Liquid storage tank tail gas treatment system and method

A technology for tail gas treatment and liquid storage tanks, which is applied in combustion methods, piping systems, gas/liquid distribution and storage, etc., and can solve problems such as excessive oxygen content and unstable pressure at the top of liquid storage tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

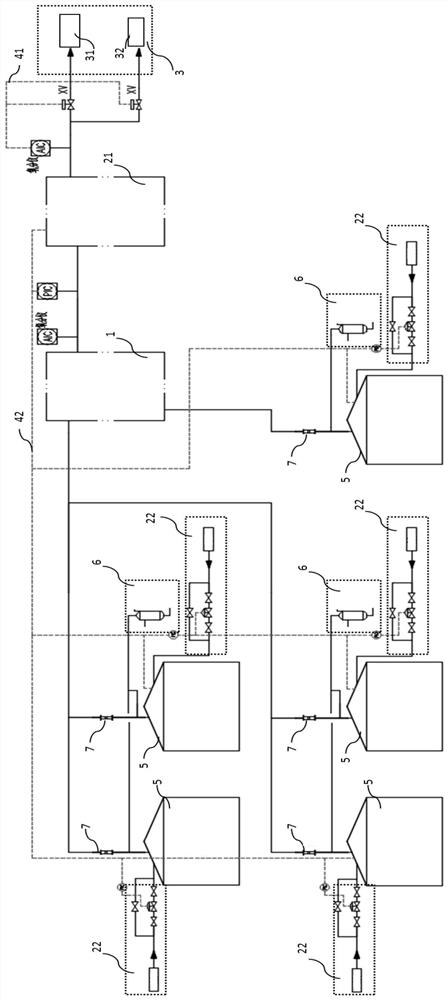

[0037] According to a preferred embodiment of the present invention, the first controller 41 is used to control: when the oxygen content in the outlet gas of the exhaust device 21 is lower than 2% by volume, the gas extraction device 21 and the tail gas The tail gas recovery device 31 of the processing unit is connected, and the tail gas pressure is sent to the low-pressure gas system, and then sent to the high-pressure gas system after downstream compression, and then the high-value light hydrocarbon components are reused; When the oxygen content is not less than 2% by volume, the exhaust device 21 is connected with the tail gas incinerator 32, and through the logic control program, the tail gas is automatically switched to the sulfur incinerator, and the flue gas is burned by the sulfur incinerator at high temperature The VOCs emission concentration is 10mg / m 3 Around, to meet the environmental emission standards. In this preferred embodiment, accurate detection of the oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com