A Piston Compressor with Anti-Shock Function

A compressor and piston technology, which is applied in the field of piston compressors with anti-liquid shock function, can solve the problems that liquid cannot be recovered, there is no anti-liquid shock compressor, etc., and achieve the effect of preventing liquid shock accidents and protecting them from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

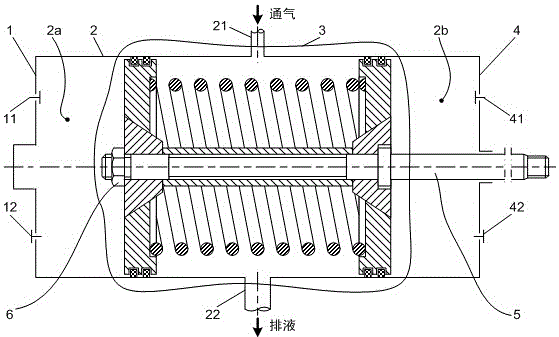

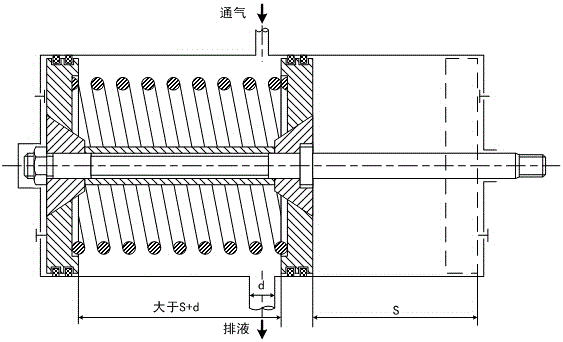

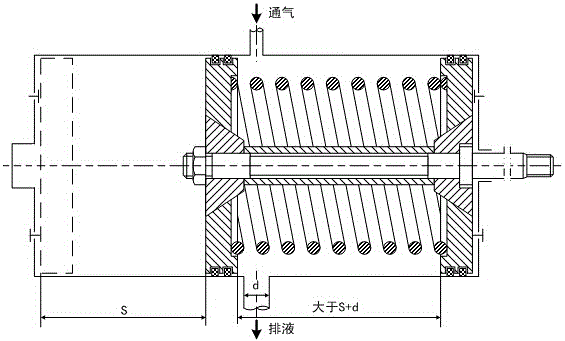

[0032] Such as Figure 1 ~ Figure 3 As shown, the cylinder head part 1, the cylinder body part 2, and the cylinder seat part 4 constitute the cylinder part of the double-acting piston compressor, and the combined piston part 3 with a special structure is coaxially placed in the cylinder part, and the combined piston 3 consists of the first piston A fastening nut 6 is mounted on the end of the piston rod 5, and suction and exhaust valve parts 11, 12, 41, 42 are respectively provided on the cover side and the shaft side of the cylinder part. Such as Figure 4 ~As shown in Figure 8, a movable end plate 32 and 37 are respectively provided at both ends of the combined piston part 3, and the center of the first movable end plate 32 and the second movable end plate 37 is provided with an inner taper hole, which respectively passes through A first locating cone 31 and a second locating cone 38 with an outer tapered surface are installed on the end of the piston rod 5, and the inner t...

Embodiment 2

[0036] Such as Figure 9 As shown, on the basis of Embodiment 1, the small ends of the two positioning cones 31 and 38 of the combined piston 3 each have a small section of cylinder, and the ends of the two small sections of the two cylinders are offset to realize the two movable end plates 32 and 37 axial distance, thereby eliminating the need for image 3 The positioning sleeve 36 in the first embodiment simplifies the structure of the piston part 3 and improves the positioning accuracy.

Embodiment 3

[0038] Such as Figure 10 As shown, on the basis of Embodiment 1, there are two positioning shoulders 5e and 5e1 on the piston rod 5 with different diameters, and the two positioning cones 31 and 38 of the combined piston part 3 respectively abut against the The two positioning shoulders 5e1 and 5e are used for axial positioning, and the outer cylindrical surfaces 5b and 5d of the corresponding shoulders 5e1 and 5e on the piston rod 5 are used for radial positioning, and the first piston is tightly positioned respectively. The fastening nut 6 and the second piston fastening nut 7 are respectively fastened to the fastening thread 5 a and the second fastening thread 5 a 1 on the piston rod 5 to form the combined piston part 3 , thereby omitting the positioning sleeve 36 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com