Alkaline-earth-silicide thermoelectric material and preparation method therefor

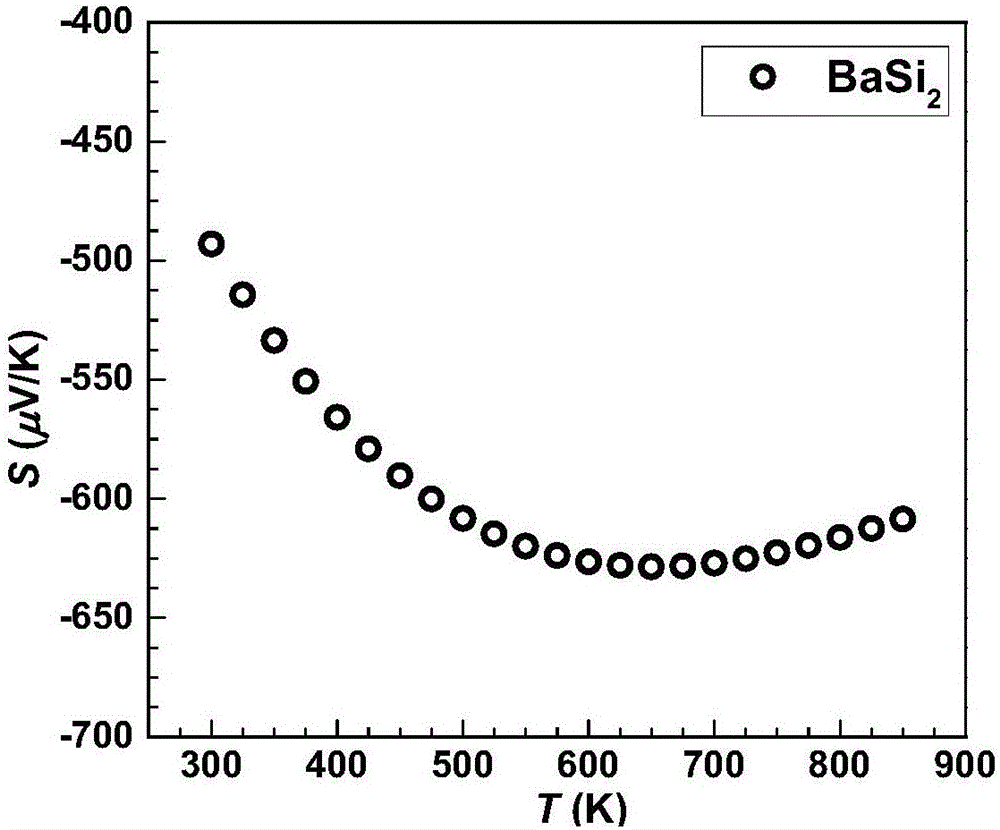

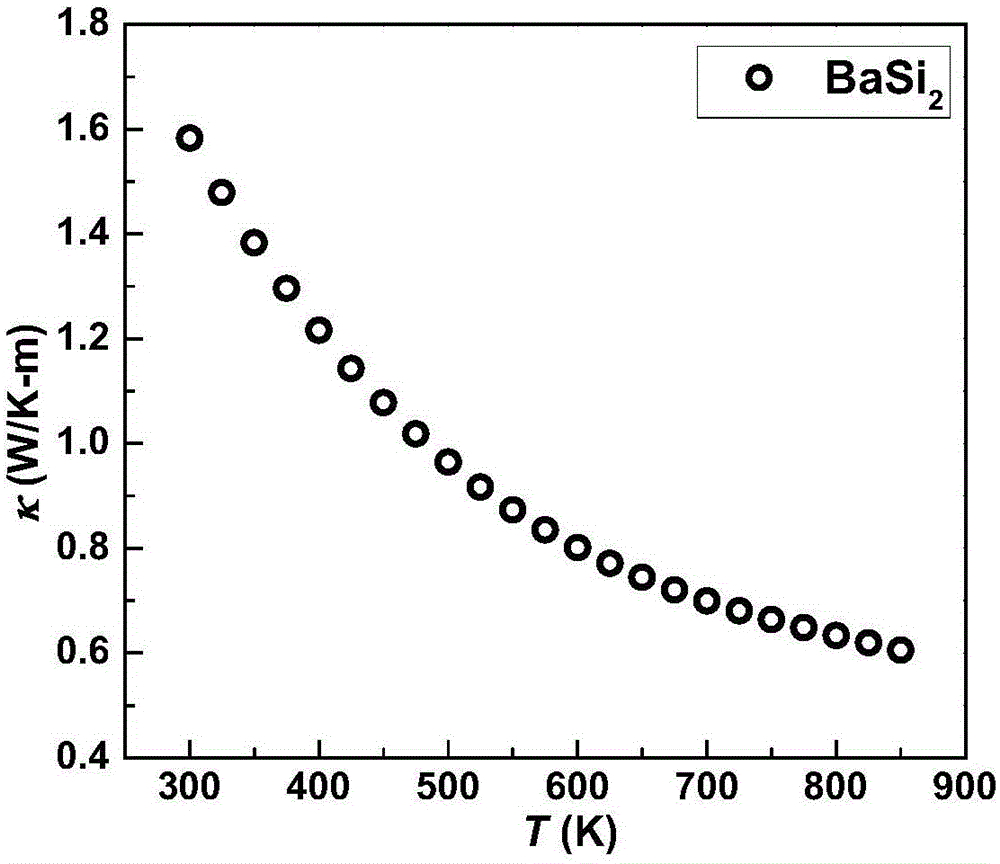

A technology of thermoelectric materials and silicides, which is applied in the direction of metal silicides, can solve the problems of preparation that are rarely reported and cannot solve the problems of strong corrosive preparation of alkaline earth metals, and achieve the problem of difficult preparations, good industrialization prospects, high plug The effect of the Erbeck coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

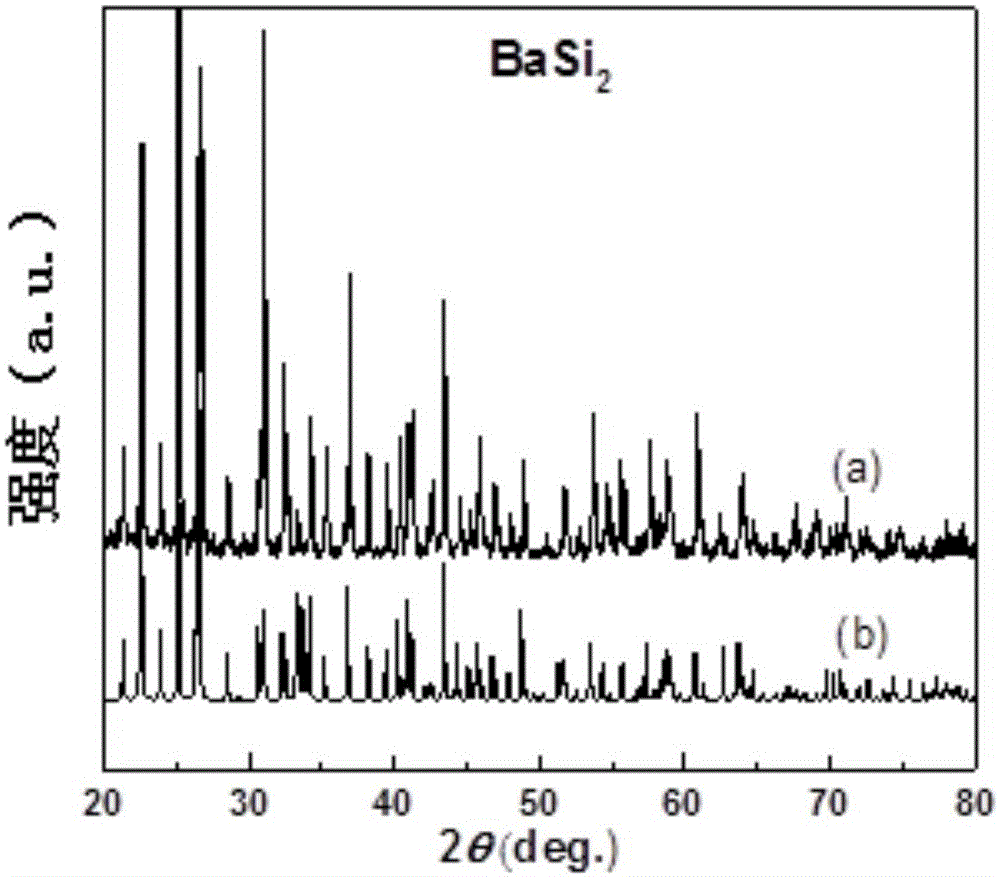

[0040] Mix the high-purity raw materials Ba and Si according to the molar ratio of 1:2, mix them evenly, put them into the copper bowl in the chamber of the arc equipment and wait for melting, close the melting chamber to vacuumize, and fill it with argon to 0.7 atmospheric pressure, so that the raw materials The melting reaction was carried out under the protection of argon. Cool the copper bowl containing the raw materials with water, adjust the distance between the tungsten electrode and the raw material, adjust the arcing current to 40A and energize it, so that the tungsten electrode and the raw material are discharged and arced, and the metal raw material undergoes sufficient chemical reaction in the molten state. The sample is cooled rapidly through a water-cooled copper bowl, and then the sample is turned over to repeat the above melting process to further homogenize the composition of the material to obtain a block. The block was vacuum-packed in a quartz tube and heat...

Embodiment 2

[0045] The general chemical formula of the alkaline earth silicide thermoelectric material in this example is SrSi 2 , the preparation method comprises the following steps:

[0046] (1) Charging: the metal elemental Sr with a purity > 99% and the elemental silicon Si are pressed according to the chemical formula SrSi 2 The stoichiometric ratio ingredients are mixed evenly to make mixed raw materials, and placed in the copper bowl in the melting chamber of the arc equipment to wait for melting;

[0047] (2) Arc discharge melting: evacuate the melting chamber of the arc equipment, and introduce inert gas, adjust the air pressure in the melting chamber of the arc equipment to 0.6 atmospheres, adjust the arc starting current to 55A, and electrify to discharge the electrodes and the mixed raw materials Arcing, the mixed raw materials undergo full chemical reaction in the molten state;

[0048] (3) Water cooling: After the chemical reaction in step (2) ends, the water cooling devi...

Embodiment 3

[0056] The general chemical formula of the alkaline earth silicide thermoelectric material in this example is SrSi 2 , the preparation method comprises the following steps:

[0057] (1) Charging: the metal elemental Sr with a purity > 99% and the elemental silicon Si are pressed according to the chemical formula SrSi 2 The stoichiometric ratio ingredients are mixed evenly to make mixed raw materials, and placed in the copper bowl in the melting chamber of the arc equipment to wait for melting;

[0058] (2) Arc discharge melting: evacuate the melting chamber of the arc equipment, and introduce inert gas, adjust the air pressure in the melting chamber of the arc equipment to 0.8 atmospheres, adjust the arc starting current to 9A, and electrify to discharge the electrodes and the mixed raw materials Arcing, the mixed raw materials undergo full chemical reaction in the molten state;

[0059] (3) Water cooling: After the chemical reaction in step (2) ends, the water cooling devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com