Powder metallurgy brake pad matched with carbon-ceramic brake disc and preparation method

A carbon-ceramic brake disc and brake pad technology, applied in metal processing equipment, mechanical equipment, friction linings, etc., to achieve the effect of high friction coefficient, wide source and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

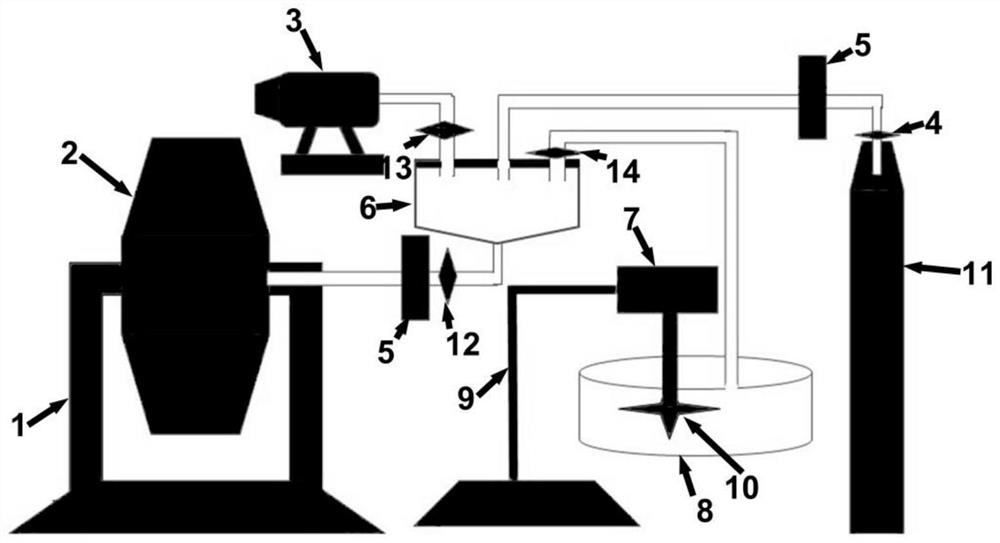

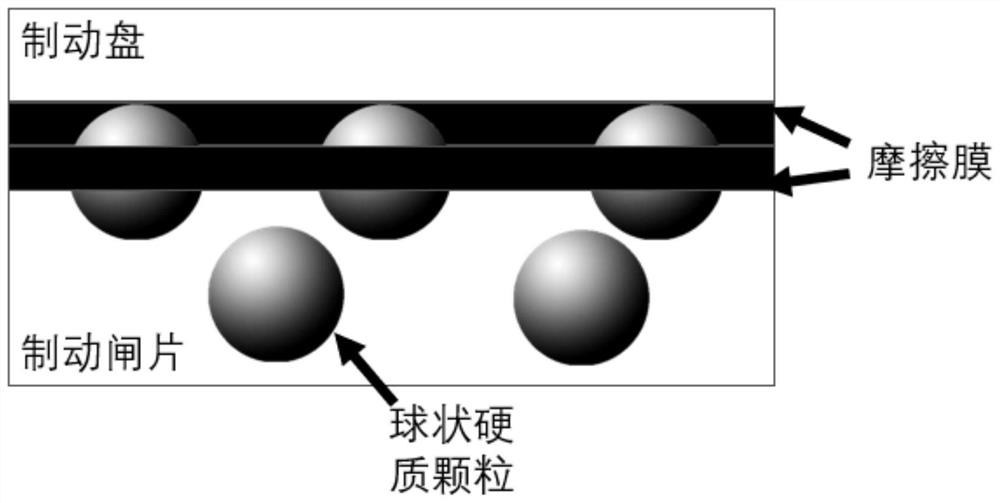

Method used

Image

Examples

Embodiment 1

[0033] 1. A powder metallurgy brake pad matched with a carbon ceramic brake disc, including the following components:

[0034] Iron powder: 50 parts by weight; copper powder: 15 parts by weight; flake graphite, 9 parts by weight; graphene: 0.4 parts by weight; ferrous sulfide powder: 8 parts by weight; spherical mixed hard powder: 17.6 parts by weight;

[0035] The spherical hard metal powder includes chromium powder: 3 parts by weight; molybdenum powder: 3 parts by weight; ferrochrome powder: 4 parts by weight; ferromolybdenum powder: 4 parts by weight.

[0036] The spherical ceramic powder includes silicon carbide: 3 parts by weight; titanium dioxide: 0.6 parts by weight.

[0037] 2. Pour the above-mentioned raw material powder into the double-cone mixer except graphene, and the mixing cylinder rotates continuously to stir the material at a speed of 120 rpm, and the powder particles are dispersed in the mixing cylinder; add graphene to ethanol, The addition of graphene is 2...

Embodiment 2

[0042] 1. A powder metallurgy brake pad matched with a carbon ceramic brake disc, including the following components:

[0043] Iron powder: 55 parts by weight; Copper powder: 12 parts by weight; Flake graphite, 12 parts by weight; Graphene: 0.5 parts by weight; Ferrous sulfide powder: 7 parts by weight; Spherical mixed hard powder: 13.5 parts by weight;

[0044] The spherical hard metal powder includes chromium powder: 2 parts by weight; molybdenum powder: 2 parts by weight; ferrochrome powder: 3 parts by weight; ferromolybdenum powder: 3 parts by weight.

[0045] The spherical ceramic powder includes silicon carbide: 2.5 parts by weight; titanium dioxide: 0.5 parts by weight.

[0046] 2. Pour the above-mentioned raw material powder into the double-cone mixer except graphene, and the mixing cylinder rotates continuously to stir the material at a speed of 120 rpm, and the powder particles are dispersed in the mixing cylinder; add graphene to ethanol, The addition of graphene i...

Embodiment 3

[0051] 1. A powder metallurgy brake pad matched with a carbon ceramic brake disc, including the following components:

[0052] Iron powder: 45 parts by weight; Copper powder: 18 parts by weight; Flake graphite, 8 parts by weight; Graphene: 0.3 parts by weight; Ferrous sulfide powder: 10 parts by weight; Spherical mixed hard powder: 18.7 parts by weight;

[0053] The spherical hard metal powder includes chromium powder: 2.1 parts by weight; molybdenum powder: 2.1 parts by weight; ferrochrome powder: 5 parts by weight; ferromolybdenum powder: 5 parts by weight.

[0054] The spherical ceramic powder includes silicon carbide: 3.5 parts by weight; titanium dioxide: 1 part by weight.

[0055] 2. Pour the above-mentioned raw material powder into the double-cone mixer except graphene, and the mixing cylinder rotates continuously to stir the material at a speed of 120 rpm, and the powder particles are dispersed in the mixing cylinder; add graphene to ethanol, The addition of graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com