Fuel-supply system

A technology of fuel supply device and fuel pressure, which is applied in the direction of liquid fuel feeder, fuel injection control, charging system, etc. It can solve the problems of large fuel pump ejection capacity, large power consumption, overpressure, etc., and achieve reduction Effects of overpressure, reduction of power consumption, and prevention of overpressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

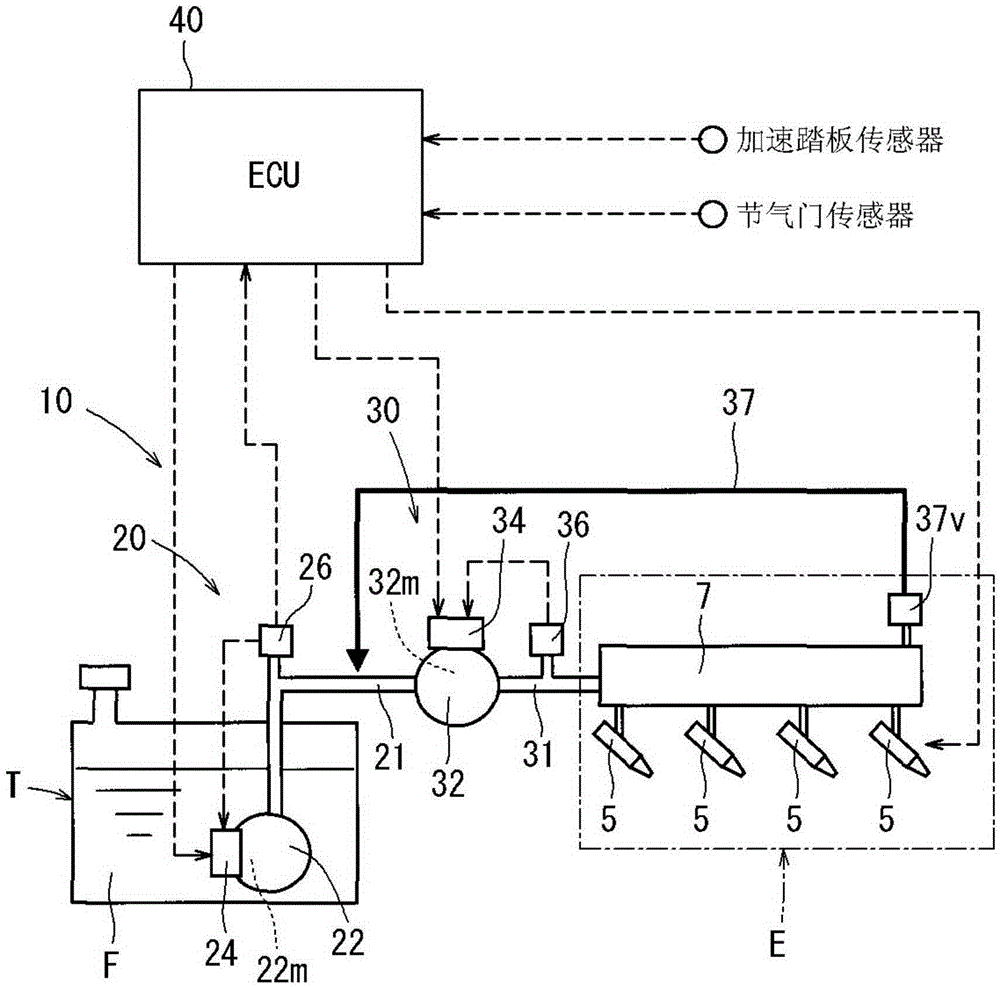

[0031] Below, based on Figure 1 to Figure 4 The fuel supply device 10 according to Embodiment 1 of the present invention will be described. The fuel supply device 10 of the present embodiment is a device for supplying the fuel F stored in the fuel tank T of the automobile to the engine E. As shown in FIG.

[0032]

[0033] Such as figure 1 As shown, the fuel supply device 10 according to the present embodiment includes a low-pressure fuel pump unit 20 and a high-pressure fuel pump unit 30 connected in series. The low-pressure fuel pump unit 20 and the high-pressure fuel pump unit 30 are configured to be able to control fuel pressure (hereinafter referred to as fuel pressure) based on a signal received from an engine control unit ECU (hereinafter referred to as ECU 40 ). Here, electric power is supplied from the battery to the low-pressure fuel pump unit 20 , the high-pressure fuel pump unit 30 , and the ECU 40 by turning on an ignition switch (not shown) of the vehicle. ...

Embodiment approach 2

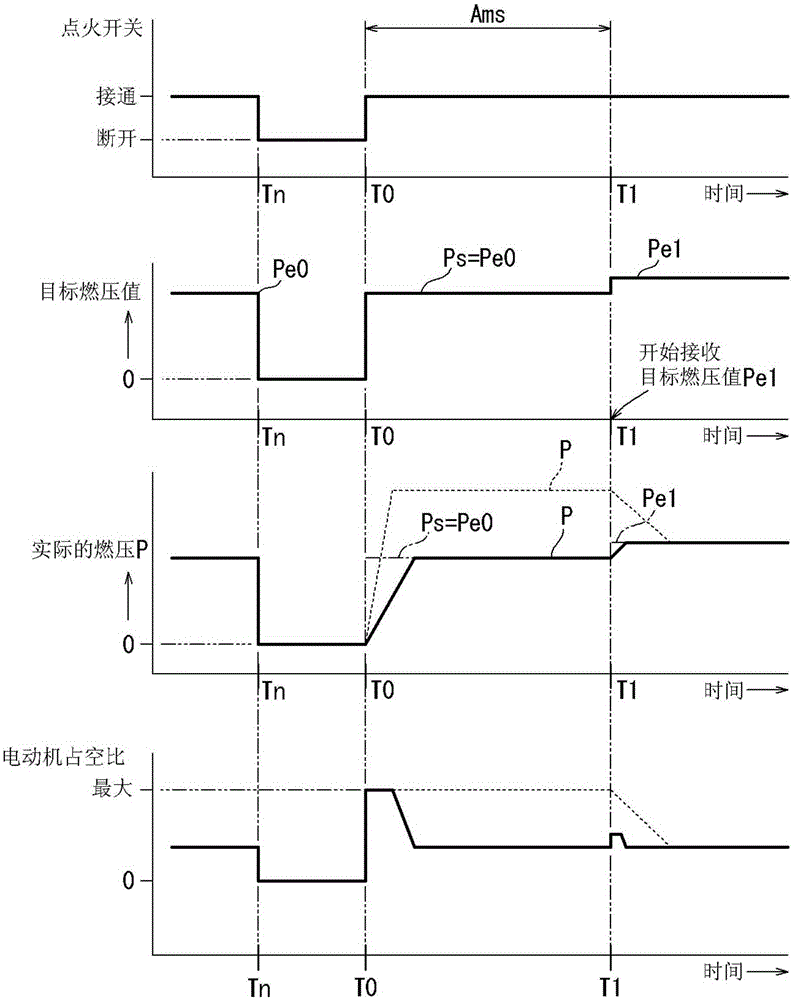

[0045] Below, based on Figure 5 to Figure 10 A fuel supply device according to Embodiment 2 of the present invention will be described. The fuel supply device according to the present embodiment is an improvement of the fuel pressure control (fuel pressure control during time T0 to T1 ) using the provisional target fuel pressure value Ps in the fuel supply device 10 according to the first embodiment. As a result, the basic structure of the fuel supply device is the same as that of the fuel supply device 10 according to the first embodiment.

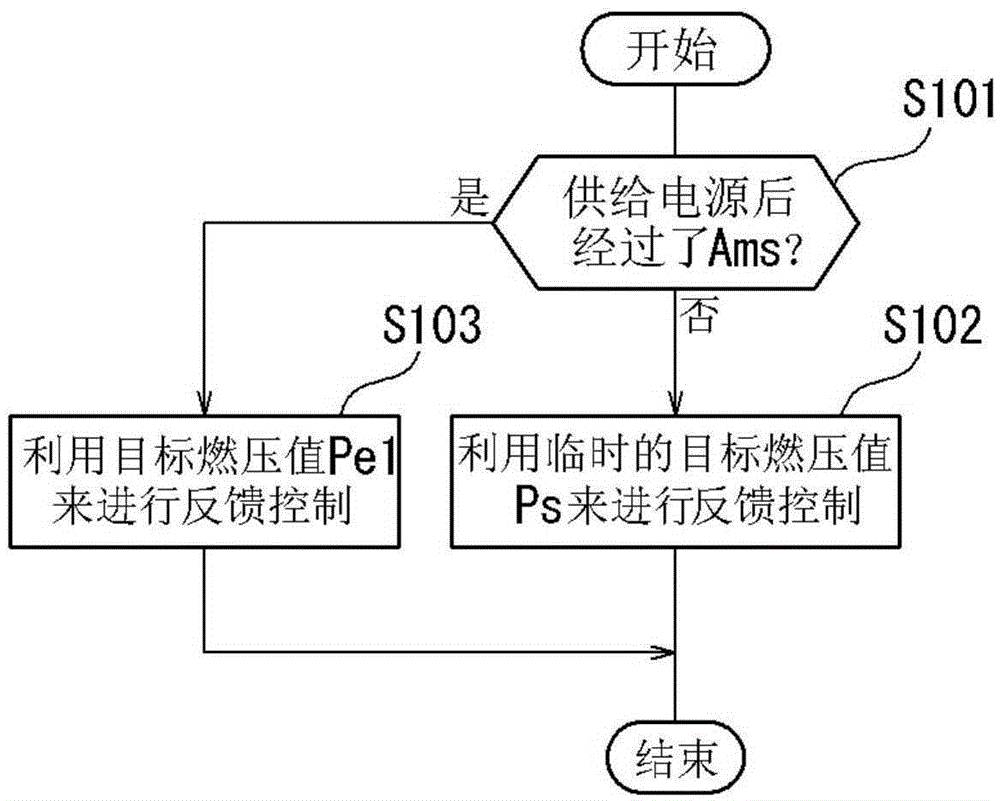

[0046] Such as Figure 5 As shown, in the fuel supply device (low pressure control unit 24 ) according to the present embodiment, when the ignition switch is turned on (time T0 ), the temporary target fuel pressure value Ps is set similarly to the case of the first embodiment. Moreover, the microcomputer of the low-voltage control unit 24 executes Figure 6 The process shown in the flowchart. For example, if Figure 5 As shown, at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com