Recovery treatment system of coking waste gas

A technology for waste gas recovery and waste gas collection, which is used in pipeline systems, gas/liquid distribution and storage, and mechanical equipment. The effect of blocked pipes, reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

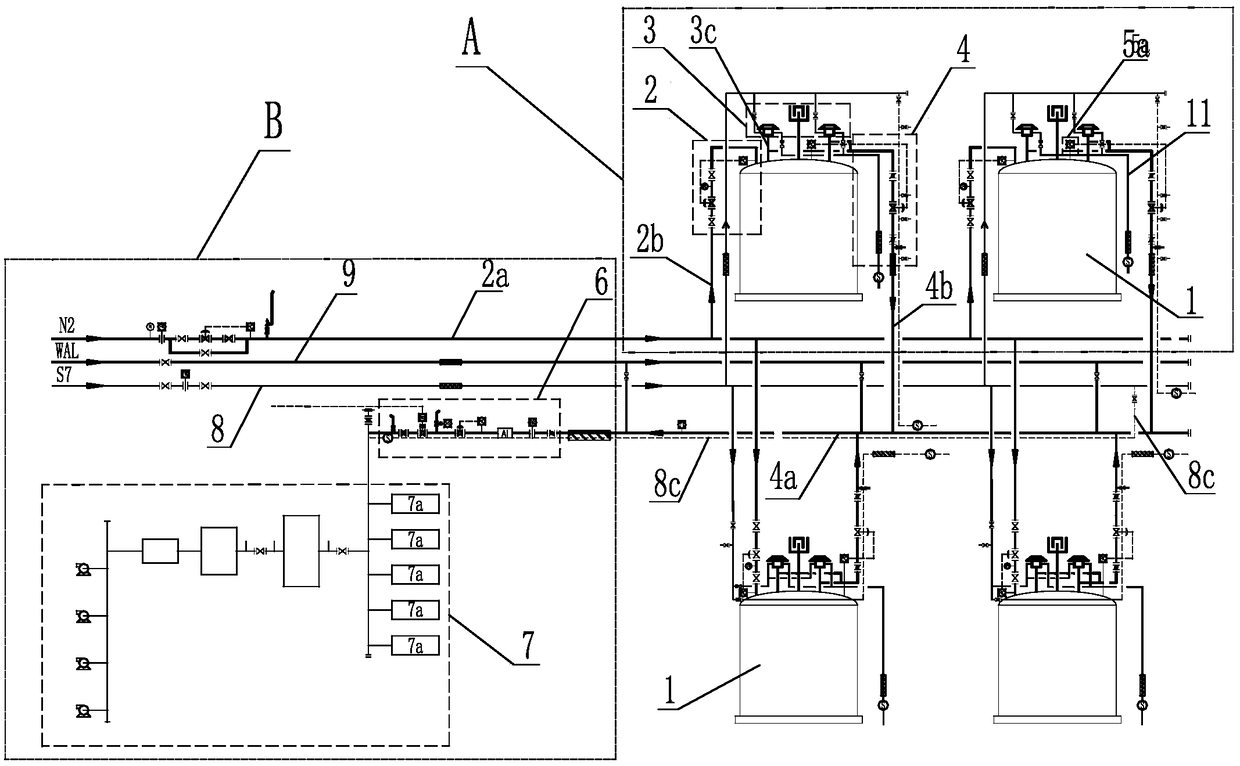

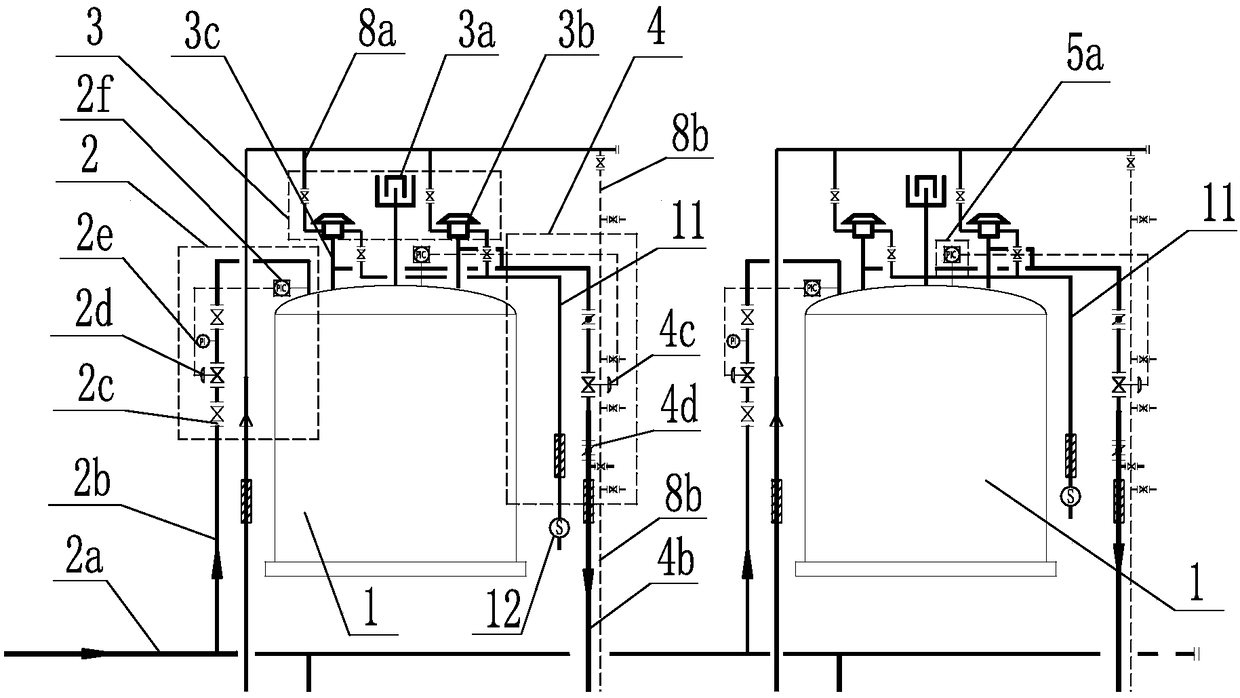

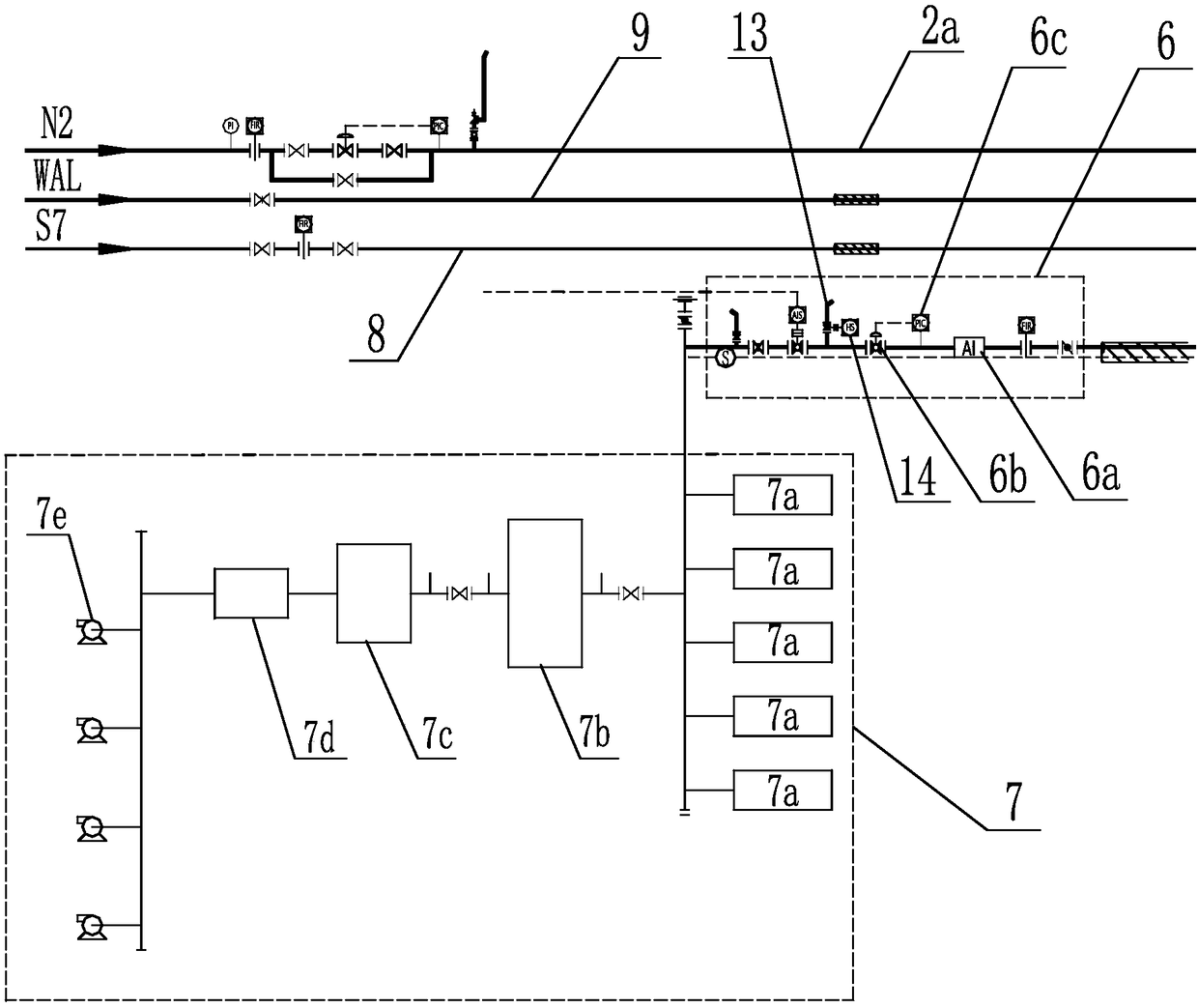

[0033] combine figure 1 As shown, a coking waste gas recovery treatment system includes several storage tanks 1 and waste gas collection pipes 4a, nitrogen pressure stabilizing device 2, tank top safety device 3, waste gas pressure regulating device 4, tank top pressure monitoring device 5 and main pipe oxygen On-line content monitoring and quick cut-off device 6, and a waste gas exhaust pipe 4b is connected between the storage tank 1 and the waste gas collection pipe 4a.

[0034] combine figure 2 and image 3 , the nitrogen pressure stabilizing device 2 includes a nitrogen g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com