Method for preparing high-thermoelectric-property metal oxide

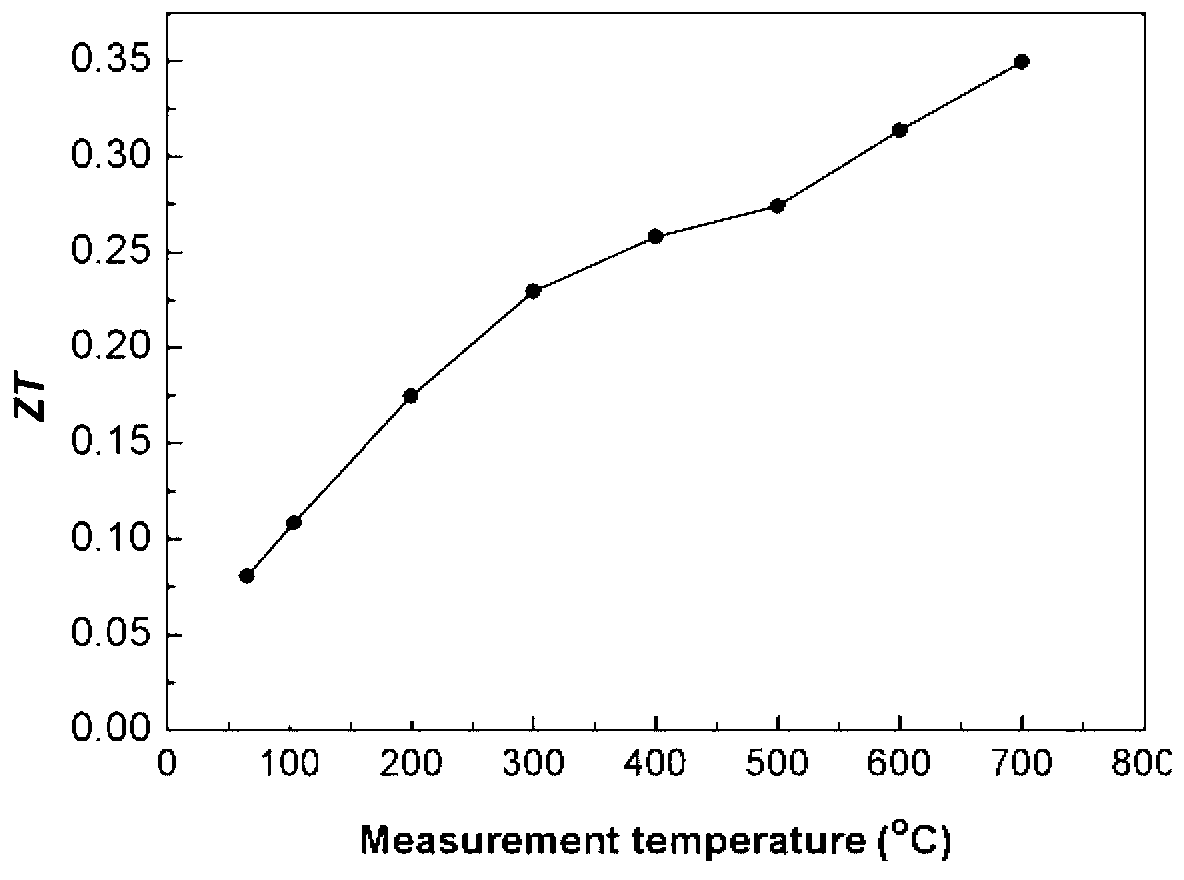

A technology of thermoelectric properties and oxides, which is applied in the field of preparing high-performance thermoelectric materials, can solve problems such as hidden dangers of safe industrial production, and achieve the effects of improving ZT value, high repeatability, and improving power factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for preparing metal oxides with high thermoelectric properties comprises the following three steps:

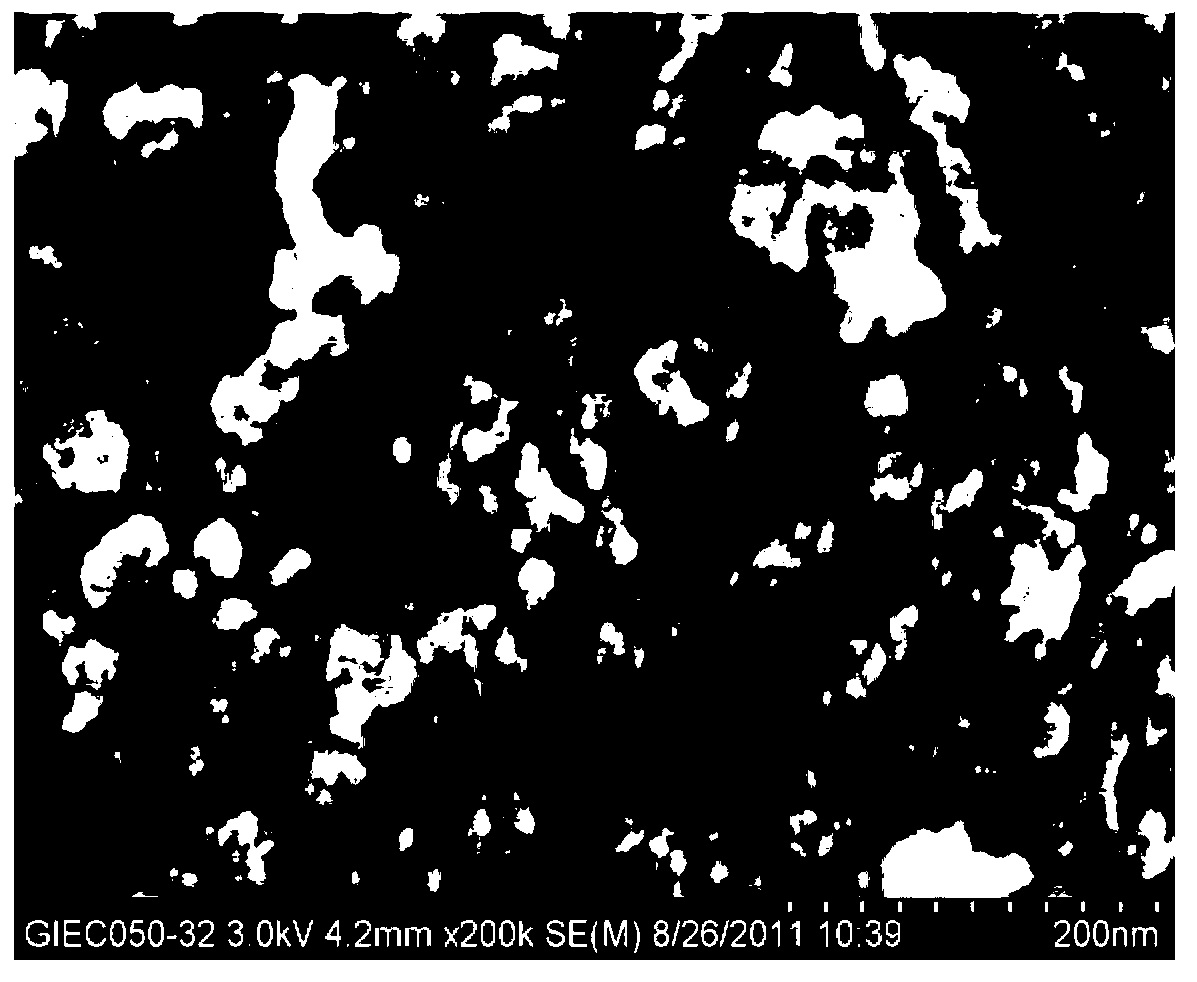

[0024] a. Stir and mix titanium dioxide nanopowder (4g) with a particle size of 5-30nm, niobium pentachloride (3.9g) and urea (23.7g) evenly, then transfer them into a 250ml crucible, and then put the crucible into a 600°C horse Keep the temperature constant in the furnace for 45 minutes, then take out the crucible and wait for cooling to obtain a light yellow powder with an average particle size of 14nm (scanning electron microscope picture is shown in figure 1 shown);

[0025] b. Weigh 4g of the yellow powder obtained in step a and 0.26g of metal titanium powder (the mass of the metal titanium powder and heteroatom-doped titanium dioxide metal oxide nanoparticles is 0.065:1) into the planetary ball mill In the agate jar, add absolute ethanol again, then ball mill on the planetary ball mill for 36 hours, and the rotating speed is 600RPM. The precipitate ob...

Embodiment 2

[0028] a. Stir and mix titanium dioxide nanopowder (4g) with a particle size of 5-30nm, niobium pentachloride (3.9g) and urea (7.9g) evenly, then transfer it into a 250ml crucible, and then put the crucible into a 700°C horse Keep the temperature in the furnace for 30 minutes, then take out the crucible and wait for cooling to obtain a light yellow powder;

[0029] B, weighing the pale yellow powder obtained in 4g step a and 0.26g metal titanium powder (the quality of the titanium dioxide metal oxide nanoparticles doped with metal titanium powder and heteroatoms is 0.065:1) put into the agate of planetary ball mill In the tank, add absolute ethanol again, then ball mill on planetary ball mill for 20 hours, the rotating speed is 600RPM. The precipitate obtained after ball milling was washed with 400ml of absolute ethanol, and dried at 120°C for 2 hours to obtain a dry product;

[0030] c, the dry product that obtains in the step b in 1 * 10 4 kgf / cm 2 It was formed by cold p...

Embodiment 3

[0032] a. Stir and mix titanium dioxide nanopowder (4g) with a particle size of 5-30nm, niobium pentachloride (13.5g) and urea (17.6g) evenly, then transfer it into a 250ml crucible, and then put the crucible into a 500°C horse Keep the temperature in the furnace for 120 minutes, then take out the crucible and wait for cooling to obtain a light yellow powder;

[0033] B, weigh the light yellow powder obtained in 4g step a and 0.02g metal titanium powder (the quality of metal titanium powder and the titanium dioxide metal oxide nanoparticle doped with heteroatoms is 0.005:1) put into the agate of planetary ball mill In the tank, add absolute ethanol again, then ball mill on planetary ball mill for 20 hours, the rotating speed is 300RPM. The precipitate obtained after ball milling was washed with 400ml of absolute ethanol, and dried at 80°C for 2 hours to obtain a dry product;

[0034] c, the dry product that obtains in the step b in 5 * 10 3 kgf / cm 2 It was formed by cold pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com