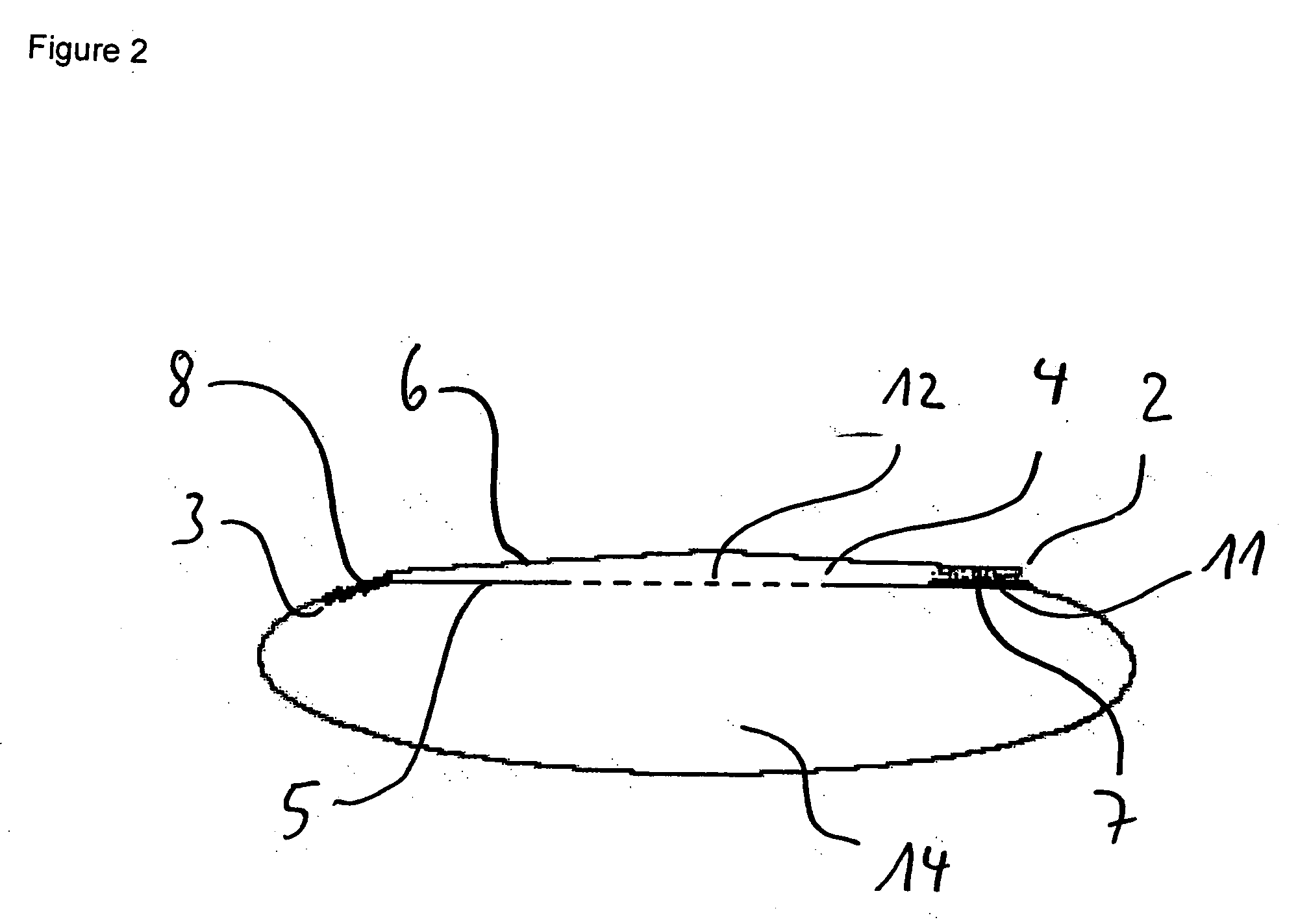

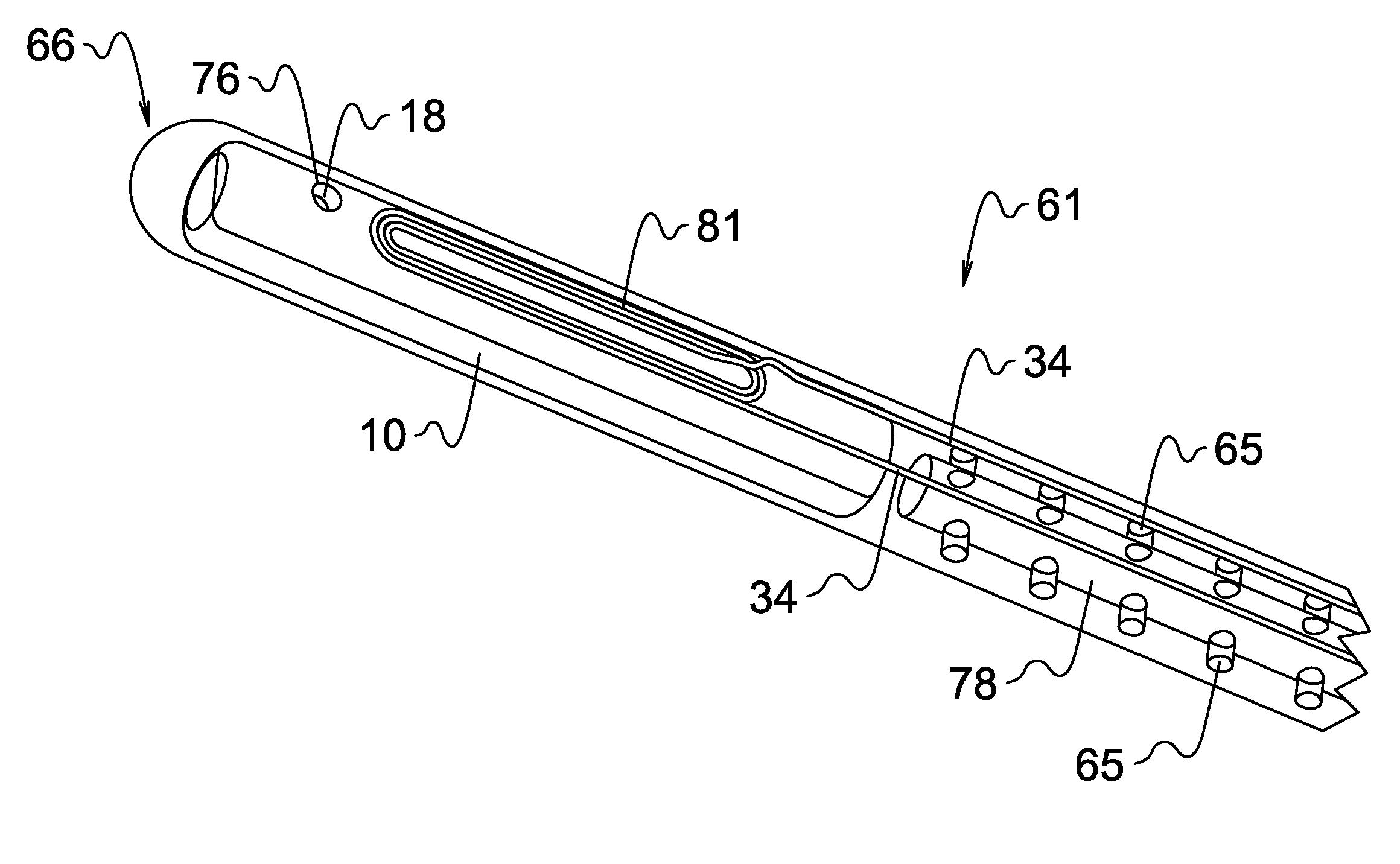

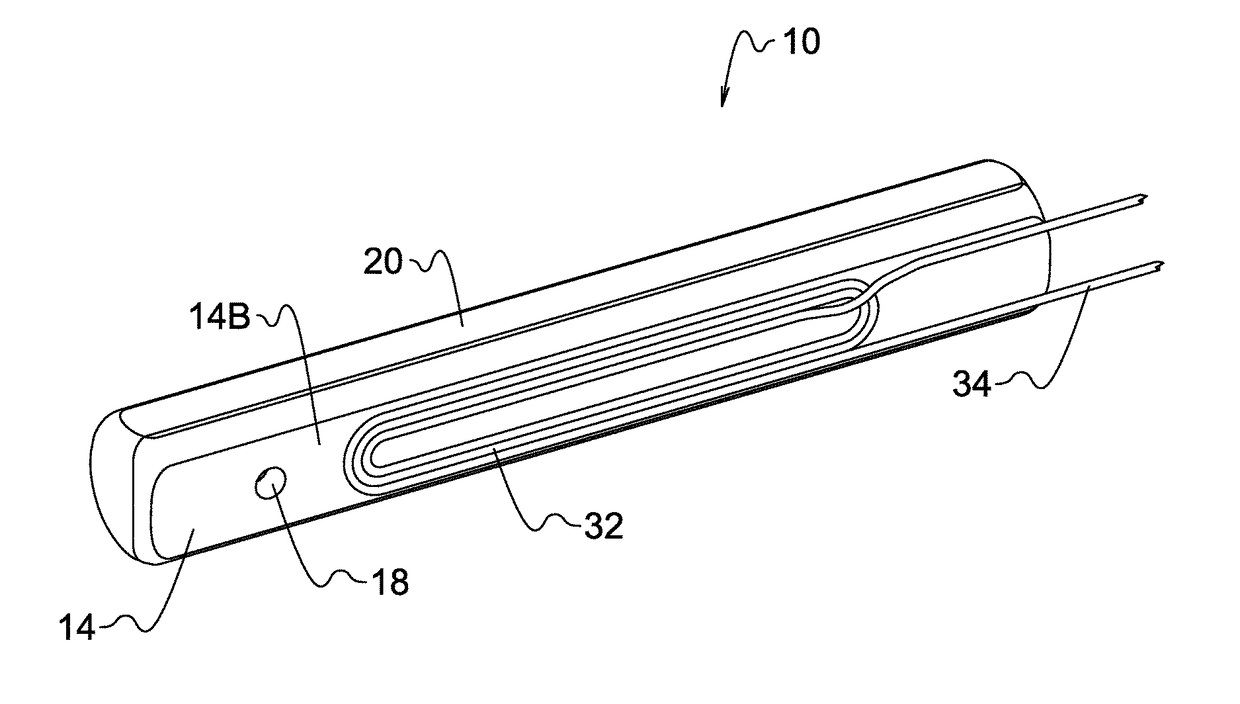

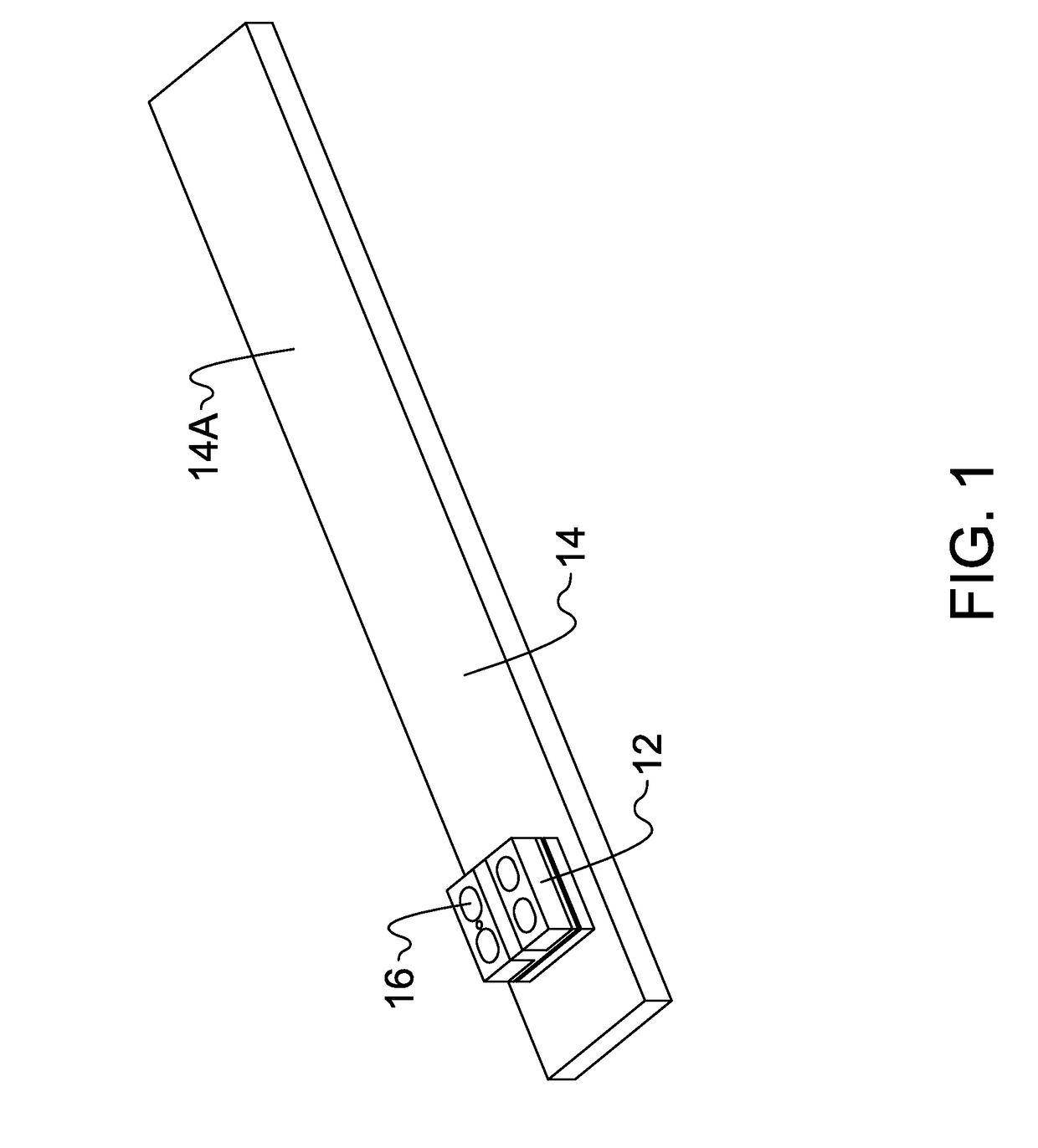

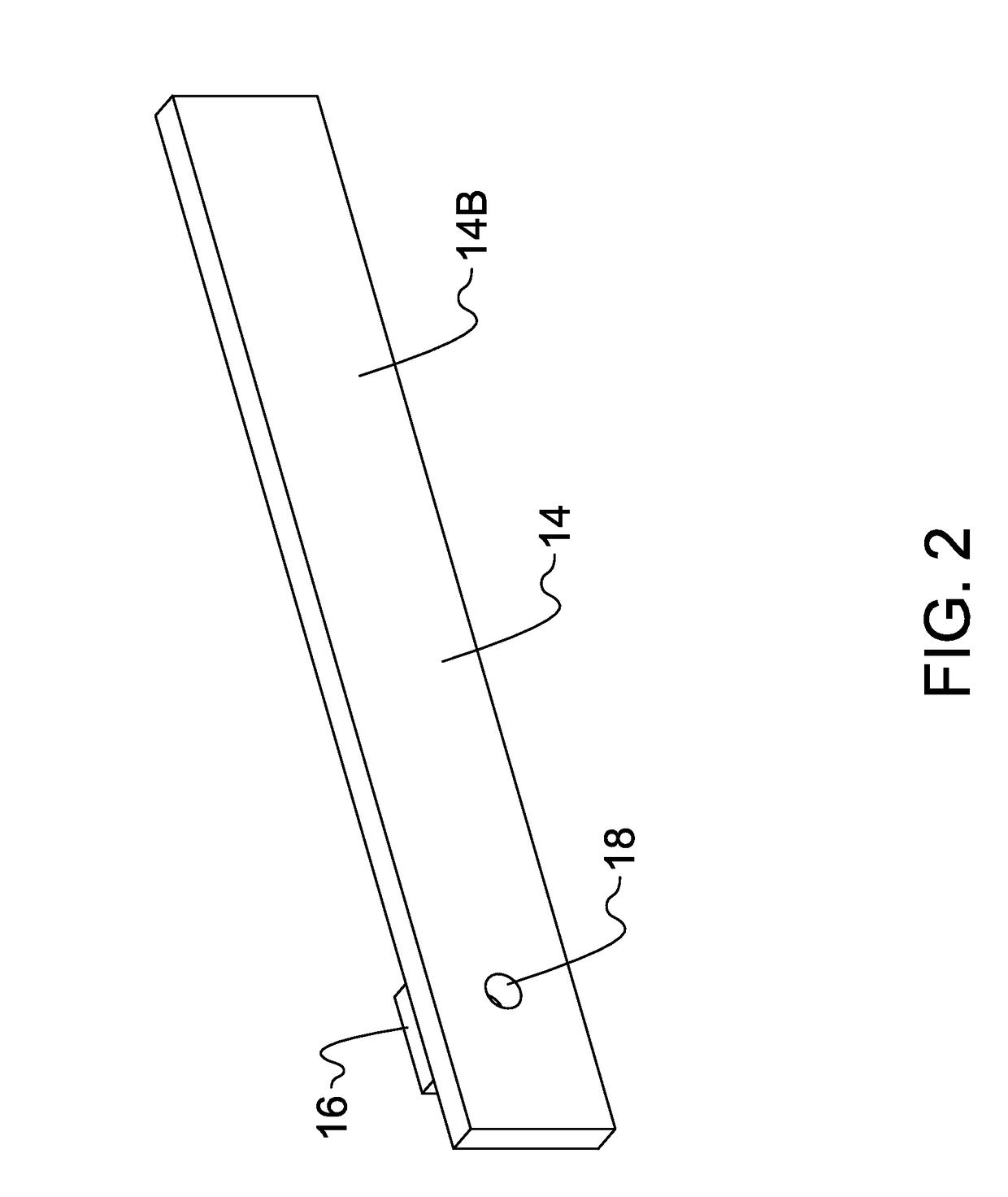

Implantable shunt system and associated pressure sensors

A pressure sensor module configured for implant at a desired site at which a pressure is to be measured. The pressure sensor module includes a pressure sensitive membrane which is in direct contact with the environment at which a pressure is to be measured. The pressure sensor module forms a part of a pressure measuring system which uses a telemetry link between the pressure sensor module and an external controller for data transmission and transfer. The pressure measuring system provides a dual stage power and data transfer capability for use with an implantable system. An exemplary use is in a three pressure sensor system including a flow control valve in a shunt to treat hydrocephalus. An embodiment of the invention includes a pressure sensor and associated electromagnetic coils embedded in the tip portion of the shunt for measuring the pressure of fluid externally of the shunt at the tip portion.

Owner:ALFRED E MANN FOUND FOR SCI RES

Plastic Bag with Overpressure Relief

ActiveUS20110188786A1Reduced strengthReduce overpressureEnvelopes/bags making machineryBox making operationsPlastic bag

Owner:LUCKMANN BURKHARD +3

Explosion-proof double-layer high-pressure hydrogen storage tank

PendingCN110566810AReduce the probability of occurrenceWeaken the destructive powerContainer filling methodsContainer discharging methodsHigh pressure hydrogenHigh pressure

The invention relates to an explosion-proof double-layer high-pressure hydrogen storage tank. A tank body of the tank comprises an inner tank and an outer tank which are integrally connected by tank holders; an interlayer between the inner tank and the outer tank is filled with an explosion inhibitor, and the interlayer is provided with an explosion inhibitor inlet and an explosion inhibitor outlet; the inner tank is connected with the outer tank by a pipeline which leads to the outside of the tank, and the pipeline is separated from the interlayer. The storage tank is mainly used for storinghigh-pressure hydrogen. The storage tank can effectively prevent spontaneous combustion of high-pressure hydrogen due to accidental leakage and inhibit gas cloud explosion, and has simple structure and obvious economic advantage.

Owner:EAST CHINA UNIV OF SCI & TECH

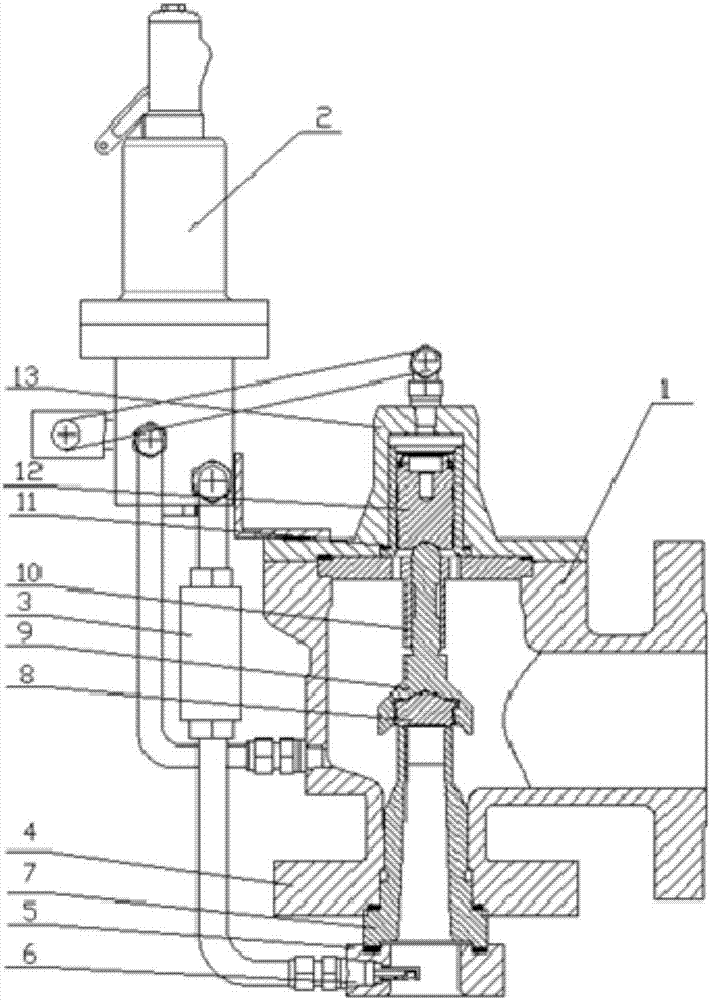

Pilot operated safety valve for high-temperature working conditions

ActiveCN107300027AAir chamber pressure dropReduce overpressureSpindle sealingsOperating means/releasing devices for valvesEngineeringSafety valve

The invention relates to the technical field of valve design, and specifically discloses a pilot operated safety valve for high-temperature working conditions. The pilot operated safety valve for the high-temperature working conditions comprises a main valve, a pilot valve and a heat exchange device, wherein the pilot valve is connected with one end of the heat exchange device, a gas chamber of the main valve and the valve body cavity of the main valve through pressure pipes respectively, and the other end of the heat exchange device is connected with a dipper-shaped pipe arranged at the main valve through a pressure pipe. According to the pilot operated safety valve for the high-temperature working conditions, an inlet seal structure is designed in the pilot valve so as to prevent a medium from entering the gas chamber of the main valve through the pilot valve, and an outlet seal structure is designed in the pilot valve so as to prevent a medium in the gas chamber of the main valve from entering the outlet of the pilot valve; in addition, a metal hard seal structure is adopted in the sealing surface of the main valve, a valve flap of the main valve is mounted on a recoil plate and can swing slightly, and when the main valve is closed, the valve flap of the main valve can be automatically calibrated so as to improve the sealing performance of the main valve while the problem of high-temperature seal of the main valve is solved.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

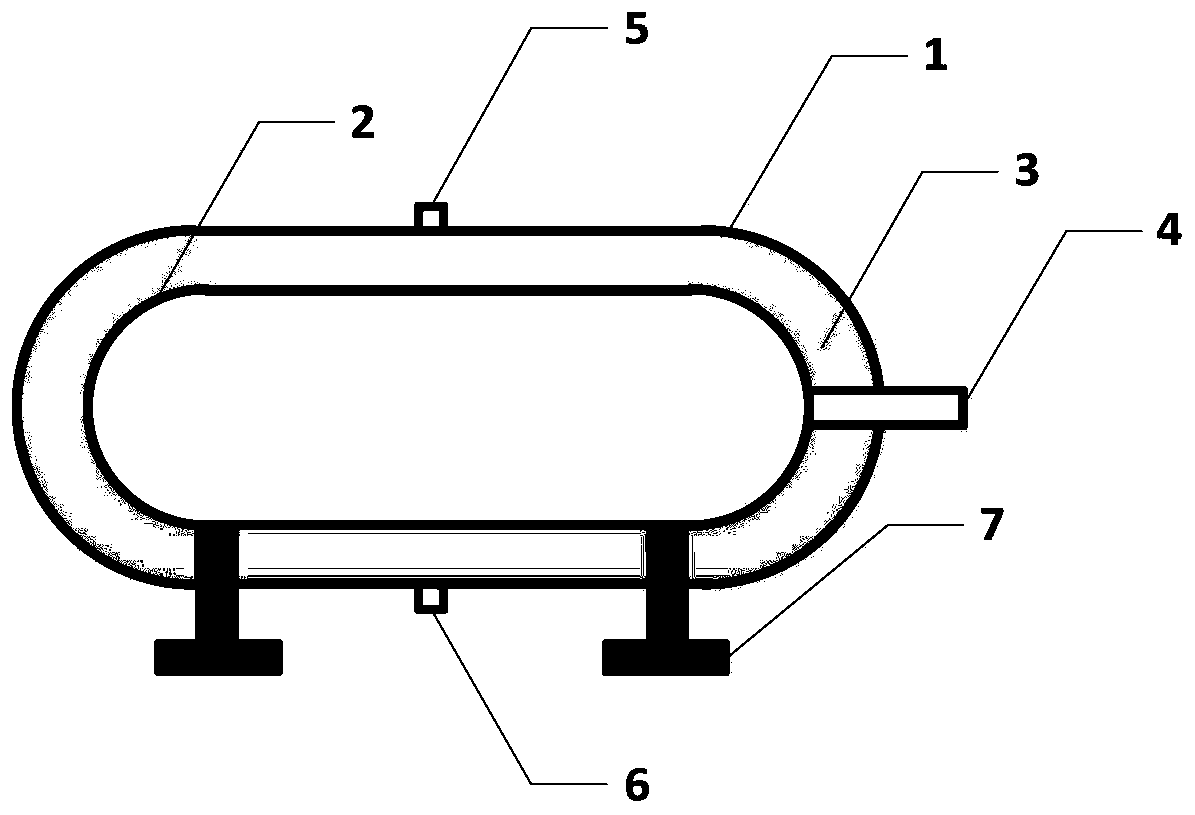

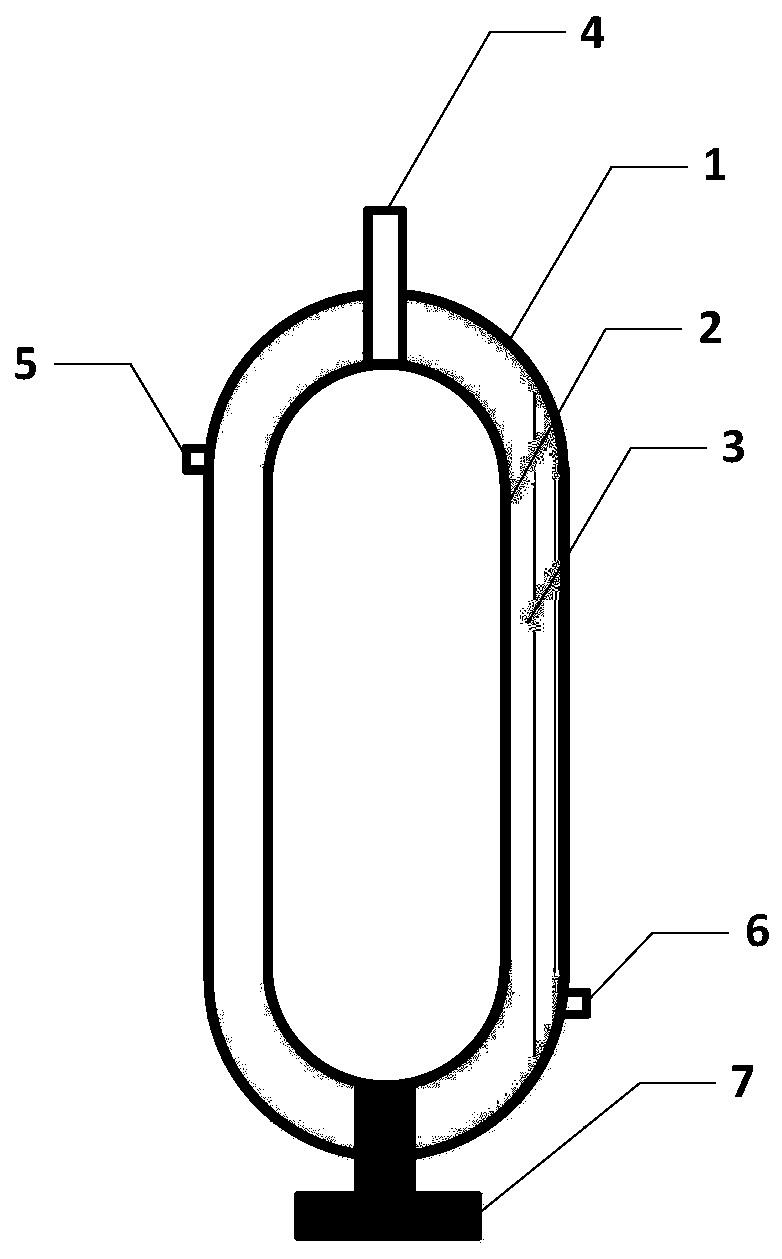

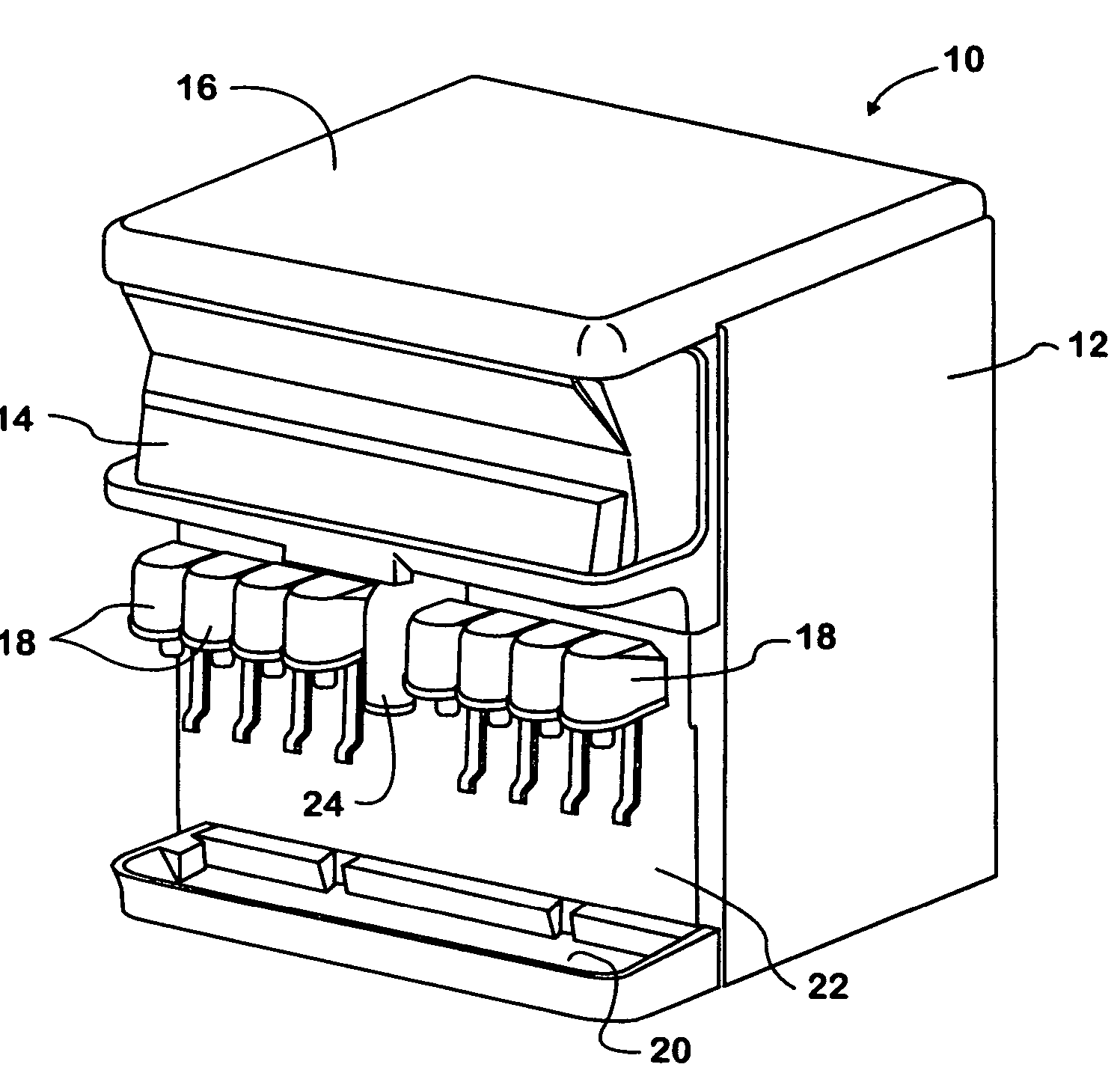

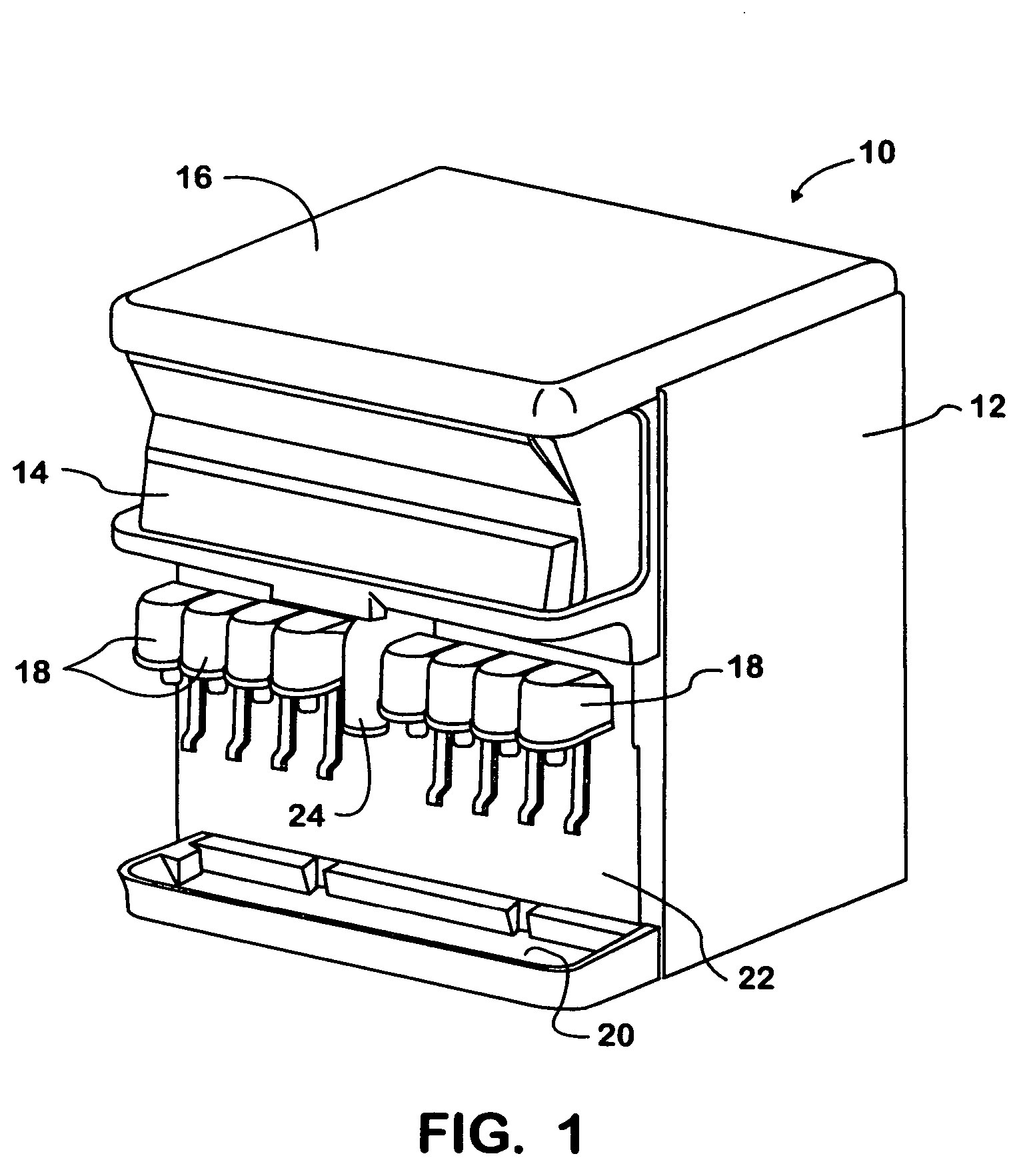

Carbonator with remote liquid level sensor

InactiveUS20060060606A1Reduce overpressureLighting and heating apparatusUsing liquid separation agentLiquid level sensorControlled delivery

A carbonator for a beverage dispenser is characterized by a carbonator tank that is placed at a generally inaccessible first location in the beverage dispenser. Liquid and CO2 are supplied to the tank to carbonate liquid in the tank and carbonated liquid at an outlet from the tank is delivered to a beverage dispensing valve. To control delivery of liquid to the carbonator tank and thereby the level of liquid in the tank, a liquid level sensor is fluid coupled to an interior of the tank and is placed in the beverage dispenser at a generally accessible second location that is remote from the first location and from the tank. Placement of the liquid level sensor remote from the carbonator tank and at an accessible location facilitates its repair and replacement.

Owner:JABLONSKI THADDEUS M +1

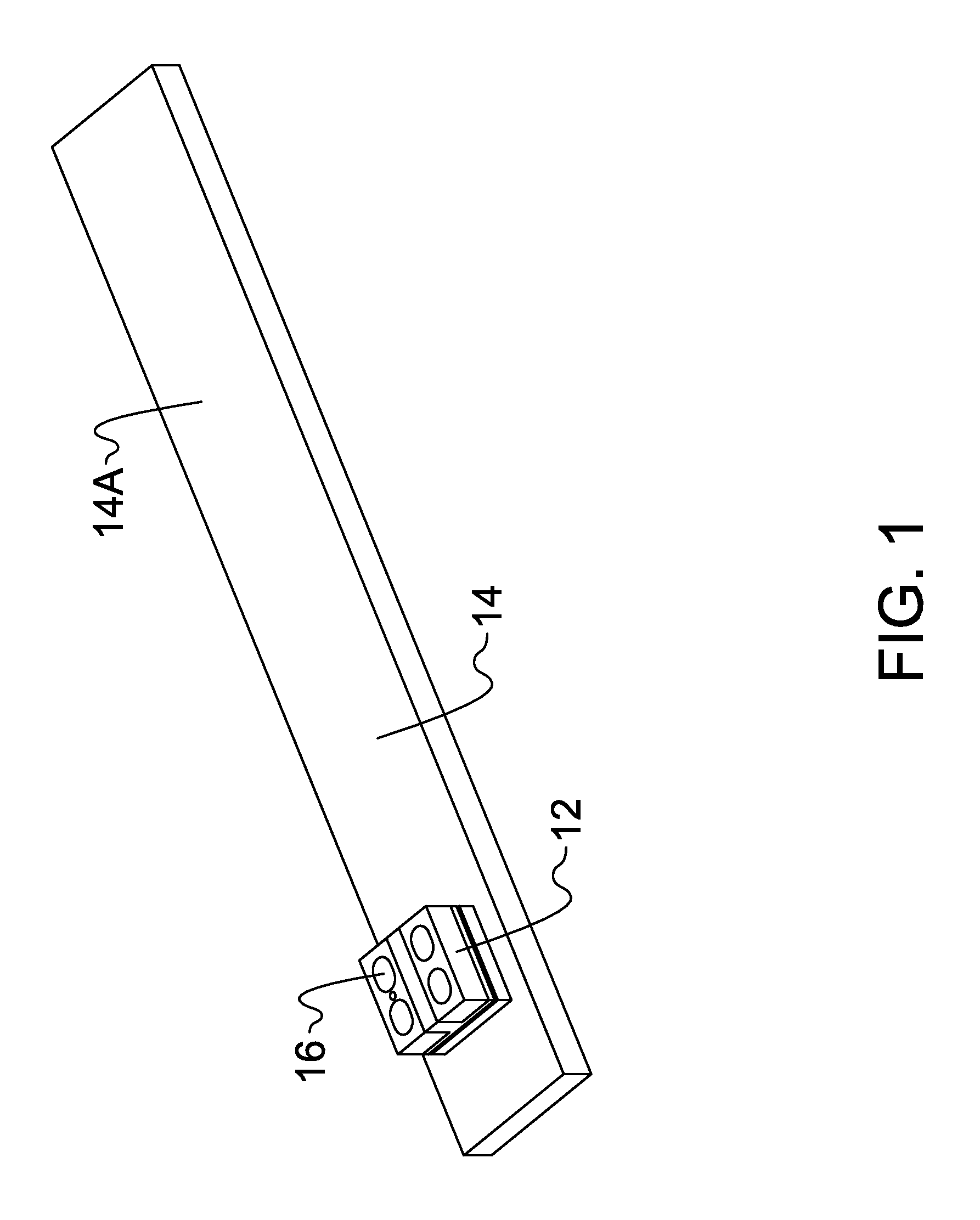

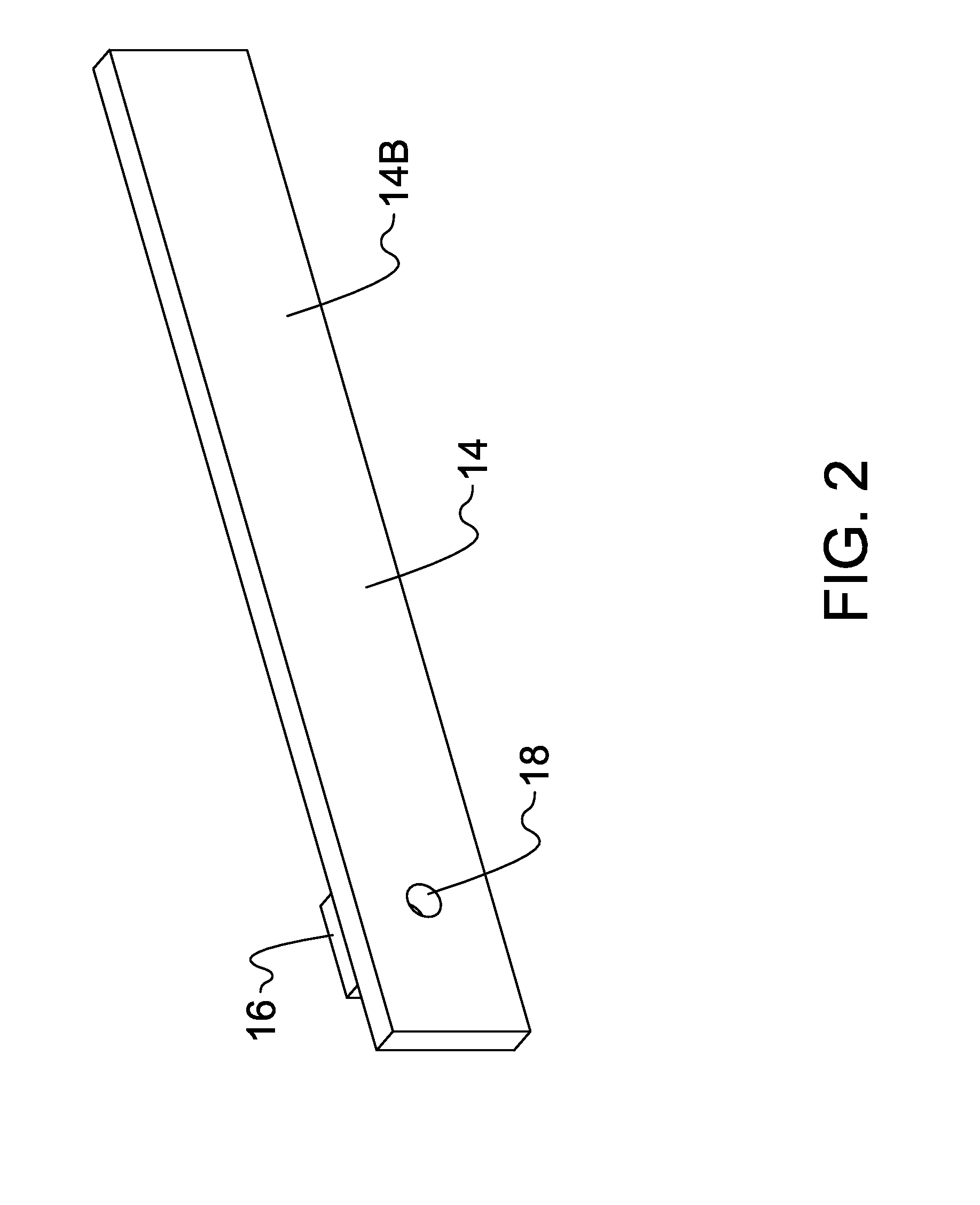

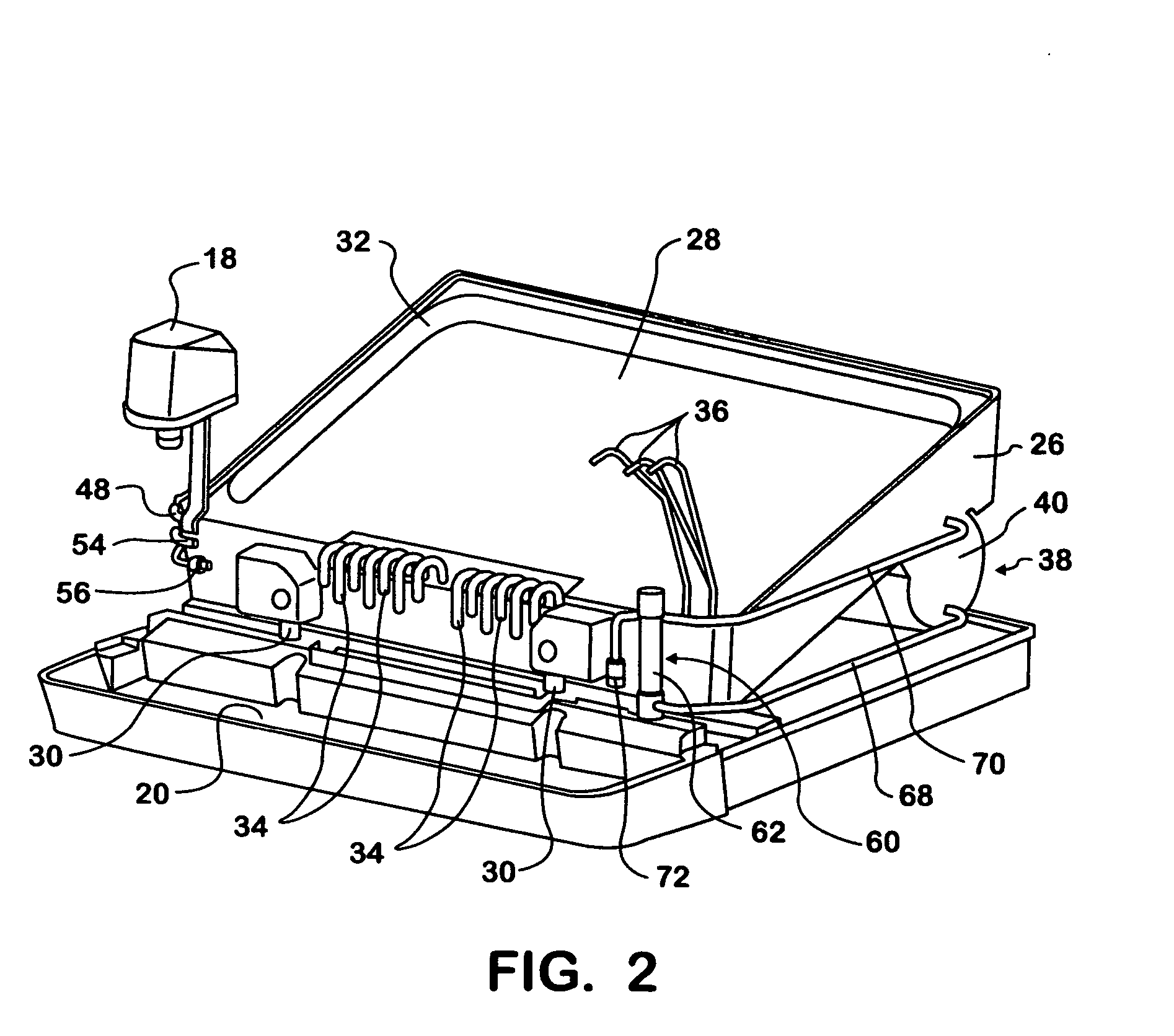

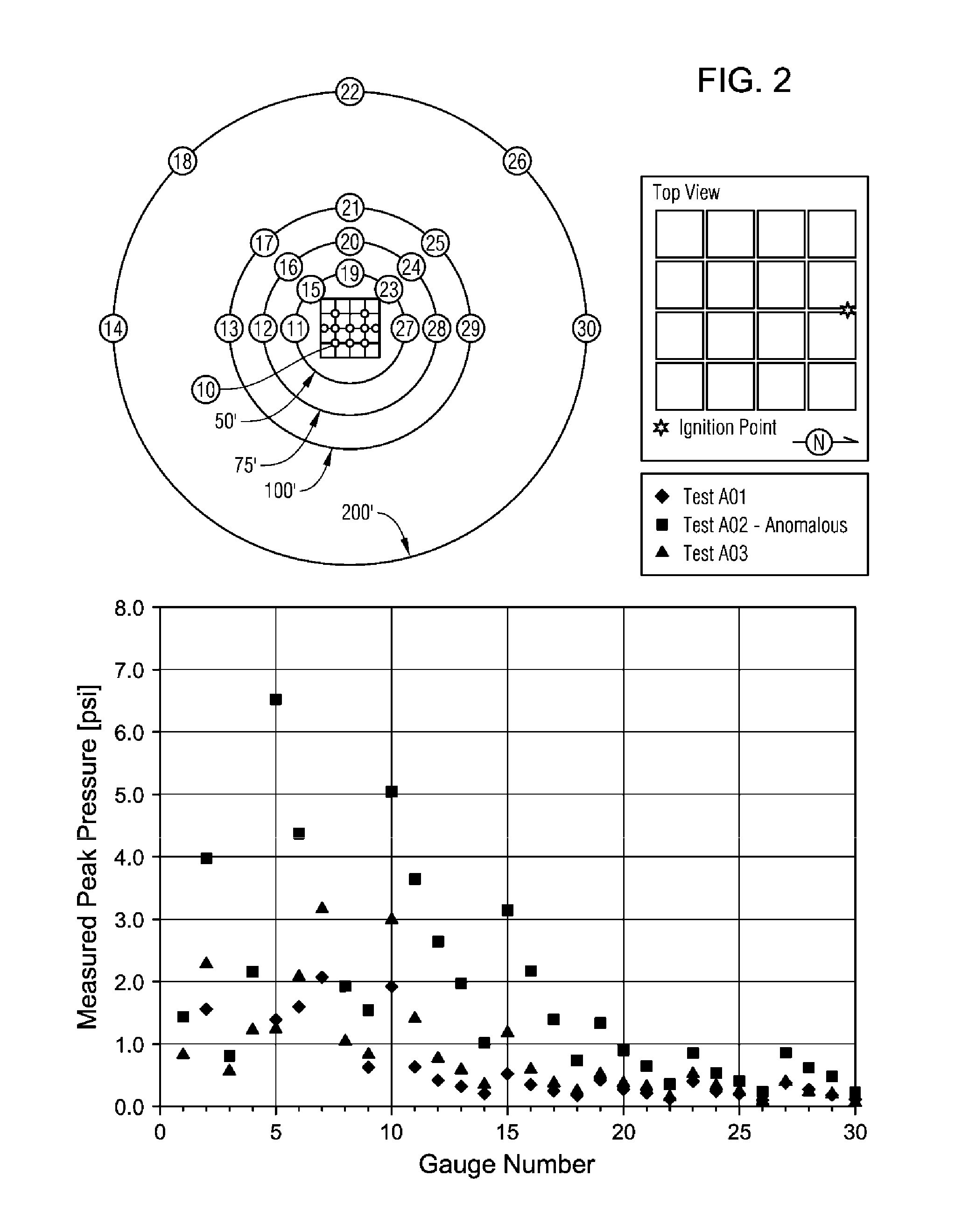

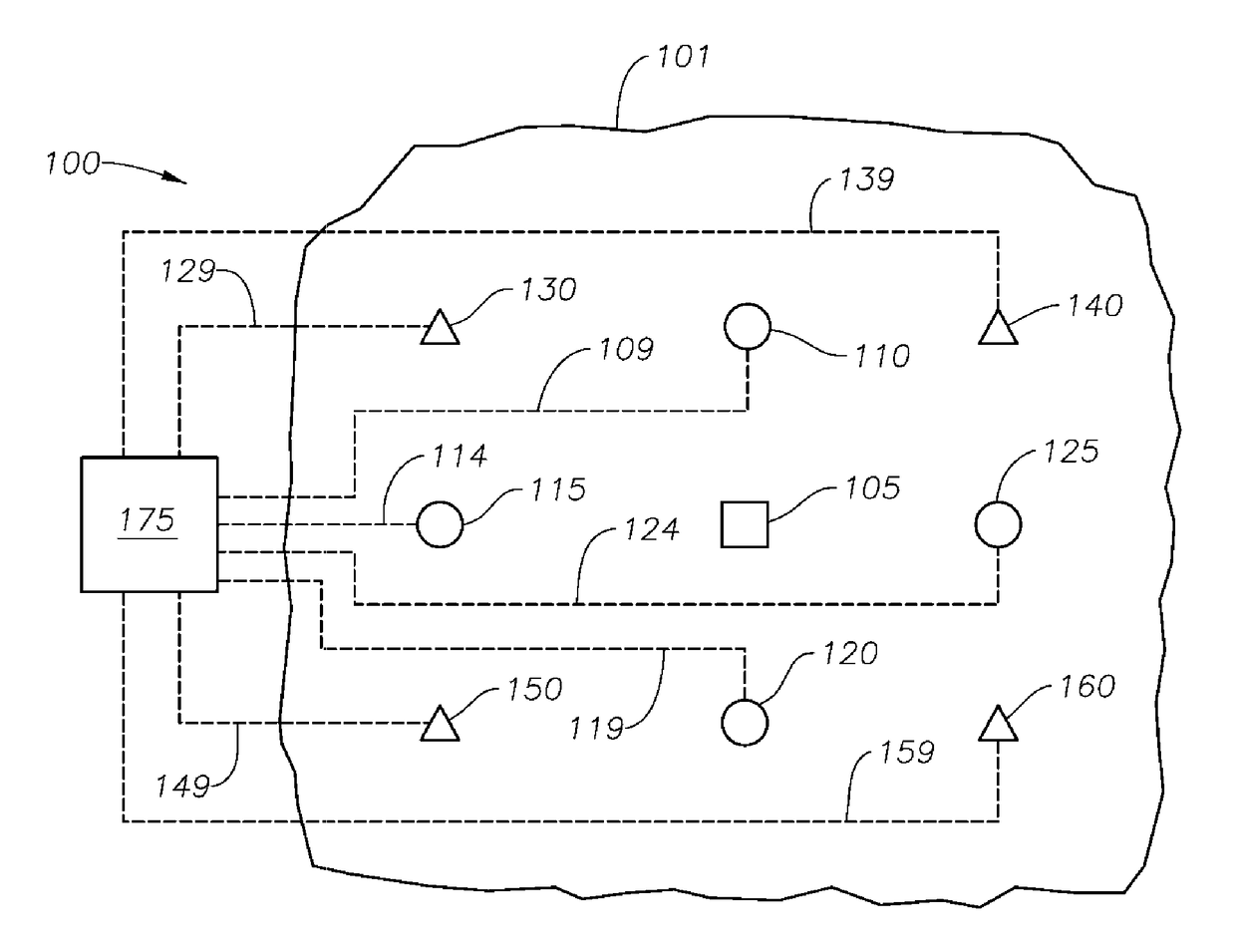

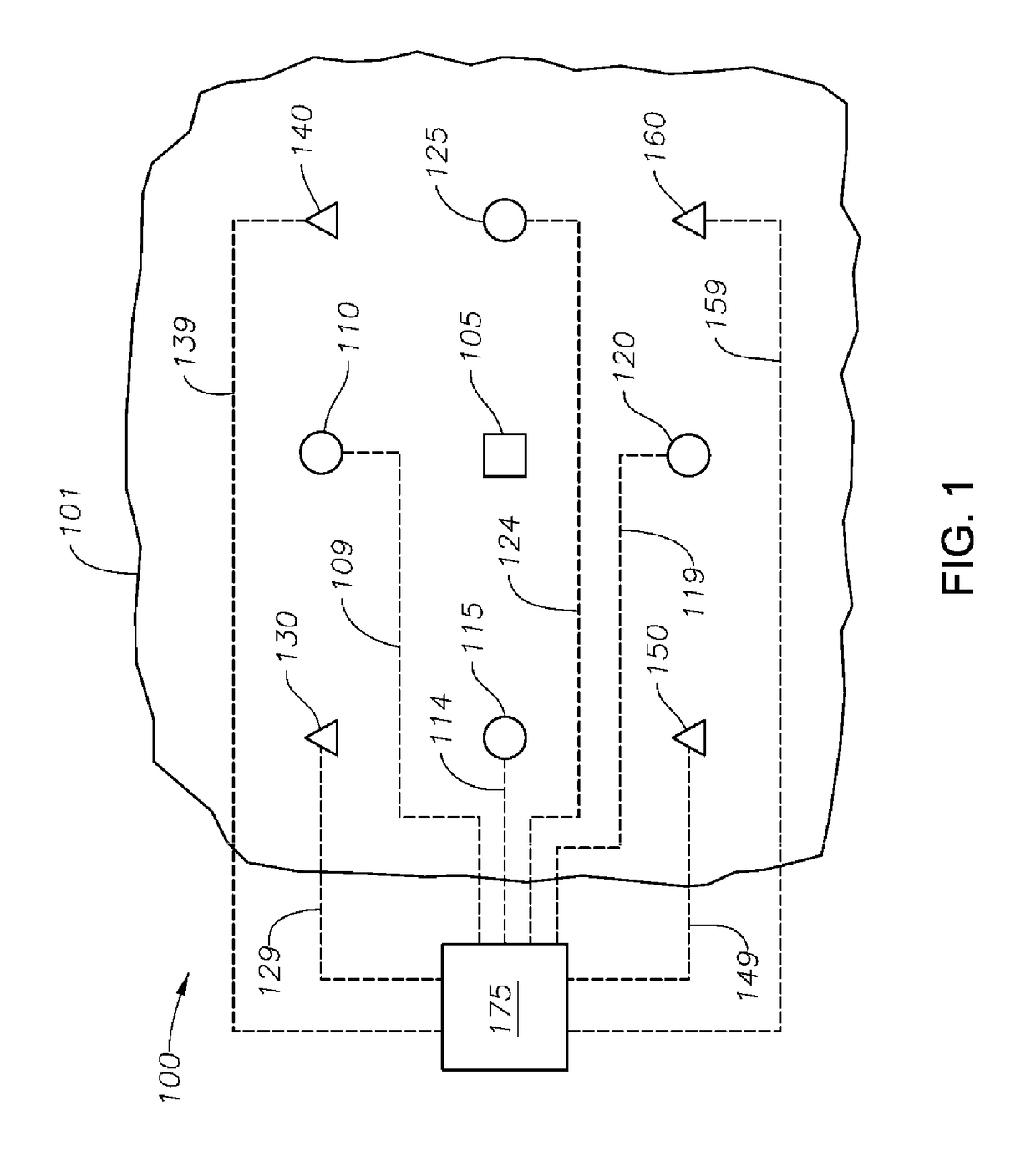

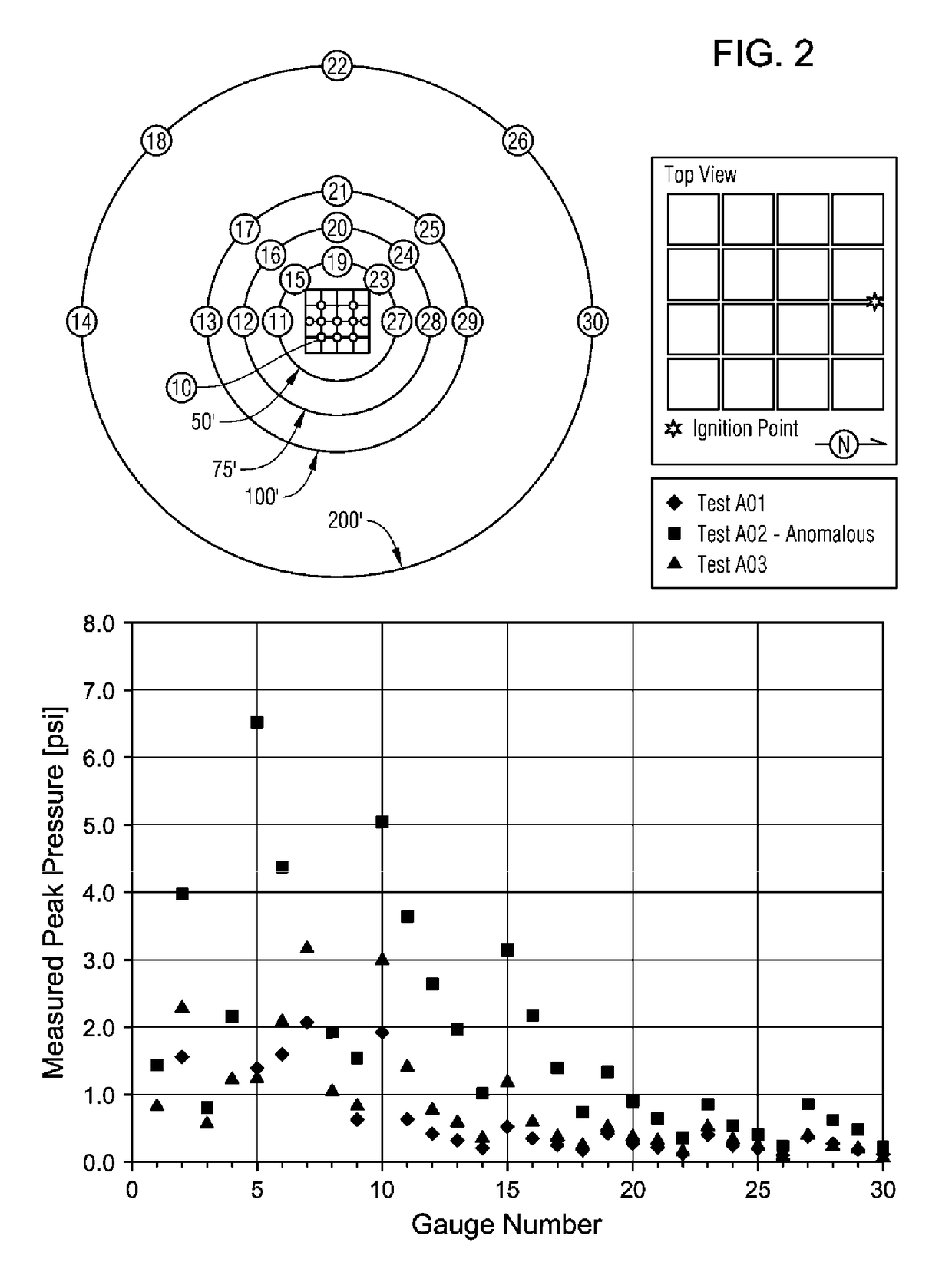

Systems and methods for reducing an overpressure caused by a vapor cloud explosion

Systems and methods for reducing an overpressure caused by an explosion of a vapor cloud are provided. In one or more embodiments, the system can include one or more sensors operable to detect the explosion of the vapor cloud. The system can also include one or more igniters operable to ignite the vapor cloud at locations throughout, after the explosion of the vapor cloud is detected, to provide a discrete combustion zone at each location. Each combustion zone can form a discrete pressure wave, thereby reducing the overpressure caused by the explosion of the vapor cloud.

Owner:EXXON RES & ENG CO

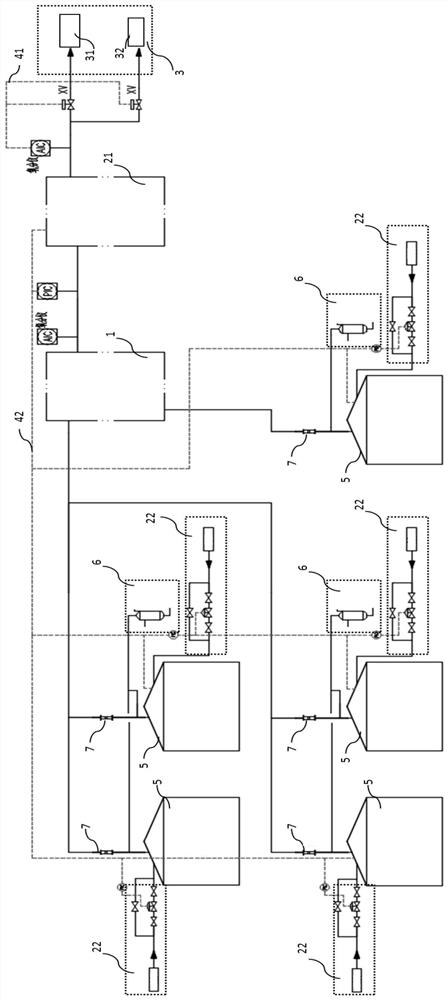

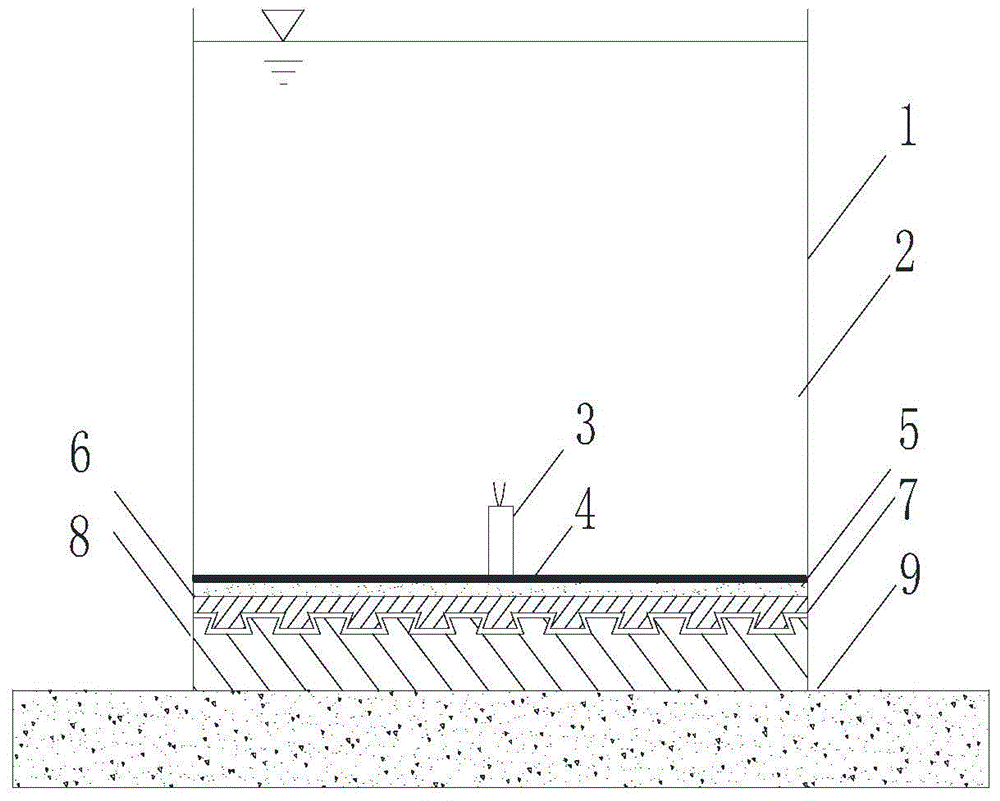

Liquid storage tank tail gas treatment system and method

PendingCN113357541ARealize airtight recyclingEliminate leaksPipeline systemsIncinerator apparatusExhaust gasPetrochemical

The invention relates to the field of gas treatment, in particular to a liquid storage tank tail gas treatment system and method. The liquid storage tank tail gas treatment system comprises a purification unit, a pressure regulating unit, a tail gas treatment unit and a control unit, the purification unit communicates with the top of a liquid storage tank, and the pressure regulating unit comprises a gas extracting device and a gas supplementing device; and the gas extracting device communicates with the purification unit, the gas supplementing device communicates with the top of the liquid storage tank, the tail gas treatment unit comprises a tail gas recovery device and a tail gas incineration device which are arranged in parallel, and the control unit comprises a first controller and a second controller. According to the liquid storage tank tail gas treatment system, the whole-course closed recovery of tail gas at the top of a sulfur-containing sewage tank of a petrochemical refinery plant, the safety control of the liquid storage tank and the recovery of high-value light hydrocarbon are realized, the effect is remarkable effect, and the liquid storage tank tail gas treatment system can be applied and popularized in similar devices in petrochemical industry, coal chemical industry and the like.

Owner:CHINA PETROLEUM & CHEM CORP

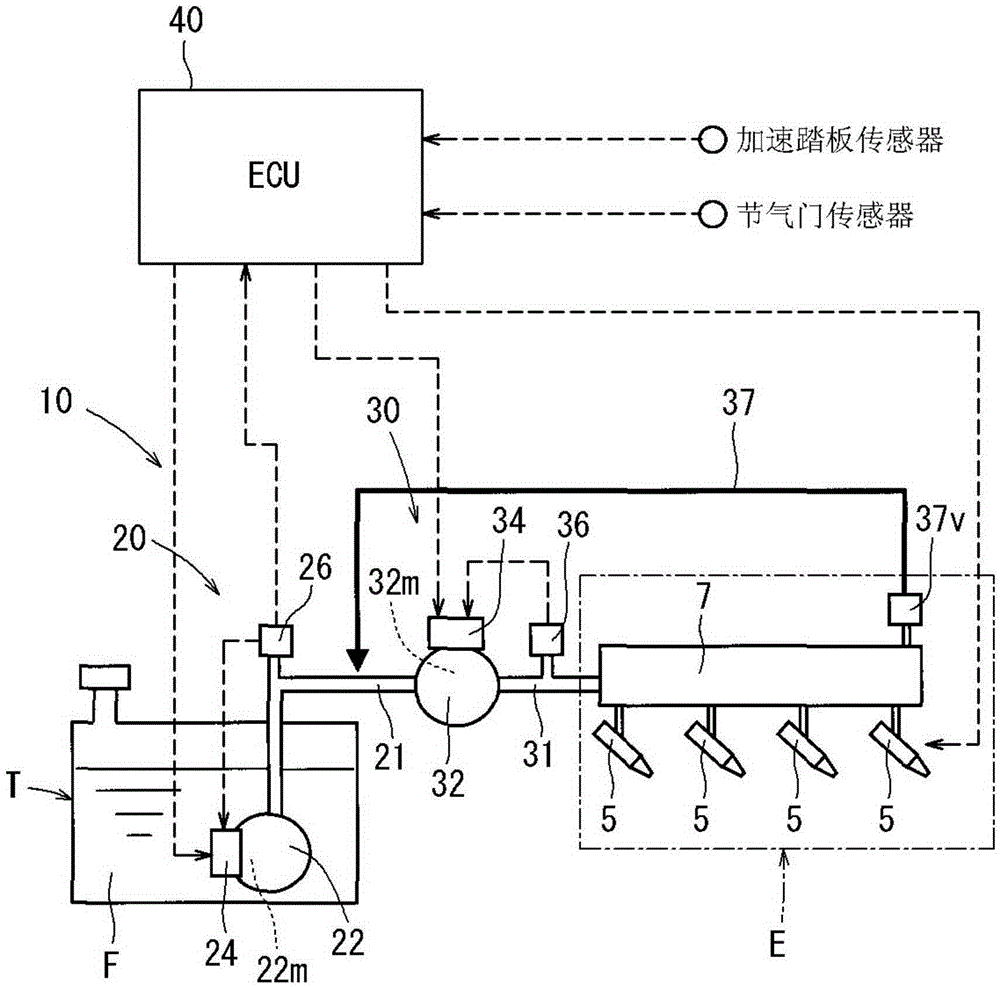

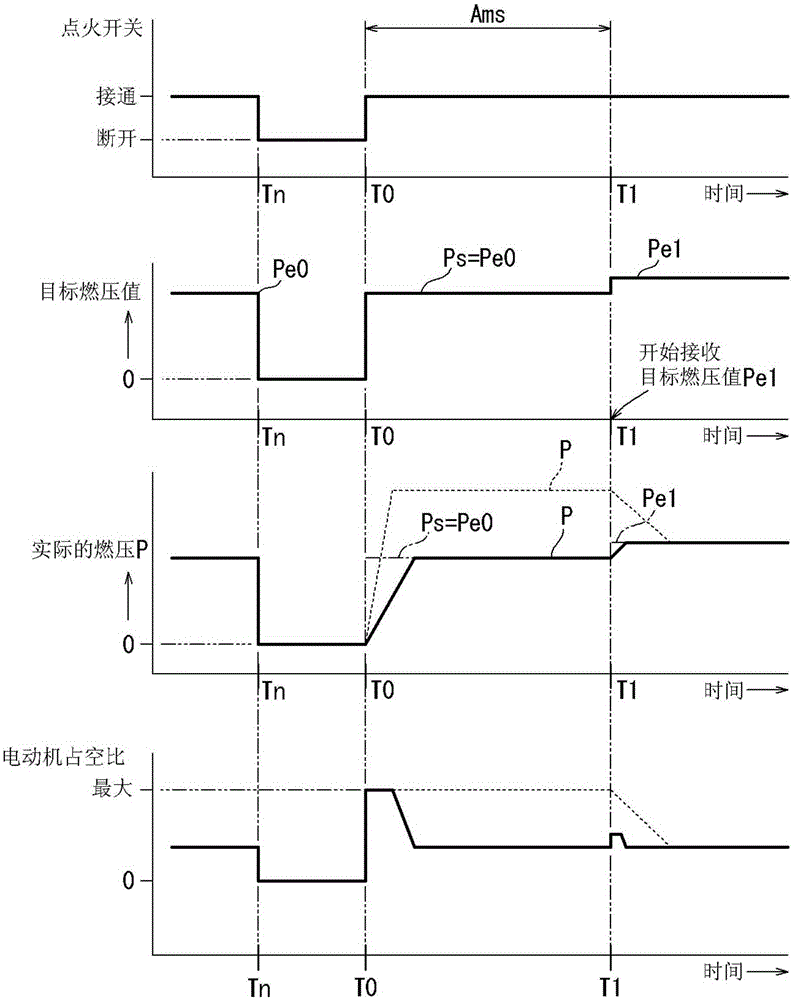

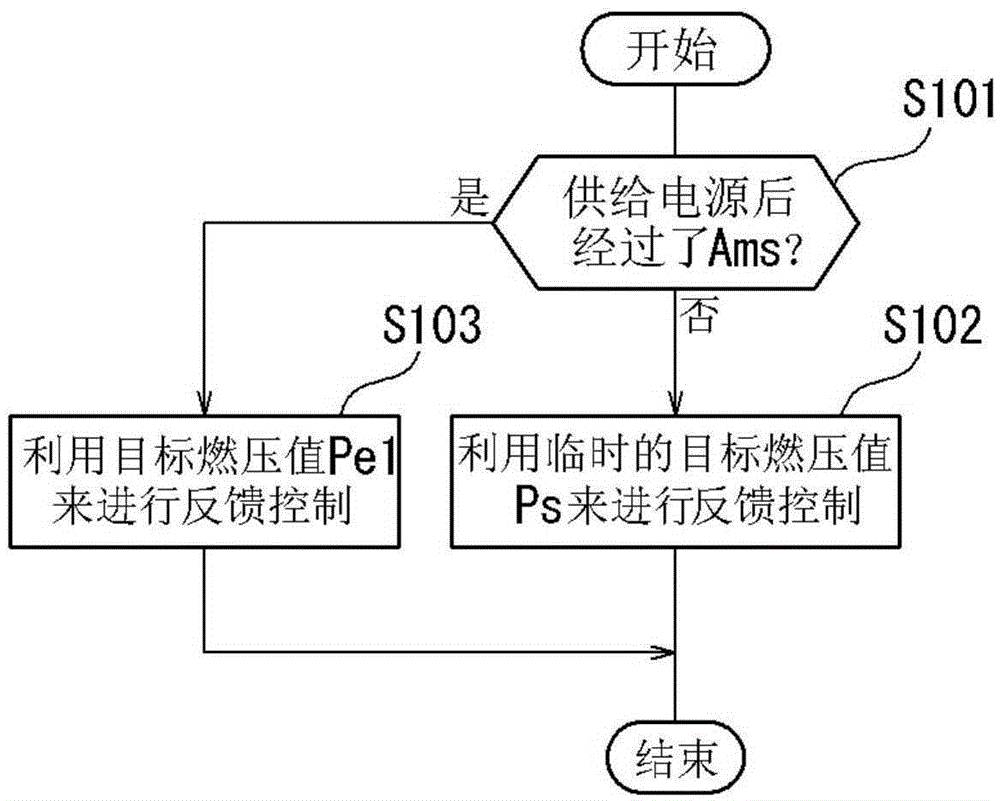

Fuel-supply system

ActiveCN105422295AReduce overpressureReduce power consumptionElectrical controlMachines/enginesFuel tankFeedback control

The invention provides a fuel-supply system. The invention aims to realize a fact that a pressure control part can properly control a fuel pressure before reception of a target fuel pressure from a control device. The fuel-supply system is provided with the components of a fuel pump which is driven through a motor and pressurizes the fuel in a fuel tank for conveying the pressurized fuel to an engine; a pressure control part which performs feedback control on voltage which is applied by the motor so that the fuel pressure approaches a target fuel pressure; the control device which transmits the target fuel pressure to the pressure control part; and a power supply device which supplies electric power to the motor, the pressure control part and the control device. After the switch of the power supply device is switched on (at a time point T0) and before the target fuel pressure (Pel) is received by the pressure control part from the control device (at a time point T1), the pressure control part utilizes a temporary target fuel pressure (Ps) for performing feedback control on the fuel pressure (P).

Owner:AISAN IND CO LTD

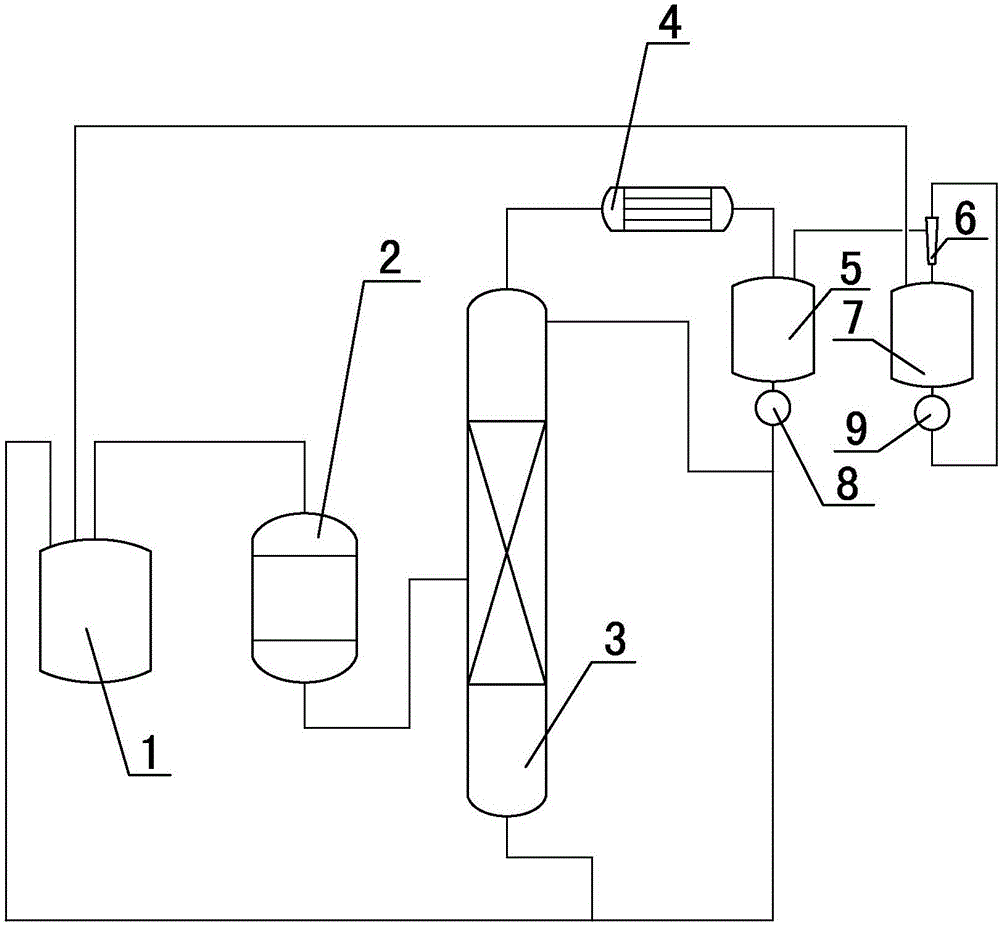

Production technology of thionyl chloride

ActiveCN106629626AAchieving zero emissionsReduce the probability of exposure to waterThionyl chlorideChemical industryGas phase

The present invention relates to the technical field of chemical industry production and in particular relates to a production technology of thionyl chloride. Sulfur and chlorine gas are reacted in a synthesis reactor to produce synthesis gas, the synthesis gas and sulfur dioxide gas enter together into a reactor, produced crude products of the thionyl chloride after the reaction in the reactor directly enter into a distillation column in a gas state, and gas phase from the top of the distillation column is condensed, the condensed gas enters into a reflux tank; and gas phase in the reflux tank enters into an evacuation tank via an ejector, the treated gas is recycled into the synthesis reactor, and qualified products are collected at the middle part of the distillation column. The production technology is simplified and the technologies of condensation, sulphur combining, light component recycling, etc. of the reacted crude products of the thionyl chloride are saved. Due to the reduction of the condensation and regasification, the technology is relatively short in routes and minimal in heat loss, and greatly reduces energy consumptions of the devices.

Owner:SHANDONG KAISHENG NEW MATERIALS

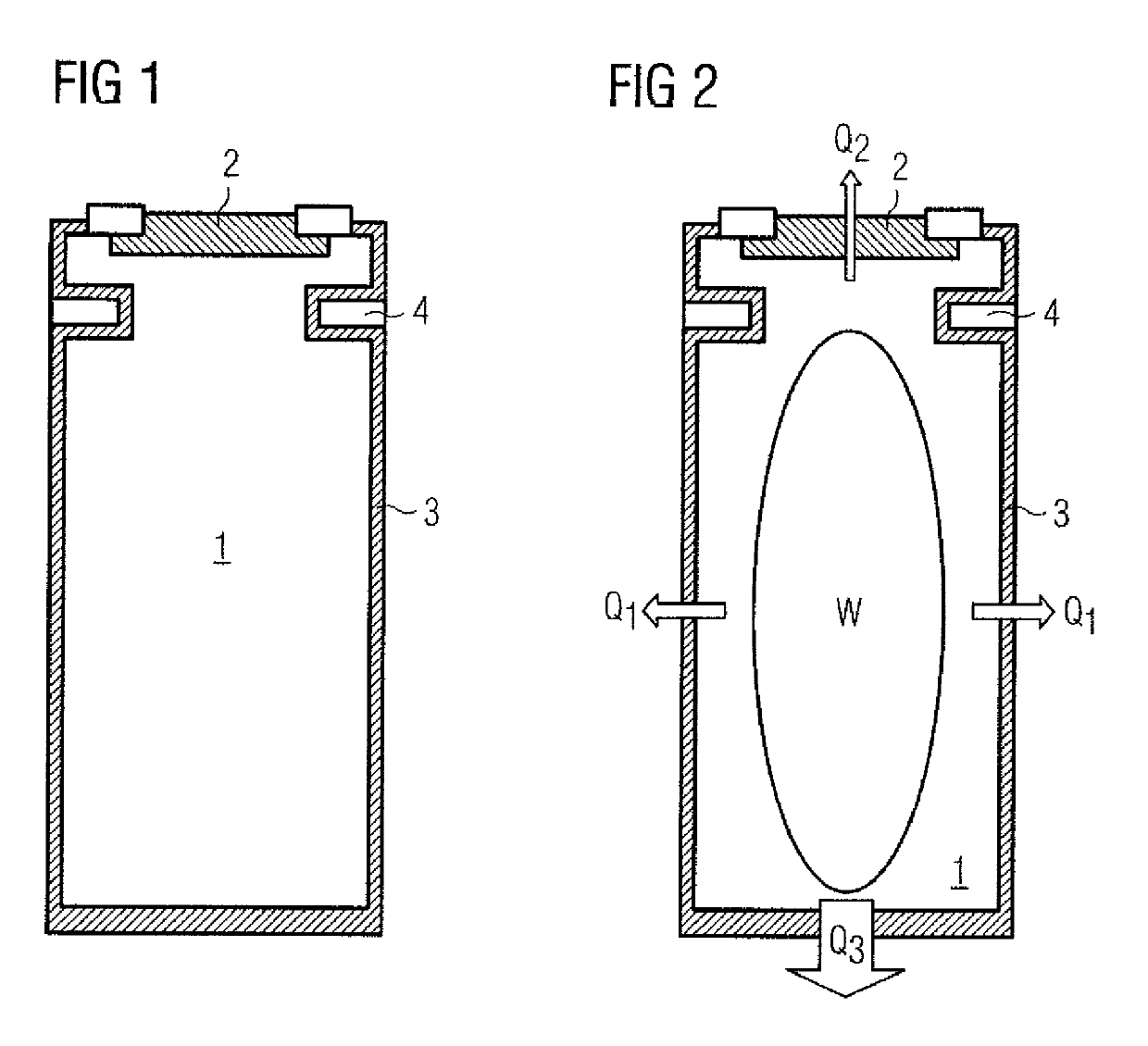

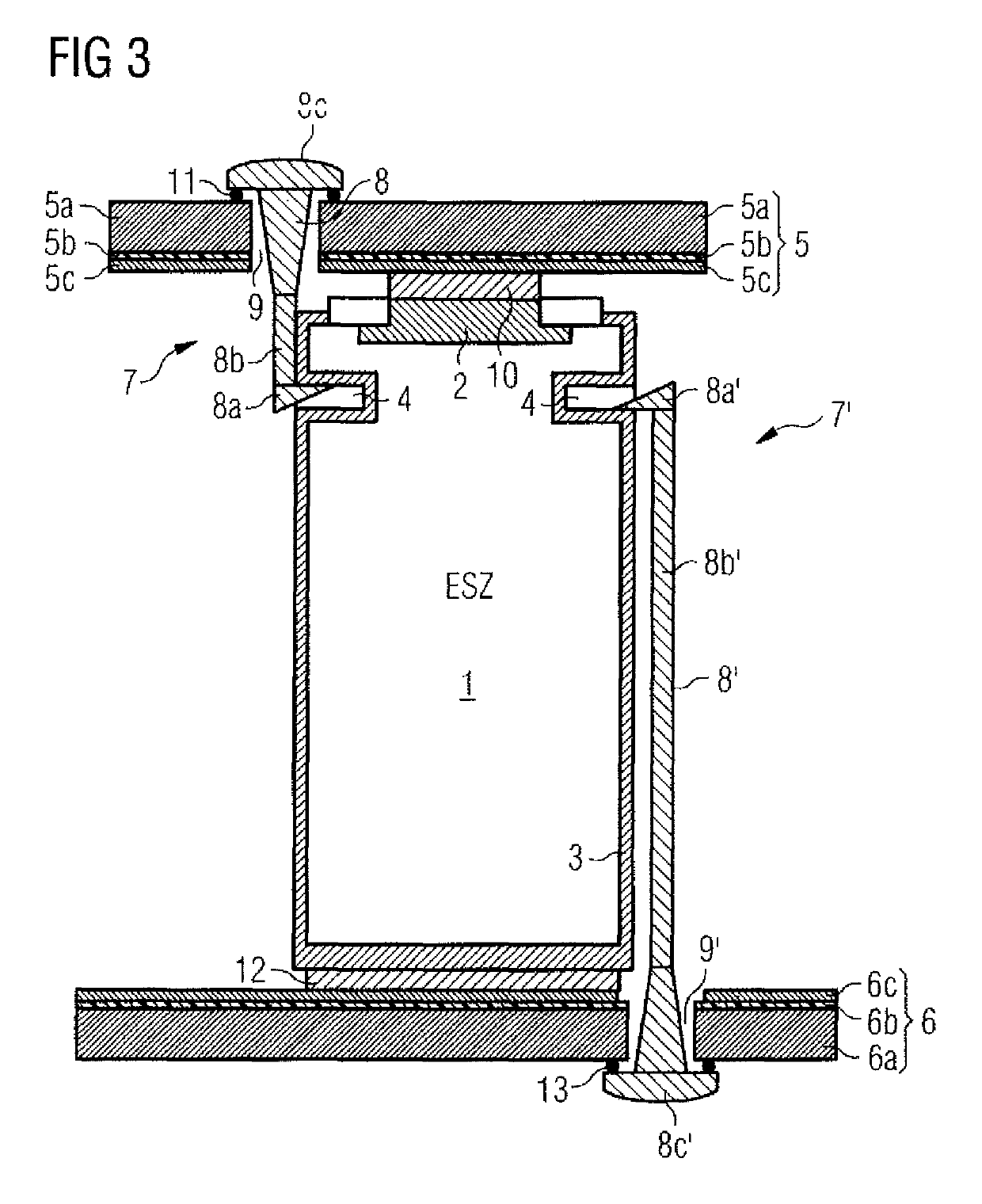

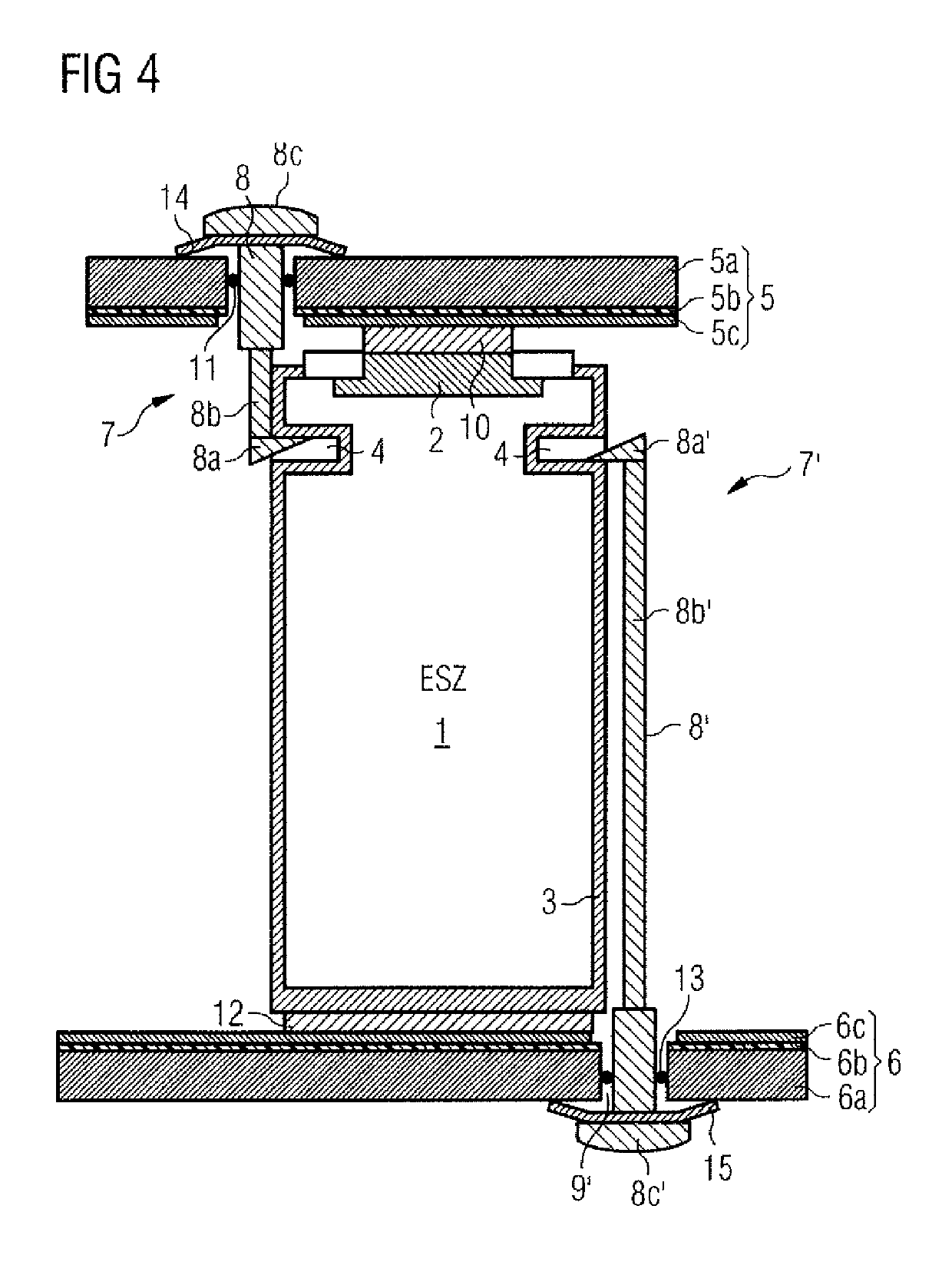

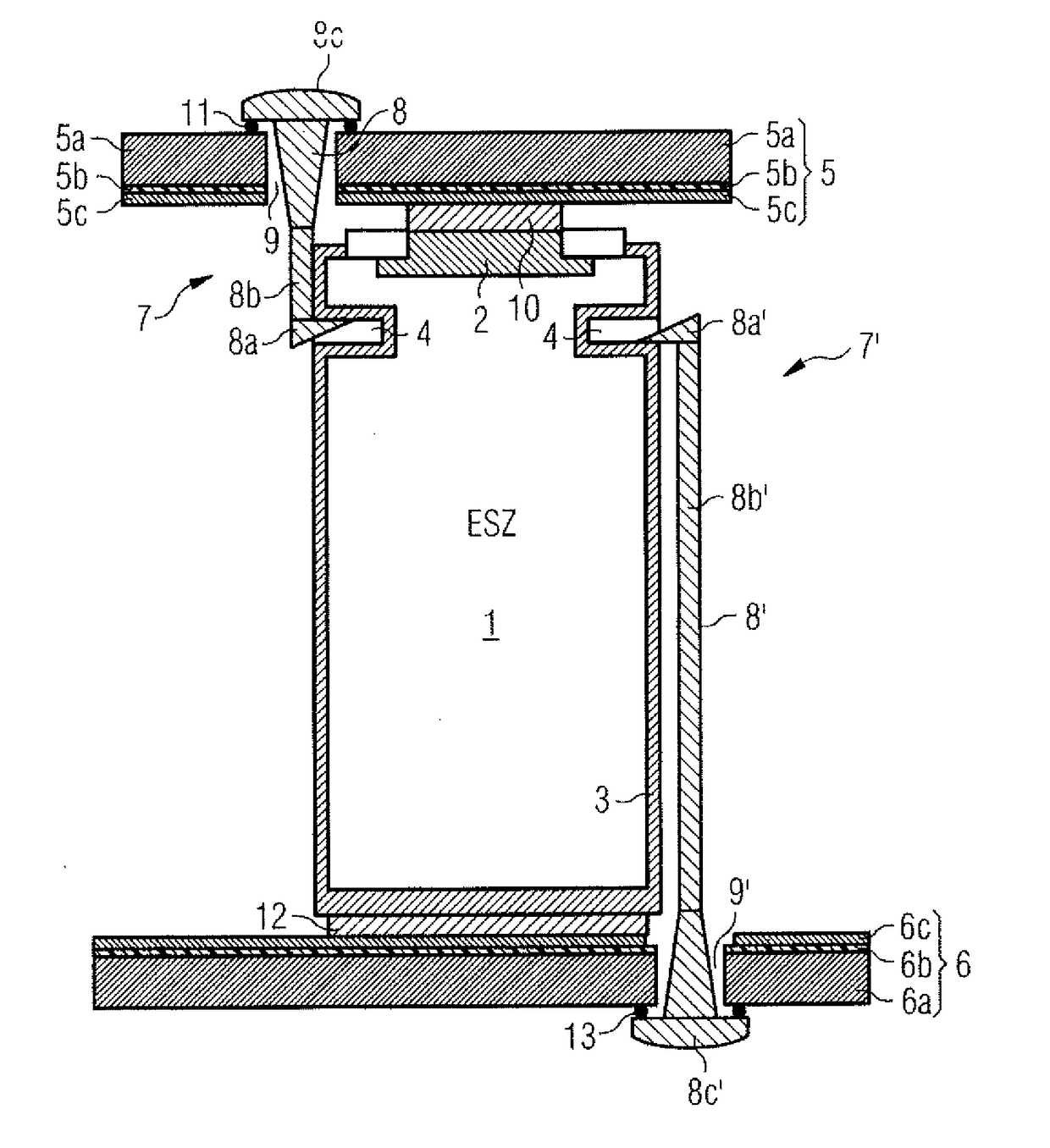

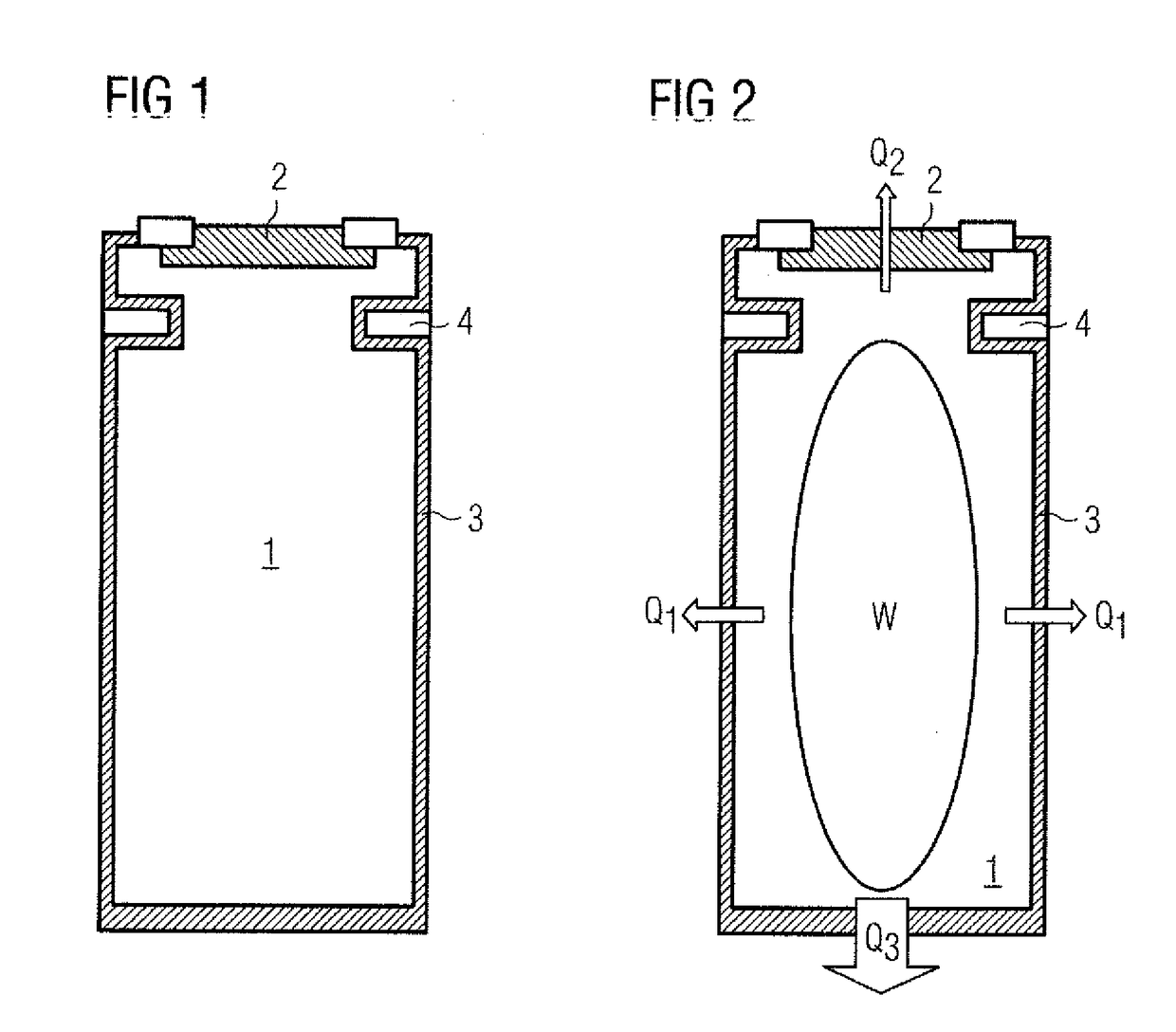

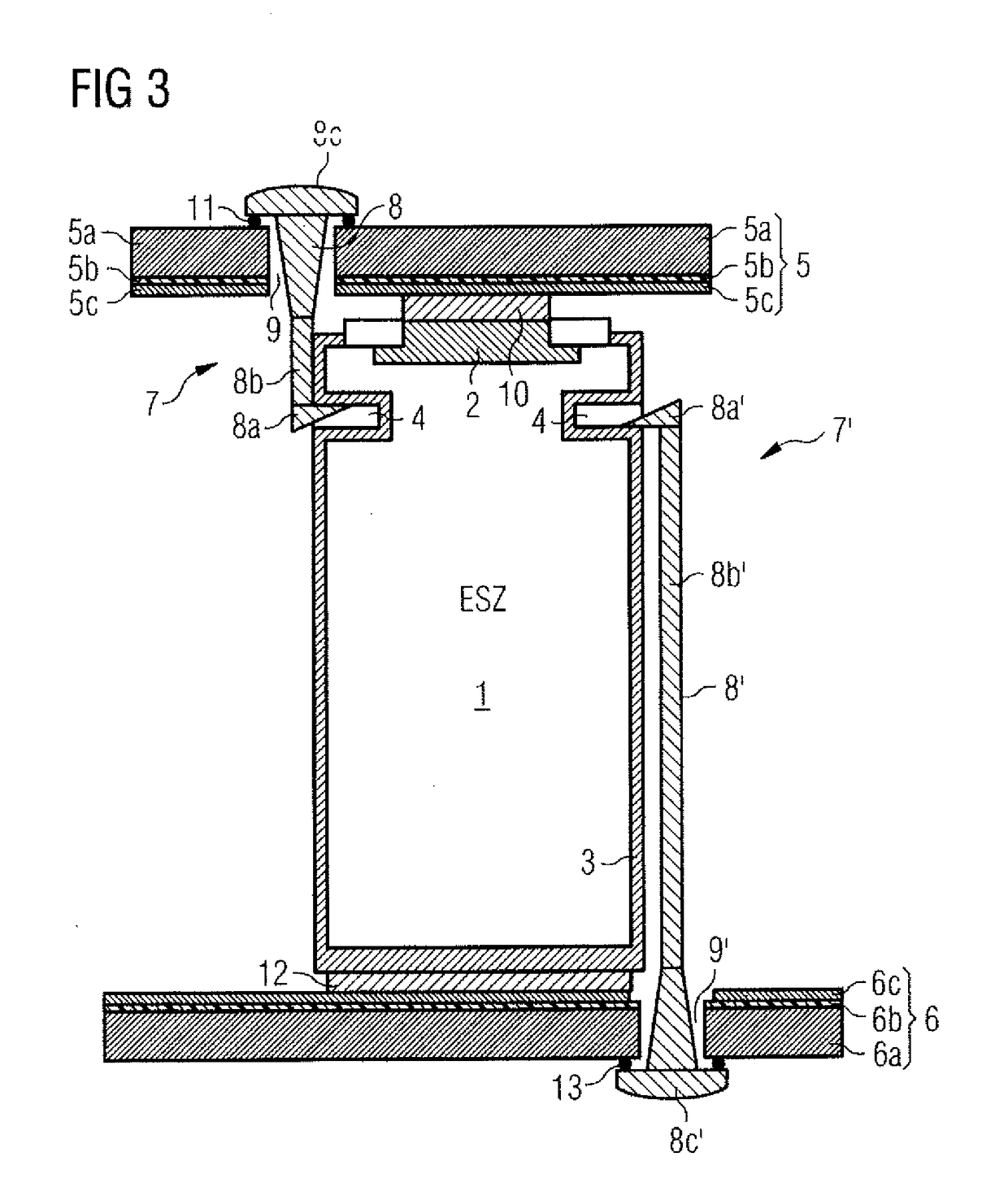

Contacting apparatus for contacting an energy storage cell

InactiveUS10340487B2Precise positioningReduce weightCoupling device connectionsCoupling device engaging/disengagingContact pressureEngineering

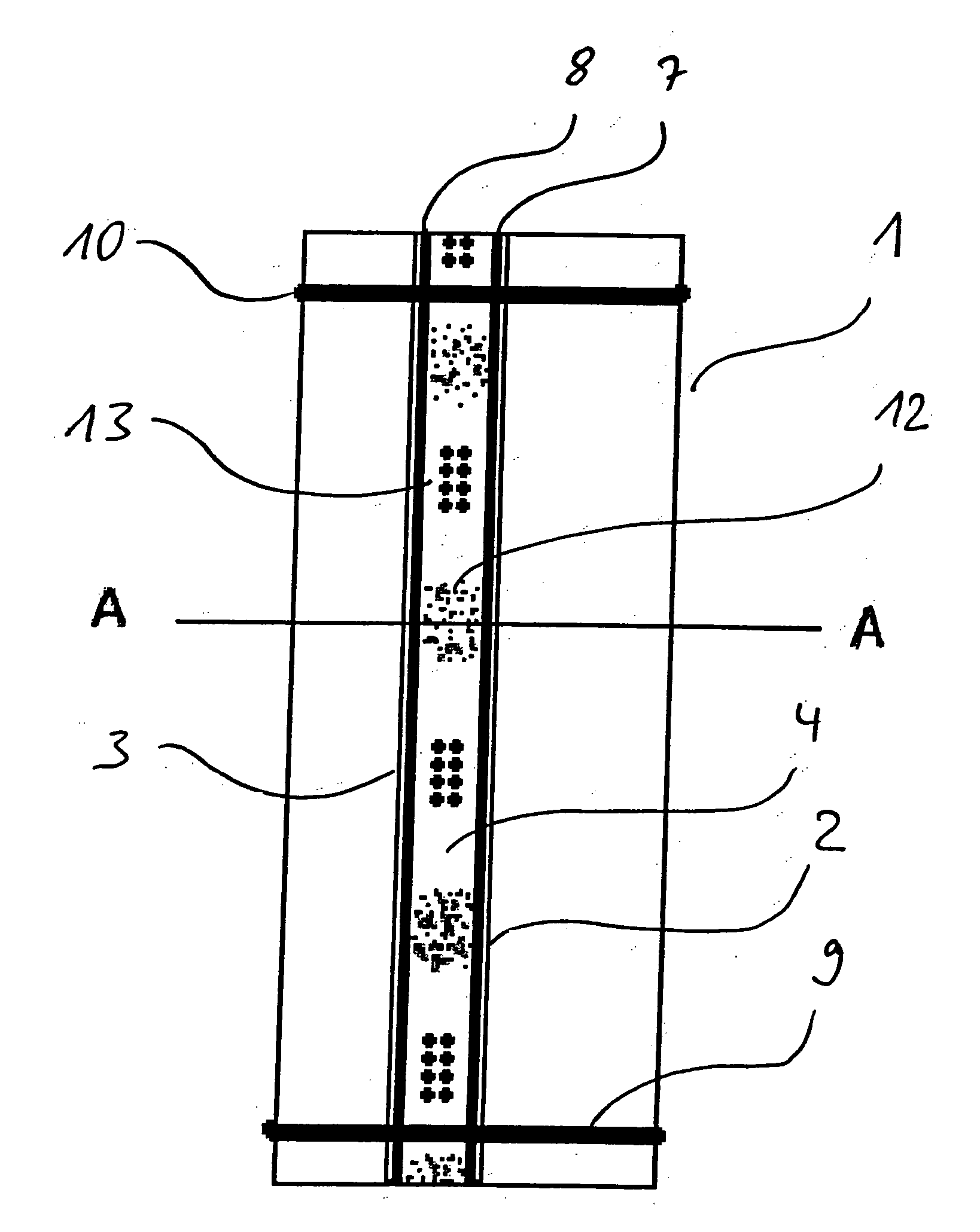

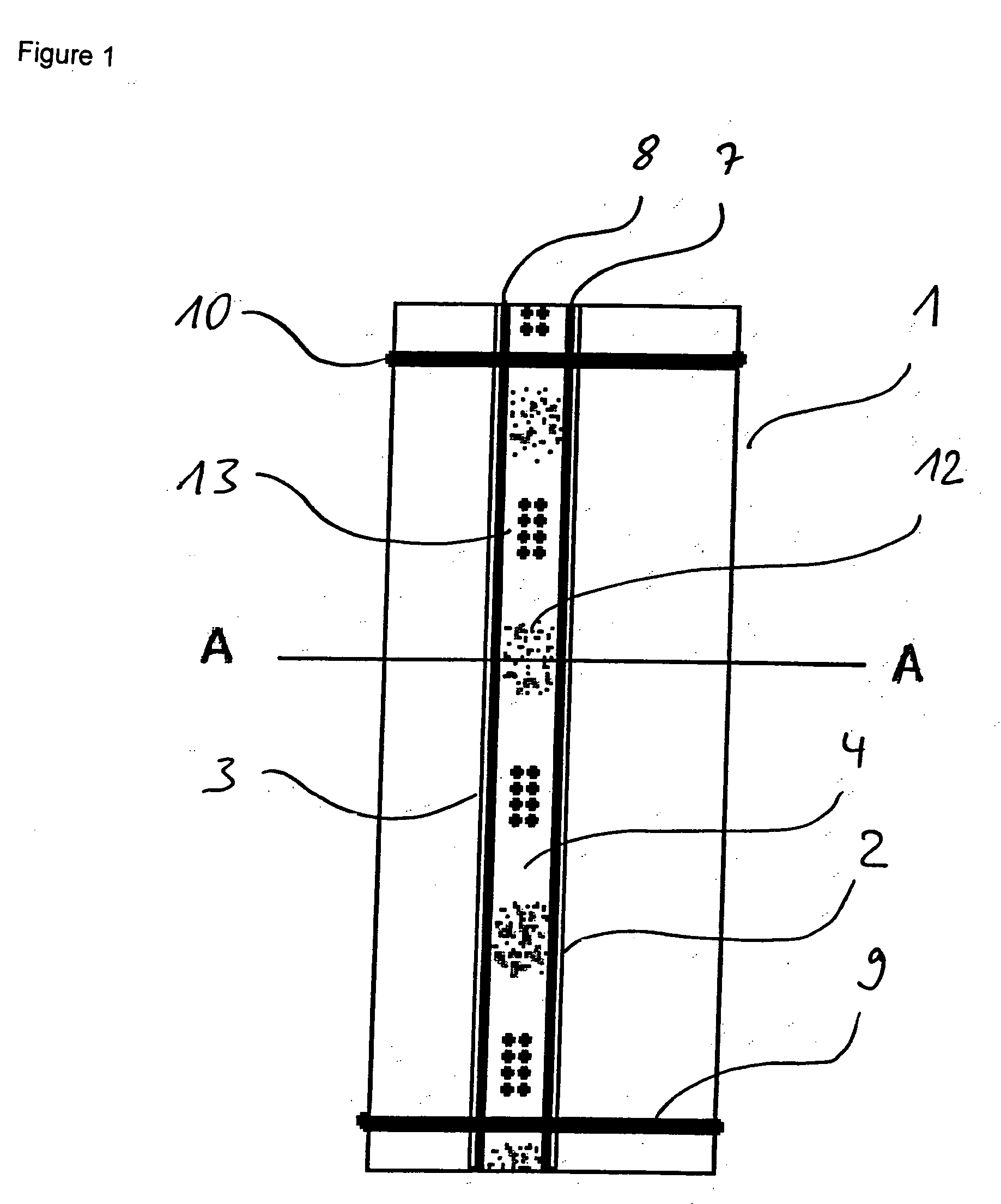

Contacting apparatus for contacting an energy storage cell (1) comprising at least one printed circuit board (5) which is provided for discharging the electrical energy stored in the energy storage cell (1), wherein at least one electric pole of the energy storage cell (1) is pressed by a releasable mechanical connection (7) with a specific contact pressing force against an electrically conductive layer (5c) of the at least one printed circuit board (5) which is located on a front side of the at least one printed circuit board (5) facing the energy storage cell (1).

Owner:TECH UNIV MUNCHEN

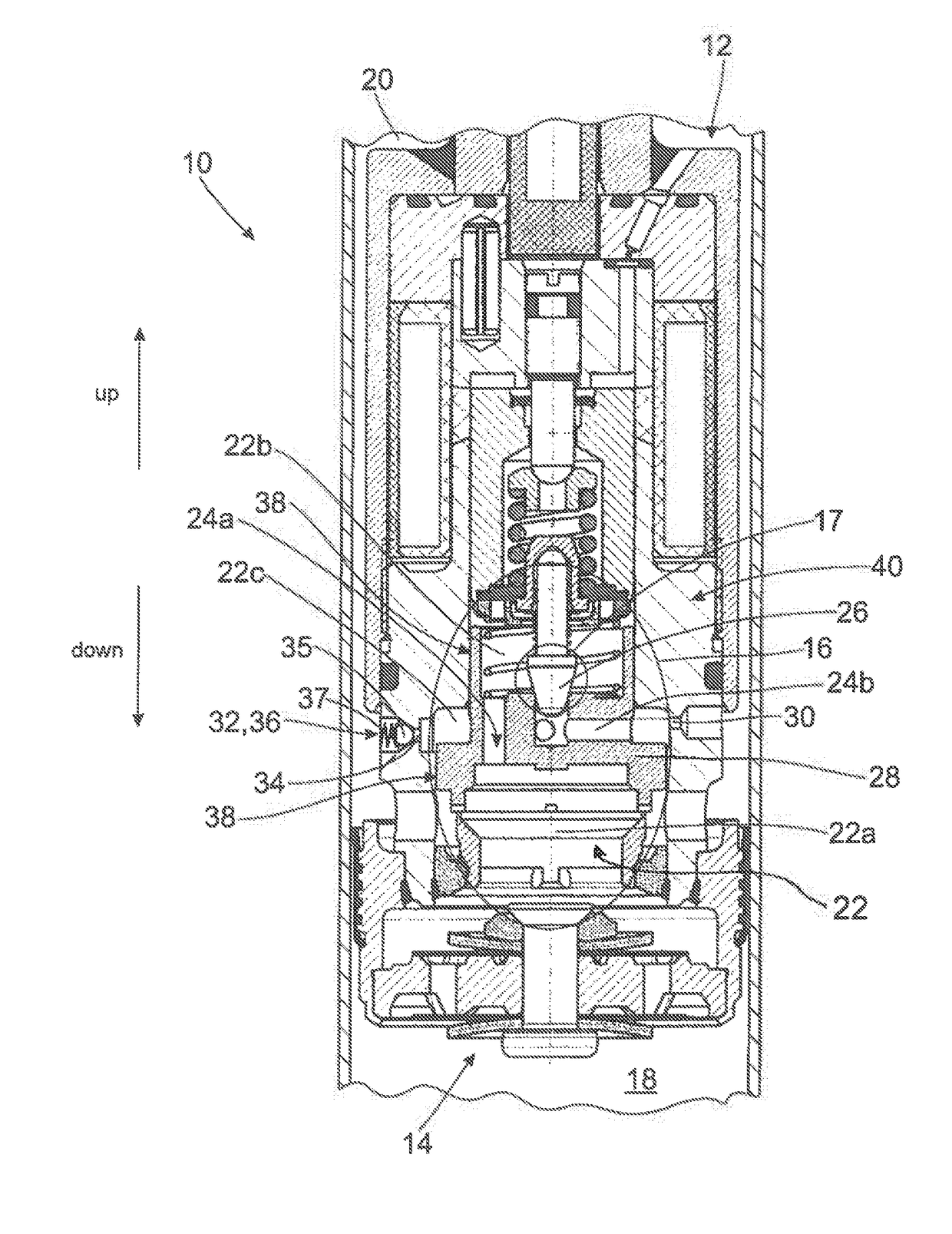

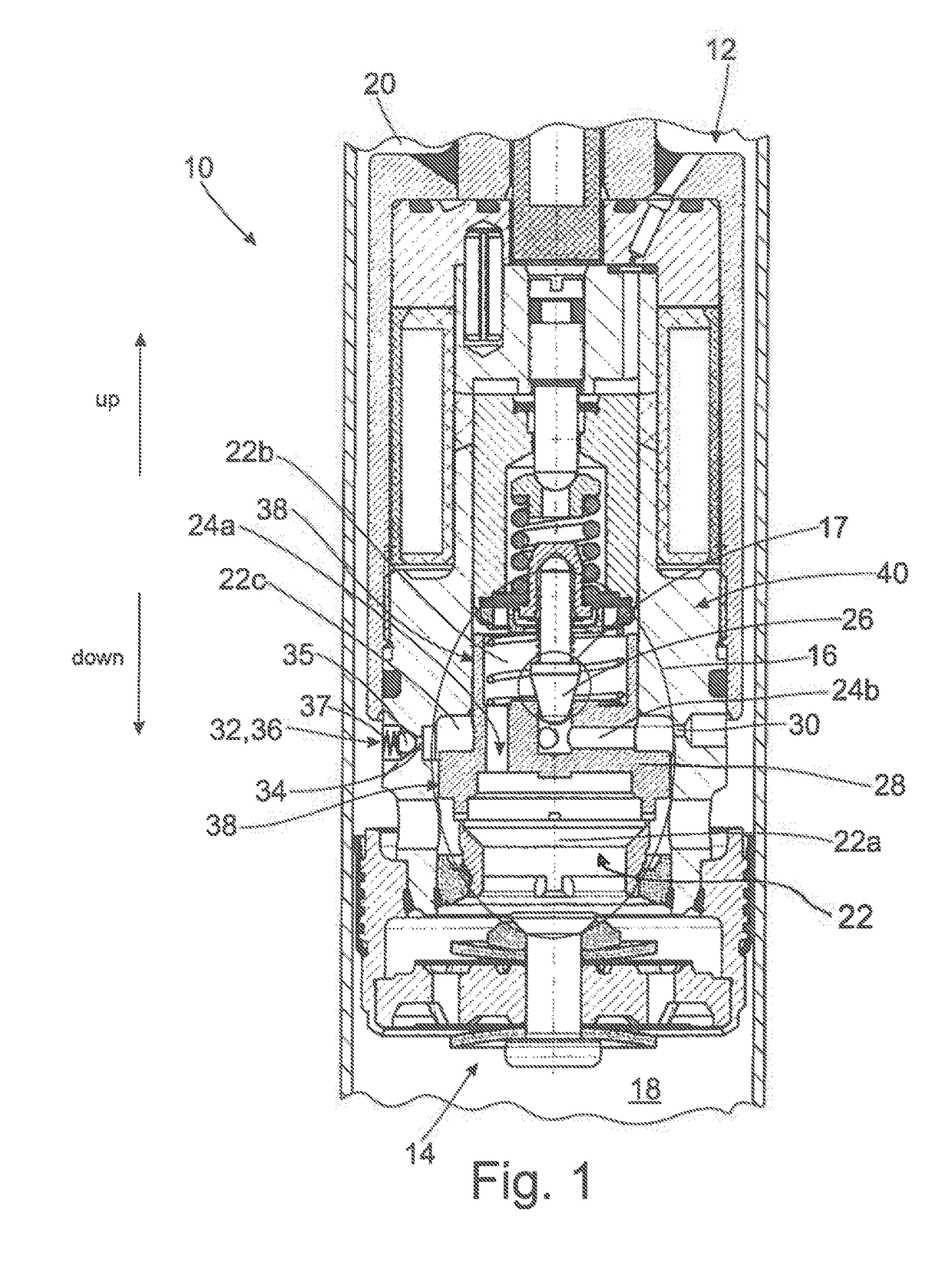

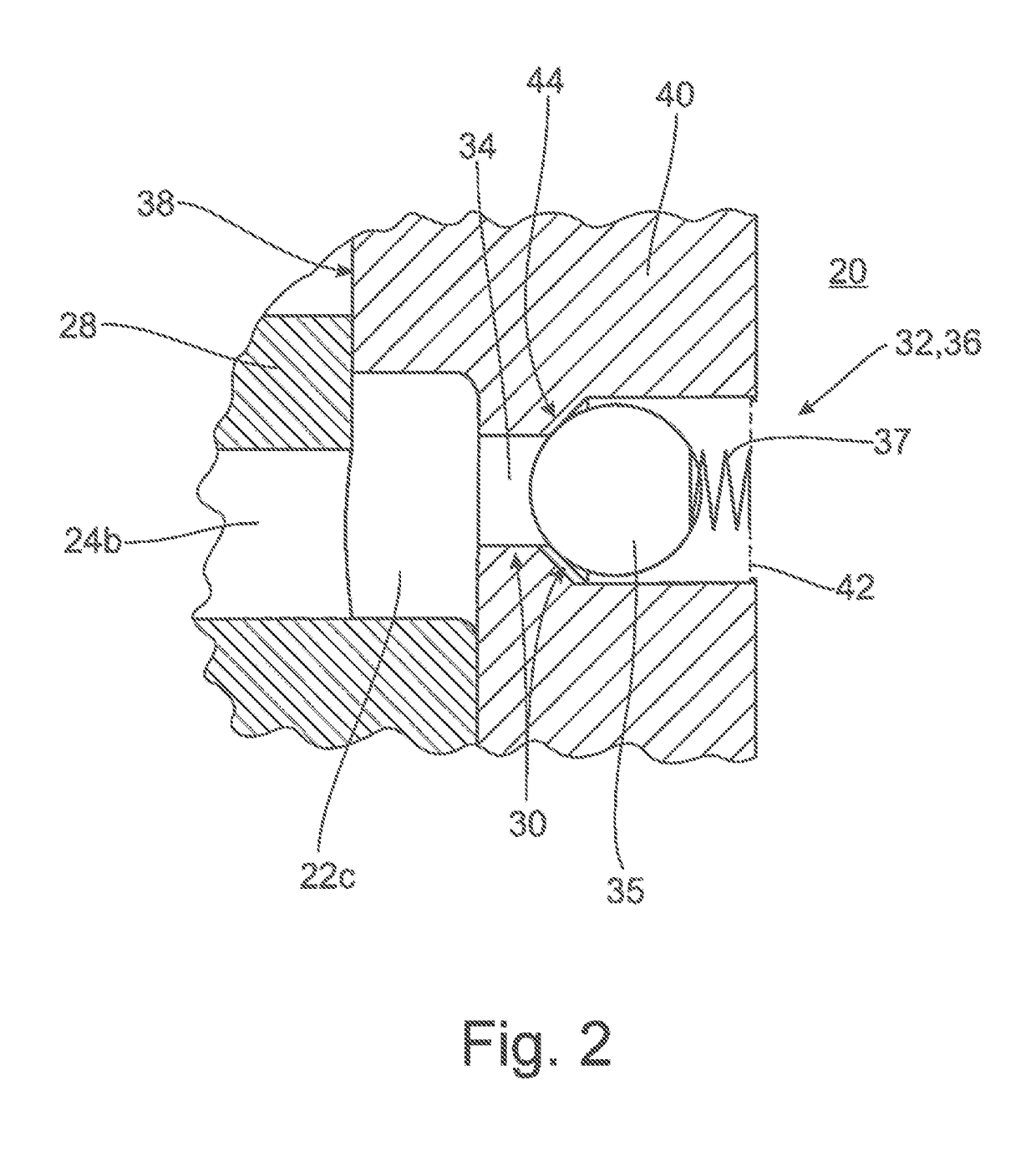

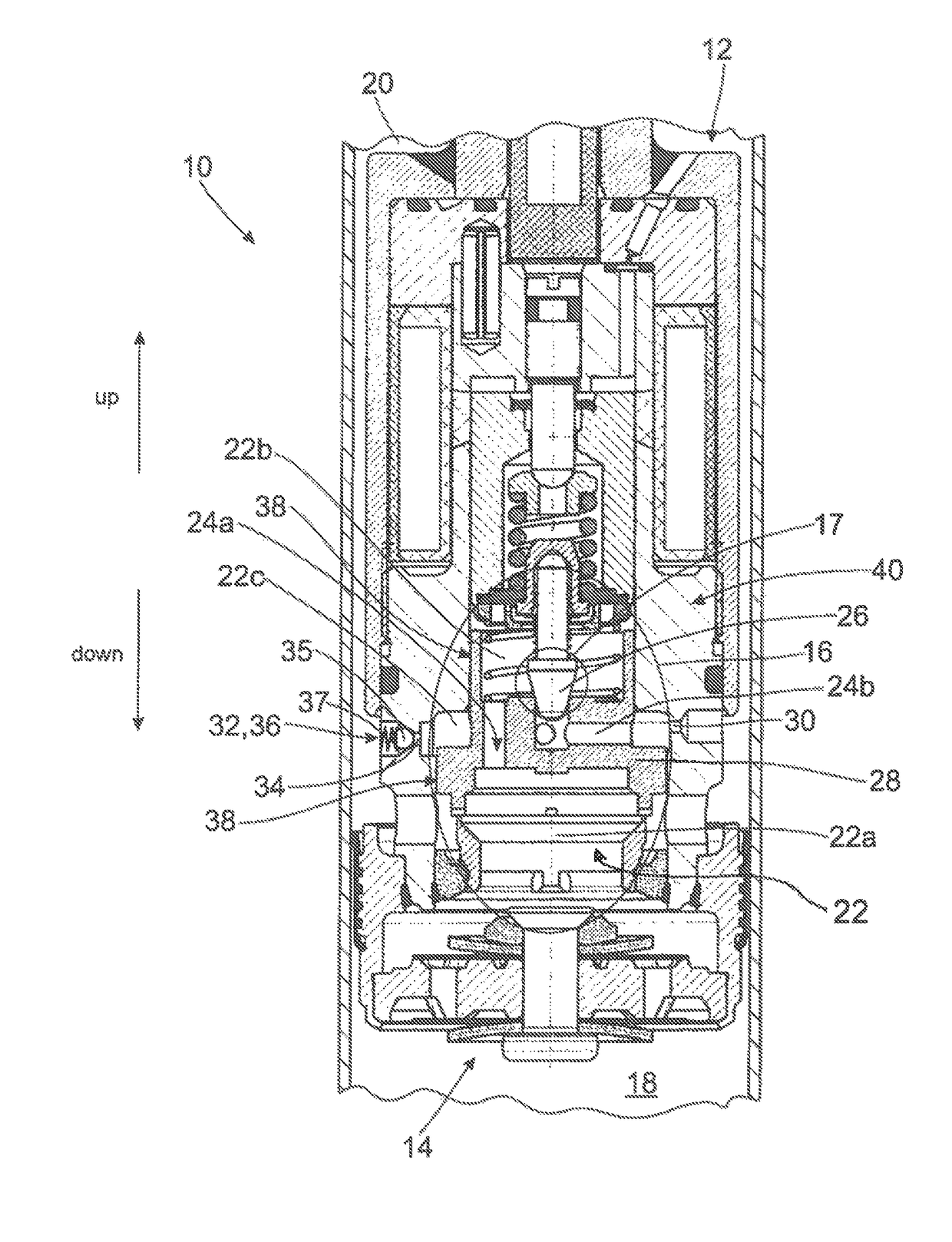

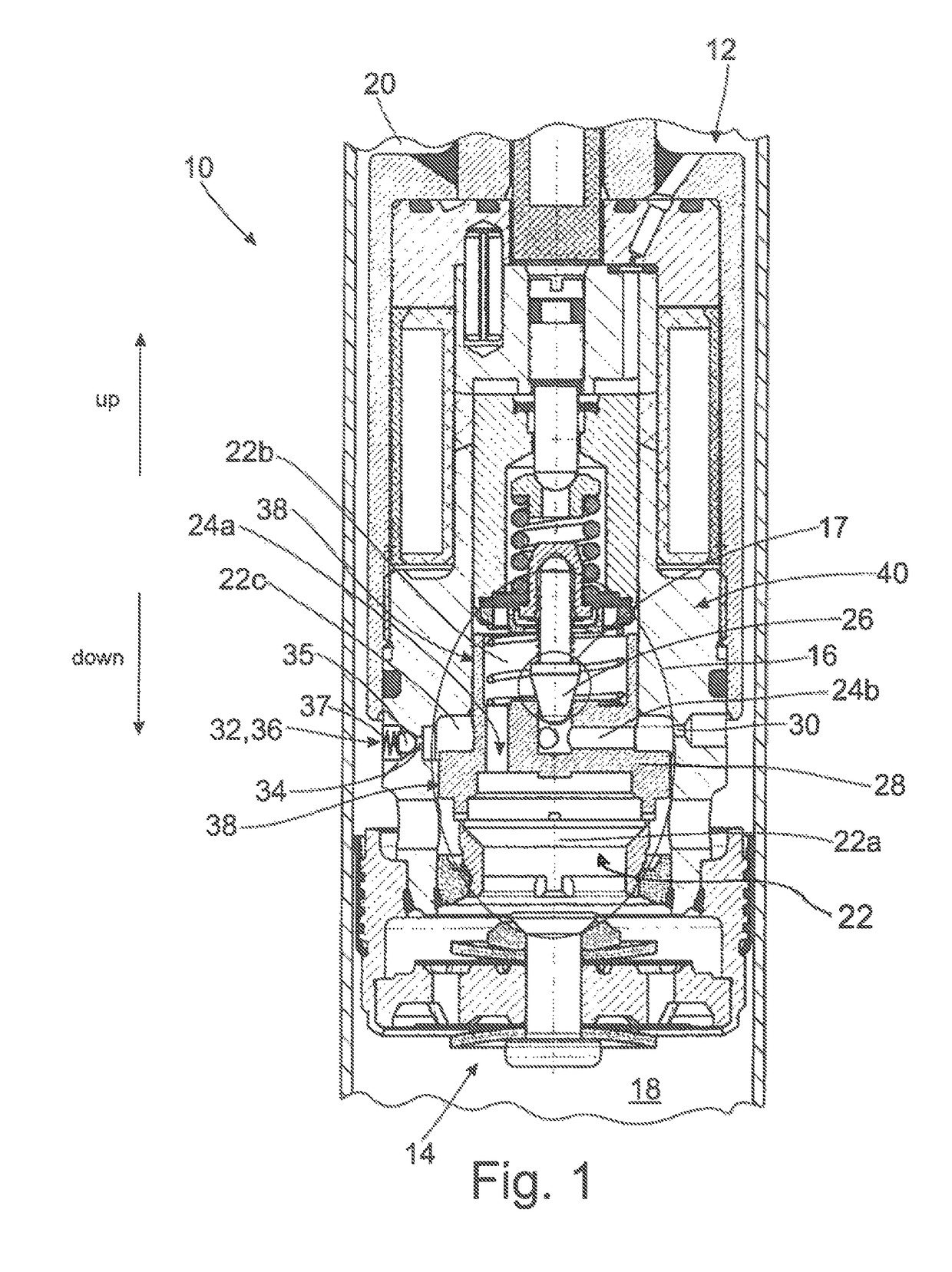

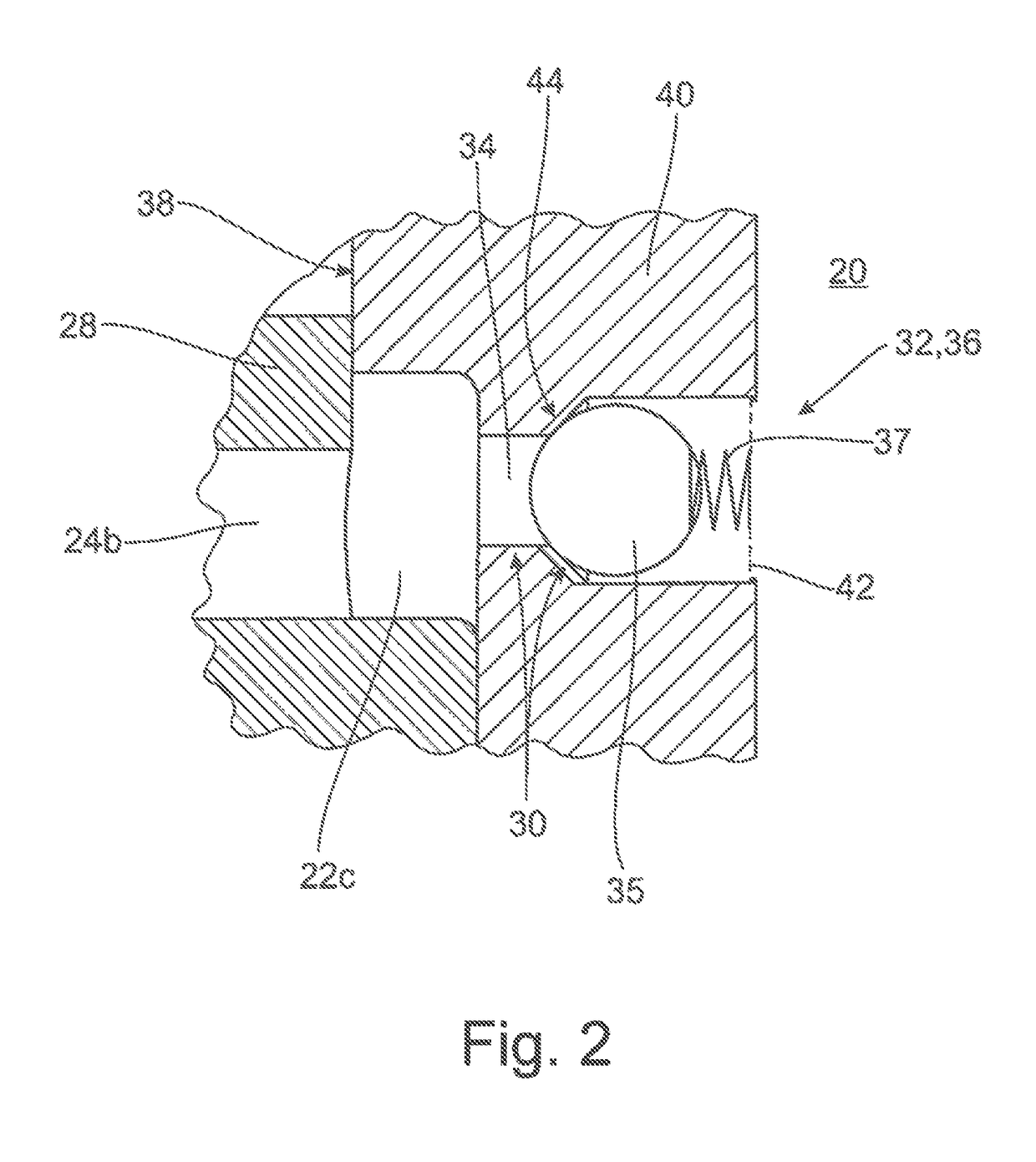

Damping Valve Comprising A Pressure Relief Valve

InactiveUS20170219042A1Increase the sectionReduce pressureSpringsEqualizing valvesEngineeringVALVE PORT

An adjustable damping valve (12) includes a pressure space (22c) for controlling the damping valve (12), which pressure space (22c) is arranged inside the damping valve (12) and is connected to a further space (20) via at least one choke orifice (30) for the flow of damping medium, and the pressure space (22c) is operatively connected to the further space (20) via a pressure relief valve (32).

Owner:ZF FRIEDRICHSHAFEN AG

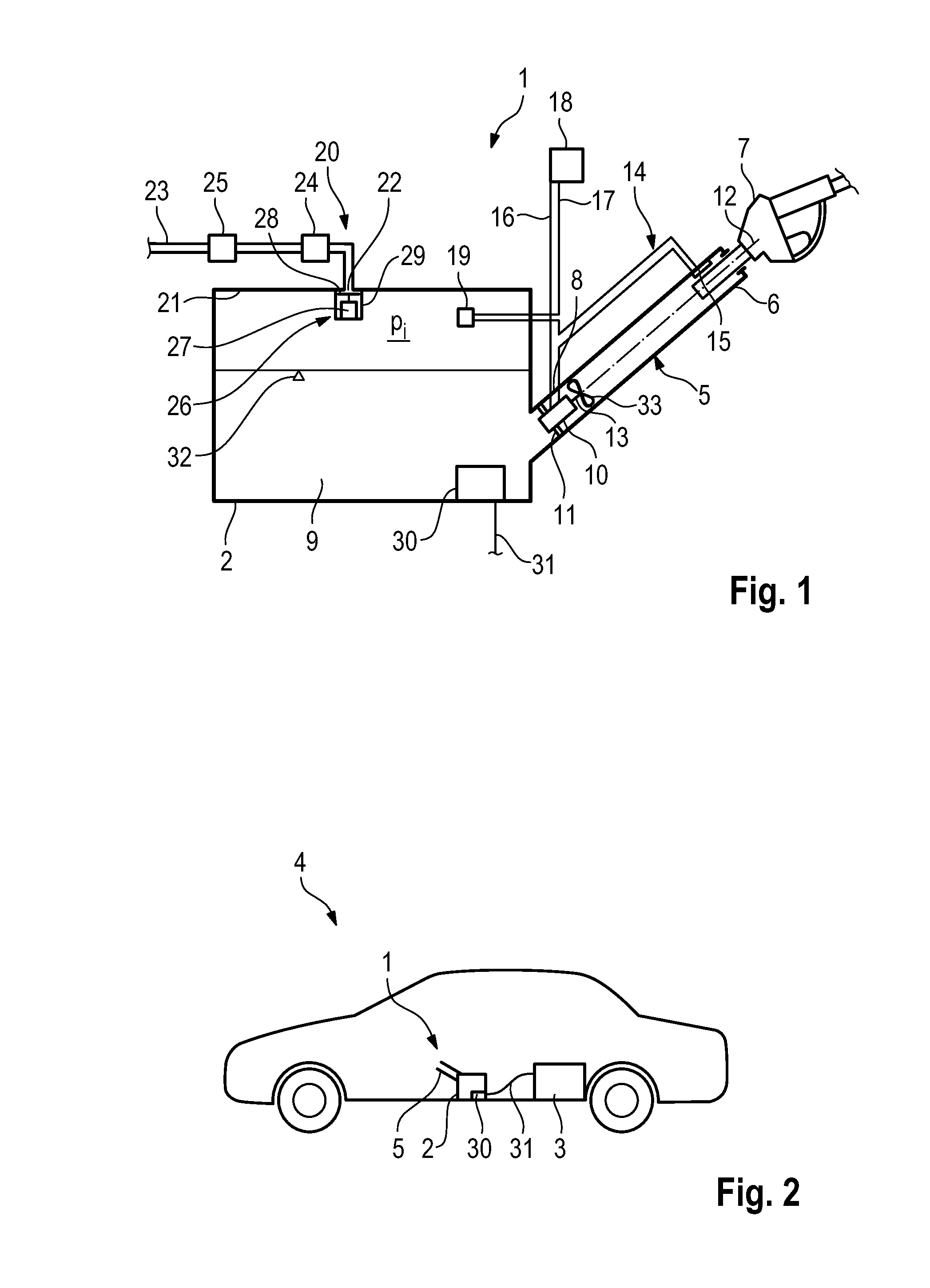

Refueling device and motor vehicle having such a refueling device

ActiveUS20120024849A1Simple and cost effective manufactureReduce overpressureClosures to prevent refillingLiquid materialFuel tankInternal combustion engine

A refueling device (1) for refueling a fuel tank (2) of an internal combustion engine (3) in a motor vehicle (4) has a filler connector (5) for feeding fuel to the fuel tank (2). An integrated fuel feed device (10) feeds the fuel from the filler connector (5) to the fuel tank (2).

Owner:DR ING H C F PORSCHE AG

Contacting Apparatus for Contacting An Energy Storage Cell

ActiveUS20170207431A1Simple and defined positioningReduce weightCoupling device engaging/disengagingSmall-sized cells cases/jacketsElectrically conductiveElectric energy

Contacting apparatus for contacting an energy storage cell (1) comprising at least one printed circuit board (5) which is provided for discharging the electrical energy stored in the energy storage cell (1), wherein at least one electric pole of the energy storage cell (1) is pressed by a releasable mechanical connection (7) with a specific contact pressing force against an electrically conductive layer (5c) of the at least one printed circuit board (5) which is located on a front side of the at least one printed circuit board (5) facing the energy storage cell (1).

Owner:TECH UNIV MUNCHEN

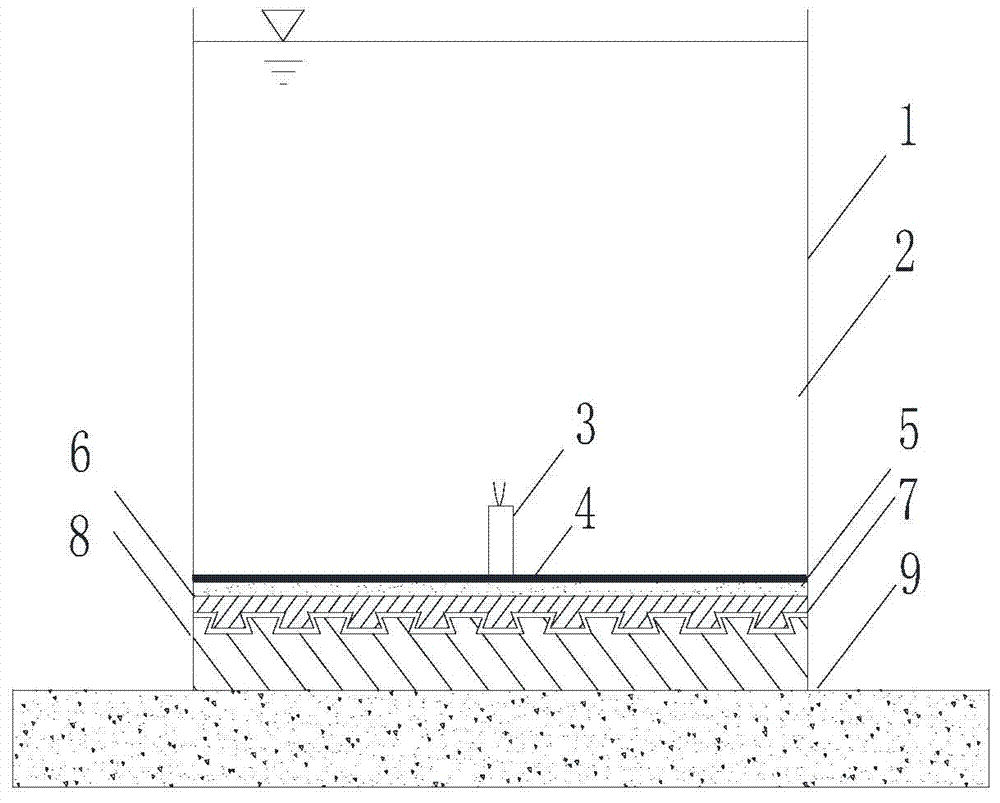

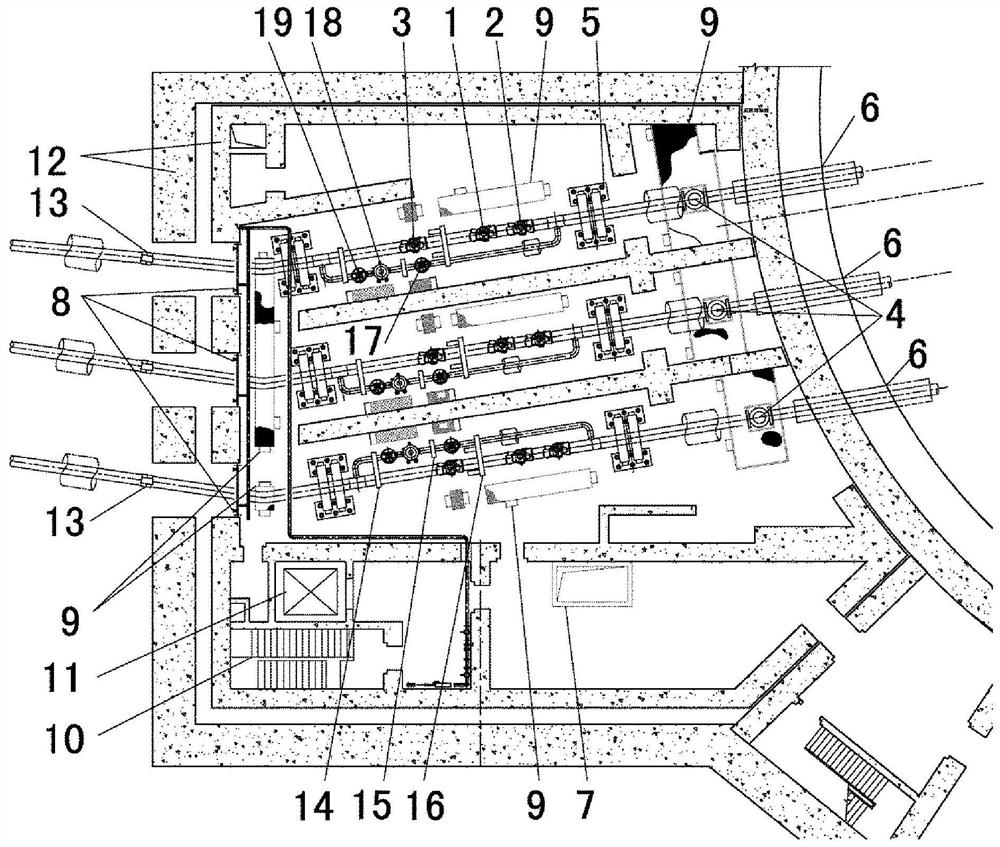

A layout method for main water supply corridor area of nuclear power plant

ActiveCN109599201BReduce overpressurePrevent overflowNuclear energy generationNuclear plant auxillary equipmentIsolation valveNuclear power

The invention relates to the field of overall layout design of a nuclear power plant, in particular to a method for arranging a main water supply corridor area of a nuclear power plant. Including the main water supply corridor area set in the nuclear island electrical power plant, outside the nuclear island containment, and three loop main water supply pipelines that run through the nuclear island containment. Each loop main water supply pipeline is arranged with a main pipeline and a Bypass pipeline, the tail end of the main pipeline runs through the nuclear island containment through the penetrating piece, and the first safety NC level isolation valve, the first regulating valve, the first safety two stage isolation valve, main feedwater check valve; the top of the bypass pipeline is connected near the top of the main pipeline, and the tail end of the bypass pipeline is connected between the main feedwater check valve and the first safety secondary isolation valve of the main pipeline The position between; the second safety NC level isolation valve, the second regulating valve, and the second safety secondary isolation valve are arranged in sequence from the top to the end of the bypass pipeline. This method can reduce the overpressure of the nuclear island containment.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Damping valve comprising a pressure relief valve

InactiveUS10100895B2Increase the sectionReduce pressureSpringsEqualizing valvesEngineeringRelief valve

An adjustable damping valve (12) includes a pressure space (22c) for controlling the damping valve (12), which pressure space (22c) is arranged inside the damping valve (12) and is connected to a further space (20) via at least one choke orifice (30) for the flow of damping medium, and the pressure space (22c) is operatively connected to the further space (20) via a pressure relief valve (32).

Owner:ZF FRIEDRICHSHAFEN AG

Method and device for abnormal overvoltage protection of power switch tube in electromagnetic heating cooking system

ActiveCN107548177BReduce target power valueReduce overpressureInduction heating controlOvervoltageProcess engineering

The invention discloses an electromagnetic heating cooking system, and an overvoltage abnormal protection method and device for a power switch tube in the electromagnetic heating cooking system. The overvoltage abnormal protection method comprises the following steps: judging whether the power switch tube is in an abnormal state; if the power switch tube is in an abnormal state, a timer is controlled to count and the number of overvoltage times of the power switch tube is counted through a counter; and when the count time of the timer reaches a preset time threshold, if the count value of thecounter exceeds a preset number of times threshold, the target power value of the electromagnetic heating cooking system is reduced according to a preset step length. The method can protect the powerswitch tube to some extent by reducing the target power value of the electromagnetic heating cooking system and reducing the overvoltage degree of the power switch tube when the power switch tube is in an abnormal state.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

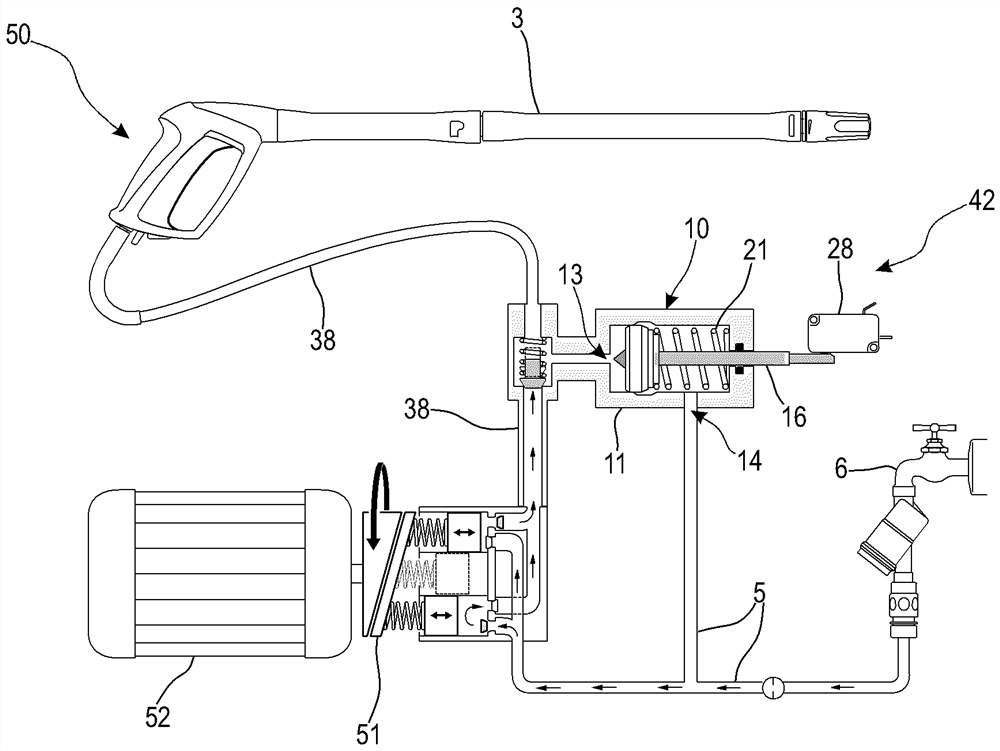

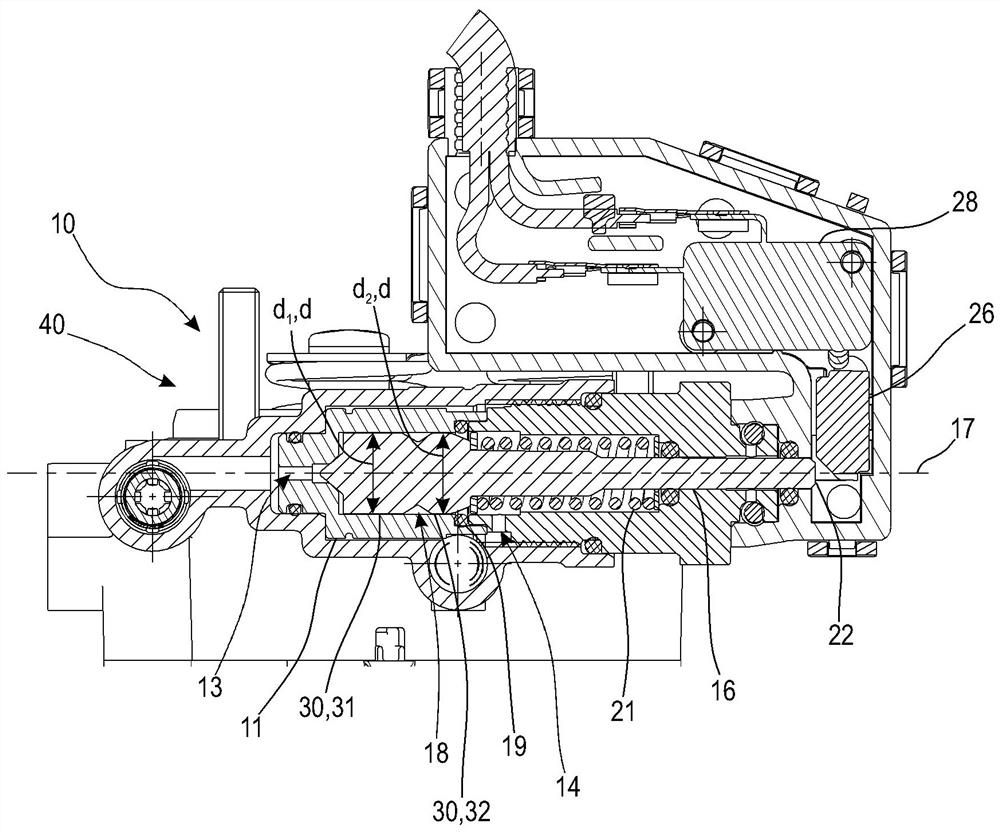

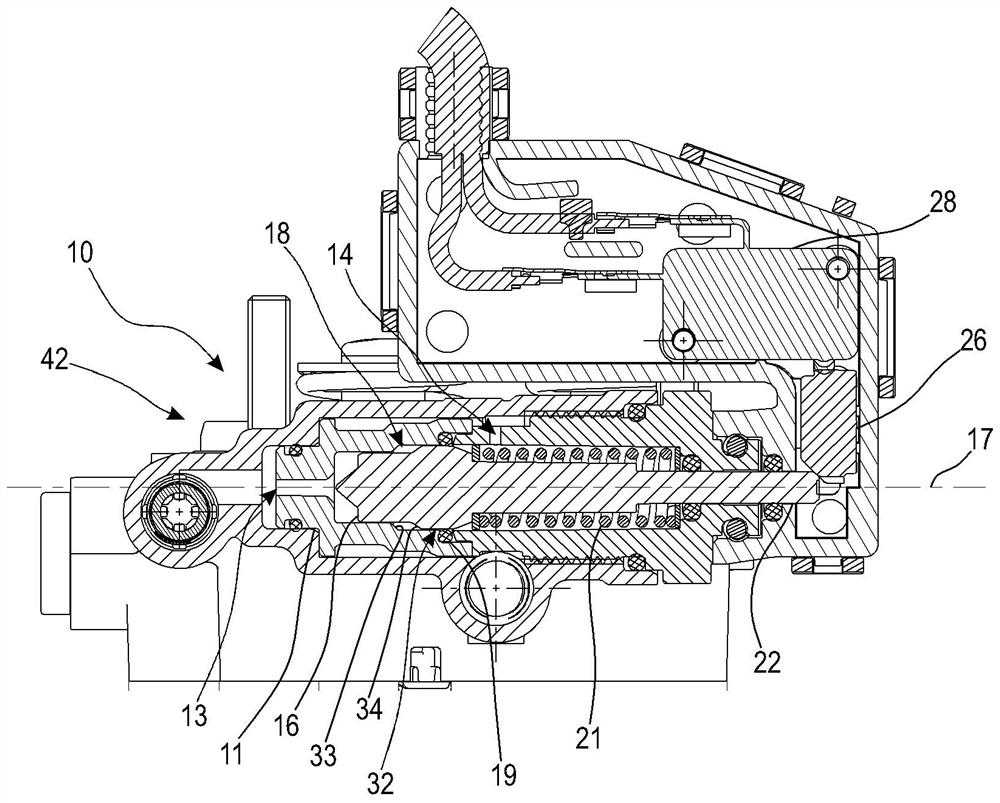

Pressure shut-off valve for high-pressure cleaner and high-pressure cleaner having pressure shut-off valve

PendingCN114484070AIncrease flow resistanceLow flow resistanceFlexible member pumpsValve members for absorbing fluid energyEngineeringThrottle

The invention relates to a pressure shut-off valve for a high-pressure cleaner and a high-pressure cleaner with a pressure shut-off valve, in particular to a pressure shut-off valve for a high-pressure cleaner. According to the invention, the pressure shut-off valve (10) has an effective throttle gap (30) between the valve housing (11) and the valve body (16) with a total length (a) measured in the direction of the longitudinal axis (17) of the valve body (16), the effective throttle gap (30) being part of a flow connection (12) between the inlet (13) and the outlet (14). The valve body (16) has a maximum diameter (d) extending radially with respect to the longitudinal axis (17). In a first closed position (40) of the pressure shut-off valve (10), the total length (a) of the effective throttle gap (30) is at least 50% of the maximum diameter (d) of the valve body (16).

Owner:ANDREAS STIHL AG & CO KG

Systems and methods for reducing an overpressure caused by a vapor cloud explosion

Systems and methods for reducing an overpressure caused by an explosion of a vapor cloud are provided. In one or more embodiments, the system can include one or more sensors operable to detect the explosion of the vapor cloud. The system can also include one or more igniters operable to ignite the vapor cloud at locations throughout, after the explosion of the vapor cloud is detected, to provide a discrete combustion zone at each location. Each combustion zone can form a discrete pressure wave, thereby reducing the overpressure caused by the explosion of the vapor cloud.

Owner:EXXON RES & ENG CO

The Method of Composite Interfacial Fitting of Dovetail Groove Metal Plate Clearance

ActiveCN104289810BIncrease profitReduce pollutionMetal working apparatusNon-electric welding apparatusInterference fitComposite effect

The invention discloses a composting method of a dovetail groove metal plate clearance fit interface. The compositing method is realized through the explosive cladding method, the rolling method and the like. According to the method, after a base plate with dovetail grooves and a surface plate with dovetail grooves are in interference fit, the base plate and the surface plate are composited together through combination of a metallurgical bonding mode and a squeezing meshing mode of the dovetail grooves under the actions of energy of explosives or a rolling mechanism. Physical and chemical properties of metal sheets on the two sides of a dovetail groove combination interface are not changed, and large-area metal sheet composition can be conducted; the explosive charge for a unit of compositing area is small, and atmospheric pollution, noise pollution, explosion vibration and overpressure are reduced; during explosive welding of the metal sheets with the dovetail grooves, no boundary effect exists, the compositing effect on the periphery is good, and the lower limit and the upper limit of an explosive welding window are both increased. The compositing technology of the dovetail groove metal plate clearance fit interface can be applied to the fields such as chemical reaction containers and ships so as to meet the requirement for large-area metal composite plates.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com