Yttrium-doped zirconium oxide (YSZ) powder having multistage nano structure, and preparation method and application thereof

A technology of yttrium-doped zirconia and nanostructure, which is applied in the field of multi-level nanostructure yttrium-doped zirconia powder and its synthesis, can solve the influence of powder morphology and thermal conductivity. There are no relevant reports, and there is no YSZ There are few reports on the synthesis of powder and YSZ powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] A second aspect of the present invention provides a method for preparing the multilevel nanostructure yttrium-doped zirconia (YSZ) powder according to the present invention, which includes the following steps:

[0072] (1) configure the reaction solution containing zirconium source and yttrium source;

[0073] The zirconium source is a zirconium source containing sulfate ions;

[0074] (2) The solution obtained in step (1) is subjected to a hydrothermal reaction to obtain a hydrothermal product;

[0075] (3) Washing the hydrothermal product obtained in step (2), drying and calcining to obtain the final powder.

[0076] In a specific embodiment of the present invention, the step (3) includes washing the hydrothermal product obtained in the step (2), drying it and putting it into a muffle furnace for calcination or direct calcination without drying to obtain the final powder body.

[0077] In a specific embodiment of the present invention, the doping amount of the yttr...

Embodiment approach

[0096] For realizing the purpose of the invention, the technical scheme that the present invention takes is as follows:

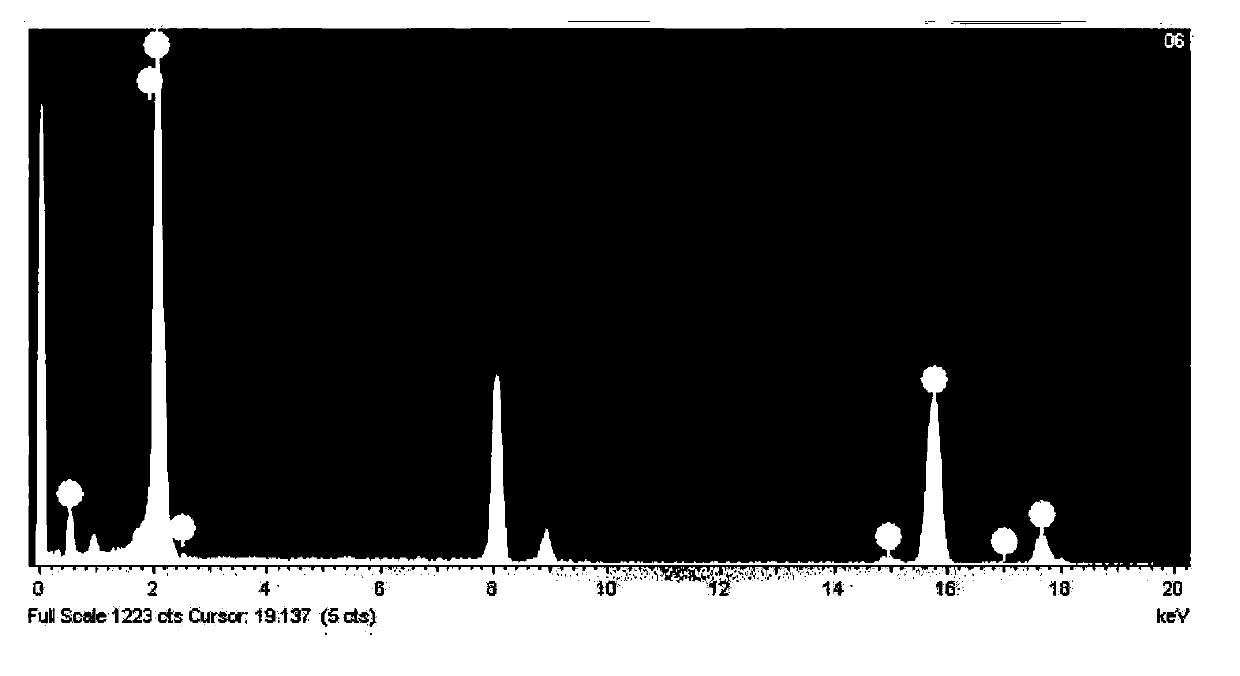

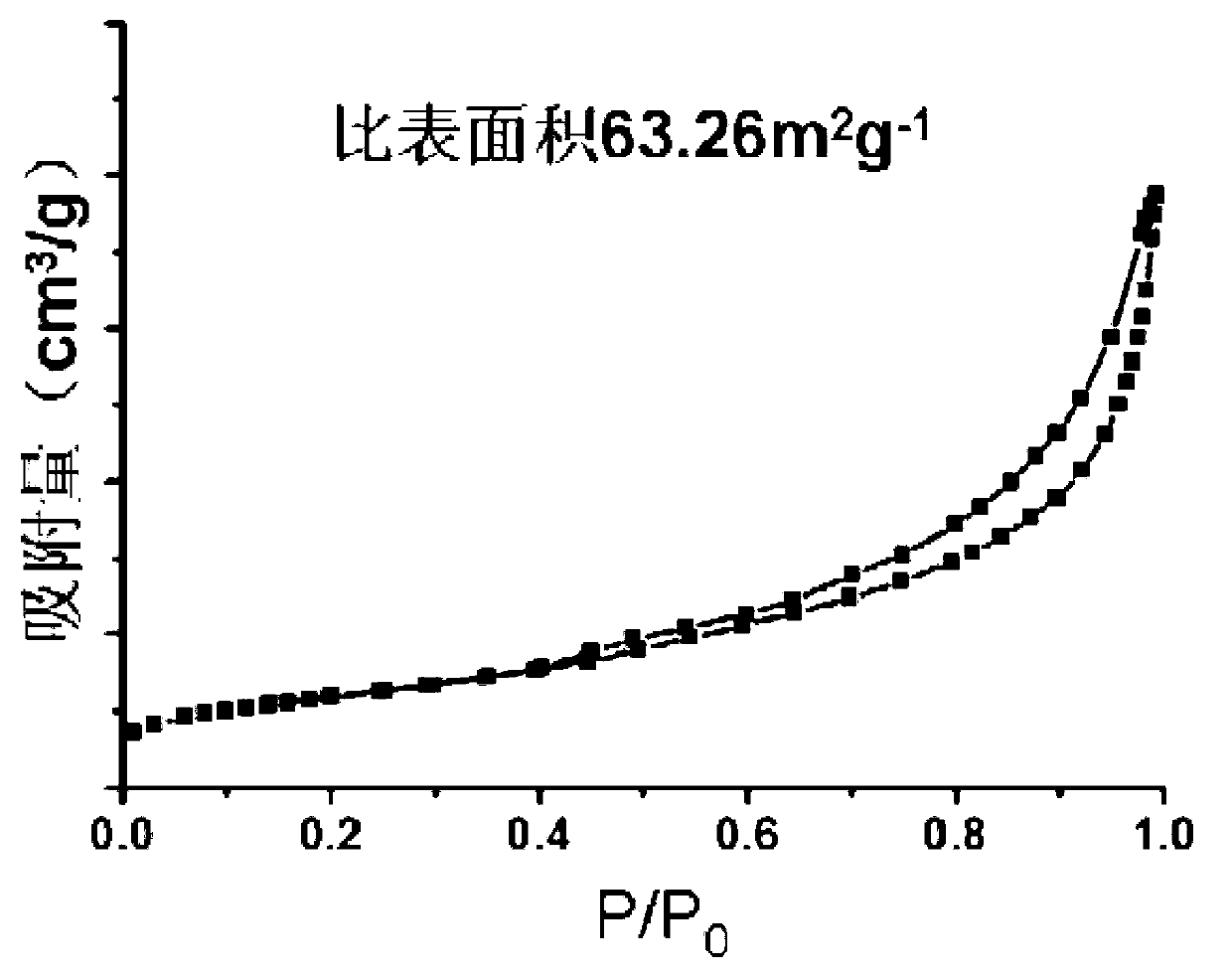

[0097] A YSZ powder with multi-level nanostructure is prepared by hydrothermal-calcination technology.

[0098] The multi-level nanostructure powder is 3-15mol% yttrium-doped zirconia powder.

[0099]The above-mentioned multilevel nanostructure YSZ powder preparation method, the process is as follows:

[0100] (1) configure the reaction solution containing zirconium source and yttrium source;

[0101] (2) Add the clarified solution obtained in step (1) into a hydrothermal kettle according to a certain filling ratio for hydrothermal treatment.

[0102] (3) The product of step (2) is washed, dried, and then put into a muffle furnace for calcination or directly calcined without drying.

[0103] In step (1), preferred zirconium source is zirconium sulfate in the selected reactant; Yttrium source is preferably all kinds of soluble yttrium salts (as chloride, ...

Embodiment 1

[0122] 0.4mmol Y(NO 3 ) 3 ·6H 2 O, 4.6mmol Zr(SO 4 ) 2 4H 2 O was dissolved in 40ml distilled water, mixed and stirred until dissolved;

[0123] Take 35mL of the clear solution and pour it into a hydrothermal kettle with a volume of 50mL, control the temperature at 200°C, react for 8 hours and cool to room temperature with the furnace;

[0124] Centrifuge the hydrothermal product, remove the supernatant, disperse it with distilled water, and then centrifuge again, repeat this process, wash twice with water, wash once with ethanol, and then dry in an oven at 80°C for 3 hours;

[0125] Put the dried powder into a corundum crucible, place it in a muffle furnace for calcination, use a heating rate of 10°C / min to rise to 700°C, and then keep it at 700°C for 4 hours to obtain the final YSZ powder.

[0126] Take 0.15 g of the prepared multi-level nanostructure YSZ powder and adopt a pressure of 6 MPa to hold the pressure for 30 seconds to obtain a disc-shaped green body; heat-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com