Patents

Literature

87results about How to "Increased ZT value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

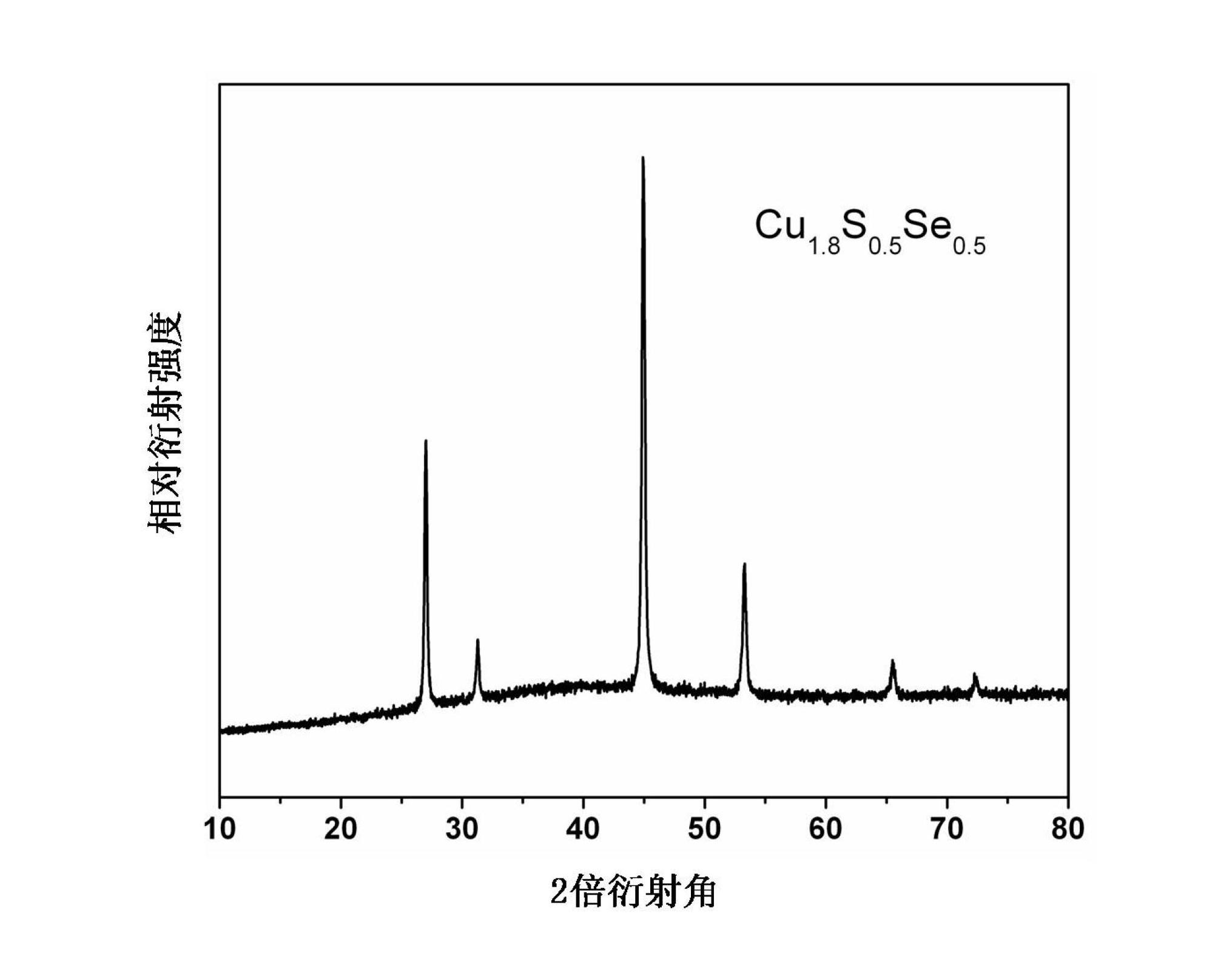

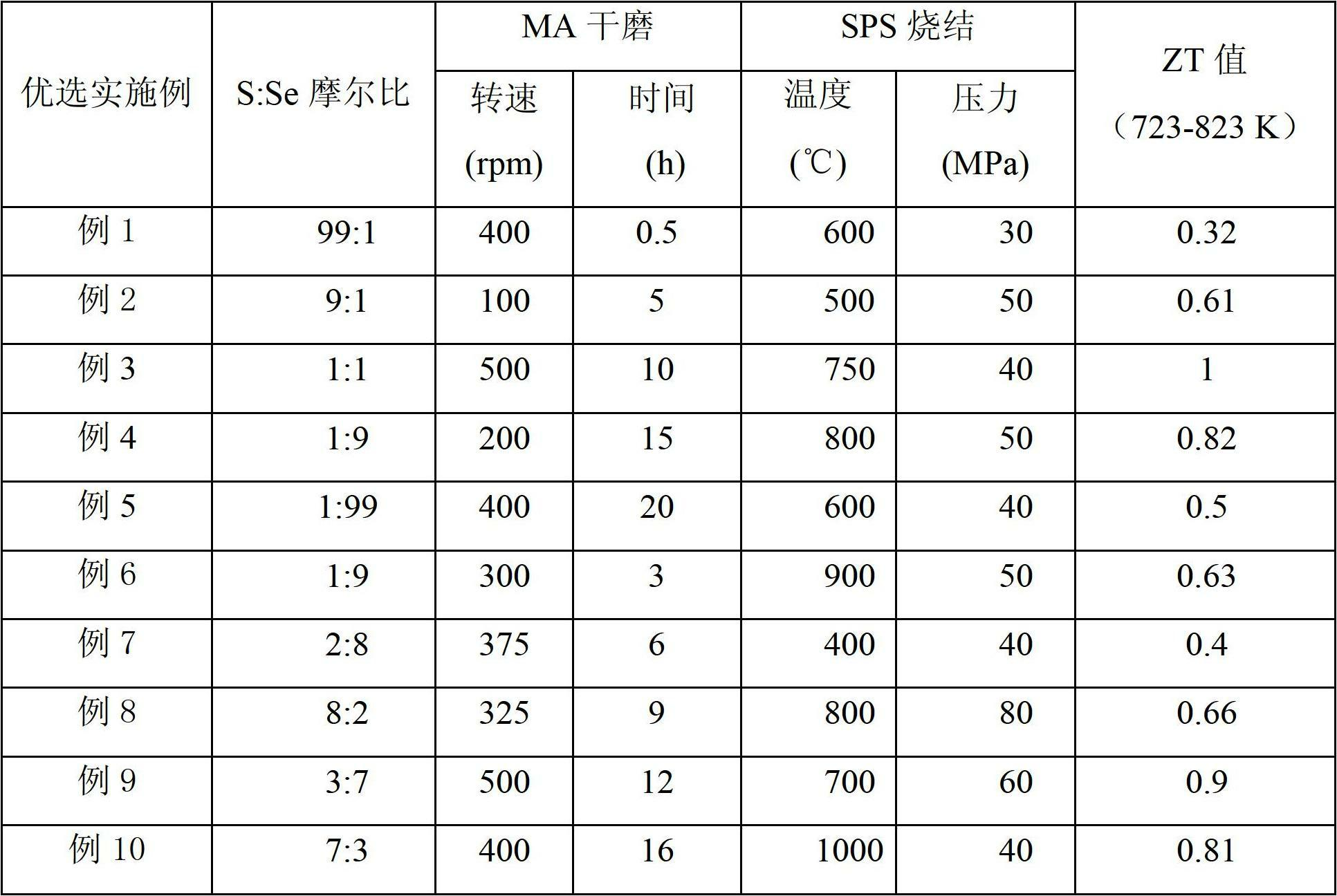

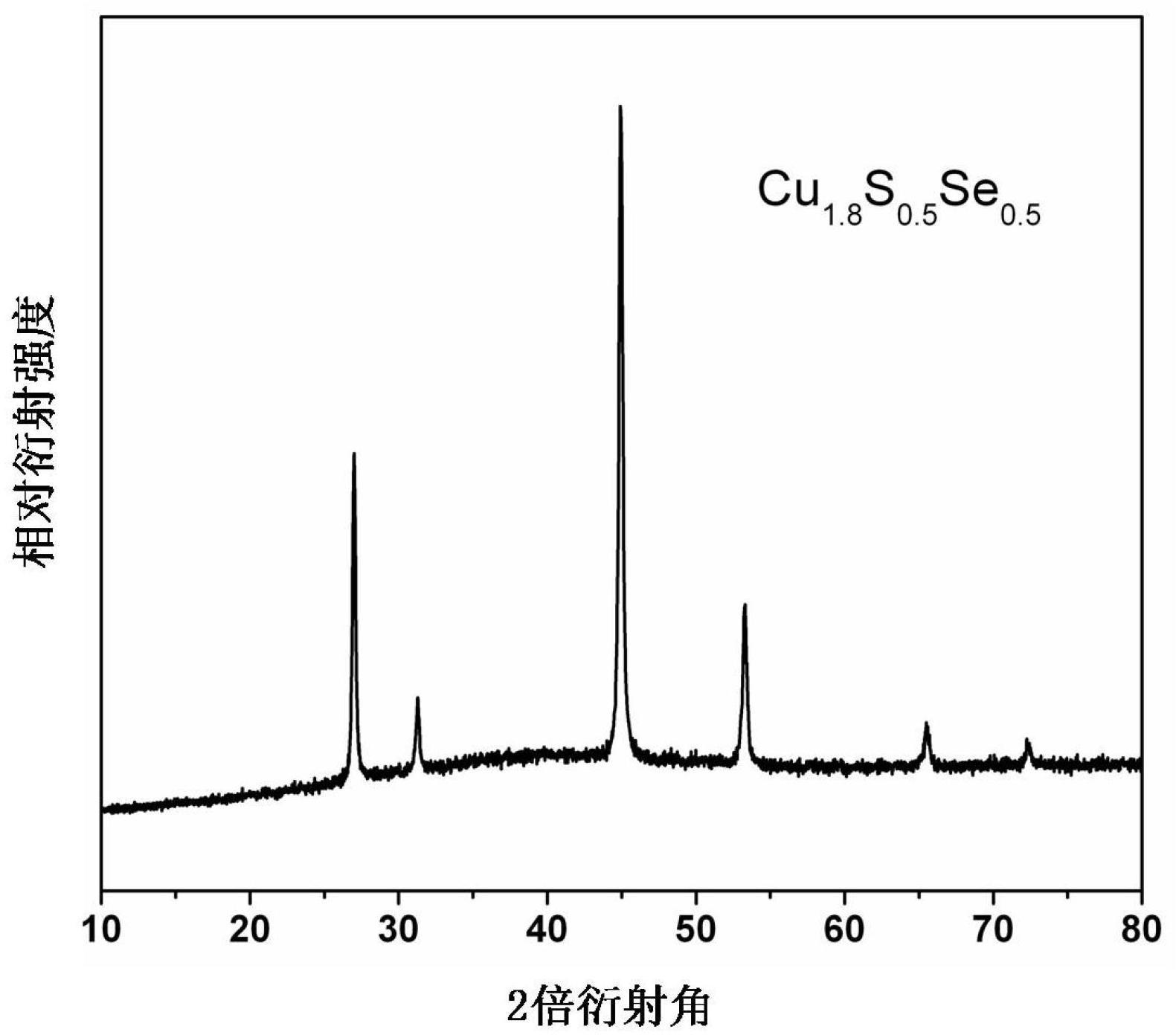

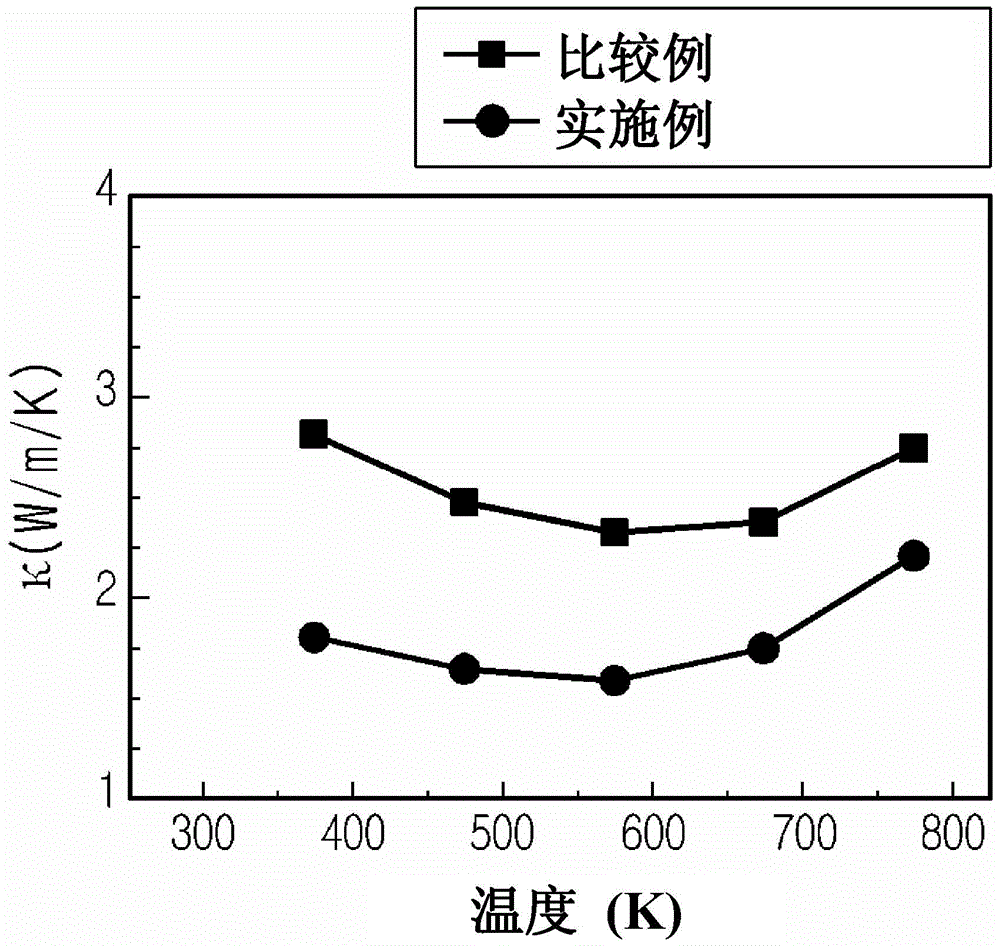

Cu-S-Se ternary thermoelectric material and preparation method thereof

InactiveCN102674842ARaise the average atomic massExcellent thermoelectric performance in the middle temperature regionThermoelectric materialsEnergy materials

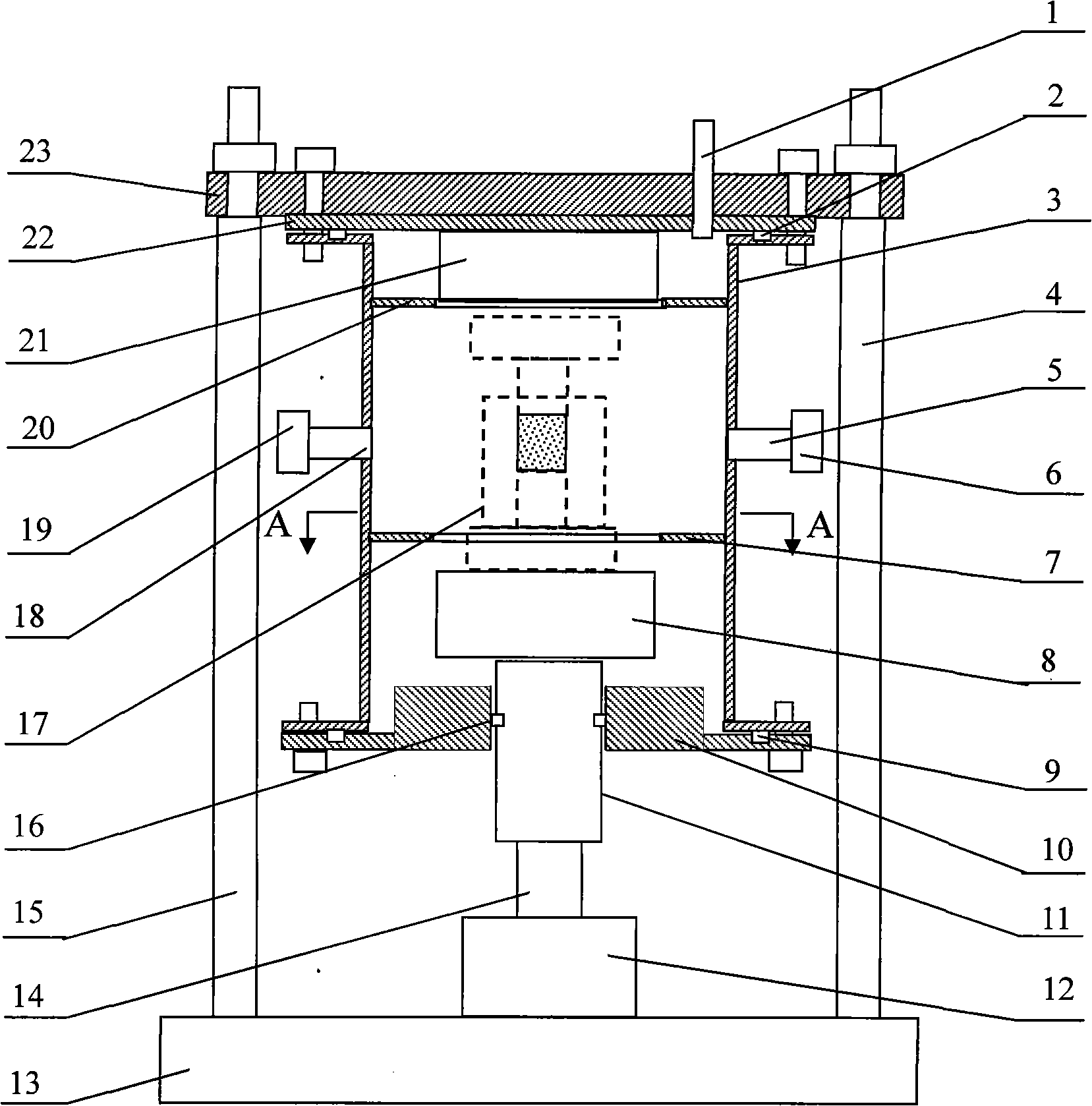

The invention relates to a Cu-S-Se ternary thermoelectric material and a preparation method of the material, belonging to the technical field of energy material. The method for preparing the Cu-S-Se ternary thermoelectric material is characterized in that high-pure metal simple substance Cu powder, high-pure Se powder and high-pure S powder are taken as raw materials and are proportioned according to the chemical general formula Cu 1.8 S 1-x Se x (wherein x is the mole fraction of Se component element and is more than or equal to 0.01 and less than or equal to 0.99); and the compound powder is synthesized by a mechanical alloying method, and a block is prepared by spark plasma sintering. The method can be used for preparing the Cu-S-Se ternary thermoelectric material simply, conveniently and accurately, and the Cu-S-Se ternary thermoelectric material has the excellent thermoelectric property at the medium temperature area.

Owner:UNIV OF SCI & TECH BEIJING

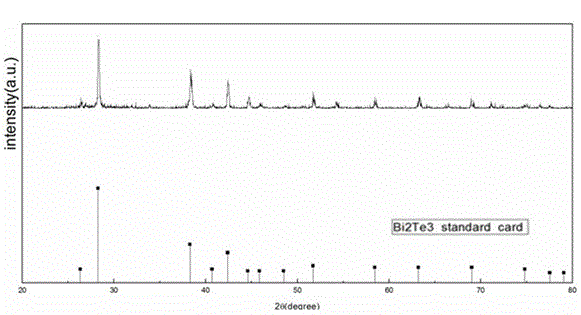

Preparation method of bismuth telluride based bulk nano crystalline thermoelectric material

InactiveCN101786162ASimple processLess investmentThermoelectric device manufacture/treatmentMicrowaveBismuth telluride

The invention relates to a bismuth telluride based bulk nano crystalline thermoelectric material and preparation method thereof. The technical scheme includes that: firstly simple substance powder with mass percent more than 99.99% is taken as raw material, burdening is carried out according to the chemical formula (SbxBi1-x)2Te3 or Bi2(SeyTe1-y)3, wherein x is more than or equal to 0.75 and less than or equal to 0.85, y is more than or equal to 0.04 and less than or equal to 0.06, mixing to be uniform is carried out, and then ball milling is carried out by a ball mill, thus obtaining bismuth telluride base alloy nano powder; secondly, the bismuth telluride base alloy obtained in the first step is loaded into a graphite mould or ceramic mould to be sintered in a micro wave irradiation pressure sintering device; temperature rises to 300-550 DEG C by heating under the condition that the pressure applied to the powder is 10-40MPa, and then heat preservation is carried out for 10-60min under the condition that the pressure applied to the powder is 30-60MPa, thus obtaining the bismuth telluride based bulk nano crystalline thermoelectric material. The invention has the characteristics of less investment, low production cost, simple technology and short period; and the obtained bismuth telluride based bulk nano crystalline thermoelectric material has high performance.

Owner:WUHAN UNIV OF SCI & TECH

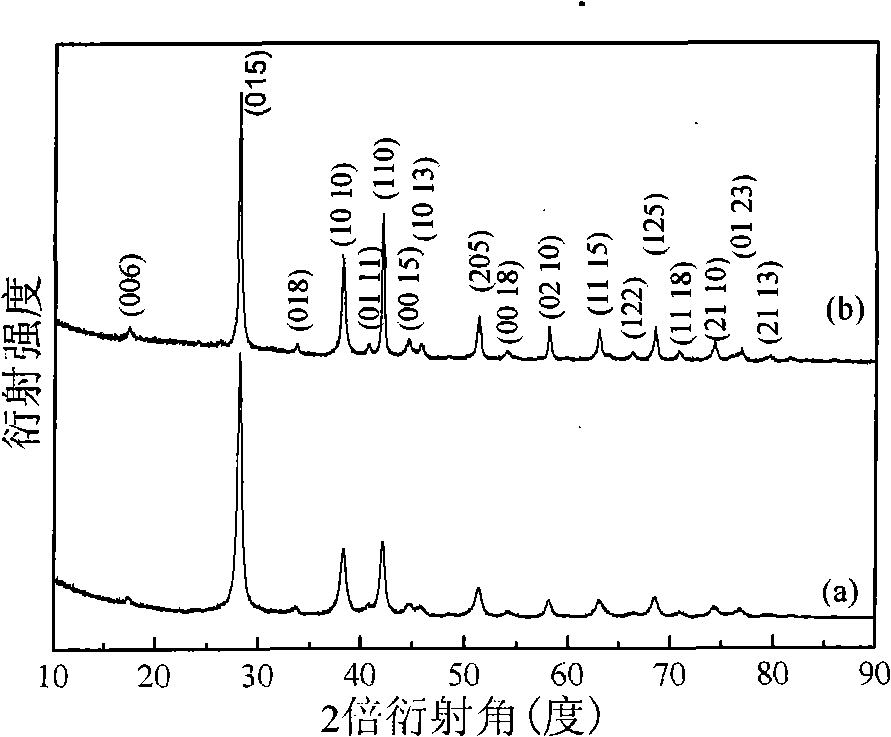

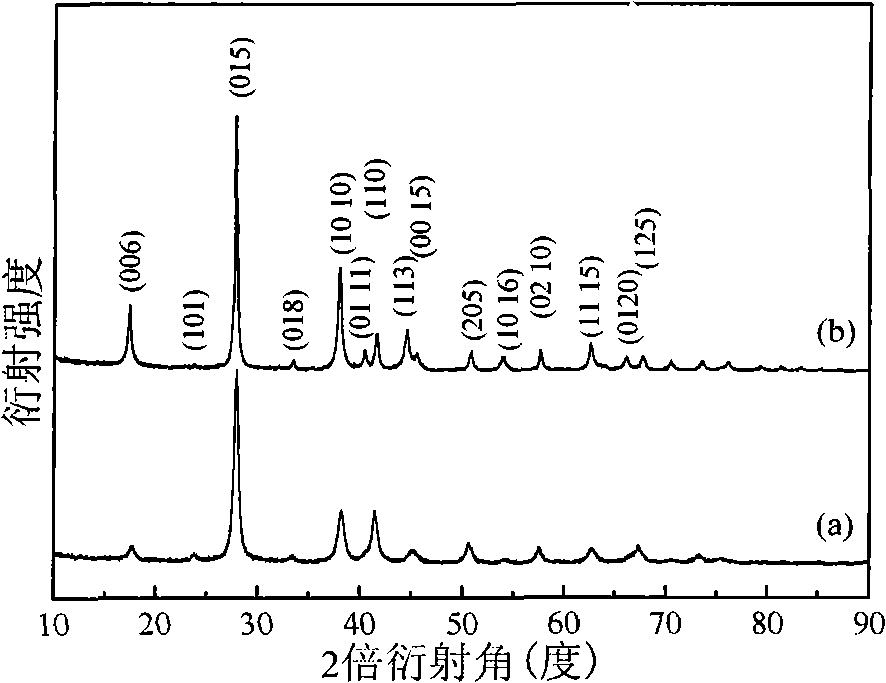

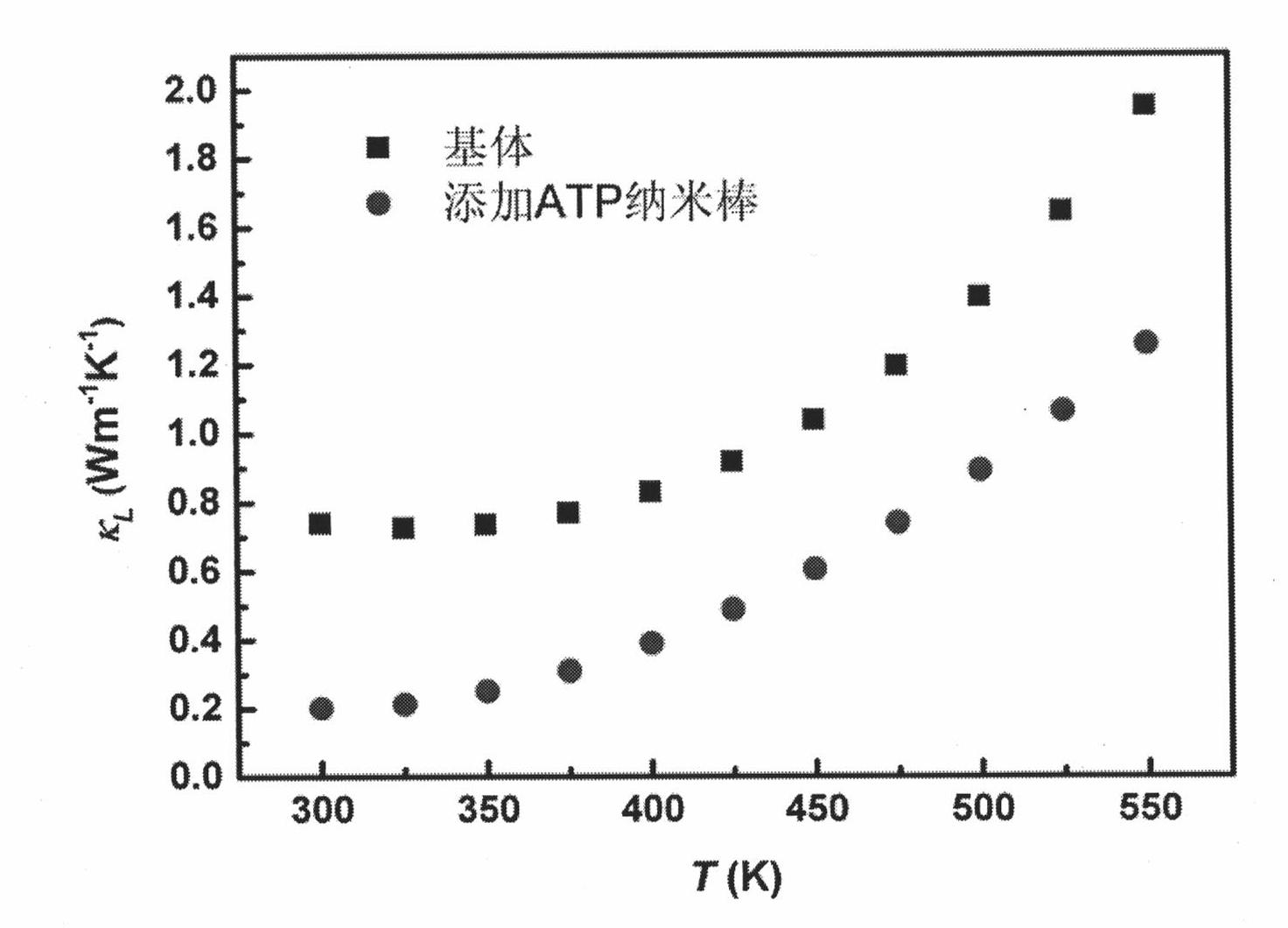

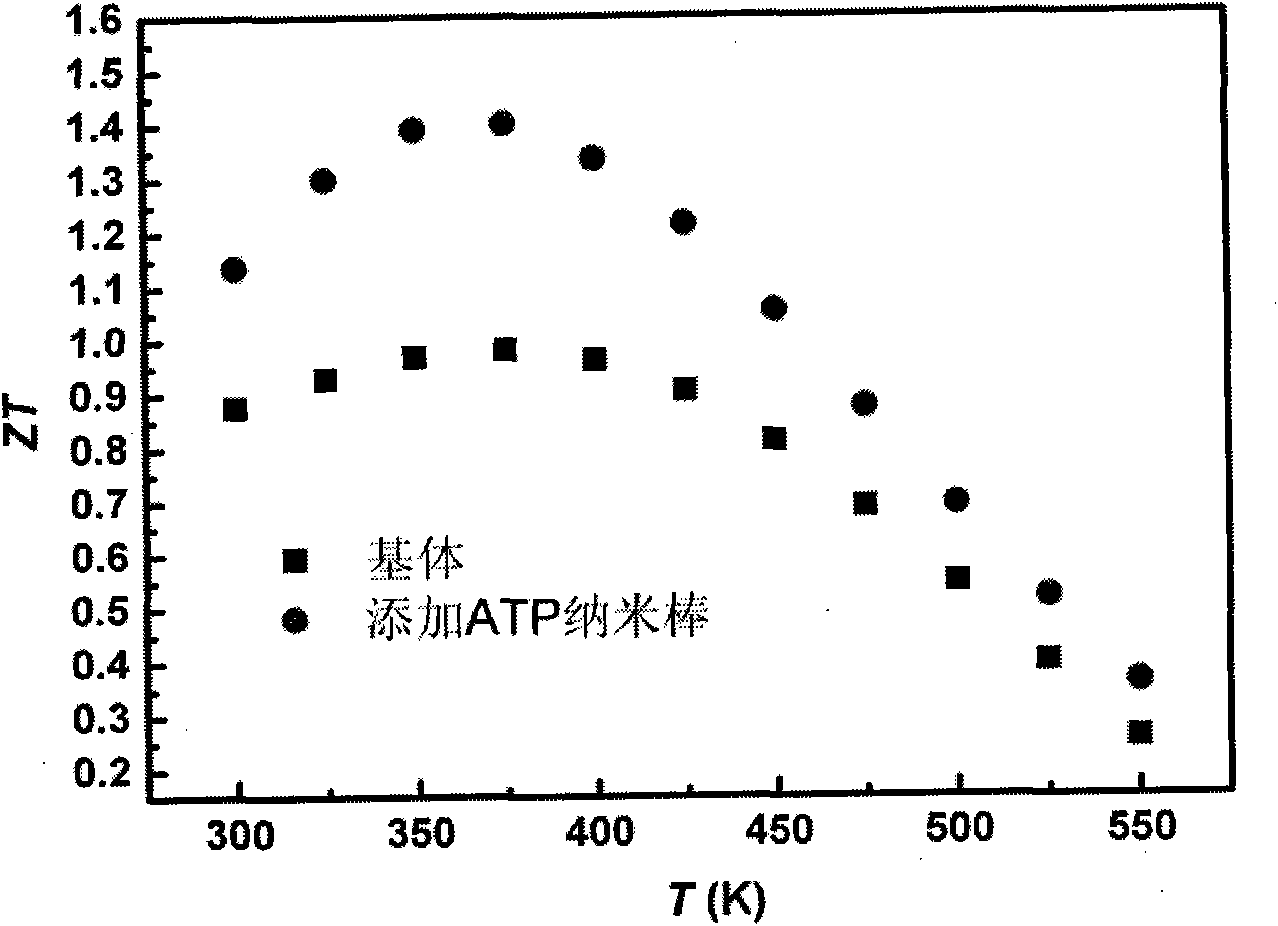

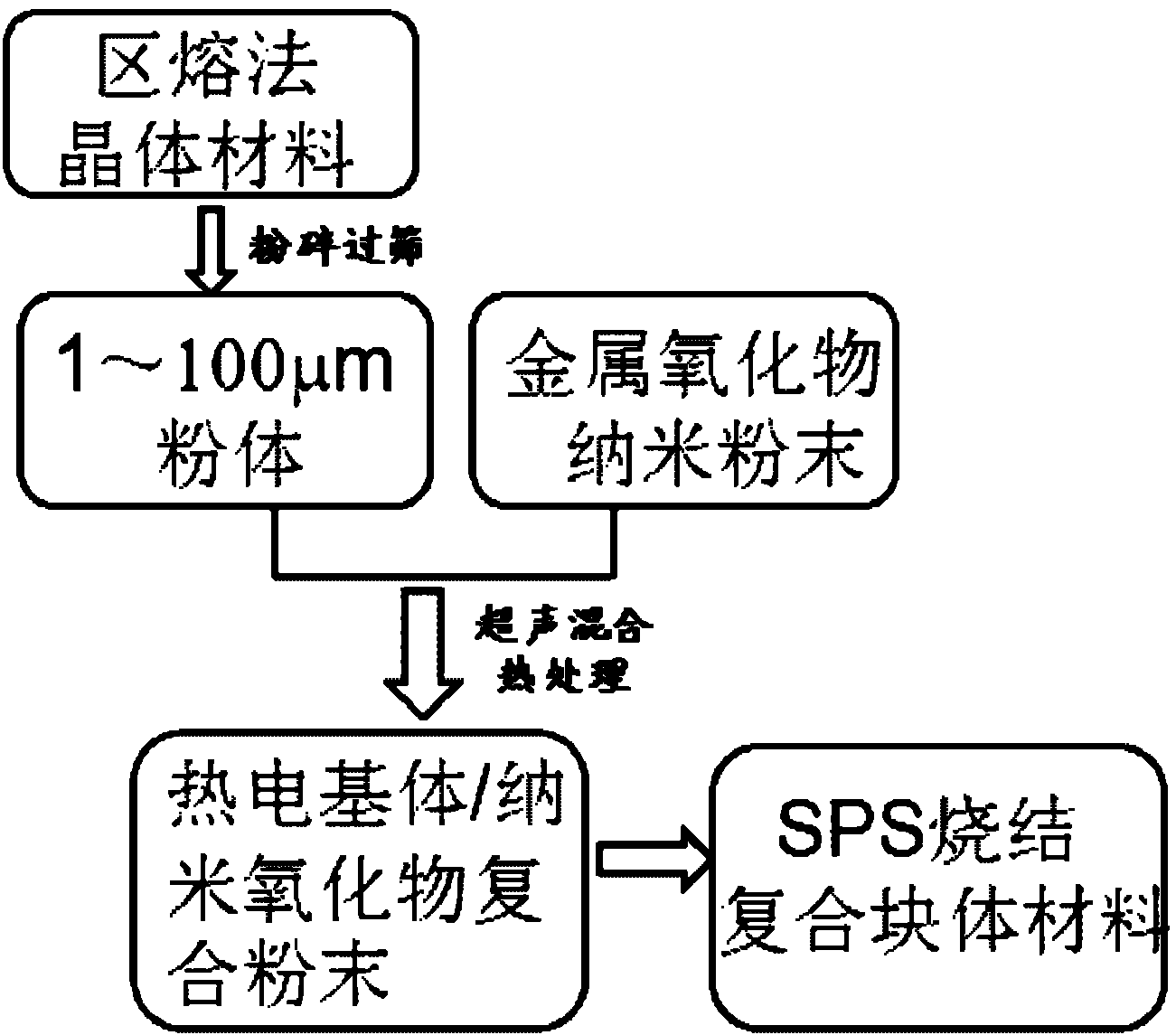

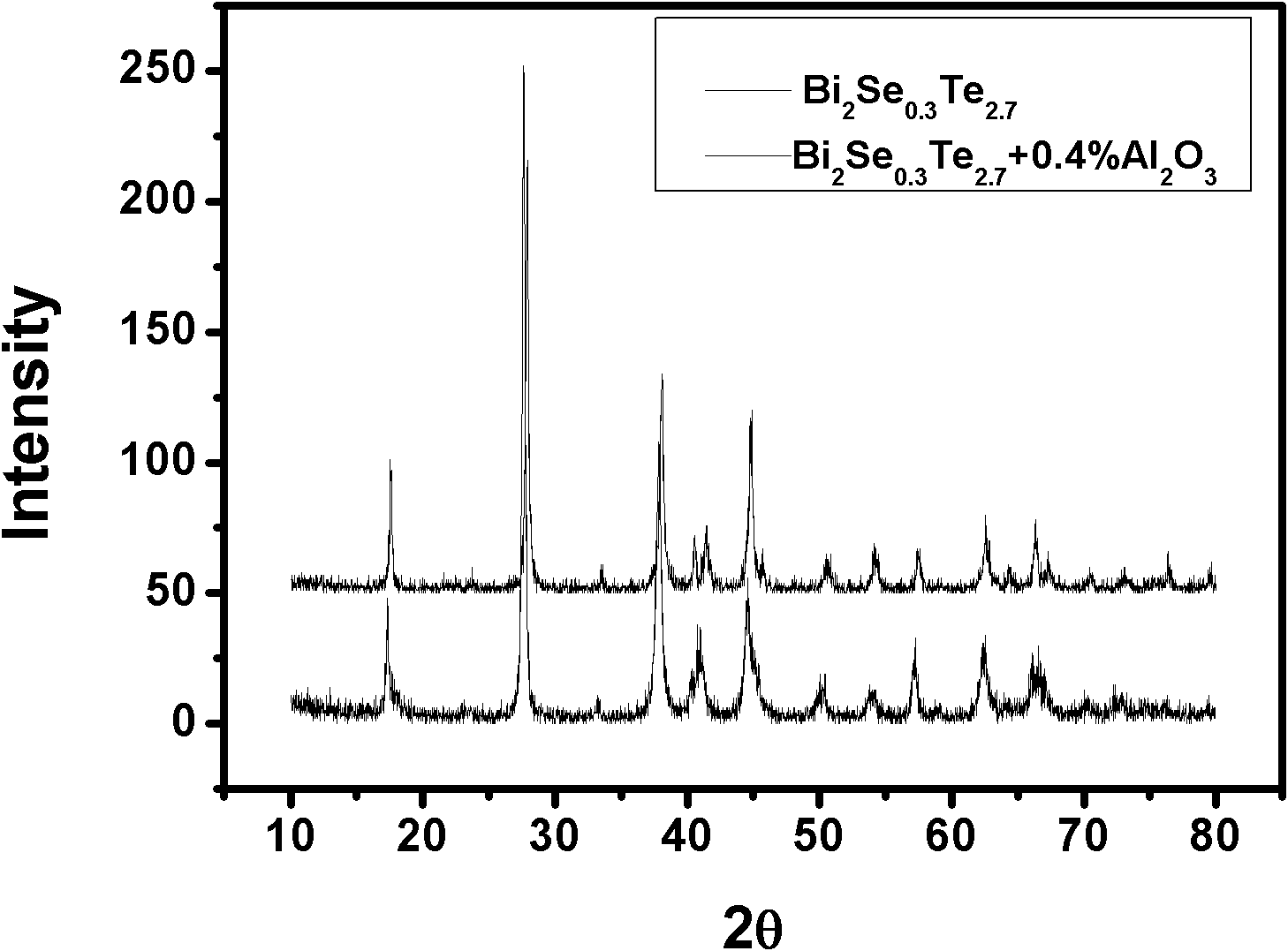

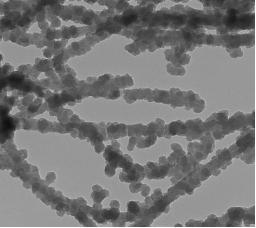

Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

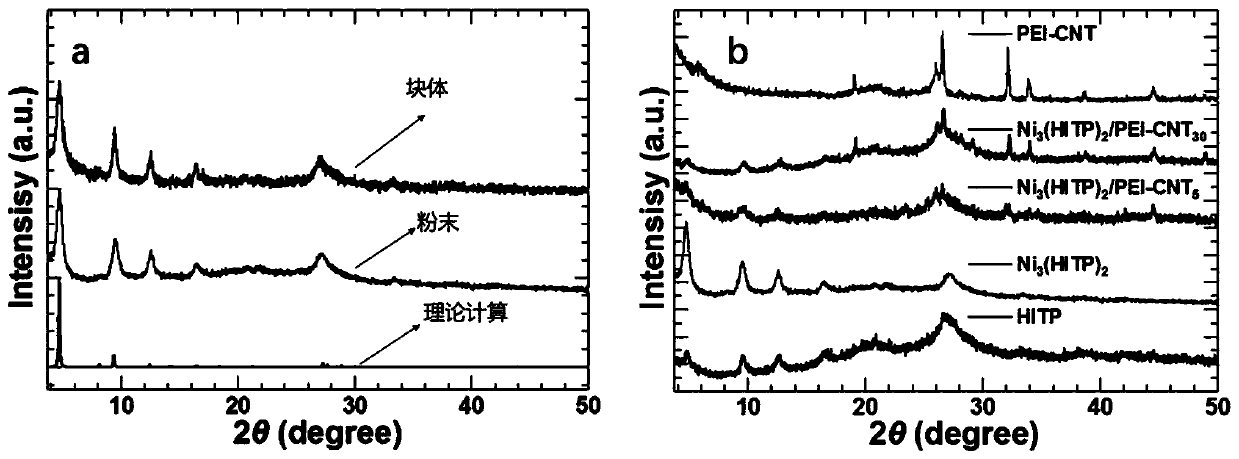

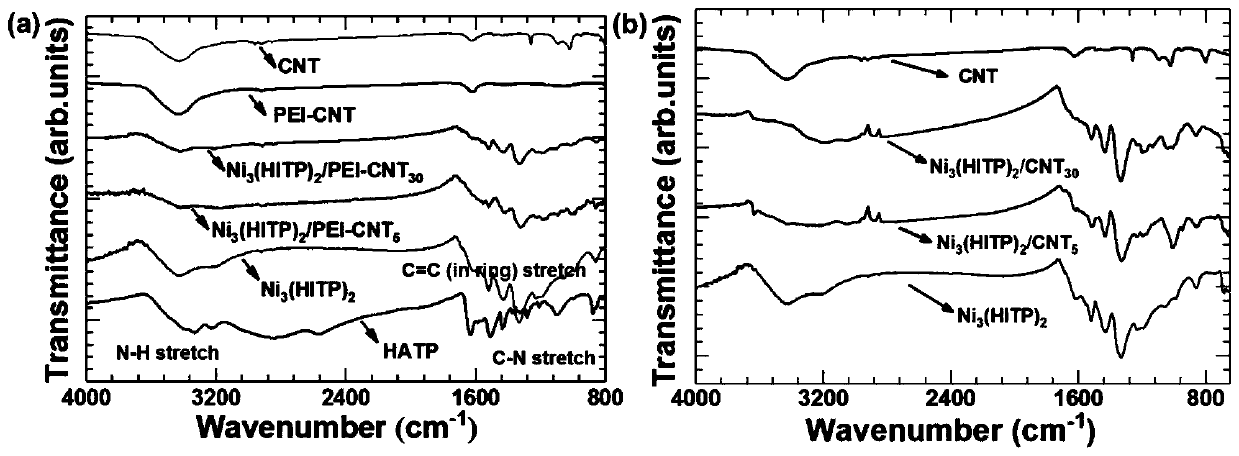

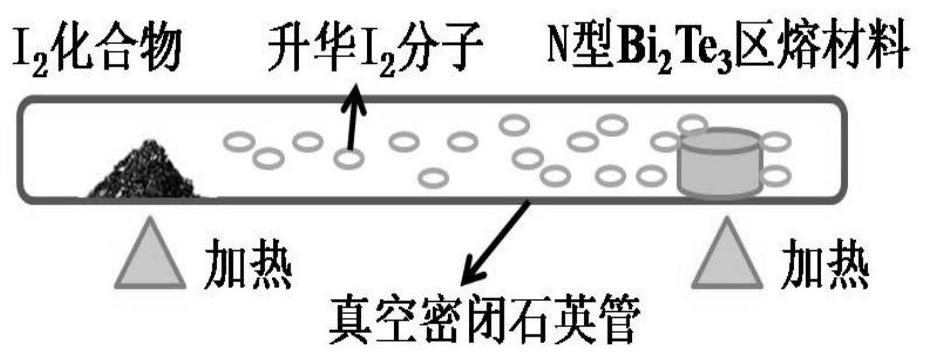

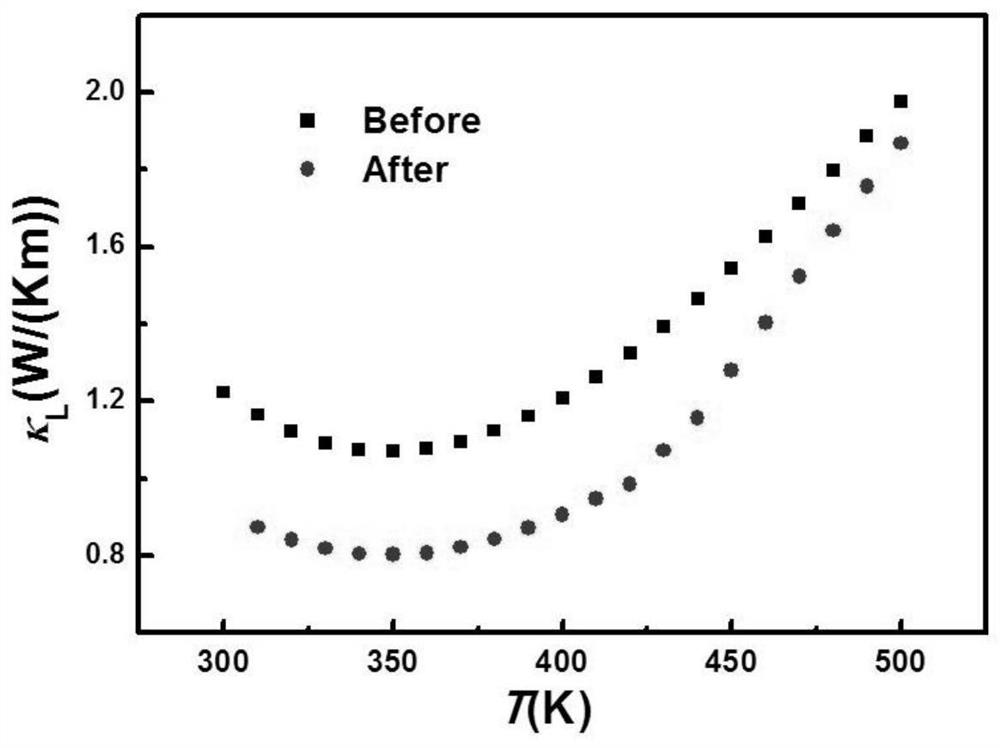

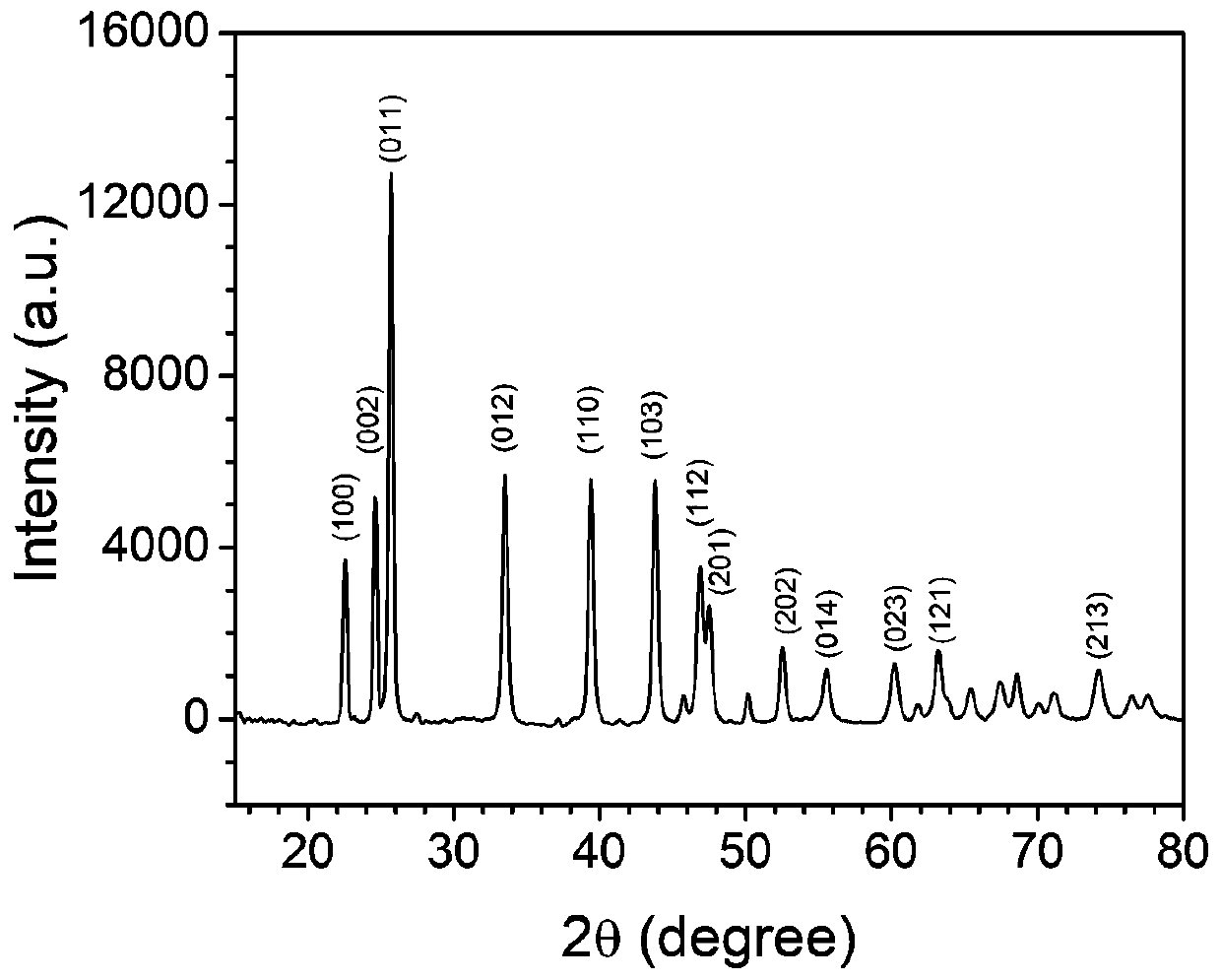

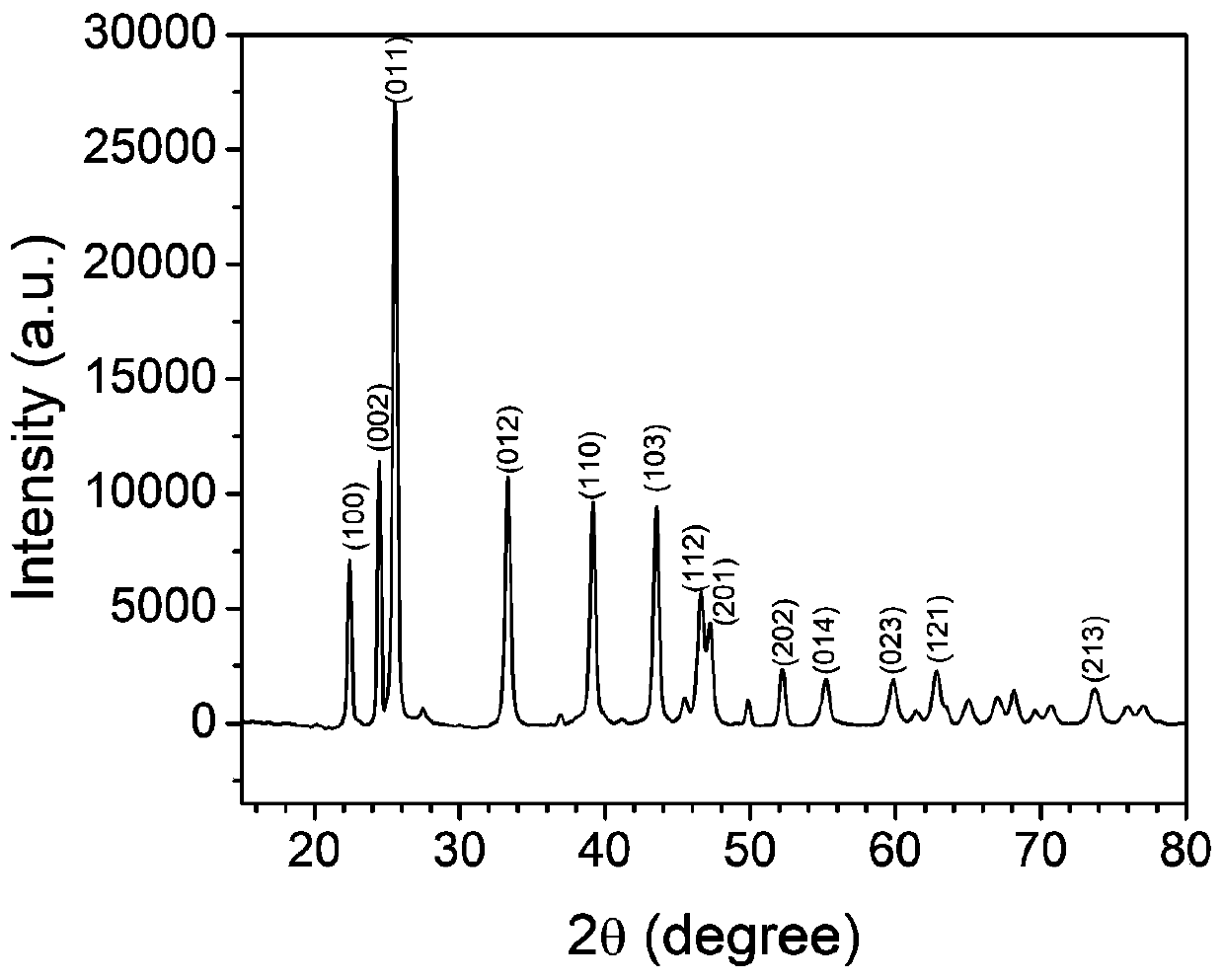

ActiveCN101994155ALower lattice thermal conductivityReduced lattice thermal conductivity κ

<sub>L</sub>Polycrystalline material growthBy zone-melting liquidsBismuth tellurideCarbon nanotube

The invention discloses a nanophase doped bismuth telluride-based thermoelectric material and a preparation method thereof. The bismuth telluride-based thermoelectric material is characterized in taking the bismuth telluride-based thermoelectric material containing a tellurium element, a bismuth element and a doped chemical element, as a matrix. The doped nanophase is a one-dimensional nanophase,and the weight of the one-dimensional nanophase accounts for 0.01-5 percent of the weight of the matrix. Attapulgite or a zinc oxide nanowire or a single-wall carbon nanotube or a multi-wall carbon nanotube is preferable to the one-dimensional nanophase. Compared with the prior art, in the bismuth telluride-based thermoelectric material, the lattice heat conductivity within the whole temperature zone range is reduced, thereby a ZT value is greatly improved and the thermoelectric performance of the bismuth telluride-based thermoelectric material is improved. The preparation method is simple and easy to implement, and compared with other methods of balling milling or liquid phase and the like, impurities are not easy to introduce in the preparation method so that the one-dimensional nanophase is evenly staggered and distributed in the matrix and the mechanical property of the material is effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for manufacturing graphene/polyaniline thermoelectric thin film

ActiveCN103311428ALow costSimple processElectrolytic coatingsThermoelectric device manufacture/treatmentAnilineFigure of merit

The invention discloses a method for manufacturing a graphene / polyaniline thermoelectric thin film, and relates to a method for manufacturing a thermoelectric thin film. The method for manufacturing the graphene / polyaniline thermoelectric thin film includes firstly, manufacturing graphene oxide powder; secondly, manufacturing graphene oxide / aniline mixed solution; thirdly, manufacturing a graphene / polyaniline composite powder material; fourthly, manufacturing the thermoelectric thin film by means of oriented deposition. The method has the advantages that the technical problem of low thermoelectric conversion efficiency due to a low figure of merit (a ZT value) of an existing organic thermoelectric material is solved, and the method can be applied to industrial temperature differential power generation.

Owner:HARBIN INST OF TECH

High-performance thermoelectric composite material and preparation method thereof

ActiveCN102339946AImprove Seeback coefficientLow thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention relates to a high-performance thermoelectric composite material and a preparation method thereof, belonging to the field of thermoelectric materials. The composite material consists of two phases. A first phase is n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3, and a second phase is nanometer powder of a metallic oxide. The nanometer powder of the metallic oxide accounts for 0.05-10% in terms of the total weight of the thermoelectric composite material. According to the preparation method provided by the invention, the n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3 powder is ultrasonically mixed with the nanometer oxide, and discharge plasma sintering is carried out on the mixture to obtain a dense block material. Compared with the bismuth-telluride-based thermoelectric base material, under the condition that the electric conductivity of the thermoelectric base material is maintained to be unchanged basically in the invention, the high-performance thermoelectric composite material, provided by the invention, achieves the advantages of obviously reduced lattice heat conductivity and increased Seeback coefficient, and therefore the thermoelectric performance of the material can be greatly improved.

Owner:中科西卡思(苏州)科技发展有限公司

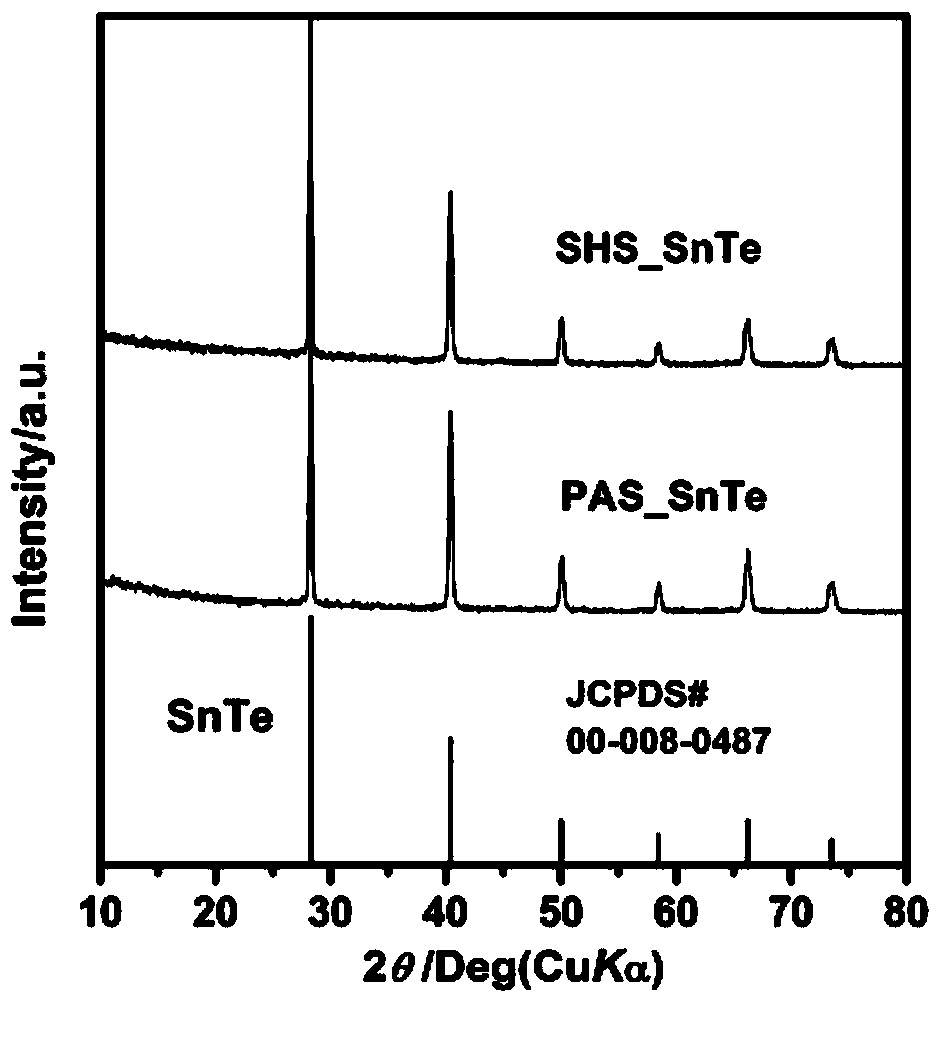

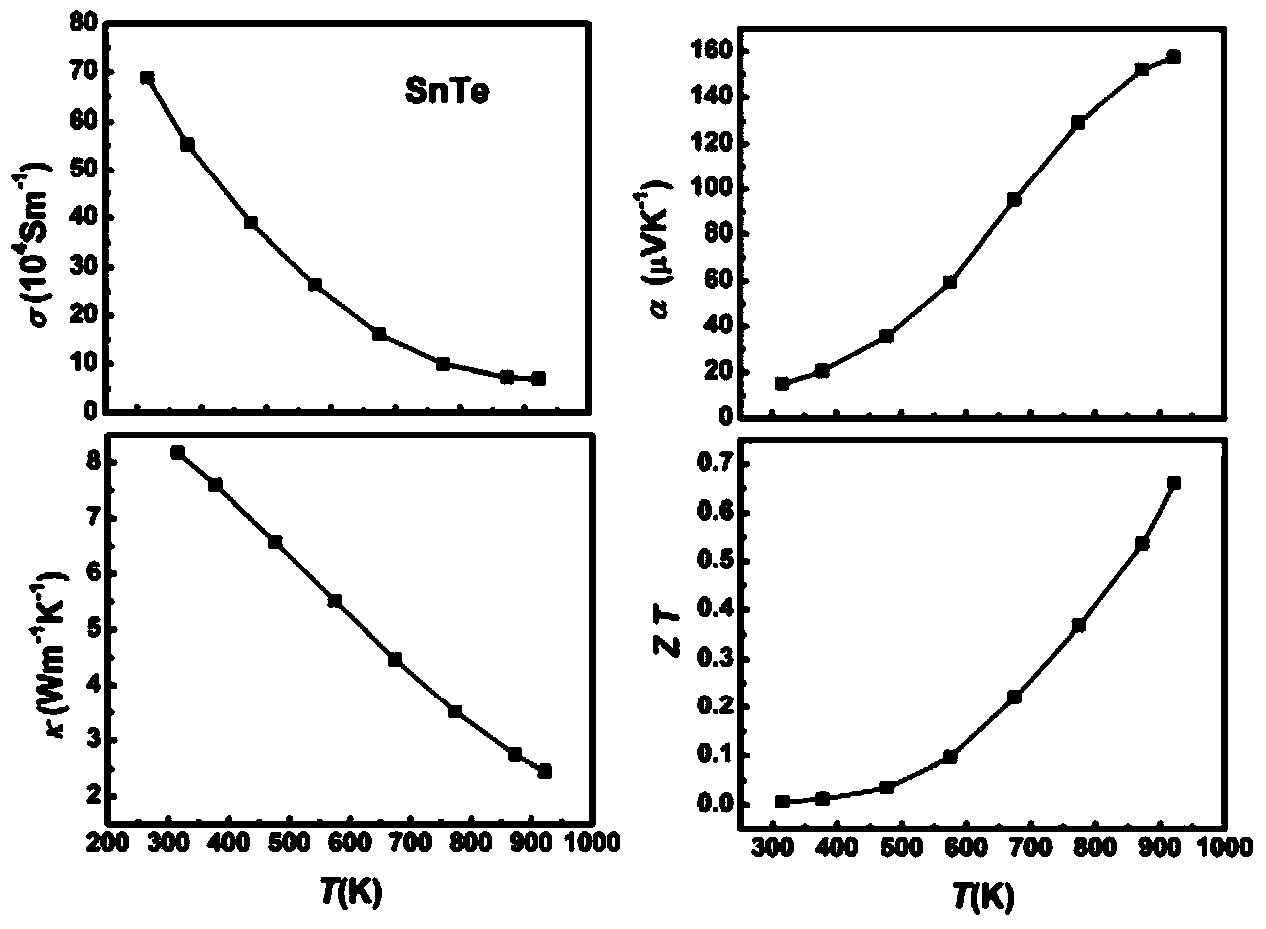

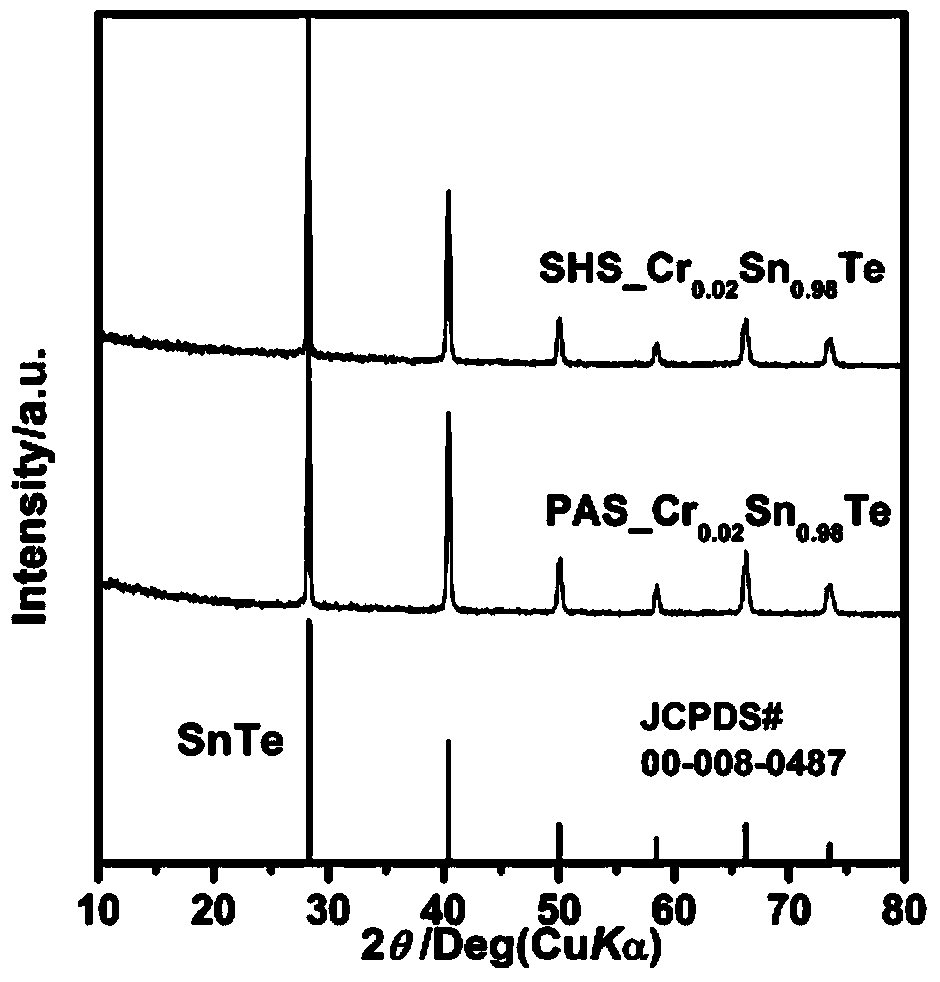

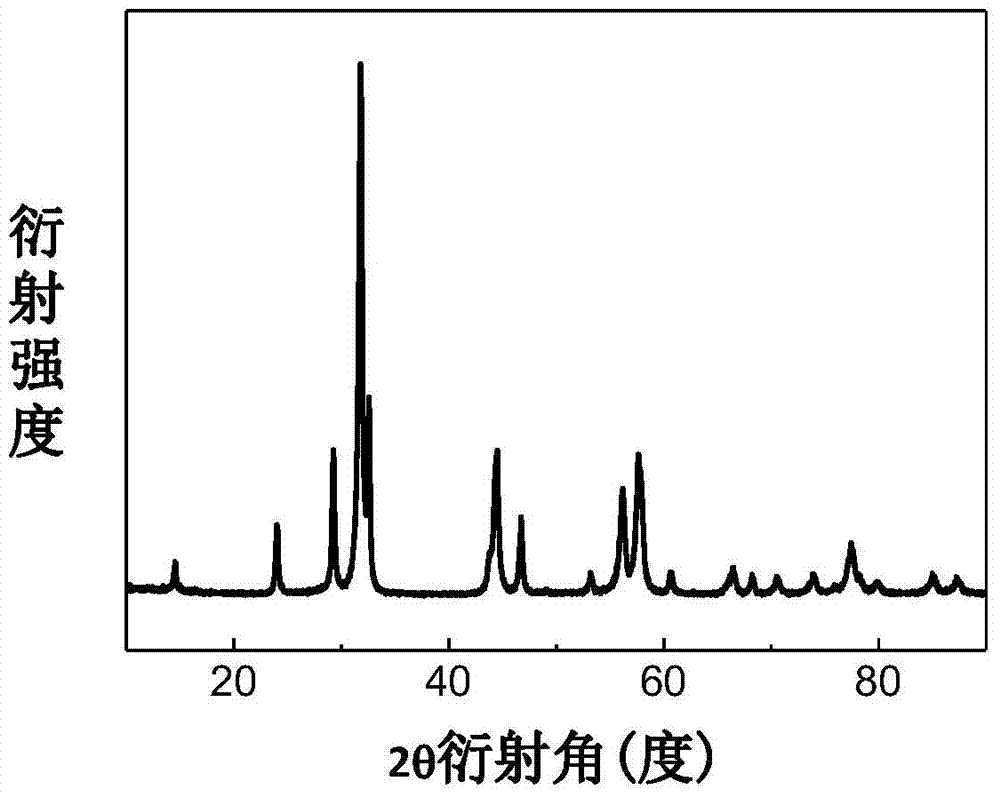

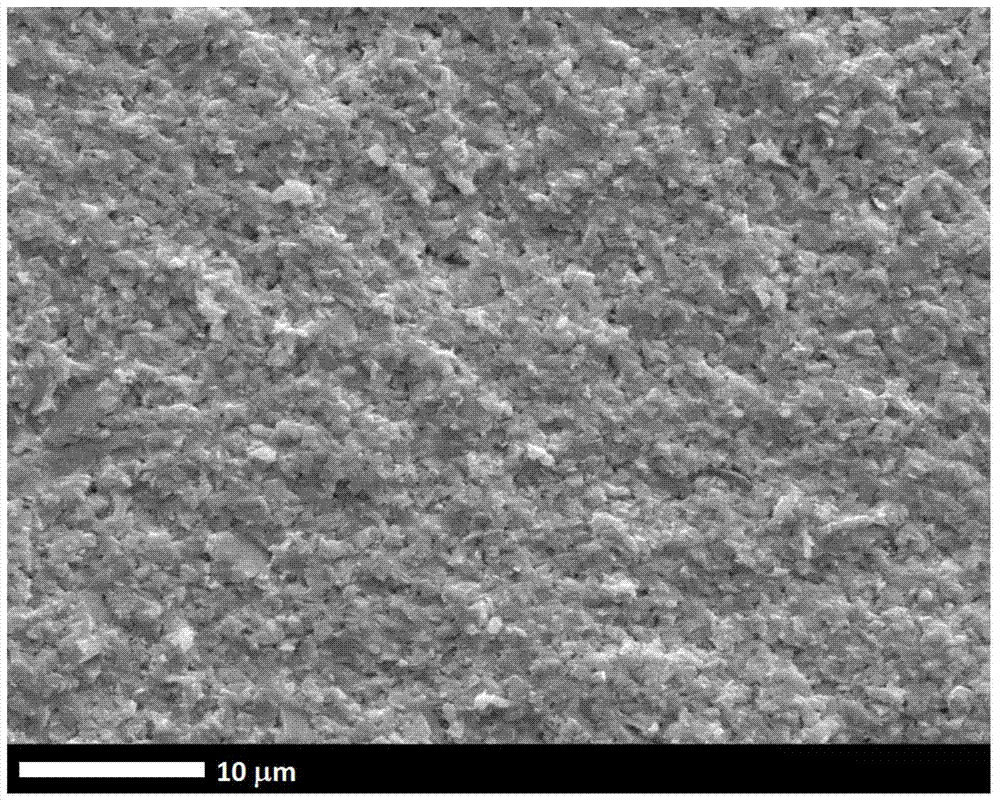

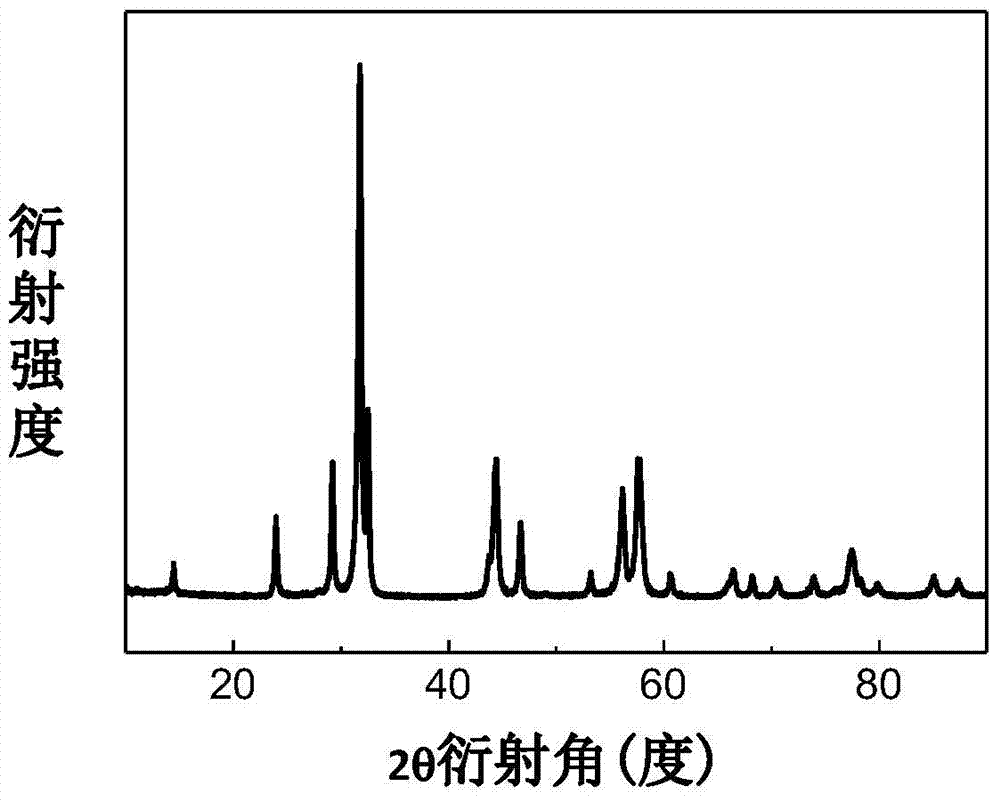

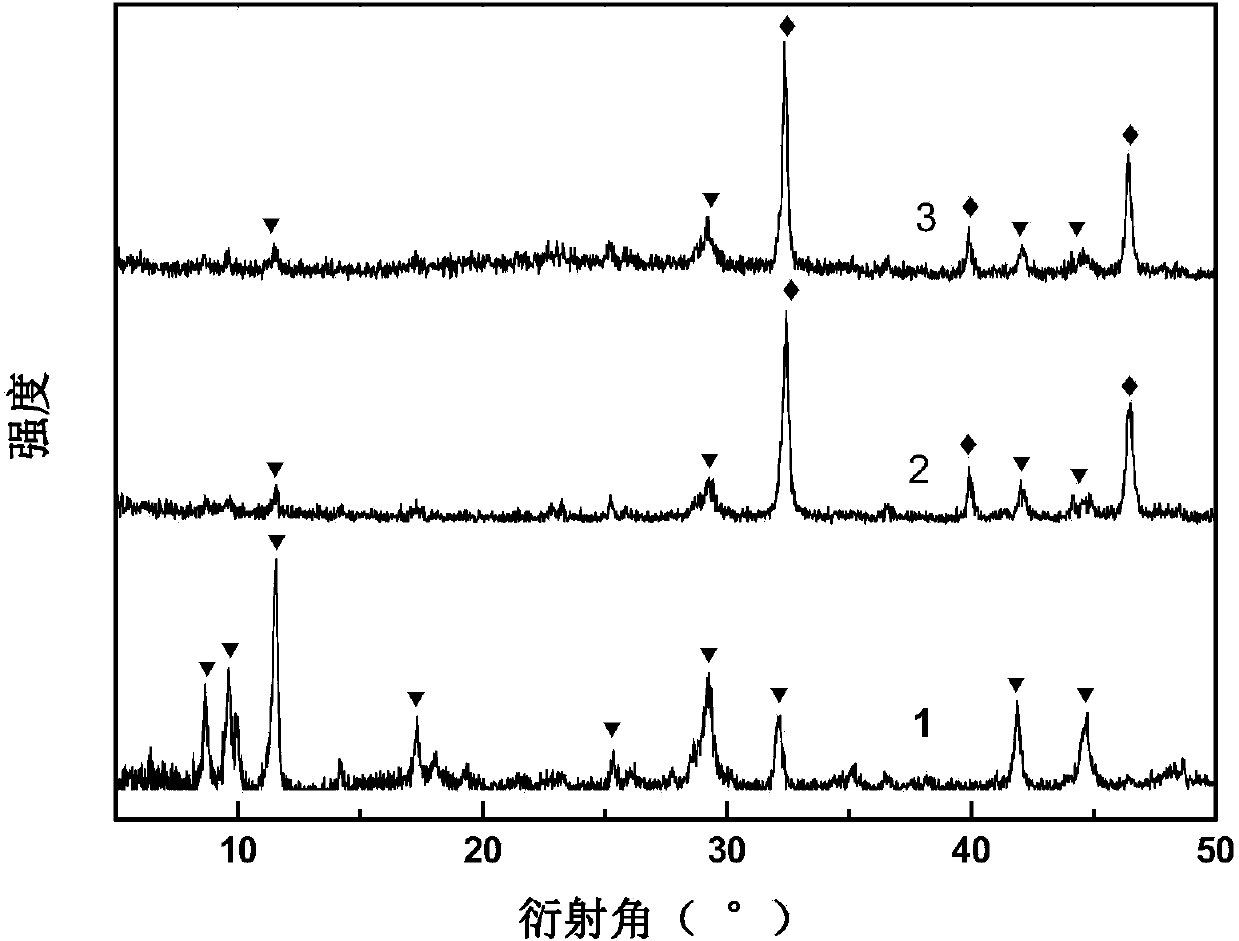

Ultrafast preparation method of high-performance SnTe based thermoelectric material

The invention relates to an ultrafast preparation method of a high-performance SnTe based thermoelectric material. The ultrafast preparation method comprises the following steps: weighing M powder, Sn powder and Te powder as raw materials according to the stoichiometric ratio of each element in the chemical formula MxSn(1-x)Te, wherein x is greater than or equal to 0 and less than or equal to 0.1, M refers to Cr, Co, Zn, Cd or In; next, grinding and evenly mixing the powder raw materials to obtain a reactant; 2) arousing a high-temperature self-propagating synthetic reaction of the reactant obtained in the step 1), and naturally cooling after the reaction is finished to obtain a single-phase SnTe based powdery thermoelectric material; 3) grinding the product obtained in the step 2) into powder, and performing spark plasma activated sintering to obtain the high-performance SnTe based bulk thermoelectric material. The ultrafast preparation method of the high-performance SnTe based thermoelectric material has the advantages of high reaction speed, simple process, efficient energy conservation, good repeatability and the like; the whole preparation process can be finished in 15 minutes, and the obtained thermoelectric figure ZT of merit of the obtained bulk material can be 1.01 at 910K.

Owner:WUHAN UNIV OF TECH

Processing method for improving performance of N-type bismuth telluride base powder sinter block thermoelectric material

ActiveCN104409623AImprove thermoelectric performanceIncreased ZT valueThermoelectric device manufacture/treatmentLow speedThermal insulation

The invention discloses a processing method for improving the performance of an N-type bismuth telluride base powder sinter block thermoelectric material. The method comprises the steps of placing an N-type bismuth telluride base block formed by thermal pressing in a mold, performing low-speed thermal deformation at 500-550 DEG C and under a pressure condition, controlling a change rate of the block in a height direction to be 0.2-3mm / min for 1-10min, then removing the pressure, performing thermal insulation for 2-60min, and repeating the procedure for at least one time. According to the processing method for improving the performance of the N-type bismuth telluride base sinter block thermoelectric material, the thermoelectric performance of the N-type bismuth telluride base material is greatly improved by using a repeated low-speed thermal deformation induction technology, and an optimal value can reach 1.2 which is the reported maximum value of an N-type material in the world at present.

Owner:浙江电联矿业科技发展有限公司

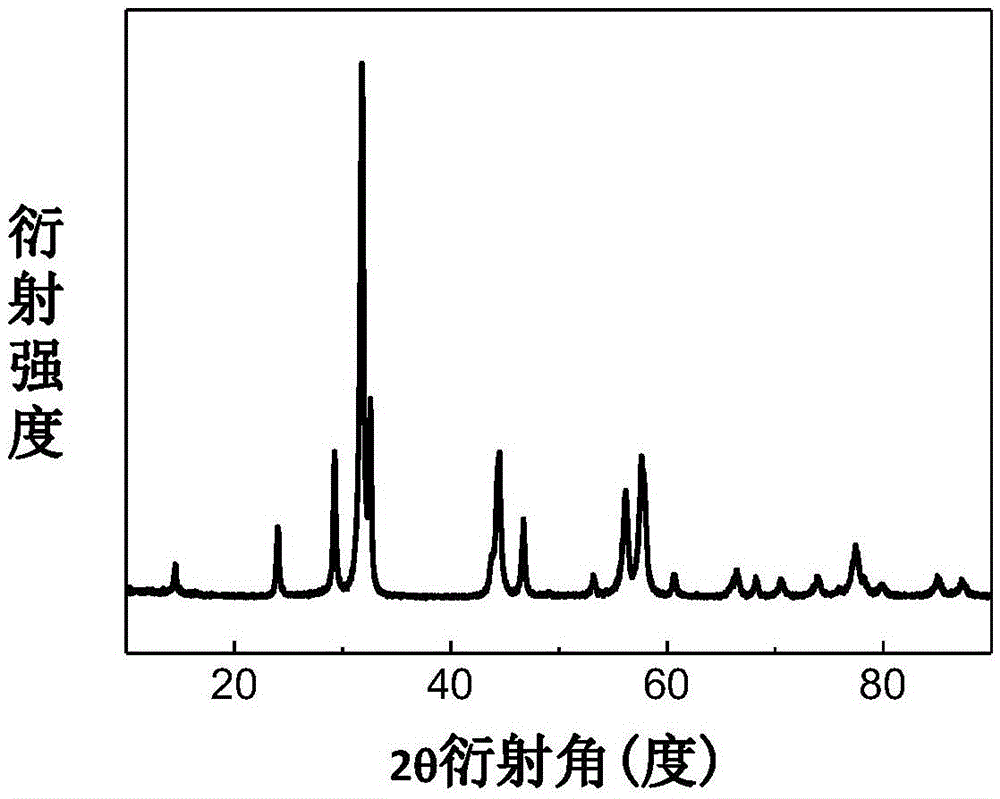

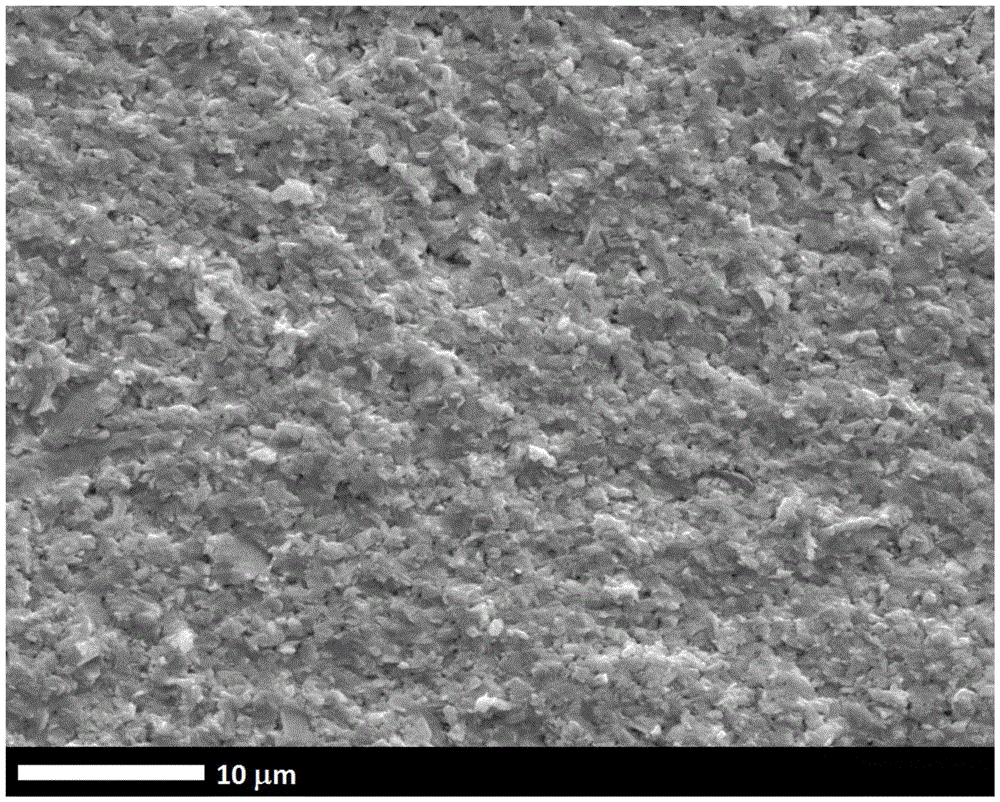

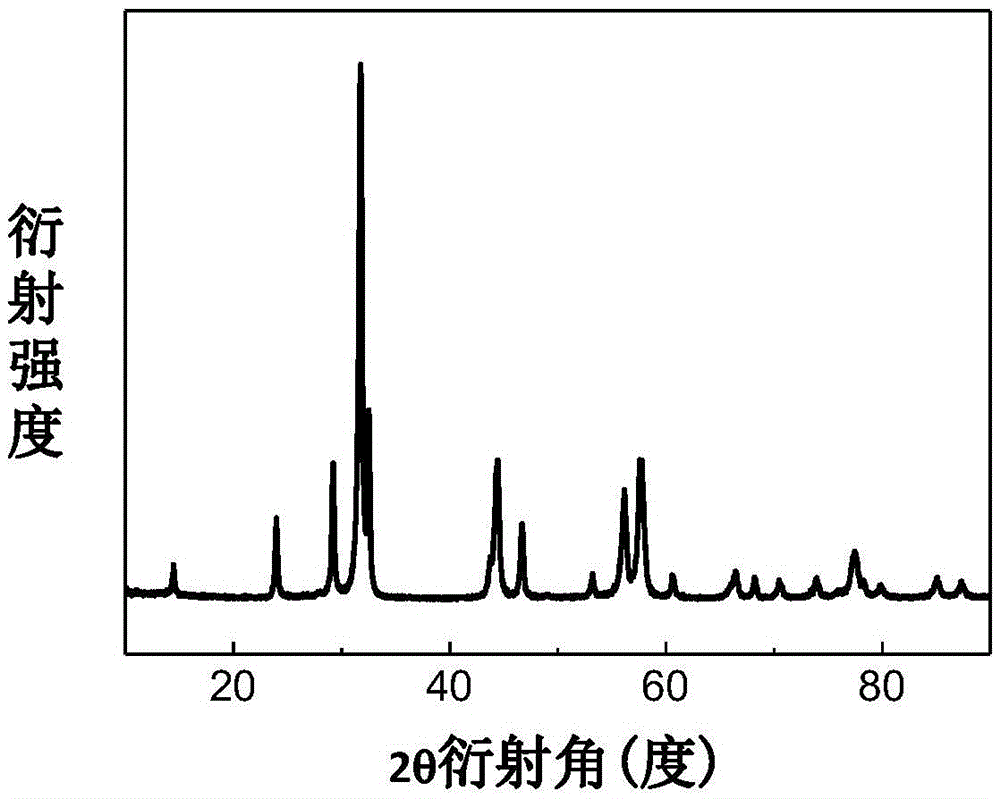

Bi2O2Se-based thermoelectric material and preparation method thereof

ActiveCN104261357ASignificant change in performanceHeating evenlySelenium/tellurium compounds with other elementsThermoelectric materialsOxide ceramic

The invention belongs to the field of oxide ceramic materials and preparation methods thereof and particularly relates to a Bi2O2Se-based thermoelectric material and a preparation method thereof. The method comprises the steps of firstly, weighing Bi2O3 powder, Bi powder, Se powder and SnO2 powder according to the stoichiometric ratio: Bi2-xSnxO2Se (0<=x<=0.10), mixing, then, carrying out vacuum tube sealing, and calcining to finish a phase forming stage; and compacting the calcined powder, and sintering by using SPS discharge plasmas to obtain the pure-phase and Sn doped Bi2O2Se-based thermoelectric material. Compared with the traditional hot-pressed sintering method, the preparation method has the advantages of uniformity in heating, high heating speed, short sintering time and the like; the defects of long reaction time, high sintering energy consumption, high operation difficulty and the like in the prior art can be effectively overcome; and the performance of a sintered sample is obviously changed, and the ZT value of the Bi2O2Se-based thermoelectric material can be greatly increased after Sn is doped.

Owner:TSINGHUA UNIV

A preparation method for antimonide molybdenum base thermoelectric material

ActiveCN101217178AShort synthesis timeHigh densityThermoelectric device manufacture/treatmentIncreasing energy efficiencyThermoelectric materialsArc melting

The invention relates to a doping molybdenum antimonide-based thermoelectric material and the preparation method, which is characterized in that the invention adopts arc melting and discharging plasma rapid sintering method for combination. The preparation method which is provided by the invention is the arc melting and the discharging plasma rapid sintering; Sb and Te / Se are firstly melted to form Sb2Te3Sb2Se3 and then are treated with the arc melting with the stoichiometric ratio of Mo and Sb; finally, the discharging plasma rapid sintering technology is introduced for preparing a dense single-phase material. The invention provides the rapid, simple and effective preparation method of the molybdenum antimonide-based thermoelectric material, which has good practical prospect.

Owner:江苏先进无机材料研究院

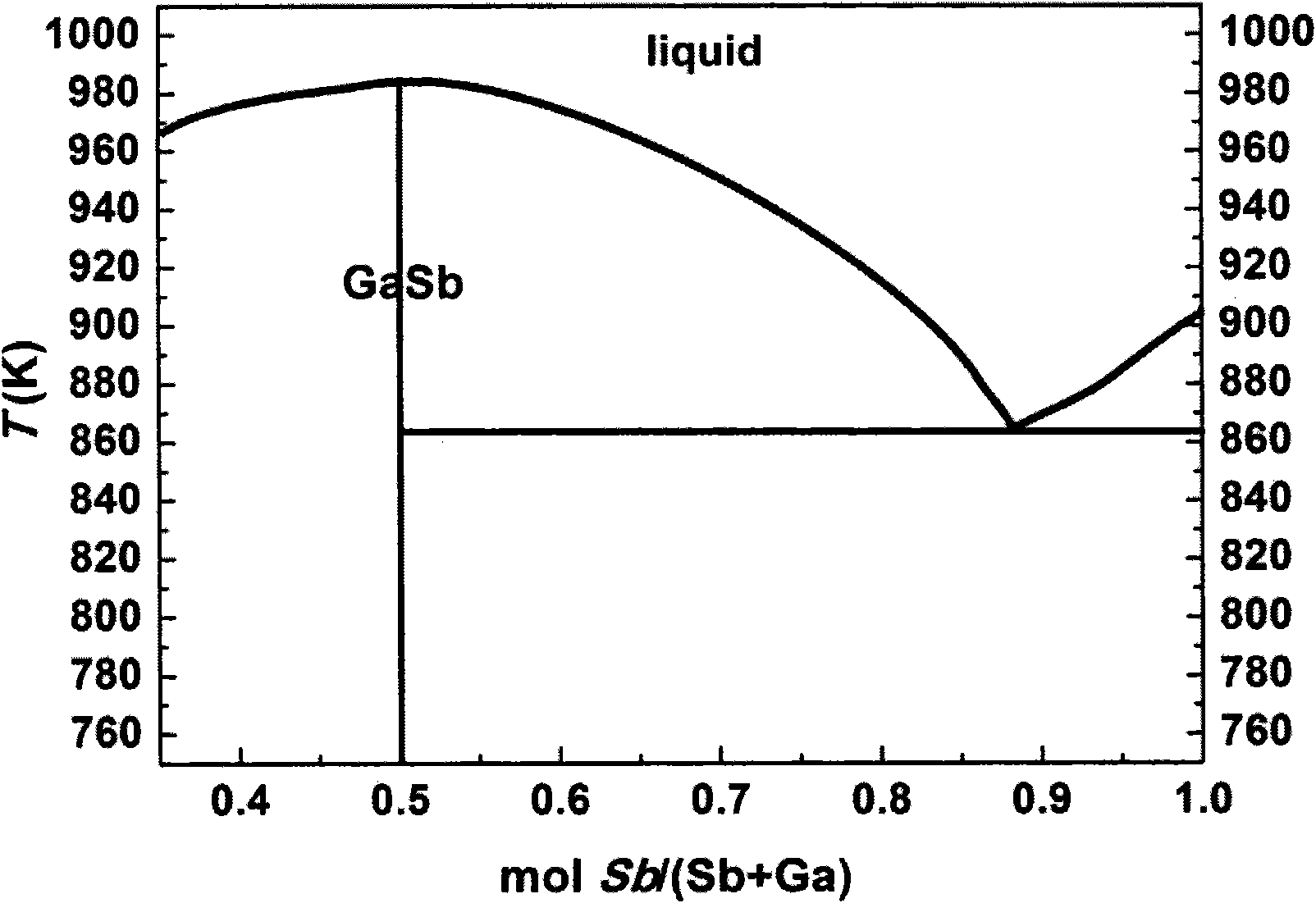

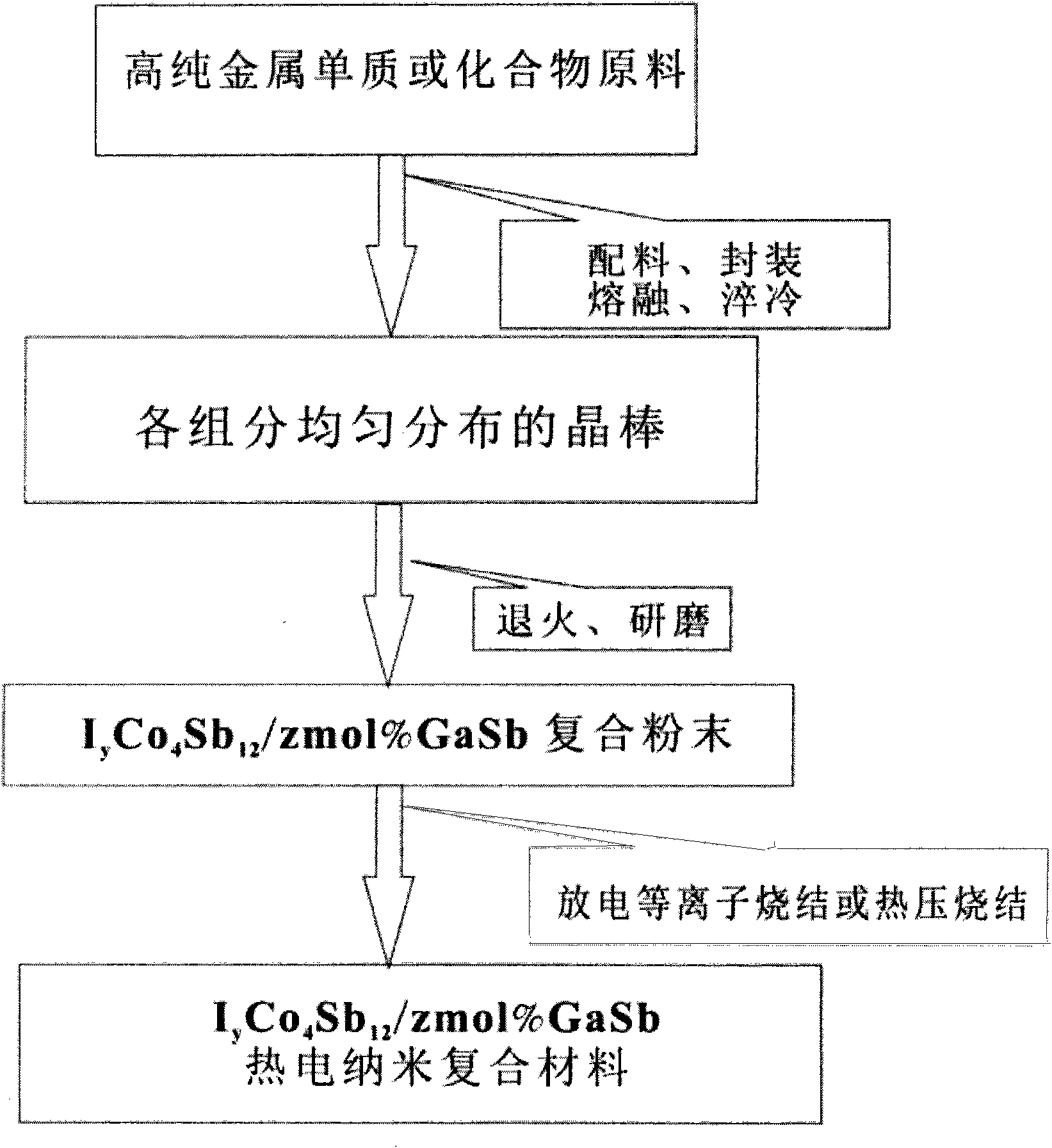

Composite material of skutterudite filling substrate and preparation method thereof

InactiveCN102031416AImprove Seebeck coefficientLow thermal conductivityMaterial nanotechnologyGallium/indium/thallium compoundsCompound aSkutterudite

The invention provides a composite material. The composite material comprises a skutterudite filling substrate shown as the following formula (I): IyCo4Sb12 (1), wherein I is at least one of Yb, Eu, Ce, La, Nd, Ba and Sr, and y is less than 1 and not more than 0.05. The composite material further comprises GaSb particles distributed in the skutterudite filling substrate, wherein the composite material contains 0.05-5 mol% GaSb particles. Compared with the thermoelectric material substrate without compounding a nanometer GaSb phase, the Seebeck coefficient of the composite material is improved to a large extent, the total heat conductivity is slightly reduced, the thermoelectric performance index ZT value is greatly increased in the whole high temperature and low temperature zone range, and the thermoelectric conversion efficiency of the material is greatly improved. The composite material has simple process and favorable industrialization prospect and is easy to control.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

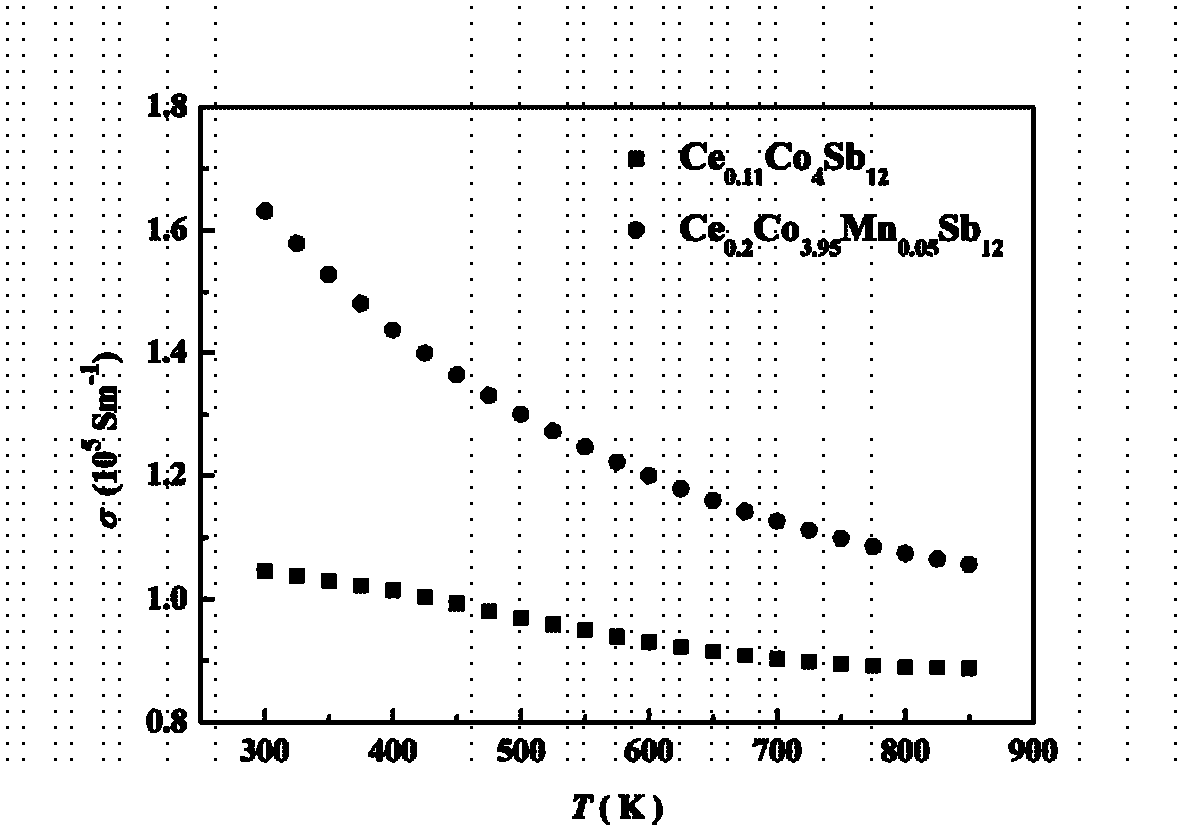

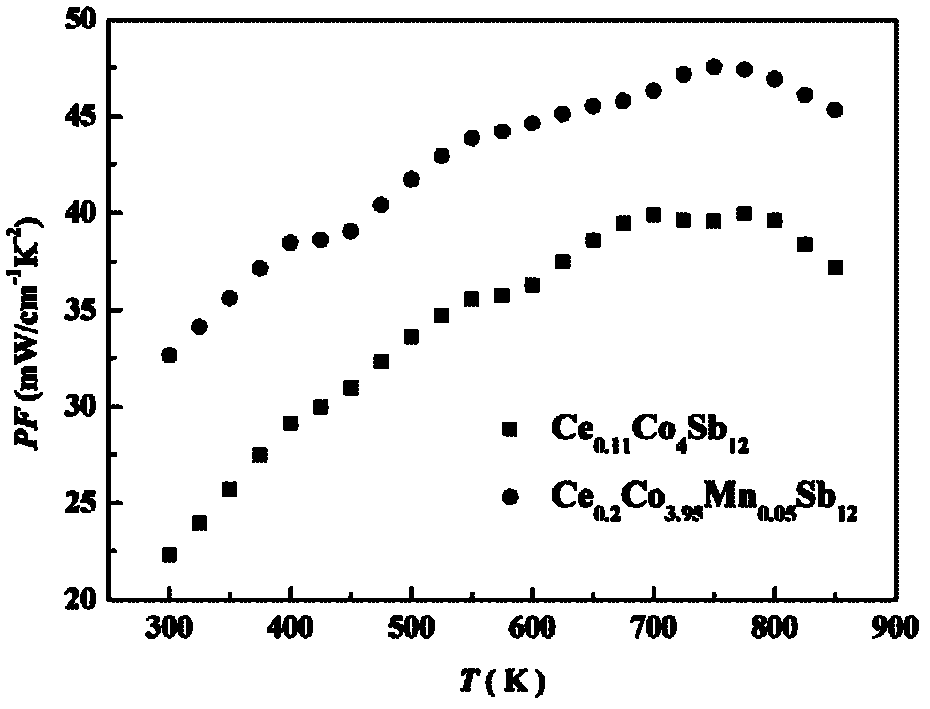

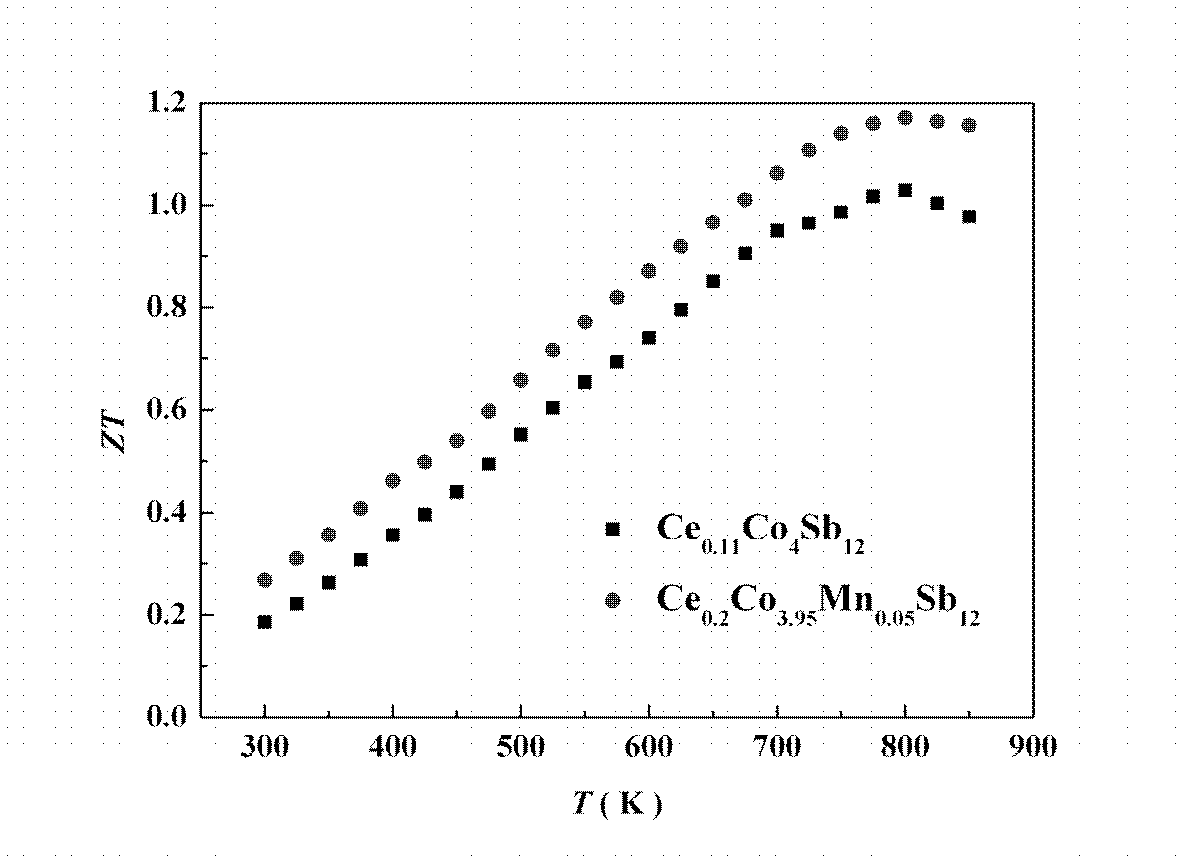

Hole compensation type skutterudite thermoelectric material and preparation method therefore

ActiveCN102881814AIncrease filling volumeHigh conductanceIron compoundsCobalt compoundsSkutteruditeElectron number

The invention relates to a hole compensation type skutterrudite thermoelectric material and a preparation method of the hole compensation type skutterudite thermoelectric material. The hole compensation type skutterudite thermoelectric material is shown in the following description: RyA(4-x)BxSb12 / z NC, wherein x is equal to or greater than 0.01 and equal to or less than 0.5, y is equal to or greater than 0.01 and equal to or less than 1 and z is equal to or greater than 0% and equal to or less than 10%; R is selected from at least one of the following group of elements: Ca, Ba, La, Ce, Pr, Nd and Yb; A is selected from at least one of the following group of elements: Fe, Co and Ni; B is selected from at least one of the following group of transition metal elements: Ti, V, Cr, Mn, Fe, Nb, Mo, Tc and Ru, and electron number of the element B is less than that of the element A; and NC is in phase II, wherein z is mole% in the phase II of the thermoelectric material. The invention also provides the preparation method of the hole compensation type skutterrudite thermoelectric material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

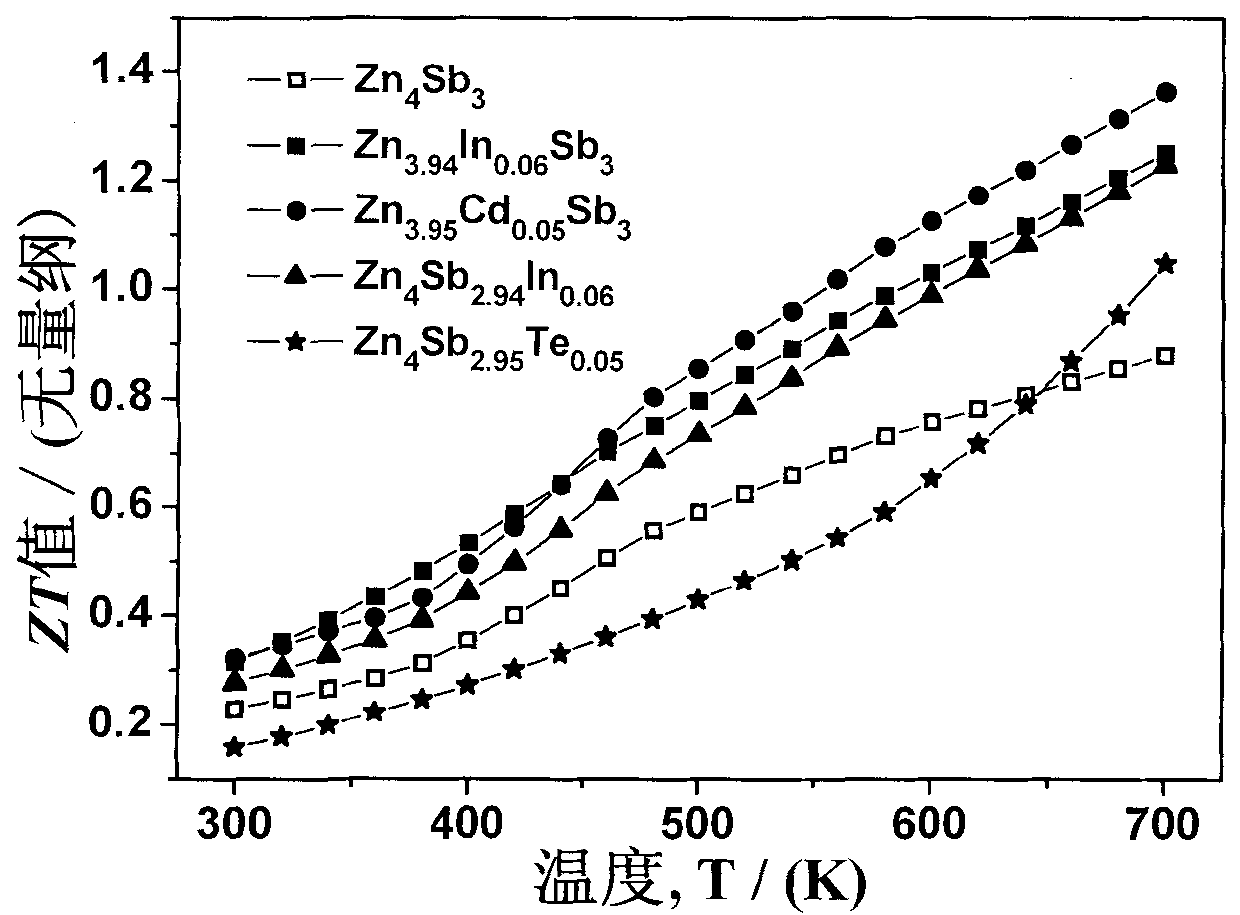

P-type Zn4Sb3 based thermoelectric material and preparation method thereof

The invention relates to a p-type Zn4Sb3 based thermoelectric material and a preparation method thereof, which belongs to the field of thermoelectric conversion new-energy materials. The chemical formula of the thermoelectric material is (Zn4-xTx) 4 (Sb3-yMy) 3, wherein T is an element In, Cd, Mg or Pb, and x is the doped stoichiometric ratio of T and has the range of 0 < / = x < / = 0.2; and M is Te, Sn or In, and y is the doped stoichiometric ratio of M and has the range of 0< / = y< / =0.2. A preparation method of fusing mother alloy at high temperature, quenching a melt and quenching the mother alloy via sintering discharging plasma under the protection of vacuum or inert gas is adopted. The ZT value of the prepared undoped p-type Zn4Sb3 thermoelectric material reaches 0.88, the ZT value of the doped material can be further improved, and the material can be used in the field of thermoelectric conversion power generation or refrigeration. The preparation method has the characteristics of simple process, short preparation cycle and low energy consumption, and is suitable for industrial production.

Owner:WUHAN UNIV OF TECH

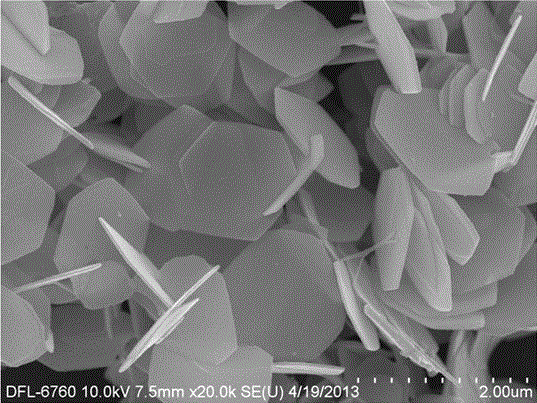

Manufacturing method of nanometer hexagonal sheet-shaped bismuth telluride thermoelectric material

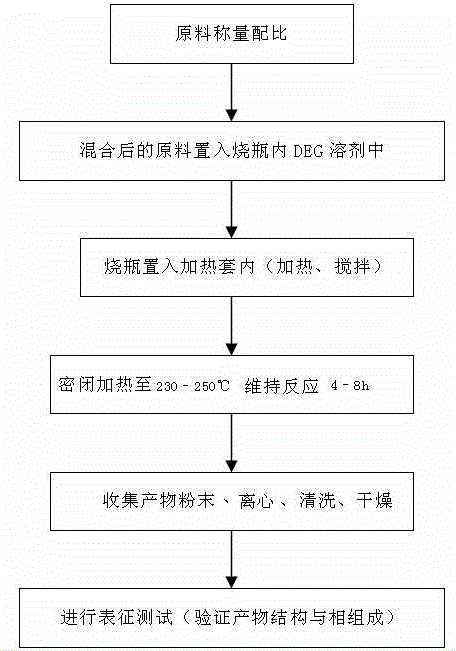

ActiveCN103910341AImprove thermoelectric performanceIncreased ZT valueMaterial nanotechnologyBinary selenium/tellurium compoundsOrganic solventBismuth telluride

A manufacturing method of a nanometer hexagonal sheet-shaped bismuth telluride thermoelectric material orderly comprises: a tellurium bismuth mixing process, an adjusting process, a sealing heating stirring process, and a purification process. The tellurium bismuth mixing process comprises: preparing a mixture of Bi and Te with a mol ratio of 2:3, and dissolving the mixture in an organic solvent to obtain a mixed solution; the adjusting process comprises: adding NaOH and polyvinylpyrrolidone to adjust the shape and size of the product; the sealing heating stirring process comprises: heating and performing heat insulation of the product under a sealing and stirring condition; the purification process comprises: purifying the product by centrifugation, cleaning, and drying. The design of the invention not only prepares the nanometer hexagonal sheet-shaped bismuth telluride thermoelectric material with a controllable product shape, but also is few in process links, short in period, low in energy consumption, and low in cost.

Owner:DONGFENG COMML VEHICLE CO LTD

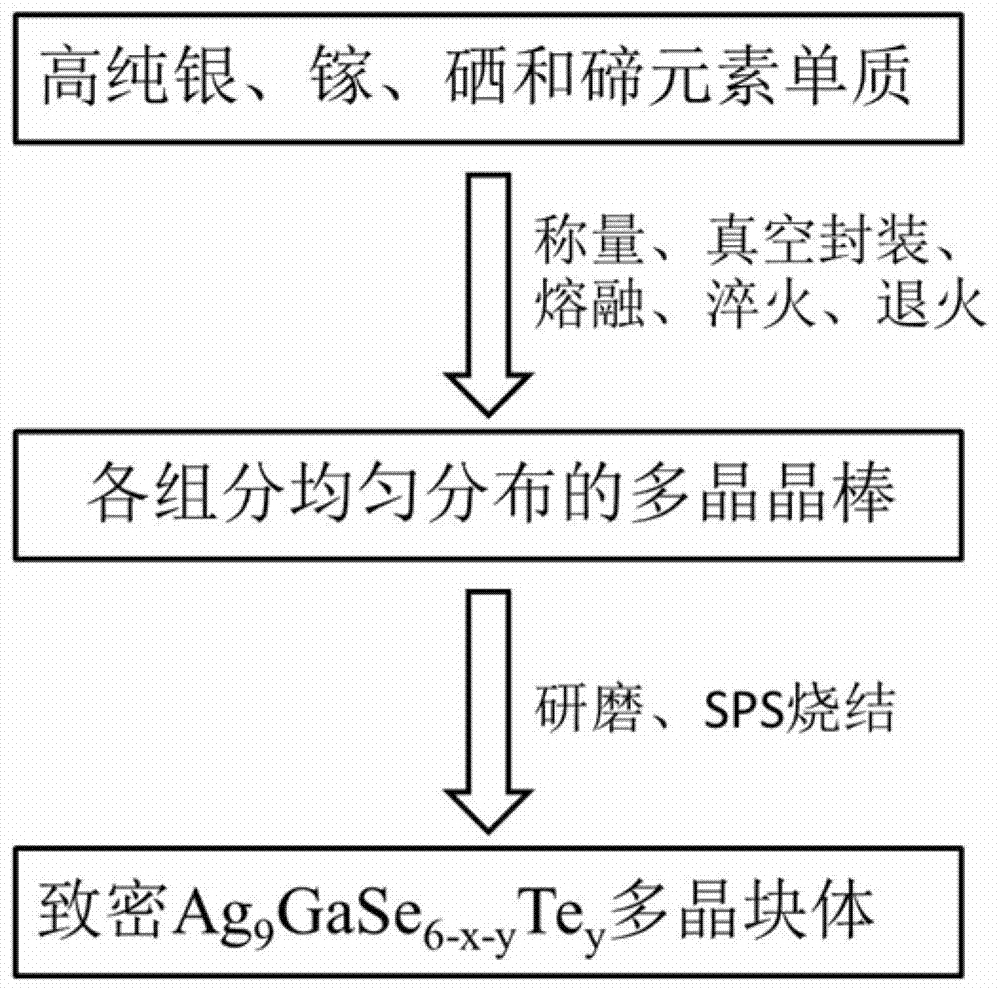

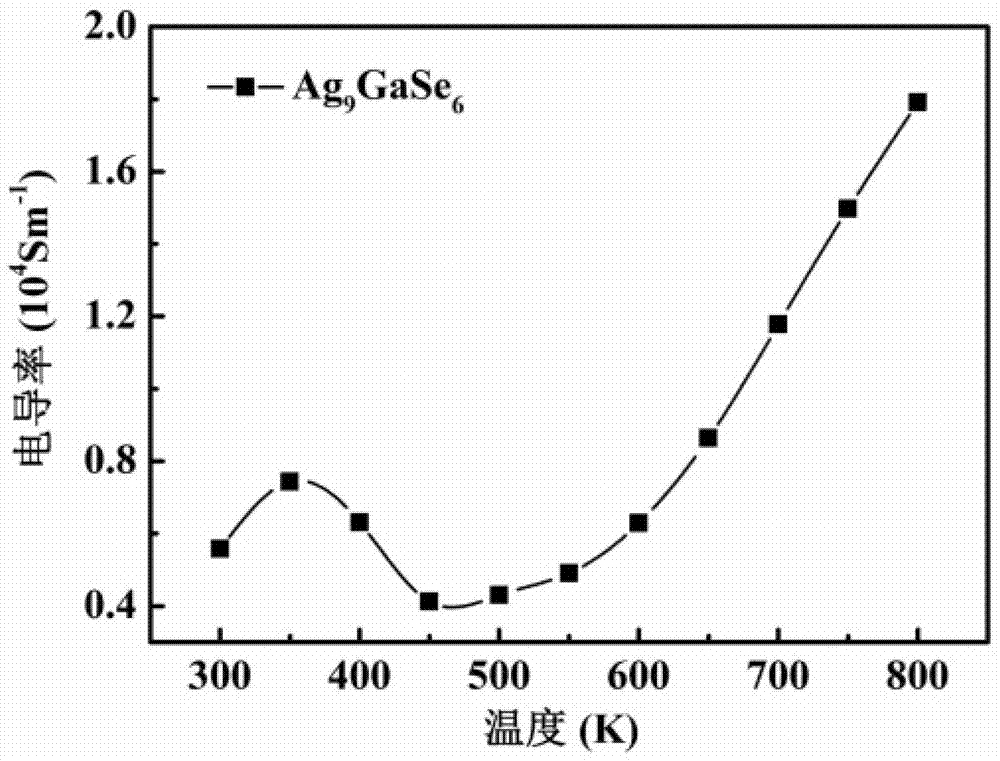

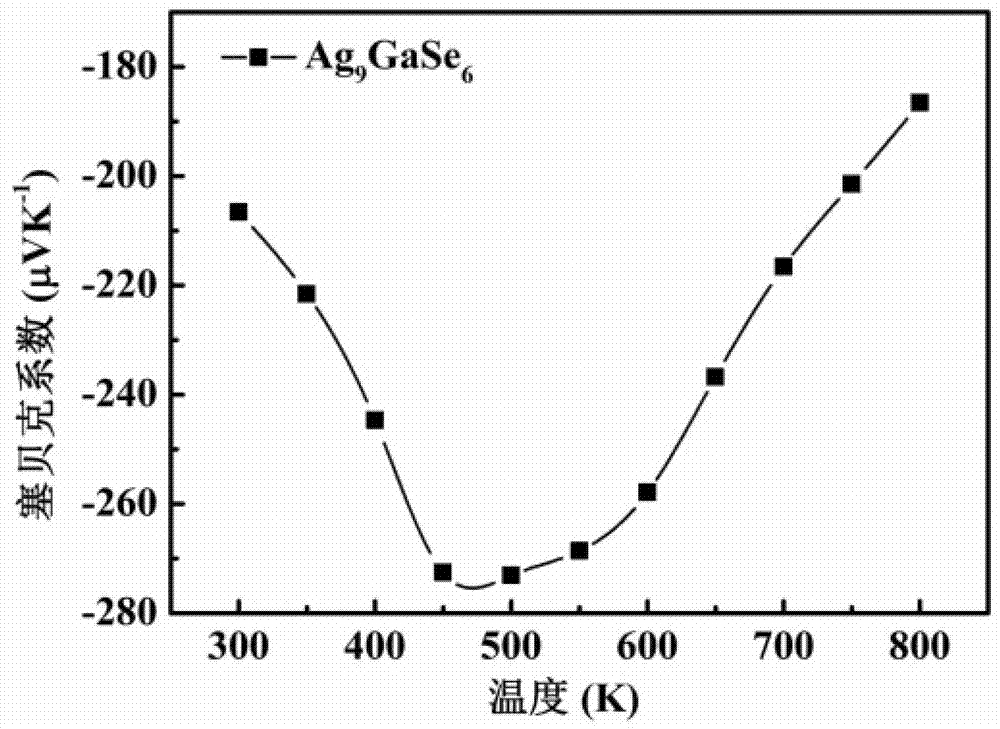

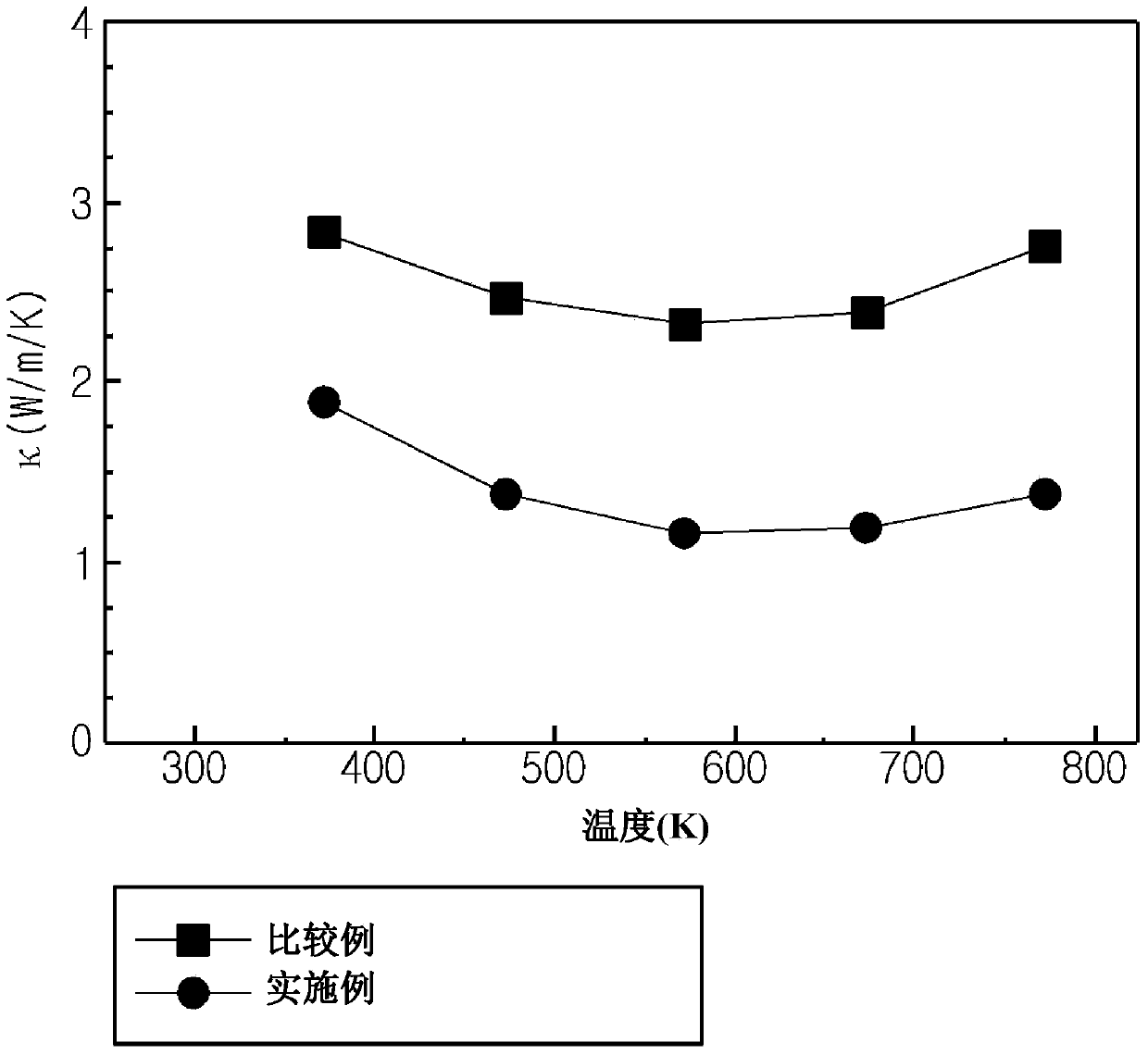

High-performance N type argyrodite thermoelectric material and preparation method thereof

InactiveCN107235477ALow thermal conductivityIncreased ZT valueSelenium/tellurium compounds with other elementsThermoelectric device junction materialsThermoelectric materialsChemical composition

The invention relates to a high-performance N type argyrodite thermoelectric material and a preparation method thereof. The chemical composition of the argyrodite thermoelectric material is Ag9GaSe(6-x-y)Tey, wherein x is larger than or equal to 0 and smaller than or equal to 0.03, y is larger than or equal to 0 and smaller than or equal to 0.75, and x and y are not equal to 0 at the same time. The provided semiconductor material has very low thermal conductivity ranging from 0.25 Wm<-1>K<-1> to 0.65 Wm<-1>K<-1>. The electric conductivity of the semiconductor material can be regulated in a very wide range and can range from 10,000 Sm<-1> to 60,000 Sm<-1>.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

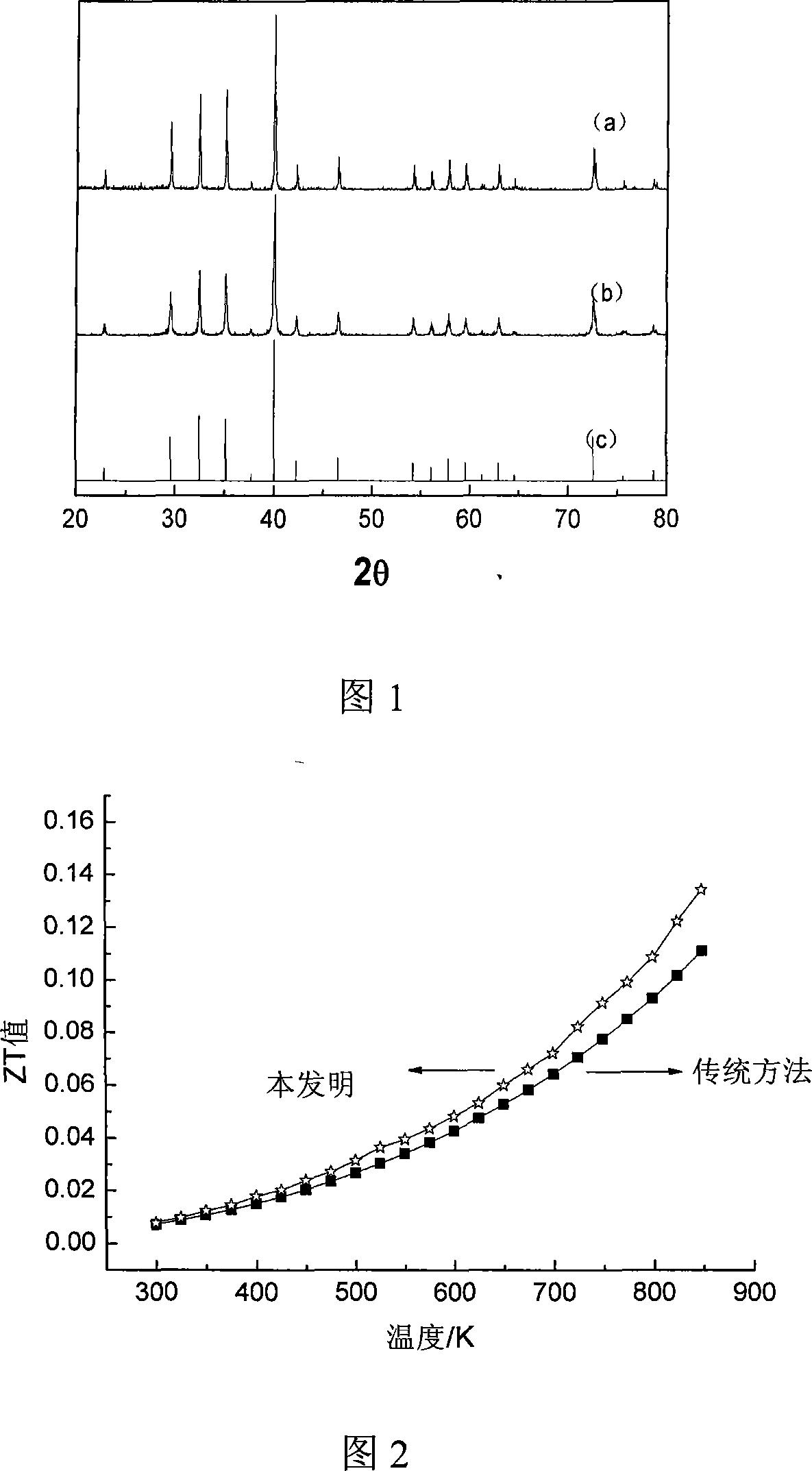

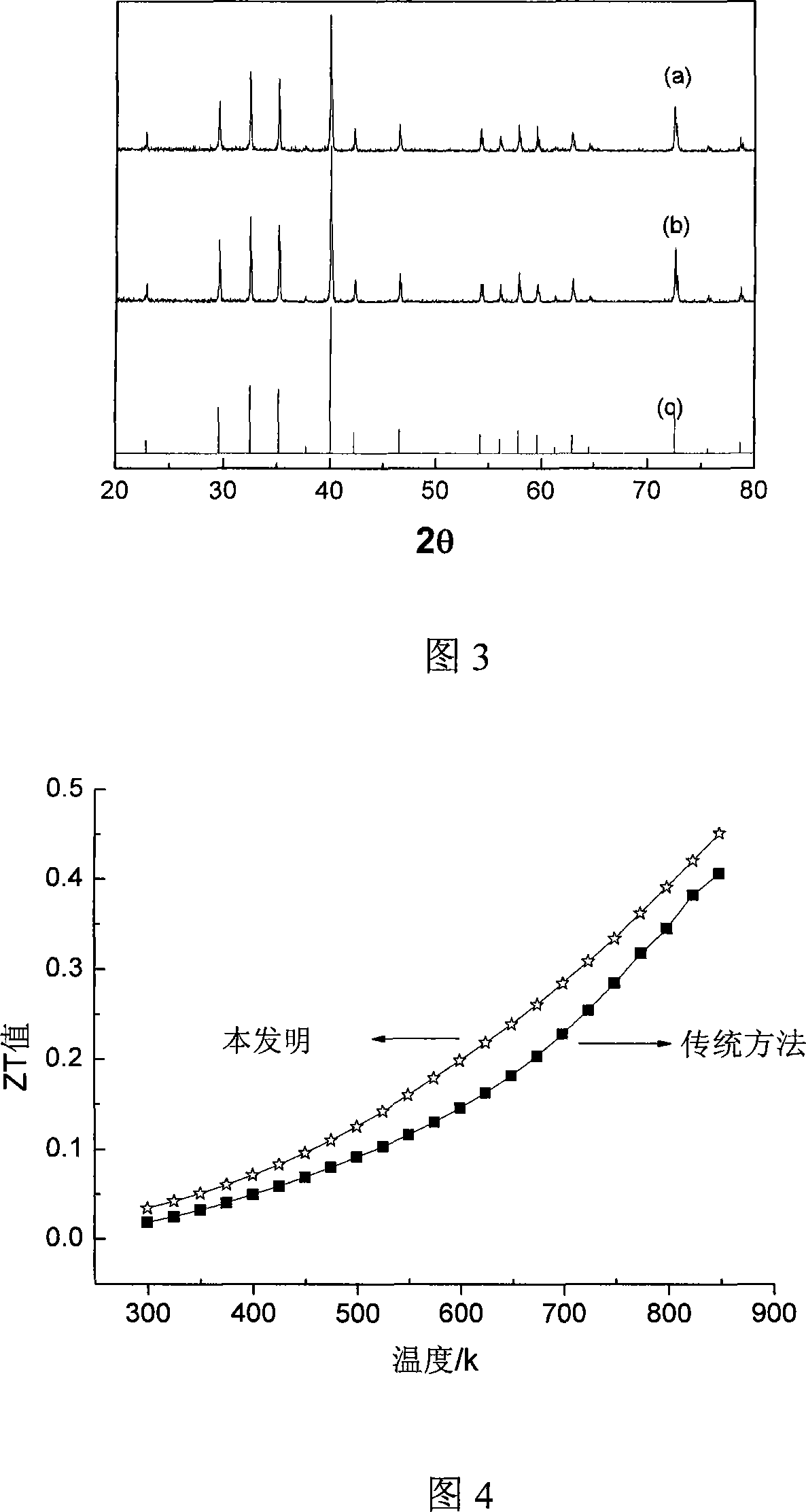

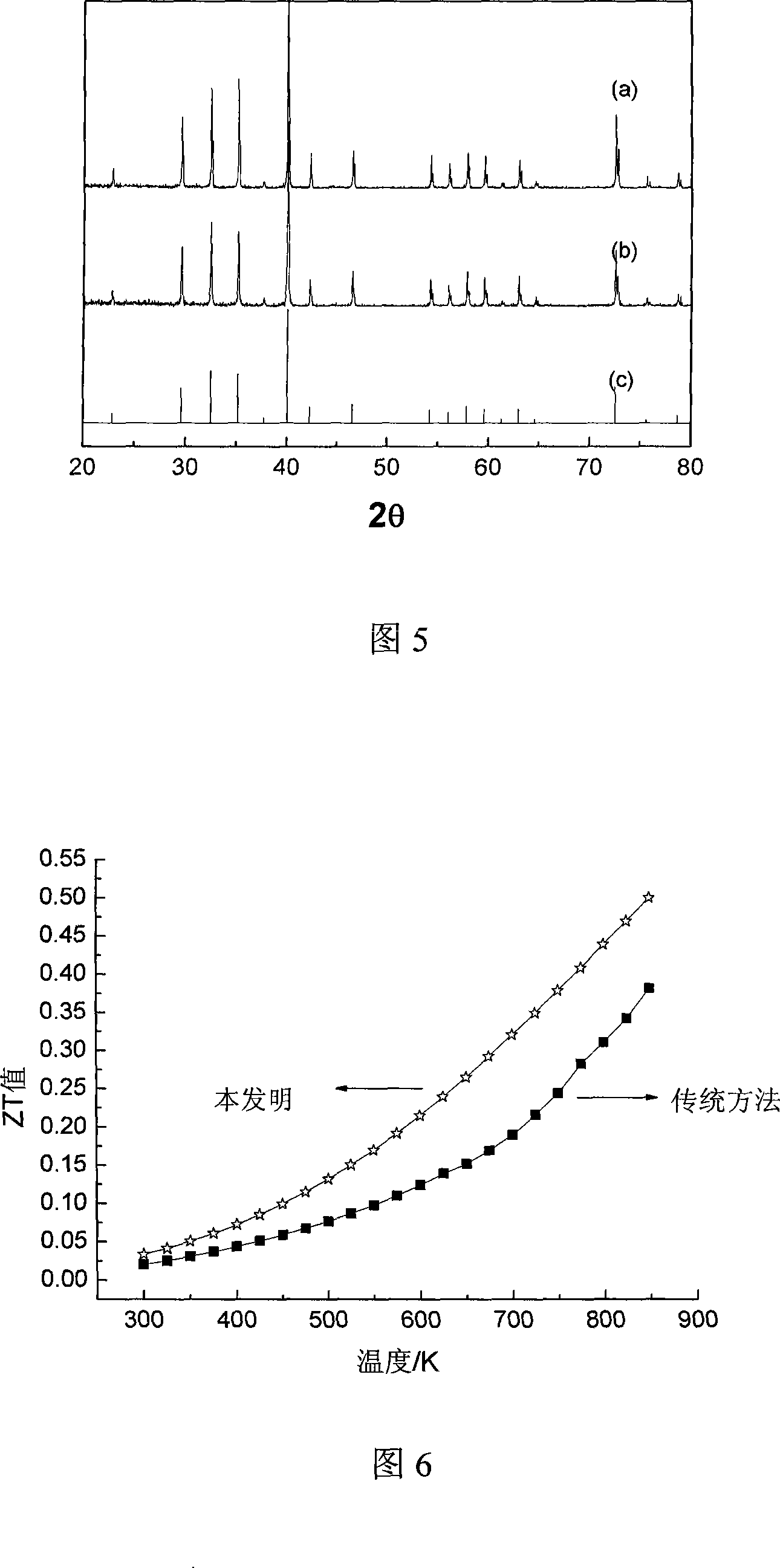

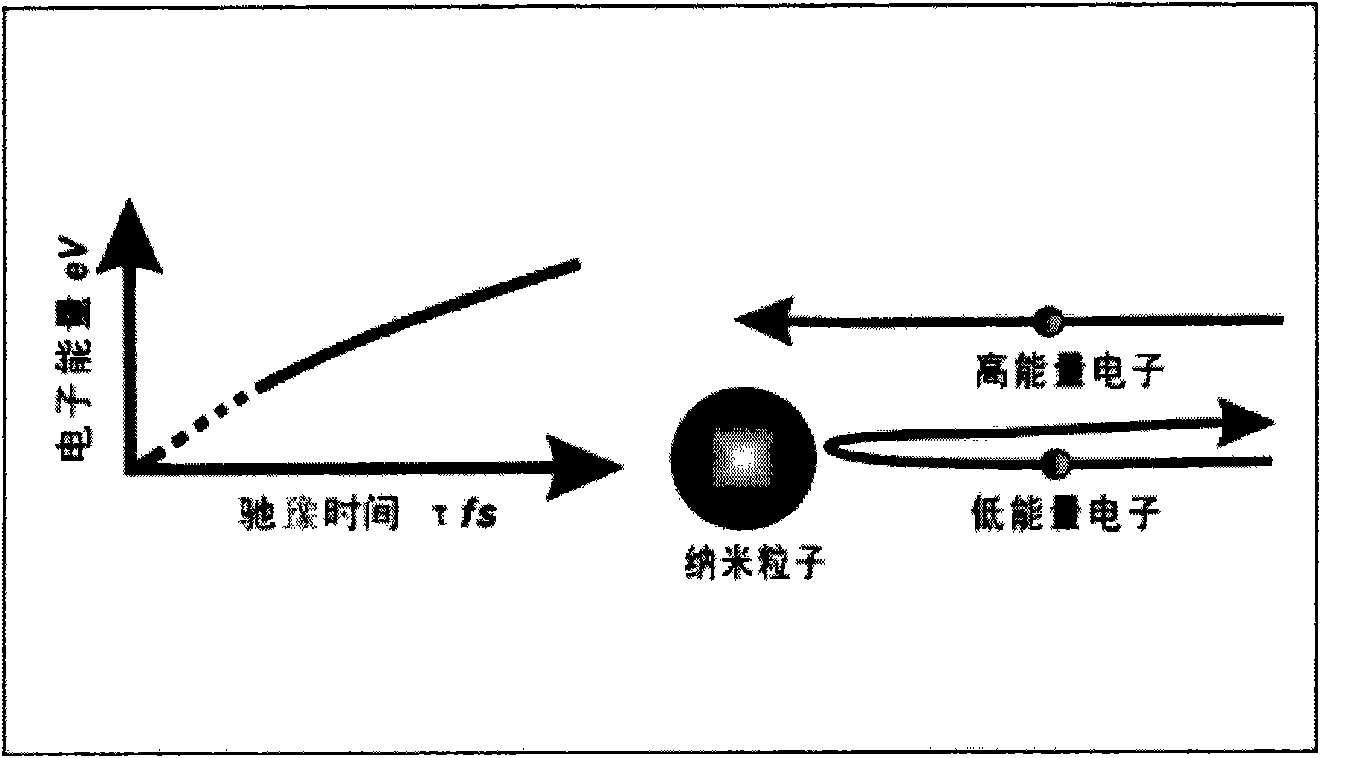

Method for preparing high-thermoelectric-property metal oxide

The invention discloses a method for preparing a high-thermoelectric-property metal oxide. The method comprises the following three steps of a, synthesizing metal oxide nano particles which are doped with heteroatom; b, mechanically ball milling and mixing the nano particles; and c, sintering the metal oxide nano particles. The metal oxide nano particles doped with the heteroatom prepared by adopting a burning method are simple and rapid to synthesize in one step, and the repetition is high. By adopting the method, the power factor which is related to the electric performance can be maximally increased while the heat conductivity is reduced, so that the ZT (zone time) value, i.e. the thermoelectric property, of a thermoelectric material can be greatly increased.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

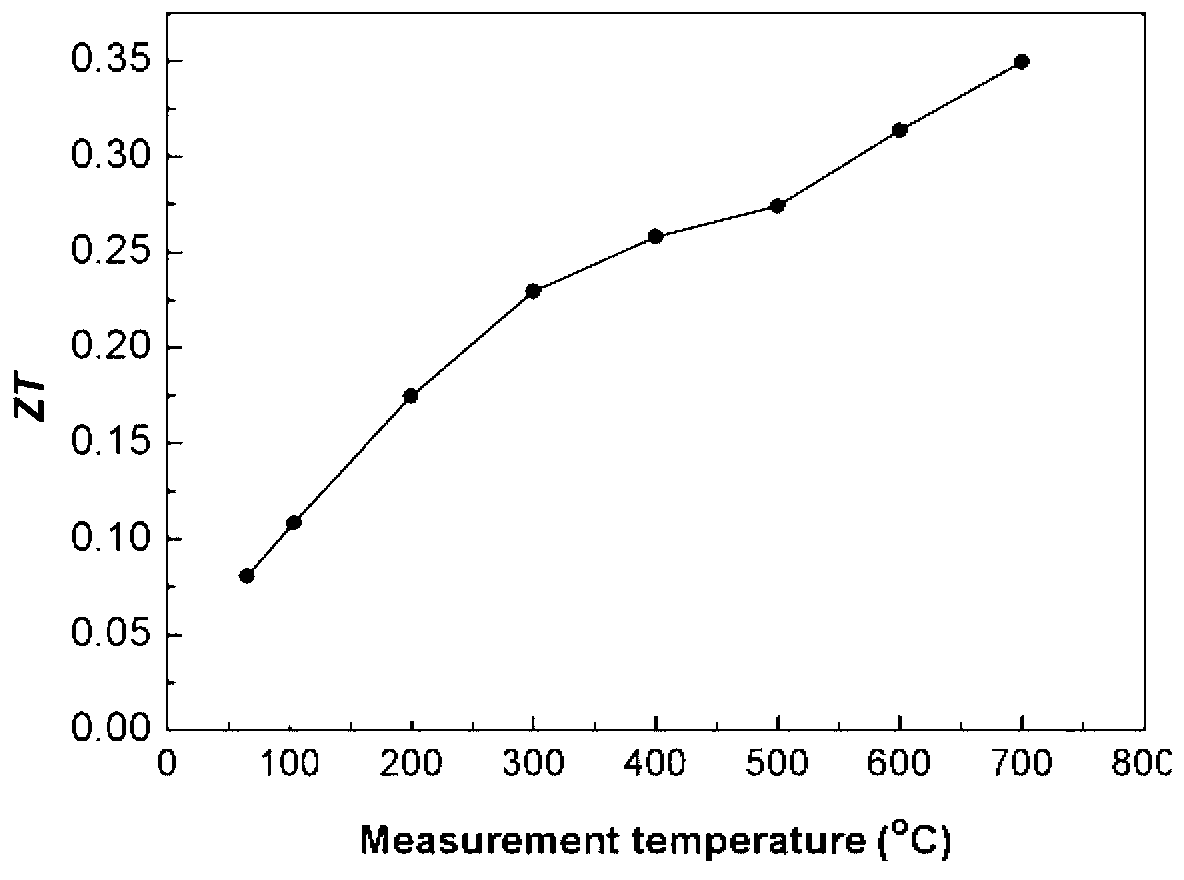

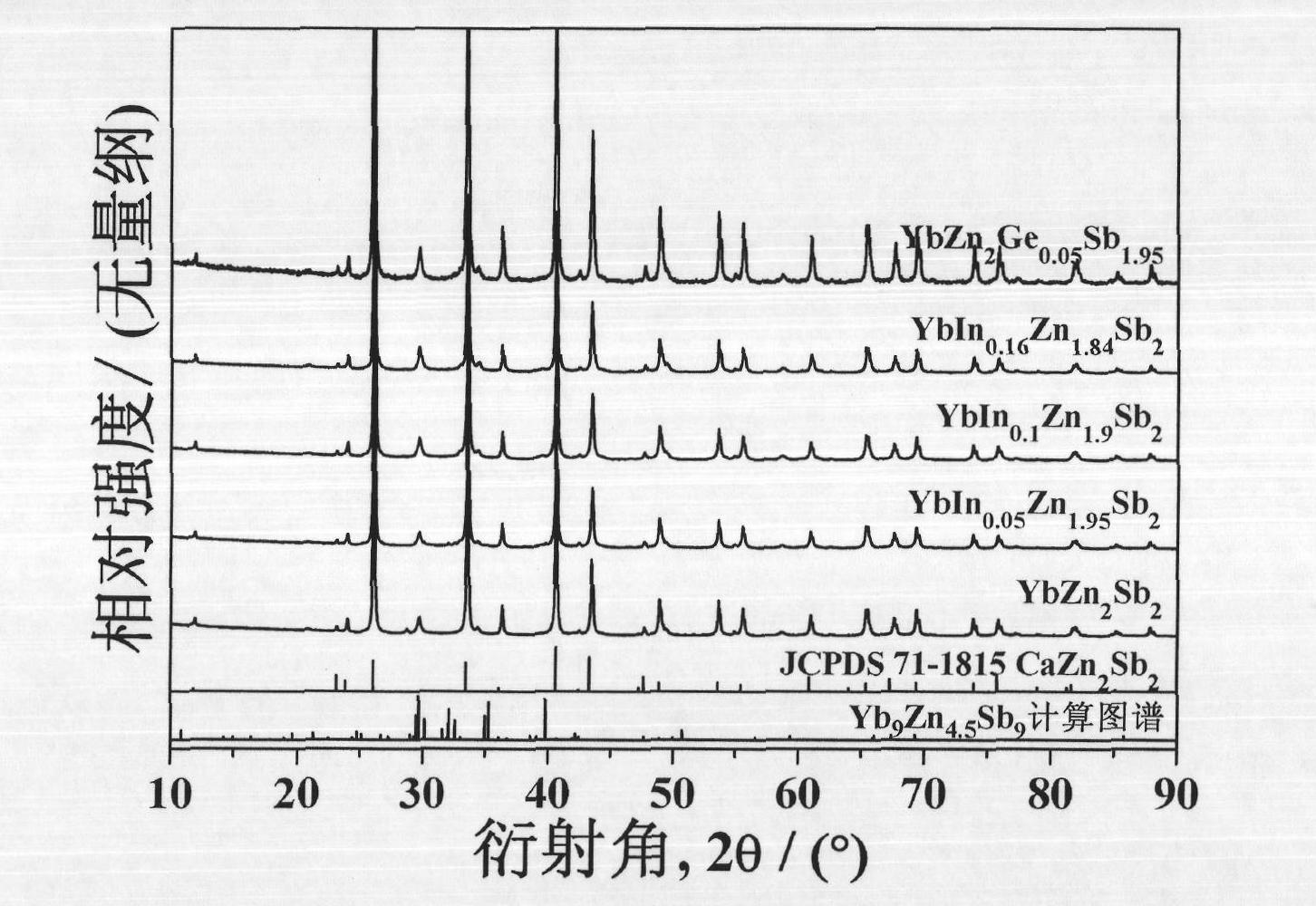

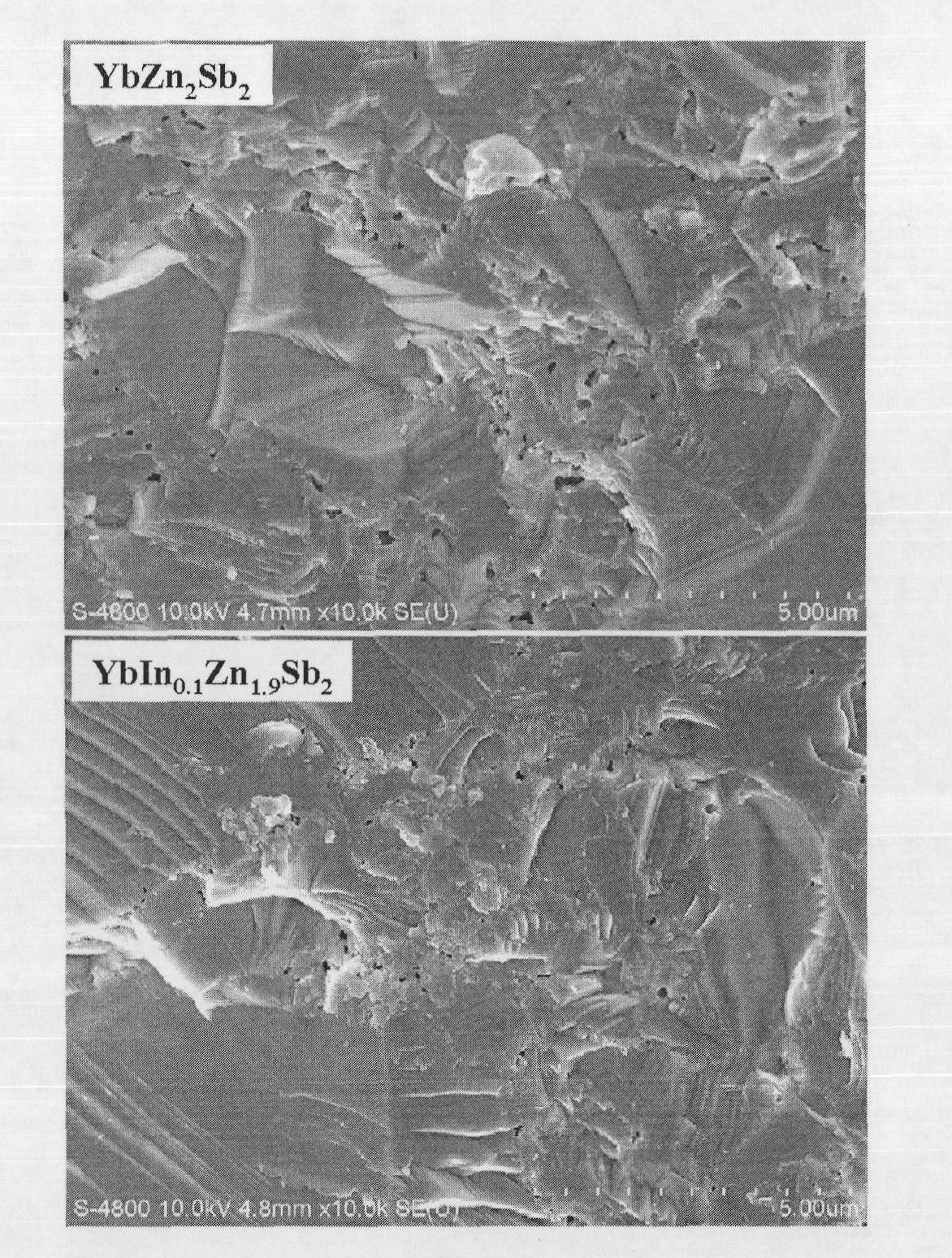

Zinc antimony based porous p-type thermoelectric material and preparation method thereof

InactiveCN101857929AShort manufacturing cycleConducive to large-scale industrial productionThermoelectric materialsMelt quenching

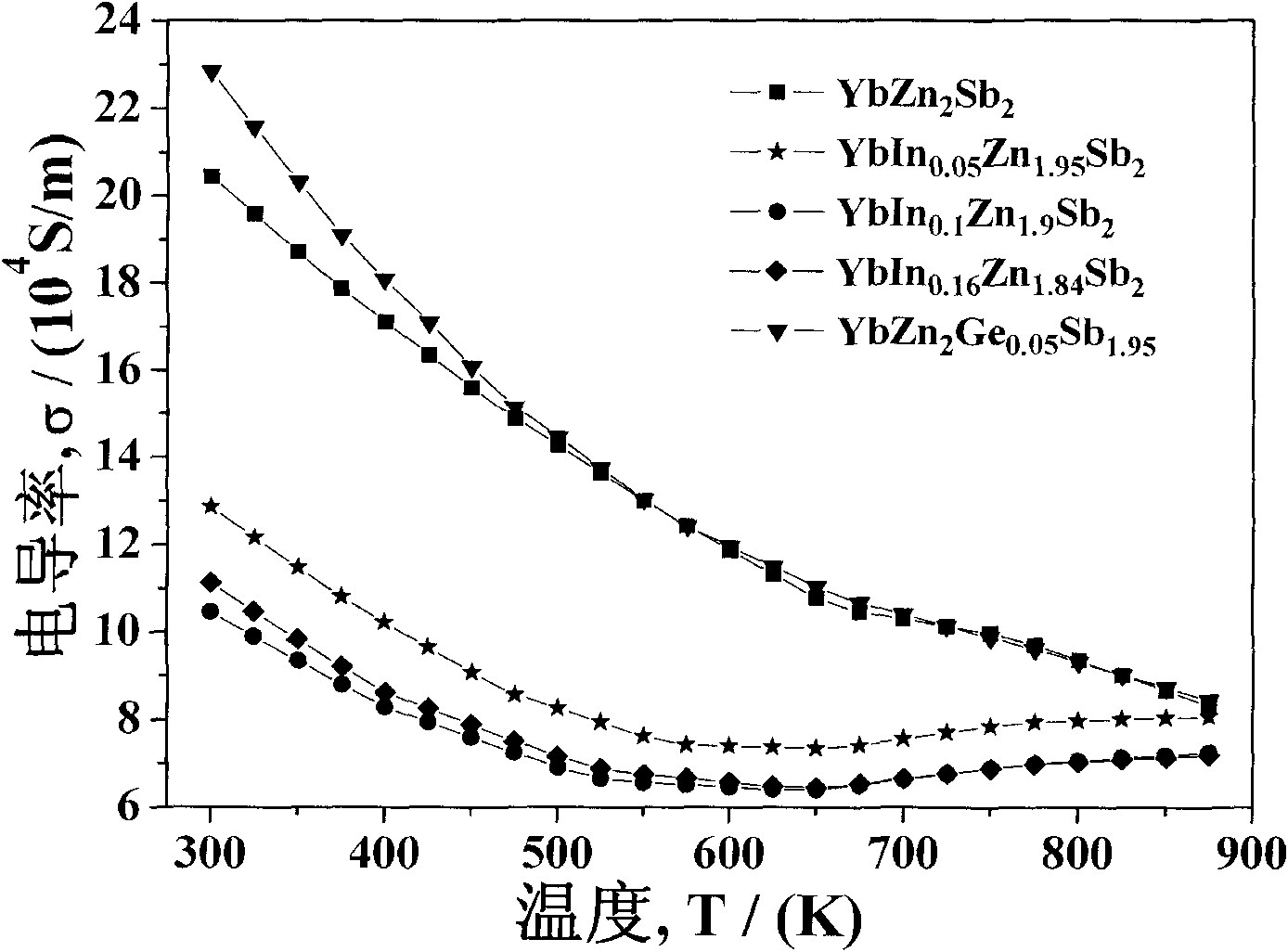

The invention relates to a zinc antimony based porous p-type thermoelectric material and a preparation method thereof. The general chemical formula of the material is R (Zn2-xTx) 2 (Sb2-yMy) 2, wherein R denotes an element Yb, Eu or Ca; T denotes In, Mn or Cd, x denotes T doping stoichiometric ratio, and x is more than or equal to zero and is less than or equal to 2; and M denotes Si, Ge or As, y denotes M doping stoichiometric ratio, and y is more than or equal to zero and is less than or equal to 2. The method adopts a technology of mother alloy high-temperature fusion in vacuum or under the protection of inert gas, a melt-quenching technology and a discharge plasma mother alloy sintering and quenching technology to prepare the zinc antimony based porous p-type thermoelectric material with aperture of 20-200nm. The ZT value of the material not doped with YbZn2Sb2 material can reach 0.59, the ZT value of the doped material can be further improved and the material can be used in the thermoelectric conversion power generation or refrigeration field. The invention has the advantages that the technology is simple, the preparation cycle is short, the energy consumption is low and the industrialized production can be realized.

Owner:WUHAN UNIV OF TECH

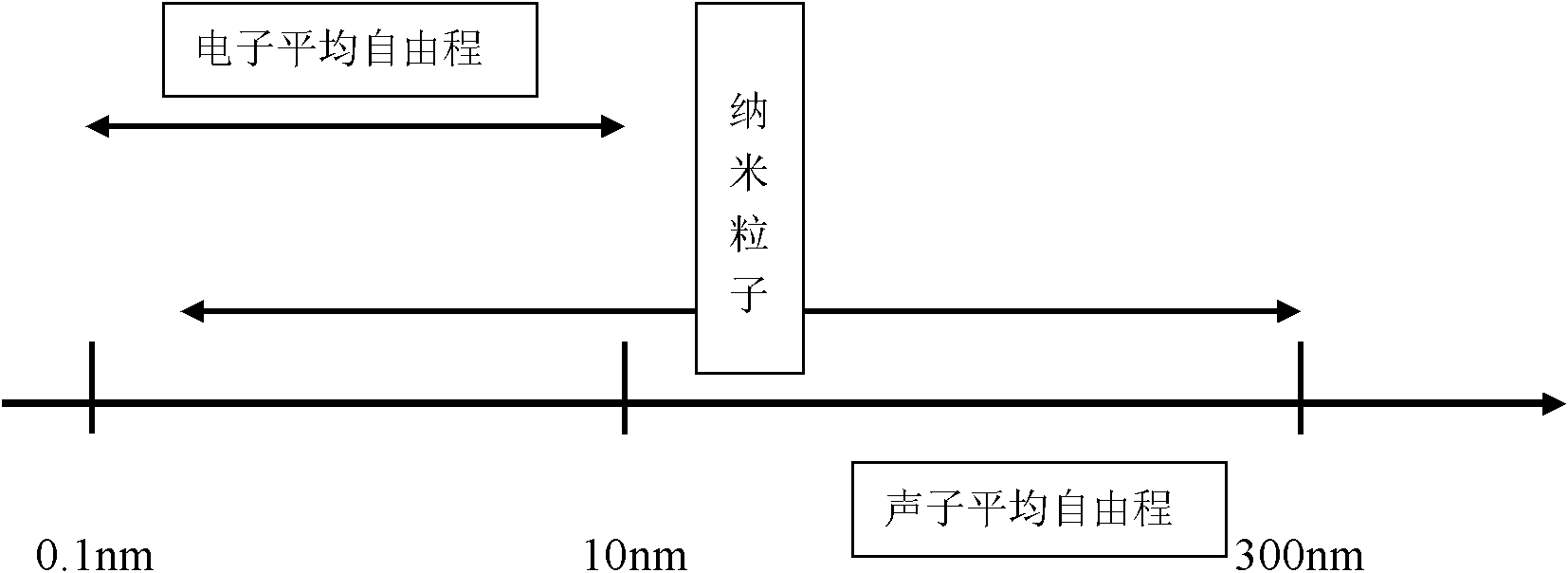

Nanostructured thermoelectric material and device and production method thereof

InactiveCN101969096AHigh crystallinityOvercoming the reduced case of quantum confinement effectsThermoelectric device manufacture/treatmentThermoelectric device detailsThermoelectric materialsNano structuring

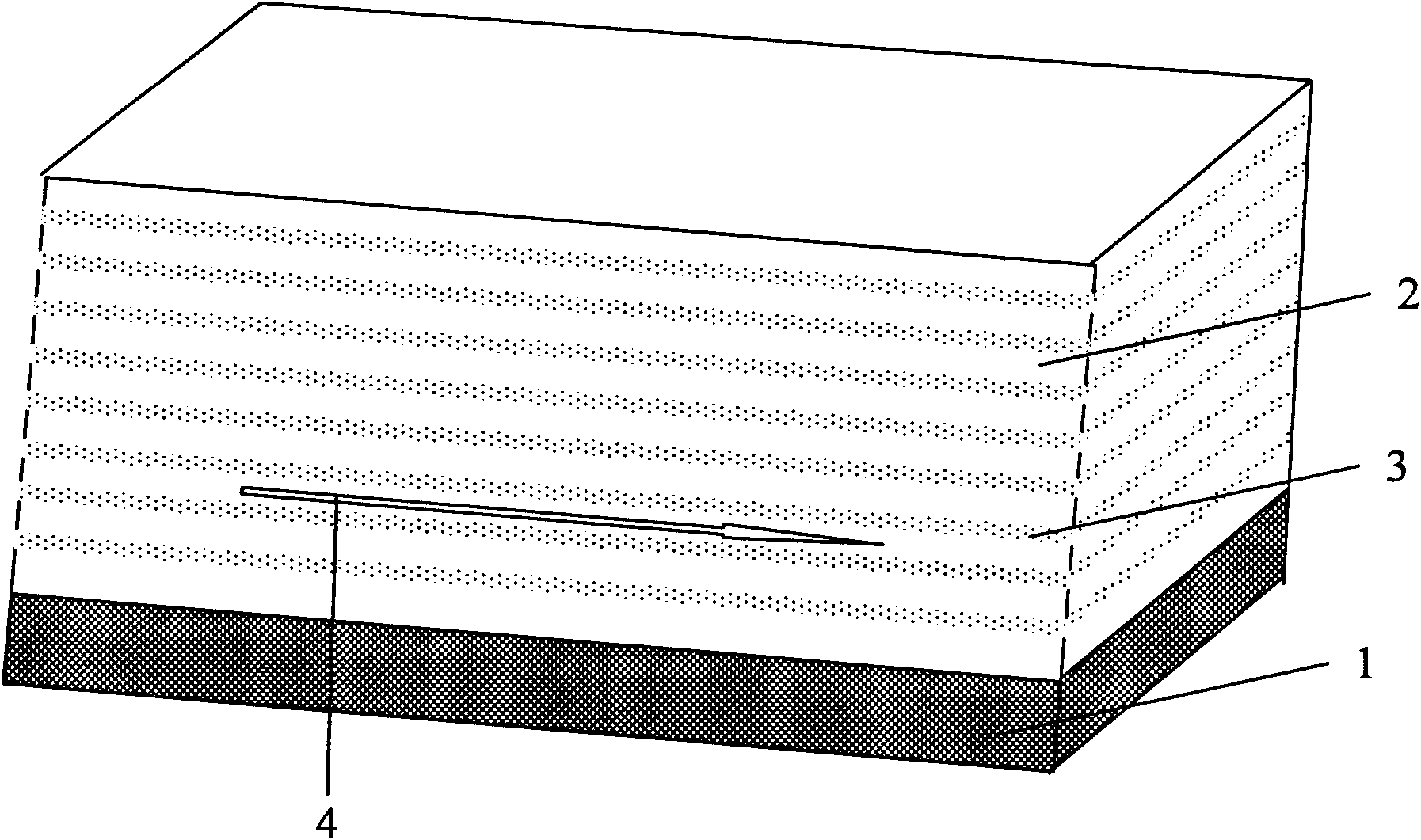

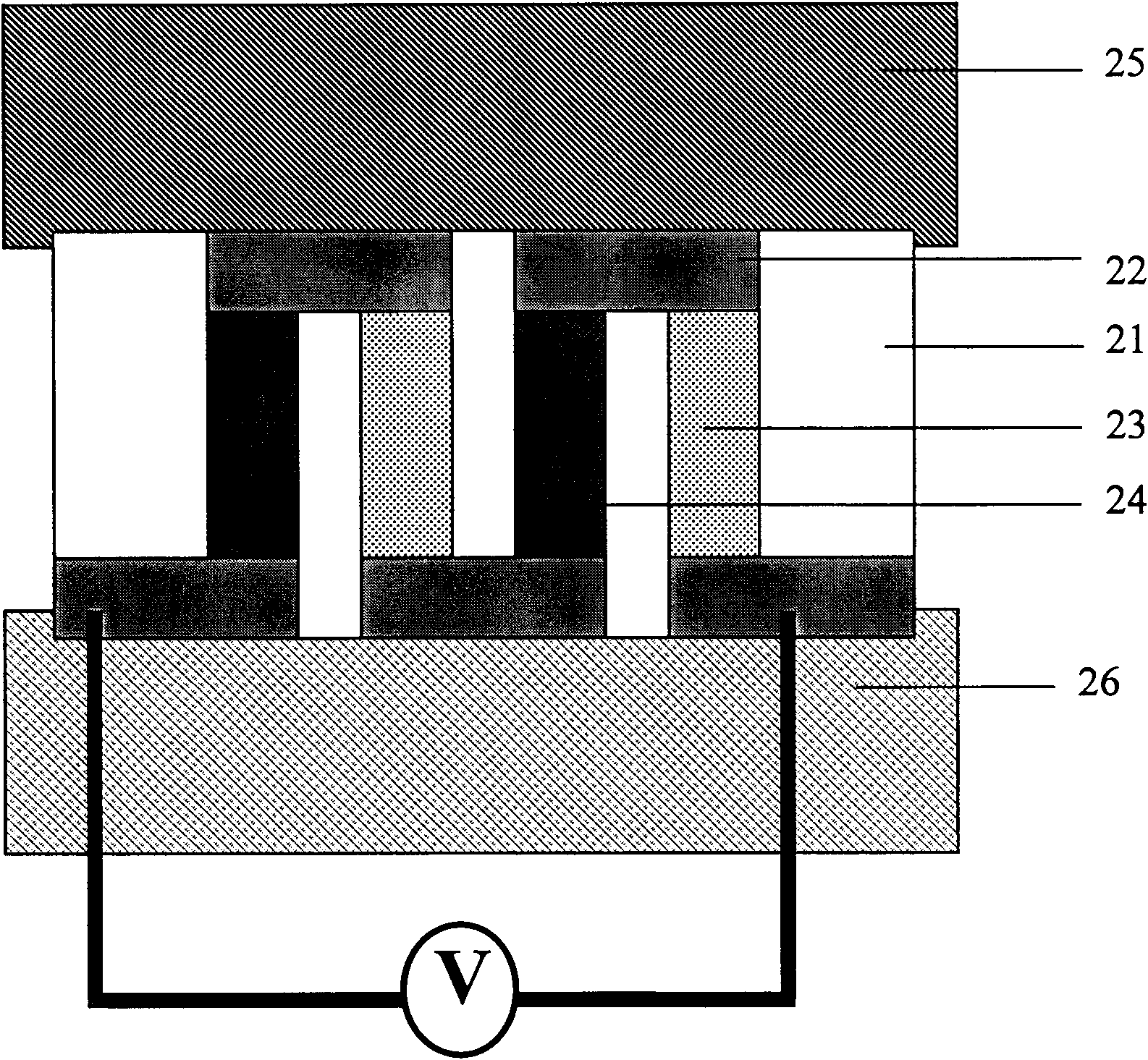

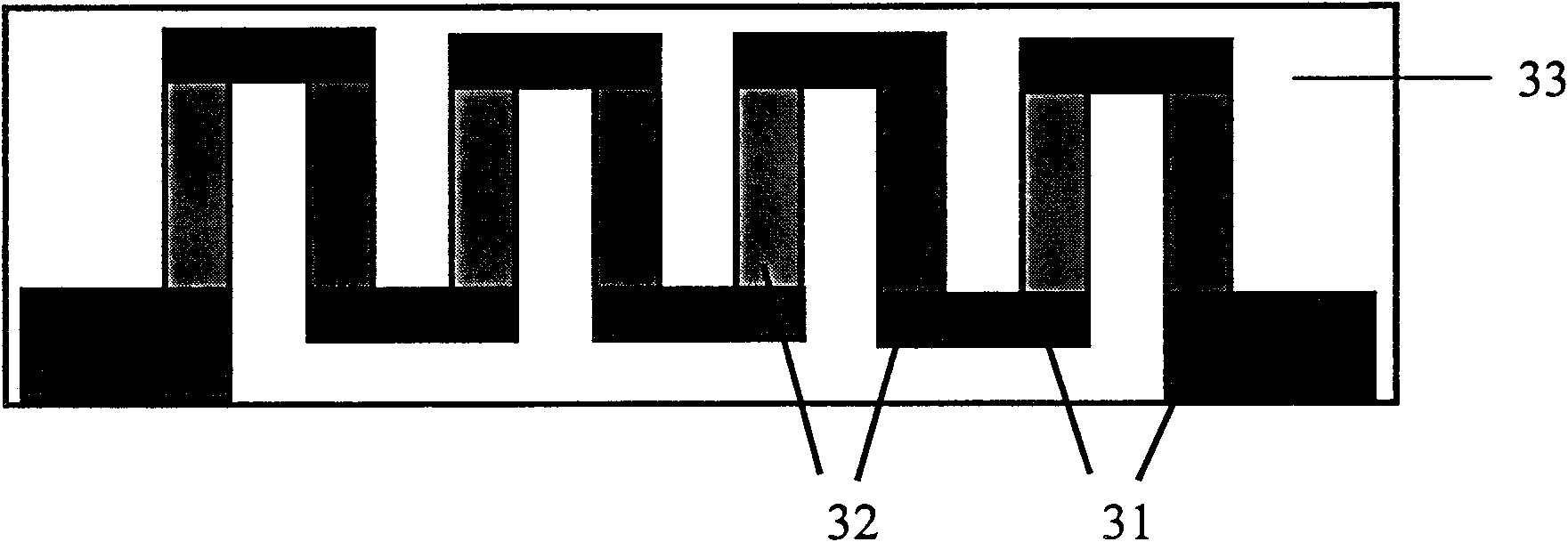

The invention discloses a nanostructured thermoelectric material, a nanostructured thermoelectric device and a production method thereof. The thermoelectric material comprises an insulating substrate and a nanostructured thermoelectric membrane, wherein the nanostructured thermoelectric membrane is composed of at least two nano-thickness thermoelectric material layers and at least two phonon scattering layers, and the thermoelectric material layers and the phonon scattering layers are overlapped alternately. The thermoelectric material can be a p-type thermoelectric material or an n-type thermoelectric material, which depends on the type of charge carrier of the thermoelectric material layers. Connecting electrodes are plated between the thermoelectric membranes of a p-type nanostructured thermoelectric material and a n-type nanostructured thermoelectric material so as to form a thermoelectric pair; and then a plurality of thermoelectric pairs are connected in parallel or in series so as to form the thermoelectric device. The nanostructured thermoelectric material of the invention has the advantages of good thermal stability, high nanostructured membrane deposition efficiency, high thermoelectric conversion efficiency, and lower cost; and the nanostructured thermoelectric device has the advantages of simple structure, easy preparation, low internal resistance, and great practical value in the fields such as refrigeration / calorification or temperature differential power generation, and the like.

Owner:SUN YAT SEN UNIV

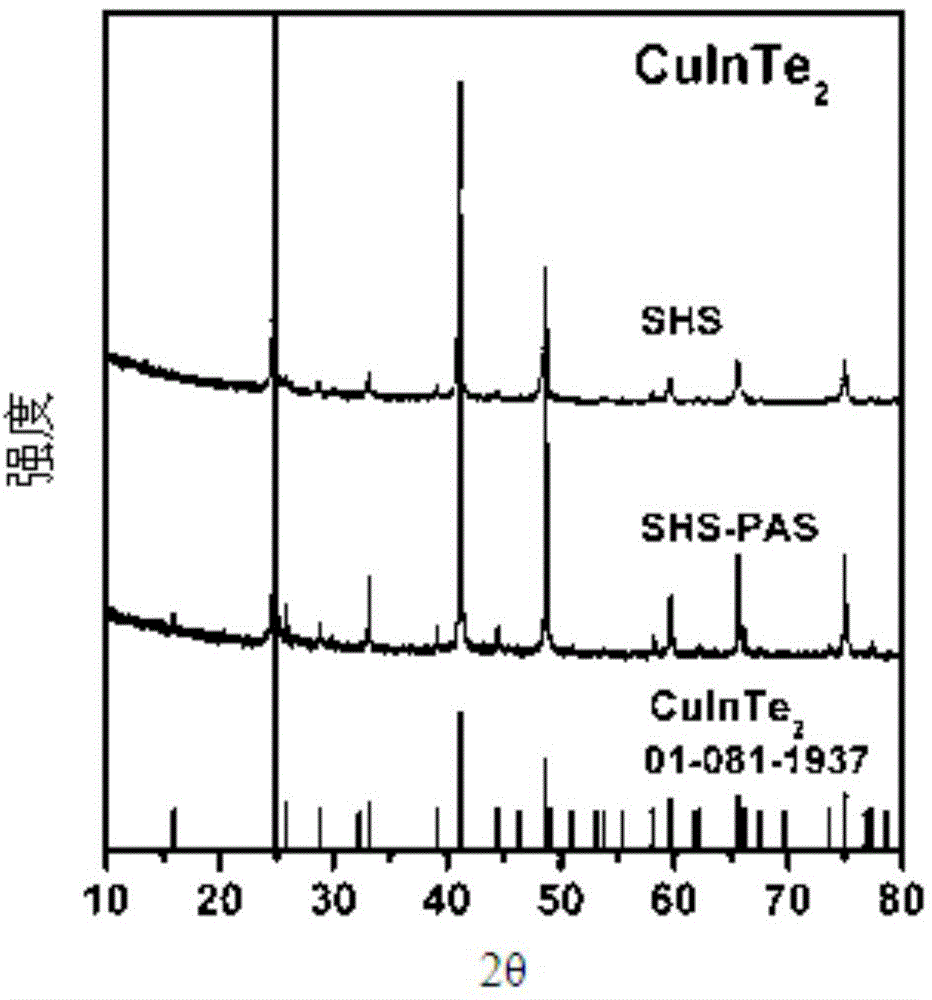

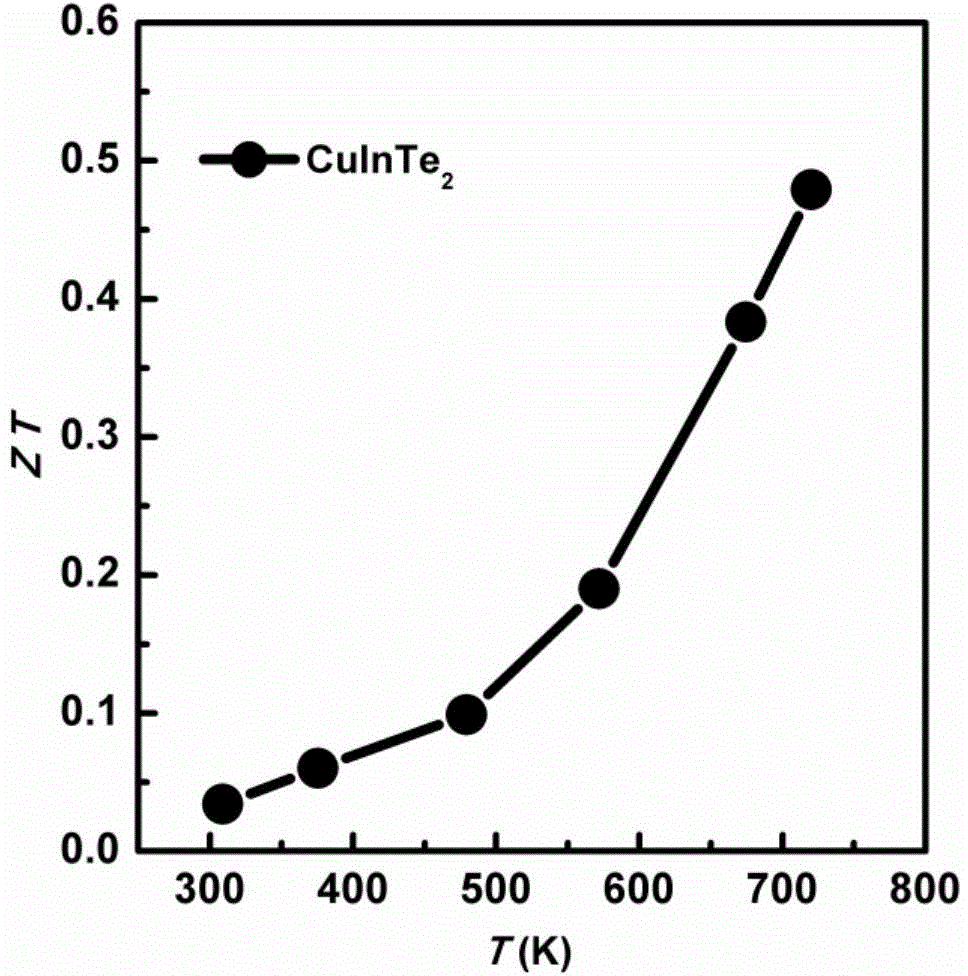

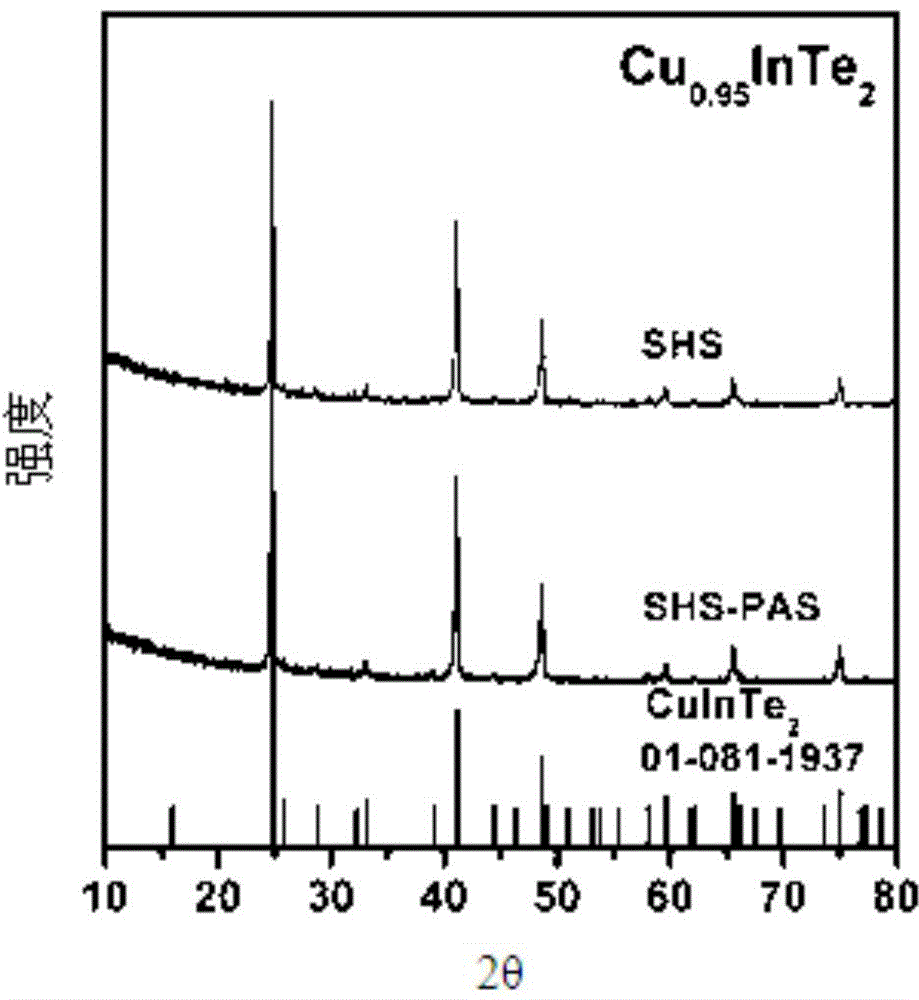

Novel method for quickly preparing high-performance CuInTe2-base thermoelectric material

InactiveCN104944385AQuick responseGood repeatabilitySelenium/tellurium compundsThermoelectric materialsFree cooling

The invention discloses a novel method for quickly preparing a high-performance CuInTe2-base thermoelectric material, which comprises the following steps: 1) weighing raw materials Cu powder, In powder and Te powder according to the stoichiometric proportion of the elements in the chemical formula Cu[1-x]InTe2 (0<=x<=0.2), grinding and uniformly mixing the powder raw materials, and pressing into a block billet; 2) initiating high-temperature self-propagating synthesis reaction on the block billet obtained in the step 1), and after the reaction finishes, naturally cooling to obtain the nearly-single-phase CuInTe2-base thermoelectric material. The method has the advantages of high reaction speed, simple technique, high efficiency, energy saving, favorable repetitiveness and the like; the whole preparation process can be completed within 15 minutes; and the optimal thermoelectric value of the obtained block can reach 0.58 under 720K.

Owner:WUHAN UNIV OF TECH

Preparation method of SrTiO3/TiO2 composite thermoelectric ceramic material

The invention relates to a preparation method of a SrTiO3 / TiO2 composite thermoelectric ceramic material and belongs to the field of thermoelectric ceramics. The preparation method is used for solving the problems that the thermoelectric performance of the existing SrTiO3 oxide is not high and the sintering temperature is high. The preparation method comprises the steps: firstly, preparing hydrated titanium dioxide fiber; secondly, adding the hydrated titanium dioxide fiber obtained in the step 1 into an Sr(NO3)2 solution, carrying out uniform ultrasonic dispersing, adjusting the pH value of the system to be 8-12 and then carrying out hydrothermal reaction and drying to obtain a composite fiber; and thirdly, carrying out compression molding on the composite fiber and carrying out anaerobic sintering at a temperature of 1100 DEG C-1300 DEG C to obtain the SrTiO3 / TiO2 composite thermoelectric ceramic material. According the preparation method disclosed by the invention, by virtue of doping rare earth elements, the conductivity of the composite thermoelectric ceramic material can be improved. By virtue of preparing the SrTiO3 / TiO2 composite fiber, the ZT value of the SrTiO3-based material is improved to 0.1-0.35 and the sintering temperature is effectively reduced.

Owner:HARBIN INST OF TECH

Novel compound semiconductor and usage for same

ActiveCN103562128AExcellent thermoelectric conversion performanceHigh thermal conductivityGallium/indium/thallium compoundsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsThermoelectric materialsSolar cell

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxMyCo4-mAmSb12-n-z-pXnQ'pTez, where M is at least one selected from the group consisting of Ca, Sr, Ba, Ti, V, Cr, Mn, Cu, Zn, Ag, Cd, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu; A is at least one selected from the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt; X is at least one selected from the group consisting of Si, Ga, Ge and Sn; Q' is at least one selected from the group consisting of O, S and Se; 0<x<1; 0<y<1; 0@m@1; 0@n@7; 0<z@2 and 0<p@2.

Owner:LG CHEM LTD

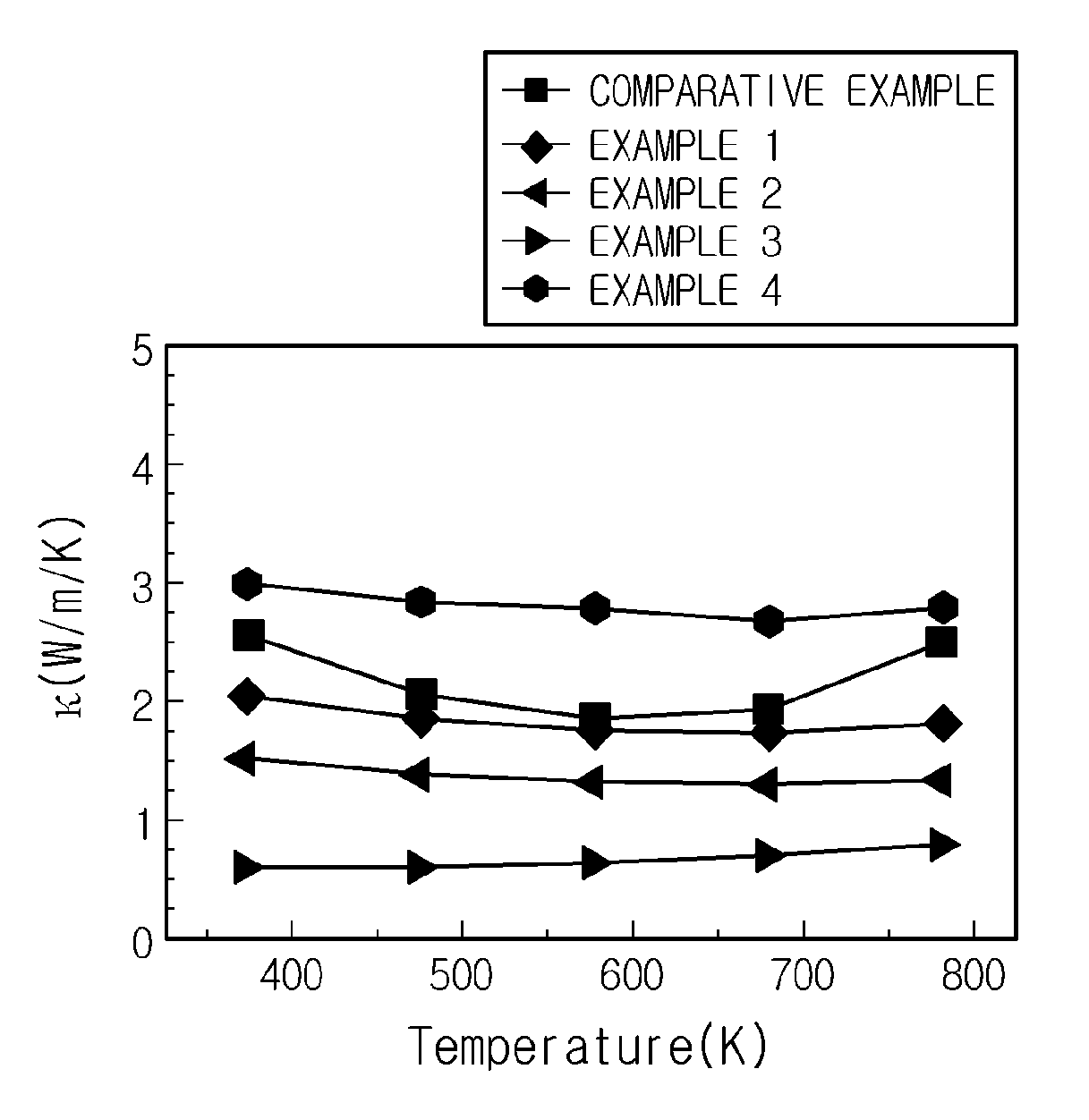

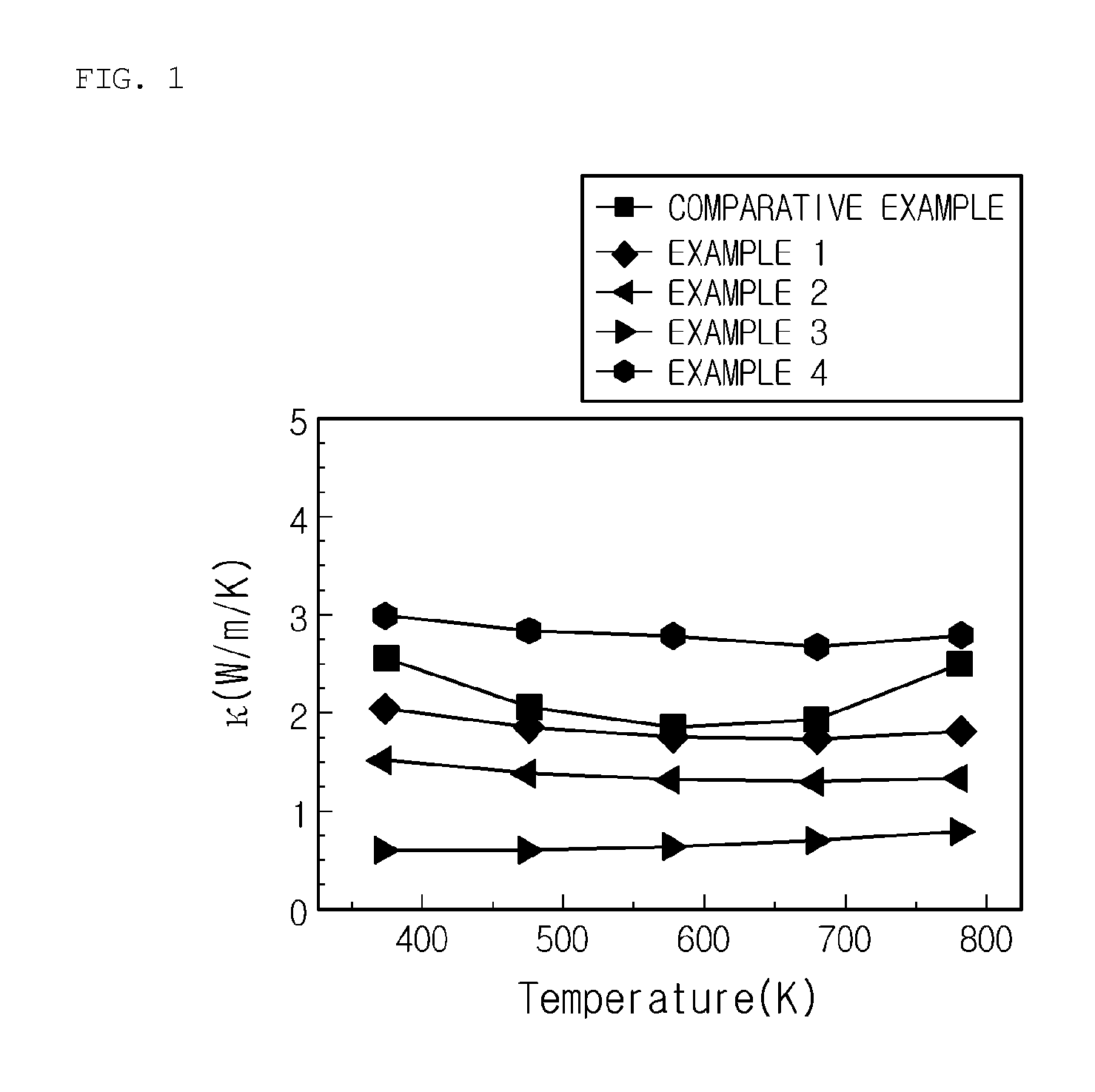

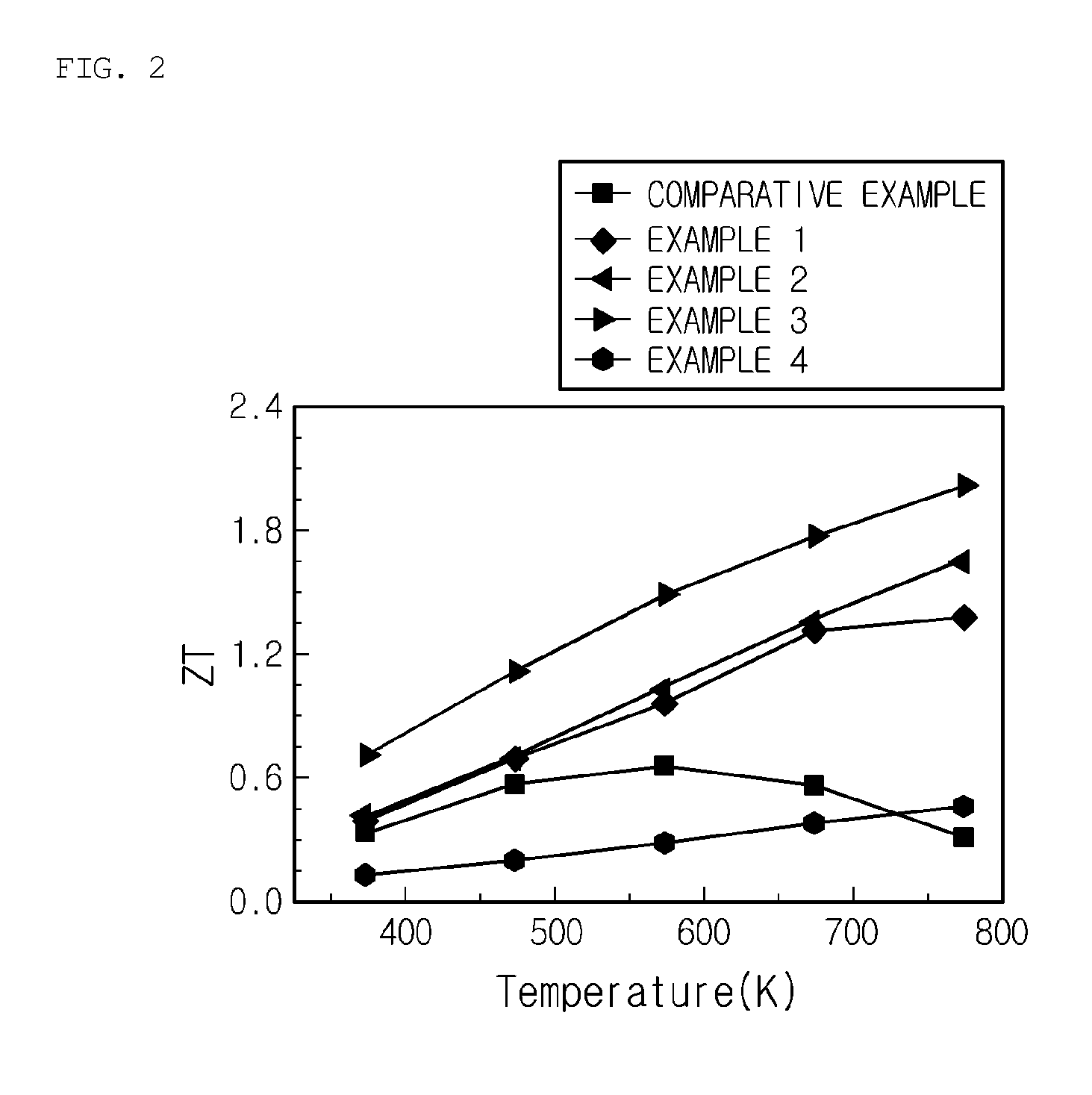

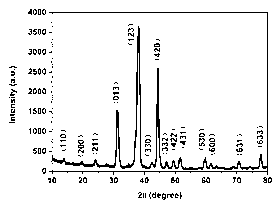

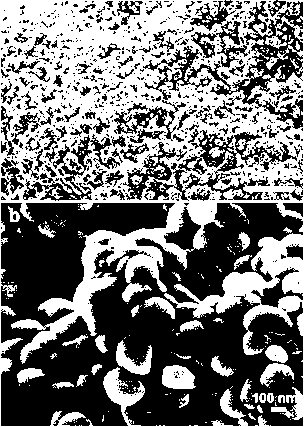

Compound semiconductors and their application

ActiveUS20130009113A1Excellent thermoelectric conversion performanceLow thermal conductivityConductive materialRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsThermoelectric materialsSolar cell

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxMyCo4-m-aAmSb12-n-z-bXnQz, where M is at least one selected from the group consisting of Ca, Sr, Ba, Ti, V, Cr, Mn, Cu, Zn, Ag, Cd, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, A is at least one selected from the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt, X is at least one selected from the group consisting of Si, Ga, Ge and Sn, Q is at least one selected from the group consisting of O, S, Se and Te, 0<x<1, 0≦y<1, 0≦m≦1, 0≦a≦1, 0≦n<9, 0≦z≦4, 0≦b≦3 and 0<n+z+b.

Owner:LG CHEM LTD

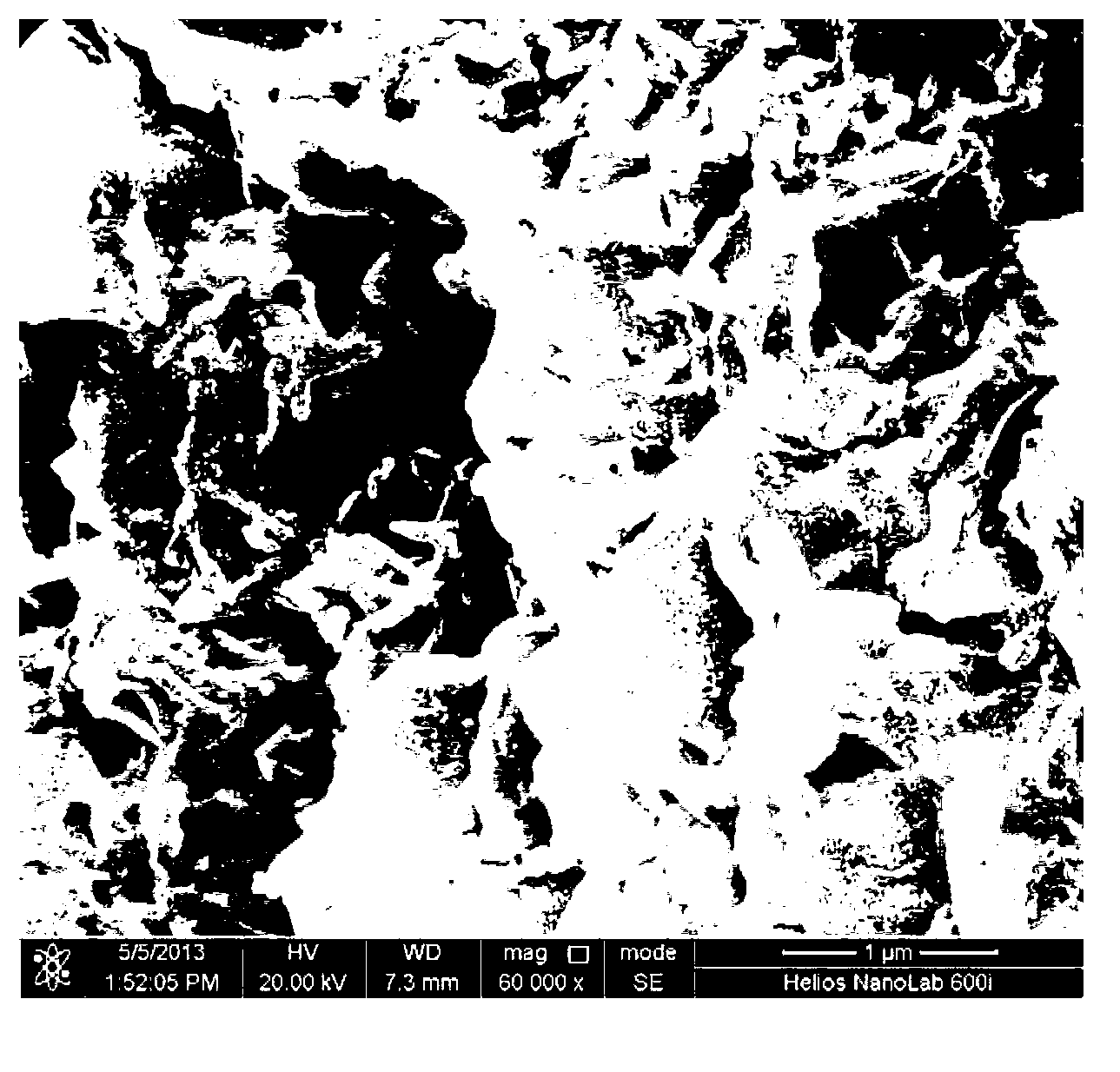

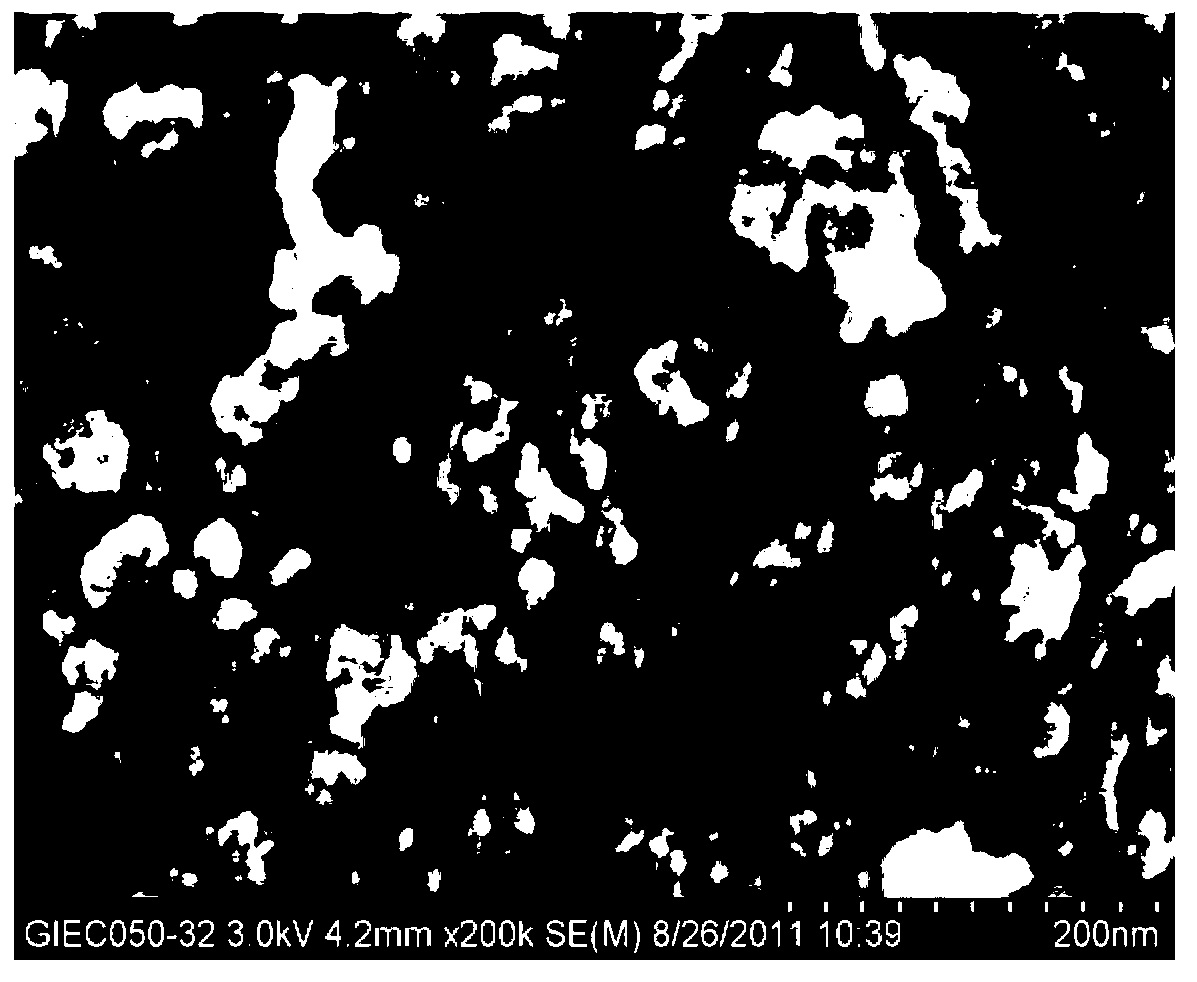

Method for preparing CoSb3 nanometer particle film

InactiveCN102796994ANo need to deal withImprove conductivityNanotechnologyChemical vapor deposition coatingThermoelectric materialsGas phase

The invention relates to a CoSb3 thermoelectric material, in particular to a method for preparing a CoSb3 nanometer particle film. The method comprises the following steps of: firstly, weighing CoC12.6H2O powder and Sb powder according to the molar ratio of 1:3; respectively filling the powder into respective crucible; putting the crucibles and glass slide substrates into a quartz pipe; placing the quartz pipe into a horizontal pipe type furnace; vacuumizing and aerating mixed air of 95 percent of argon and 5 percent of hydrogen for multiple times and removing oxygen in the quartz pipe; raising the temperature of the tubular pipe; performing chemical vapor deposition on the glass slide substrates in a low-pressure state to acquire the CoSb3 nanometer particle film; and testing Seebeck coefficient, conductivity and heat conductivity of the CoSb3 nanometer particle film and calculating a zone time (ZT) value of the CoSb3 nanometer particle film. According to the invention, the CoSb3 nanometer particle film is synthesized by one step, the process is simple, and the diameter of the prepared CoSb3 nanometer particle is between 200 and 400nm; and moreover, the CoSb3 thermoelectric material has good conductivity and low heat conductivity, can be directly used for thermoelectricity researches, and is used for novel high-efficiency thermoelectric conversion devices.

Owner:CHANGZHOU UNIV

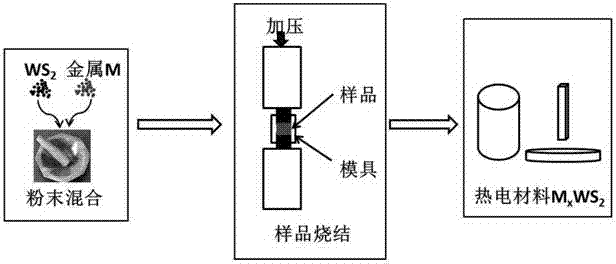

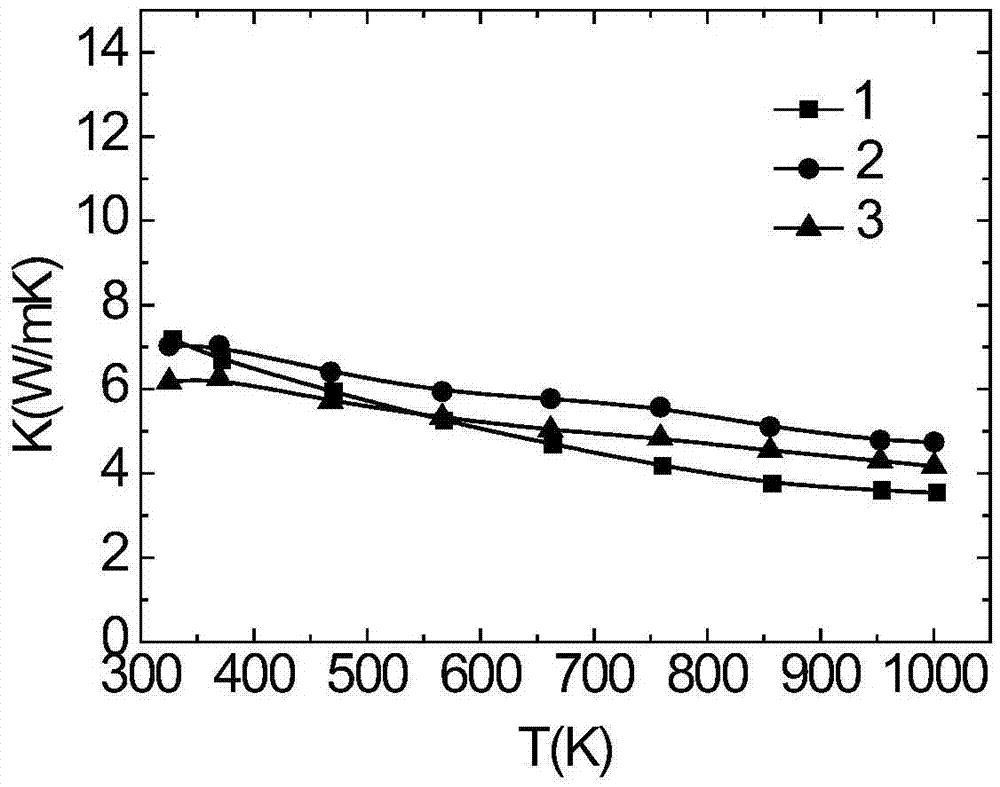

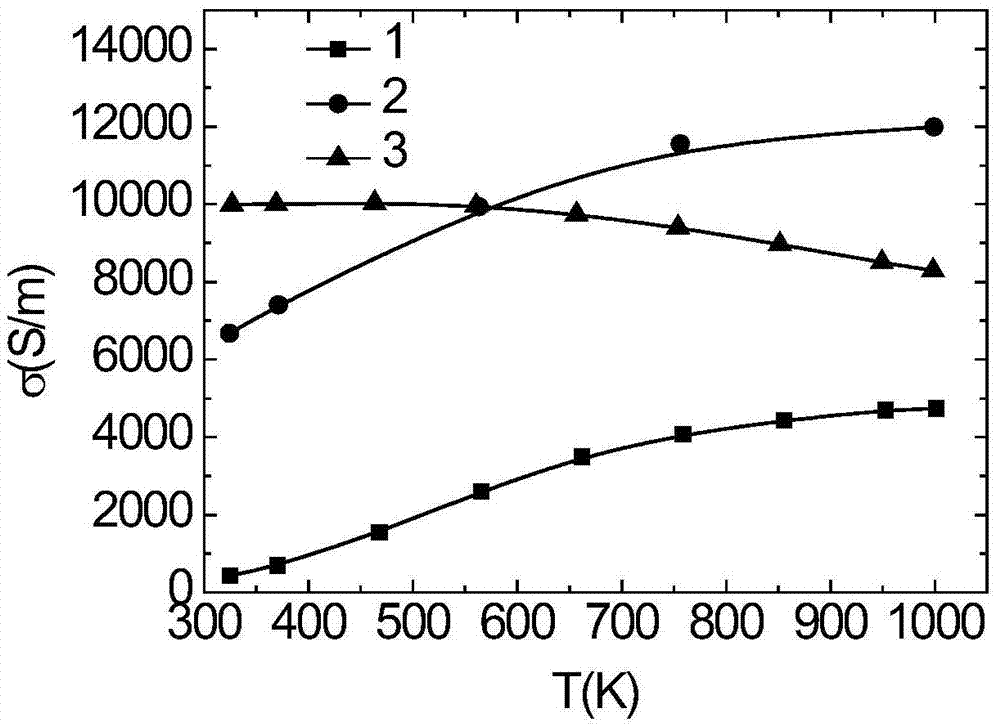

Metal-doped tungsten disulfide thermoelectric material and preparation method

ActiveCN106898689AGood orientationIncreased ZT valueThermoelectric device manufacture/treatmentThermoelectric device junction materialsMaterials preparationElectrochemistry

The invention relates to a series of metal-doped tungsten disulfide thermoelectric materials and a preparation method. The metal-doped tungsten disulfide thermoelectric materials have a chemical general formula of MxWS2, wherein M is one or more than two selected from Ti, V, Nb, Zr, Ta, Hf, Yb and Re, x is a mole fraction of the M metal to WS2 and 0<x< / =1. The material preparation method comprises steps: solid powder mixing and material spark plasma sintering are carried out, metal and tungsten sulfide are firstly weighed at a certain molar ratio, mechanical grinding and mixing are carried out, the mixed powder is subjected to spark plasma sintering under proper pressure and temperature, and an MxWS2 thermoelectric material is obtained after sintering. The thermoelectric material of the invention has high conductance and Seebeck coefficients, the thermoelectric performance is good, and besides, the MxWS2 material can be applied to fields such as electrochemistry, photoelectrocatalysis and electronic devices.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel compound semiconductor and usage for same

ActiveCN103502143AExcellent thermoelectric conversion performanceIncreased ZT valueGallium/indium/thallium compoundsAntimony compoundsThermoelectric materialsChemical compound

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxCo4Sb12-n-zQ'nSez, where Q' is at least one selected from the group consisting of O and S, 0<x@0.5, 0<n@2 and 0@z<2.

Owner:LG CHEM LTD

A bi2o2se-based thermoelectric material and its preparation method

ActiveCN104261357BSignificant change in performanceHeating evenlySelenium/tellurium compounds with other elementsThermoelectric materialsOxide ceramic

Owner:TSINGHUA UNIV

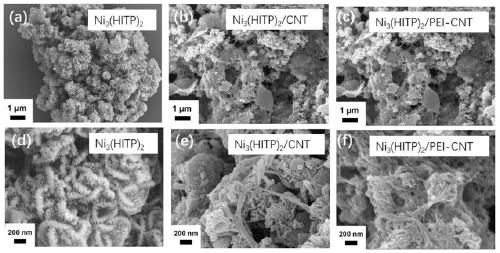

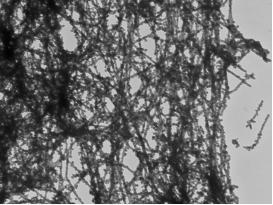

Preparation method of composite material based on metal organic framework and carbon nanotubes, and preparation method of device

ActiveCN111253759ALower lattice thermal conductivityDoping effect weakenedThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsThermal insulation

The invention discloses a preparation method of a composite material based on a metal organic framework and carbon nanotubes, and a preparation method of a device. The preparation method comprises thefollowing steps: firstly, preparing a P-type Ni<3>(HITP)<2> / CNT composite material and an N-type Ni<3>(HITP)<2> / CNT composite material; then respectively tabletting the P-type Ni<3>(HITP)<2> / CNT composite material and the Ni<3>(HITP)<2> / CNT composite material by using a square tabletting mold at a pressure of 10-30 MPa for 5-30 minutes so as to obtain a P-type composite block material and an N-type composite block material, then assembling the P-type composite block material and the N-type composite block material; and connecting connecting parts by using a conductive silver adhesive or a copper wire so as to obtain the device. The N-type stable MOF / CNT composite material with the highest performance is successfully prepared and applied to device circuits, and the porous composite material with high conductivity and low thermal conductivity has potential application value in the fields of catalytic materials, gas adsorption materials, thermal insulation materials and high-performancethermoelectric materials.

Owner:XI AN JIAOTONG UNIV

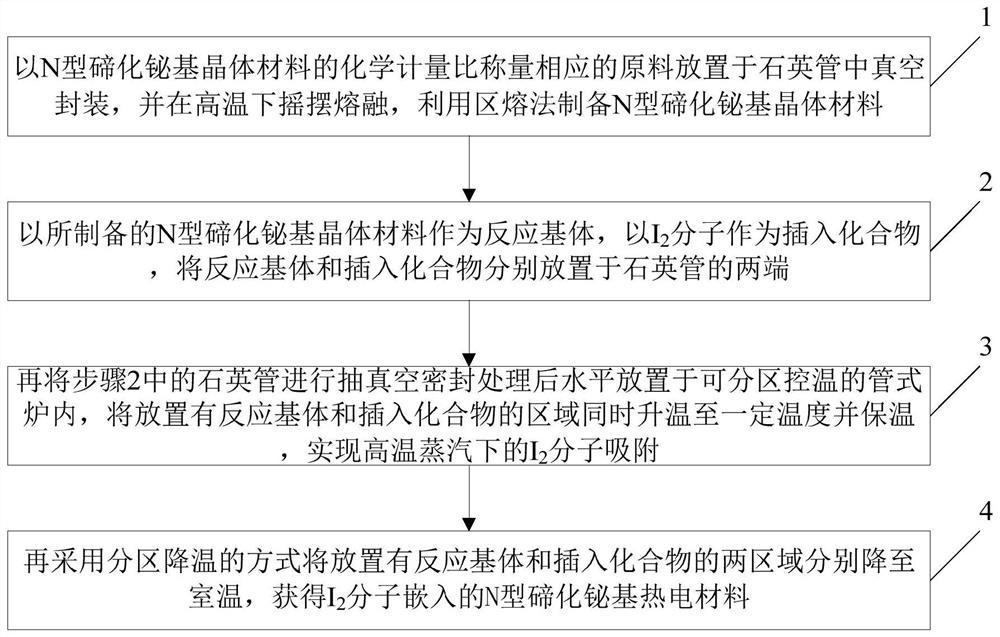

A kind of preparation method of n-type bismuth telluride-based thermoelectric material

InactiveCN108550689BGuaranteed electrical performanceLow thermal conductivityThermoelectric device with dielectric constant thermal changeBismuth tellurideMolecular adsorption

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Thermoelectric thin film with chemical composition of Mg3.2Bi1.5Sb0.5 and preparation method thereof

ActiveCN111349902ALow thermal conductivityIncreased ZT valueVacuum evaporation coatingSputtering coatingSputteringChemical composition

The invention provides a thermoelectric thin film with a chemical composition of Mg3.2Bi1.5Sb0.5 and a preparation method thereof, and belongs to the technical field of thermoelectric materials. The thermoelectric thin film is prepared by means of vacuum magnetron sputtering, and the obtained thermoelectric thin film has a two-dimensional spatial structure and is low in thermal conductivity; and meanwhile, the thin film structure can form a quantum confinement effect, thereby increasing the power factor of materials. According to the thermoelectric thin film with the chemical composition of Mg3.2Bi1.5Sb0.5, a c-axis oriented LaAlO3 single crystal is used as a substrate of vacuum magnetron sputtering, the c-axis oriented LaAlO3 single crystal has a very high lattice matching degree with Mg3.2Bi1.5Sb0.5, the preferential growth of the thermoelectric thin film in the c-axis direction can be induced, and finally, the carrier mobility of the thermoelectric thin film is greatly increased andthe thermoelectric performance of the thermoelectric thin film is further greatly increased. A Mg3.2Bi1.5Sb0.5 alloy target is prepared by ball milling and then hot pressing, the obtained alloy target is not prone to cracking in the magnetron sputtering process, and the deposited thin film is uniform in composition.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

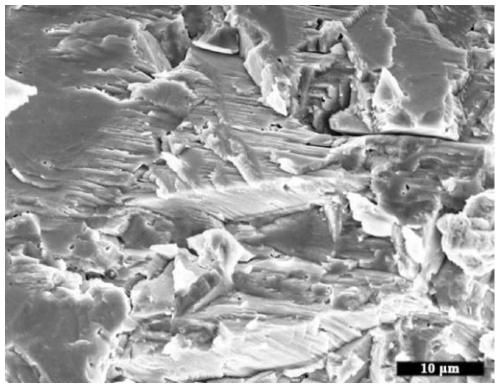

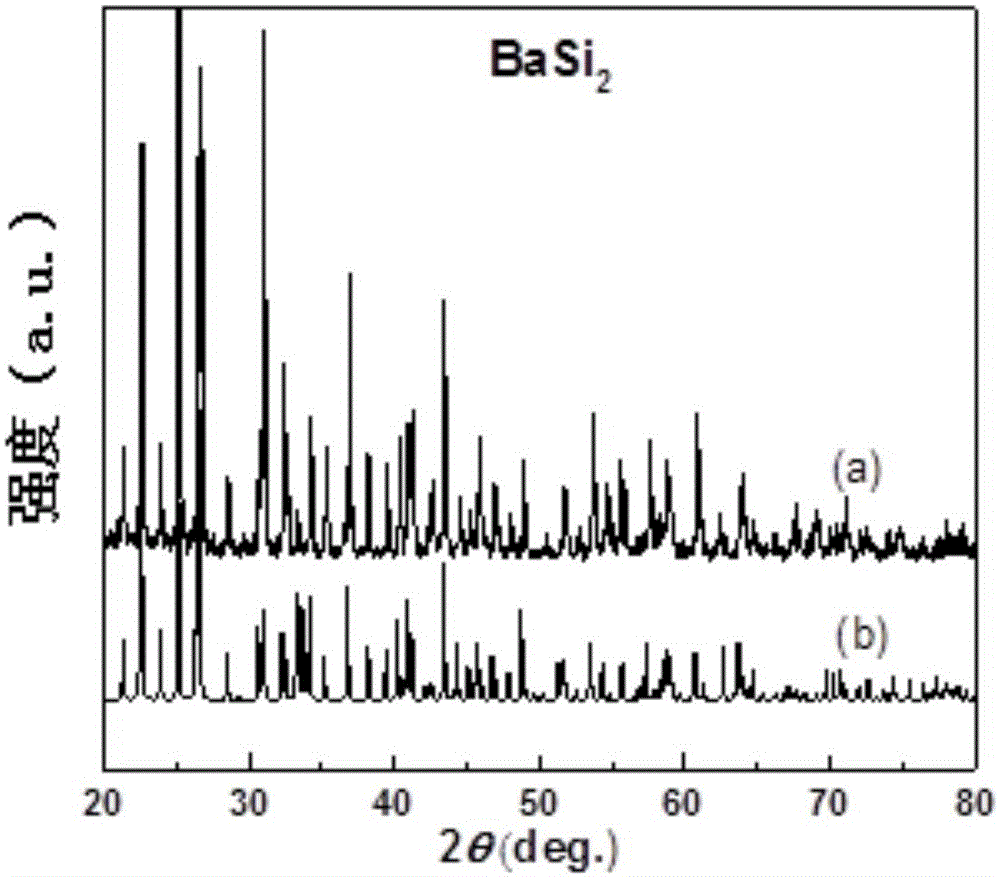

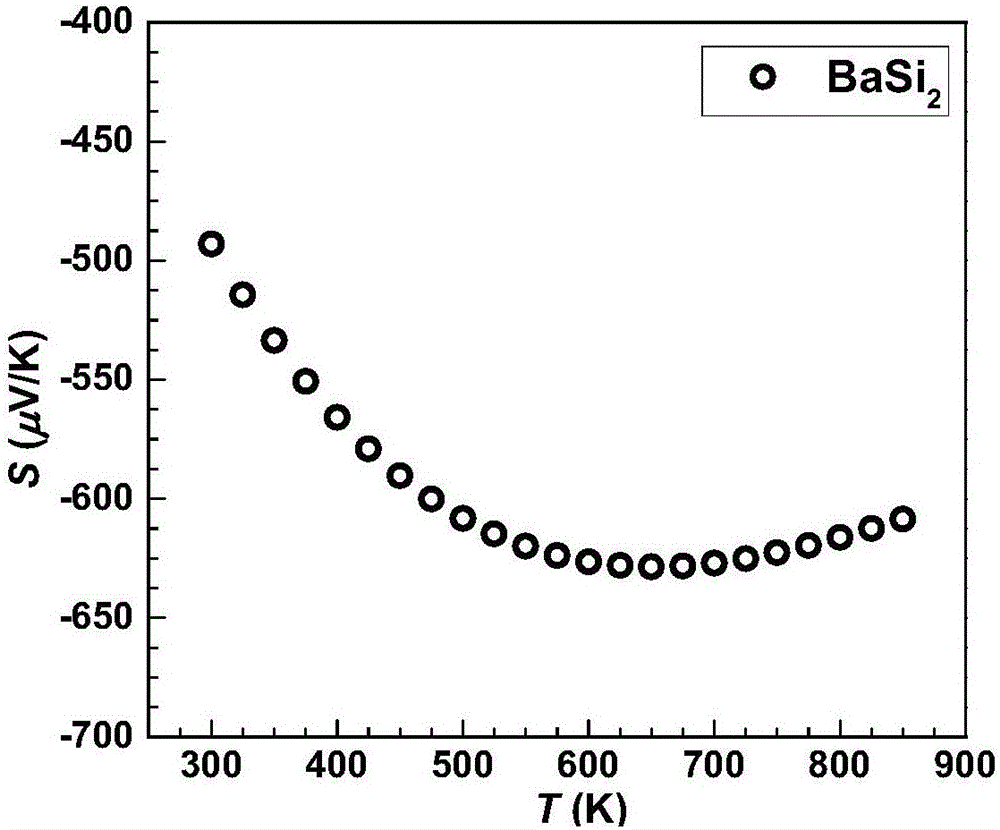

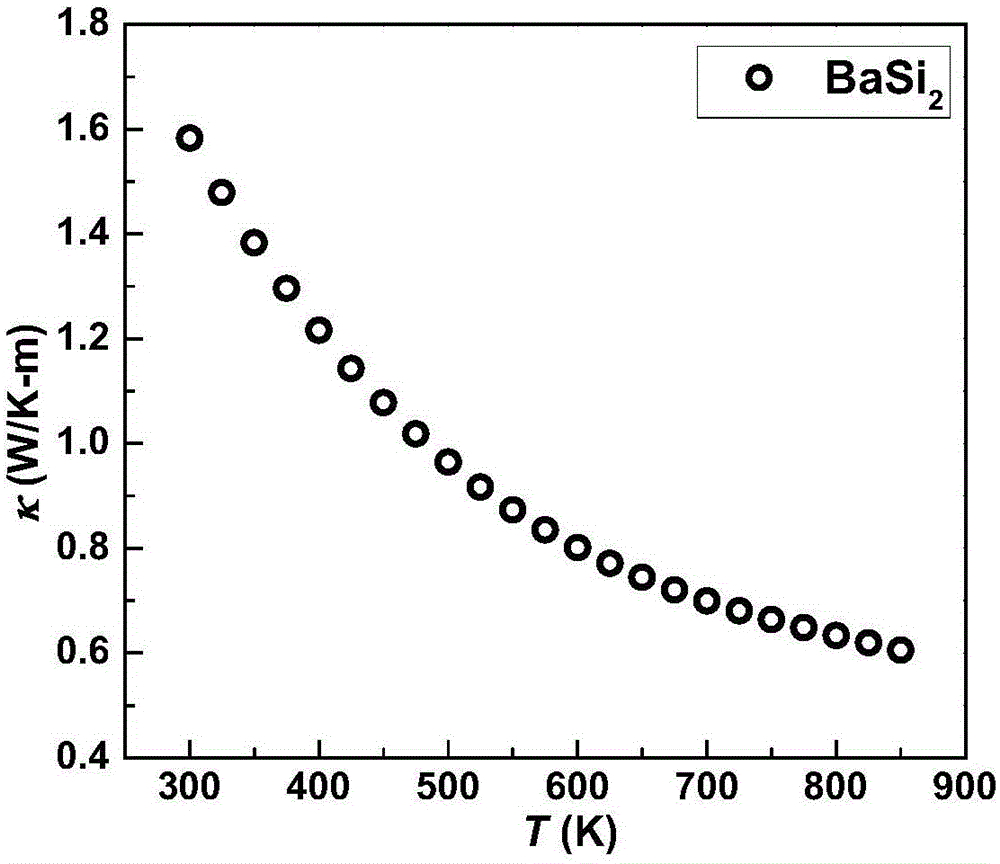

Alkaline-earth-silicide thermoelectric material and preparation method therefor

InactiveCN105036138AHigh crystallinityHigh purityMetal silicidesThermoelectric materialsChemical measurement

The invention relates to an alkaline-earth-silicide thermoelectric material and a preparation method therefor. The chemical general formula of the thermoelectric material is ASi2, wherein A is either Sr or Ba. The preparation method comprises the steps of adopting a metal element with purity higher than 99% as a raw material, proportioning materials according to the stoichiometric ratio of the chemical formula ASi2, then, carrying out arc-discharge melting and water cooling so as to prepare a ASi2 block material, and then, carrying out heat treatment, grinding and sintering, thereby preparing the alkaline-earth-silicide thermoelectric material. Compared with the prior art, the alkaline-earth-silicide thermoelectric material and the preparation method therefor have the advantages that by applying an arc melting technology to the field of preparation of the alkaline-earth-silicide thermoelectric material, the problem of difficulty of preparation resulting from high melting point of alkaline-earth silicide is solved, meanwhile, the problem of safety of preparation caused by the high vapor pressure and high corrosiveness of alkali metal elements is solved, the process is simple, the preparation cycle is short, the safety is high, and the prospect for industrialization is good.

Owner:TONGJI UNIV

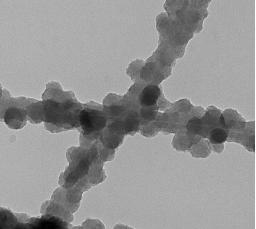

Preparation method for cadmium supported bismuth telluride nanowires

InactiveCN109467060AUniform performanceEasy to scaleNanotechnologyMetal selenides/telluridesBismuth tellurideTe element

The invention aims to provide a simple preparation method for cadmium supported bismuth telluride nanowires with high thermoelectric conversion efficiency by screening. The method has the characteristics of short preparation time, simple process and large-scale production. The preparation method of the cadmium loaded bismuth telluride nanowires comprises the following steps: step 1, preparing tellurium nanowires; step 2, taking tellurium nanowires as a template agent, adding a bismuth source, and performing reaction under the hydrothermal condition to prepare the bismuth telluride nanowires; step 3, separating and washing the bismuth telluride nanowires prepared in the step 2, adding a cadmium source to a shaking table as a reaction container for cadmium support to obtain the final cadmiumsupported bismuth telluride nanowires.

Owner:韩金玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com