Semiconductor chilling plate and application thereof in real-time fluorescent quantitative PCR instrument

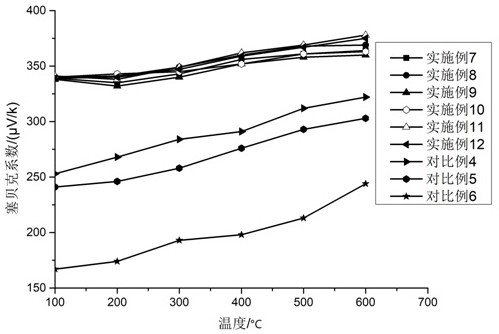

A technology of real-time fluorescence quantification and refrigeration sheet, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, and specific-purpose bioreactors/fermenters, etc., which can solve the defects of detection instruments, the troubles of product quality inspection of manufacturers, and the lack of refrigeration Problems such as sheet performance testing equipment, etc., to achieve high Seebeck coefficient, excellent cooling effect, and high thermoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A method for preparing a thermoelectric material, comprising the steps of:

[0038] According to the element molar ratio of 1:2.8:12:0.2:0.5, y contains Eu and Nd with a molar mass of a+b=1, and a is 0.3, and b is 0.7; the metals Co, Fe, Sb, Ru, Eu and Nd are placed in the quartz tube, wherein before the quartz tube is used, a layer of carbon film is attached to the inner wall of the quartz tube by pyrolysis of acetone to prevent the reaction of the rare earth metal bath quartz tube; -3 Under the condition of Pa vacuum, 15kPa of high-purity argon gas is introduced, and then sealed, and the sealed quartz tube is placed in a high-frequency induction furnace for melting. ℃, keep warm for 4h, then slowly rise to 1100°C at a rate of 1°C / min, keep warm for 26h, cool to 950°C, keep warm for 24h, take it out quickly and transfer it to a water pool for quenching, smash the quartz tube, and take out the smelted The sample was packaged again under the same conditions, annealed at ...

Embodiment 2

[0040] A method for preparing a thermoelectric material, comprising the steps of:

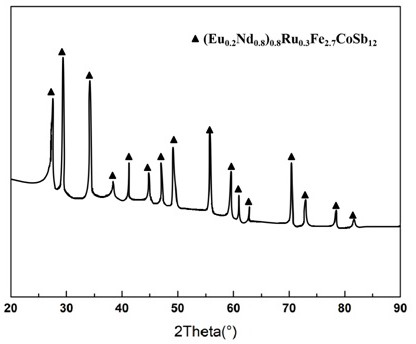

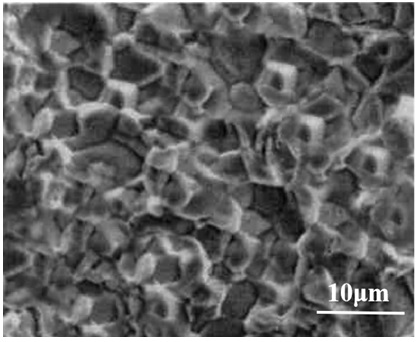

[0041] According to the element molar ratio of 1:2.7:12:0.3:0.8, y contains Eu and Nd with a molar mass of a+b=1, and a is 0.2, and b is 0.8; the metals Co, Fe, Sb, Ru, Eu and Nd are placed in the quartz tube, wherein before the quartz tube is used, a layer of carbon film is attached to the inner wall of the quartz tube by pyrolysis of acetone to prevent the reaction of the rare earth metal bath quartz tube; - 3 Under the condition of Pa vacuum, 20kPa high-purity argon gas is introduced, and then sealed, and the sealed quartz tube is placed in a high-frequency induction furnace for melting. ℃, keep warm for 3h, then slowly rise to 1150°C at a rate of 1°C / min, keep warm for 24h, cool to 1000°C, keep warm for 24h, take it out quickly and transfer it to a water pool for quenching, smash the quartz tube, and take out the smelted The sample was packaged again under the same conditions, annealed at...

Embodiment 3

[0043] A method for preparing a thermoelectric material, comprising the steps of:

[0044] According to the element molar ratio of 1:2.7:12:0.3:0.8, y contains Eu and Nd with a molar mass of a+b=1, and a is 0.5, and b is 0.5; the metals Co, Fe, Sb, Ru, Eu and Nd are placed in the quartz tube, wherein before the quartz tube is used, a layer of carbon film is attached to the inner wall of the quartz tube by pyrolysis of acetone to prevent the reaction of the rare earth metal bath quartz tube; - 3 Under the condition of Pa vacuum, 20kPa high-purity argon gas is introduced, and then sealed, and the sealed quartz tube is placed in a high-frequency induction furnace for melting. ℃, keep warm for 3h, then slowly rise to 1150°C at a rate of 1°C / min, keep warm for 24h, cool to 1000°C, keep warm for 24h, take it out quickly and transfer it to a water pool for quenching, smash the quartz tube, and take out the smelted The sample was packaged again under the same conditions, annealed at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com