Pressure shut-off valve for high-pressure cleaner and high-pressure cleaner having pressure shut-off valve

A cut-off valve and cleaner technology, applied in the field of pressure cut-off valves, can solve problems such as unreliable switching and high manufacturing costs, and achieve the effects of improving flow resistance, reducing manufacturing costs, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

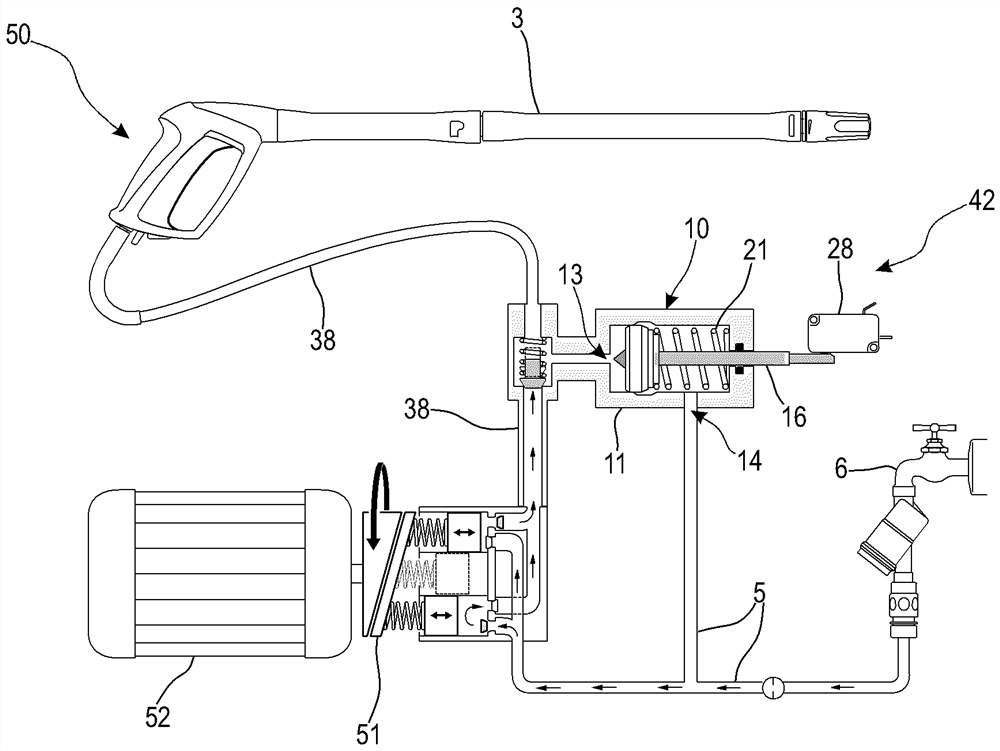

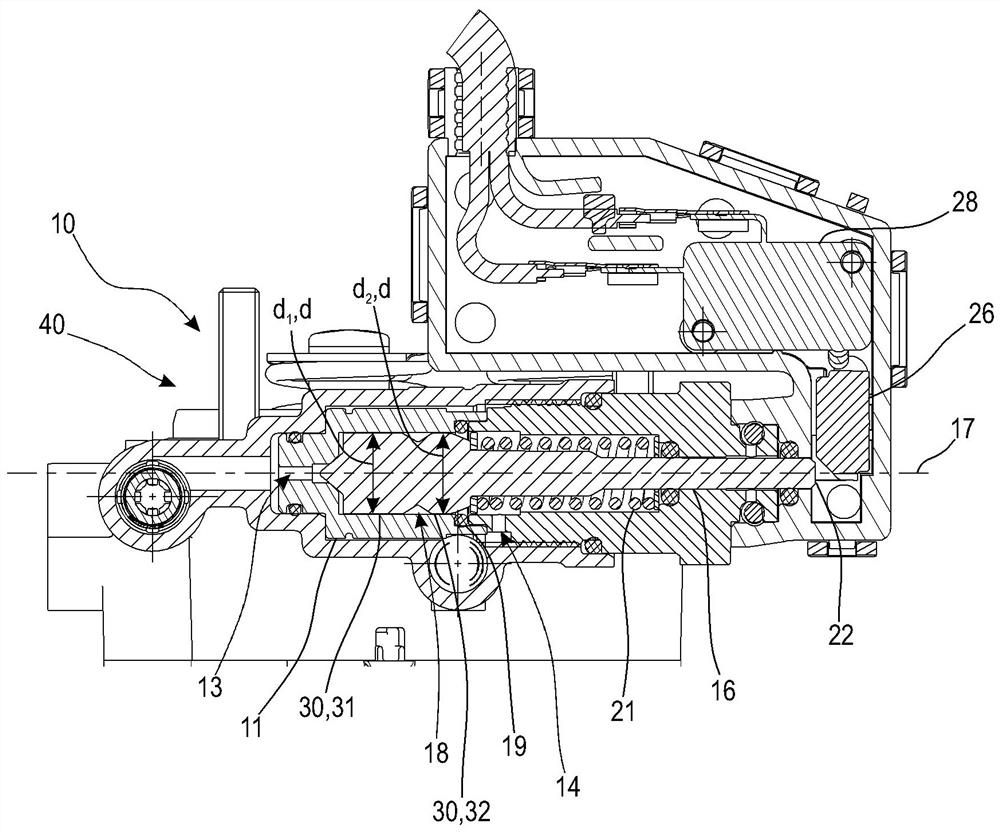

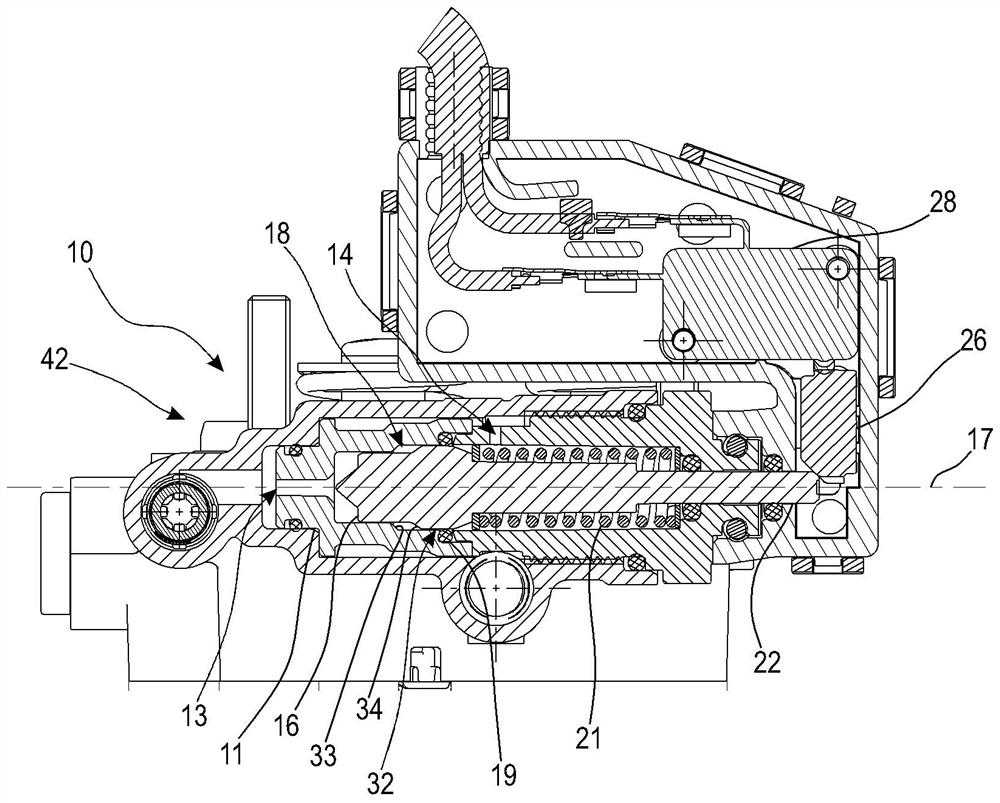

[0034] figure 1 Shown is a schematic illustration of a design of a high-pressure cleaner 1 according to the invention. The high-pressure cleaner 1 comprises a housing 2 which encloses the various system components of a hydraulic unit 50 ( Figure 3~5 ) and protect it, for example, from jets of water. A low-pressure connection 4 is provided on the housing 2, through which the suction line 5 of the high-pressure cleaner 1 ( Figure 3~5 ) with an external liquid connection 6 ( Figure 3~5 ) especially water fittings can be connected. The high-pressure cleaner 1 is then supplied with cleaning liquid via the low-pressure connection 4 during its operation. The cleaning liquid is preferably water. Other liquids, such as water mixed with cleaning agents, can also be provided as cleaning liquids. A hose drum 7 is arranged on the housing 2 of the high-pressure cleaner 1 . A high-pressure hose 8 is wound around the hose drum 7 . The high-pressure hose 8 is connected with the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com