Degassing method of liquefied petroleum gas waste alkali residue

A technology for liquefied petroleum gas and waste alkali residue, which is applied in the petroleum industry, hydrocarbon distillation, etc., can solve the problems of direct gas discharge to the atmosphere, the problem of liquid hydrocarbon entering the alkali residue tank, environmental pollution, etc., so as to avoid potential safety hazards and environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

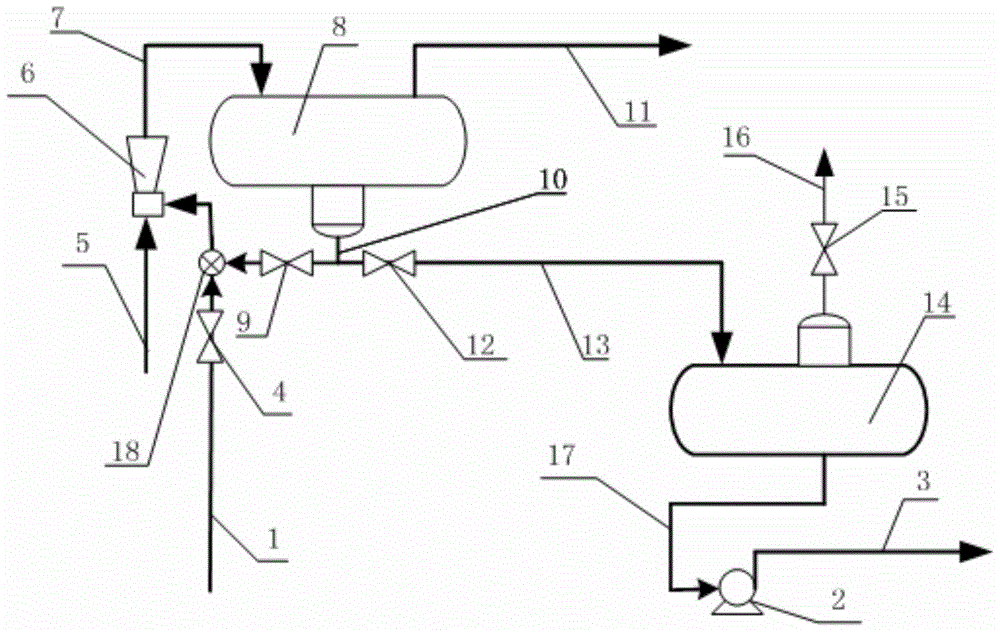

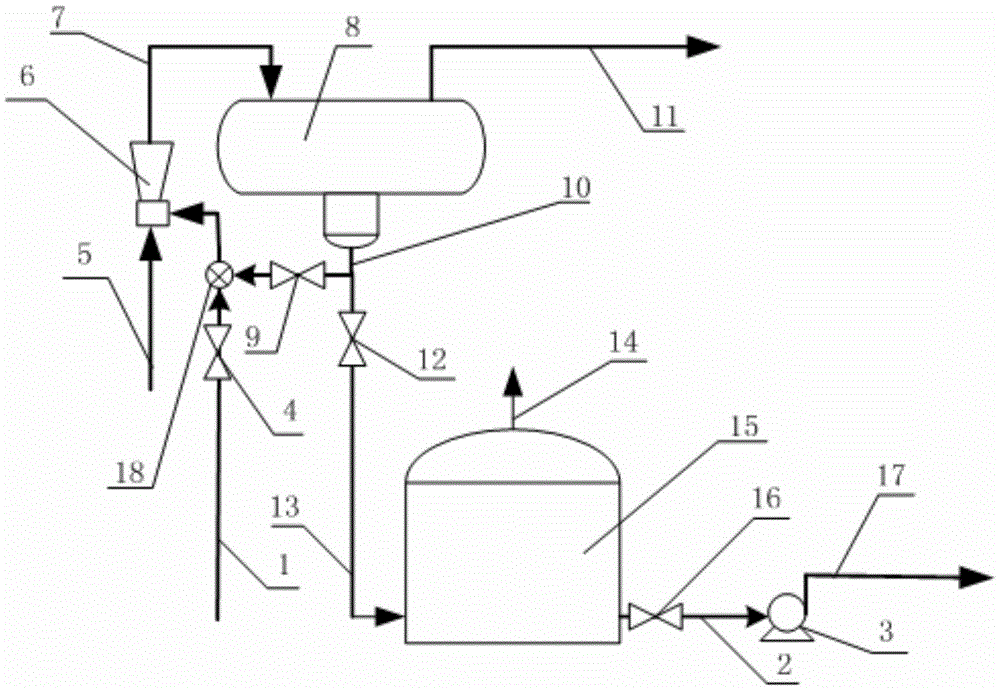

[0020] In a liquefied petroleum gas alkali washing and waste alkali residue degassing system, the liquefied petroleum gas and the lye including circulating lye and fresh lye are contacted in the alkali washing tower, and then enter the settling tank together with the lye, and the liquefied petroleum gas Discharge from the top of the settling tank, 20% of the lye at the bottom of the settling tank by weight enters the mixer as the circulating lye and mixes it with fresh lye and returns to the alkali washing tower, and 80% enters the alkali slag degassing tank as spent lye. The amount of liquefied petroleum gas contained in alkali residue is 12% (volume). The top of the alkali slag degassing tank is equipped with a gas discharge pipeline connected to the low-pressure gas pipe network, and the bottom of the alkali slag degassing tank is equipped with an alkali slag pump to transport the alkali slag to the subsequent processing device. The operating conditions of the alkali slag d...

Embodiment 2

[0022] In a liquefied petroleum gas alkali washing and waste alkali residue degassing system, the liquefied petroleum gas and the lye including circulating lye and fresh lye are contacted in the alkali washing tower, and then enter the settling tank together with the lye, and the liquefied petroleum gas Discharge from the top of the settling tank, 50% of the lye at the bottom of the settling tank by weight enters the mixer as the circulating lye and mixes it with fresh lye and returns to the alkali washing tower, and 50% enters the alkali slag degassing tank as spent lye. The amount of liquefied petroleum gas contained in the alkali residue is 11% (volume). The top of the alkali slag degassing tank is equipped with a gas discharge pipeline connected to the low-pressure gas pipe network, and the bottom of the alkali slag degassing tank is equipped with an alkali slag pump to transport the alkali slag to the subsequent processing device. The operating conditions of the alkali sl...

Embodiment 3

[0024] In a liquefied petroleum gas alkali washing and waste alkali residue degassing system, the liquefied petroleum gas and the lye including circulating lye and fresh lye are contacted in the alkali washing tower, and then enter the settling tank together with the lye, and the liquefied petroleum gas Discharge from the top of the settling tank, 40% of the lye at the bottom of the settling tank by weight enters the mixer as the circulating lye and mixes it with fresh lye and returns to the alkali washing tower, and 60% enters the alkali slag degassing tank as spent lye. The amount of liquefied petroleum gas contained in alkali slag is 10% (volume). The top of the alkali slag degassing tank is equipped with a gas discharge pipeline connected to the low-pressure gas pipe network, and the bottom of the alkali slag degassing tank is equipped with an alkali slag pump to transport the alkali slag to the subsequent processing device. The operating conditions of the alkali slag dega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com