De-noising and dust removal blast hole stemming method for drilling blasting of earth and stone in urban and rural areas

A blast hole plugging and earthwork technology, which is applied in the field of geotechnical engineering, can solve the problems of difficulty in guaranteeing blast hole blocking effect, affecting production and life, polluting the environment, etc., and achieves the effect of ensuring construction efficiency, simple method and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

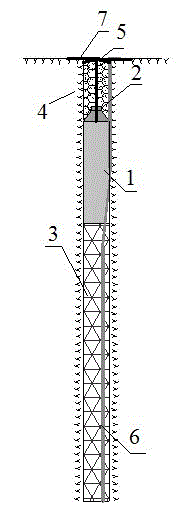

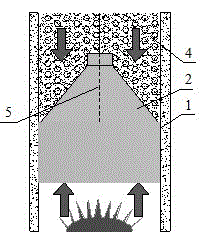

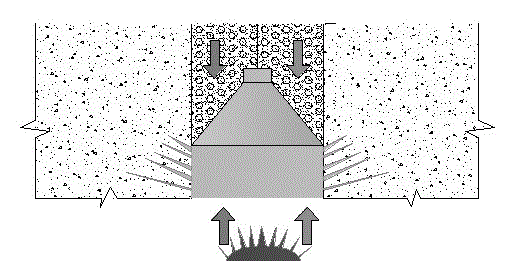

[0031] For above-mentioned blast hole, the specific implementation mode of the inventive method is as follows:

[0032] (1) The water bag used in this specific implementation is cylindrical, with a diameter of 80mm and a length of 1.5m. The water bag is made of an ordinary plastic water bag filled with water and put into a cloth bag, which can prevent the water bag from being pierced by the edges and corners of the rocks on the hole wall, and can withstand a certain pressure. One end of the water bag is tied with a nylon rope that can bear the weight of the water bag, and the diameter of the nylon rope is 0.5cm.

[0033] After the powder charging is completed, the nylon rope is used to hang the water bag into the blast hole at a preset position, which is 5-10 cm above the powder charging section. The position of the water bag in the blast hole can be adjusted by the nylon rope tied to the end of the water bag.

[0034] (2) The funnel used in this specific implementation is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com