Patents

Literature

40results about How to "Low thermal diffusivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

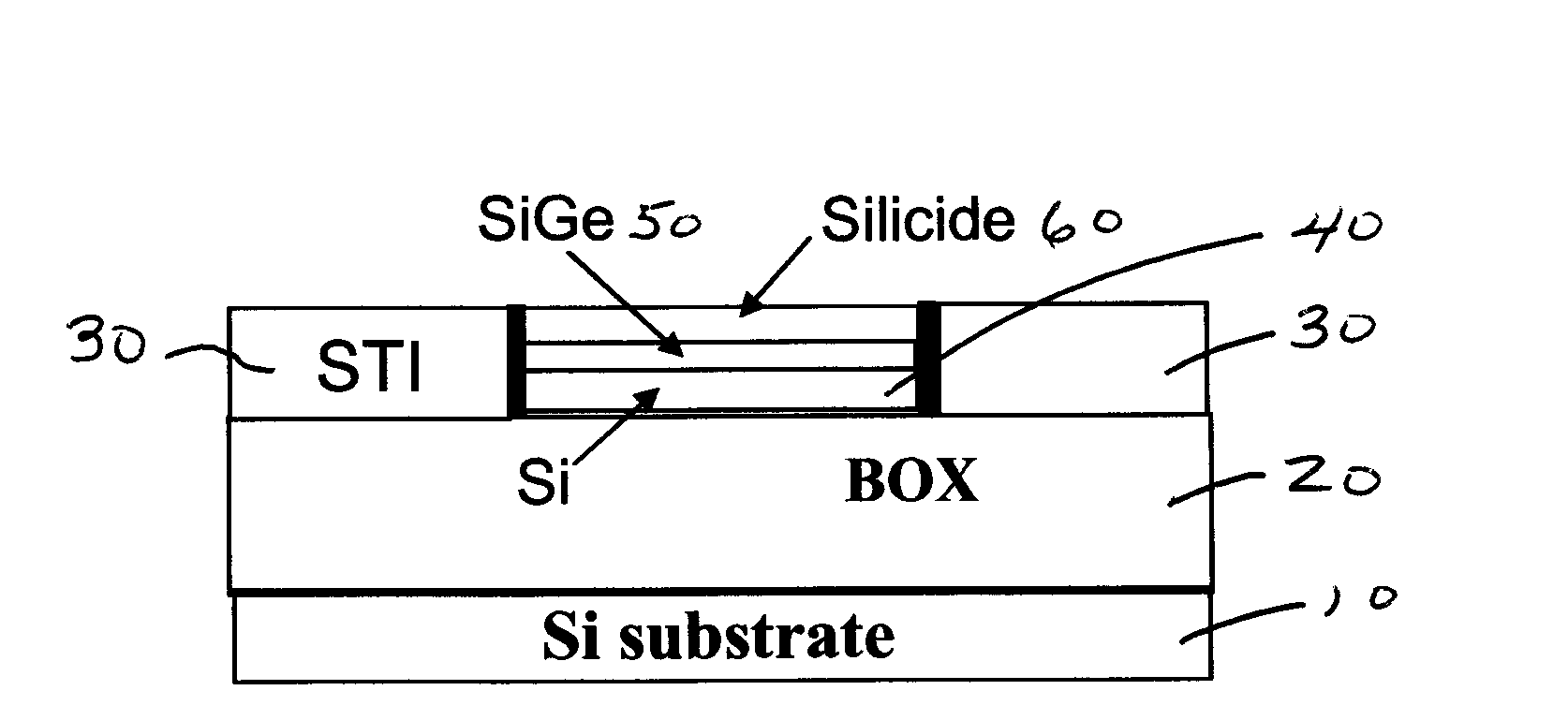

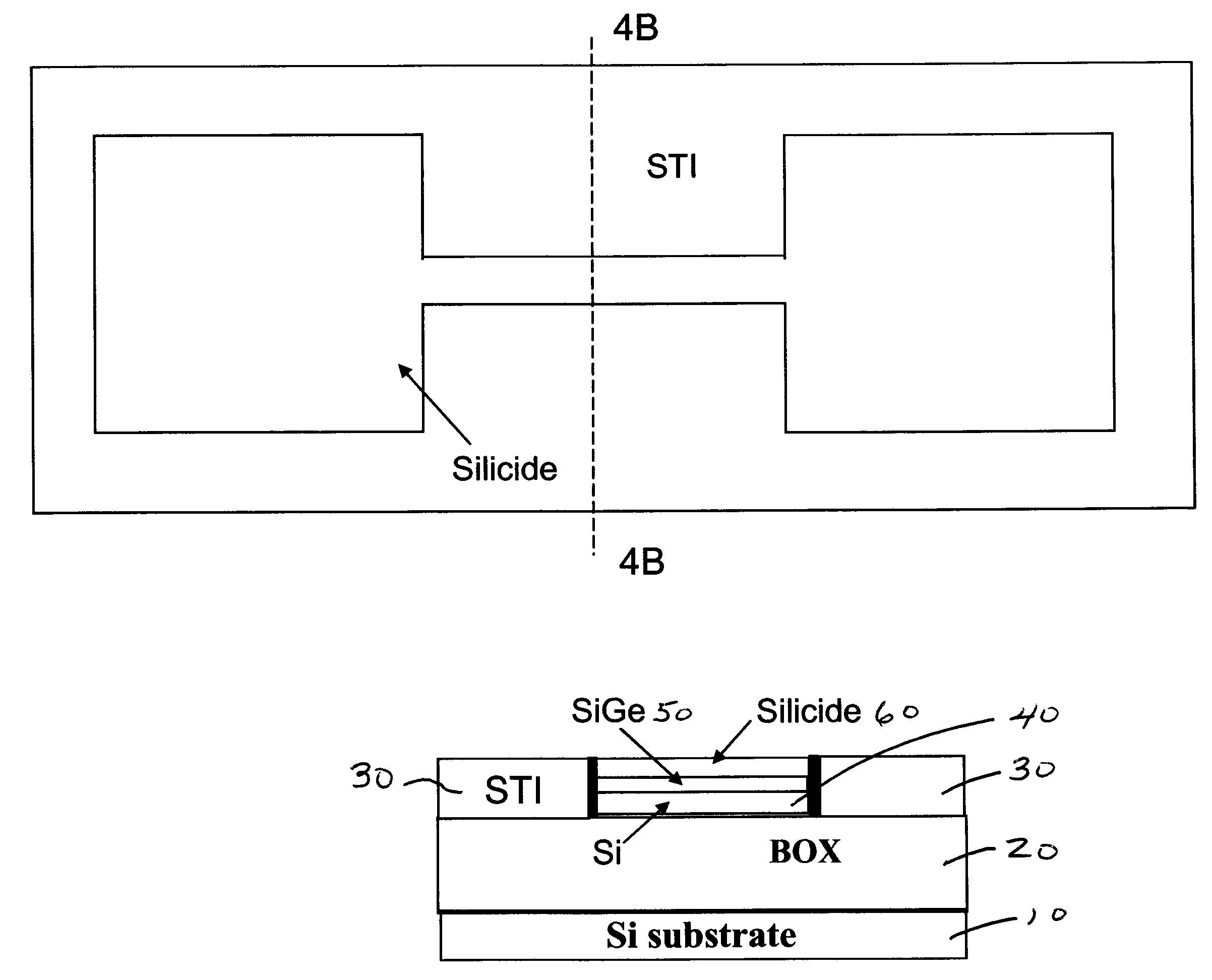

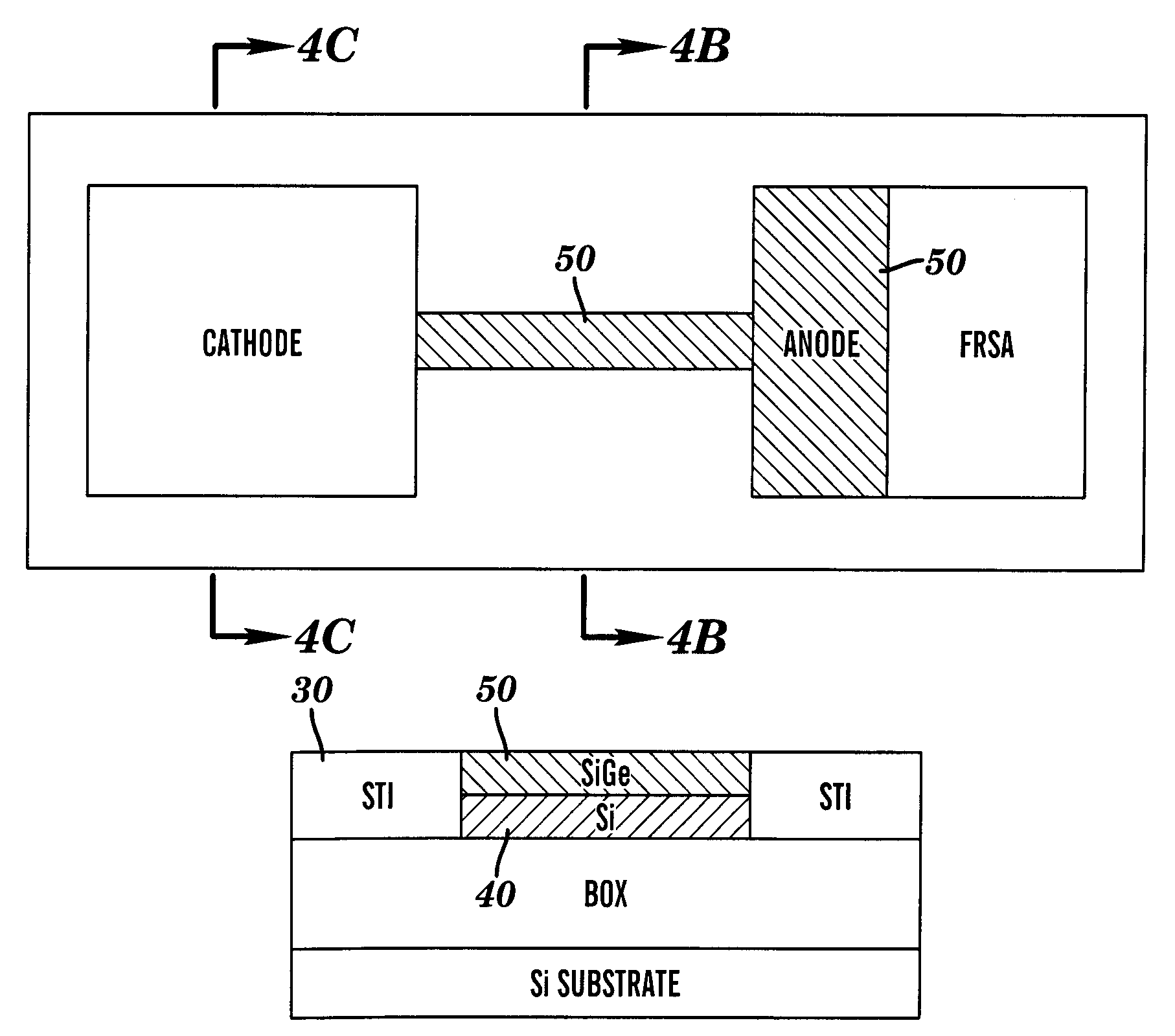

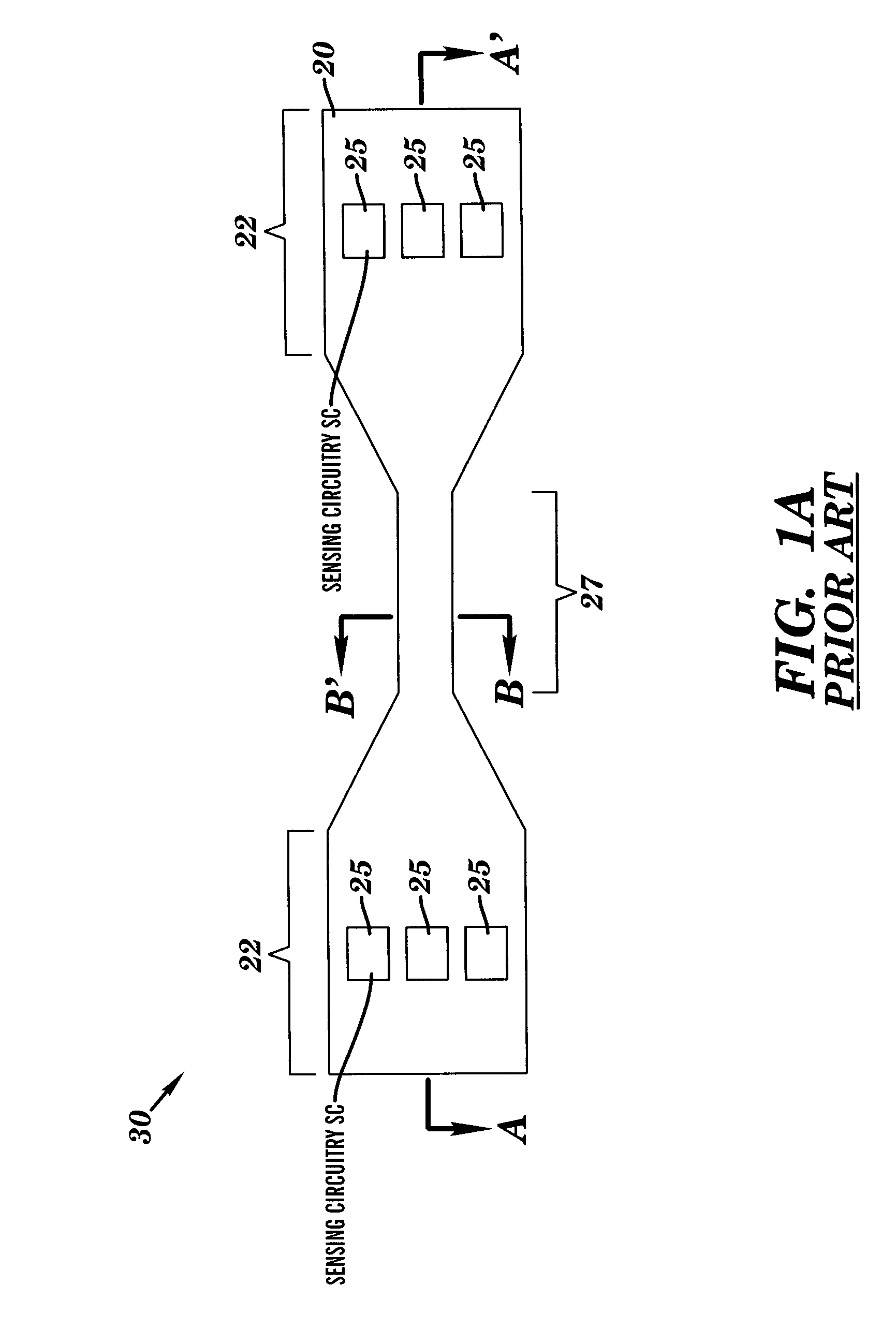

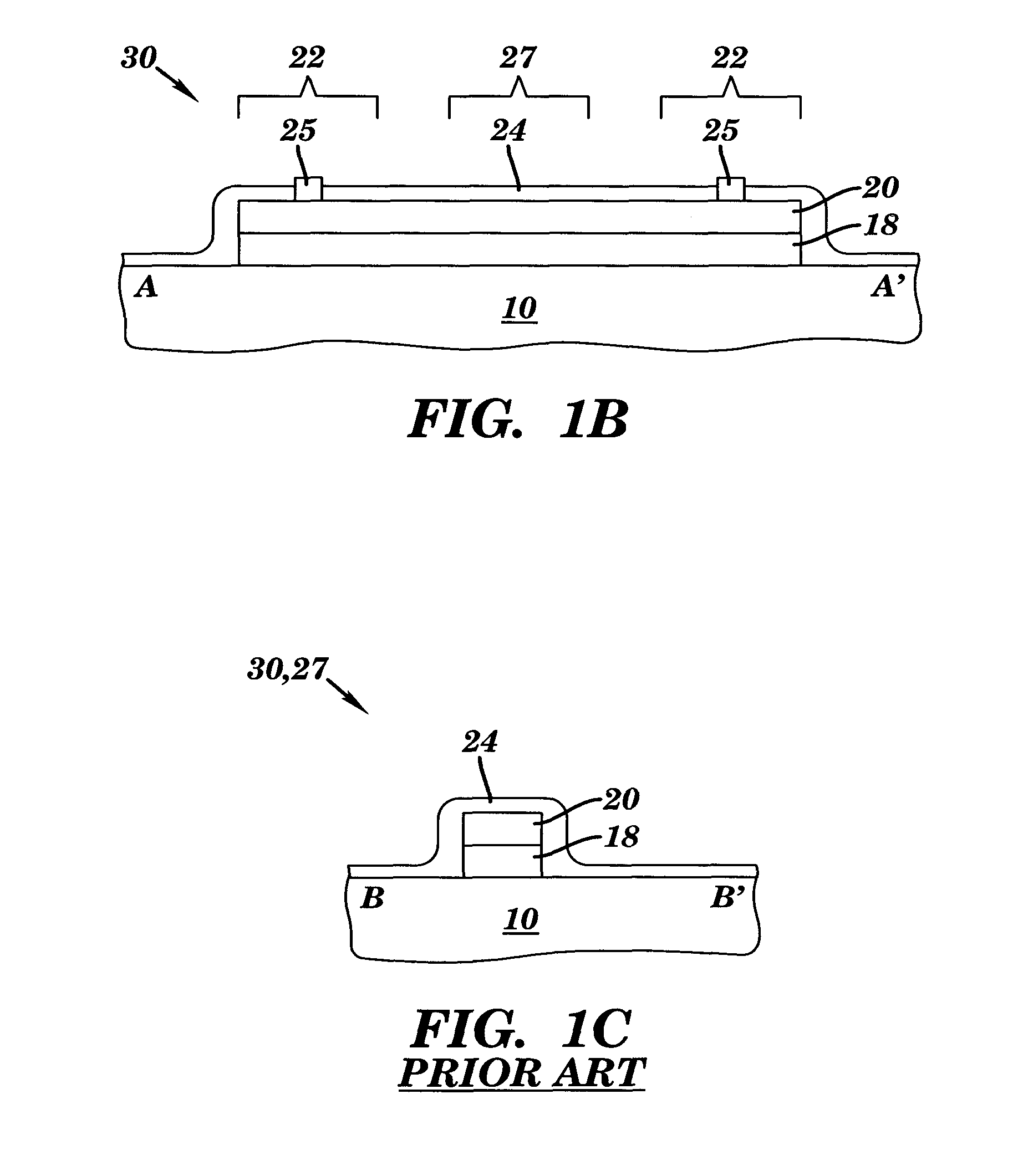

Efuse containing sige stack

InactiveUS20080169529A1Program have been very successfulLower melting temperatureSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsSingle crystal

An eFuse, includes: a substrate and an insulating layer disposed on the substrate; a first layer including a single crystal or polycrystalline silicon disposed on the insulating layer; a second layer including a single crystal or polycrystalline silicon germanium disposed on the first layer, and a third layer including a silicide disposed on the second layer. The Ge has a final concentration in a range of approximately five percent to approximately twenty-five percent.

Owner:GLOBALFOUNDRIES INC

Method for preparing high-hardness wear-resistant powder metallurgical rolling sleeve

The invention relates to a method for preparing a high-hardness abrasion-resistant powder metallurgic roller sleeve, which is characterized in that the method adopts powder metallurgic technology for manufacture, and comprises the following steps: firstly, powder mixing, namely mixing iron powder, carbon powder, chromium powder or ferrochrome powder and a lubricant, and guaranteeing that the total composition comprises the following components in percentage by weight: 0.3 to 2 percent of carbon, 0.3 to 4 percent of chromium, not more than 2 percent of unavoidable impurities, and the balance being iron; secondly, forming, wherein the density after forming is more than 6.8g / cm; thirdly, sintering; fourthly, machine processing; fifthly, quenching; sixthly, cold treatment; and seventhly, tempering. Compared with the prior art, the method has the advantages that the product mainly comprises the iron, the carbon and the chromium and does not comprise noble metal element such as nickel, molybdenum and tungsten, so that the cost is low; the mechanical properties such as the tensile strength, the hardness and the microhardness of the product are superior to those of products obtained by casting technology; and both the thermal diffusivity and the thermal conductivity of the product are lower than those of the products obtained by the casting technology.

Owner:NBTM NEW MATERIALS GRP

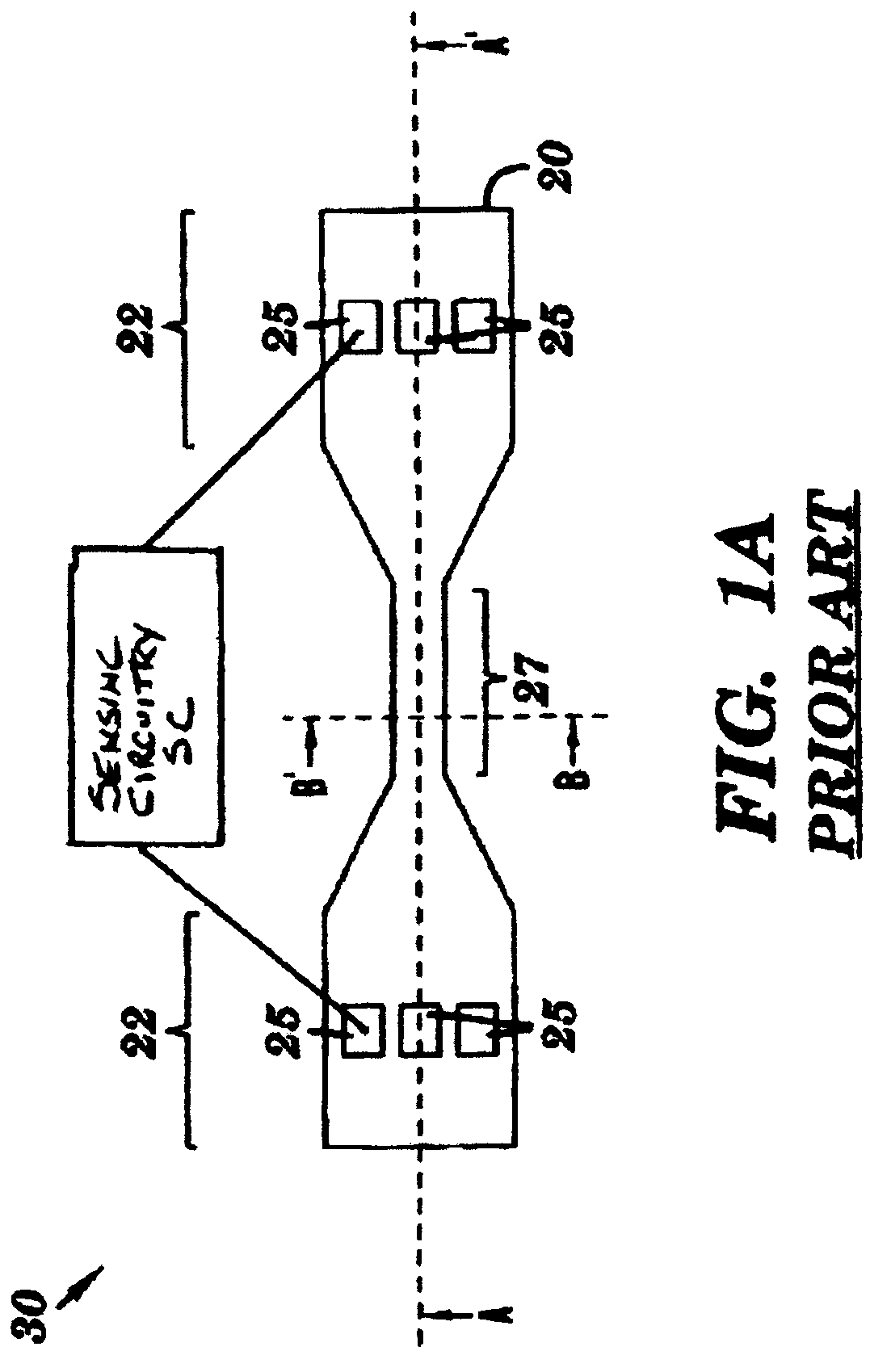

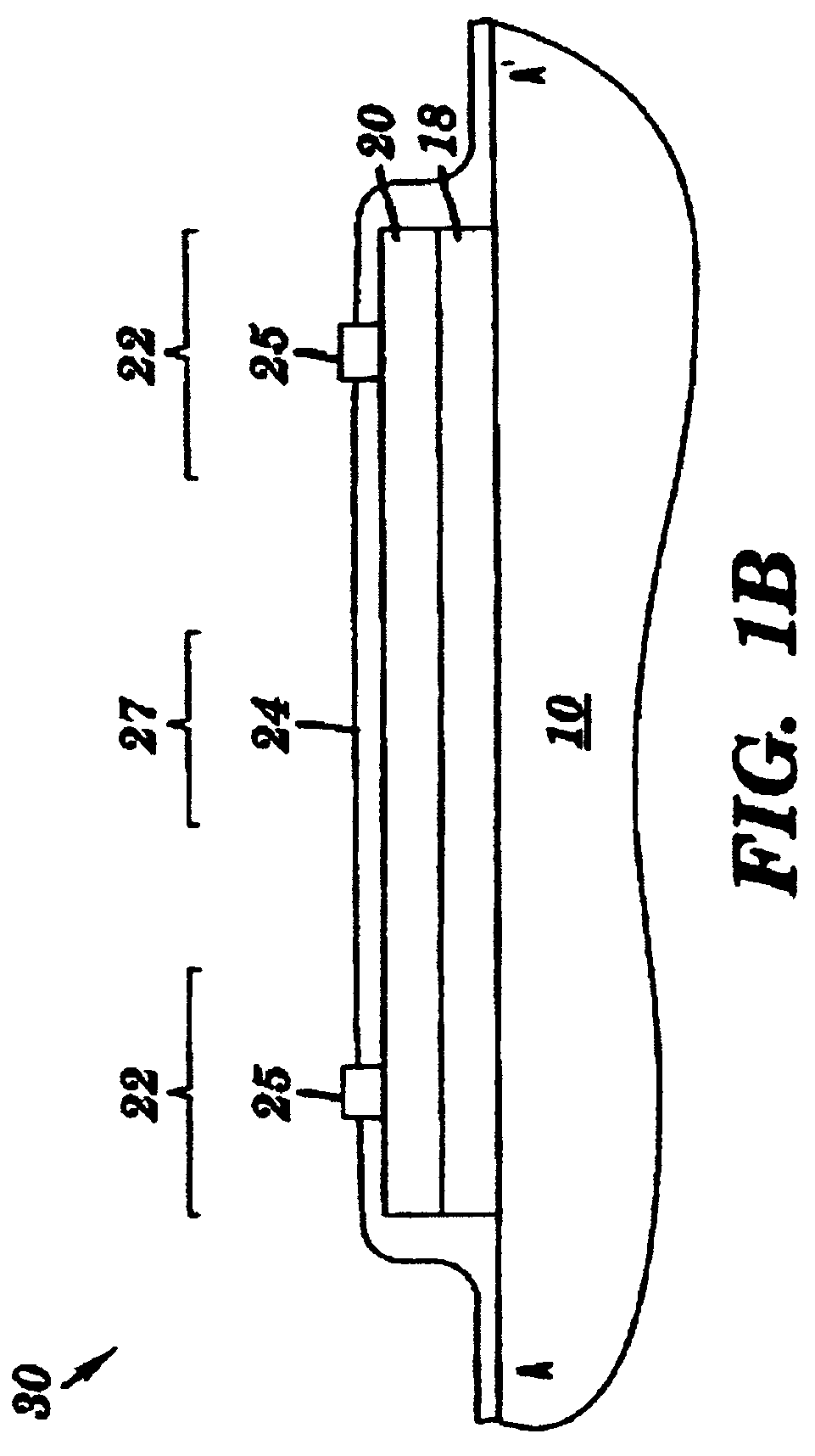

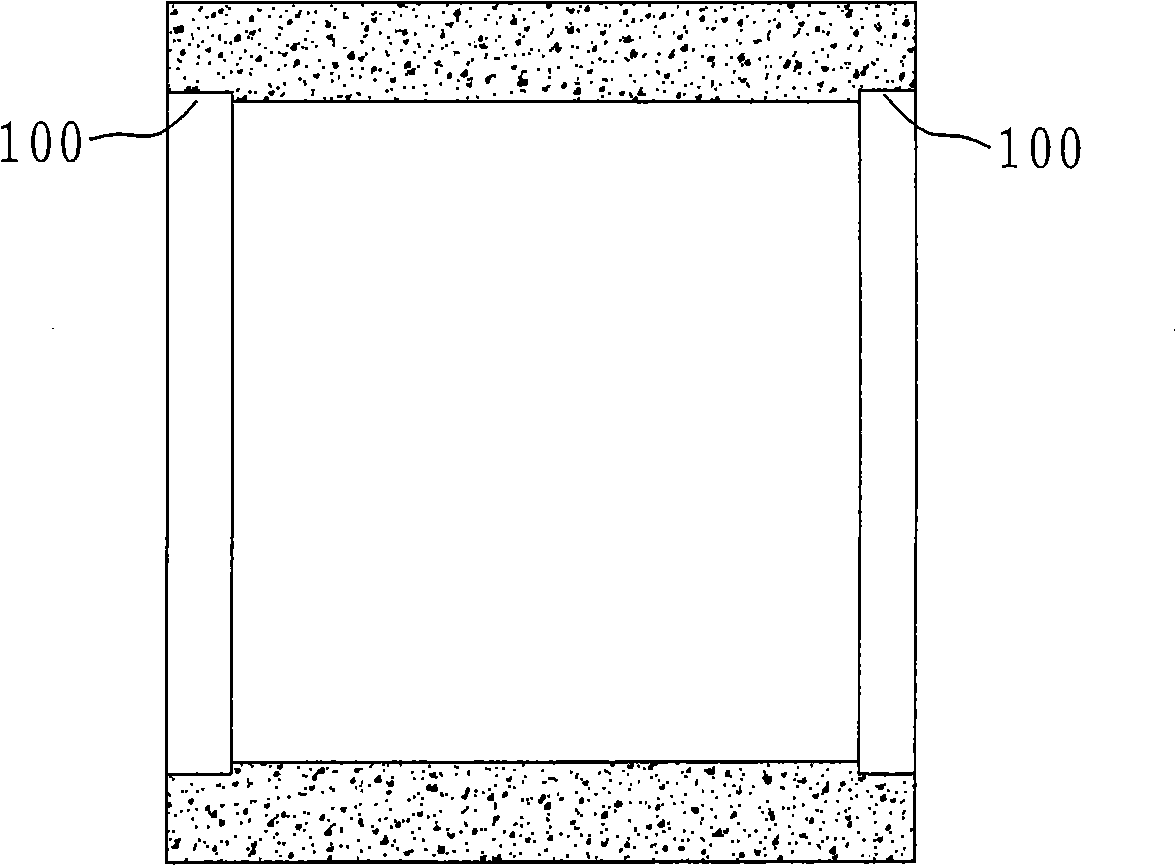

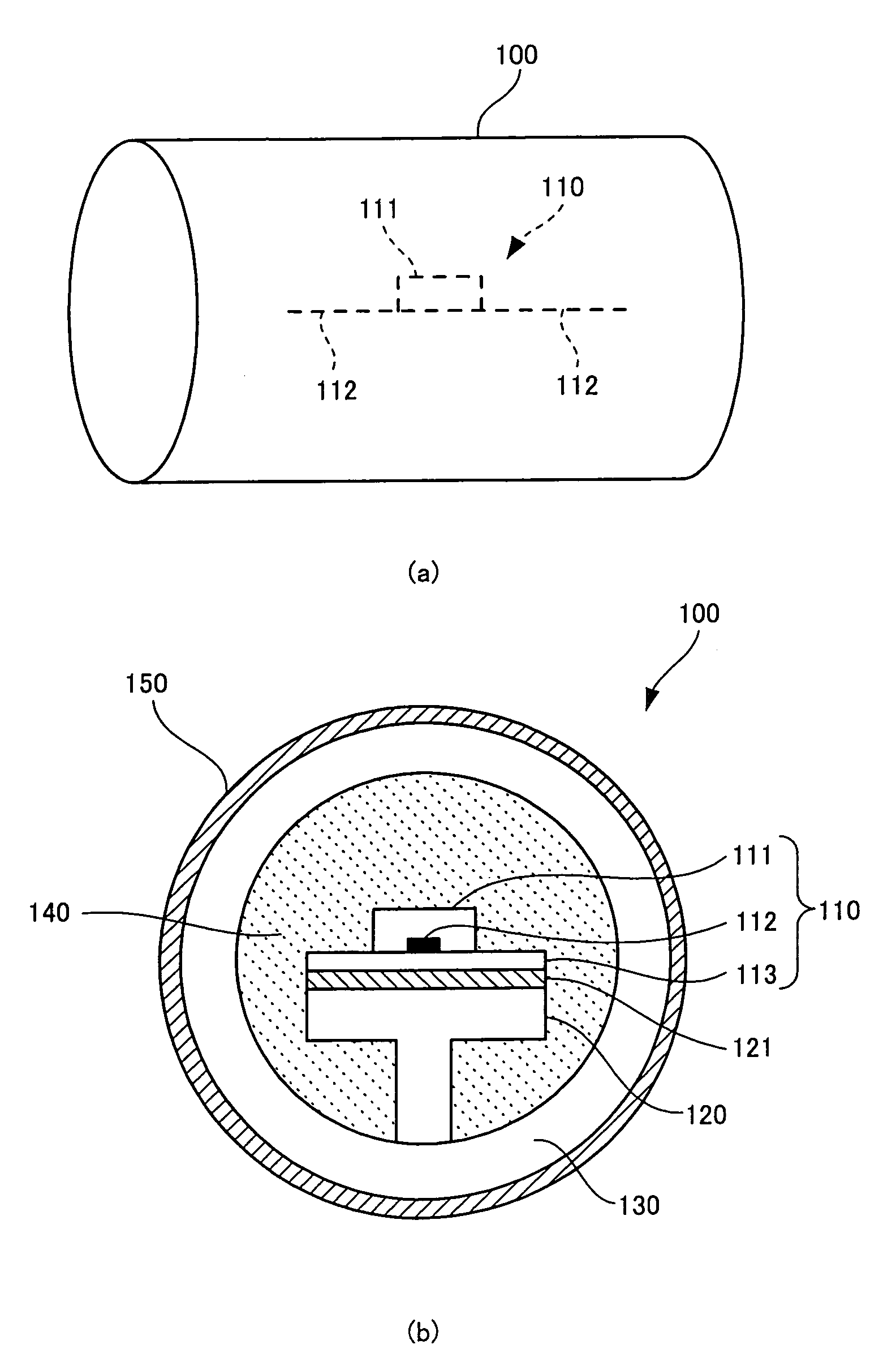

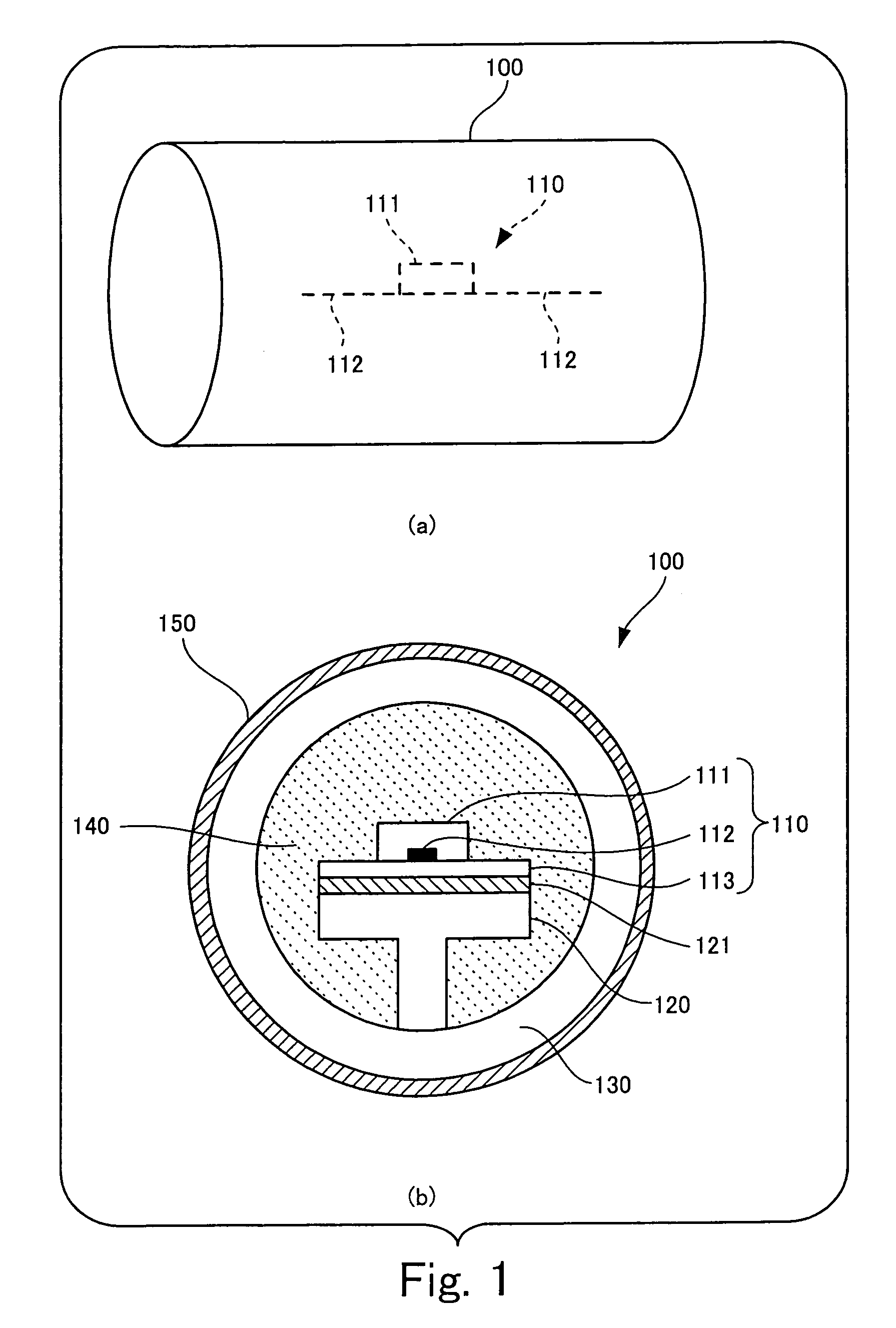

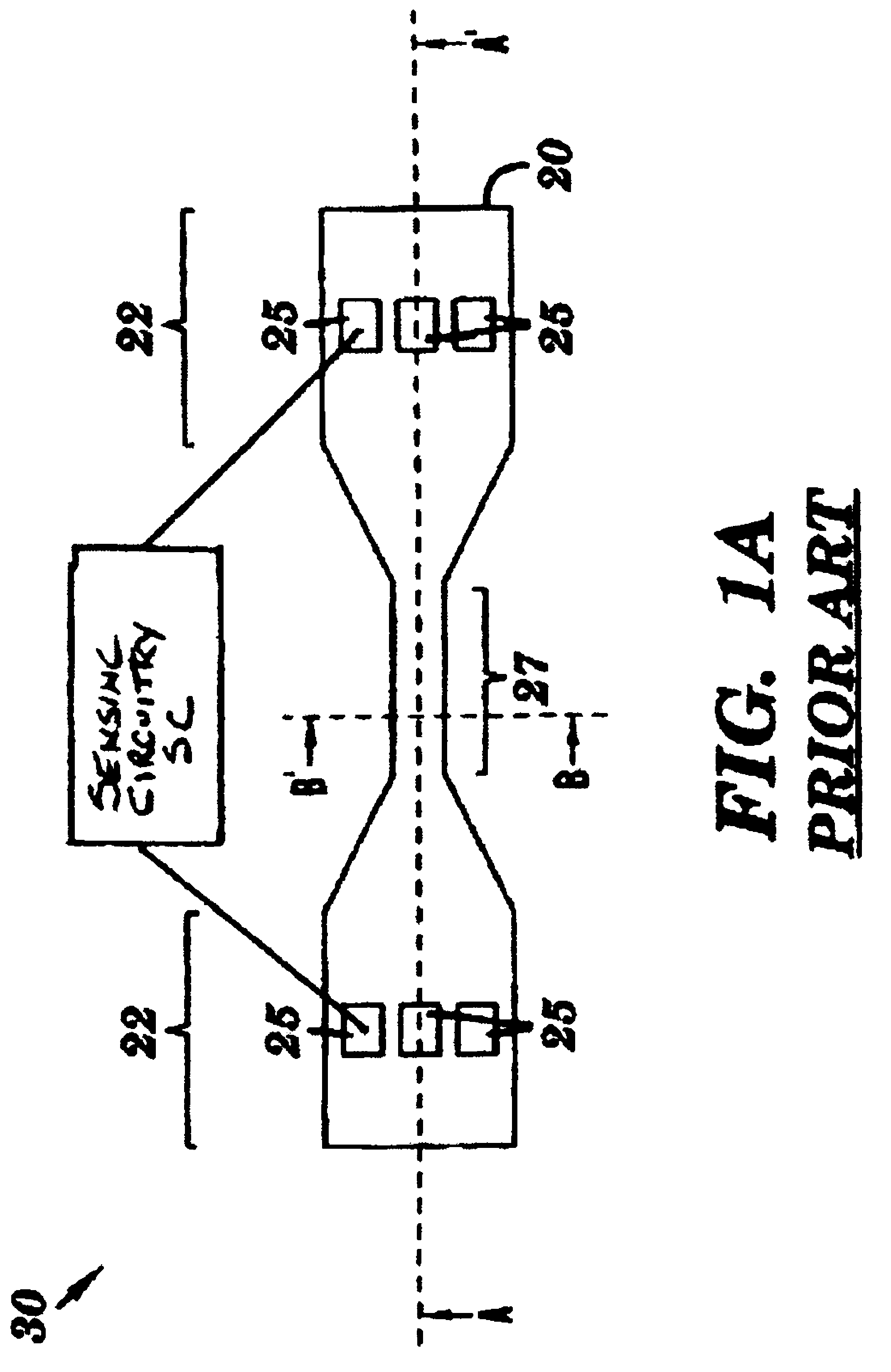

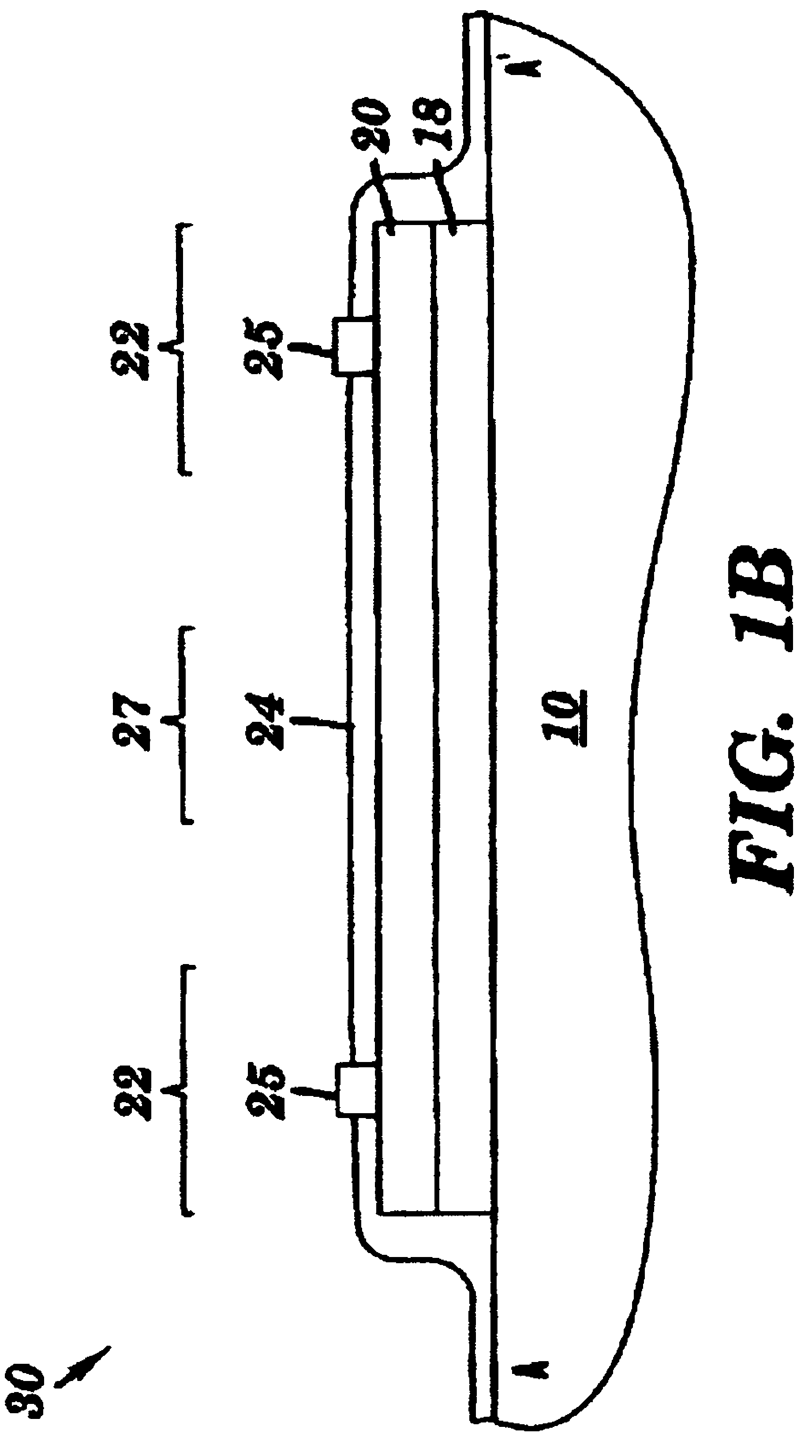

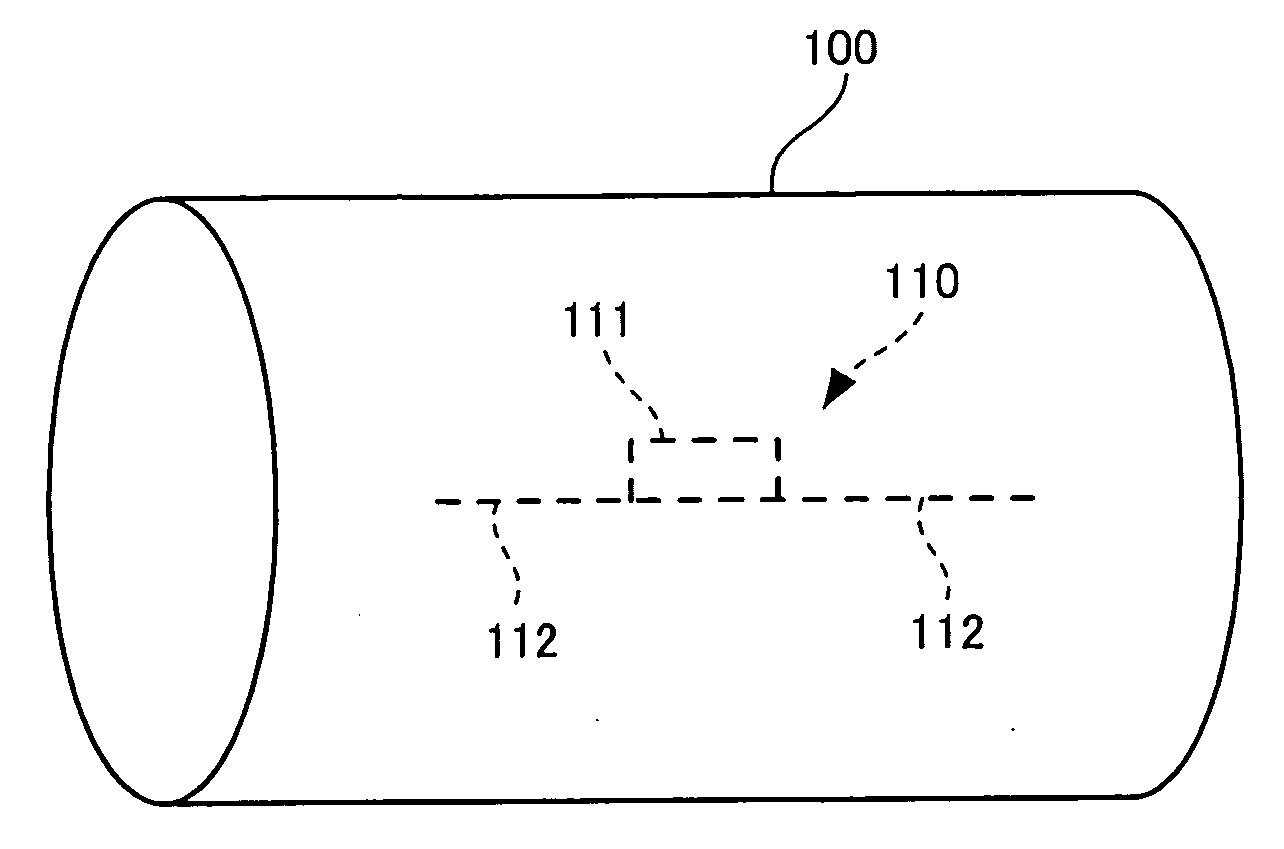

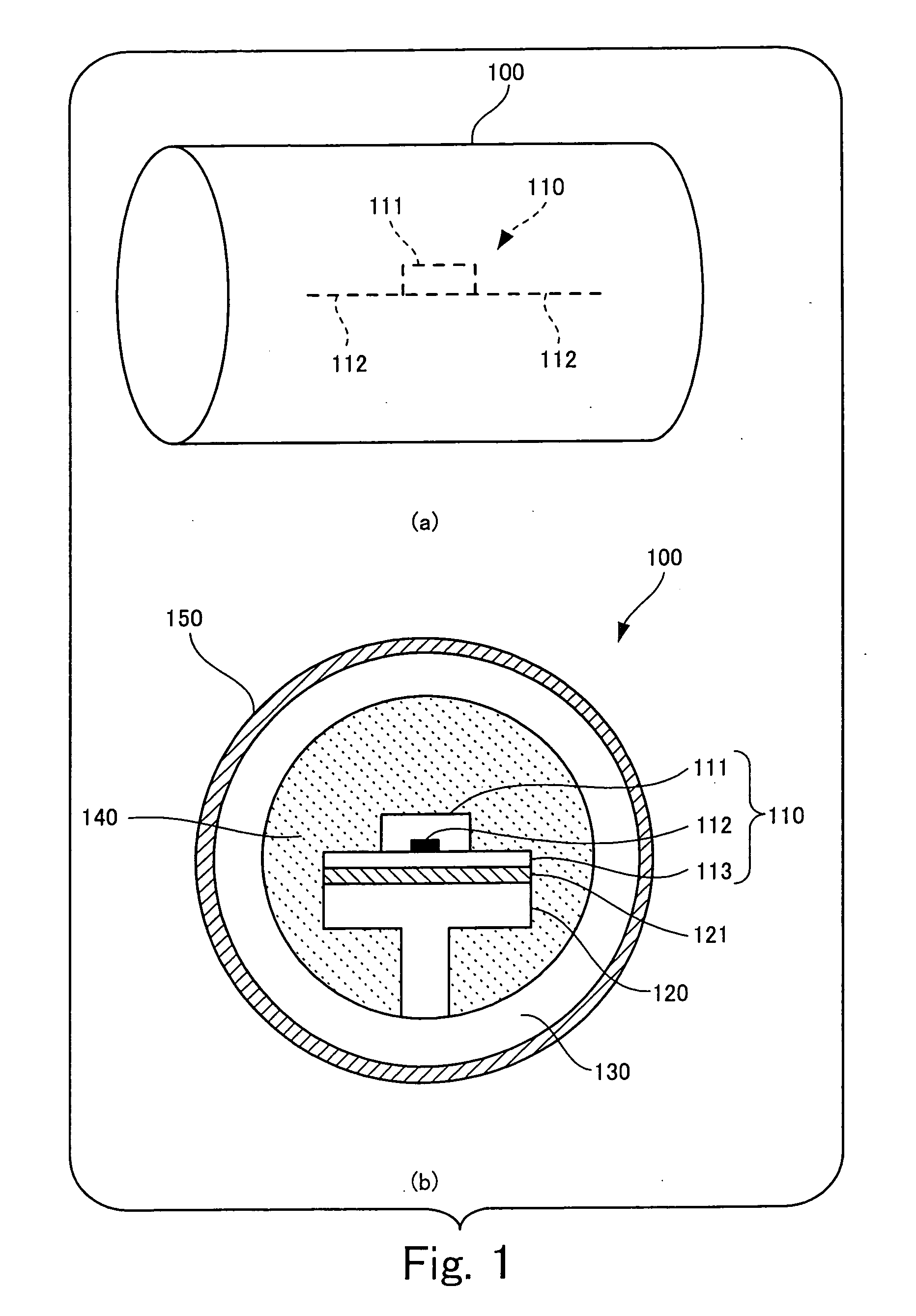

RFID tag

InactiveUS7463156B2Improve performanceLow thermal conductivityRecord carriers used with machinesBurglar alarm by hand-portable articles removalThermal energy storageThermal diffusivity

A RFID tag includes an inlet in which an antenna for communication and a circuit chip performing radio communication with the antenna are electrically connected to each other. The RFID tag further includes a thermal storage section which encloses the inlet, which is made of a nonmetal, and which prevents thermal diffusion into the inlet and a thermal insulating section which encloses the thermal storage section, which prevents thermal conduction to the thermal storage section, and which has higher thermal diffusivity than thermal diffusivity of the thermal storage section and lower thermal conductivity than thermal conductivity of the thermal storage section.

Owner:FUJITSU LTD

Compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and preparation method thereof

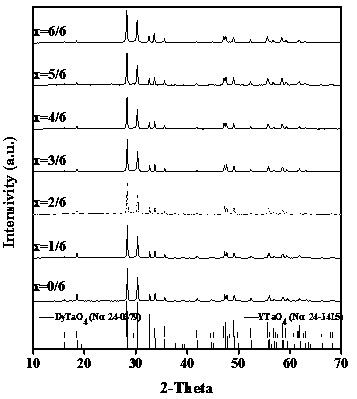

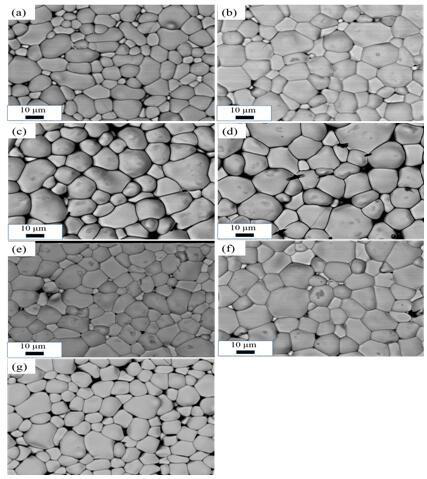

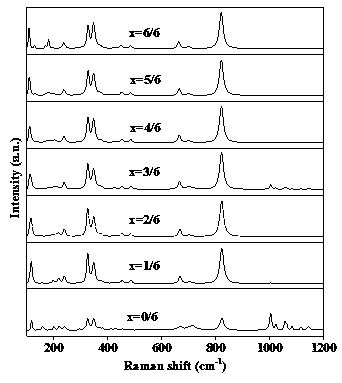

The invention discloses compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and a preparation method thereof, and belongs to the technical field of high temperatureresistant material of thermal barrier ceramic coating. The structural formula is (Y1-xDyx)TaO4 (x=0.1-0.9). Previously dried rare earth oxides (Y2O3, Dy2O3) and tantalum pentoxide (Ta2O5) are weighedaccording to the stoichiometric ratio required. Then, the materials are ball milled with ethanol as a solvent to obtain mixed powder A; the mixed powder A is sieved and compacted in a mold, and then ablank undergoes isostatic cool pressing to prepare a compact blank; and finally, the compact blank undergoes pressureless sintering to obtain the compact dual rare earth tantalate solid solution high-temperature ceramic. The dual rare earth tantalate solid solution high-temperature ceramic prepared by the method has characteristics of high process purity, low impurity content, high compactness, uniform grain size, low heat conductivity, large coefficient of thermal expansion, good toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH

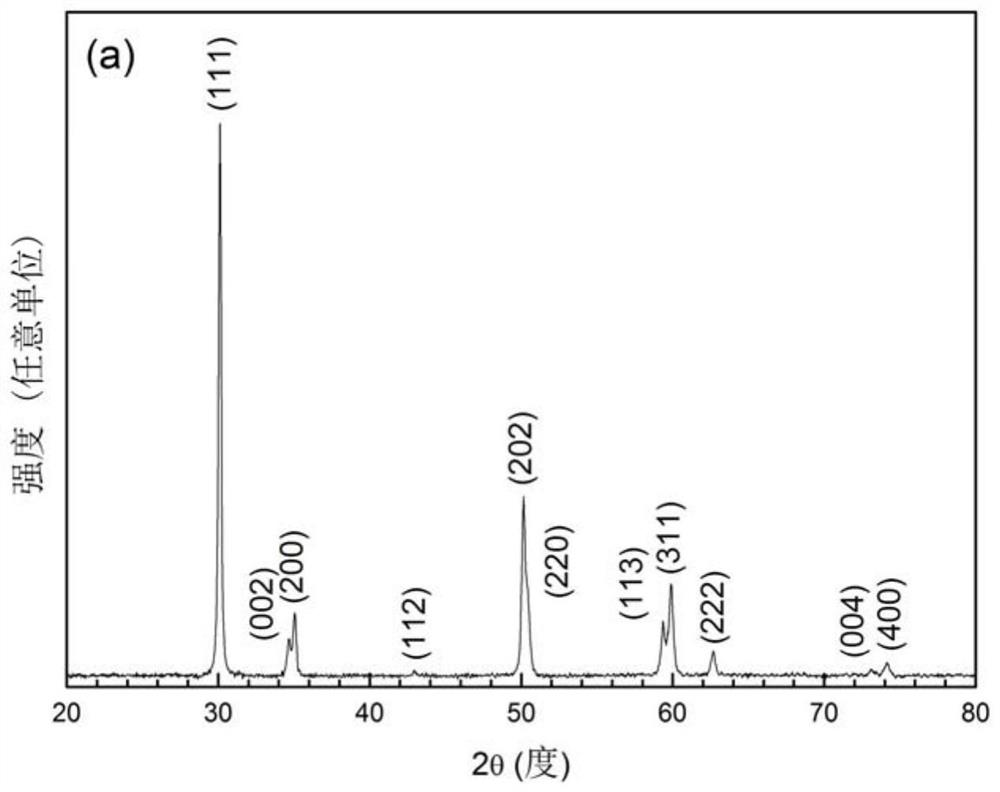

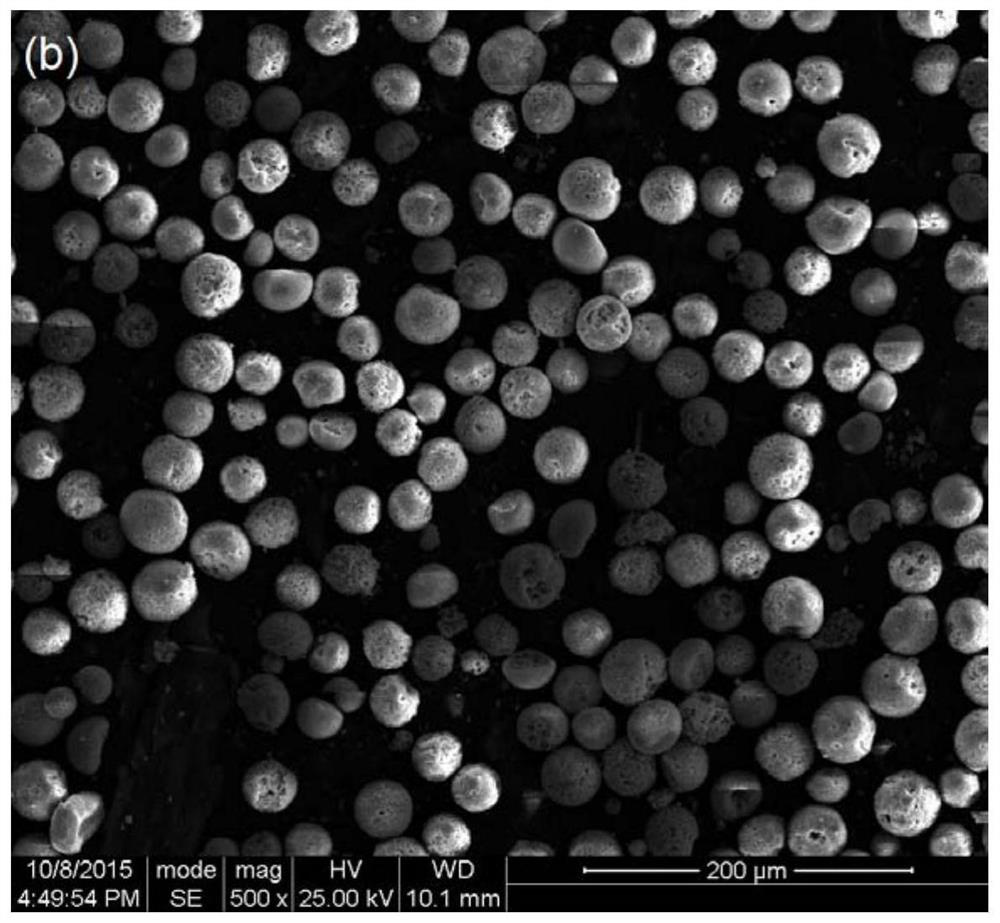

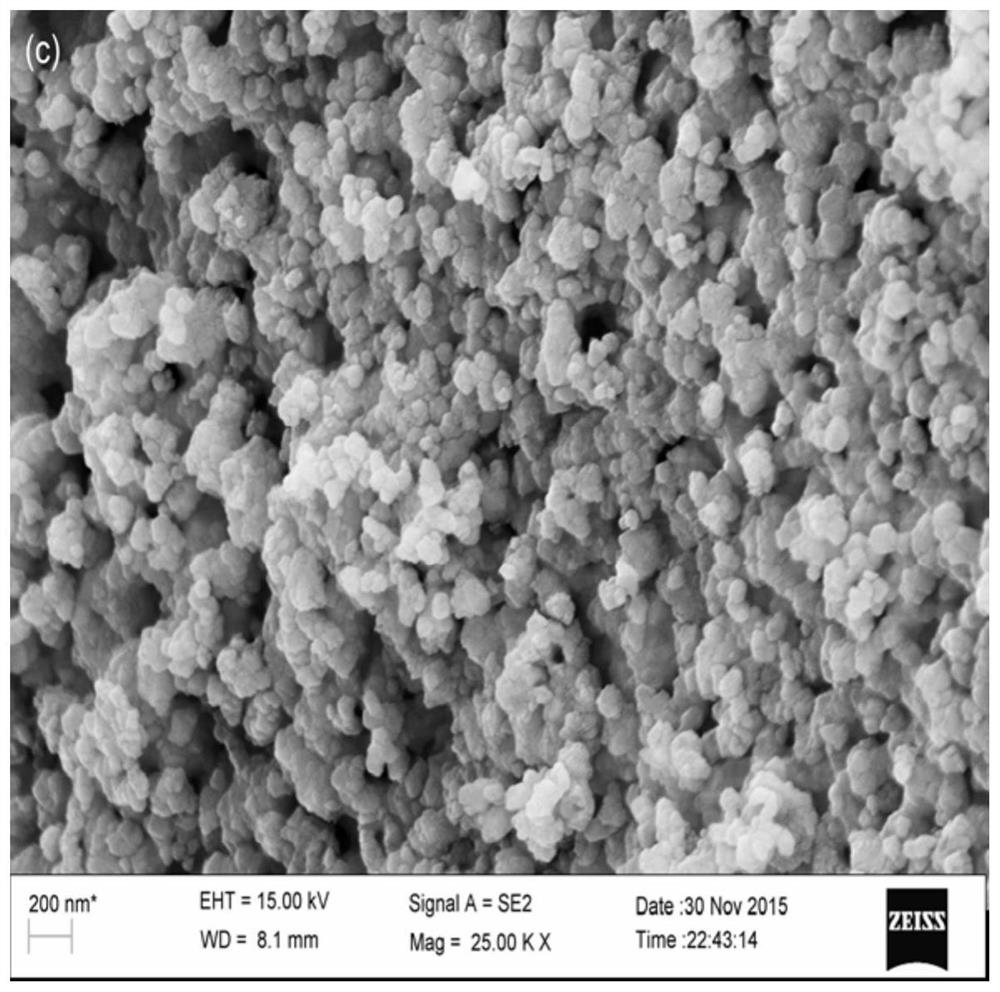

High-performance thermal barrier coating and ceramic layer thereof

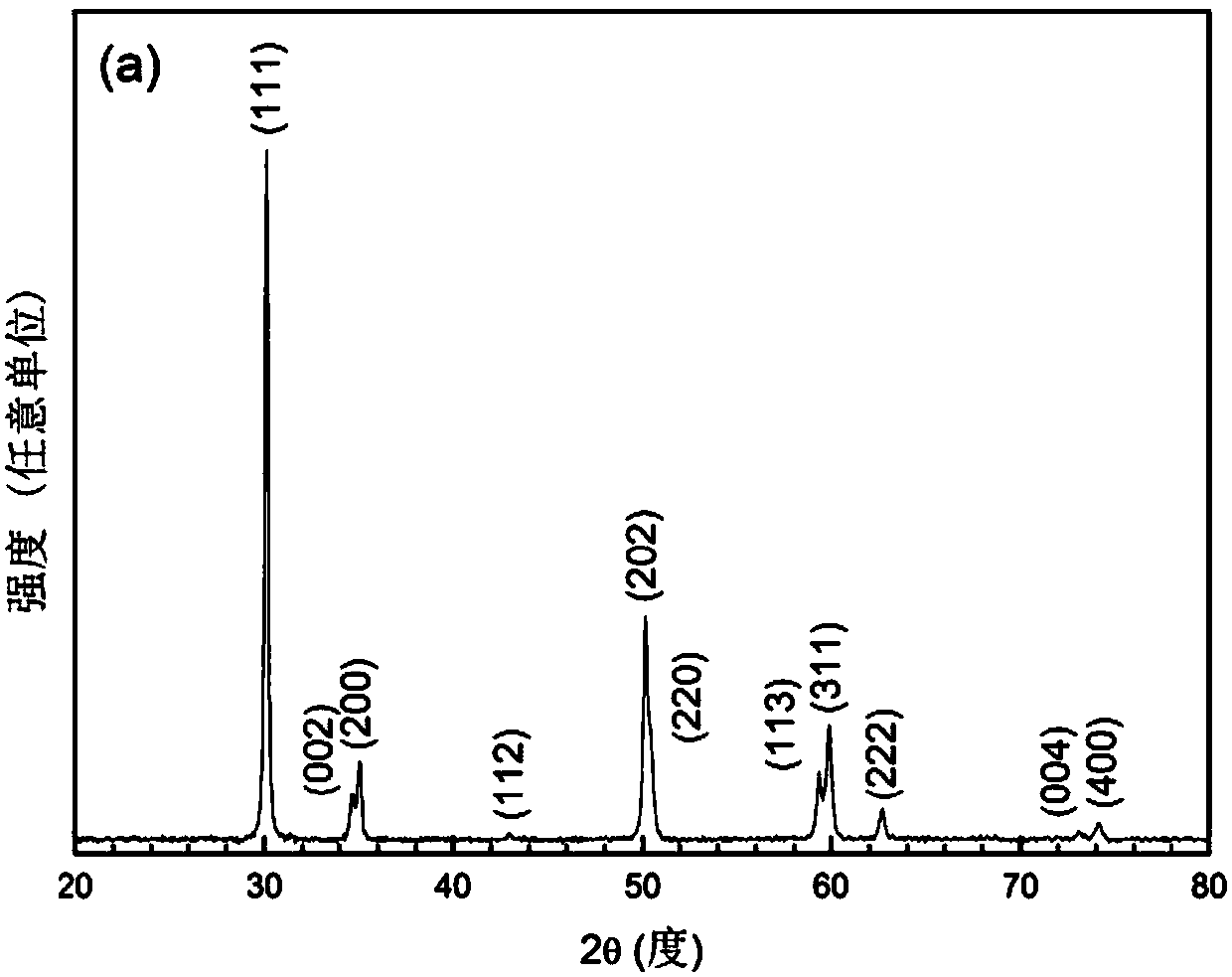

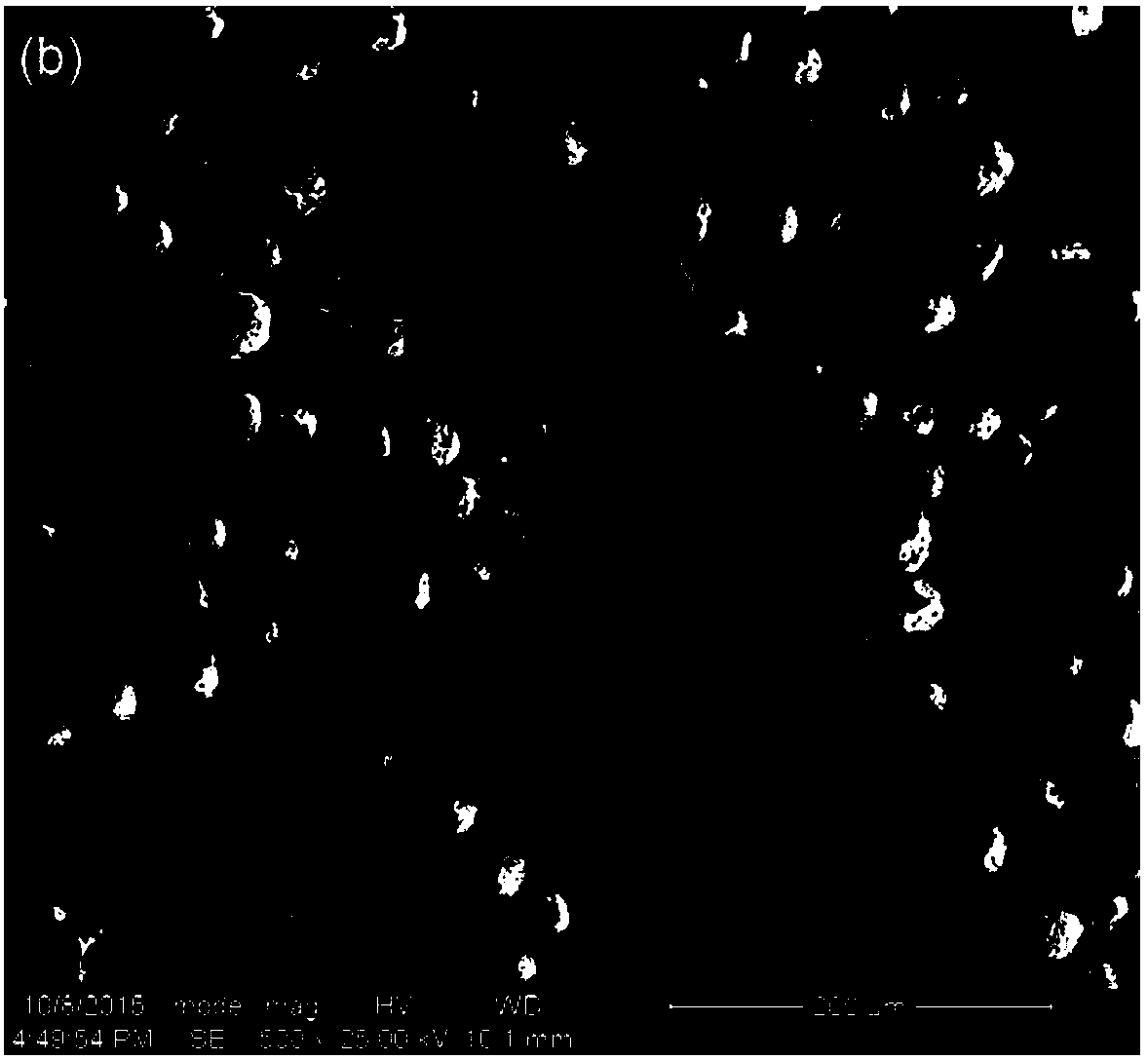

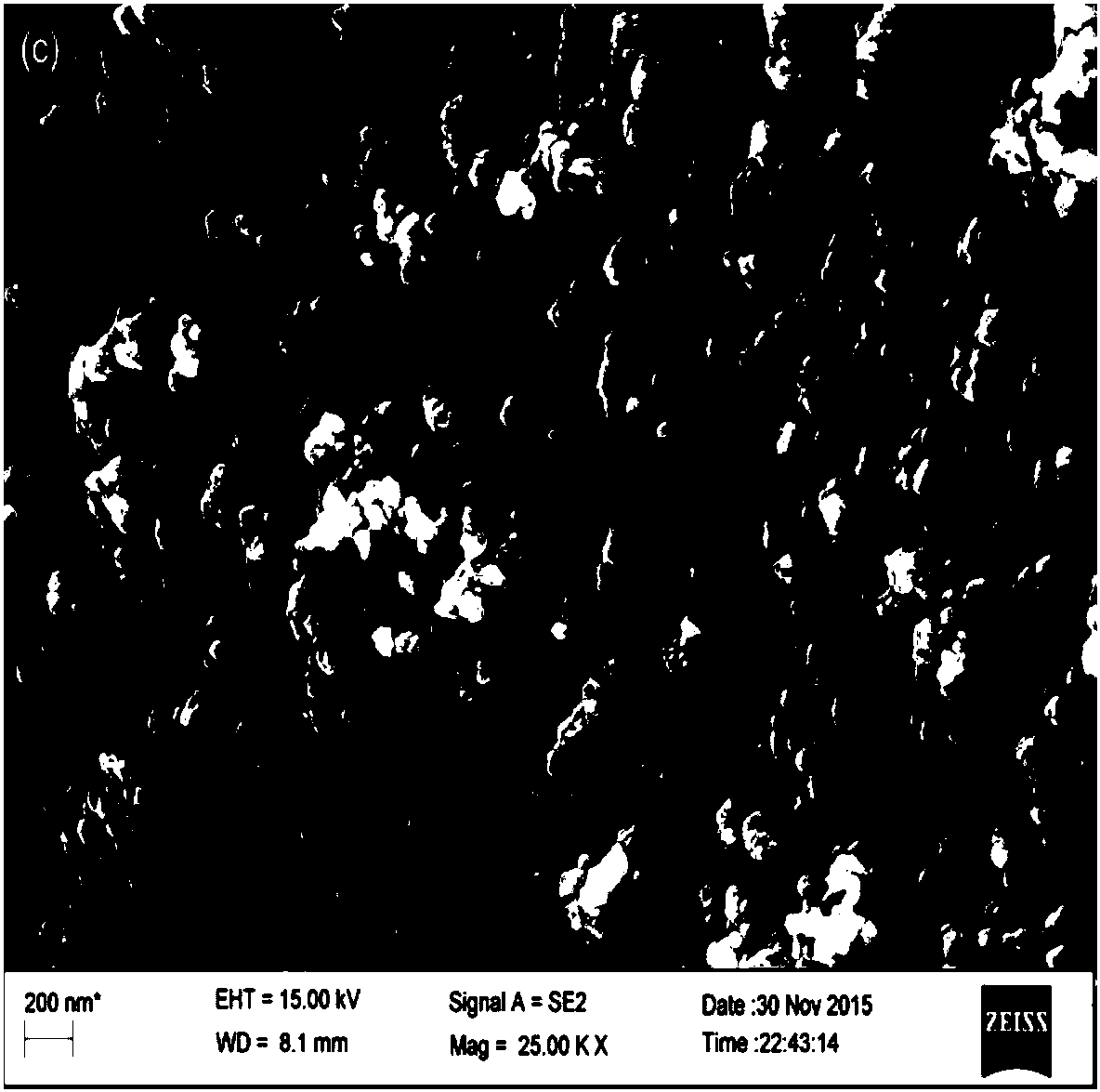

ActiveCN107815633AImprove efficiencyIncrease working temperatureMolten spray coatingNano structuringThermal diffusion coefficient

The invention discloses a preparation method for a high-performance thermal barrier coating and specifically discloses a 4YSZ (4mol% Y2O3 stabilized ZrO2) thermal barrier coating and the preparation method of the 4YSZ thermal barrier coating. The 4YSZ powder which is of a fine nano-structure, uniform ingredients and a pure tetragonal phase structure is prepared utilizing a sol-spray pyrolysis synthetic process, and the 4YSZ powder is subjected to spray drying granulation, screening and atmospheric plasma spraying (APS) in sequence to prepare the coating. The high-performance thermal barrier coating prepared by the invention is of a pure tetragonal phase nano-structure with uniform ingredients, compared with a traditional YSZ casting, the high-performance thermal barrier coating has the advantages of being low in thermal diffusion coefficient, good in high temperature phase stability and thermal shock resistance, simple in preparation process and low in cost and the like; and the high-performance thermal barrier coating is more conducive to improving the efficiency and working temperature of a turbine engine, and the service life of the engine is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

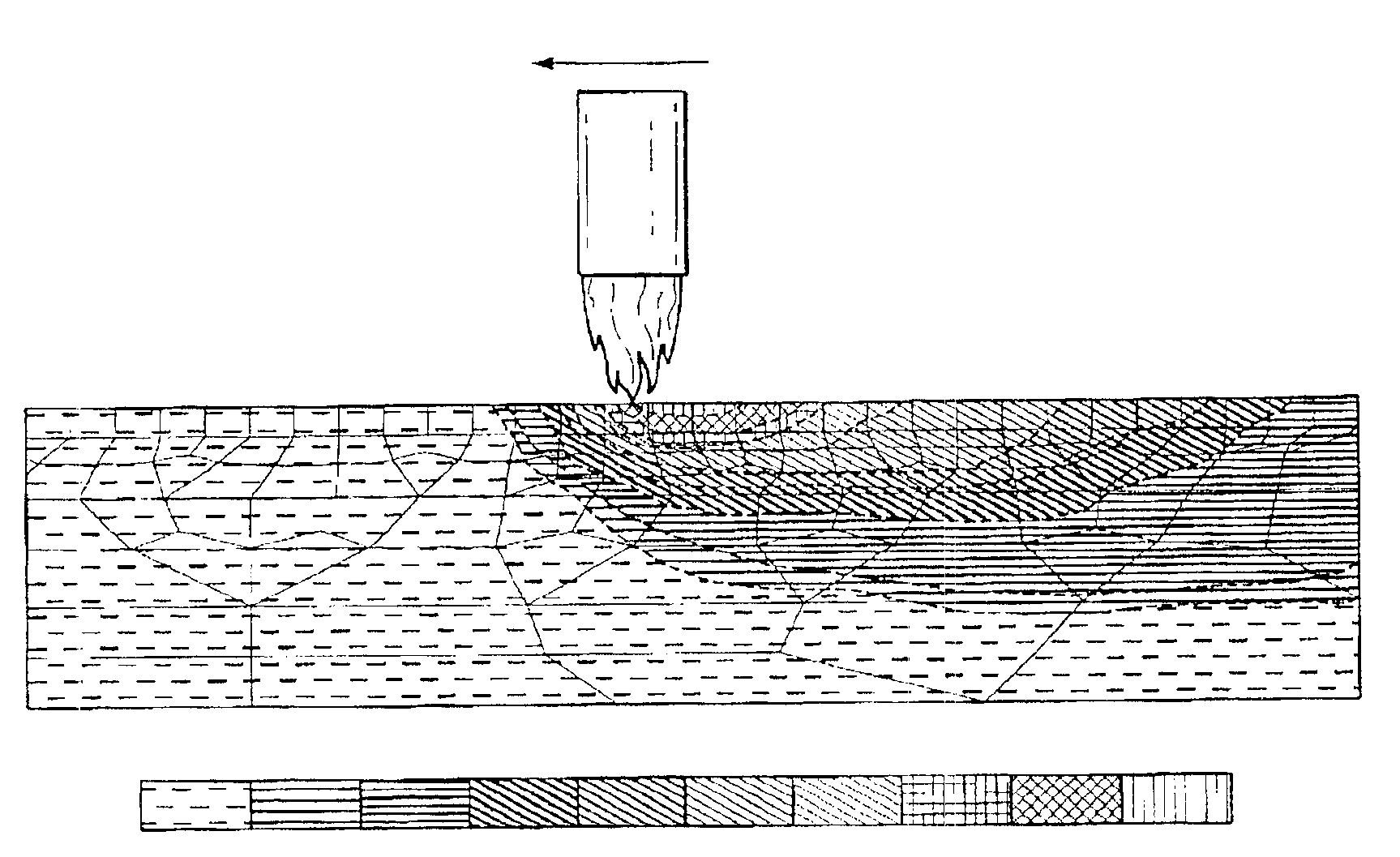

Method for controlled surface scratch removal and glass resurfacing

InactiveUS6877341B1Reduce processing stepsSignificant timeFuel supply regulationIndirect carbon-dioxide mitigationSurface layerMaterials science

Disclosed are a method and system for removing scratches from a planar panel of translucent or transparent material, such as glass, without removal from its frame. A heat source supplying a controlled amount of heat is moved across the surface of the planar panel at a controlled velocity and at a controlled distance from the surface so as to progressively melt a thin surface layer at portions of the surface heated by the moving heat source. The melted material re-flows under surface tension to smooth scratches in the surface layer. Movement of the heat source is repeated over different portions of the surface until all scratched areas have been treated. The treated panels have a smooth surface with scratches removed, and have good optical and structural qualities.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

eFuse containing SiGe stack

InactiveUS8004059B2Program have been very successfulLower melting temperatureSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsSingle crystal

An eFuse, includes: a substrate and an insulating layer disposed on the substrate; a first layer including a single crystal or polycrystalline silicon disposed on the insulating layer; a second layer including a single crystal or polycrystalline silicon germanium disposed on the first layer, and a third layer including a silicide disposed on the second layer. The Ge has a final concentration in a range of approximately five percent to approximately twenty-five percent.

Owner:GLOBALFOUNDRIES INC

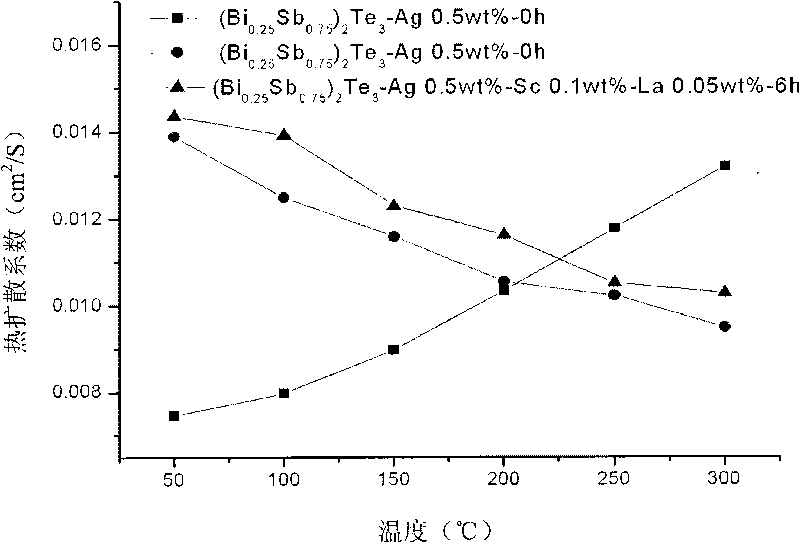

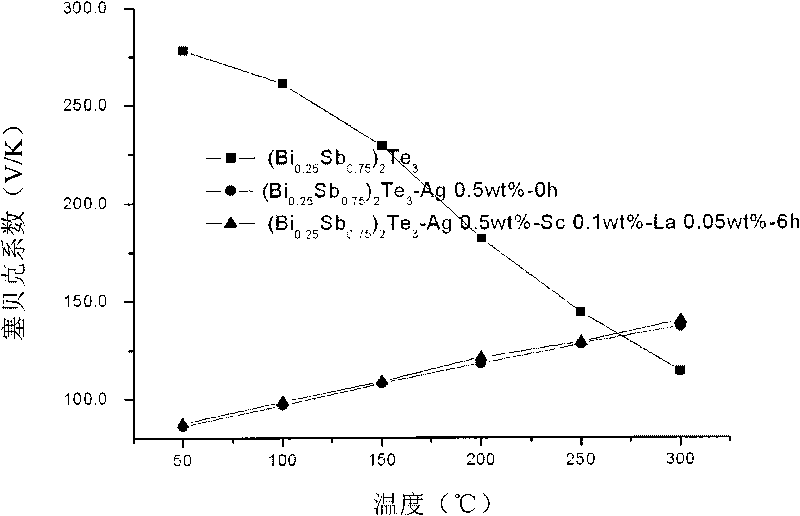

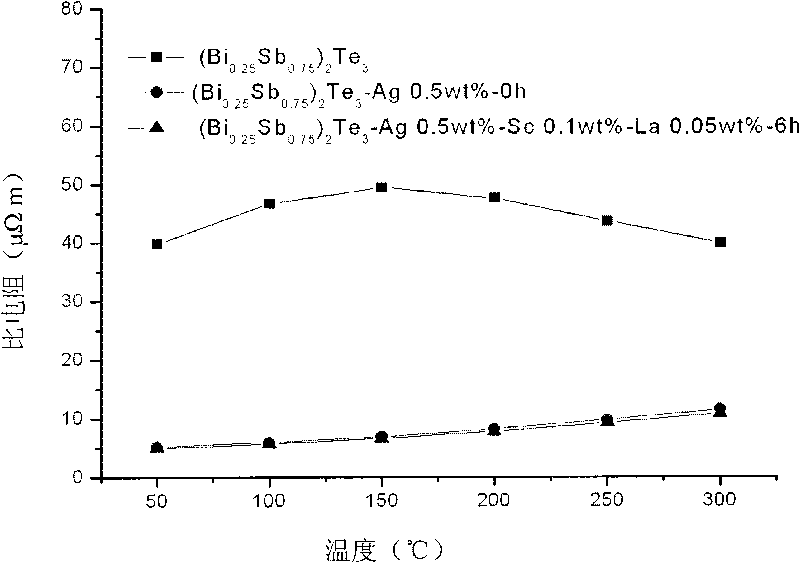

Thermoelectric materials

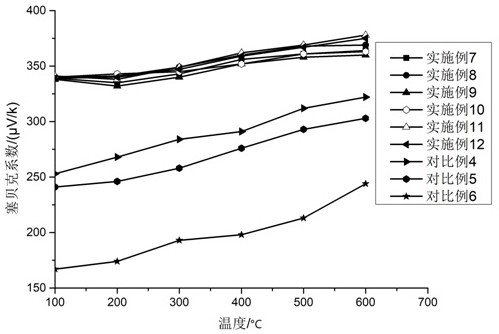

InactiveCN101740713ALow thermal diffusivityHigh Seebeck coefficientThermoelectric device junction materialsLow noiseMetallurgy

Disclosed herein is a thermoelectric material for intermediate- and low-temperature applications, in which any one or a mixture of two or more selected from among La, Sc and MM is added to a Ag-containing metallic thermoelectric material or semiconductor thermoelectric material. The thermoelectric material has a low thermal diffusivity, a high Seebeck coefficient, a low specific resistivity, a high power factor and a low thermal conductivity, and thus has a high dimensionless figure of merit, thus showing very excellent thermoelectric properties. The thermoelectric material provide thermoelectric sensors having high sensitivity and low noise and, in addition, is widely used as a thermoelectric material for intermediate- and low-temperature applications, because it shows excellent thermoelectric performance in the intermediate- and low-temperature range.

Owner:KOREA ELECTROTECH RES INST

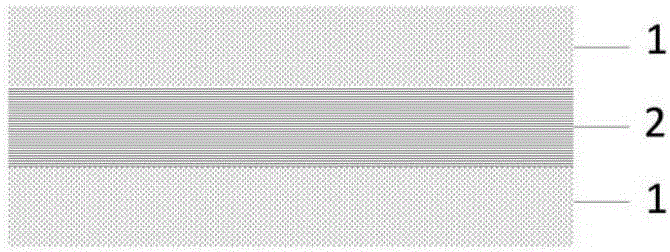

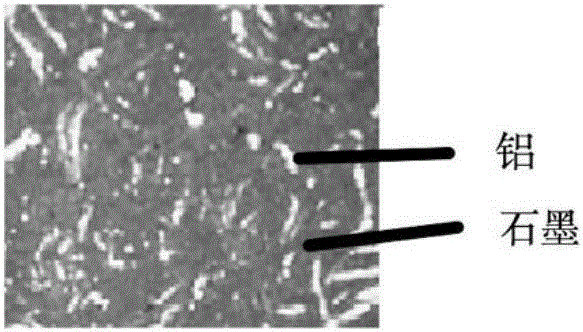

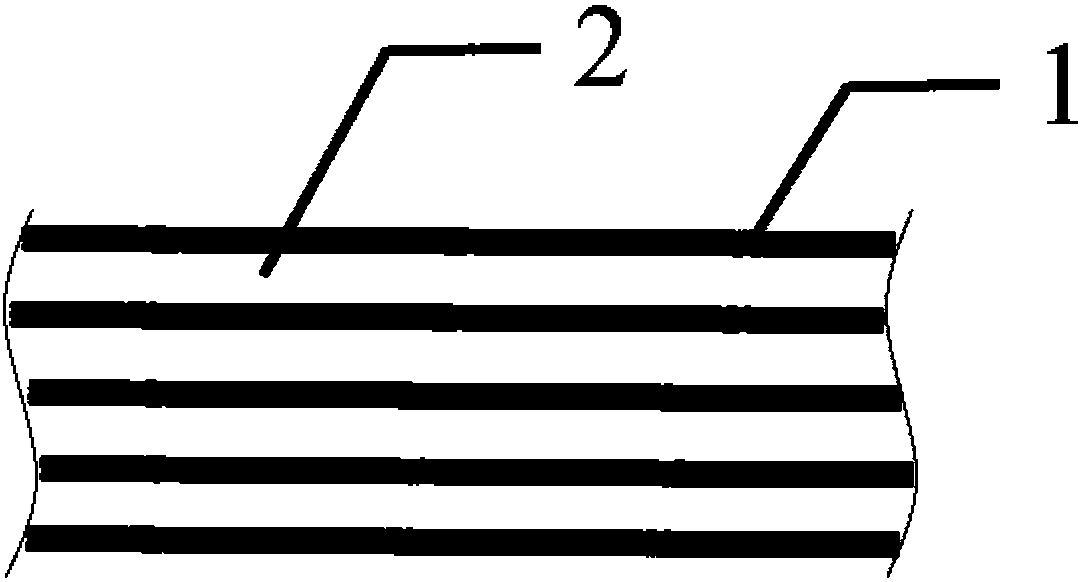

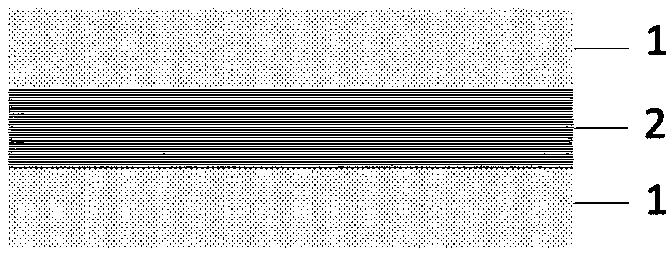

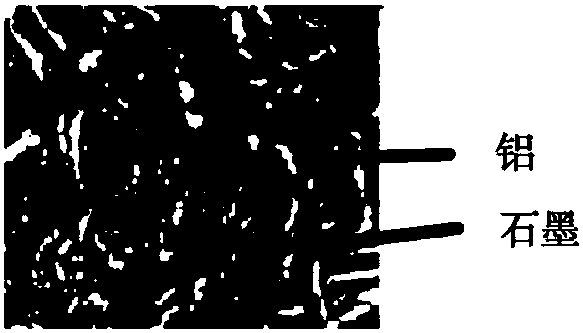

Novel heat dissipation insulating composite material and preparation method therefor

ActiveCN106531874AGood thermal conductivitySmall coefficient of thermal expansionSemiconductor devicesAluminum compositesHigh pressure

The invention belongs to the technical field of a functional material, and relates to a novel heat dissipation insulating composite material and a preparation method therefor. Specifically, the novel heat dissipation insulating composite material consists of graphite, aluminum and ceramic, and adopts a sandwich structure, wherein a ceramic sheet layer is positioned in the middle, and graphite / aluminum composite sheet layers are positioned on the two sides; and the graphite / aluminum composite sheet layers consist of a graphite sheet layer with pores and aluminum for filling the pores. Integral forming of the graphite, metal aluminum and ceramic is realized by a high-pressure forging method to form the brand new composite material; the composite material has high thermal conduction, high insulativity and enhanced mechanical strength; and raw materials are low in coat, and the preparation method is simple and easy to implement, so that the composite material has high market competitiveness.

Owner:南京劲峰洋光电科技有限公司

eFuse with partial SiGe layer and design structure therefor

InactiveUS7960809B2Program have been very successfulImprove perceptionSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Owner:GLOBALFOUNDRIES INC

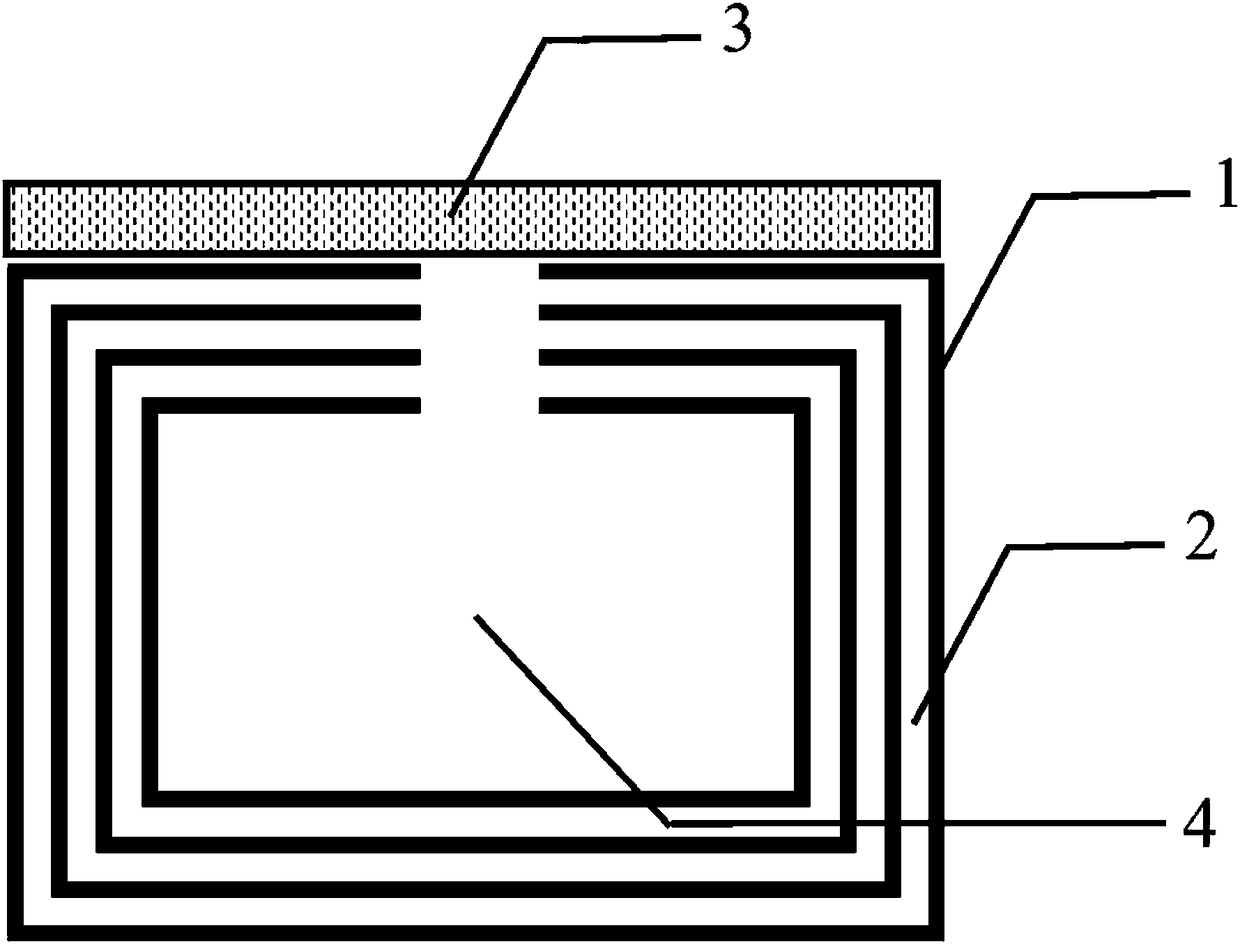

RFID tag

InactiveUS20080001762A1Improve performanceLow thermal conductivityRecord carriers used with machinesBurglar alarm by hand-portable articles removalThermal conductivityThermal energy storage

ARFID tag includes an inlet in which an antenna for communication and a circuit chip performing radio communication with the antenna are electrically connected to each other. The RFID tag further includes a thermal storage section which encloses the inlet, which is made of a nonmetal, and which prevents thermal diffusion into the inlet and a thermal insulating section which encloses the thermal storage section, which prevents thermal conduction to the thermal storage section, and which has higher thermal diffusivity than thermal diffusivity of the thermal storage section and lower thermal conductivity than thermal conductivity of the thermal storage section.

Owner:FUJITSU LTD

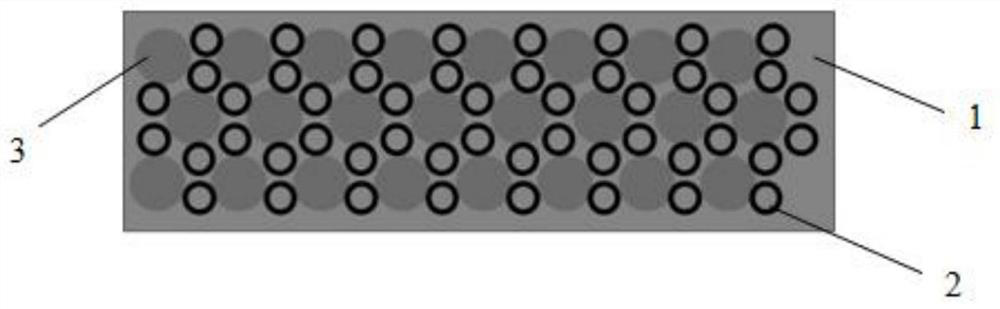

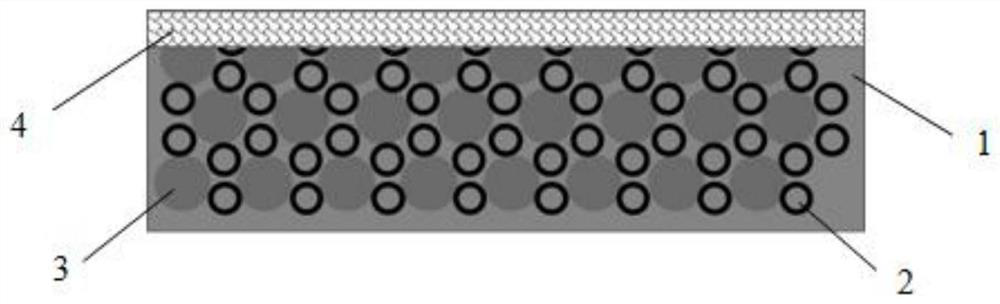

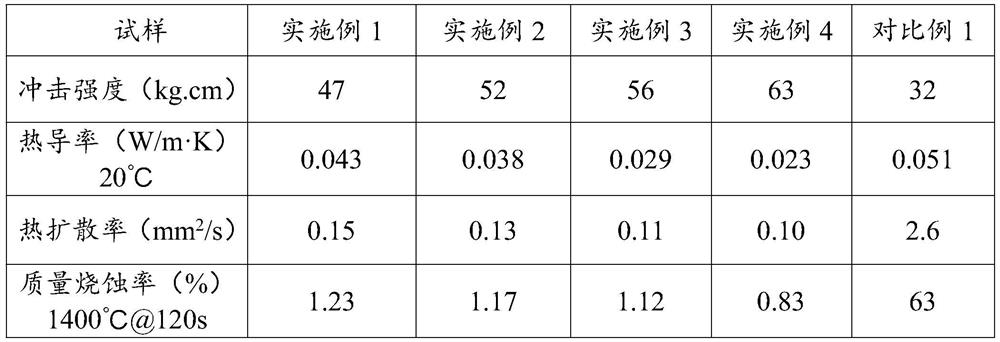

Ceramizable heat-preservation fireproof coating and preparation method thereof

InactiveCN113292920AImprove mechanical propertiesImprove high temperature resistanceFireproof paintsWeather resistanceThermal diffusivity

The invention relates to a ceramizable heat-preservation fireproof coating comprising the following preparation raw material components in parts by weight: 5 to 30 parts of high-temperature-resistant silicon resin, 35 to 75 parts of heat-preservation filler, 5 to 15 parts of other functional fillers, 2 to 5 parts of auxiliaries and 50 to 500 parts of a diluting solvent. According to the coating, high-temperature-resistant silicon resin is used as a matrix, and the heat-preservation filler and other functional fillers are added, so that the mechanical property, high-temperature resistance, weather resistance and other properties of the coating are improved, and the coating can be subjected to ceramization reaction at the high temperature of 500 DEG C or above, so that the coating can bear high-temperature heating of 1400 DEG C and cannot be burnt through for a long time; and moreover, the coating has relatively low thermal diffusivity, can provide better heat preservation capability when the temperature is rapidly changed, has a good protection effect when being applied to the field of lithium ion batteries, and effectively solves the problems existing in a protection material in the prior art.

Owner:宁波卓翔科技有限公司

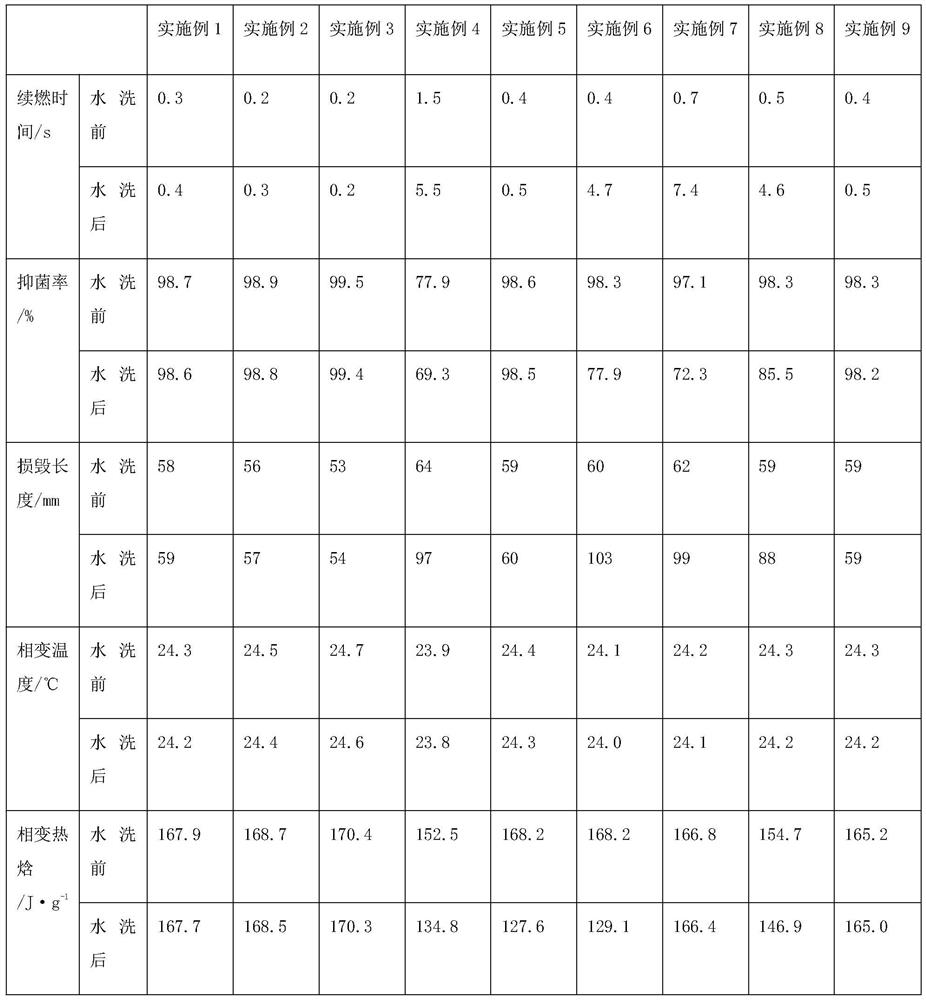

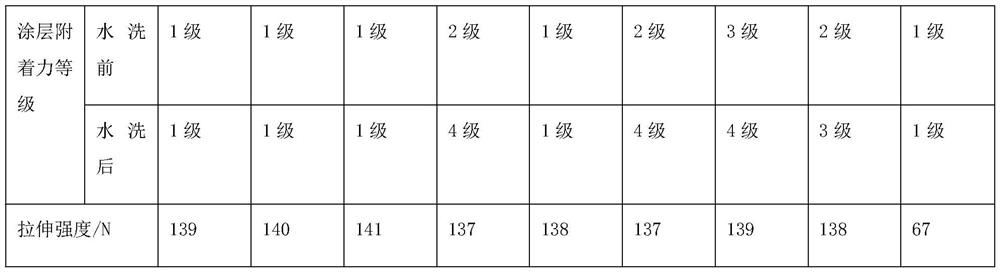

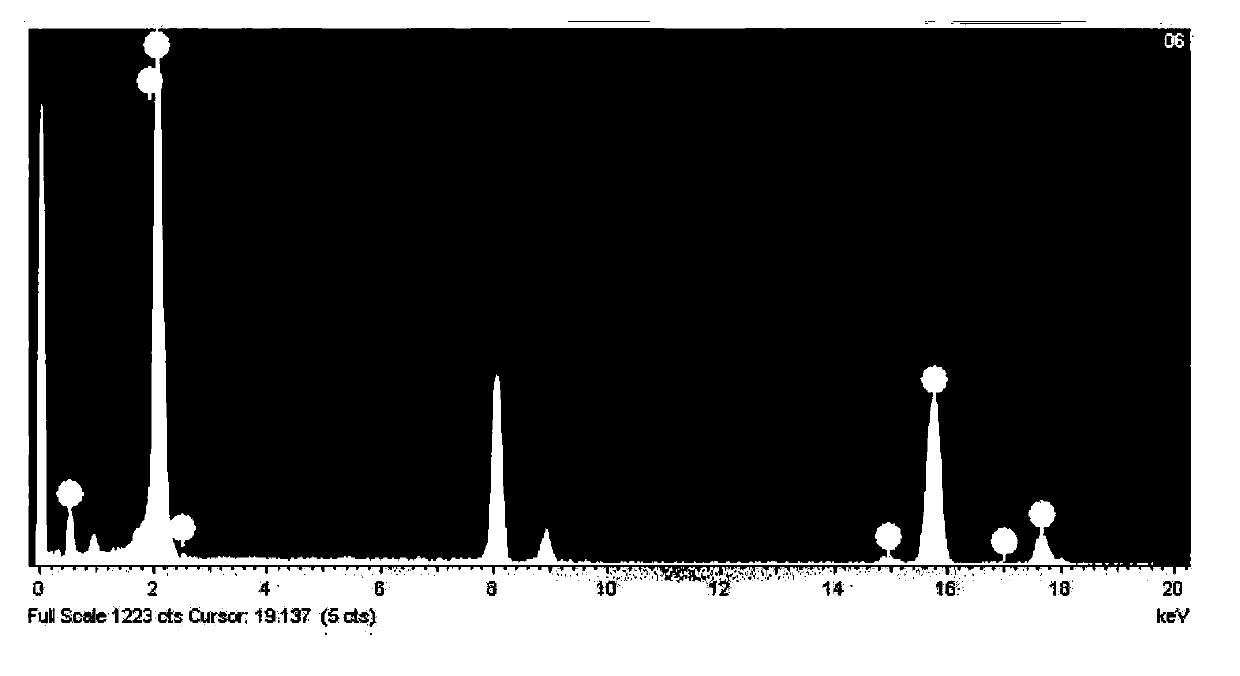

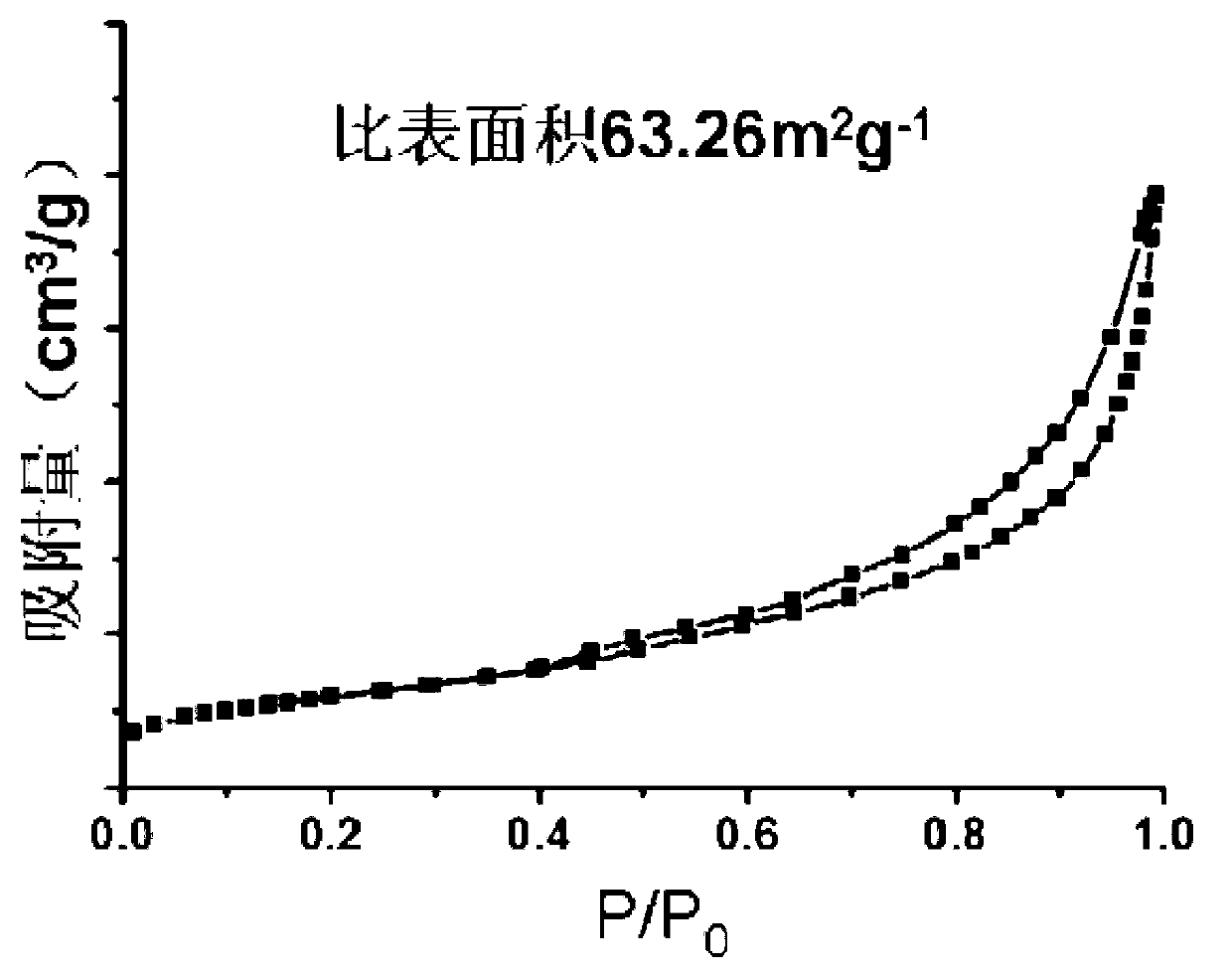

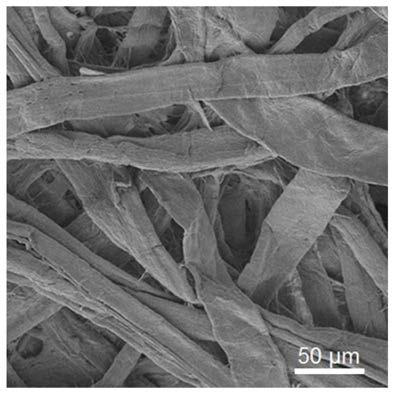

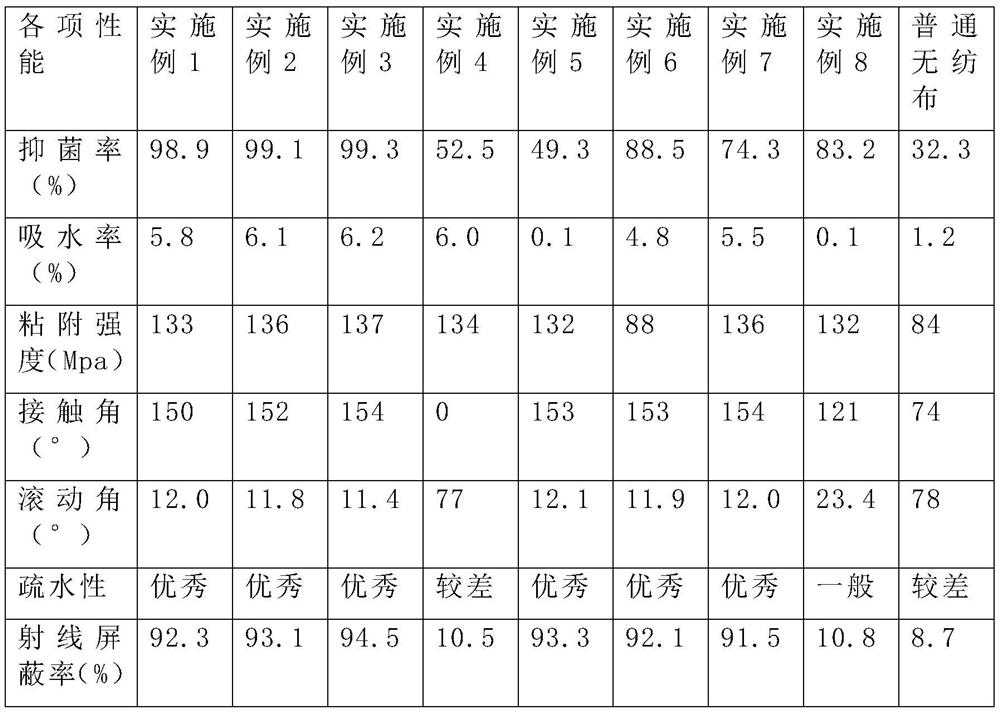

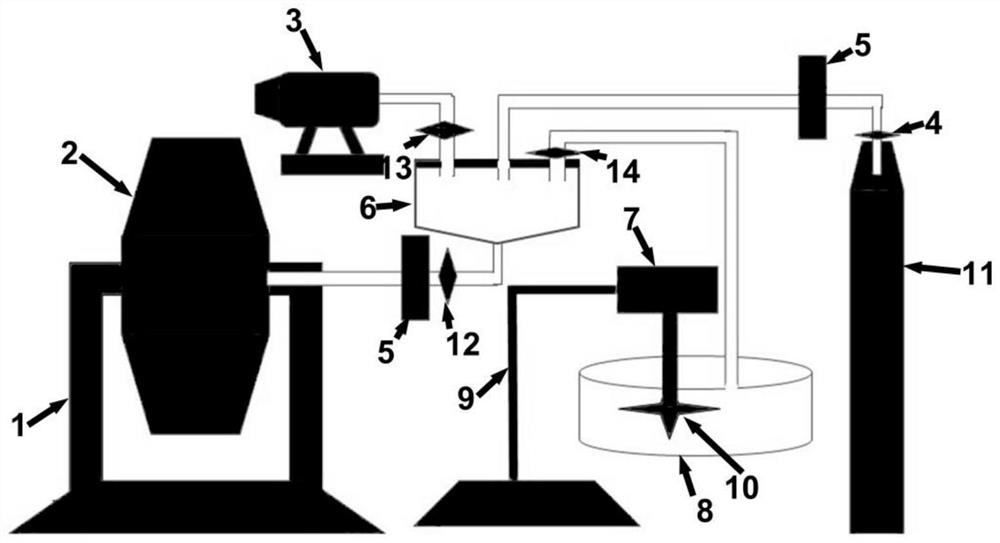

Flame-retardant temperature-regulating environment-friendly non-woven fabric and preparation method thereof

ActiveCN112411198AImprove thermal stabilityImprove compactnessTextiles and paperPolyelectrolytePolymer science

The invention discloses a flame-retardant temperature-regulating environment-friendly non-woven fabric and a preparation method thereof. The preparation method comprises the following steps: graftingamino and nano-silver on the surface of a modified carbon nanotube, introducing the modified carbon nanotube into a non-woven fabric base material, grafting sulfydryl and hydroxyl on a temperature-regulating capsule to modify the modified temperature-regulating capsule, respectively preparing a cationic flame-retardant coating and an anionic flame-retardant coating, sequentially coating thenon-woven fabric base material with a modified temperature-regulating capsule coating, the cationic flame-retardant coating and the anionic flame-retardant coating, and adsorbing polyelectrolyte or nanoparticles with opposite charges between the coatings by utilizing intermolecular force between the coatings and the non-woven fabric base material. Thus, the non-woven fabric with flame-retardant and temperature-regulating functions is constructed within a nanoscale range, a core material in the prepared non-woven fabric temperature-regulating capsule is not prone to leakage, the adhesive force betweenthe coatings is good, the non-woven fabric is more washable, meanwhile, the non-woven fabric has a certain antibacterial function, and market requirements can be met.

Owner:李建勋

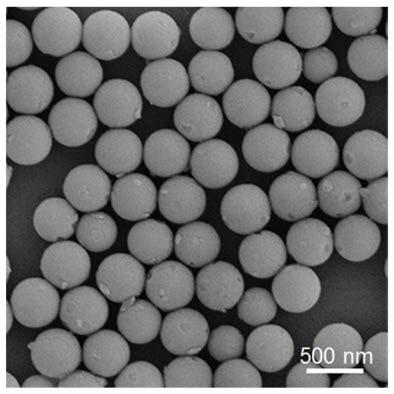

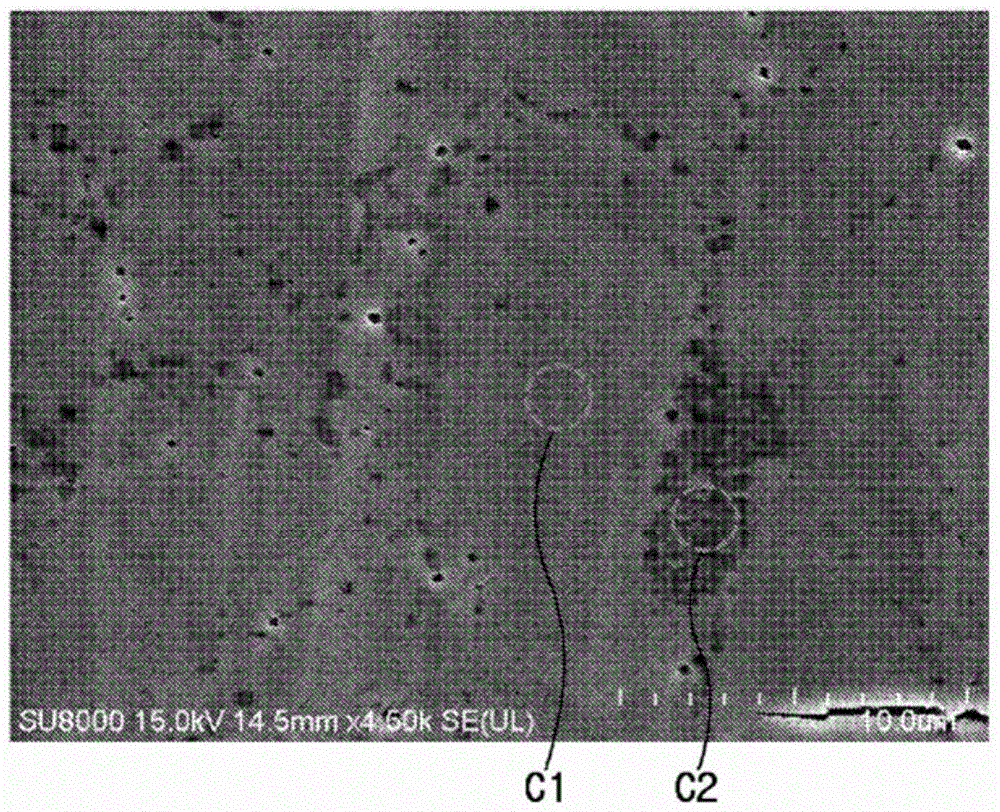

Yttrium-doped zirconium oxide (YSZ) powder having multistage nano structure, and preparation method and application thereof

ActiveCN102976405ALow thermal diffusivityLow thermal conductivityMaterial nanotechnologyZirconium oxidesFlower likeNano structuring

The invention provides yttrium-doped zirconium oxide (YSZ) powder having a multistage nano structure. The powder has a flower-like structure, wherein the flower-like structure is a multistage nano structure formed by the self assembly of laminated polycrystalline structures; the inside is formed by the stacking of multiple layers of folded laminated polycrystalline structures; the maximum integral particle size of the flower-like structure does not exceed 15 mu m. The invention also provides a preparation method and application of the powder. According to the invention, the YSZ power having specific morphology is obtained and can be used in the field of thermal barrier coatings.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

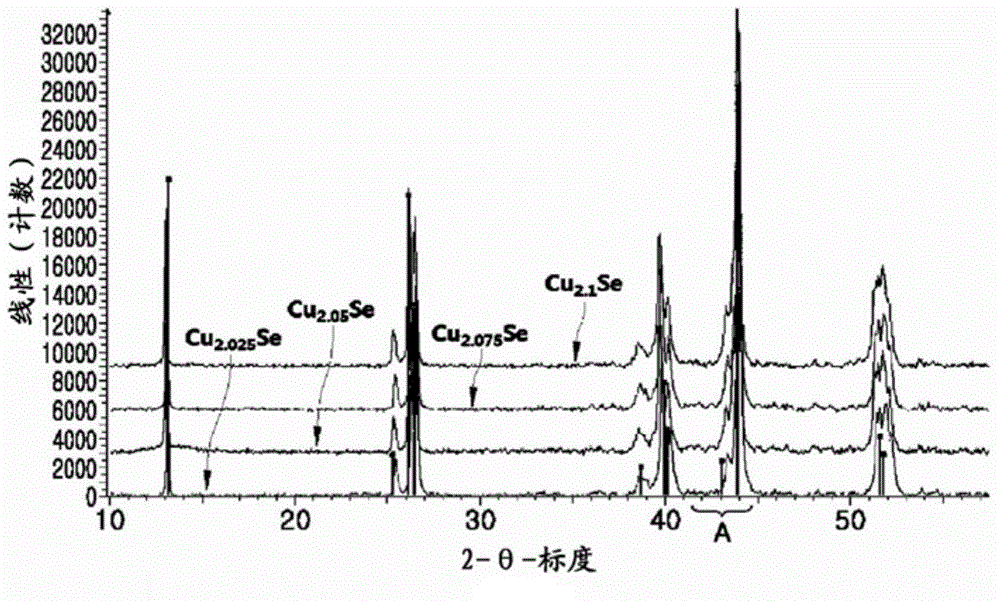

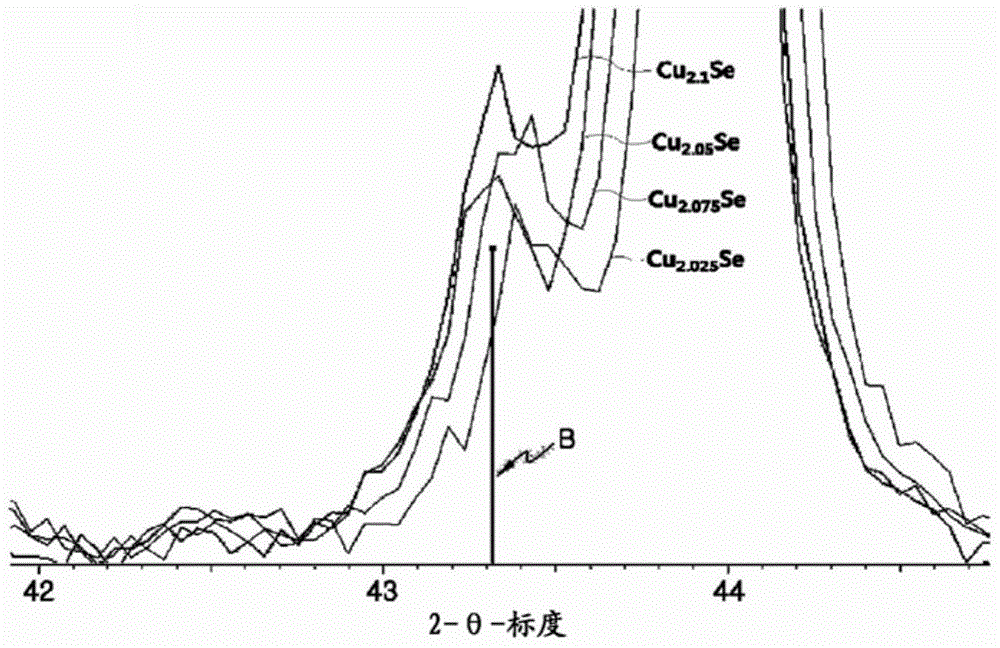

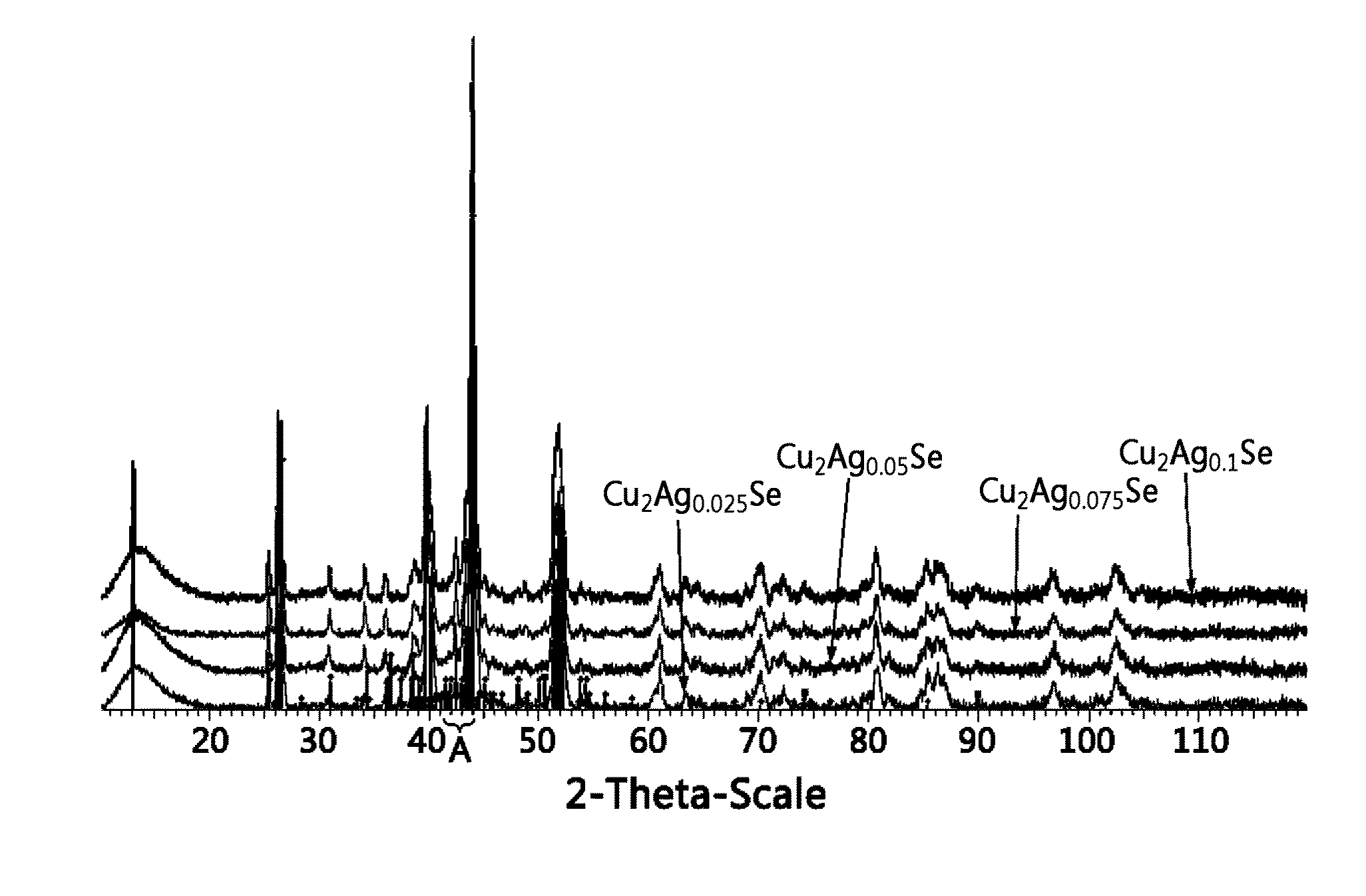

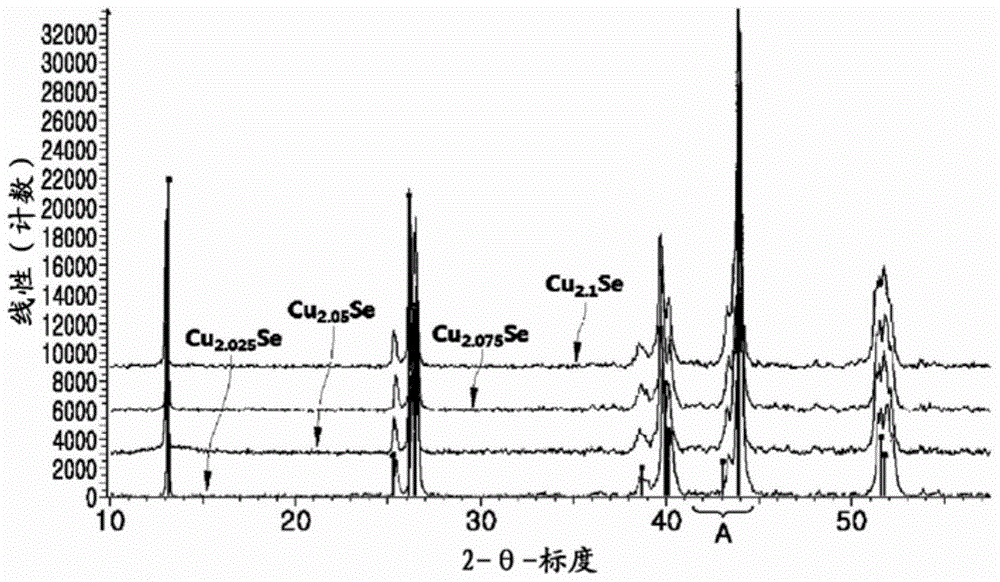

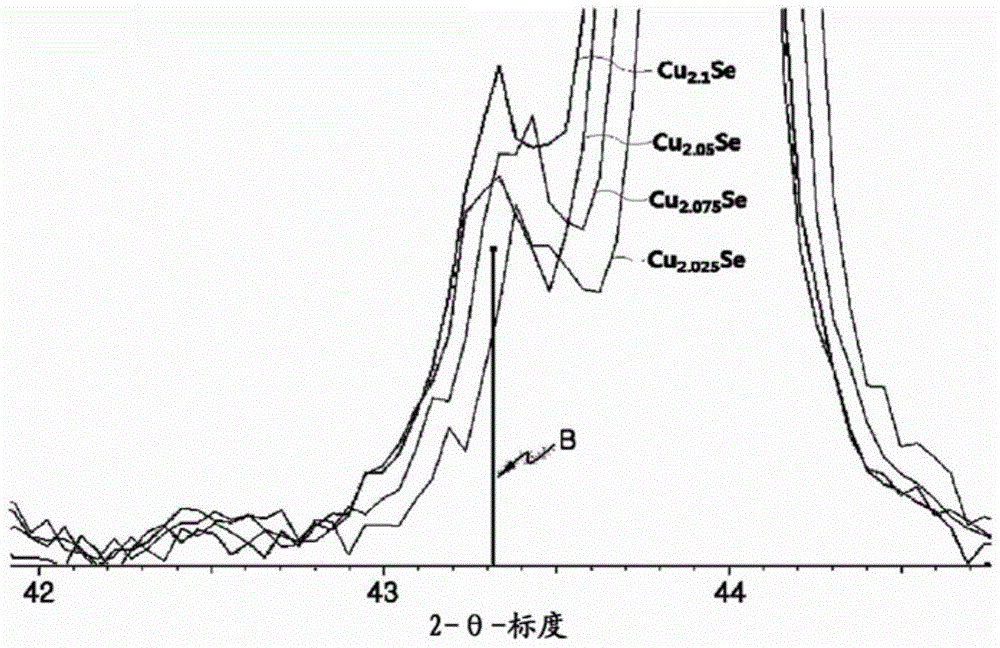

Thermoelectric material

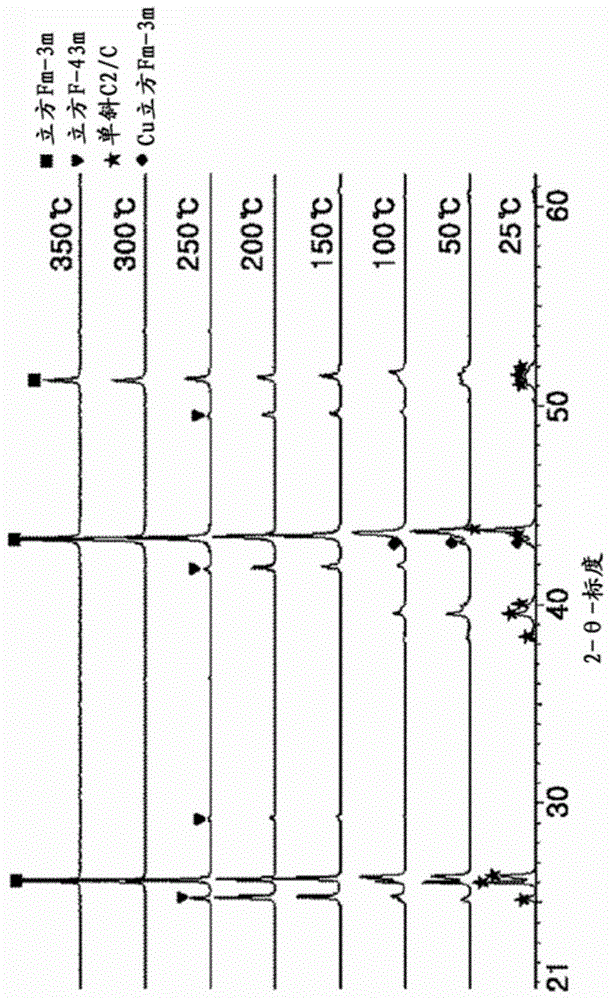

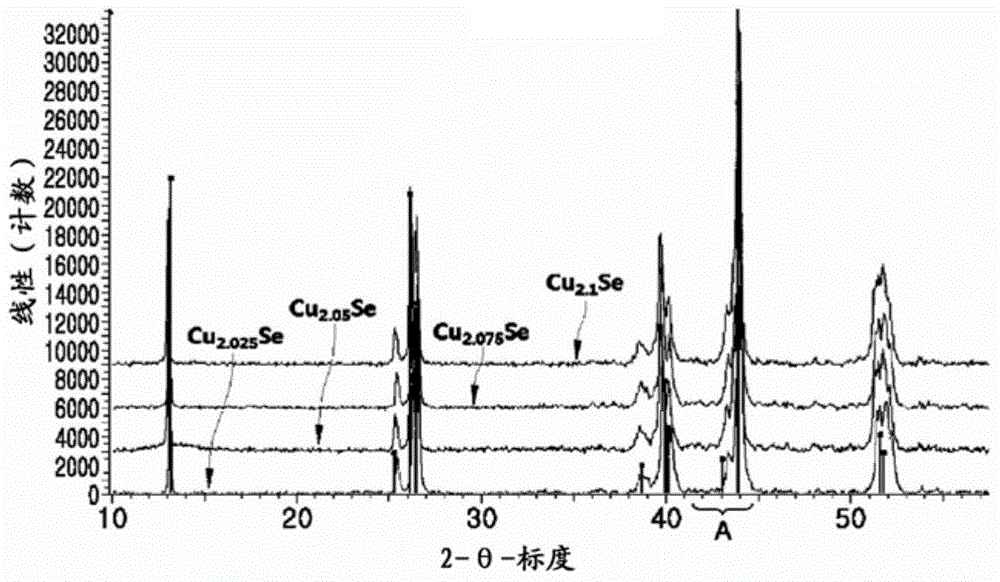

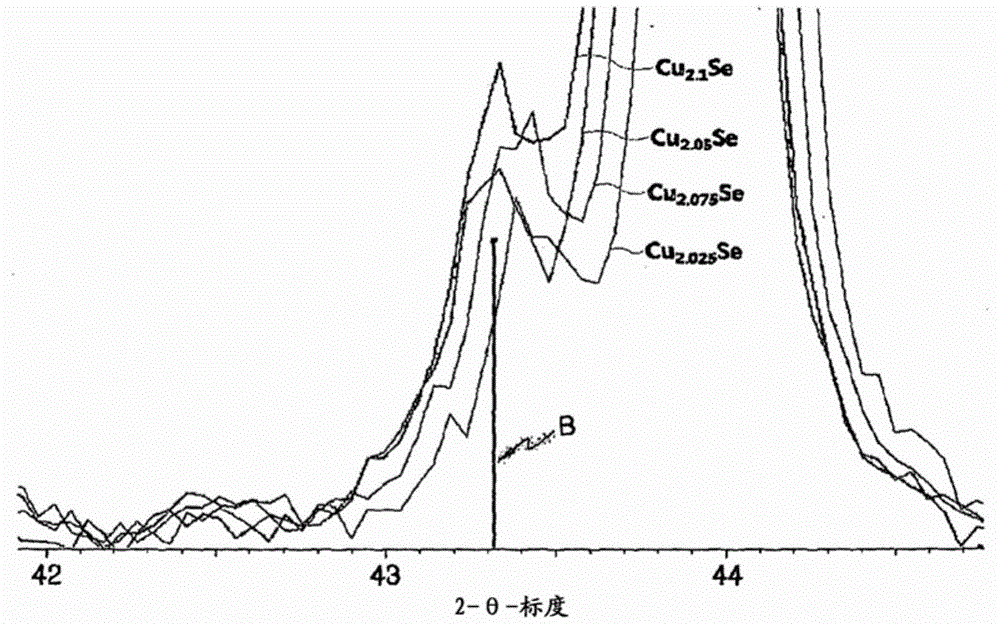

ActiveCN104885241AExcellent thermoelectric conversion performanceIncreased ZT valueCopper compoundsMetal selenides/telluridesThermoelectric materialsCrystal structure

Disclosed is a method of manufacturing a thermoelectric material having high thermoelectric conversion performance at a wide temperature range. The method of manufacturing a thermoelectric material according to the present invention comprises the following steps: forming a mixture by mixing copper and selenium according to the following chemical formula 1: Cu_xSe; and forming the mixture by heat treating the mixture. In chemical formula 1, 2<x<=2.6. The thermoelectric material can include an induced nano DOT (INDOT) as a copper containing particle. Here, INDOT represents a particle with a diameter, for example, between 1 nanometer and 100 nanometers which is spontaneously generated during a thermal material formation process. This nano DOT, that is INDOT, can exist on a grain boundary of a semiconductor.

Owner:LG CHEM LTD

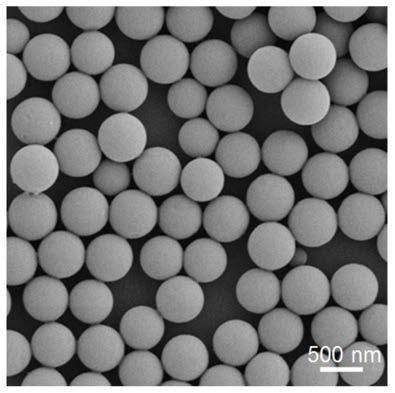

GSP film material for solar photo-thermal steam conversion and preparation method thereof

ActiveCN111252836AImprove light absorption capacityLow thermal diffusivityGroup 4/14 element organic compoundsSolar heating energyFiberFilm material

The invention relates to a preparation method of a GSP film material for solar photo-thermal steam conversion in the technical field of energy materials. The method comprises the steps: dispersing organosilicon powder in water, adding a chloroauric acid solution, and carrying out ultrasonic reaction to obtain gold complex organosilicon spheres; carrying out liquid nitrogen freezing, drying in vacuum to obtain gold complex organosilicon sphere powder; carrying out a reaction on the gold complex organosilicon sphere powder under the protection of protective gas; calcining at the temperature of 500 DEG C to 1000 DEG C, to obtain gold nanoparticle doped carbonized organosilicon sphere powder; dispersing the gold nanoparticle doped carbonized organosilicon sphere powder into water; dropwise coating on fiber filter paper; and carrying out vacuum filtration, to obtain the GSP film material. The surface plasmon polariton effect generated by the prepared GSP film material under the irradiationof sunlight enables the sunlight to be fully absorbed; the GSP film material has a better heat conduction effect due to the low heat conduction coefficient and the high heat diffusion coefficient of the film material, the heat loss in the heat transfer process is reduced, and the GSP film material has high water evaporation rate.

Owner:YANGZHOU UNIV

Thermoelectric material

ActiveCN104885240AExcellent thermoelectric conversion performanceLow thermal diffusivityCopper compoundsThermoelectric device junction materialsThermoelectric materialsCopper

Disclosed is a method of manufacturing a thermoelectric material having high thermoelectric conversion performance at a wide temperature range. The method of manufacturing a thermoelectric material according to the present invention comprises the following steps: forming a mixture by mixing copper and selenium according to the following chemical formula 1: Cu_xSe; and forming the mixture by heat treating the mixture. In chemical formula 1, 2<x<=2.6. The thermoelectric material can include an induced nano DOT (INDOT) as a copper containing particle. Here, INDOT represents a particle with a diameter, for example, between 1 nanometer and 100 nanometers which is spontaneously generated during a thermal material formation process. This nano DOT, that is INDOT, can exist on a grain boundary of a semiconductor.

Owner:LG CHEM LTD

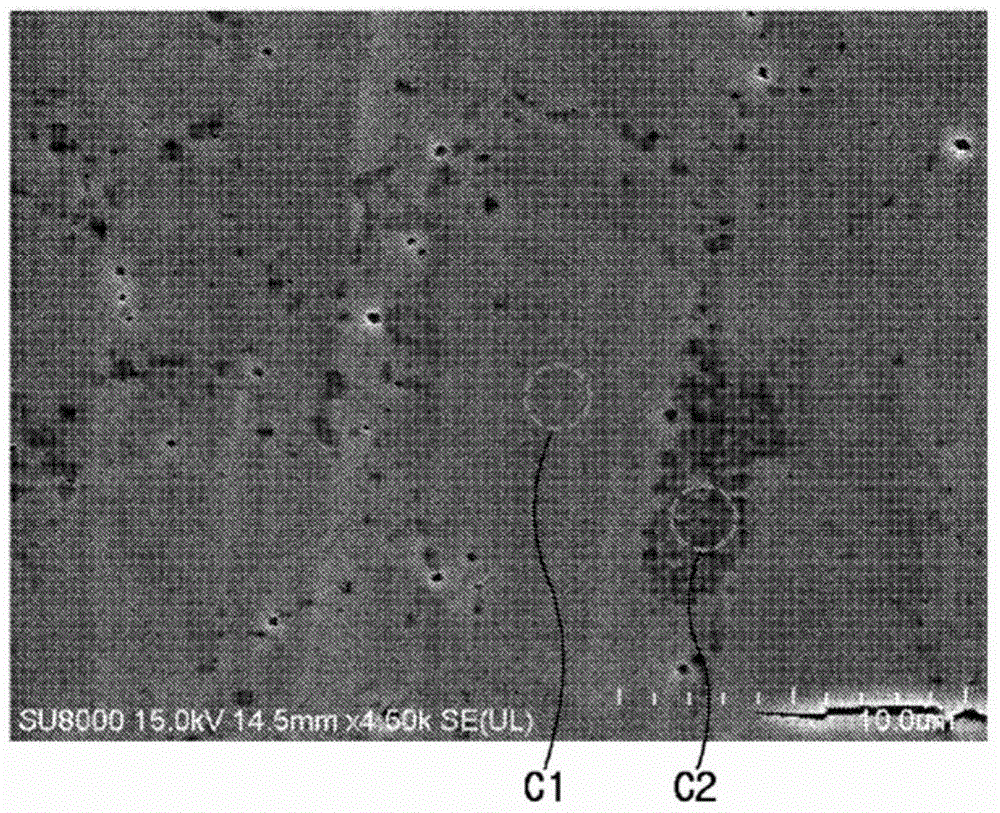

Nanofiber-based biomedical non-woven fabric and preparation method thereof

ActiveCN111876897AStrong water absorptionStrong hydrophobicFibre typesSynthetic resin layered productsMicroorganismSpinning

The invention discloses a nanofiber-based biomedical non-woven fabric and a preparation method thereof. Firstly, phase-change temperature-adjusting microcapsules are added into nuclear layer liquid offirst fibers, a large number of hydrophilic groups are introduced into the nuclear layer liquid to prepare fibers A with super-hydrophilic performance, and alkali liquor is used for preparing multiple holes in the surfaces of the fibers A, so that the binding force of the fibers A and antibacterial capsules is increased; and a spinning solution is modified through an electrochemical method, modified ceramic with anti-radiation and anti-bacterial capacity is added, second fibers with super-hydrophobic performance are obtained, and a first non-woven fabric and a second non-woven fabric are bonded through a bonding agent to obtain the biomedical non-woven fabric which has the phase change temperature adjustment capacity, the moisture absorption capacity, the anti-bacterial capacity, the blood repelling capacity and the anti-radiation capacity, while the wearing comfort of medical staff is improved, invasion of microorganisms and pathogens can be effectively resisted, and high practicability is achieved.

Owner:广西烯旺智能科技有限公司

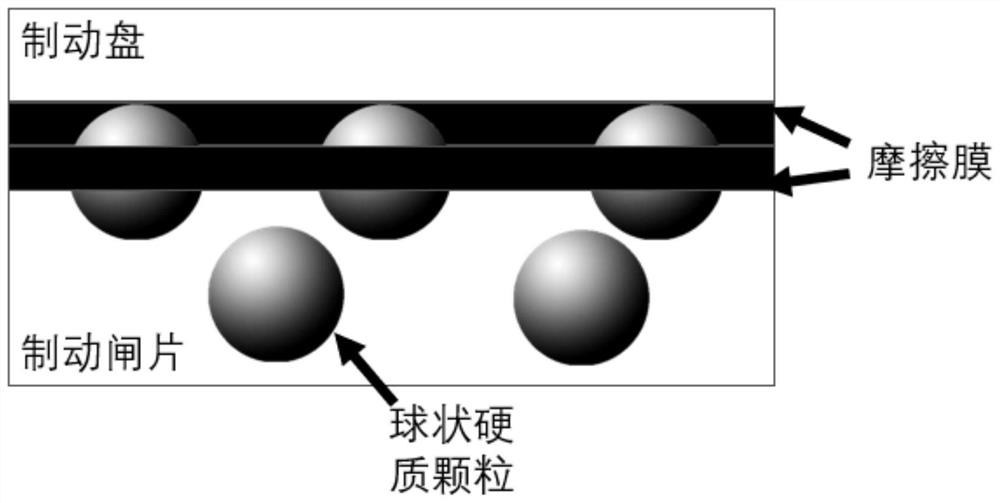

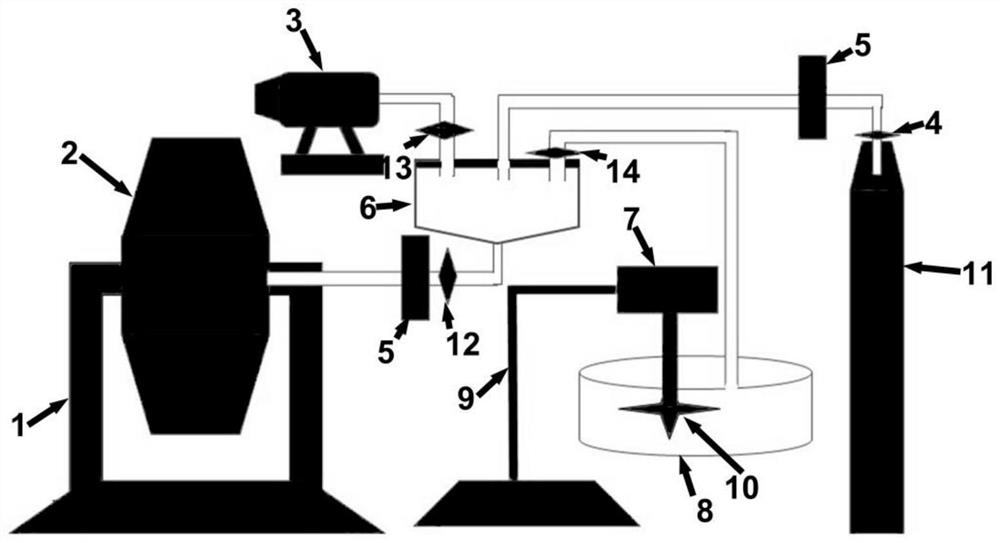

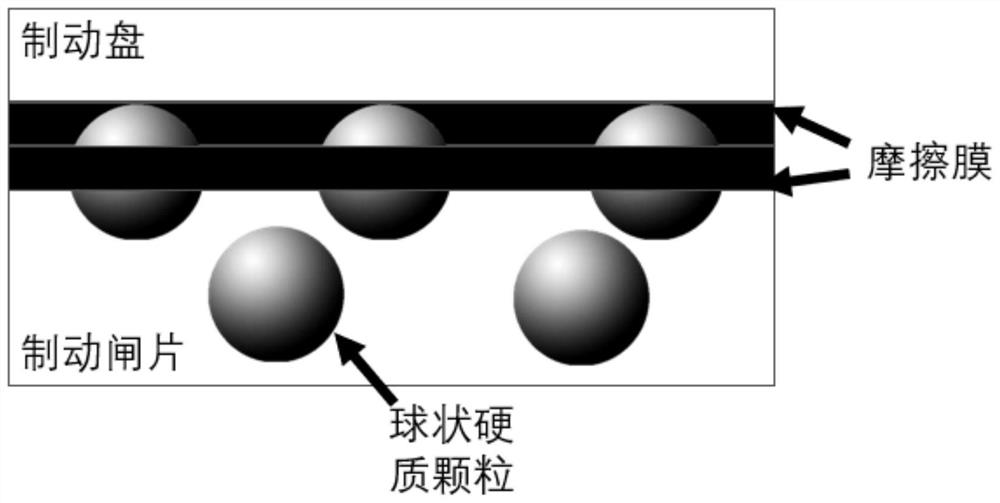

Powder metallurgy brake pad matched with carbon-ceramic brake disc and preparation method

ActiveCN112059171AHigh strengthWide variety of sourcesTransportation and packagingMetal-working apparatusPearlitePowder metallurgy

The invention discloses a powder metallurgy brake pad matched with a carbon-ceramic disc and a preparation method of the powder metallurgy brake pad. The components comprise iron powder, copper powder, flake graphite, graphene, ferrous sulfide powder, spherical chromium powder, molybdenum powder, ferrochrome powder, ferromolybdenum alloy powder, silicon carbide and titanium dioxide. The prepared iron-based brake pad is formed through the steps of powder mixing, pressing and sintering under oscillation pressure, and has the outstanding advantages that (1) the iron powder is high in strength, wide in source and low in price; (2) the graphene is uniformly distributed in the matrix and reacts with iron to generate pearlite, so that the strength of the matrix is further improved, and the friction coefficient stability and wear resistance at high temperature are improved; and (3) spherical hard particles are well combined with the interface of the iron matrix, and the damage to the carbon ceramic disc is small. The copper-based brake pad prepared through the method can be matched with the carbon ceramic disc to provide a stable and high friction coefficient and lower abrasion loss at a high speed, the service life of the brake disc is prolonged, and the copper-based brake pad is easy to prepare, low in cost and applicable to a high-speed railway train brake system with the speed of 350km / h or above.

Owner:UNIV OF SCI & TECH BEIJING

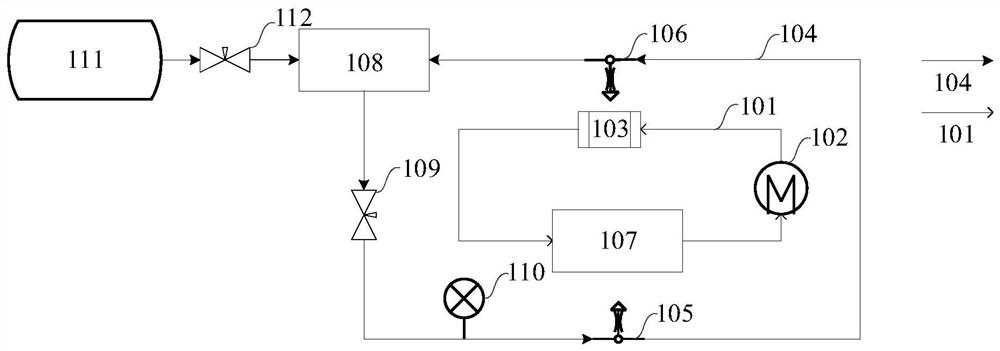

Battery protection system and vehicle

ActiveCN113422125ARapid coolingLow thermal diffusivityBattery isolationSecondary cellsControl engineeringCooling fluid

The embodiment of the invention provides a battery protection system and a vehicle. The battery protection system comprises a first pipeline loaded with cooling liquid, a fluid driving assembly and a heat conduction assembly which are arranged on the first pipeline, a second pipeline, and a first spray head and a second spray head which are arranged on the second pipeline, wherein the first pipeline is connected with a battery assembly; the second pipeline is used for transferring a refrigerant medium; the first spray head is opposite to the battery assembly, and the second spray head is opposite to the heat conduction assembly; when what is determined is that the battery assembly meets the preset thermal runaway condition, the first spray head is used for spraying a refrigerant medium to the battery assembly; the fluid driving assembly is used for driving the cooling liquid to circularly flow in the first pipeline; and the second spray head is used for spraying refrigerant medium to the heat conduction assembly. According to the embodiment of the invention, the temperature of the thermal runaway battery assembly can be rapidly reduced, and risks caused by thermal runaway of the battery assembly are reduced.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

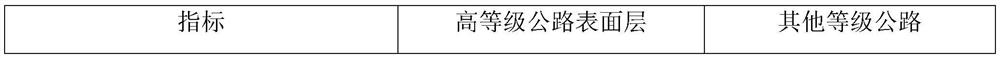

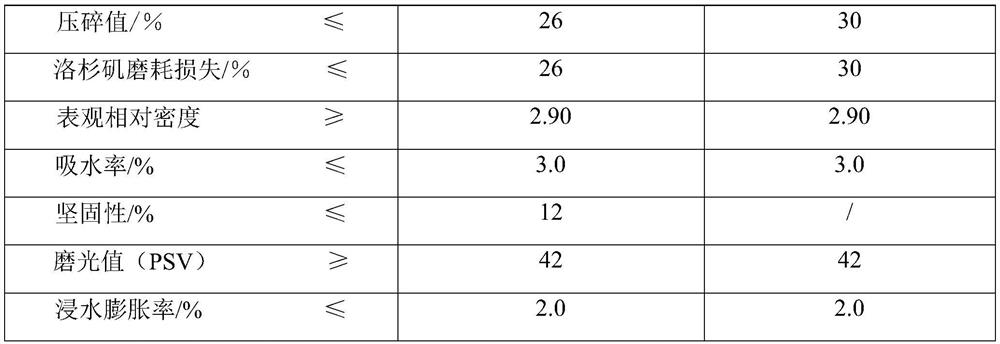

Antiskid anti-icing-night visible asphalt pavement material and preparation method thereof

The invention discloses an anti-skid anti-icing night visible asphalt pavement material and a preparation method thereof. The asphalt pavement material comprises the following components in parts by mass: 50-65 parts of steel slag coarse aggregate, 20-30 parts of steel slag fine aggregate, 10-15 parts of waste glass fine aggregate, 3-5 parts of filler containing a phase change material and 3.8-5.1 parts of modified asphalt. The preparation method comprises the following steps: mixing coarse and fine aggregates, and then respectively heating the coarse and fine aggregates, the filler containing the phase-change material and the modified asphalt; then putting the heated mixed aggregate into a stirring pot which is preheated in advance for stirring, and then sequentially and respectively adding the heated modified asphalt and the filler containing the phase-change material for stirring. The asphalt pavement material has good skid resistance and wear resistance, the thermal performance of the pavement is improved, and the icing resistance of the pavement is improved; meanwhile, the night visibility of the asphalt pavement is enhanced, the preparation process is simple, the cost is low, the source is wide, and high-added-value utilization of the steel slag and the waste glass is realized.

Owner:WUHAN UNIV OF TECH

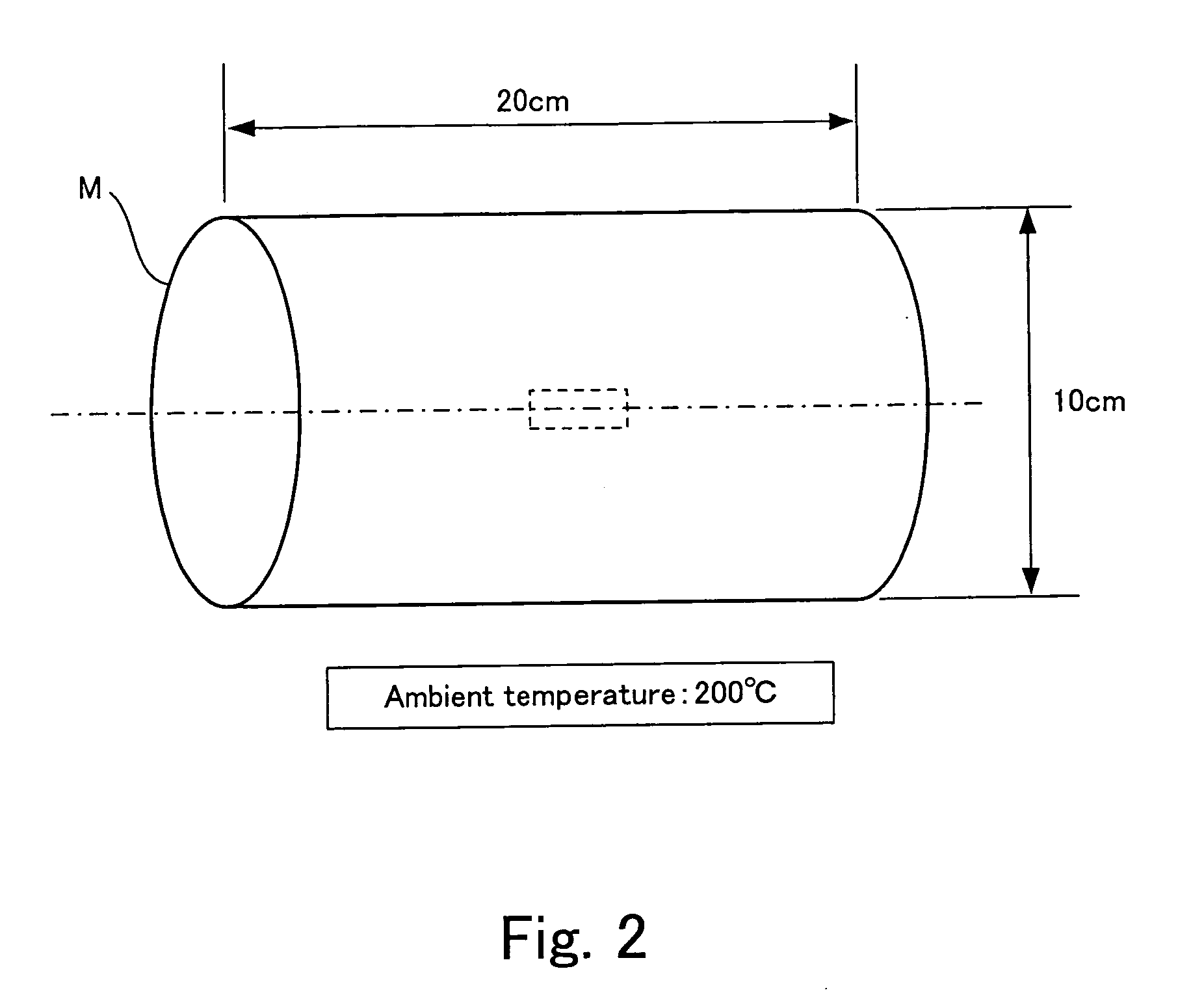

Open-type thermal buffering device and method

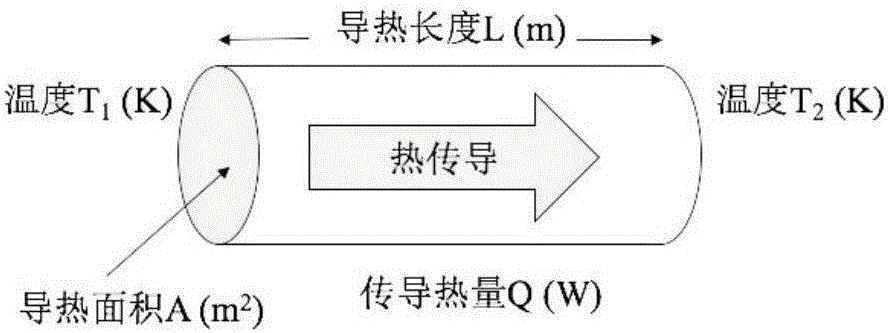

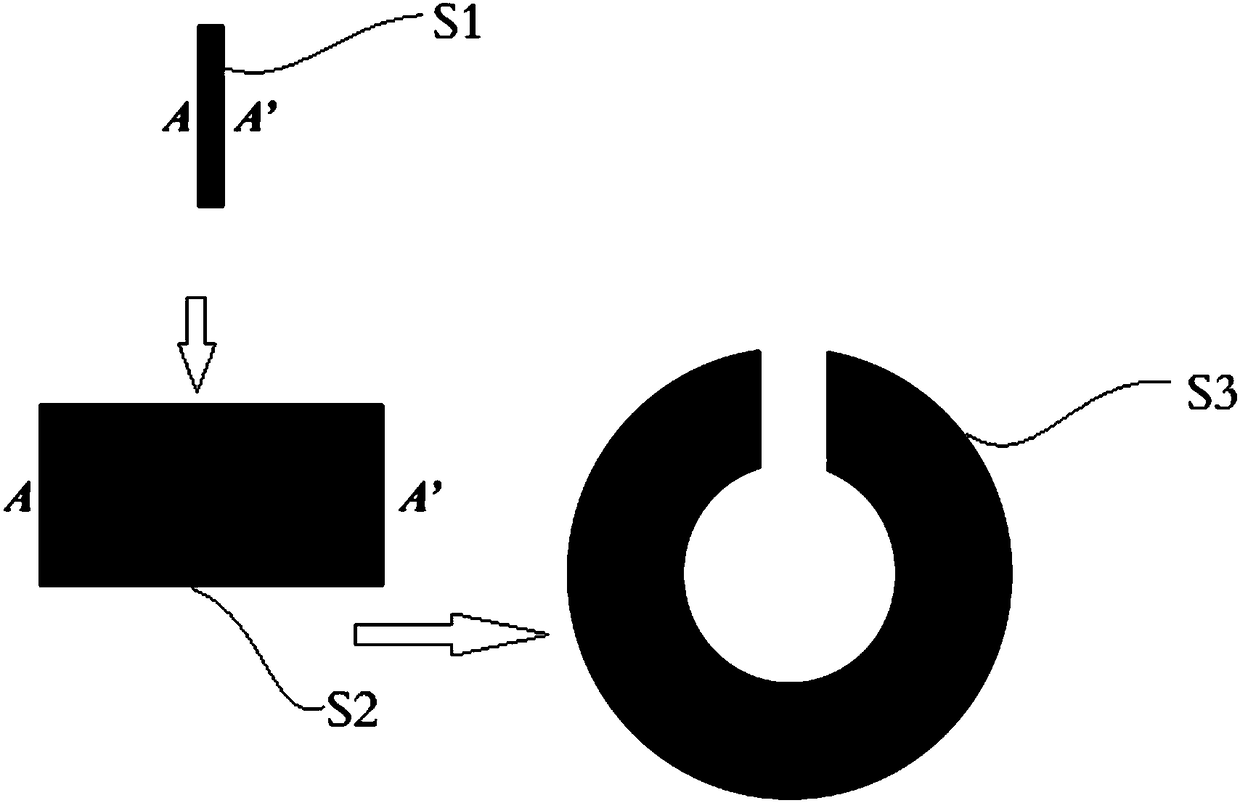

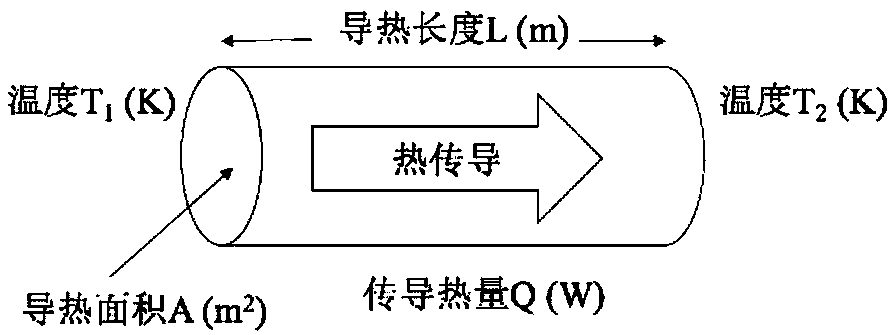

ActiveCN108412060AFacilitate heat exchangeGood for thermal energy storageClimate change adaptationPassive housesHeat flowThermal diffusion coefficient

The invention discloses an open-type thermal buffering device and method. The open-type thermal buffering method comprises the steps that materials with anisotropic thermal diffusivity are subjected to stretching and transformation; and the stretched plate-type materials are subjected to annular deformation, and thermal diffusivity after the coordinate of the plate-type materials is transformed isobtained. According to the open-type thermal buffering device and method thereof, acute change of the exterior temperature can be smoothed, the average temperature of the outside world is quickly achieved, and the open-type thermal buffering device is not isolated with the outside world and can communicate with the outside world; and the open-type thermal buffering device is a passive device, energy saving and environmental protection are achieved, both thermal sources and cold sources are taken from the external environment, and the open-type thermal buffering device and method can be widelyapplied to the condition that periodic thermal pulses ate converted into uniform thermal flow.

Owner:CHANGSHU ZJU INST FOR OPTO ELECTRONICS TECH COMMLIZATION IOTEC

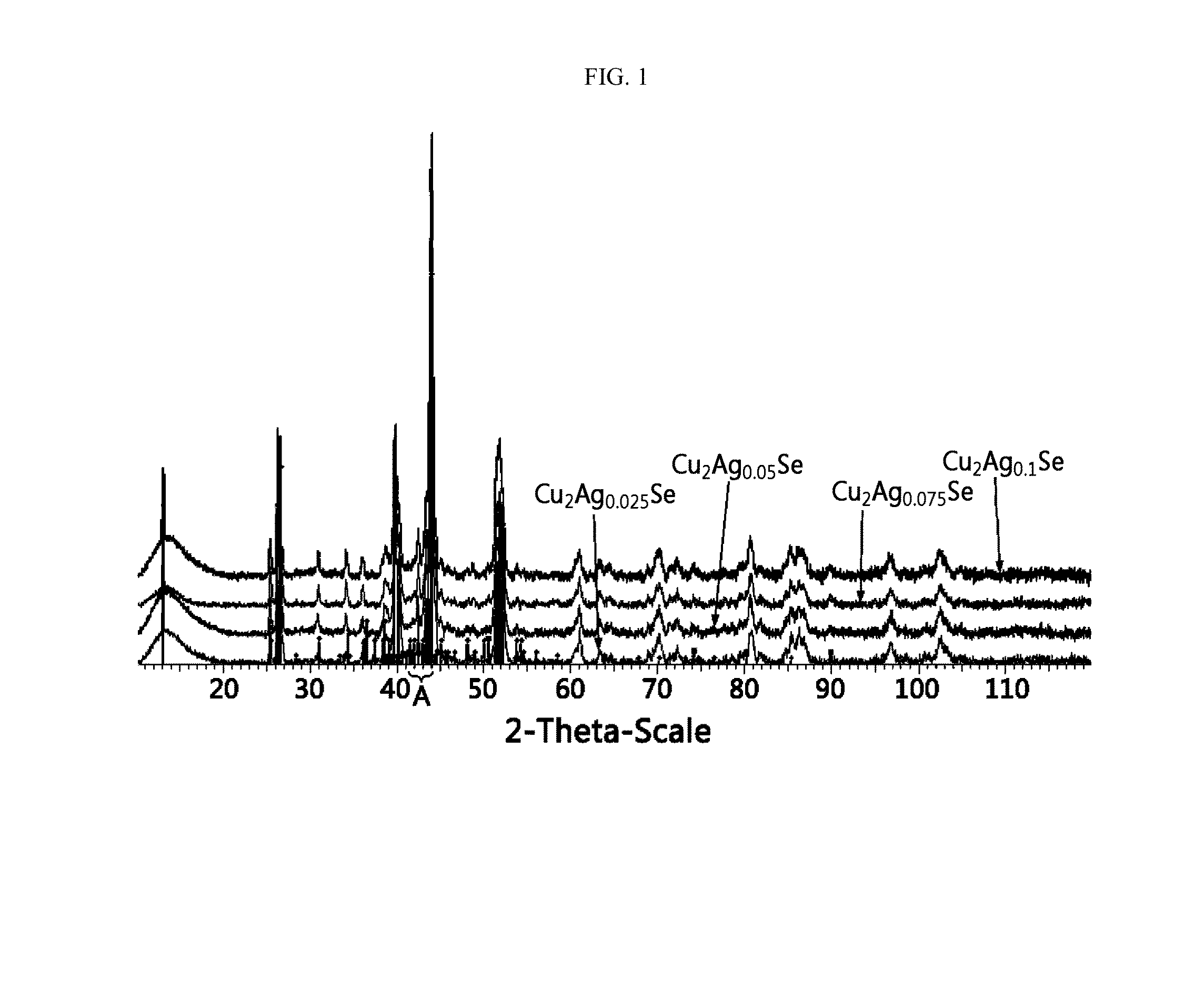

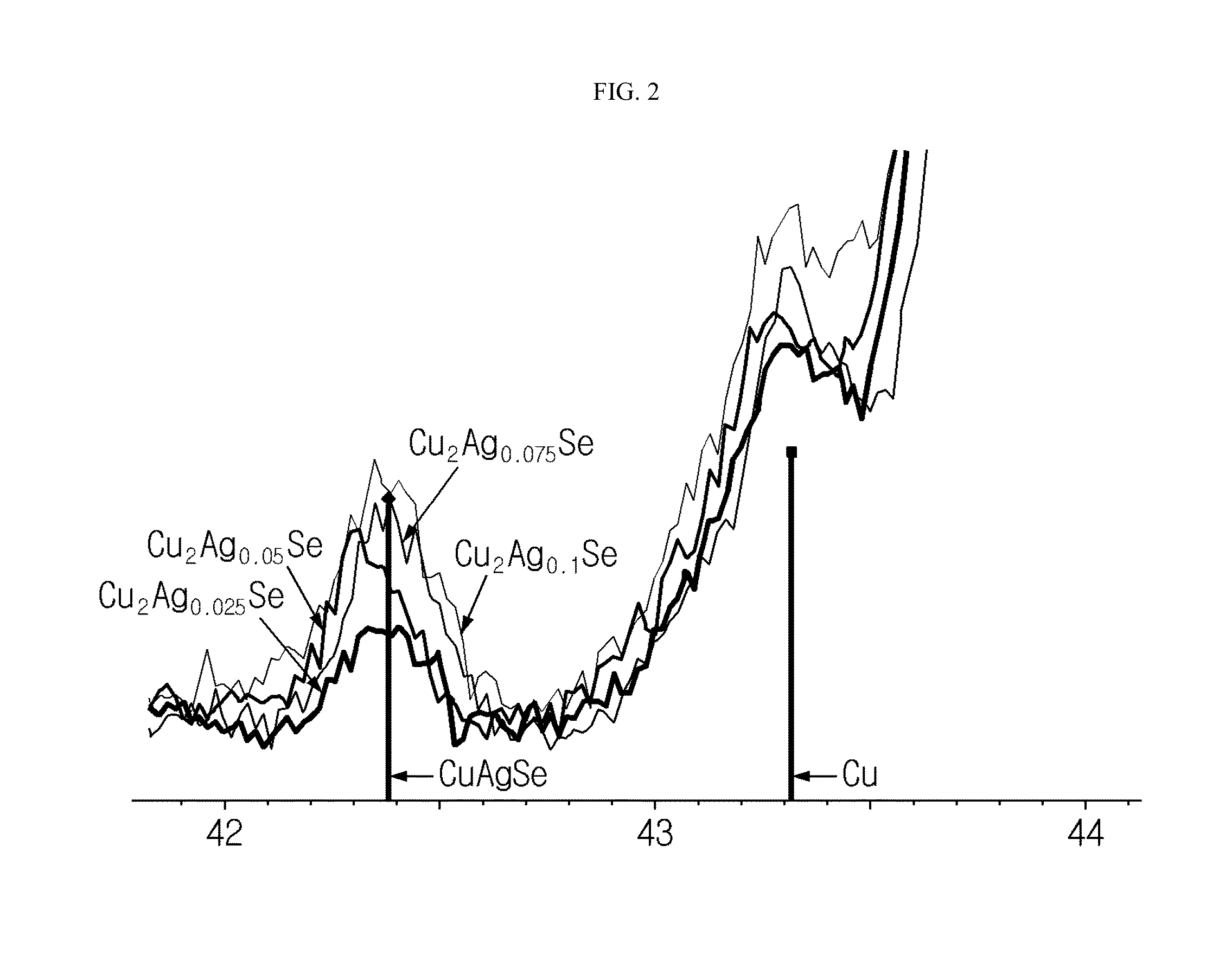

Thermoelectric materials and their manufacturing method

ActiveUS20160218267A1Excellent thermoelectric conversion performanceLow thermal diffusivitySelenium/tellurium compounds with other elementsThermoelectric device junction materialsMetallurgyThermoelectric materials

Disclosed is a thermoelectric material with excellent thermoelectric conversion performance. The thermoelectric material includes a matrix having Cu and Se, a Cu-containing particle, and an Ag-containing structure.

Owner:LG CHEM LTD

thermoelectric material

ActiveCN104885240BExcellent thermoelectric conversion performanceLow thermal diffusivityCopper compoundsMetal selenides/telluridesThermoelectric materialsEngineering

A thermoelectric conversion material having excellent performance is disclosed. A thermoelectric material according to the present invention includes: a matrix including Cu and Se; and Cu-containing particles.

Owner:LG CHEM LTD

Titanium alloy casting benching method

The invention discloses a titanium alloy casting benching method. During the line drawing, the correction needs to be strictly carried out according to the processing reference, other processing surfaces are considered, and the wall thickness after the processing needs to be uniform; when casting defects are discovered, remediation measures need to be taken for remediation; during the shaping, generally, large surfaces are knocked, and meanwhile, the force cannot be too strong; during the hole drilling, the feeding quantity needs to be small, the feeding speed needs to be uniform, when the cutting resistance is increased or the cutting chip shape and color abnormity is discovered, a drill bit needs to be replaced in time, or the cutting edge needs to be ground again; a screw tap trimming and grinding method is adopted, the screw tap calibration part is trimmed to be narrow, the bottom hole diameter is increased by 0.1mm, the uniform and slow manual tapping is adopted, the sufficient cooling liquid is maintained, and qualified titanium alloy parts are processed. The titanium alloy casting benching method has the advantages that the cutting chip bonding is reduced, the tapping difficulty is reduced, the durability of the drill bit is improved, the quality of the processed parts is improved, the dimension precision is ensured, the processing efficiency is effectively improved, and the production cost is reduced.

Owner:青岛齐力铸钢有限公司

A high-performance thermal barrier coating and its ceramic layer

The invention discloses a preparation method for a high-performance thermal barrier coating and specifically discloses a 4YSZ (4mol% Y2O3 stabilized ZrO2) thermal barrier coating and the preparation method of the 4YSZ thermal barrier coating. The 4YSZ powder which is of a fine nano-structure, uniform ingredients and a pure tetragonal phase structure is prepared utilizing a sol-spray pyrolysis synthetic process, and the 4YSZ powder is subjected to spray drying granulation, screening and atmospheric plasma spraying (APS) in sequence to prepare the coating. The high-performance thermal barrier coating prepared by the invention is of a pure tetragonal phase nano-structure with uniform ingredients, compared with a traditional YSZ casting, the high-performance thermal barrier coating has the advantages of being low in thermal diffusion coefficient, good in high temperature phase stability and thermal shock resistance, simple in preparation process and low in cost and the like; and the high-performance thermal barrier coating is more conducive to improving the efficiency and working temperature of a turbine engine, and the service life of the engine is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

A powder metallurgy brake pad matched with a carbon-ceramic brake disc and its preparation method

ActiveCN112059171BAvoid damageResist damageTransportation and packagingMetal-working apparatusFerrochromeFlake graphite

Owner:UNIV OF SCI & TECH BEIJING

In-situ synthesis process for preparing complex-phase TiN/O'-sialon material

An in-situ synthesis process for preparing complex-phase TiN / O'-Sialon material features that the cheap TiO2 is used as the reinforcing phase, which reacts on other raw materials in clacination procedure to self-grow TiN in situ, and the complex-phase TiN / O'-Sialon material is synthesized by one step. Its technological steps include sieving, precalcining, proportioning, wet grinding, ultrasonic vibration, drying, die pressing, isostatic pressure shaping and high-temp. calcining. Its advantages include excellent comprehensive performance, uniformly distributed small TiN particles having good compatibility with base phase, low cost and simple process.

Owner:NORTHEASTERN UNIV

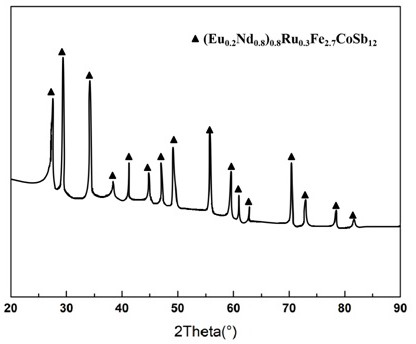

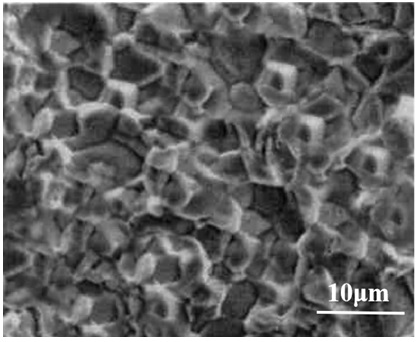

Semiconductor chilling plate and application thereof in real-time fluorescent quantitative PCR instrument

ActiveCN113903853AImprove compactnessImprove cooling effectBioreactor/fermenter combinationsHeating or cooling apparatusThermoelectric materialsHigh density

The invention discloses a semiconductor chilling plate and application of the semiconductor chilling plate in a real-time fluorescent quantitative PCR instrument. A thermoelectric material is cut into an element, and the element is used as upper electrodes to prepare the semiconductor chilling plate. The composition formula of the thermoelectric material is (EuaNdb)yRuxFe<3-x>CoSb12, wherein a + b = 1, x is greater than or equal to 0.1 and less than or equal to 0.4, and y is greater than or equal to 0.2 and less than or equal to 0.8. The preparation method comprises the steps of placing metals Co, Fe, Sb, Ru, Eu and Nd in a quartz tube according to an atomic ratio, carrying out sealed smelting under a vacuum condition, then rapidly taking out and quenching, taking out a sample, packaging, annealing, taking out and grinding under the same condition, placing in a stone mill mold, and carrying out SPS smelting under vacuum to prepare the thermoelectric material. The prepared semiconductor chilling plate has a high Seebeck coefficient, a high ZT value and high density and low thermal diffusivity, and the semiconductor chilling plate has an excellent cooling effect on electronic elements.

Owner:HANGZHOU ANYU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com